Balancing Disassembly Line in Product Recovery to Promote the Coordinated Development of Economy and Environment

Abstract

:1. Introduction

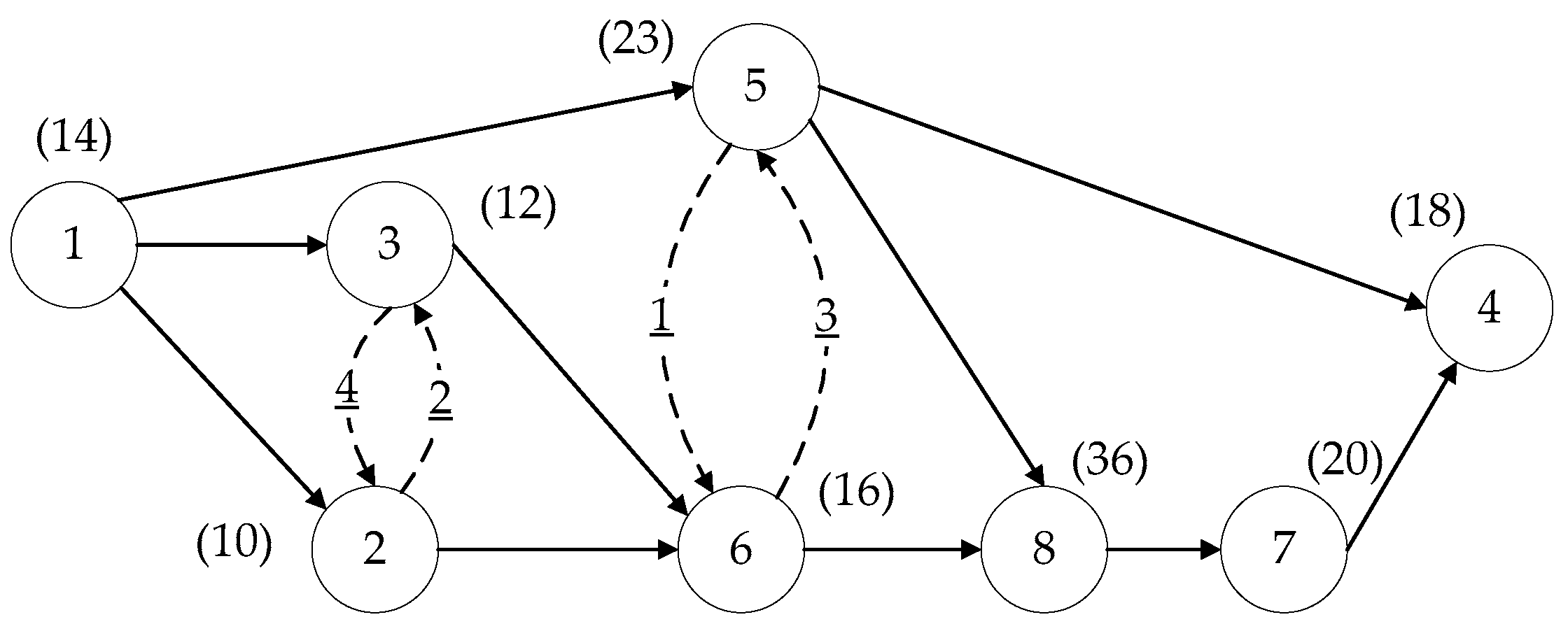

2. Problem Definition and Formulation

- m Number of workstations; i.e., k = 1, …, m

- n Number of tasks, which is equal to the number of parts for removal; i.e., i, j = 1, …, n

- ti Disassembly time of task i

- sdij Sequence-dependent time increment influence of i on j

- ti′ ti′ = ti + sdij, total disassembly time of task i considering sequence-dependent relationships

- Pl lth part in a disassembly sequence; e.g., for sequence {1, 5, 2, 3, 6, 8, 7, 4}, P2 = 5

- dPl Demand quantity for the lth part in a disassembly sequence

- hPl Binary value; hPl = 1 if the lth part in a disassembly sequence is hazardous, else hPl = 0

- ct Cycle time; maximum time available at each workstation

- IPi Set of parts for successors of task i

3. The Basic ABC Algorithm

4. The Improved DABC Algorithm for SDDLBP

4.1. Solution Representation

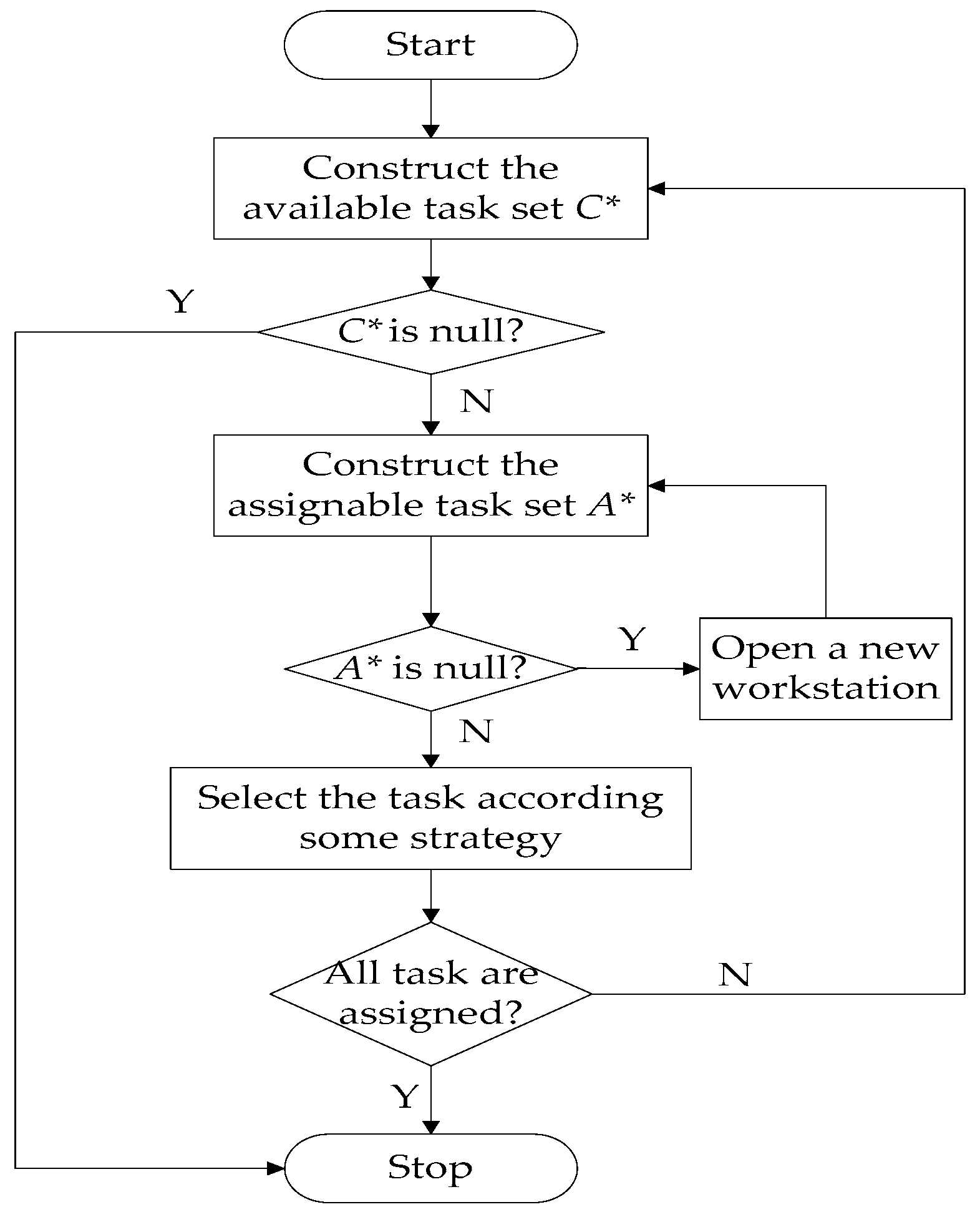

4.2. Population Initialization

- (1)

- A task can be added to the available task set (C*) if and only if it has not been assigned to a workstation and all of its predecessors have been assigned.

- (2)

- A task can be added to the assignable task set (A*) if and only if it belongs to the set of C* and its total processing time considering sequence-dependent time increment is less than, or equal to, the idle time of the current workstation.

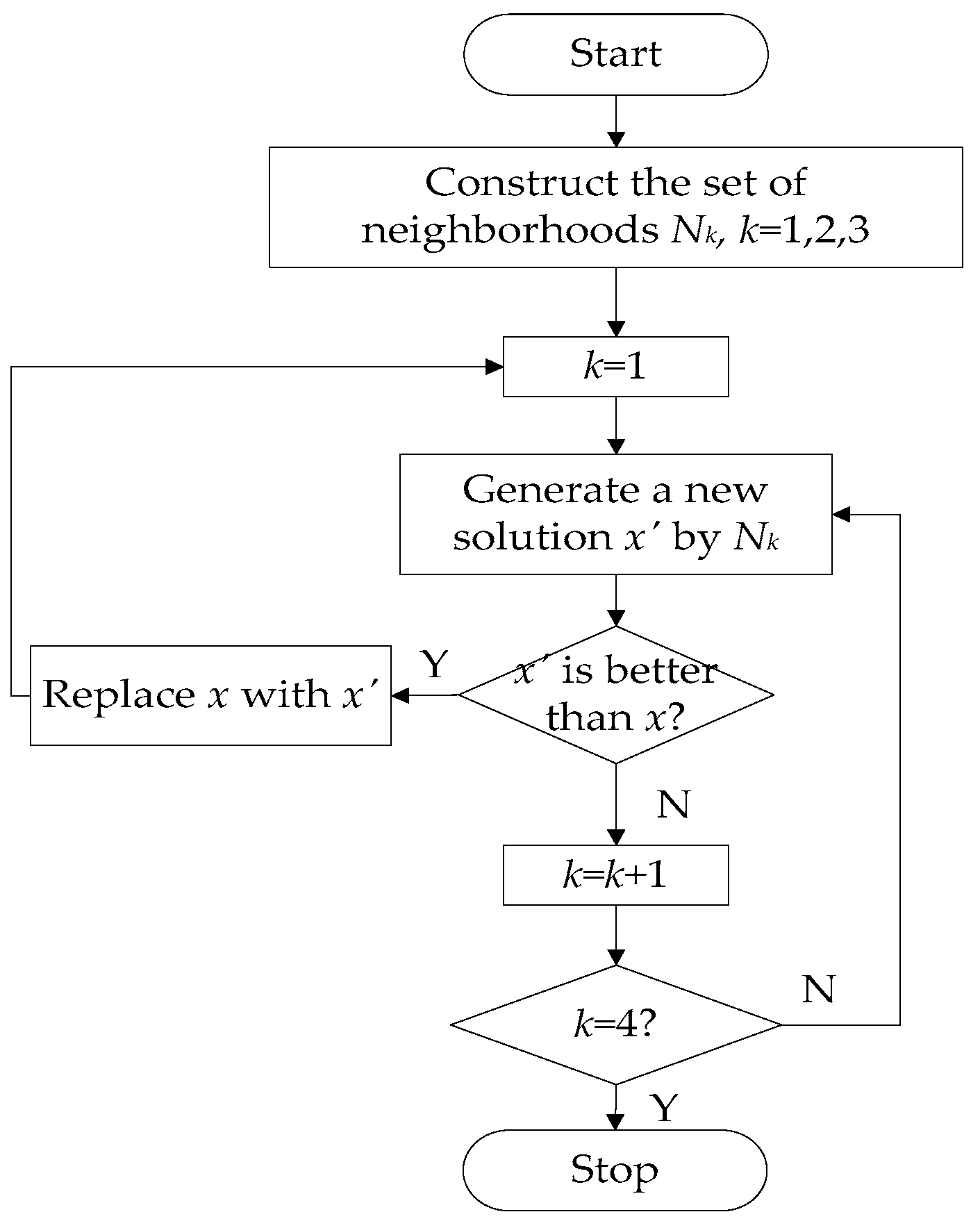

4.3. The Improved Employed Bee Phase

4.4. The Improved Onlooker Bee Phase

4.5. The Improved Scout Phase

4.6. The Pseudo-Code of the Improved DABC Algorithm

5. Computational Results and Comparisons

5.1. Calibrating Uplimit

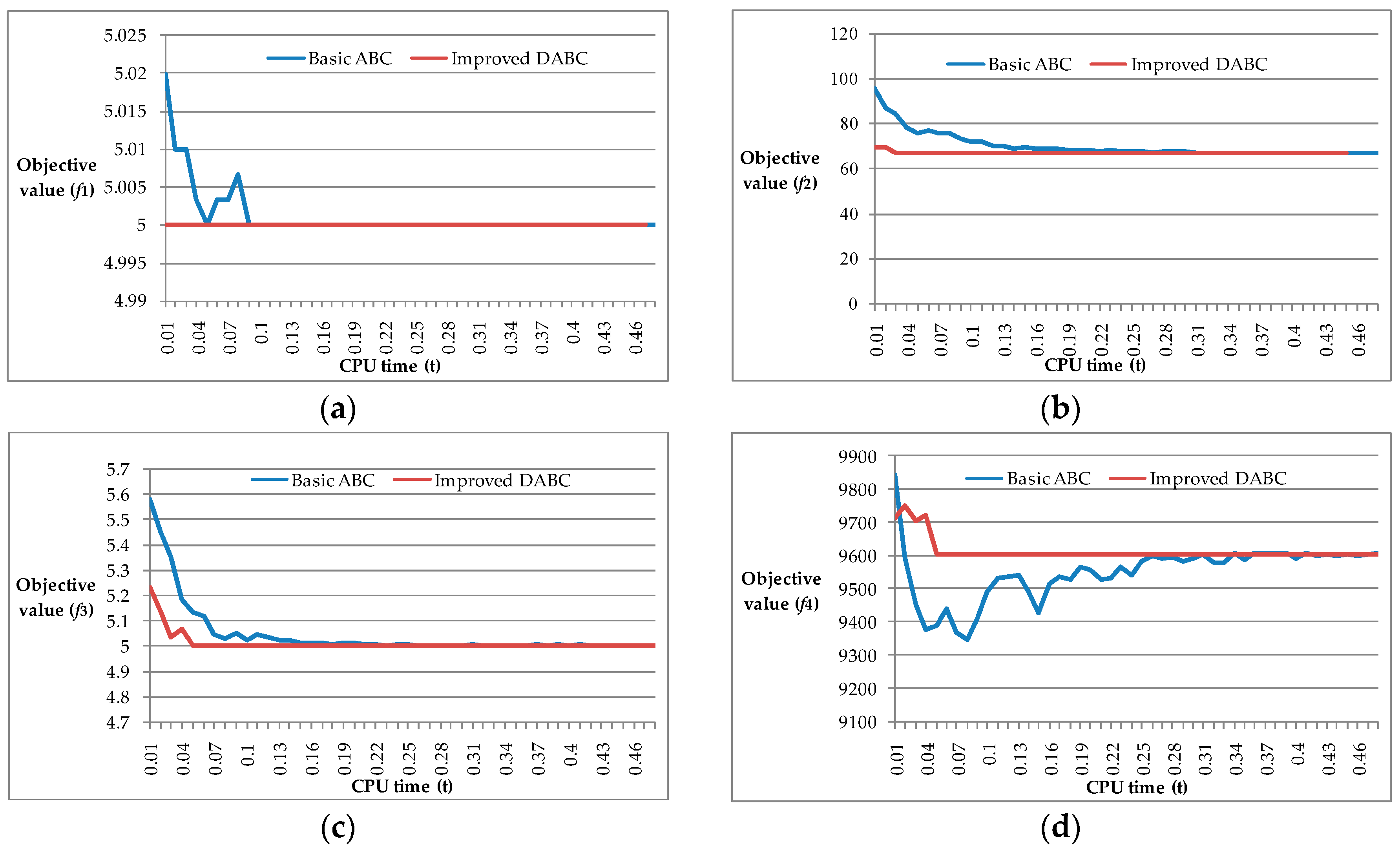

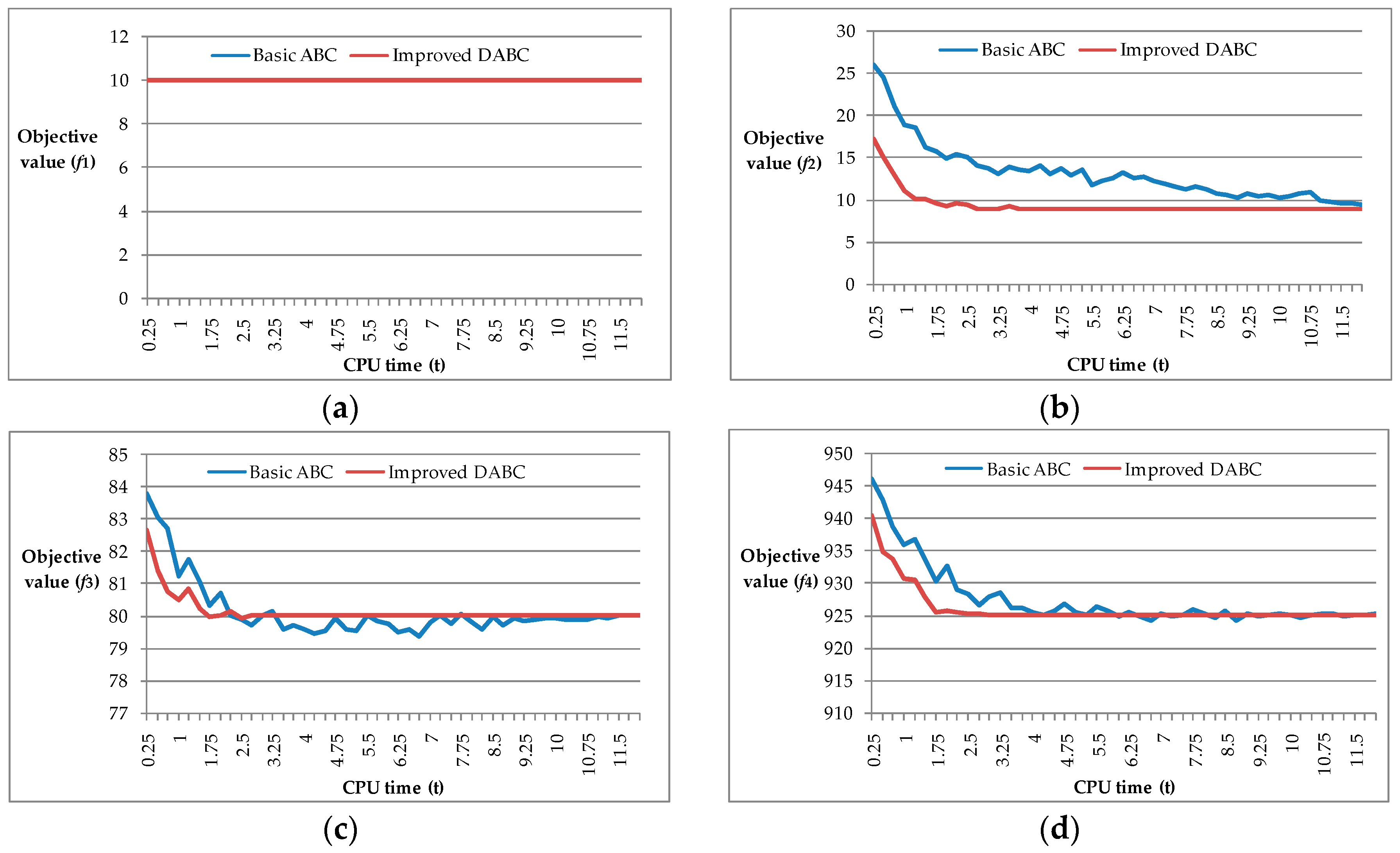

5.2. Comparison with the Basic ABC Algorithm

5.3. Comparison with Existing Meta-Heuristic Algorithms Reported in the Literature

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Xie, M.; Wang, J.; Chen, K. Coordinated development analysis of the “resources-environment-ecology-economy-society” complex system in china. Sustainability 2016, 8, 582. [Google Scholar] [CrossRef]

- Barba-Sánchez, V.; Atienza-Sahuquillo, C. Environmental proactivity and environmental and economic performance: Evidence from the winery sector. Sustainability 2016, 8, 1014. [Google Scholar] [CrossRef]

- Gungor, A.; Gupta, S.M. Issues in environmentally conscious manufacturing and product recovery: Survey. Comput. Ind. Eng. 1999, 36, 811–853. [Google Scholar] [CrossRef]

- Akçalı, E.; Çetinkaya, S. Quantitative models for inventory and production planning in closed-loop supply chains. Int. J. Prod. Res. 2011, 49, 2373–2407. [Google Scholar] [CrossRef]

- Ilgin, M.A.; Gupta, S.M. Environmentally conscious manufacturing and product recovery (ecmpro): A review of the state of the art. J. Environ. Manag. 2010, 91, 563–591. [Google Scholar] [CrossRef] [PubMed]

- Jasiulewicz-Kaczmarek, M.; Saniuk, A. Human factor in sustainable manufacturing. In Universal Access in Human-Computer Interaction. Access to the Human Environment and Culture; Springer International Publishing: Basel, Switzerland, 2015; Volume 9178, pp. 444–455. [Google Scholar]

- Güngör, A.; Gupta, S.M. Disassembly line in product recovery. Int. J. Prod. Res. 2002, 40, 2569–2589. [Google Scholar] [CrossRef]

- Özceylan, E.; Paksoy, T. Reverse supply chain optimisation with disassembly line balancing. Int. J. Prod. Res. 2013, 51, 5985–6001. [Google Scholar] [CrossRef]

- Gungor, A.; Gupta, S.M. A solution approach to the disassembly line balancing problem in the presence of task failures. Int. J. Prod. Res. 2001, 39, 1427–1467. [Google Scholar] [CrossRef]

- Altekin, F.T.; Kandiller, L.; Ozdemirel, N.E. Profit-oriented disassembly-line balancing. Int. J. Prod. Res. 2008, 46, 2675–2693. [Google Scholar] [CrossRef]

- Koc, A.; Sabuncuoglu, I.; Erel, E. Two exact formulations for disassembly line balancing problems with task precedence diagram construction using an and/or graph. IIE Trans. 2009, 41, 866–881. [Google Scholar] [CrossRef]

- Altekin, F.T.; Akkan, C. Task-failure-driven rebalancing of disassembly lines. Int. J. Prod. Res. 2012, 50, 4955–4976. [Google Scholar] [CrossRef]

- Mcgovern, S.M.; Gupta, S.M. Combinatorial optimization analysis of the unary np-complete disassembly line balancing problem. Int. J. Prod. Res. 2007, 45, 4485–4511. [Google Scholar] [CrossRef]

- Lu, C.; Huang, H.Z.; Fuh, J.Y.H.; Wong, Y.S. A multi-objective disassembly planning approach with ant colony optimization algorithm. Proc. IME B J. Eng. Manuf. 2008, 222, 1465–1474. [Google Scholar] [CrossRef]

- Mcgovern, S.M.; Gupta, S.M. A balancing method and genetic algorithm for disassembly line balancing. Eur. J. Oper. Res. 2007, 179, 692–708. [Google Scholar] [CrossRef]

- Aydemir-Karadag, A.; Turkbey, O. Multi-objective optimization of stochastic disassembly line balancing with station paralleling. Comput. Ind. Eng. 2013, 65, 413–425. [Google Scholar] [CrossRef]

- Ding, L.P.; Feng, Y.X.; Tan, J.R.; Gao, Y.C. A new multi-objective ant colony algorithm for solving the disassembly line balancing problem. Int. J. Adv. Manuf. Technol. 2010, 48, 761–771. [Google Scholar] [CrossRef]

- Prakash, P.; Ceglarek, D.; Tiwari, M.K. Constraint-based simulated annealing (cbsa) approach to solve the disassembly scheduling problem. Int. J. Adv. Manuf. Technol. 2012, 60, 1125–1137. [Google Scholar] [CrossRef]

- Kalayci, C.B.; Hancilar, A.; Gungor, A.; Gupta, S.M. Multi-objective fuzzy disassembly line balancing using a hybrid discrete artificial bee colony algorithm. J. Manuf. Syst. 2014, 37, 672–682. [Google Scholar] [CrossRef]

- Tuncel, E.; Zeid, A.; Kamarthi, S. Solving large scale disassembly line balancing problem with uncertainty using reinforcement learning. J. Intell. Manuf. 2014, 25, 647–659. [Google Scholar] [CrossRef]

- Avikal, S.; Jain, R.; Mishra, P.K. A kano model, ahp and m-topsis method-based technique for disassembly line balancing under fuzzy environment. Appl. Soft Comput. 2014, 25, 519–529. [Google Scholar] [CrossRef]

- Kalayci, C.B.; Gupta, S.M. Artificial bee colony algorithm for solving sequence-dependent disassembly line balancing problem. Expert Syst. Appl. 2013, 40, 7231–7241. [Google Scholar] [CrossRef]

- Scholl, A.; Boysen, N.; Fliedner, M. The sequence-dependent assembly line balancing problem. OR Spectr. 2008, 30, 579–609. [Google Scholar] [CrossRef]

- Andrés, C.; Miralles, C.; Pastor, R. Balancing and scheduling tasks in assembly lines with sequence-dependent setup times. Eur. J. Oper. Res. 2008, 187, 1212–1223. [Google Scholar] [CrossRef]

- Yolmeh, A.; Kianfar, F. An efficient hybrid genetic algorithm to solve assembly line balancing problem with sequence-dependent setup times. Comput. Ind. Eng. 2012, 62, 936–945. [Google Scholar] [CrossRef]

- Hamta, N.; Ghomi, S.M.T.F.; Jolai, F.; Shirazi, M.A. A hybrid pso algorithm for a multi-objective assembly line balancing problem with flexible operation times, sequence-dependent setup times and learning effect. Int. J. Prod. Econ. 2013, 141, 99–111. [Google Scholar] [CrossRef]

- Kalayci, C.B.; Gupta, S.M. Ant colony optimization for sequence-dependent disassembly line balancing problem. J. Manuf. Technol. Manag. 2013, 24, 413–427. [Google Scholar] [CrossRef]

- Kalayci, C.B.; Gupta, S.M. Simulated annealing algorithm for solving sequence-dependent disassembly line balancing problem. IFAC Proc. Vol. 2013, 46, 93–98. [Google Scholar] [CrossRef]

- Kalayci, C.B.; Gupta, S.M. A particle swarm optimization algorithm with neighborhood-based mutation for sequence-dependent disassembly line balancing problem. Int. J. Adv. Manuf. Technol. 2013, 69, 197–209. [Google Scholar] [CrossRef]

- Kalayci, C.B.; Gupta, S.M. A tabu search algorithm for balancing a sequence-dependent disassembly line. Prod. Plan. Control 2014, 25, 149–160. [Google Scholar] [CrossRef]

- Kalayci, C.B.; Polat, O.; Gupta, S.M. A variable neighbourhood search algorithm for disassembly lines. J. Manuf. Technol. Manag. 2015, 26, 182–194. [Google Scholar] [CrossRef]

- Kalayci, C.B.; Polat, O.; Gupta, S.M. A hybrid genetic algorithm for sequence-dependent disassembly line balancing problem. Ann. Oper. Res. 2016, 242, 321–354. [Google Scholar] [CrossRef]

- Karaboga, D. An Idea Based on Honey Bee Swarm for Numerical Optimization; Technical Report-TR06; Erciyes University: Kayseri, Turkey, 2005. [Google Scholar]

- Karaboga, D.; Akay, B. A comparative study of artificial bee colony algorithm. Appl. Math. Comput. 2009, 214, 108–132. [Google Scholar] [CrossRef]

- Szeto, W.Y.; Wu, Y.; Ho, S.C. An artificial bee colony algorithm for the capacitated vehicle routing problem. Eur. J. Oper. Res. 2011, 215, 126–135. [Google Scholar] [CrossRef]

- Pan, Q.K.; Tasgetiren, M.F.; Suganthan, P.N.; Chua, T.J. A discrete artificial bee colony algorithm for the lot-streaming flow shop scheduling problem. Inf. Sci. Int. J. 2011, 181, 2455–2468. [Google Scholar] [CrossRef]

- Tapkan, P.; Ozbakir, L.; Baykasoglu, A. Modeling and solving constrained two-sided assembly line balancing problem via bee algorithms. Appl. Soft Comput. 2012, 12, 3343–3355. [Google Scholar] [CrossRef]

- Pan, Q.-K. An effective co-evolutionary artificial bee colony algorithm for steelmaking-continuous casting scheduling. Eur. J. Oper. Res. 2016, 250, 702–714. [Google Scholar] [CrossRef]

- Karaboga, D.; Basturk, B. On the performance of artificial bee colony (abc) algorithm. Appl. Soft Comput. 2008, 8, 687–697. [Google Scholar] [CrossRef]

- Karaboga, D.; Ozturk, C. Neural networks training by artificial bee colony algorithm on pattern classification. Neural Netw. World 2009, 19, 279–292. [Google Scholar]

| Objectives | Environmental Benefits | Economic Benefits |

|---|---|---|

| Objective 1: Minimize the number of opened workstations | Saves resources | Reduces the disassembly cost |

| Objective 2: Distribute idle times across opened workstations evenly | Conserves energy | Raises productivity |

| Objective 3: Process hazardous parts/materials early | Reduces pollution | Protects useful subassemblies |

| Objective 4: Remove high-demand subassemblies as a priority | Minimizes the space required for landfills | Maximizes profit |

| Method | f1 | f2 | f3 | f4 | t | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| AVG | SD | AVG | SD | AVG | SD | AVG | SD | AVG | SD | |

| ABC | 5 | 0 | 67 | 0 | 5 | 0 | 9605 | 0 | 2.4 | 1.73 |

| ACO | 5 | 0 | 67 | 0 | 5 | 0 | 9605 | 0 | 5.36 | 5.61 |

| GA | 5 | 0 | 67 | 0 | 5 | 0 | 9605 | 0 | 5.3 | 4.62 |

| PSO | 5 | 0 | 67 | 0 | 5 | 0 | 9605 | 0 | 0.81 | 0.16 |

| RFD | 5 | 0 | 67 | 0 | 5 | 0 | 9605 | 0 | 3.62 | 3.45 |

| SA | 5 | 0 | 67 | 0 | 5 | 0 | 9605 | 0 | 0.59 | 0.71 |

| TS | 5 | 0 | 67 | 0 | 5 | 0 | 9605 | 0 | 0.87 | 1.05 |

| VNS | 5 | 0 | 67 | 0 | 5 | 0 | 9605 | 0 | 0.83 | - |

| VNSGA | 5 | 0 | 67 | 0 | 5 | 0 | 9605 | 0 | 0.65 | 0.35 |

| Our method | 5 | 0 | 67 | 0 | 5 | 0 | 9605 | 0 | 0.05 | 0.03 |

| An Optimal Sequence (DS1) | A Feasible Sequence (DS2) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Task | Workstations | Task | Workstations | ||||||||||

| 1 | 2 | 3 | 4 | 5 | 1 | 2 | 3 | 4 | 5 | 6 | |||

| 6 | 14 (+ 2 + 1) | 5 | 23 (+ 4 + 4) | Time to remove parts | |||||||||

| 1 | 14 (+ 4) | 10 | 10 | ||||||||||

| 5 | 23 (+ 4) | 9 | 14 (+ 3) | ||||||||||

| 10 | 10 | 1 | 14 (+ 4) | ||||||||||

| 7 | 19 | 6 | 14 | ||||||||||

| 4 | 17 | 4 | 17 | ||||||||||

| 8 | 36 | 7 | 19 | ||||||||||

| 9 | 14 | 8 | 36 | ||||||||||

| 2 | 10 (+ 3) | 3 | 12 (+ 2) | ||||||||||

| 3 | 12 | 2 | 10 | ||||||||||

| Total time 35 | 37 | 36 | 36 | 39 | Total time 31 | 27 | 32 | 36 | 36 | 24 | |||

| Idle time 5 | 3 | 4 | 4 | 1 | Idle time 9 | 13 | 8 | 4 | 4 | 16 | |||

| f1 = 5; f2 = 52 + 32 + 42 + 42 + 12 = 67; f3 = 5 × 1 = 5; | f1 = 6; f2 = 92 + 132 + 82 + 42 + 42 + 162 = 602; f3 = 7 × 1 = 7; | ||||||||||||

| f4 = 1 × 750 + 5 × 295 + 8 × 360 + 9 × 500 = 9605 | f4 = 3 × 360 + 5 × 750 + 7 × 295 + 10 × 500 = 11,895 | ||||||||||||

| Method | f1 | f2 | f3 | f4 | t | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| AVG | SD | AVG | SD | AVG | SD | AVG | SD | AVG | SD | |

| ABC | 10 | 0 | 10.07 | 2.16 | 80 | 1.14 | 925.57 | 5.07 | 124.6 | 146.79 |

| ACO | 10 | 0 | 17.77 | 1.41 | 82.8 | 1.32 | 949.37 | 6.31 | 244.67 | 161.49 |

| GA | 10 | 0 | 12.13 | 2.56 | 79.77 | 0.73 | 924.9 | 2.4 | 156.37 | 138.27 |

| PSO | 10 | 0 | 13.97 | 1.96 | 80.63 | 2.46 | 932.5 | 11.53 | 40.74 | 24.71 |

| RFD | 10 | 0 | 16 | 0 | 80.6 | 0.62 | 939.83 | 2.29 | 222.25 | 119.24 |

| SA | 10 | 0 | 11.7 | 1.82 | 83.43 | 3.22 | 940.93 | 12.4 | 297.91 | 141.19 |

| TS | 10 | 0 | 13.3 | 1.7 | 83.1 | 2.87 | 941.3 | 12.51 | 273.02 | 142.14 |

| VNS | 10 | 0 | 9 | 0 | 80 | 0 | 925 | 0 | 40.86 | - |

| VNSGA | 10 | 0 | 9 | 0 | 80 | 0 | 925 | 0 | 35.55 | 20.02 |

| Our method | 10 | 0 | 9 | 0 | 80 | 0 | 925 | 0 | 3.75 | 0.53 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Wang, S. Balancing Disassembly Line in Product Recovery to Promote the Coordinated Development of Economy and Environment. Sustainability 2017, 9, 309. https://doi.org/10.3390/su9020309

Liu J, Wang S. Balancing Disassembly Line in Product Recovery to Promote the Coordinated Development of Economy and Environment. Sustainability. 2017; 9(2):309. https://doi.org/10.3390/su9020309

Chicago/Turabian StyleLiu, Jia, and Shuwei Wang. 2017. "Balancing Disassembly Line in Product Recovery to Promote the Coordinated Development of Economy and Environment" Sustainability 9, no. 2: 309. https://doi.org/10.3390/su9020309

APA StyleLiu, J., & Wang, S. (2017). Balancing Disassembly Line in Product Recovery to Promote the Coordinated Development of Economy and Environment. Sustainability, 9(2), 309. https://doi.org/10.3390/su9020309