1. Introduction

Climate-related change does not just affect portions of our planet but also the assets owned and managed by manufacturers itself. According to the Economics Intelligence Unit 2015 expected losses would more than triple (US

$13.8 trillion) should global warming reach 6 °C [

1]. The report also indicated that only a few global investors have addressed this risk to date; a modest minority of those investors is even able to quantify the carbon footprint of their own portfolios. Although direct damage of carbon emissions is more localized, indirect impacts can affect the entire global economy. Accordingly, asset managers and investors are facing significant challenges diversifying out of assets affected by climate change. However, lack of greenhouse gas (GHG) information in various industrial sectors and lack of governmental enforcement for reporting GHGs are absolute reasons for not having many forecasting models to estimate the economic cost of future climate change. Researchers are making progress in developing models which will soon be available on a commercial scale throughout the world. Having models have an integrated, consistent framework is essential to predict economic growth, GHG emissions, climate change, and the damaging impacts of climate change on the economy. These should in turn be helpful to inform policymakers/industries in setting emission targets in relation to financial performance. Policymakers all over the world are also making progress. On 22 April 2016, an agreement to mitigate the causes of climate change was signed by over 177 countries, including the two biggest polluters, China and the United States in the Paris Agreement under the United Nations Framework Convention [

2].

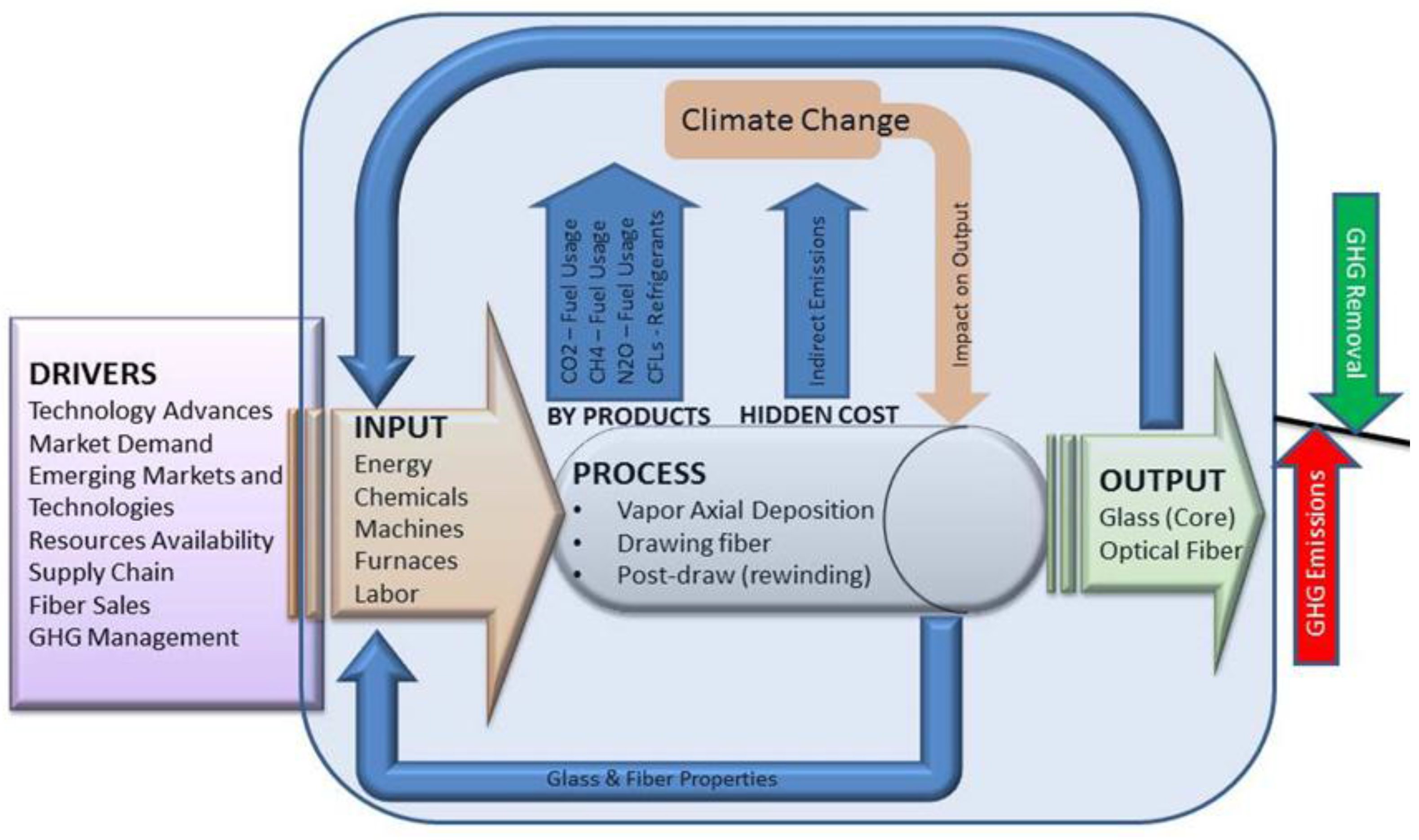

This is why the company Optical Fiber Solutions (OFS) is choosing to spread its GHG knowledge on the optical fiber industry to the public: to try and broaden the knowledge of everyone trying to accurately reflect their own GHG output as culture shifts towards more sustainable practices. The purpose of this case study is to gain insight on the assortment of GHGs in this optical fiber manufacturing company and where they are emitted in the manufacturing process. This case study will also provide an estimation for the current emission factor for optical fiber production, which before this paper, has never been fully and publicly published. Admittedly, this paper only analyzes the emissions from one company, so drawing a general emission factor is a bit difficult. However, OFS currently holds a “World-Leading” market share [

3] with its only major competitor being Corning Inc., so using our provided emission factor for optical fiber production is a decent estimation for the full optical fiber market.

OFS will be analyzing its carbon footprint using international standards. A carbon footprint, according to ISO/TS 14067, is the “sum of GHG emissions and removals in a product system, expressed as CO

2 equivalents and based on a life cycle assessment using the single impact category of climate change.” [

4] In this case, OFS is looking to calculate the carbon footprint of its optical fiber manufacturing using a gate-to-gate approach, which will be explained later in the Methods section.

The telecommunication industry has a huge potential to reduce its carbon footprint, as 2% of the total carbon footprint of the planet comes directly from running data centers across the world, which uses cables like optical fibers to get the job of data transferring done [

5]. In a 2007 economic analysis of the environmental benefits of broadband services, The American Consumer estimated that widespread adoption and use of broadband-based applications could lead to an “incremental reduction of more than 1 billion tons of greenhouse gas emissions (GHGs) over ten years” as it would lead to a greater use of e-commerce, telecommunications, and teleconferencing [

6].

General Introduction to the Optical Fiber Industry

Fiber optic technology has many applications leading to tremendous growth in the industry. The applications range from global networks to desktop computers transmitting voice, data, and video information over vast distances in fractions of the time. These feats are accomplished using shockingly few variations in fiber designs. More than just the telecom industry, other large industries utilize these fiber networks, including the oil and gas industry, utilities, private data networks, healthcare/biomedical, among others. Different fibers required for each industry depend on length, cost of installation, and actual application. Specialty fibers have applications in other industries such as the biomedical, automotive, and submarine industries. These markets are wide open for all players and waiting for major innovation breakthroughs.

With reference to the telecommunications industry, TIA TR-42 has initiated a study group for green initiatives in telecommunications infrastructures. The group suggested creating a technical service bulletin (TSB) that includes measures to make telecommunications infrastructures “greener.” For the data center segment within the telecommunications industry, the green metric indicates a reduction in energy consumption and ultimately reduction in CO

2 emissions. The global consortium “Green Grid” is dedicated to improving energy efficiency in data centers and business computing systems all over the world. One of its services is to define metrics for energy efficiency improvements. The “Data Center Energy Productivity (DCeP)” paper publishes a useful metric defined as “useful work produced” by a data center divided by the total energy consumed by a data center [

7]. Optical fibers play a significant role in the denominator of the equation when compared to 10 G copper (a very common network cable in data centers today) by reducing network operational and cooling energy.

Data center electrical energy consumption is projected to significantly increase in the next five years. Currently, the biggest data network, the Internet, consumes about 0.4% of the electricity in broadband-enabled countries and the Internet’s energy consumption is expected to increase to 1% as access to broadband increases [

8]. A current estimation projects about 14% of CO

2eq from all telecom comes from broadband devices in 2020, up from 3% in 2007 [

9]. Solutions to mitigate energy requirements, reduce CO

2 emissions, and support environmental initiatives are being widely adopted. Optical connectivity via optical fibers provides best solution by reduction in power consumption (electronic and cooling) and optimized pathway space utilization necessary to support the movement to greener data centers [

10].

3. Results

The carbon footprint of optical fiber products from OFS was quantified and general emission factors were calculated. In addition, hotspots across the life cycle of optical fiber products were identified.

Table 2 shows the results of calculating Scope 1 emissions using the method explained in the “Methods” section. All emission factors used in these results are acquired from 40CFR98 Code of Federal Regulations of the United States, which derive its emission factors from international standards [

11]. As can be seen by the results, the boilers are the most significant portion of the carbon footprint for the direct emissions of the plant, and this number has gone down from 2013 to 2015 with a slight uptick in 2016. Another thing to note is the air-conditioning (AC) Unit, when applicable, also contributes a large portion of the Scope 1 emissions. Additionally, it is important to consider any non-operational releases such as material spills as these can be significant contributors. The data below shows the impact of such a spill of the AC Unit’s refrigerant R134a, a highly potent GHG, into the atmosphere, which is why the 2013 and 2014 numbers are higher than expected. Entries in the fuel oil and AC Units in the Emission Value and Amount column are blank as there were no recorded values to put in those spots for that year. The values of General VOCs and Acetone in the Amount column are blank as their emission are directly equal to metric tons of CO

2eq, so there is no need for an intermediary step in which the amounts units change.

Table 3 shows the results of calculating Scope 2 emissions using the method explained in the “Methods” section. These results were computed using the general method in the Methods and the purchased electricity emission factors are directly from the GHG Protocol [

12]. This is by far the largest contribution to the carbon footprint in a gate-to-gate scope. OFS uses approximately 100 million kilowatt-hours of electricity each year. For reference, an average American house only uses about 11,000 kilowatt-hours of electricity each year [

15]. The amount of electricity used by OFS has gone up by about 10 million kilowatt-hours from 2013 to 2016, increasing the carbon footprint of the plant. This increase in energy usage is closely correlated to the increased production of optical fiber from 2013 to 2016.

Table 4 shows the calculated results of Scope 3 emissions using the method explained in the “Methods” section.

Section 3.1 in this report discusses where the emission factors in this table came from and the difficulties with reporting this section. Raw Materials A, B, and C were omitted from this table for security and privacy reasons. These values are indeed used in the final emission factor calculation, but their values will not be provided in this paper. While this section is the lowest of the three, an interesting point is raised regarding the interpretation of these results. From 2013 to 2016, production of optical fiber increased at OFS, therefore, more raw materials are required to make more fiber. This resulted in the Scope 3 emissions rising from 2013 to 2016. However, the true test of how well OFS is stabilizing its carbon footprint is to look at the specific GHGs and total emission factors for optical fiber in

Table 5.

Table 5 shows percent change in production of fiber, percent change of calculated specific GHG emissions, and emission factors for optical fiber production. The values for the percent changes are blank in 2013 as this value was used as the base value and all subsequent percentage are based from that 2013 number. From 2013 to 2016, the specific GHG emissions of optical fiber at this plant have decreased by about 27% and production has increased by 48%. These results show that OFS is using less carbon emissions over the past few years to make more products, which is good from both an environmental and economic standpoint. The emission factor for the production of optical fiber at OFS, in consequence, has decreased, meaning that less CO

2eq is emitted for the production of each fiber. The units for the emission factor are metric tons of CO

2eq per million meters of fiber produced or kilograms of CO

2eq per kilogram of fiber produced.

Table 6 illustrates how the amounts of the raw materials carbon footprint compare with that of the manufacturing stage. As illustrated, the manufacturing stage makes up about 95% of the carbon footprint in comparison to the roughly 5% attributable to the raw materials’ stage. Most of this table is affected by Scope 2, which accounts for about 90% of the total footprint. Without Scope 2, the relationship between Scope 1 and Scope 3 would be about 60:40 respectively.

Figure 6 illustrates the six main raw materials used for the manufacturing of optical fiber and compares their emission rates per year considering a cradle approach. Because of an increase in production from 2013 to 2016, more raw materials had to be bought. When more of these raw materials are bought, the Scope 3 emissions increase. Note that the y-axis of

Figure 6 is blank for security purposes.

Also, correlations between carbon emissions and production of fiber were analyzed. Each of the major raw materials was also analyzed for emission increases or decreases per year of production.

Figure 7 compares and illustrates the correlation between amount of fiber in million meters of fiber (FMM) produced and emissions for each specific scope. This figure exemplifies the how Scopes 1, 2 and 3 emissions change with the change in production. The figure shows an increase in production of fiber, a decrease in Scope 1 emissions and an increase in Scope 2 and 3 emissions. The increase in Scope 3 makes sense as it takes more raw materials to make more products. The interesting point of this graph is that as production increased, Scope 1, or direct emissions from the plant, decreased. This shows that OFS has been innovating to reduce their impact environmentally. It is also interesting to point out that Scope 2 increases by about 10% from 2013 to 2016. Scope 2 values on this graph are a representation of its magnitude, but not its scale as all emissions were subtracted from by the emissions from 2013.

Challenges

Many of the challenges in calculations arise from Scope 3 calculations of purchased goods. To find out the amount of carbon emissions generated by purchased goods, one only needs to know the quantity purchased and the emission factor of the product. An emission factor is a factor that can convert units of product purchased into units of CO

2 emitted by a certain amount of product. The best way to determine the emission factor of a product is to ask the manufacturer, as they should have a sustainability report that might have that information. Unfortunately, none of the companies that OFS purchases raw materials from has this specific information about their products. So instead, OFS had to use generic emission factors found in literature for each of its raw materials. Aluminum sulfate’s emission factor was the emission factor for the powder and not the liquid 25% by mass material that OFS uses. Raw Material A used at OFS has similar manufacturing properties as plastic, so the emission factor used is an average of different plastics’ emission factors. Raw Material C’s emission factor was difficult to find, so the emission factor used was that of a silicone product as they are both similar products. The emission factor for Raw Material B was very difficult to find, so instead, OFS used the emission factor of a generic chemical, which is 3 kg/kg. All of these numbers besides Raw Material A’s emission factor came from Appendix 7 of the WSTP South End Plant Process Selection Report [

16]. Raw Material A’s emission factor was from Exhibit 8 of the plastics report by the United States Environmental Protection Agency [

17].

4. Discussion

There were a few noteworthy portions of the results that are correlated with current attempts at the plant to be more environmentally conscious and more efficient with our energy. From 2013 to 2016, the amount of carbon emissions from the natural gas boilers decreased. This is due in part because of implementing improved maintenance practices, an energy assessment being done on all the boilers, and a full replacement of a boiler at the end of 2013 to a more energy efficient one. Another project to try to improve the carbon footprint is to replace all of the 36 electrical zirconium furnaces to more energy efficient graphite furnaces as their idle power suck is half that of a zirconium furnace. From 2013 to 2016, 12 of the 36 have been replaced. There is an increase in electricity usage for those four years, which is most likely a consequence of the 48% increase in production. In comparison, electricity usage was only up 10% from 2013 to 2016. It is however important to note that taking on large energy efficiency projects does cost a company a significant amount of money. For example, the transfer from zirconium furnace to graphite furnace costs $312,000 per furnace switch. As prior mentioned, from 2013 to 2016, 12 of the 36 have been replaced, which means $3.744 million was spent replacing those furnaces. Accounting for a 47.81% increase in production to the nominal increase in electricity output of 10.40%, electricity output for the plant was down 37.41%. Knowing that per year OFS spends about $7 million dollars on electricity, OFS saved $2.62 million in 2016 alone compared to 2013. Though it seems like a large expense, it turns out that if this trend continues, OFS can expect this switch to save the company $1.496 million by the end of 2017. And these savings will continue to improve the company’s bottom line for years to come. This is why it is very important to also look at the cost-benefit analysis of any energy-saving and environmental-helping causes, as they tend to be surprising.

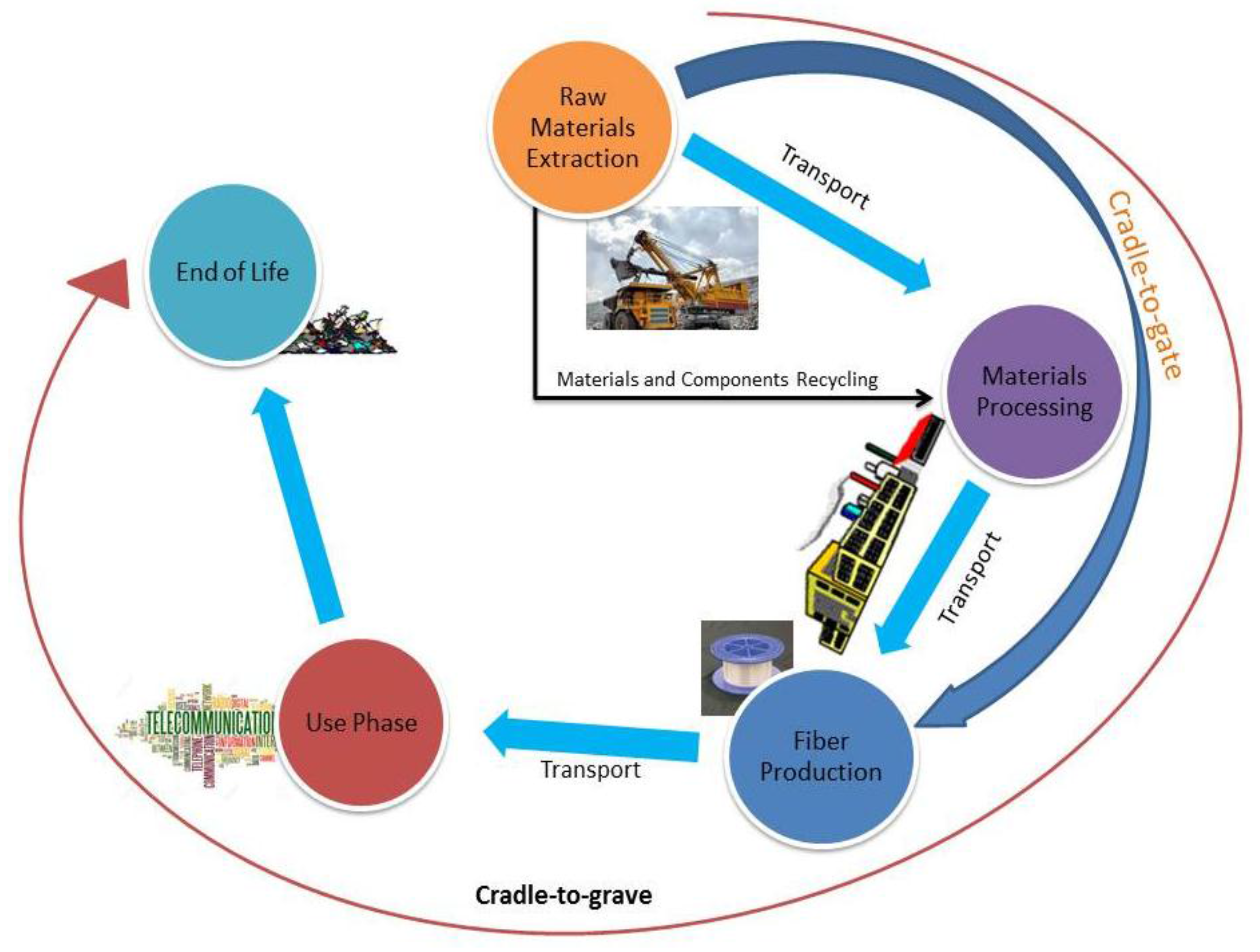

In general, the industrial sector produces goods for consumers by using energy to transform materials into useful products. Traditionally over the years, manufacturing systems have been designed based on a linear model starting with raw material extraction and ending with landfill disposal. A circular economy model challenges this approach by providing opportunities to re-manufacture and reuse end-of-life consumer products, leading to more efficient use of materials. By analyzing the pathways and transformations that occur as materials cycle from nature through manufacturing systems, industries have the opportunity to better understand the material requirements, reuse, and the associated use of energy and production of byproducts, waste products, and emissions to air, water, and soil. Carbon foot-printing by energy usage is the first step for this circular approach. No published literature is available for optical fiber production, as the carbon efficiency evaluation of Fiber to the x (FTTX) deployment currently excludes optical fiber production in calculations [

18]. Based on the published FTTX L model, the amount of CO

2 emitted due to the use of fibers is far less than the amount of CO

2 that is emitted during the manufacturing; in fact, the former amount is several times lesser than the later, according to our calculations. That is why OFS uses every opportunity in all functional areas to develop products that not only function well but also have higher energy efficiency thereby emitting less CO

2 when used. In a wide range of fields, from manufacturing to FTTX, the OFS intention is to make products that help customers to reduce their environmental impact.

Perhaps, telecommunication industries are also being asked to make their networks “greener” as part of the overall push toward sustainability in business. Spending to bring information technology activity across the world into a greener space is expected to be significant. With reference to the data center market alone, Pike Research reports [

19] that the amount of money spent to make data centers greener over the next four years will grow to

$45 billion by 2016, at a compound annual growth rate of nearly 28 percent [

20]. Optical fibers play very important role in tallying the carbon emissions from every part of a fiber to the home (FTTH) lifecycle, and in addition the optical fiber manufacturers are also able to spot places where reductions might be made. Since fiber networks use less energy to power the signal, they also generate less heat, and therefore require less cooling. Based on the EPA report [

21], each kilowatt of network power in a data center requires a kilowatt of power for the cooling devices. Therefore, reducing energy use by powering a fiber-optic network will indeed need less energy to cool. This also means that data centers need less heating/ventilation/air-conditioning (HVAC) equipment in addition to the energy savings, year after year. Several key studies are reported expressing carbon footprint for FTTX deployment using life-cycle analysis (LCA), but the purifying and drawing of optical fiber in its production were excluded in those studies and no meaningful carbon footprint numbers exists in the literature yet.

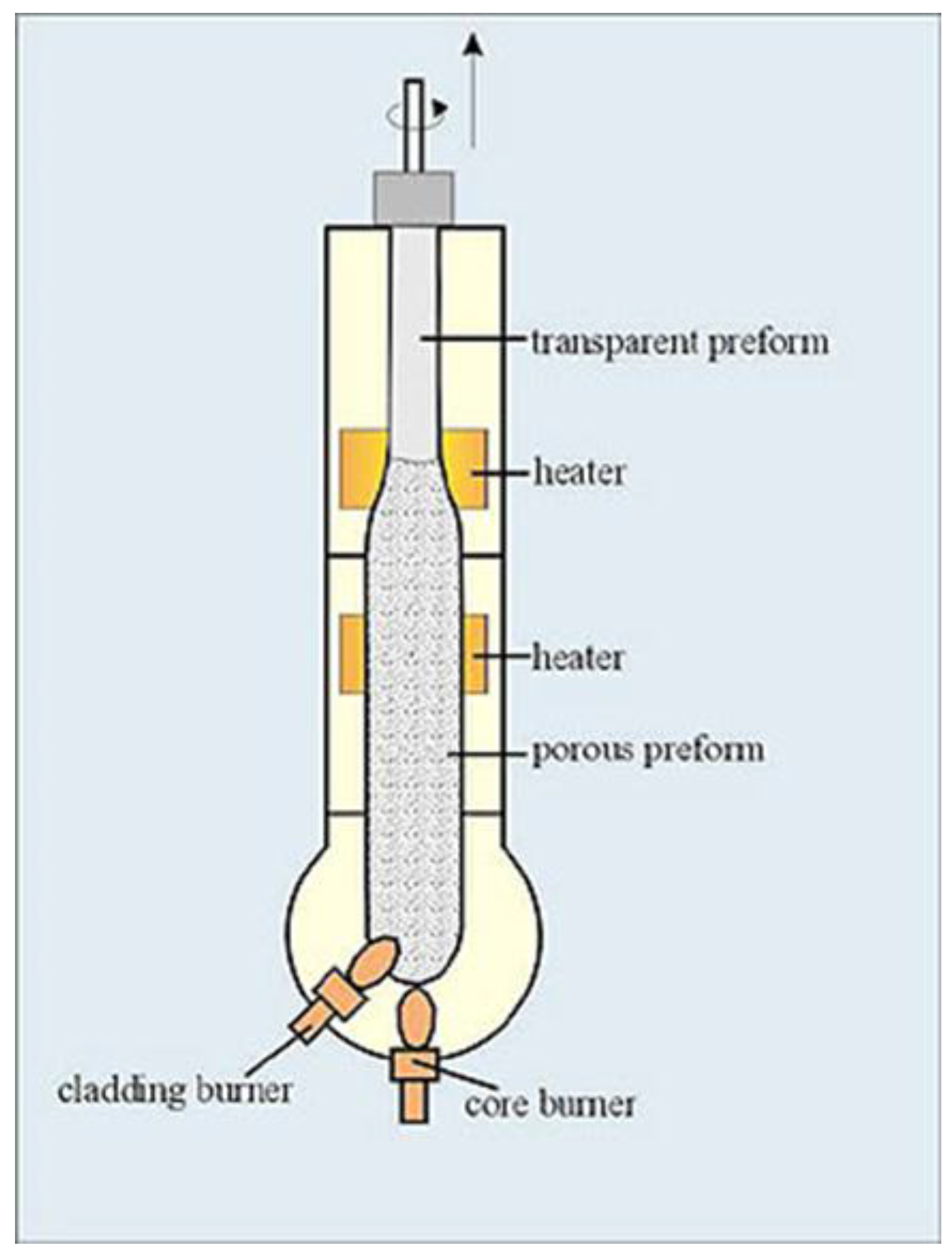

The carbon footprint associated with making optical fibers is immensely complex and requires a comprehensive LCA, proceeding from raw material extraction and transportation to manufacturing (or service provision), to distribution, to consumer use, and to end-of-life disposal. Pure silica glass is the major component of optical fiber, and this pure silica has to be dug out of the ground. The silica has to be turned into SiCl4. Other components have to be brought together: coatings, inks, several gases like hydrofluoric acid, and so on. All of this involves transporting things around the world. However, the different raw materials coming into a production process can be produced in different countries. The whole lot then has to be processed in a controlled environment, and every stage in the process requires lots of energy. So far, the available studies and methods for defining a fiber carbon footprint are far from comprehensive. More detailed, robust analytic techniques are in high demand as companies receive customer requests and regulatory pressure for this information. In addition, LCA efforts by nature can be resource-intensive, complex, and fraught with uncertainty due to the dynamics of supply chains, multitude of parts within a product, and lack of key data.

Fully leveraging on high technological prowess and comprehensive strength, OFS seeks to contribute even further to creating low carbon manufacturing which is sustainable at higher level.

Future Research

LCA study should also be performed on the environmental impact of all OFS products and services throughout their life spans. The LCA study provides OFS with a methodology to evaluate and quantify the impact of a product throughout all life-cycle phases and then makes decisions on how to reduce the impacts in each life cycle phase to optimize the environmental performance of the product.

Another study to consider would be a study that compares the emissions from the production to the emissions from the actual usage of the product and tries to balance making the production more environmentally friendly and to make improvements to the final product for better performance. This would increase the scope of this paper to cradle-to-grave.