Assessing the Rebound Hammer Test for Rammed Earth Material

Abstract

1. Introduction

2. Schmidt Rebound Hammer Test

3. Specimen Manufacturing and the Homogeneity of RE Specimens

3.1. Material Used

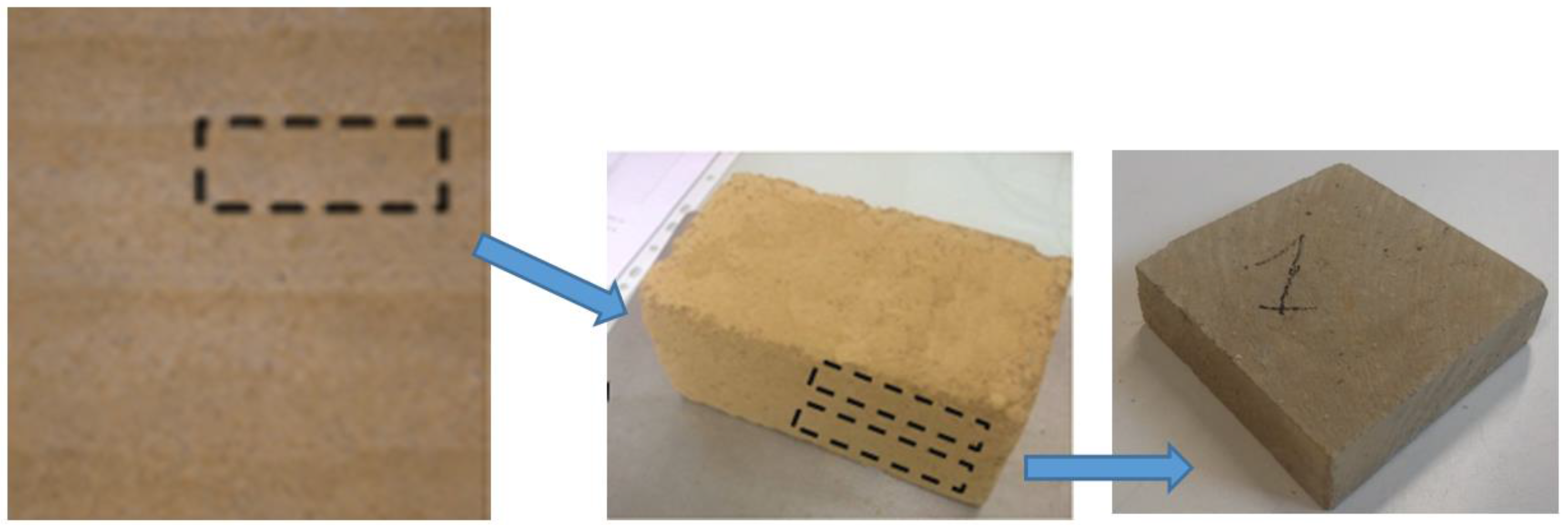

3.2. Inhomogeneity of RE Specimens

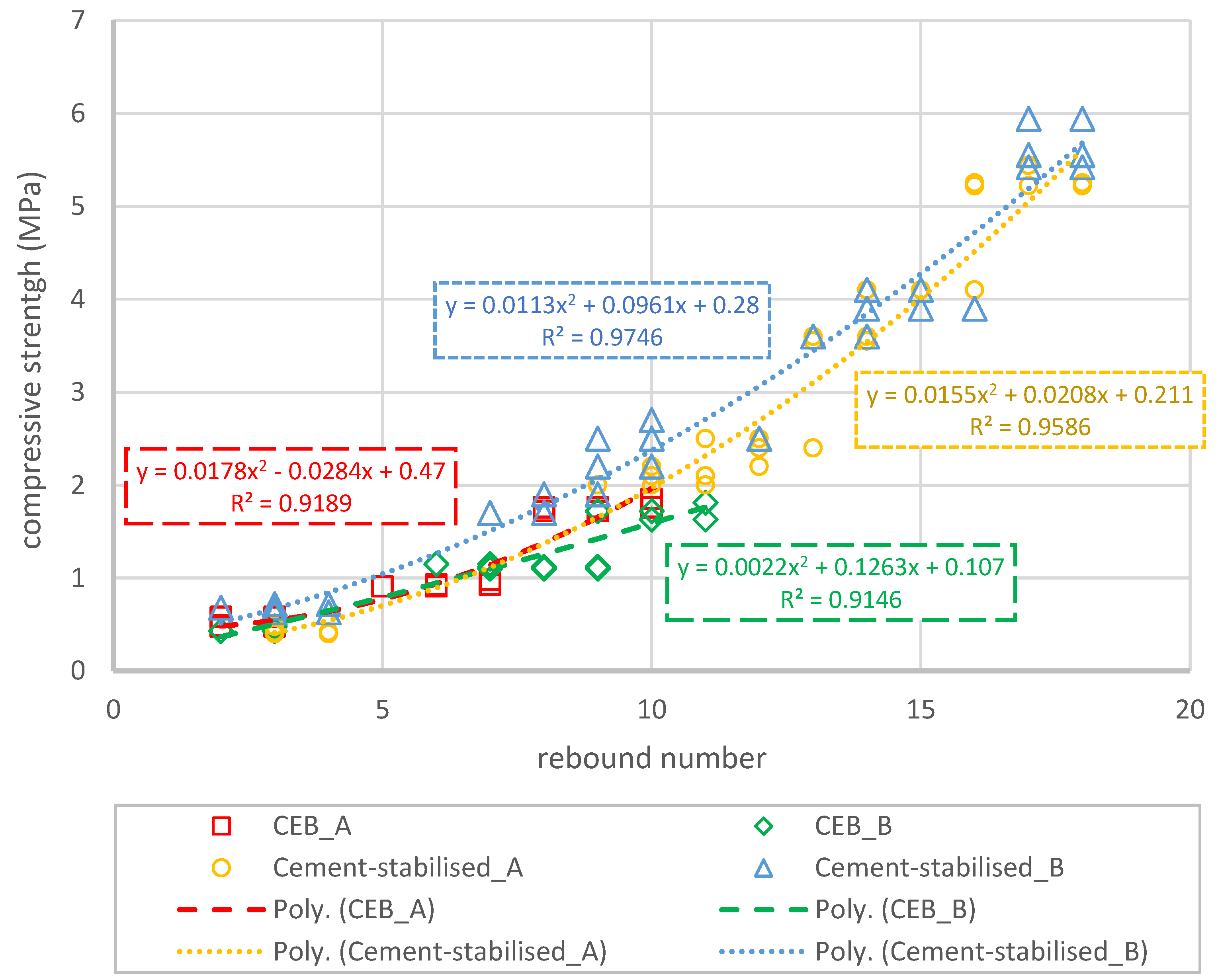

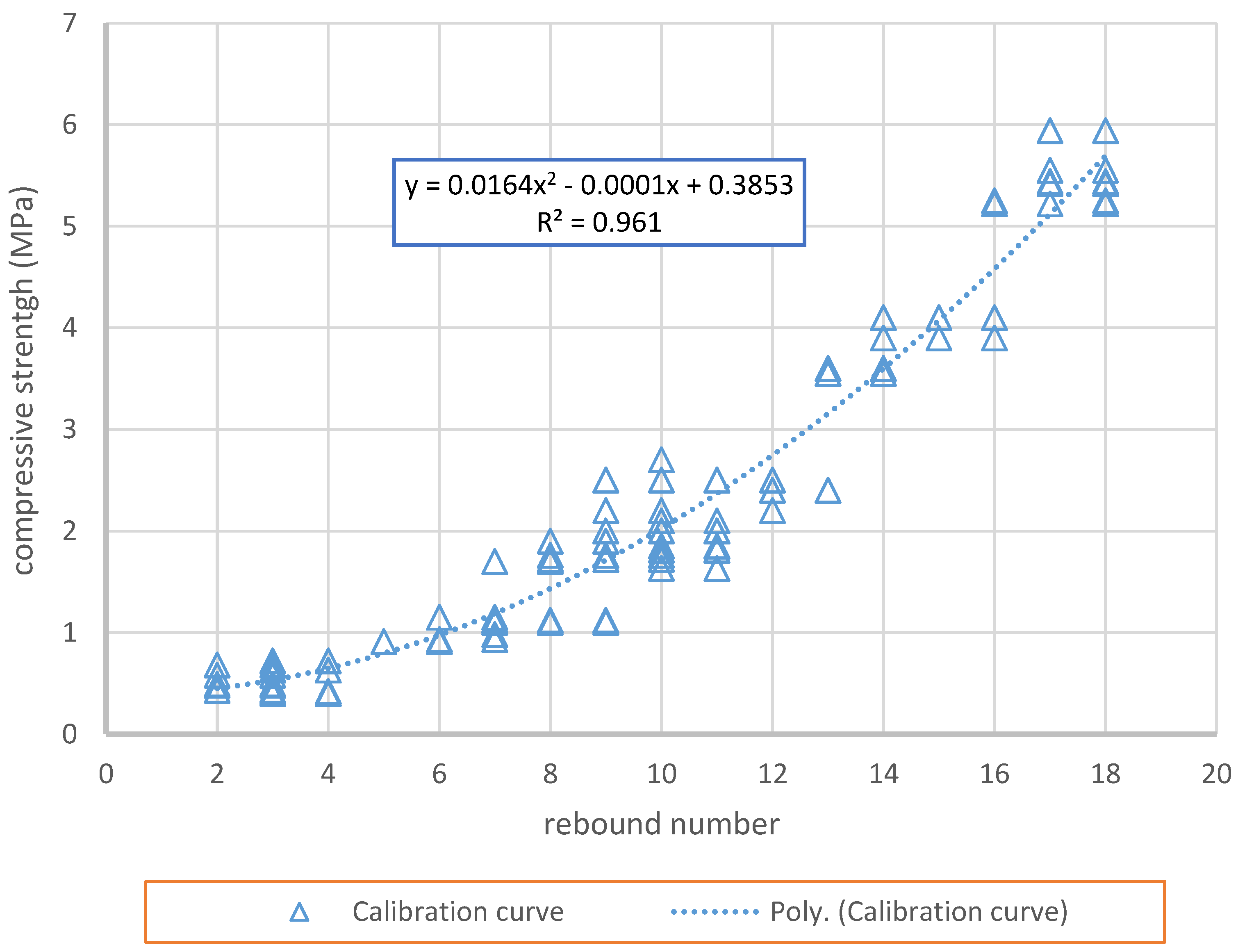

4. Calibration Curve

- Compressed earth blocks (CEBs): different CEBs with different densities were manufactured to represent the different zones in an RE layer. The dimensions of earthen blocks were 9.5 × 14 × 29.4 cm3. When the CEBs were tested in the longitudinal direction, the corresponding slenderness ratio was 3.1. Three different dry densities were targeted to produce: 1650, 1800, and 1950 kg/m3. The manufacturing water content was 12%, which corresponded to the Proctor optimum. The targeted dry densities were reached by calculating the amount of soil put in the mold. For each dry density expected, three specimens were manufactured. Before the manufacturing, the soil was sieved at 2 cm to take out the big gravels that provided a certain homogeneity for CEBs. The representativeness of earthen blocks for RE material has been discussed in a previous study (Bui et al. [1]). The specimens were unmolded after the manufacture and cured in ambient conditions (25 °C and 60% RH).

- Cement stabilized soil technique: different amounts of cement CEM II were tried to produce different compressive strengths. Five compositions were used: the specimens stabilized by cement at 0, 2, 4, 6, and 8% of the weight of the total mix, respectively. In order to consider specimens as homogenous, the soil was sieved at 1 cm before manufacturing. The moisture content and the Atterberg’s plastic limit of the soil corresponded to 2% and 17% (in weight), respectively. The manufacturing water content for all mixtures was chosen at 18% (including the residual moisture content in the soil), which was slightly superior to the plastic limit. It was observed that this water content enabled an acceptable workability for the molding. First, the soil and the cement were mixed without water; then, the water was added until the target water content. The standard molds for mortar specimens (4 cm × 4 cm × 16 cm) were used. For each composition, three specimens were manufactured in the same way a classical mortar is manufactured. The specimens were unmolded after one day and then cured in ambient conditions (25 °C and 60% RH). When the specimens were tested under uniaxial compression tests, the corresponding slenderness ratio was 1, so a corrector ratio was applied to calculate the compressive strength, following European standards and recent investigations ([34,35,36]). The specimens were tested after 28 days of curing. The dry densities of cement-stabilized soil specimens were 1810 ± 34 kg/m3.

5. The Application of the Obtained Calibration Curve on RE Material

5.1. RE Specimen Manufacturing

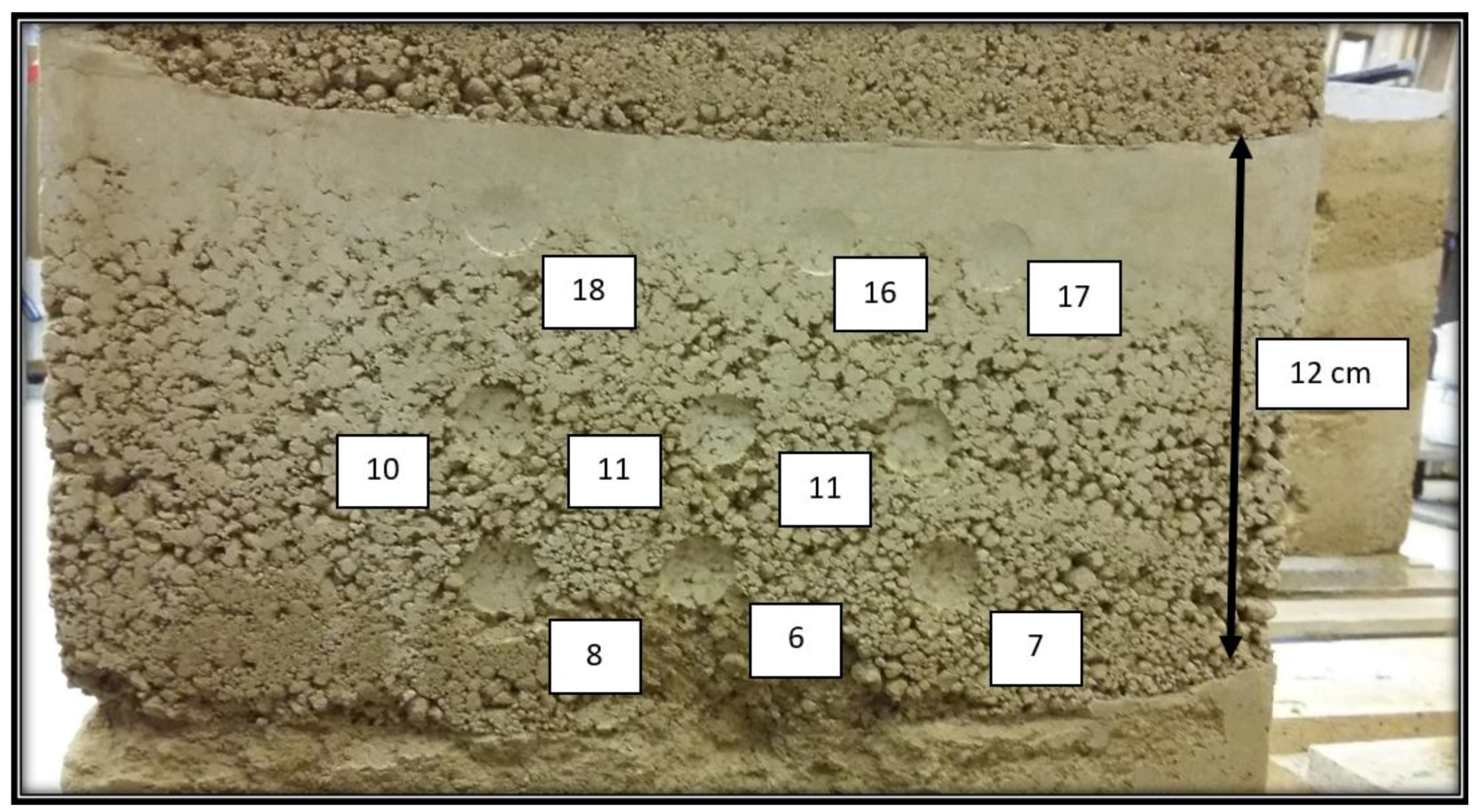

5.2. Rebound Hammer Tests on RE Specimens

5.3. Predicting the Compressive Strength Following the Calibration Curve

5.4. The Compressive Strength of RE Specimens Following Uniaxial Compression Tests

6. Conclusions and Prospects

Acknowledgments

Conflicts of Interest

References

- Bui, Q.B.; Morel, J.C.; Hans, S.; Meunier, N. Compression behaviour of nonindustrial materials in civil engineering by three scale experiments: the case of rammed earth. Mater. Struct. 2009, 42, 1101–1116. [Google Scholar] [CrossRef]

- Walker, P.; Keable, R.; Martin, J.; Maniatidis, V. Rammed Earth-Design and Construction Guidelines; BRE Bookshop, IHS BRE Press: Watford, UK, 2005. [Google Scholar]

- Minke, G. Building with Earth: Design and Technology of a Sustainable Architecture; Birkhäuser Architecture: Basel, Switzerland, 2012. [Google Scholar]

- Morel, J.C.; Mesbah, A.; Oggero, M.; Walker, P. Building houses with local materials: Means to drastically reduce the environmental impact of construction. Build. Environ. 2001, 36, 1119–1126. [Google Scholar] [CrossRef]

- Reddy, B.V.V.; Kumar, P.P. Embodied energy in cement stabilised rammed earth walls. Energy Build. 2010, 42, 380–385. [Google Scholar] [CrossRef]

- Soudani, L.; Fabbri, A.; Morel, J.C.; Woloszyn, M.; Chabriac, P.A.; Wong, H.; Grillet, A.C. Assessment of the validity of some common assumptions in hygrothermal modelling of earth based materials. Energy Build. 2016, 116, 498–511. [Google Scholar] [CrossRef]

- Paul, W.L.; Taylor, P.A. A comparison of occupant comfort and satisfaction between a green building and a conventional building. Building Environ. 2008, 43, 1858–1870. [Google Scholar] [CrossRef]

- Taylor, P.; Luther, M.B. Evaluating rammed earth walls: A case study. Sol. Energy 2004, 76, 79–84. [Google Scholar] [CrossRef]

- Bui, Q.B.; Morel, J.C.; Reddy, B.V.V.; Ghayad, W. Durability of rammed earth walls exposed for 20 years to natural weathering. Build. Environ. 2009, 44, 912–919. [Google Scholar] [CrossRef]

- Jaquin, P. Influence of Arabic and Chinese Rammed Earth Techniques in the Himalayan Region. Sustainability 2012, 4, 2650–2660. [Google Scholar] [CrossRef]

- Maniatidis, V.; Walker, P. Structural capacity of rammed earth in compression. J. Mater. Civ. Eng. 2008, 20, 230–238. [Google Scholar] [CrossRef]

- Bui, Q.B.; Morel, J.C. Assessing the anisotropy of rammed earth. Constr. Build. Mater. 2009, 23, 3005–3011. [Google Scholar] [CrossRef]

- Bui, Q.B.; Morel, J.C.; Hans, S.; Walker, P. Effect of moisture content on the mechanical characteristics of rammed earth. Constr. Build. Mater. 2014, 54, 163–169. [Google Scholar] [CrossRef]

- Cheah, J.S.J.; Walker, P.; Heath, A.; Morgan, T.K.K.B. Evaluating shear test methods for stabilised rammed earth. Constr. Mater. 2012, 165, 325–334. [Google Scholar] [CrossRef]

- Jaquin, P.A.; Augarde, C.E.; Gallipoli, D.; Toll, D.G. The strength of unstabilised rammed earth materials. Géotechnique 2009, 59, 487–490. [Google Scholar] [CrossRef]

- Champiré, F.; Fabbri, A.; Morel, J.C.; Wong, H.; McGregor, F. Impact of relative humidity on the mechanical behavior of compacted earth as a building material. Constr. Build. Mater. 2016, 110, 70–78. [Google Scholar] [CrossRef]

- Hall, M.; Djerbib, Y. Rammed earth sample production: context, recommendations and consistency. Constr. Build. Mater. 2004, 18, 281–286. [Google Scholar] [CrossRef]

- Arrigoni, A.; Beckett, C.; Ciancio, D.; Dotelli, G. Life cycle analysis of environmental impact vs. durability of stabilised rammed earth. Constr. Build. Mater. 2017, 142, 128–136. [Google Scholar] [CrossRef]

- Allinson, D.; Hall, M. Hygrothermal analysis of a stabilised rammed earth test building in the UK. Energy Build. 2010, 42, 845–852. [Google Scholar] [CrossRef]

- McGregor, F.; Heath, A.; Maskell, D.; Fabbri, A.; Morel, J.C. A review on the buffering capacity of earth building materials. Constr. Mater. 2015, 169, 241–251. [Google Scholar] [CrossRef]

- Taylor, P.; Fuller, R.J.; Luther, M.B. Energy use and thermal comfort in a rammed earth office building. Energy Build. 2008, 40, 793–800. [Google Scholar] [CrossRef]

- El-Nabouch, R.; Bui, Q.B.; Plé, O.; Perrotin, P. Assessing the in-plane seismic performance of rammed earth walls by using horizontal loading tests. Eng. Struct. 2017, 145, 153–161. [Google Scholar] [CrossRef]

- Bui, Q.B.; Bui, T.T.; Limam, A. Seismic assessment of rammed earth walls using pushover tests. Cogent Eng. 2016, 3, 1200835. [Google Scholar] [CrossRef]

- Bui, Q.B.; Morel, J.C.; Hans, S.; Do, A.-P. First exploratory study on dynamic characteristics of rammed earth buildings. Eng. Struct. 2011, 33, 3690–3695. [Google Scholar] [CrossRef]

- Miccoli, L.; Drougkas, A.; Müller, U. In-plane behaviour of rammed earth under cyclic loading: Experimental testing and finite element modelling. Eng. Struct. 2016, 125, 144–152. [Google Scholar] [CrossRef]

- Lombillo, I.; Villegas, L.; Fodde, E.; Thomas, C. In situ mechanical investigation of rammed earth: Calibration of minor destructive testing. Constr. Build. Mater. 2014, 51, 451–460. [Google Scholar] [CrossRef]

- Bui, Q.B.; El-Nabouch, R.; Perrotin, P.; Plé, O. Assessing a nondestructive method to determine the Young’s modulus of rammed earth material. In Proceedings of the 6th BIOT Conference on Poromechanics, Paris, France, 10–13 July 2017; ASCE: Reston, VA, USA, 2017. [Google Scholar]

- Khadka, B.; Shakya, M. Comparative compressive strength of stabilized and un-stabilized rammed earth. Mater. Struct. 2016, 49, 3945–3955. [Google Scholar] [CrossRef]

- Liang, R.; Hota, G.; Lei, Y.; Li, Y.; Stanislawski, D.; Jiang, Y. Nondestructive Evaluation of Historic Hakka Rammed Earth Structures. Sustainability 2013, 5, 298–315. [Google Scholar] [CrossRef]

- Proceq. Silver Schmidt Operating Instructions; Proceq: Schwerzenbach, Switzerland, 2017; p. 32. [Google Scholar]

- Szilagyi, K.; Borosnyoi, A.; Zsigovics, I. Understanding the rebound surface hardness of concrete. J. Civ. Eng. Manag. 2015, 21, 185–192. [Google Scholar] [CrossRef]

- Bui, Q.B.; Hans, S.; Morel, J.C. The compressive strength and pseudo elastic modulus of rammed earth. In Proceedings of the International Symposium on Earthen Structures, Bangalore, India, 22–24 August 2007; Interline Publishers: Bengaluru, India, 2007; pp. 217–223. [Google Scholar]

- El-Nabouch, R.; Bui, Q.B.; Perrotin, P.; Plé, O. Experimental and numerical studies on cohesion and friction angle of rammed earth material. In Proceedings of the 6th BIOT Conference on Poromechanics, Paris, France, 10–13 July 2017; ASCE: Reston, VA, USA, 2017. [Google Scholar]

- Eurocode 2. EN 1992: Design of Concrete Structures; European Committee for Standardization: Brussels, Belgium, 2004. [Google Scholar]

- Aubert, J.E.; Maillard, P.; Morel, J.C.; Al Rafii, M. Towards a simple compressive strength test for earth bricks? Mater. Struct. 2016, 49, 1641–1654. [Google Scholar] [CrossRef]

- European Standard. EN 772-1: Methods of Test for Masonry Units—Part 1: Determination of Compressive Strength; European Committee for Standardization: Brussels, Belgium, 2000. [Google Scholar]

| Soil | Clay | Silt | Sand | Gravel |

|---|---|---|---|---|

| Soil A | 19% | 65% | 16% | 0% |

| Soil B | 5% | 51% | 33% | 11% |

© 2017 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bui, Q.-B. Assessing the Rebound Hammer Test for Rammed Earth Material. Sustainability 2017, 9, 1904. https://doi.org/10.3390/su9101904

Bui Q-B. Assessing the Rebound Hammer Test for Rammed Earth Material. Sustainability. 2017; 9(10):1904. https://doi.org/10.3390/su9101904

Chicago/Turabian StyleBui, Quoc-Bao. 2017. "Assessing the Rebound Hammer Test for Rammed Earth Material" Sustainability 9, no. 10: 1904. https://doi.org/10.3390/su9101904

APA StyleBui, Q.-B. (2017). Assessing the Rebound Hammer Test for Rammed Earth Material. Sustainability, 9(10), 1904. https://doi.org/10.3390/su9101904