1. Introduction

A detailed analysis of the interconnections between energy options, economic growth, and protection of the natural environment—as well as potential social repercussions—highlights an incontrovertible vision of the developing and dismantling of renewable energy technological infrastructure to foster the so-called green economy. There is growing awareness in the world that the challenges linked to the affirmation of such technologies for the diffusion of green energy require appropriate measurement and evaluation of the economic, environmental, and social impacts associated with their entire life cycle.

It is well known that photovoltaic technology (PV) produces a no-cost, solar generated, renewable source of green power, the atmospheric emissions of which (i.e., carbon dioxide and other greenhouse gases) rate at “zero value”. However, during their entire life cycle, from the production of PV modules to their final disposal, considerable quantities of non-renewable resources and different forms of renewable energy generate pollution and waste with a high environmental impact.

In the prospect of the disposal of the modules produced in recent years, some countries (especially Italy) have to address the various issues involved (technological, economic, environmental, etc.) with respect to the problem of their disposal to guarantee genuine sustainability from a technical-economic and socio-environmental perspective. The significant amounts of largely recyclable waste likely to be produced over the coming years imposes the need to plan the disposal of PV systems at the end of their life cycle with effective operations of demolition, dismantling, and removal, disposal and/or recycling of the different components in a context of environmental responsibility. The estimates on PV waste in Europe [

1] foresee, over the next decades, a significant increase of the same, from more than 33,000 tons in 2020, to about 133,000 tons in 2030, and to almost 4 million and 9.5 million tons, respectively, in 2040 and 2050. First-generation technologies based on silicon mono- and polycrystalline (c-SI) will have an incidence of 40%, followed by those of second-generation thin film, with a constant increase of those that use amorphous silicon (a-Si), cadmium telluride (CdTe), and copper indium selenide (CIS) or copper indium gallium selenide (CIGS). The useful lifespan of third-generation modules—based mainly on a concentration of technologies or on organic materials—tends to increase to about 30 years [

2], compared to 20–25 years for first-generation modules that are still to play a marginal role in the medium-long term.

At the national level, given the ratio between the quantity of waste produced and PV power units installed, estimated at 70/80 t for each MWp installed [

3], a considerable increase in the production of PV waste is envisaged; starting from 2030, approximately 5000 tons, compared to 1000 t in 2020, and becoming 1 million tons by 2040.

Our work analyzes the peculiarities of the photovoltaic sector in Europe as a whole, and in Italy in particular, in order to highlight the main initiatives taken at the national level for the end of life management of the modules.

The study is structured in four parts, starting with a synthesis of elements relating to the energy scenario at European and national levels, with particular reference to the evolution of renewable energy sources (RES), regulations, and strategies. Subsequently, we conducted an in-depth analysis of the technical and economic aspects associated with the end-of-life management of the modules, together with an assessment of the Italian scenario, in light of recent community legislation on waste electrical and electronic equipment (WEEE). In the final section we outline the main considerations, highlighting the fact that—based on the experience gained so far—rarely do enterprises operating in the PV sector in Italy adopt the logic of advanced integration in the management of PV modules; i.e., approaches aimed to modify upstream and downstream processes of obsolete PVs from the perspective of environmental improvement.

At the national scale, the entire production chain is impacted by various critical elements limiting complete integration. Upstream, the deficiency is evident in the production of cells—an industrial sector in which Italy was a pioneer in the 1980s. Downstream, instead, the lack of best practices tested and implemented for the disposal and recycling of the modules at end-of-life constitutes a serious limit to the realization of sustainable management of the PV supply chain through the involvement and awareness on the part of the actors in the process.

2. Background

The European Union has long been engaged in promoting an energy system fed mainly from renewable energy sources (RES)—predicting to be almost fully supplied RES by 2050—prospecting a significant effect on the economy, employment, scientific and technological research, and environmental protection.

In this perspective, the European Commission has launched the

Energy Roadmap 2050 (COM(2011) 885/2) [

4], which confirms and renews the previous measures provided for in the “Climate and Energy Package” [

5,

6] and the

Roadmap for moving to a low-carbon economy in 2050 (COM(2011) 112) [

7]. Both instruments—designed to give greater impetus to the process of decarburizing the energy system—envisage a reduction of emissions of greenhouse gases by 80%–95% compared to the levels of 1990 by the year 2050. The path traced to achieve such economically sustainable goals is based on internal operations, primarily on the improvement of energy efficiency—in particular in the civil sector (residential and tertiary)—as well as on the increasingly spread supply, especially in the sector of electricity generation (COM(2015) 80) [

8]. In other words, a framework strategy for a Union of resilient energy, accompanied by a forward-looking policy on climate change.

As concerns the diffusion of renewable sources of energy, the recent report on the progress made in the field of renewable energies (COM(2015) 293) [

9] has shown how the EU envisages the surpassing of the preassigned target from the Directive on renewable sources (2009/28/EC) [

10] to 2020 by about twenty countries.

Given the thrust of the initiatives undertaken at the European level, Italy over the last few decades has promoted the development of renewables through diversified incentive schemes, adopting planning tools and addressing relevant issues. Since the 1980s, various measures have been approved to support the production of energy from fossil fuels using

feed-in tariff,

market-based, mechanisms, capital account funding, as well as tax concessions. In Italy in particular, a significant role was taken in the past by the Provision of the Interministerial Committee Prices no. 6 of 29 April 1992 (CIP 6/92), established to give an initial impulse to the diffusion of RES. CIP 6 is characterized by a remuneration of renewable energy plants, although not contemplating the reservation of an incentive mechanism exclusively for renewable sources [

11]. Subsequent to CIP 6, the system of

Green Certificates (GC) was established in 1999 (i.e., a mechanism that introduced the obligation for manufacturers and importers of electricity from conventional sources to make a share of energy produced from renewable sources available on the network). More recently introduced were the

Feed-in Scheme (which stimulated electricity produced exclusively by photovoltaic plants),

All-inclusive feed-in tariff (an alternative to the system of green certificates for installations of smaller size),

Simplified purchase and resale arrangements (a simplified mode at the disposal of producers for the sale of electricity available on the network, as an alternative to bilateral contracts or for direct sale on the stock exchange), and

Net metering (a service to enable the owner or whoever manages the plants to compensate for network electricity taken and consumed during a different period from that of production. In 2010, the Ministry of Economic Development issued (transposing Directive 2009/28/CE) the

National Action Plan for Renewable Energy Sources (NAP RES), which defines, inter alia, specific actions for each technology and application, together with the quantitative targets in the different areas of intervention (electricity, air conditioning, and transport) [

12]. The NAP RES provides detailed information on actions to be taken in order to achieve the binding target to cover 17% of gross national consumption with energy produced from renewable sources by 2020. This objective of a general nature is to be pursued through the establishment of a specific target in the sectors of electricity, air conditioning, and transport. In particular, in Italy, it is expected that the RES meet:

- ➢

10.14% of the energy consumption associated with transport, through the increasing contribution of biofuels, the improvement of energy efficiency, and the development of electric traction;

- ➢

26.39% of electricity consumption, also through the improvement of infrastructure and storage systems, as well as the spreading of the smart grid;

- ➢

17.09% of consumption in the sector of air conditioning, through (among others) the development of district heating and diffusion of cogeneration.

It also provides for the sharing of national targets with the Regions (burden-sharing) in order to promote the harmonization of the various levels of public planning of the laws of the sector and of procedures for the authorization of plants and infrastructure.

The objectives set out in the NAP RES (regulated at the national scale by Italian Legislative Decree no. 28 approved on 3 March 2011 [

13]) include—in addition to systemically redefining the institutional, financial, and legal framework—a series of instruments to boost renewable sources in order to achieve greater efficiency, effectiveness, and stability, as well as the reduction of costs borne by users/consumers.

More recently (March 2013), the Ministry of Economic Development published the

National Energy Strategy (SEN), a tool to address and plan the definition of a regulatory framework in the medium–long term that is stable and consistent over time [

14]. In particular, priorities for the development of the Italian energy sector have been set defining the strategic guidelines for the future based on supranational trajectories, albeit in a free market context.

A central element of the SEN supports the sustainability of renewable energies, in a perspective of decarbonization of the energy sector and the reduction of the vulnerability of supplies of fossil fuels, which currently represent over 80% of our energy balance and account for approximately 90% coming from abroad.

In 2014, 17.07% of the final energy consumption in Italy was from renewable sources, surpassing the objective estimated for Italy by Directive 2009/28/EC of 17% in 2020. In particular, the thermal sector accounted for 49% of total renewable energy consumption, followed by the electricity sector (46%) and transport (5%).

Achievement in the advancement of the target depended not only on the increase of renewable resources, but also on economic factors such as the decline of overall energy consumption and the availability of new official data on certain sectors—in particular with regard to the use of biomass for heating.

Regarding the production of electricity from RES, this was mainly due to the increase in PV and wind energy. The production of new total power of installed generation over the last five years has exceeded the value of new plants powered by fossil fuels.

In 2015, global PV-installed power reached 240 GW [

15], and is expected to reach almost 310 GW by the end of 2016, with an increase in overall power of approximately 70 GW [

16]. In the medium-term (2020), overall capacity could triple, reaching 700 GW [

17], while in the long-term (2050), it could reach 4500 GW [

18].

At the European level, newly-connected photovoltaic power in Europe was approximately 8 GW in 2015 [

15].

A strong thrust to the growth of the PV market comes from the main newly-industrialized countries (China, India, etc.) that have implemented projects for the decarbonization of their respective energy systems, appreciating solar technology. Even the United States has been investing in PV systems in recent years, acquiring a prominent position in the world after China and Japan [

19], boasting the highest rate of growth in installed capacity among the non-European countries.

The forecasts by the European Environment Agency (EEA) based on the NAP RES submitted by the Member States estimate a considerable increase in the power of PV systems in Italy, whose objectives (8 GW) have in fact already been largely exceeded (over 18 GW of installed power in 2014, approximately 9 GW of which were installed in 2011) [

20].

It is worth noting that in the future, previous annual PV growth rates registered in various countries (including Italy) are unlikely to continue. Previously, they were mainly favored by incentive schemes. Incentive policies in Italy date back to the late 1990s with a program called

Photovoltaic Roofs, and continued until the “Fifth Feed-in Scheme”, which came into force on 27 August 2012 and ended in July 2013. The

Photovoltaic Roofs Programme (2001–2003) granted capital contributions for the construction of photovoltaic plants of small power (1 to 50 kWp) connected to the electric network. In 2005, the

Energy Account came into force, which no longer provides a contribution for the construction of photovoltaic systems but provides remuneration of kWh produced at a higher price than in the market for a period of 20 years. It is a form of support which differs depending on the power of the plant and of its level of architectural integration. It replaces the previous state contributions to funds intended for putting installations into service. Over time, this mechanism has been modified several times, coherent with the changing needs of the market, passing from the I Energy Account to the V Energy Account [

21].

An interesting study [

22] made by experts from the academic, institutional, and industrial fields shows that PV could become competitive with conventional energy sources over the next few years in various countries, albeit with different dynamics. As regards Italy, experts currently estimate that the investment costs per power unit of a PV plant are comparable with those of a coal-fired power plant [

23]. Among the many factors contributing most to the achievement of grid parity, some are due to the increasing cost of electricity produced by conventional plants and the others to the strong decrease in the price of PV modules, narrowing over the last three years by around 75% due to lower production costs. Among the countries involved in this challenge, Germany, Italy, Denmark, Spain, and Australia, followed by France, Japan, Brazil, and Turkey, are distinguished. Photovoltaic technology over the next 3–4 years could reach grid-parity in 50% of potential markets, and even in 80% of the market by the end of 2017 [

24]. Moreover, it is noteworthy that grid parity has already been reached in the small plants installed in Southern Italy, while larger ones could potentially be achieved not only thanks to an effective regulatory framework, but also by the introduction of technological innovations capable of reducing the costs of the plant [

25].

The recent evolutionary dynamics that characterize the PV sector in Italy are distinguished by a strong trend in growth for both installed capacity and for production, and are of two-fold interest. On one hand, PV has contributed to the process of decarbonization of our energy system; on the other, it has revealed the need to tackle the issues related to the economic-environmental sustainability of the entire PV supply chain. In this context, there is an urgent need to plan the end-of-life of the modules, the growing quantities of which will require—in the space of a few decades—the implementation of appropriate procedures for their recovery and recycling, as well as the adoption of appropriate technologies for the treatment of waste arising from their decommissioning.

3. The End-of-Life of Photovoltaic Modules

Before proceeding to the analysis of the main environmental implications and the economic and legislative issues related to the management and disposal of PV modules at the end of their life in Italy, it seems useful to outline a synthetic framework of the fabrication technologies that are currently available.

PV technology is structured in different kinds of modules, which vary in terms of materials used, size, weight, and performance. Consequently, the rate of energy efficiency ranges from 10% in the case of amorphous silicon to about 16% for modules in cadmium telluride (CdTe) and copper indium selenide (CIS) or copper indium gallium selenide (CIGS), to 18–22% for modules based on crystalline silicon (c-Si) (about 18.5% for the modules are of polycrystalline silicon and almost 23% for those of monocrystalline) up to higher percentages for third-generation modules [

26]. On average, over 80% of the weight of the materials used in the production of a module in crystalline silicon is from roofing materials (glass), from the support frame of anodized aluminum, as well as from ethylene vinyl acetate (EVA) sealant. The weight of these substances increases significantly in the CdTe and CIS or CIGS modules, despite having a different composition.

In the composition of the photovoltaic modules (albeit in small quantities of different metals) are some toxic (for example, lead and cadmium), and other rare (e.g., tellurium and indium) and precious metals (e.g., the silver used in contacts). Therefore, the management of PV panels at the end of their life cycle proves to be a particularly important stage in order to develop materials that would be dispersed if subjected to incineration and scattered in the environment with harmful effects if decommissioned.

From the analysis of the scientific publications present in the literature, it is suggested that these issues were the subject of study only starting from the 1990s. Previously, attention was directed mostly to the phases of the PV supply chain according to an approach from cradle-to-gate, without considering the environmental aspects associated with the end-of-life of the modules. Instead, in the course of the last few decades, a handful of studies have supplied information on the toxicity of components used in certain types of modules [

27,

28,

29,

30,

31,

32,

33,

34,

35], adopting different systems of evaluation and prospects. Other studies have evaluated the economic and technological impacts of the different processes for the disposal and recycling of modules [

36,

37,

38,

39] and innovative recycling methods that have been identified [

40,

41,

42].

However, the specificity of such studies represents the main obstacle to methodical comparison of the environmental performance of PV systems.

Based on some studies [

1,

3,

43,

44], the percentages of recoverable materials used in the production of modules are particularly high for glass and aluminum (97% and 100%, respectively); they are more contained but equally relevant for copper and tellurium (about 80%), lower for rare metals such as indium and gallium (75% or 99%, respectively) that do have a significant value, despite representing only 1% of the weight of the panel [

43]. Other studies conducted recently [

45,

46] have highlighted the importance of a process of dematerialization in the production phase of the modules that—in conjunction with the progressive improvement of their efficiency—has resulted in positive effects on costs and on the management of end-of-life.

In the last decade, the life cycle analysis (LCA) method has been applied to the systematic assessment of environmental issues in the PV supply chain by following a cradle-to-grave or cradle-to-cradle approach, in order to realize a “closure of the loop” [

47,

48,

49,

50,

51].

However, official data on the amount of PV waste produced and on the disposal and/or recycling techniques adopted in international (and particularly European) contexts is still fragmentary. In addition, their difficult comparability does not allow one to attain the knowledge base required to process correct assessments and rigor in order to assess the environmental impacts of different PV supply chains.

Moreover, although multiple technological processes are under development for the processing and recycling of PV modules, only two are on an industrial scale: one applied to crystalline silicon modules by Deutsche Solar, and the other refined by First Solar for thin film cadmium telluride modules [

52]. Other processes exploring experimental mechanical, thermal, and chemical techniques are conducted and funded by major European Union research programs: REcovery of SOlar Valuable materials, Enrichment, and Decontamination (RESOLVED) and Sustainability EvaluatioN of Solar Energy systems (SENSE).

The disposal of a first-generation PV module actually allows high recovery rates of components (more than 80% of the total weight of the module) through the separation of the plastic components of the panel using a heating process, followed by manual recovery of the solar cells, glass, and metals and/or alloys such as aluminum, copper, steel, etc. Nevertheless, this process has two main limitations: the first derives from the need for various manual activities, which limits production efficiency and economic benefits; the second is linked to the widespread market availability of many different silicon-based solar cells that require specific treatments—not all of which have yet been tested. However, research and development on automated processes for treating crystalline silicon modules has recently begun.

The disposal of second-generation modules through the process employed by First Solar achieves high recycling rates (90% for glass and 95% for semiconductor material), noticeably reducing the risk of environmental damage associated with the release of cadmium into the environment.

Recently, the process was subject to further studies in order to test its effectiveness with emergent technologies (CIS, CIGS). Several systems are currently undergoing testing for the treatment of several types of the wide variety of modules available, and innovative modules still undergoing experimentation. More specifically, dye-sensitized solar cells, organic cells, and hybrid solar cells, for which it is difficult to make forecasts regarding the implementation of adequate end-of-life management strategies.

Most PV waste generated is pre-consumer waste, and this relatively small amount—e.g., just under 17,000 tons in 2015 in Europe (of which 800 t was in Italy) [

3,

46] and at the global level could reach between 43,000 and 250,000 tons by the end of 2016 [

18]—makes recovery and recycling economically inconvenient. However, several forecasts predict that from 2025 to 2030, when the modules entering into production in recent decades reach their end-of-life, the decommissioning stage of the PV supply chain may be able to set much more ambitious goals for recycling and recovery, even for Italy.

Relative to the rare metals present in photovoltaic panels (i.e., indium, silver, germanium, and gallium), despite representing only a total of about 1% of the weight of the panel, they still have significant value, estimated for 2050—on the basis of the amount of forms to be disposed of in Italy and projections of price at 2050 (equal to 1348 €/kg for silver, 773 €/kg for indium, 754 €/kg for gallium, and 1163 €/kg for the germanium)—respectively equal about 130 million € of indium, over 1 billion € of silver, about 21 million € of germanium, and almost 2 billion € of gallium [

43].

Moreover, also of considerable interest is the collection and recycling of copper and tellurium for the benefits that could derive from both an economic and environmental perspective. The reuse of tellurium in the productive cycle of CdTe modules would reduce its demand and contribute to optimize the use of increasingly meagre natural resources. The recovery of copper may well prove economically useful for Italy, which meets its internal demand (approximately 1 Mt in 2013) mainly by resorting to imports (61.4%), and only 38.6% from recycling [

53].

The proper management of end-of-life of PV waste is essential not only to enable recovery and recycling for other production processes of often-limited natural resources, but also to properly dispose of hazardous substances such as cadmium present in thin-film modules and the lead in c-Si modules. The toxicity of cadmium for animals, plants, and humans has been widely documented in recent years: the excessive accumulation of this metal causes chlorosis in plants, and necrosis, toxicity, or death in animals. In humans, the effects from acute intoxication lead to weakness, fever, and vomiting, while the effects of chronic intoxication lead to pulmonary emphysema, kidney dysfunction, and damage to the skeletal apparatus. Lead has different biochemical and physiological effects, as it interferes with some enzymes and can cause damage to the peripheral paresis, etc.) and central nervous system (headache, tremors, irritability, hallucinations, memory loss, coma, etc.), as well as to the cardiovascular system, the endocrine system, kidneys, etc. The amount of lead present in c-Si modules vary from 1.64 to 11.4 g for panels being superior to those of cadmium in CdTe modules, ranging from 0.32 to 11.4 g. Furthermore, the potential for the leaching of lead varies from 13% in conditions of pH 6–7 to 90% in the presence of a pH 3–4, presenting values much higher than expected for cadmium (29% and 40%, respectively). The costs relating to pollution caused by the leaching of materials containing improperly disposed of lead and cadmium were approximately estimated to be equal to 1174 €/kg and 46 €/kg, respectively. Based on such evaluation, it is possible to envisage that, in 2050, improper disposal of 2151 tons of lead content primarily in c-Si modules (which have a mean leaching of 1741.2 t) and 877 t of cadmium contained in CdTe modules (with an average leaching of 302.5 t) may have a cost, respectively, of over 2 billion € and about 14 million € [

43].

4. The Management of End-of-Life of PV Modules: An Analysis of the Italian Scenario

In Italy, a considerable thrust towards the responsible management of the end-of-life of PV modules was the Legislative Decree No. 49 of 14 March 2014 [

54] that implements the Directive on Waste Electrical and Electronic Equipment (WEEE) (Directive 2012/19/EU) [

55]. According to this decree, decommissioned PV panels were included in the types of household and professional WEEE for enhancing the use of secondary raw materials in order to promote a more efficient use of the natural resources used in their production.

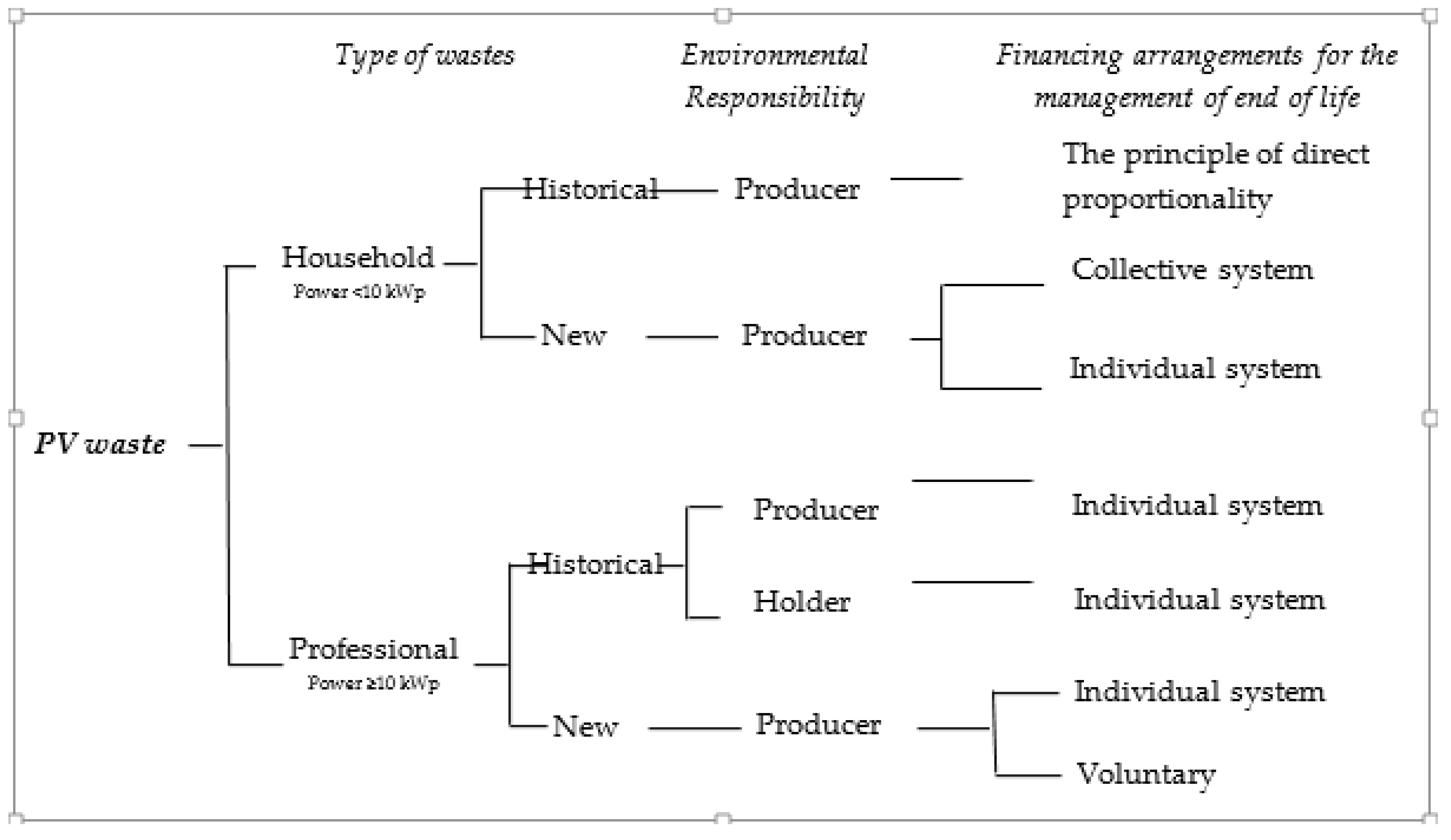

At their end-of-life, the modules are differentiated based on the power of the plant to which they belong (considered as household waste less than 10 kWp from the decommissioning of power plants; professional in other cases), depending on the period in which they were placed on the market, and therefore handled differently from both a technical and economic point of view, in a perspective of “extended producer responsibility” [

56]. This now represents one of the most important meta-principles of environmental policy (

Figure 1). The panels at the end of life that come from plants installed before the entry into force of the Legislative Decree 49/2014 are defined as “historical, while those entered in the subsequent period are regarded as “new” waste.

The environmental responsibility of historical PV waste coming from private households for conveyance to the “collection centers” is borne by producers on the market according to the principle of direct proportionality. This sees them involved financially based on market share, calculated in relation to the weight of the modules placed on the domestic market in the year in which the operations of waste management took place.

In the case of new PV waste from private households, instead, the producers offer estimates of the costs of collection and treatment of the modules, and may choose whether to fulfill the job on an individual basis—considering the waste resulting from the disposal of its own photovoltaic modules—or from a collective system calculated on the basis of the weight of the modules that are placed on the market in the year of reference.

The financing of the operations of management of the professional historical modules to be dismantled is instead at the expense of the producer only in the case of the supply of new photovoltaic panels in the replacement of an equivalent product (technology, size, power, efficiency); in other cases, it is to be borne by the holder.

The environmental responsibility of the new professional PV waste is finally charged to the manufacturer from the date of the introduction of the system on the market; the producer can subscribe to voluntary agreements with users in order to provide alternative ways of financing the management of such waste.

The Decree also defines the minimum goals guaranteeing (until 14 August 2015) that at least 75% (by weight) of the modules be recovered, and that at least 65% (by weight) undergo the recycling process. Subsequently, until 14 August 2018, objectives will be even more ambitious, since recovery of 80% and recycling of 70% is estimated. The public body member for monitoring the attainment of the objectives set is the Italian National Institute for Environmental Protection and Research (ISPRA). It annually transmits a detailed report to the Ministry of the Environment and Protection of the Territory and the Sea informing about the quantities and categories of electrical and electronic equipment (EEE) placed on the market, prepared for reuse, recycled, and recovered, as well as on the WEEE collected separately and exported. The cited Ministry sends a report to the European Commission on the implementation of Directive 2012/19/EU every three years.

However, it should be noted that, in Italy, the commitment to dispose of PV modules in an appropriate manner was already prescribed in the precepts of the Fourth Feed-in Scheme (Ministerial Decree 5 May 2011) [

57], in reference to the systems put into operation after 30 June 2012.

For such modules, a certification issued by the manufacturer of photovoltaic modules was requested (or in the case of its absence, the liable party, certifying adherence to a system or consortium) had to be transmitted to the Manager of Energy Services (GSE), which is the state-owned company that promotes and supports renewable energy sources (RES) in Italy [

58].

The manufacturer of photovoltaic modules (or in the case of its absence, the liable party) was in fact obliged to ensure the recovery and recycling of the modules with the adherence to a consortium that guarantees the management of the end-of-life of the devices.

In the event of non-compliance with those obligations, the holders of the plants would have been excluded from the benefits provided by incentive tariffs of the Fifth Feed-in Scheme (Ministerial Decree 5 July 2012) [

59].

In implementing the rules of application for the recognition of incentive tariffs (Ministerial Decree 5 May 2011 and Ministerial Decree 5 July 2012), the Technical Regulation of 21 December 2012 was subsequently issued, laying down provisions for the “definition and verification of the requirements of the Systems/Consortia for the recovery and recycling of PV modules at the end of life”.

According to a cradle-to-grave approach, the Technical Regulation considers the waste generated by the disposal of PV modules “downstream” in their use, by tracing, geo-referencing, and monitoring them from their origin and for the entire period in which they have access to incentive mechanisms.

On the other hand, Legislative Decree 49/2014 defines the measures for the prevention of environmental impacts from the design and production of PV modules (i.e., from their cradle), giving producers the environmental liability of the PV waste starting from the placing of the modules on the market.

Flanked by the pre-existent regulatory framework, a dual mechanism for financing the operations of PV waste management could be delineated. This is supported by both manufacturers in the year in which they manifest the related costs and by holders of plants in fulfilling the obligations of the Technical Regulation, or even by holders whereby the GSE could apply deductions from incentive mechanisms of the I, II, III, and IV energy accounts (valid until 29 June 2012) [

60]. However, this would imply an excessively burdensome environmental cost for the treatment of waste PV.

A potential solution was offered by the Environmental Provision attached to the Stability Law 2014 [

61], stipulating “environmental regulations in order to promote measures to green economy and for the containment of the excessive use of natural resources”, recently approved (December 2015). On the basis of this provision, all PV modules installed after the date of entry into force of Legislative Decree 49/2014 are to be managed by the GSE with the same modalities by which managed modules were promoted according to the IV and V energy account schemes, such as the registration of serial numbers, geo-referencing of the modules, as well as the subscription to a system/consortium of collection, which is a trust payment fund paid by the manufacturers to guarantee appropriate management of the modules at their end of life.

The proposed solution has the undoubted advantage of guaranteeing the environmental costs related to the disposal of the PV modules. This is especially relevant in the case where the manufacturer and/or importer of the modules has ceased its activity or in the event the collection system and treatment no longer exist. In Italy, various GSE-accredited operators are currently active as a system/consortium for recovery and recycling. The GSE has defined the technical and financial requirements and/or consortia or systems to manage the end-of-life of waste, of the modules installed in plants operating from 1 July 2012 In addition, the GSE has processed the operating instructions for the management and disposal of incentives for photovoltaic panels, which describes the process that the person responsible for the installations should be encouraged to recover and dispose of the photovoltaic WEEE and the documentation to be submitted to the GSE in order to verify respect of the burdens imposed by legislation. These instructions also illustrate the modalities according to which the GSE establishes the value of the share held by incentive tariffs and the procedures needed to ensure the management of photovoltaic WEEE, where the liable party is insolvent and requires the intervention of the GSE for the complete management of the processes linked to photovoltaic WEEE. These include Cobat, Ecoem [

62], Ecolight [

63], Ecoped [

64], Eco-PV [

65], E-cycle s.c.a.r.l. [

66], ERP Italy [

67], My Energy [

68], RAEcycle, Remedia, and PV CYCLE Italy [

69].

The latter, instituted in 2012, is a consortium handling only the steps related to the points of collection and transport to recycling facilities. It is an affiliate of a non-profit association called PV Cycle with headquarters in Brussels. It was created in 2007 by EU organizations working in the field (manufacturers, importers, retailers, but also research bodies) with the aim of launching a voluntary program for the return and recycling of the modules at their end of life. The mission of the PV Cycle Association focuses on the mapping of the modules at their end-of-life and on their traceability for the correct management of the operations of recovery and recycling of materials.

The members of the association contribute to the cost of collection and recycling through annual financing and a variable fee, calculated on the number of modules placed on the market in the previous year.

The PV Cycle association currently counts well over 250 members who represent 90% of the EU PV market. Present throughout Europe, it holds over 300 collection point certificates, of which approximately 80 are in Italy, positioned second only to Germany (108). In 2013, the quantity of PV modules collected in the European context was equal to 3067 t from 18 countries, and from the beginning of the activities of the organization (from 2010 to 2015), 11,395 t were collected, of which 1757 t was in Italy [

70].

The intervention of PV Cycle is limited to the steps of collecting and/or transport of the modules in crystalline silicon and in thin film, outsourcing all other operating steps. This contributes to the activities of the national consortia, increasingly oriented to manage—by means of integrated systems—the entire chain of disposal, treatment, recovery, and recycling of materials from end-of-life or forms which are no longer working.

Some consortia use—albeit with modifications—technologies already developed within the WEEE sector which combine manual operation to equipment for automatic separation and allow a high recovery of components with a reduced environmental impact, through control of the air flows of the powders resulting from milling, etc.

For panels in crystalline silicon, the Remedia consortium [

71], for example, uses an operational model through which it has managed for years with efficiency and safety in all types of WEEE. Briefly, the approach includes three main phases: removing the aluminum frame and the connection box, trituration, and treatment carried out in a similar way to the recycling of flat screens for modules not in silicon for which different phases are still in the course of study and experimentation.

Other consortia have instead developed specific technologies for the treatment of PV panels. This is the case of RAEcycle, whose Solar Glass ML plant enables the treatment of about 40–60 PV panels per hour with a power consumption of 38 kWh through a semi-automated process [

72].

An important contribution to “closing the circle” of the national photovoltaic spinneret was offered by the Cobat consortium, endorsing in September 2011 a program agreement with the Committee of the Italian Photovoltaic Industries (IFI), representing over 80% of photovoltaic industries. At the same time, the consortium participated in the FUTURAEE project, originating from collaboration with the company S.E.A. (Ecological Environment Services).

By adhering to the COBAT System (which has been operating with excellent results for over 20 years in the sector of collecting and recycling exhausted lead batteries and has a widespread logistics network over the entire national territory), all manufacturers of PV modules associated with the Committee of the IFIS, as well as importers and distributors, ensure the collection and recycling of end-of-life PV modules.

Within the scope of the COBAT and IFI agreement of having a program management system, PV panels are facilitated by the provision of a mapping geo-referenced position of all plants installed in Italy, with the implementation of a traceability system in the life cycle of the modules through a centralized database accessible to the competent authorities. Only 25% of panels used in Italy are produced by local companies, while the remaining 75% are imported from abroad.

After the wasted PV modules have been collected, they are sent to the company SEA Srl, which has developed a technology able to recover 98% of the materials contained in the photovoltaic modules in silicon.

The facilities used for the treatment of these devices also make it possible to recover the aluminium and electrical connections, glass, PV cells (in the form of silica powder), the polymeric support of the same, and the connection ribbon (which has been shot-peened <2 mm) from the phases of preliminary disassembly.

In 2014, the Cobat consortium managed approximately 70 tons of PV waste—a quantity showing strong growth with respect to 2013 (22.5 t). An important part of the PV waste is coming from maintenance activities and from the presence of defects in production, with a minor part from the modules that have reached their end-of-life phase [

73].

5. Conclusions

In the coming years, the Italian PV sector will need to tackle the challenges posed by technological innovations and those linked to sustainable management in terms of energy, environmental, and economic policy, and the activities of the disposal and recycling of photovoltaic modules at the end of life, with a long-term plan for the complex tasks involved.

Recently, at the national level, interesting initiatives to find new treatments and recycling processes “tailored” for the photovoltaic sector—pursuant to the spinneret approach—should set more ambitious objectives for the recovery of glass and aluminum in order to retrieve parts and components from the modules. From the metallic components of the matrix of cells, recovery is possible for the internal copper to the ribbon, silver, tin, and lead of the solder pastes used industrially in the processes of taping (tabbing busses and ribbons of the cells), the silicon of the wafer, and even the silver content in the serigraphic pastes with which the antireflection treatment of the cells is carried out.

A strong critical element within the scope of recycling is the removal of the encapsulation of the laminate used in modules (the most widespread is ethyl vinyl acetate, EVA) due to the high-energy consumption of thermal processes at high temperatures, for the use of solvents, and for the treatment of the fumes in the process. However, there are numerous physical/mechanical methods, such as chemicals and heat, given the composition of the back sheet of the module.

Currently, the technologies used for managing the end of life of PV modules in Italy are those already developed within the WEEE sector, albeit with some expedients. Thus, by combining manual operations with equipment for automatic separation, full recovery of components with a negligible environmental impact is enabled through the control of air and dust flows resulting from milling, soundproofing the noisier components, and the full recovery of hazardous parts (batteries, capacitors, etc.). By sharing skills and knowledge among industrial organizations, innovative industrial processes can be developed to improve the energy balance and the environmental performance of the entire life cycle of a module and to render even more green photovoltaic energy [

74].

In short, key planning of ecological photovoltaic systems will undoubtedly have a strategic role for the reduction upstream in the PV supply chain, the use of high-risk materials and substances, and liquid, solid, and gaseous fuels which are hazardous for human health and the environment, consequently rendering the downstream treatment of PV waste for re-circulation more efficient and adequate, in order to promote a circular economy perspective.