Monitoring and Optimization of the Process of Drying Fruits and Vegetables Using Computer Vision: A Review

Abstract

:1. Introduction

- (1)

- transfer of energy, mostly as heat, generally from the surrounding environment and/or an energy source to the wet solid;

- (2)

- transfer of mass, as moisture, from inside of the solid to the surface and its subsequent evaporation due to the process described in Point 1.

2. Literature Review

3. Fundamentals of Food-Drying

3.1. Quality Aspect in Drying

3.1.1. Nutritional Quality Changes

Vitamin C

Carotenoids

Phenols

Vitamin E

3.1.2. Color Changes

Chlorophylls and Carotenoids

Enzymatic Browning

Non-Enzymatic Browning

3.1.3. Physical Changes

Shrinkage

Texture

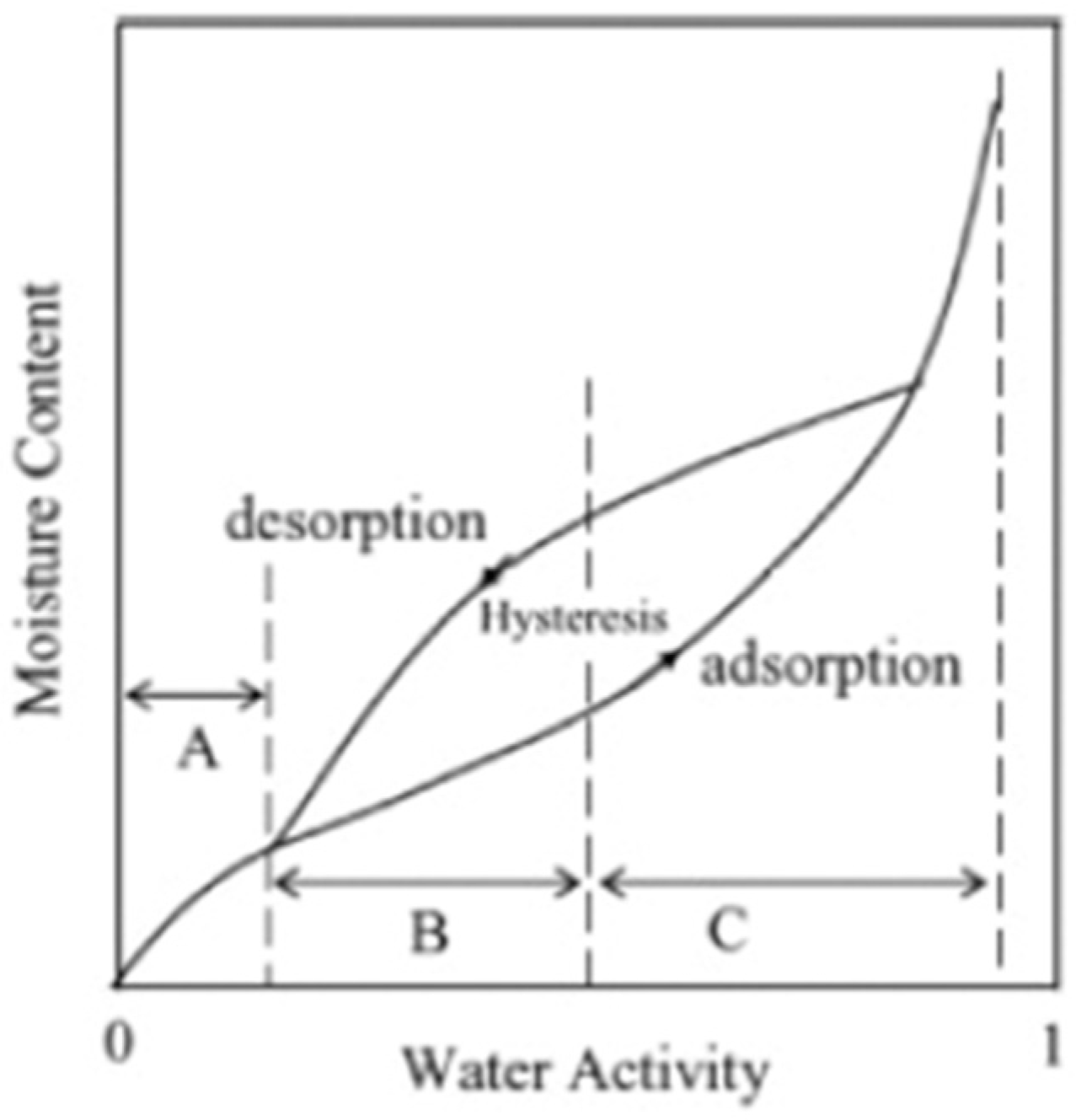

Moisture Content (w) and Water Activity (aw)

3.2. Energy Aspects in Drying

- dewatering the food prior to the drying process;

- reducing inlet and outlet gas humidity;

- reducing heat losses;

- recovering heat between hot and cold streams;

- adopting lower cost and/or renewable heat sources, such as solar energy and biofuel;

- combining heat and power to reduce drying time drastically;

- using smart drying technology to avoid over-drying.

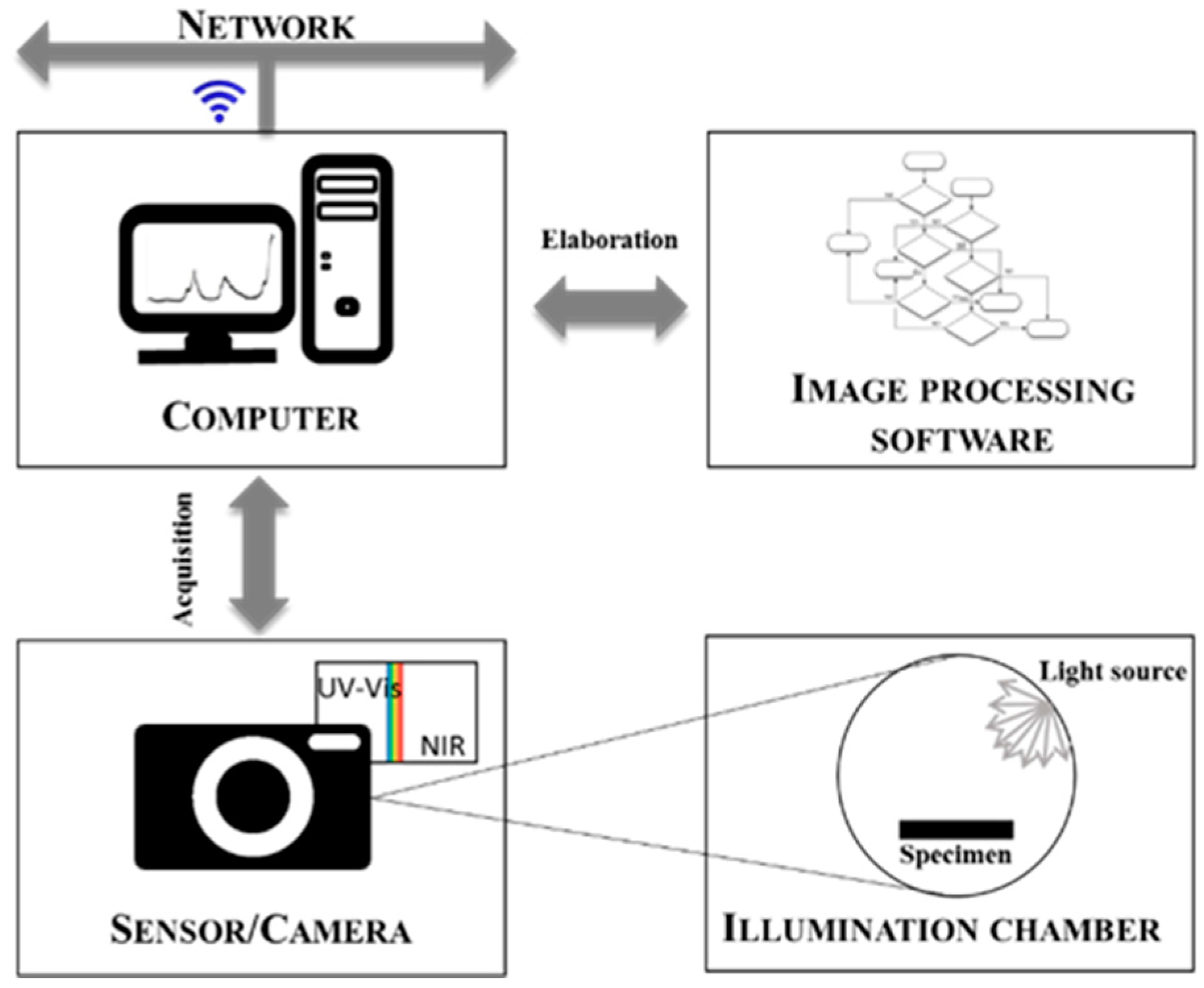

4. Fundamental of Computer Vision

4.1. Analysis of Images in the Visible Region

4.2. Single-Point Spectroscopy

4.2.1. Single-Point UV-Vis Spectroscopy

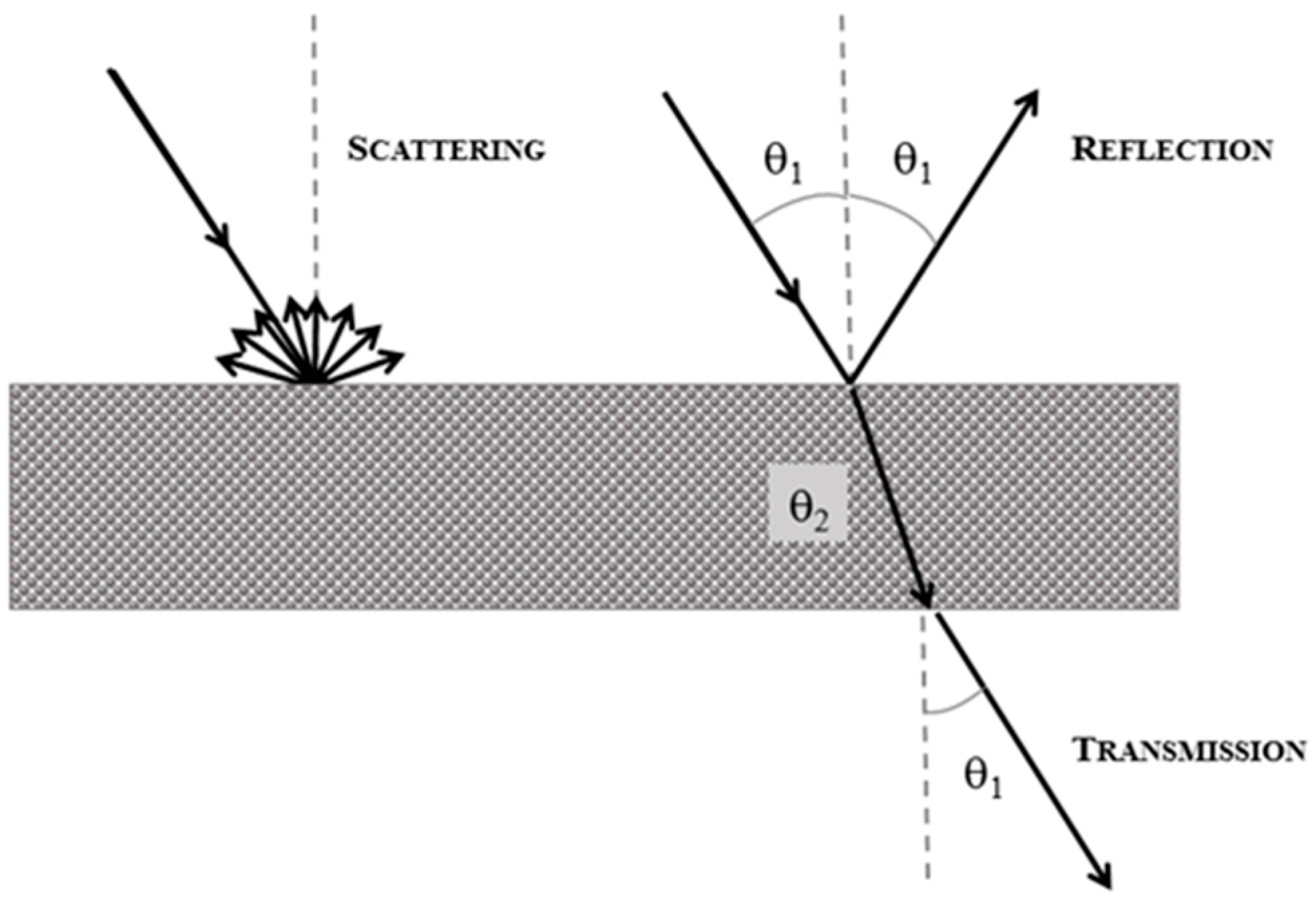

4.2.2. Single-Point NIR Spectroscopy

4.2.3. Advantages and Disadvantages of Single-Point Spectroscopy

4.3. Hyper- and Multi-Spectral Imaging

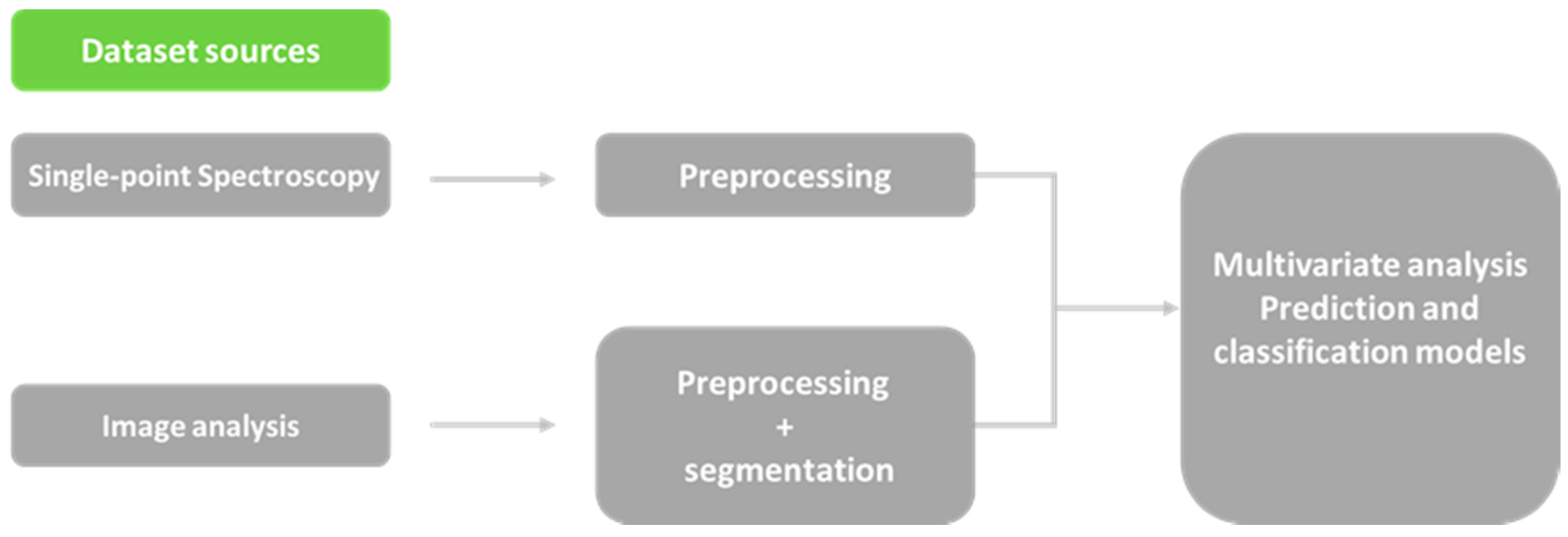

4.4. Data Processing and Chemometrics

- Noise reduction methods (e.g., moving-average and Savitzky–Golay smoothing) can reduce high-frequency noises associated with instrument detectors and electronic circuits.

- Baseline correction methods (e.g., Savitzky–Golay filters for derivative, multiplicative scatter correction (MSC), standard normal variate (SNV)) are used to reduce or eliminate multiplicative and additive scatter factors and noises.

- Resolution enhancement methods (e.g., first and second derivatives and Fourier self-deconvolution) point out information from overlapping bands.

- Mean centering and normalization are preprocessing methods frequently used because they are simple and effective ways to enhance information prior to multivariate analysis.

- Thresholding is the simplest segmentation method; pixels are partitioned depending on their intensity value. The Otsu method is an algorithm that works on this principle and is generally used for food quality inspection [144].

- Edge-based segmentation methods attempt to find the edges directly by their high gradient magnitudes [145].

- Region-based segmentation is based on pixel-level similarity, following criteria such as grey level, color and texture to identify a single object in images [146].

5. Applications

5.1. Quality Control of Fruit during Drying

5.2. Quality Control of Vegetables during Drying

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Filkova, I.; Munjundar, A.S. Handbook of Industrial Drying; CRC Press: Boca Raton, FL, USA, 2014; ISBN 9781466596665. [Google Scholar]

- Koszela, K.; Otrza̧sek, J.; Zaborowicz, M.; Boniecki, P.; Mueller, W.; Raba, B.; Lewicki, A.; Przybył, K. Quality assessment of microwave-vacuum dried material with the use of computer image analysis and neural model. Proc. SPIE Int. Soc. Opt. Eng. 2014, 9159, 1–9. [Google Scholar] [CrossRef]

- Ratti, C. Hot air and freeze-drying of high-value foods: A review. J. Food Eng. 2001, 49, 311–319. [Google Scholar] [CrossRef]

- An, K.; Zhao, D.; Wang, Z.; Wu, J.; Xu, Y.; Xiao, G. Comparison of different drying methods on Chinese ginger (Zingiber officinale Roscoe): Changes in volatiles, chemical profile, antioxidant properties, and microstructure. Food Chem. 2016, 197, 1292–1300. [Google Scholar] [CrossRef] [PubMed]

- Dev, S.R.S.; Geetha, P.; Orsat, V.; Gariépy, Y.; Raghavan, G.S.V. Effects of Microwave-Assisted Hot Air Drying and Conventional Hot Air Drying on the Drying Kinetics, Color, Rehydration, and Volatiles of Moringa oleifera. Dry. Technol. 2011, 29, 1452–1458. [Google Scholar] [CrossRef]

- Keglevich, G. Milestones in Microwave Chemistry; Keglevich, G., Ed.; Springer International Publishing: Cham, Switzerland, 2016; ISBN 9783319306308. [Google Scholar]

- Mujumdar, A.S.; Law, C.L. Drying Technology: Trends and Applications in Postharvest Processing. Food Bioprocess Technol. 2010, 3, 843–852. [Google Scholar] [CrossRef]

- Sagar, V.R.; Suresh Kumar, P. Recent advances in drying and dehydration of fruits and vegetables: A review. J. Food Sci. Technol. 2010, 47, 15–26. [Google Scholar] [CrossRef] [PubMed]

- Afolabi, I.S. Moisture Migration and Bulk Nutrients Interaction in a Drying Food Systems: A Review. Food Nutr. Sci. 2014, 5, 692–714. [Google Scholar] [CrossRef]

- Aghilinategh, N.; Rafiee, S.; Gholikhani, A.; Hosseinpur, S.; Omid, M.; Mohtasebi, S.S.; Maleki, N. A comparative study of dried apple using hot air, intermittent and continuous microwave: Evaluation of kinetic parameters and physicochemical quality attributes. Food Sci. Nutr. 2015, 3, 519–526. [Google Scholar] [CrossRef] [PubMed]

- Ren, G.; Chen, F. Determination of moisture content of ginseng by near infra-red reflectance spectroscopy. Food Chem. 1997, 60, 433–436. [Google Scholar] [CrossRef]

- Fernández, L.; Castillero, C.; Aguilera, J.M. An application of image analysis to dehydration of apple discs. J. Food Eng. 2005, 67, 185–193. [Google Scholar] [CrossRef]

- Pu, Y.Y.; Sun, D.W. Vis-NIR hyperspectral imaging in visualizing moisture distribution of mango slices during microwave-vacuum drying. Food Chem. 2015, 188, 271–278. [Google Scholar] [CrossRef] [PubMed]

- ElMasry, G.; Wang, N.; ElSayed, A.; Ngadi, M. Hyperspectral imaging for nondestructive determination of some quality attributes for strawberry. J. Food Eng. 2007, 81, 98–107. [Google Scholar] [CrossRef]

- Huang, M.; Wang, Q.; Zhang, M.; Zhu, Q. Prediction of color and moisture content for vegetable soybean during drying using hyperspectral imaging technology. J. Food Eng. 2014, 128, 24–30. [Google Scholar] [CrossRef]

- Nahimana, H.; Zhang, M. Shrinkage and Color Change during Microwave Vacuum Drying of Carrot. Dry. Technol. 2011, 29, 836–847. [Google Scholar] [CrossRef]

- Yadollahinia, A.; Jahangiri, M. Shrinkage of potato slice during drying. J. Food Eng. 2009, 94, 52–58. [Google Scholar] [CrossRef]

- Hu, M.-H.; Dong, Q.-L.; Malakar, P.K.; Liu, B.-L.; Jaganathan, G.K. Determining Banana Size Based on Computer Vision. Int. J. Food Prop. 2015, 18, 508–520. [Google Scholar] [CrossRef]

- Nicolaï, B.M.; Beullens, K.; Bobelyn, E.; Peirs, A.; Saeys, W.; Theron, K.I.; Lammertyn, J. Nondestructive measurement of fruit and vegetable quality by means of NIR spectroscopy: A review. Postharvest Biol. Technol. 2007, 46, 99–118. [Google Scholar] [CrossRef]

- Leiva-Valenzuela, G.A.; Lu, R.; Aguilera, J.M. Assessment of internal quality of blueberries using hyperspectral transmittance and reflectance images with whole spectra or selected wavelengths. Innov. Food Sci. Emerg. Technol. 2014, 24, 2–13. [Google Scholar] [CrossRef]

- Pedro, A.M.K.; Ferreira, M.M.C. Nondestructive determination of solids and carotenoids in tomato products by near-infrared spectroscopy and multivariate calibration. Anal. Chem. 2005, 77, 2505–2511. [Google Scholar] [CrossRef] [PubMed]

- Yang, H.; Irudayaraj, J. Rapid determination of vitamin C by NIR, MIR and FT-Raman techniques. J. Pharm. Pharmacol. 2002, 54, 1247–1255. [Google Scholar] [CrossRef] [PubMed]

- Romaric, G. Bayili Phenolic compounds and antioxidant activities in some fruits and vegetables from Burkina Faso. Afr. J. Biotechnol. 2011, 10, 13543–13547. [Google Scholar] [CrossRef]

- Lopez, J.; Uribe, E.; Vega-Gálvez, A.; Miranda, M.; Vergara, J.; Gonzalez, E.; Di Scala, K. Effect of air temperature on drying kinetics, vitamin c, antioxidant activity, total phenolic content, non-enzymatic browning and firmness of blueberries variety O’Neil. Food Bioprocess Technol. 2010, 3, 772–777. [Google Scholar] [CrossRef]

- Su, Y.; Zhang, M.; Mujumdar, A.S. Recent Developments in Smart Drying Technology. Dry. Technol. 2015, 33, 260–276. [Google Scholar] [CrossRef]

- Kahl, J.; Baars, T.; Bügel, S.; Busscher, N.; Huber, M.; Kusche, D.; Rembiałkowska, E.; Schmid, O.; Seidel, K.; Taupier-Letage, B.; et al. Organic food quality: A framework for concept, definition and evaluation from the European perspective. J. Sci. Food Agric. 2012, 92, 2760–2765. [Google Scholar] [CrossRef] [PubMed]

- Scopus. Available online: www.scopus.com (accessed on 18 October 2017).

- Pubmed. Available online: www.ncbi.nlm.nih.gov/pubmed (accessed on 18 October 2017).

- Google Scholar. Available online: scholar.google.com (accessed on 18 October 2017).

- De Lima, A.G.B.; Da Silva, J.V.; Pereira, E.M.A.; Dos Santos, I.B.; Barbosa de Lima, W.M.P. Drying of bioproducts: Quality and energy aspects. In Drying and Energy Technologies; Springer International Publishing: Cham, Switzerland, 2015; ISBN 9783319197678. [Google Scholar]

- Nindo, C.I.; Sun, T.; Wang, S.W.; Tang, J.; Powers, J.R. Evaluation of drying technologies for retention of physical quality and antioxidants in asparagus (Asparagus officinalis, L.). LWT Food Sci. Technol. 2003, 36, 507–516. [Google Scholar] [CrossRef]

- Vicente, A.R.; Manganaris, G.A.; Sozzi, G.O.; Crisosto, C.H. Nutritional Quality of Fruits and Vegetables. In Postharvest Handling: A Systems Approach, 2nd ed.; Elsevier Inc.: London, UK, 2009; ISBN 9780123741127. [Google Scholar]

- Liu, C.; Russell, R.M. Nutrition and gastric cancer risk: An update. Nutr. Rev. 2008, 66, 237–249. [Google Scholar] [CrossRef] [PubMed]

- Ashebir, D.; Jezik, K.; Weingartemann, H.; Gretzmacher, R. Change in color and other fruit quality characteristics of tomato cultivars after hot-air drying at low final-moisture content. Int. J. Food Sci. Nutr. 2009, 60 (Suppl. 7), 308–315. [Google Scholar] [CrossRef] [PubMed]

- Ariahu, C.C.; Abashi, D.K.; Chinma, C.E. Kinetics of ascorbic acid loss during hot water blanching of fluted pumpkin (Telfairia occidentalis) leaves. J. Food Sci. Technol. 2011, 48, 454–459. [Google Scholar] [CrossRef] [PubMed]

- Shofian, N.M.; Hamid, A.A.; Osman, A.; Saari, N.; Anwar, F.; Dek, M.S.P.; Hairuddin, M.R. Effect of freeze-drying on the antioxidant compounds and antioxidant activity of selected tropical fruits. Int. J. Mol. Sci. 2011, 12, 4678–4692. [Google Scholar] [CrossRef] [PubMed]

- Gruszecki, W.I. Carotenoids in lipids Membranes. In Carotenoids: Physical, Chemical, and Biological Functions and Properties; CRC Press: Boca Raton, FL, USA, 2010; pp. 19–30. [Google Scholar]

- Lefsrud, M.; Kopsell, D.; Sams, C.; Wills, J.; Both, A.J. Dry matter content and stability of carotenoids in kale and spinach during drying. HortScience 2008, 43, 1731–1736. [Google Scholar]

- Urrea, D.; Eim, V.S.; González-Centeno, M.R.; Minjares-Fuentes, R.; Castell-Palou, A.; Juárez, M.D.; Rosselló, C. Effects of air drying temperature on antioxidant activity and carotenoids content of carrots (Daucus carota). In Proceedings of the European Drying Conference, Palma de Mallorca, Spain, 26–28 October 2011; Volume 6, pp. 26–28. [Google Scholar]

- Divya, P.; Puthusseri, B.; Neelwarne, B. Carotenoid content, its stability during drying and the antioxidant activity of commercial coriander (Coriandrum sativum L.) varieties. Food Res. Int. 2012, 45, 342–350. [Google Scholar] [CrossRef]

- Seybold, C.; Fröhlich, K.; Bitsch, R.; Otto, K.; Böhm, V. Changes in contents of carotenoids and vitamin E during tomato processing. J. Agric. Food Chem. 2004, 52, 7005–7010. [Google Scholar] [CrossRef] [PubMed]

- Strati, I.F.; Oreopoulou, V. Recovery and isomerization of carotenoids from tomato processing. Waste Biomass Valoriz. 2016, 7, 843–850. [Google Scholar] [CrossRef]

- Siriamornpun, S.; Kaisoon, O.; Meeso, N. Changes in colour, antioxidant activities and carotenoids (lycopene, β-carotene, lutein) of marigold flower (Tagetes erecta L.) resulting from different drying processes. J. Funct. Foods 2012, 4, 757–766. [Google Scholar] [CrossRef]

- Chinnici, F.; Bendini, A.; Gaiani, A.; Riponi, C. Radical Scavenging Activities of Peels and Pulps from cv. Golden Delicious Apples as Related to Their Phenolic Composition. J. Agric. Food Chem. 2004, 52, 4684–4689. [Google Scholar] [CrossRef] [PubMed]

- Liu, R.H. Potential synergy of phytochemicals in cancer prevention: Mechanism of action. J. Nutr. 2004, 134, 3479S–3485S. [Google Scholar] [PubMed]

- Wlodzimierz, O.; Grajek, A. The influence of food processing and home cooking on the antioxidant stability in foods. In Functional Food Product Development; Smith, J., Charter, E., Eds.; Wiley-Blackwell: Oxford, UK, 2010; pp. 178–205. ISBN 9781405178761. [Google Scholar]

- Vega-Gálvez, A.; Ah-Hen, K.; Chacana, M.; Vergara, J.; Martínez-Monzó, J.; García-Segovia, P.; Lemus-Mondaca, R.; Di Scala, K. Effect of temperature and air velocity on drying kinetics, antioxidant capacity, total phenolic content, colour, texture and microstructure of apple (var. Granny Smith) slices. Food Chem. 2012, 132, 51–59. [Google Scholar] [CrossRef] [PubMed]

- Lodge, J.K. Vitamin E bioavailability in humans. J. Plant Physiol. 2005, 162, 790–796. [Google Scholar] [CrossRef] [PubMed]

- Delgado, T.; Pereira, J.A.; Ramalhosa, E.; Casal, S. Effect of hot air convective drying on the fatty acid and vitamin E composition of chestnut (Castanea sativa Mill.) slices. Eur. Food Res. Technol. 2016, 242, 1299–1306. [Google Scholar] [CrossRef]

- Lešková, E.; Kubíková, J.; Kováčiková, E.; Košická, M.; Porubská, J.; Holčíková, K. Vitamin losses: Retention during heat treatment and continual changes expressed by mathematical models. J. Food Compos. Anal. 2006, 19, 252–276. [Google Scholar] [CrossRef]

- Shewfelt, R.L. What is quality? Postharvest Biol. Technol. 1999, 15, 197–200. [Google Scholar] [CrossRef]

- Roshanak, S.; Rahimmalek, M.; Goli, S.A.H. Evaluation of seven different drying treatments in respect to total flavonoid, phenolic, vitamin C content, chlorophyll, antioxidant activity and color of green tea (Camellia sinensis or C. assamica) leaves. J. Food Sci. Technol. 2015, 53, 721–729. [Google Scholar] [CrossRef] [PubMed]

- Maskan, M. Kinetics of colour change of kiwifruits during hot air and microwave drying. J. Food Eng. 2001, 48, 169–175. [Google Scholar] [CrossRef]

- Brennan, J.G. Food Processing Handbook; Wiley-VCH Verlag: Weinheim, Germany, 2006; ISBN 9783527307197. [Google Scholar]

- Madhava Naidu, M.; Vedashree, M.; Satapathy, P.; Khanum, H.; Ramsamy, R.; Hebbar, H.U. Effect of drying methods on the quality characteristics of dill (Anethum graveolens) greens. Food Chem. 2016, 192, 849–856. [Google Scholar] [CrossRef] [PubMed]

- Marangoni, A.G. Chlorophyll Degradation in Green Tissues: Olives, Cabbage and Pickles. In Kinetic Analysis of Food Systems; Springer: Cham, Switzerland, 2017; pp. 55–63. ISBN 9783319512921. [Google Scholar]

- Cui, Z.-W.; Xu, S.-Y.; Sun, D.-W. Effect of Microwave-Vacuum Drying on the Carotenoids Retention of Carrot Slices and Chlorophyll Retention of Chinese Chive Leaves. Dry. Technol. 2004, 22, 563–575. [Google Scholar] [CrossRef]

- Mencarelli, F.; Agostini, R.; Botondi, R.; Massantini, R. Ethylene production, ACC content, PAL and POD activities in excised sections of straight and bent gerbera scapes. J. Hortic. Sci. 1995, 70, 409–416. [Google Scholar] [CrossRef]

- Cecchini, M.; Contini, M.; Massantini, R.; Monarca, D.; Moscetti, R. Effects of controlled atmospheres and low temperature on storability of chestnuts manually and mechanically harvested. Postharvest Biol. Technol. 2011, 61, 131–136. [Google Scholar] [CrossRef]

- Degl’Innocenti, E.; Pardossi, A.; Tognoni, F.; Guidi, L. Physiological basis of sensitivity to enzymatic browning in “lettuce”, “escarole” and “rocket salad” when stored as fresh-cut products. Food Chem. 2007, 104, 209–215. [Google Scholar] [CrossRef]

- Taylor, S.L.; Kinsella, J.E.; Archer, D.; Gregory, J.F.; Harlander, S.K.; Lund, D.B.; Schneeman, B.O.; Macrae, R. Food Science and Technology. Enzym. Food Process. 1993, ii–iib. [Google Scholar] [CrossRef]

- Grncarevic, M.; Hawker, J.S. Browning of Sultana Grape Berries During Drying. J. Sci. Food Agric. 1971, 22, 270–272. [Google Scholar] [CrossRef]

- Yingsanga, P.; Srilaong, V.; Kanlayanarat, S.; Noichinda, S.; McGlasson, W.B. Relationship between browning and related enzymes (PAL, PPO and POD) in rambutan fruit (Nephelium lappaceum Linn.) cvs. Rongrien and See-Chompoo. Postharvest Biol. Technol. 2008, 50, 164–168. [Google Scholar] [CrossRef]

- Ioannou, I.; Mohamed, G. Prevention of enzymatic browning in fruits and vegetables. Eur. Sci. J. 2013, 9, 310–341. [Google Scholar] [CrossRef]

- Perera, C.O. Selected Quality Attributes of Dried Foods. Dry. Technol. 2005, 23, 717–730. [Google Scholar] [CrossRef]

- Martins, S.I.F.S.; Jongen, W.M.F.; Van Boekel, M.A.J.S. A review of Maillard reaction in food and implications to kinetic modelling. Trends Food Sci. Technol. 2000, 11, 364–373. [Google Scholar] [CrossRef]

- Manzocco, L.; Calligaris, S.; Mastrocola, D.; Nicoli, M.C.; Lerici, C.R. Review of non-enzymatic browning and antioxidant capacity in processed foods. Trends Food Sci. Technol. 2000, 11, 340–346. [Google Scholar] [CrossRef]

- Hodge, J.E. Dehydrated foods. Chemistry of browning reactions in model systems. Agric. Food Chem. 1953, 1, 928–943. [Google Scholar] [CrossRef]

- Cernîşev, S. Effects of conventional and multistage drying processing on non-enzymatic browning in tomato. J. Food Eng. 2010, 96, 114–118. [Google Scholar] [CrossRef]

- Garza, S.; Ibarz, A.; Pagán, J.; Giner, J. Non-enzymatic browning in peach puree during heating. Food Res. Int. 1999, 32, 335–343. [Google Scholar] [CrossRef]

- Wegener, S.; Kaufmann, M.; Kroh, L.W. Influence of L-pyroglutamic acid on the color formation process of non-enzymatic browning reactions. Food Chem. 2017, 232, 450–454. [Google Scholar] [CrossRef] [PubMed]

- Contreras-Calderón, J.; Mejía-Díaz, D.; Martínez-Castaño, M.; Bedoya-Ramírez, D.; López-Rojas, N.; Gómez-Narváez, F.; Medina-Pineda, Y.; Vega-Castro, O. Evaluation of antioxidant capacity in coffees marketed in Colombia: Relationship with the extent of non-enzymatic browning. Food Chem. 2016, 209, 162–170. [Google Scholar] [CrossRef] [PubMed]

- Hurtado, A.; Guàrdia, M.D.; Picouet, P.; Jofré, A.; Ros, J.M.; Bañón, S. Stabilisation of red fruit-based smoothies by high-pressure processing. Part II: Effects on sensory quality and selected nutrients. J. Sci. Food Agric. 2016. [Google Scholar] [CrossRef] [PubMed]

- Sharma, S.K.; Juyal, S.; Rao, V.K.; Yadav, V.K.; Dixit, A.K. Reduction of non-enzymatic browning of orange juice and semi-concentrates by removal of reaction substrate. J. Food Sci. Technol. 2014, 51, 1302–1309. [Google Scholar] [CrossRef] [PubMed]

- Jaeger, H.; Janositz, A.; Knorr, D. The Maillard reaction and its control during food processing. The potential of emerging technologies. Pathol. Biol. 2010, 58, 207–213. [Google Scholar] [CrossRef] [PubMed]

- Aprajeeta, J.; Gopirajah, R.; Anandharamakrishnan, C. Shrinkage and porosity effects on heat and mass transfer during potato drying. J. Food Eng. 2015, 144, 119–128. [Google Scholar] [CrossRef]

- Bonazzi, C.; Dumoulin, E. Quality Changes in Food Materials as Influenced by Drying Processes. Mod. Dry. Technol. 2011, 3, 1–20. [Google Scholar] [CrossRef]

- Nadia, D.M. Effect of Air Drying on Color, Texture and Shrinkage of Sardine (Sardina pilchardus) Muscles. J. Nutr. Food Sci. 2011, 1, 113. [Google Scholar] [CrossRef]

- Dehghannya, J.; Gorbani, R.; Ghanbarzadeh, B. Shrinkage of Mirabelle Plum during Hot Air Drying as Influenced by Ultrasound-Assisted Osmotic Dehydration. Int. J. Food Prop. 2016, 19, 1093–1103. [Google Scholar] [CrossRef]

- Kerdpiboon, S.; Devahastin, S.; Kerr, W.L. Comparative fractal characterization of physical changes of different food products during drying. J. Food Eng. 2007, 83, 570–580. [Google Scholar] [CrossRef]

- Prothon, F.; Ahrné, L.; Sjöholm, I. Mechanisms and prevention of plant tissue collapse during dehydration: A critical review. Crit. Rev. Food Sci. Nutr. 2003, 43, 447–479. [Google Scholar] [CrossRef] [PubMed]

- De Bruijn, J.; Rivas, F.; Rodriguez, Y.; Loyola, C.; Flores, A.; Melin, P.; Borquez, R. Effect of Vacuum Microwave Drying on the Quality and Storage Stability of Strawberries. J. Food Process. Preserv. 2016, 40, 1104–1115. [Google Scholar] [CrossRef]

- Bourne, M.C. Texture, Viscosity, and Food. In Food Texture and Viscosity; Elsevier: London, UK, 2002; pp. 1–32. ISBN 9780121190620. [Google Scholar]

- Guiné, R.P.F.; Barroca, M.J. Effect of drying treatments on texture and color of vegetables (pumpkin and green pepper). Food Bioprod. Process. 2012, 90, 58–63. [Google Scholar] [CrossRef]

- Kotwaliwale, N.; Bakane, P.; Verma, A. Changes in textural and optical properties of oyster mushroom during hot air drying. J. Food Eng. 2007, 78, 1207–1211. [Google Scholar] [CrossRef]

- Tan, S. Determinants of eating quality in fruit and vegetables. Proc. Nutr. Soc. Aust. 2000, 24, 183–190. [Google Scholar]

- Martynenko, A.; Janaszek, M.A. Texture Changes During Drying of Apple Slices. Dry. Technol. 2014, 32, 567–577. [Google Scholar] [CrossRef]

- Lin, T.M.; Durance, T.D.; Scaman, C.H. Characterization of vacuum microwave, air and freeze dried carrot slices. Food Res. Int. 1999, 31, 111–117. [Google Scholar] [CrossRef]

- Gabriel, A.A. Estimation of water activity from pH and Brix values of some food products. Food Chem. 2008, 108, 1106–1113. [Google Scholar] [CrossRef] [PubMed]

- Sablani, S.S. Evaluating water activity and glass transition concepts for food stability. J. Food Eng. 2007, 78, 266–271. [Google Scholar] [CrossRef]

- Wikipedia Moisture Sorption Isotherm. Available online: https://en.wikipedia.org/wiki/Moisture_sorption_isotherm (accessed on 1 November 2017).

- Strumiłło, C.; Jones, P.L.; Zyłła, R. Energy Aspects in Drying. In Handbook of Industrial Drying, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2006; pp. 1075–1099. ISBN 978-1-57444-668-5. [Google Scholar]

- Baker, C.G.J. Energy Efficient Dryer Operation—An Update on Developments. Dry. Technol. 2005, 23, 2071–2087. [Google Scholar] [CrossRef]

- Kudra, T. Energy aspects in drying. Dry. Technol. 2004, 22, 917–932. [Google Scholar] [CrossRef]

- Grabowski, S.; Marcotte, M.; Poirier, M.; Kudra, T. Drying Characteristics of Osmotically Pretreated Cranberries—Energy and Quality Aspects. Dry. Technol. 2002, 20, 1989–2004. [Google Scholar] [CrossRef]

- Yongsawatdigul, J.; Gunasekaran, S. Microwave-vacuum drying of cranberries: Part I. Energy use and efficiency. J. Food Process. 1996, 20, 121–143. [Google Scholar] [CrossRef]

- Raghavan, G.S.V.; Rennie, T.J.; Sunjka, P.S.; Orsat, V.; Phaphuangwittayakul, W.; Terdtoon, P. Overview of new techniques for drying biological materials with emphasis on energy aspects. Braz. J. Chem. Eng. 2005, 22, 195–201. [Google Scholar] [CrossRef]

- Kemp, I.C. Reducing dryer energy use by process integration and pinch analysis. Dry. Technol. 2005, 23, 2089–2104. [Google Scholar] [CrossRef]

- Li, J.B.; Huang, W.Q.; Zhao, C.J. Machine vision technology for detecting the external defects of fruits—A review. Imaging Sci. J. 2015, 63, 241–251. [Google Scholar] [CrossRef]

- Davies, E.R. The application of machine vision to food and agriculture: A review. Imaging Sci. J. 2009, 57, 197–217. [Google Scholar] [CrossRef]

- Menesatti, P.; Angelini, C.; Pallottino, F.; Antonucci, F.; Aguzzi, J.; Costa, C. RGB color calibration for quantitative image analysis: The “3D Thin-Plate Spline” warping approach. Sensors 2012, 12, 7063–7079. [Google Scholar] [CrossRef] [PubMed]

- Gunasekaran, S. Computer vision technology for food quality assurance. Trends Food Sci. Technol. 1996, 7, 245–256. [Google Scholar] [CrossRef]

- Gunasekaran, S.; Chen, P.L. Nondestructive Food Evaluation: Techniques to Analyze Properties and Quality; Marcel Dekker Inc.: New York, NY, USA, 2001. [Google Scholar]

- Batchelor, B.; Waltz, F. Programmable color filter Representation of color. In Intelligent Machine Vision Techniques, Implementations and Applications; Springer: London, UK, 2001; pp. 345–422. ISBN 978-1-4471-1129-0. [Google Scholar]

- Vijayarekha, K. Machine Vision Application for Food Quality: A Review. Res. J. Appl. Sci. Eng. Technol. 2012, 4, 5453–5458. [Google Scholar]

- ElMasry, G.; Sun, D.-W. Hyperspectral imaging for food quality analysis and control. In Hyperspectral Imaging for Food Quality Analysis and Control; Sun, D.-W., Ed.; Academic Press: London, UK, 2010; Volume 1, pp. 3–43. ISBN 9788578110796. [Google Scholar]

- Munjanja, B.; Sanganyado, E. UV-Visible Absorption, Fluorescence ,and Chemiluminescence Spectroscopy. In Handbook of Food Analysis; Nollet, L.M., Fidel, T., Eds.; CRC Press: London, UK, 2004; pp. 572–583. [Google Scholar]

- Abbott, J. Quality measurement of fruits and vegetables. Postharvest Biol. Technol. 1999, 15, 207–225. [Google Scholar] [CrossRef]

- Reid, L.M.; O’Donnell, C.P.; Downey, G. Recent technological advances for the determination of food authenticity. Trends Food Sci. Technol. 2006, 17, 344–353. [Google Scholar] [CrossRef]

- Nawrocka, A.; Lamorska, J. Determination of Food Quality by Using Spectroscopic Methods. In Advances in Agrophysical Research; InTech: Rijeka, Croatia, 2013; pp. 347–368. ISBN 978-953-51-1184-9. [Google Scholar]

- Molina-Diaz, A.; Garcia-Reyes, J.F.; Gilbert-Lopez, B. Solid-phase spectroscopy from the point of view of green analytical chemistry. TrAC Trends Anal. Chem. 2010, 29, 654–666. [Google Scholar] [CrossRef]

- Wu, W.-L.; Zhao, Z.-M.; Dai, X.; Su, L.; Zhao, B.-X. A fast-response colorimetric and fluorescent probe for hypochlorite and its real applications in biological imaging. Sens. Actuators B Chem. 2016, 232, 390–395. [Google Scholar] [CrossRef]

- He, H.J.; Sun, D.W. Microbial evaluation of raw and processed food products by Visible/Infrared, Raman and Fluorescence spectroscopy. Trends Food Sci. Technol. 2015, 46, 199–210. [Google Scholar] [CrossRef]

- Williams, P.; Norris, K. Chemical principles. In Near-Infrared Technology in the Agricultural and Food Industries; Miller, C.E., Ed.; American Association of Cereal Chemists: St. Paul, MN, USA, 2001; pp. 19–37. [Google Scholar]

- Moscetti, R.; Haff, R.P.; Monarca, D.; Cecchini, M.; Massantini, R. Near-infrared spectroscopy for detection of hailstorm damage on olive fruit. Postharvest Biol. Technol. 2016, 120, 204–212. [Google Scholar] [CrossRef]

- Moscetti, R.; Radicetti, E.; Monarca, D.; Cecchini, M.; Massantini, R. Near infrared spectroscopy is suitable for the classification of hazelnuts according to Protected Designation of Origin. J. Sci. Food Agric. 2015, 95, 2619–2625. [Google Scholar] [CrossRef] [PubMed]

- Jha, S.N. Spectroscopy and chemometrics. In Rapid Detection of Food Adulterants and Contaminants; Jha, S.N., Ed.; Academic Press: London, UK, 2016; pp. 163–164. ISBN 9780124200845. [Google Scholar]

- Goddu, R.F. Determination of Unsaturation by Near-Infrared Spectrophotometry. Anal. Chem. 1957, 29, 1790–1794. [Google Scholar] [CrossRef]

- Gassman, P.G.; Hooker, W.M. Near-Infrared Studies. Norbornenes and Related Compounds. J. Am. Chem. Soc. 1965, 87, 1079–1083. [Google Scholar] [CrossRef]

- Aines, R.D.; Rossman, G.R. Water in minerals? A peak in the infrared. J. Geophys. Res. 1984, 89, 4059–4071. [Google Scholar] [CrossRef]

- Iwamoto, M.; Uozumi, J.; Nishinari, K. Preliminary Investigation of the State of Water in Foods by Near Infrared Spectroscopy. In Proceedings of the International NIR/NIT Conference, Budapest, Hungary, 3 December 1987. [Google Scholar]

- Bush, S.G.; Jorgenson, J.W.; Miller, M.L.; Linton, R.W. Transmission near-infrared technique for evaluation and relative quantitation of surface groups on silica. J. Chromatogr. A 1983, 260, 1–12. [Google Scholar] [CrossRef]

- Weyer, L.G. Near-Infrared Spectroscopy of Organic Substances. Appl. Spectrosc. Rev. 1985, 21, 1–43. [Google Scholar] [CrossRef]

- Whetsel, K.B.; Roberson, W.E.; Krell, M.W. Near-Infrared Spectra of Primary Aromatic Amines. Anal. Chem. 1958, 30, 1598–1604. [Google Scholar] [CrossRef]

- Russell, R.A.; Thompson, H.W. Vibrational Band Intensities and the Electrical Anharmonicity of the NH Group. Proc. R. Soc. Lond. A Math. Phys. Eng. Sci. 1956, 234, 318–326. [Google Scholar] [CrossRef]

- Tobergte, D.R.; Curtis, S. Practical Guide and Spectral Atlas for Interpretive Near-Infrared Spectroscopy; CRC Press: Boca Raton, FL, USA, 2013; Volume 53, ISBN 9788578110796. [Google Scholar]

- Law, D.P.; Tkachuk, R. Near Infrared Diffuse Reflectance Spectra of Wheat and Wheat Components. Cereal Chem. 1977, 56, 256–265. [Google Scholar]

- Wheeler, O.H. Near Infrared Spectra Of Organic Compounds. Chem. Rev. 1959, 59, 629–666. [Google Scholar] [CrossRef]

- Chabert, B.; Lachenal, G.; Vinh Tung, C. Epoxy resins and epoxy blends studied by near infra-red spectroscopy. Macromol. Symp. 1995, 94, 145–158. [Google Scholar] [CrossRef]

- Pasquini, C. Near Infrared Spectroscopy: Fundamentals, practical aspects and analytical applications. J. Braz. Chem. Soc. 2003, 14, 198–219. [Google Scholar] [CrossRef]

- Cozzolino, D.; Cynkar, W.U.; Shah, N.; Smith, P. Multivariate data analysis applied to spectroscopy: Potential application to juice and fruit quality. Food Res. Int. 2011, 44, 1888–1896. [Google Scholar] [CrossRef]

- Gómez-Caravaca, A.M.; Maggio, R.M.; Cerretani, L. Chemometric applications to assess quality and critical parameters of Virgin and Extra-Virgin Olive Oil. A Review. Anal. Chim. Acta 2016, 913. [Google Scholar] [CrossRef] [PubMed]

- Mollazade, K.; Omid, M.; Tab, F.A.; Mohtasebi, S.S. Principles and Applications of Light Backscattering Imaging in Quality Evaluation of Agro-food Products: A Review. Food Bioprocess Technol. 2012, 5, 1465–1485. [Google Scholar] [CrossRef]

- Moscetti, R.; Saeys, W.; Keresztes, J.C.; Goodarzi, M.; Cecchini, M.; Danilo, M.; Massantini, R. Hazelnut Quality Sorting Using High Dynamic Range Short-Wave Infrared Hyperspectral Imaging. Food Bioprocess Technol. 2015, 8, 1593–1604. [Google Scholar] [CrossRef]

- Menesatti, P.; Zanella, A.; D’Andrea, S.; Costa, C.; Paglia, G.; Pallottino, F. Supervised Multivariate Analysis of Hyper-spectral NIR Images to Evaluate the Starch Index of Apples. Food Bioprocess Technol. 2008, 2, 308–314. [Google Scholar] [CrossRef]

- Karoui, R.; Blecker, C. Fluorescence Spectroscopy Measurement for Quality Assessment of Food Systems—A Review; Springer: Berlin/Heidelberg, Germany, 2010; Volume 4. [Google Scholar]

- Zhang, B.; Huang, W.; Li, J.; Zhao, C.; Fan, S.; Wu, J.; Liu, C. Principles, developments and applications of computer vision for external quality inspection of fruits and vegetables: A review. Food Res. Int. 2014, 62, 326–343. [Google Scholar] [CrossRef]

- Mahesh, S.; Jayas, D.S.; Paliwal, J.; White, N.D.G. Hyperspectral imaging to classify and monitor quality of agricultural materials. J. Stored Prod. Res. 2015, 61, 17–26. [Google Scholar] [CrossRef]

- Rinnan, Å; van den Berg, F.; Engelsen, S.B. Review of the most common pre-processing techniques for near-infrared spectra. TrAC Trends Anal. Chem. 2009, 28, 1201–1222. [Google Scholar] [CrossRef]

- Xu, L.; Zhou, Y.P.; Tang, L.J.; Wu, H.L.; Jiang, J.H.; Shen, G.L.; Yu, R.Q. Ensemble preprocessing of near-infrared (NIR) spectra for multivariate calibration. Anal. Chim. Acta 2008, 616, 138–143. [Google Scholar] [CrossRef] [PubMed]

- Wold, S.; Sjöström, M.; Eriksson, L. PLS-regression: A basic tool of chemometrics. Chemom. Intell. Lab. Syst. 2001, 58, 109–130. [Google Scholar] [CrossRef]

- Wang, H.; Peng, J.; Xie, C.; Bao, Y.; He, Y. Fruit Quality Evaluation Using Spectroscopy Technology: A Review. Sensors 2015, 15, 11889–11927. [Google Scholar] [CrossRef] [PubMed]

- Dey, V.; Zhang, Y.; Zhong, M. A Review on Image Segmentation Techniques With remote sensing perspective. In Proceedings of the ISPRS TC VII Symposium—100 Years ISPRS, Vienna, Austria, 5–7 July 2010; Volume XXXVIII, pp. 31–42. [Google Scholar]

- Kang, S.P.; Sabarez, H.T. Simple colour image segmentation of bicolour food products for quality measurement. J. Food Eng. 2009, 94, 21–25. [Google Scholar] [CrossRef]

- Du, C. Recent developments in the applications of image processing techniques for food quality evaluation. Trends Food Sci. Technol. 2004, 15, 230–249. [Google Scholar] [CrossRef]

- Brosnan, T.; Sun, D.W. Improving quality inspection of food products by computer vision—A review. J. Food Eng. 2004, 61, 3–16. [Google Scholar] [CrossRef]

- Lu, R. Quality evaluation of Fruit by Hyperspectral Imaging. In Computer Vision Technology for Food Quality Evaluation; Academic Press: Cambridge, MA, USA, 2008; Chapter 14; pp. 319–348. ISBN 9780123736420. [Google Scholar]

- Cen, H.; He, Y. Theory and application of near infrared reflectance spectroscopy in determination of food quality. Trends Food Sci. Technol. 2007, 18, 72–83. [Google Scholar] [CrossRef]

- Chen, L.; Opara, U.L. Approaches to analysis and modeling texture in fresh and processed foods—A review. J. Food Eng. 2013, 119, 497–507. [Google Scholar] [CrossRef]

- Wu, D.; Sun, D.-W. Advanced applications of hyperspectral imaging technology for food quality and safety analysis and assessment: A review—Part II: Applications. Innov. Food Sci. Emerg. Technol. 2013, 19, 15–28. [Google Scholar] [CrossRef]

- Romano, G.; Nagle, M.; Müller, J. Two-parameter Lorentzian distribution for monitoring physical parameters of golden colored fruits during drying by application of laser light in the Vis/NIR spectrum. Innov. Food Sci. Emerg. Technol. 2016, 33, 498–505. [Google Scholar] [CrossRef]

- Barzaghi, S.; Gobbi, S.; Torreggiani, D.; Giangiacomo, R. Near infrared spectroscopy for the control of osmo–air dehydrated apple rings. J. Near Infrared Spectrosc. 2008, 149, 143–149. [Google Scholar] [CrossRef]

- Sampson, D.J.; Chang, Y.K.; Rupasinghe, H.P.V.; Zaman, Q.U. A dual-view computer-vision system for volume and image texture analysis in multiple apple slices drying. J. Food Eng. 2014, 127, 49–57. [Google Scholar] [CrossRef]

- Sturm, B.; Hofacker, W.C.; Hensel, O. Optimizing the Drying Parameters for Hot-Air-Dried Apples. Dry. Technol. 2012, 30, 1570–1582. [Google Scholar] [CrossRef]

- Behroozi Khazaei, N.; Tavakoli Hashjin, T.; Ghassemian, H.; Khoshtaghaza, M.H.; Banakar, A. Application of machine vision in modeling of grape drying process. J. Agric. Sci. Technol. 2013, 15, 1095–1106. [Google Scholar]

- Dénes, L.D.; Zsom-Muha, V.; Baranyai, L.; Felföldi, J. Modelling of apple slice moisture content by optical methods. Acta Aliment. 2012, 41, 39–51. [Google Scholar] [CrossRef]

- Romano, G.; Argyropoulos, D.; Nagle, M.; Khan, M.T.; Müller, J. Combination of digital images and laser light to predict moisture content and color of bell pepper simultaneously during drying. J. Food Eng. 2012, 109, 438–448. [Google Scholar] [CrossRef]

- Hafezi, N.; Sheikhdavoodi, M.J.; Sajadiye, S.M. Shrinkage characteristic of potato slices based on computer vision. Agric. Eng. Int. 2015, 17, 287–295. [Google Scholar]

- Martynenko, A.I. Porosity Evaluation of Ginseng Roots from Real-Time Imaging and Mass Measurements. Food Bioprocess Technol. 2011, 4, 417–428. [Google Scholar] [CrossRef]

- Mulet, A.; Garcia-Reverter, J.; Bon, J.; Berna, A. Effect of Shape on Potato and Cauliflower Shrinkage during Drying. Dry. Technol. 2000, 18, 1201–1219. [Google Scholar] [CrossRef]

- Liu, C.; Liu, W.; Lu, X.; Chen, W.; Yang, J.; Zheng, L. Potential of Multispectral Imaging for Real-Time Determination of Colour Change and Moisture Distribution in Carrot Slices during Hot Air Dehydration; Elsevier Ltd.: Amsterdam, The Netherlands, 2016; Volume 195, ISBN 8655162919398. [Google Scholar]

- Ozaki, Y.; McClure, W.F.; Christy, A.A. (Eds.) Near-Infrared Spectroscopy in Food Science and Technology; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2006. [Google Scholar]

- Moscetti, R.; Monarca, D.; Cecchini, M.; Haff, R.P.; Contini, M.; Massantini, R. Detection of Mold-Damaged Chestnuts by Near-Infrared Spectroscopy. Postharvest Biol. Technol. 2014, 93, 83–90. [Google Scholar] [CrossRef]

- Chen, Q.; Zhang, C.; Zhao, J.; Ouyang, Q. Recent advances in emerging imaging techniques for non-destructive detection of food quality and safety. TrAC Trends Anal. Chem. 2013, 52, 261–274. [Google Scholar] [CrossRef]

- Feng, Y.-Z.; Sun, D.-W. Application of hyperspectral imaging in food safety inspection and control: A review. Crit. Rev. Food Sci. Nutr. 2012, 52, 1039–1058. [Google Scholar] [CrossRef] [PubMed]

- Giangiacomo, R. Study of water-sugar interactions at increasing sugar concentration by NIR spectroscopy. Food Chem. 2006, 96, 371–379. [Google Scholar] [CrossRef]

- Kays, S.; Franklin Barton, I.I.; Windham, W. Predicting protein content by near infrared reflectance spectroscopy in diverse cereal food products. J. Near Infrared Spectrosc. 2000, 8, 35–43. [Google Scholar] [CrossRef]

- Wesley, I.J.; Larroque, O.; Osborne, B.G.; Azudin, N.; Allen, H.; Skerritt, J.H. Measurement of Gliadin and Glutenin Content of Flour by NIR Spectroscopy. J. Cereal Sci. 2001, 34, 125–133. [Google Scholar] [CrossRef]

- Bobelyn, E.; Serban, A.S.; Nicu, M.; Lammertyn, J.; Nicolai, B.M.; Saeys, W. Postharvest quality of apple predicted by NIR-spectroscopy: Study of the effect of biological variability on spectra and model performance. Postharvest Biol. Technol. 2010, 55, 133–143. [Google Scholar] [CrossRef]

- Giovanelli, G.; Sinelli, N.; Beghi, R.; Guidetti, R.; Casiraghi, E. NIR spectroscopy for the optimization of postharvest apple management. Postharvest Biol. Technol. 2014, 87, 13–20. [Google Scholar] [CrossRef]

- Moscetti, R.; Haff, R.P.; Ferri, S.; Raponi, F.; Monarca, D.; Liang, P.; Massantini, R. Real-Time Monitoring of Organic Carrot (var. Romance) During Hot-Air Drying Using Near-Infrared Spectroscopy. Food Bioprocess Technol. 2017, 10, 2046–2059. [Google Scholar] [CrossRef]

| Molecular Classes/Molecule | Bond | Features (nm) | Reference | |

|---|---|---|---|---|

| 1st Overtone | 2nd Overtone | |||

| Aliphatic hydrocarbons | C-H | 1700 | 1150 | [117] |

| Aromatic hydrocarbons | C-H | 1685 | 1143 | |

| Olefins (1-octene) | C-H | 1620 | [118] | |

| Olefins | C-H | 1680 | 1180 | |

| Norbornene | C-H | 1645–1675 | [119] | |

| Water | O-H | 1453 | 979 | [120] |

| Alcohol and phenols | O-H | 1405–1425 | 945–985 | [121] |

| Silanols | O-H | 1385 | [122] | |

| Primary amines (R-NH2) | N-H | 1500 and 1530 | 1000 | [123] |

| Secondary amines (R2-NH) | N-H | 1520–1540 | ||

| Aromatic amines (Ar-NH2) | N-H | 1450–1490 | 1020 | [124] |

| Cyclic amines | N-H | 1450 | [125] | |

| (pyrroles, indoles, carbazoles) | ||||

| Ethanamide (CH3CONH2) | N-H | 1430 and 1490 | [126] | |

| N-methyl ethanamide (CH3CONHCH3) | N-H | 1475 | ||

| Wheat protein | N-H | 1500 and 1570 | [127] | |

| Aldehydes and ketones | C=O | 2900 | 1960 | [128] |

| Esters | C=O | 1900–1950 | ||

| Peptides | C=O | 1920 | ||

| Carboxylic acids | C=O | 1900 | ||

| Epoxides | C-O | 1640–1650 | [129] | |

| Organophosphorus compounds | P-H | 1891 | ||

| Aliphatic and aromatic thiols | S-H | 1970–1980 | [126] | |

| Phosphorus-thiol group | P-S-H | 1970 and 1999 | ||

| Products | Dryer Type | CV Device | Features | Resolution | Attribute(s) | Algorithm | Metric | Reference | |

|---|---|---|---|---|---|---|---|---|---|

| Error Metric | R2 | ||||||||

| Mango (var. Nam Dokmai) | AD | Vis-NIR | 473, 532 and 875 nm | 5 nm | Browning index, | -- | -- | 0.63 | [151] |

| w | 0.91 | ||||||||

| Hardness (h) | 0.70 | ||||||||

| Litchi (var. Chinensis Sonn.) | AD | Vis-NIR | 473, 532 and 875 nm | 5 nm | Browning index, | 0.81 | |||

| w | 0.80 | ||||||||

| h | 0.55 | ||||||||

| Apple (var. Golden delicious and Pink lady) | OD + AD | NIR | 1000–2500 nm | 0.8–5 nm | w | PLS-DA | 3.33 (RPD) | 0.93 | [152] |

| 13.79 (RER) | |||||||||

| Mango (var. Nam Dokmai) | MVD | HSI | 880–1720 nm | 7 nm | w | PLS | 4.716 | 0.97 | [13] |

| MSI | 1342, 1405 nm | w | PLS | 5.582 | 0.96 | ||||

| Apple (var. Granny Smith) | AD | CV | RGB | 1280 × 1024 pixels | L* | COM | <5% (SE) | 0.91 | [12] |

| a* | 0.94 | ||||||||

| b* | 0.95 | ||||||||

| Apple (var. Empire) | AD | CV | RGB | 640 × 480 pixels | Area | -- | -- | 1 | [153] |

| Thickness | 0.97 | ||||||||

| Volume | 0.95 | ||||||||

| Hue angle | 1 | ||||||||

| L* | 0.90 | ||||||||

| Chroma (C*) | 0.94 | ||||||||

| Texture | 0.90 | ||||||||

| Apple (var. Jonagold) | AD | CV | Visible | 1280 × 768 pixels | ΔE* | Third order polynomial | 0.95 | [154] | |

| Shrinkage | P = 0.04 | 0.68 | |||||||

| Sultana grape (var. Vitis vinifera L) | AD | CV | Visible | -- | w | Page’s model | -- | 0.99 | [155] |

| Shrinkage | 0.99 | ||||||||

| ΔE* | 0.95 | ||||||||

| Apple (var. Idared) | AD | NIR | 740–1400 nm | 9 nm | w, (dry bulb) | PLS | RMSEP < 5.09, RPD = 5.09 | 0.98 | [156] |

| w, (wet bulb) | RMSEP < 24.82, RPD = 6.63 | 0.99 | |||||||

| MSI | 532, 635, 650, 780, 808, 850, 1064 nm | 5 nm | w, (dry bulb) | PLS | RMSEP 38.41 | 0.94 | |||

| w, (wet bulb) | RMSEP 13.2 | 0.71 | |||||||

| Species | Dryer Type | CV Device | Features | Resolution | Attribute(s) | Algorithm | Metric | Reference | |

|---|---|---|---|---|---|---|---|---|---|

| Error Metric | R2 | ||||||||

| Yellow pepper (var. Capsicum annuum) | AD | CV (CCD camera + laser diode) | Visible (CCD camera; 532 and 635 nm) | 1280 × 1024 pixels | w | -- | 7.28 | 0.93 | [157] |

| L* | -- | 0.9 | |||||||

| a* | 0.93 | ||||||||

| b* | 0.72 | ||||||||

| Green pepper (var. Capsicum annuum) | AD | CV (CCD camera + laser diode) | Visible (CCD camera; 532 and 635 nm) | 1280 × 1024 pixels | w (635 nm) | 8.77 | 0.9 | ||

| L* | -- | 0.87 | |||||||

| a* | 0.97 | ||||||||

| b* | Low | ||||||||

| Red pepper (var. Capsicum annuum) | AD | CV (CCD camera + laser diode) | Visible (CCD camera; 532 and 635 nm) | 1280 × 1024 pixels | w (532 nm) | 9.95 | 0.89 | ||

| L* | -- | Low | |||||||

| a* | Low | ||||||||

| b* | Low | ||||||||

| Soybean (var. Glycine max) | MVD | HSI | 400–1000 nm | 0.12 mm/pixel | Color | Segmentation PLS | RMSEP = 1.0 | 0.74 | [15] |

| 0.64 mm/pixel | w | RMSEP = 4.7 | 0.94 | ||||||

| Ginseng (var. Panax ginseng), (var. Panax quinquefolium) | AD | NIR | 1100–2500 nm | 8 nm | w | First derivative, SNV, PLS | SEP = 0.14 | 1 | [11] |

| Potato (var. Solarium tuberosum) | IR | CV (digital camera) | Visible range | 3648 × 2736 pixels | Shape | Image processing, segmentation | -- | [158] | |

| Shrinkage | |||||||||

| Ginseng (var. Panax ginseng) | AD | CV (CCD camera) | Visible range | 1040 × 1392 pixels | Density, shrinkage, porosity | Image processing, segmentation | -- | [159] | |

| Potato (var. Solarium tuberosum) | AD | Computer vision (black/white video camera) | Visible range | 510 × 492 pixels | Shrinkage | Segmentation | BIAS = 0.6% | 0.99 | [160] |

| Cauliflower (var. Snow March) | BIAS = 0.6% | 0.97 | |||||||

| Carrot (var. Daucus carota) | MVD | CV (CCD digital camera) | Visible range | 3264 × 2448 pixels | Shrinkage, color | -- | -- | 1 | [16] |

| Carrot (var. Daucus carota) | AD | MSI | 19 wavelengths from 405–970 nm | -- | w, color | PLS, LS-SVM, BPNN | RMSEP = 1.482 | 0.99 | [161] |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Raponi, F.; Moscetti, R.; Monarca, D.; Colantoni, A.; Massantini, R. Monitoring and Optimization of the Process of Drying Fruits and Vegetables Using Computer Vision: A Review. Sustainability 2017, 9, 2009. https://doi.org/10.3390/su9112009

Raponi F, Moscetti R, Monarca D, Colantoni A, Massantini R. Monitoring and Optimization of the Process of Drying Fruits and Vegetables Using Computer Vision: A Review. Sustainability. 2017; 9(11):2009. https://doi.org/10.3390/su9112009

Chicago/Turabian StyleRaponi, Flavio, Roberto Moscetti, Danilo Monarca, Andrea Colantoni, and Riccardo Massantini. 2017. "Monitoring and Optimization of the Process of Drying Fruits and Vegetables Using Computer Vision: A Review" Sustainability 9, no. 11: 2009. https://doi.org/10.3390/su9112009

APA StyleRaponi, F., Moscetti, R., Monarca, D., Colantoni, A., & Massantini, R. (2017). Monitoring and Optimization of the Process of Drying Fruits and Vegetables Using Computer Vision: A Review. Sustainability, 9(11), 2009. https://doi.org/10.3390/su9112009