Assessment of Phosphorus Recovery from Swine Wastewater in Beijing, China

Abstract

1. Introduction

2. Materials and Methods

2.1. Basic Data Collection and Phosphorus Estimation

2.2. Phosphorus Recovery Potential Analysis

2.3. Water Environment Capacity Analysis

3. Results and Discussion

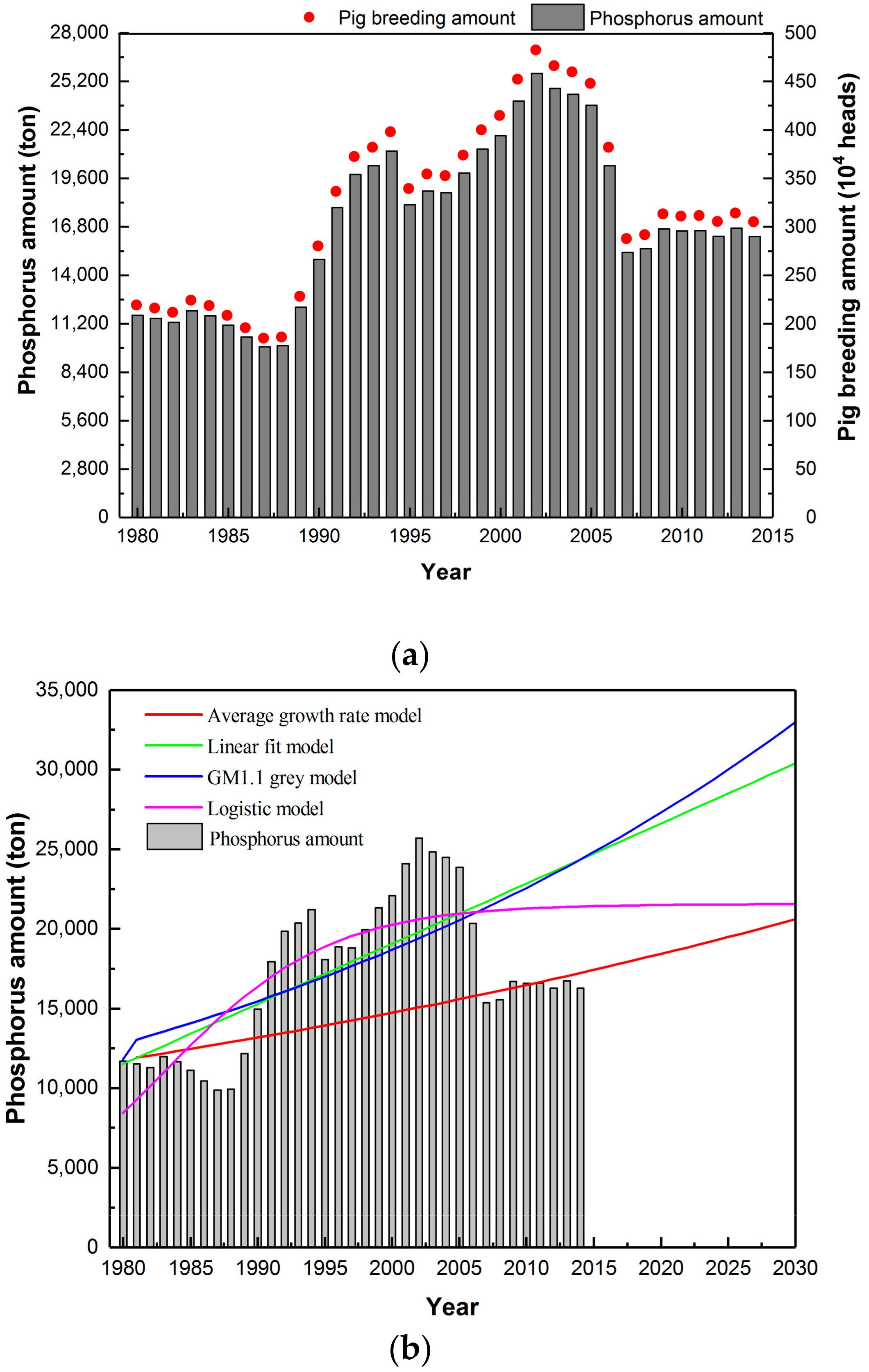

3.1. Phosphorus Estimation

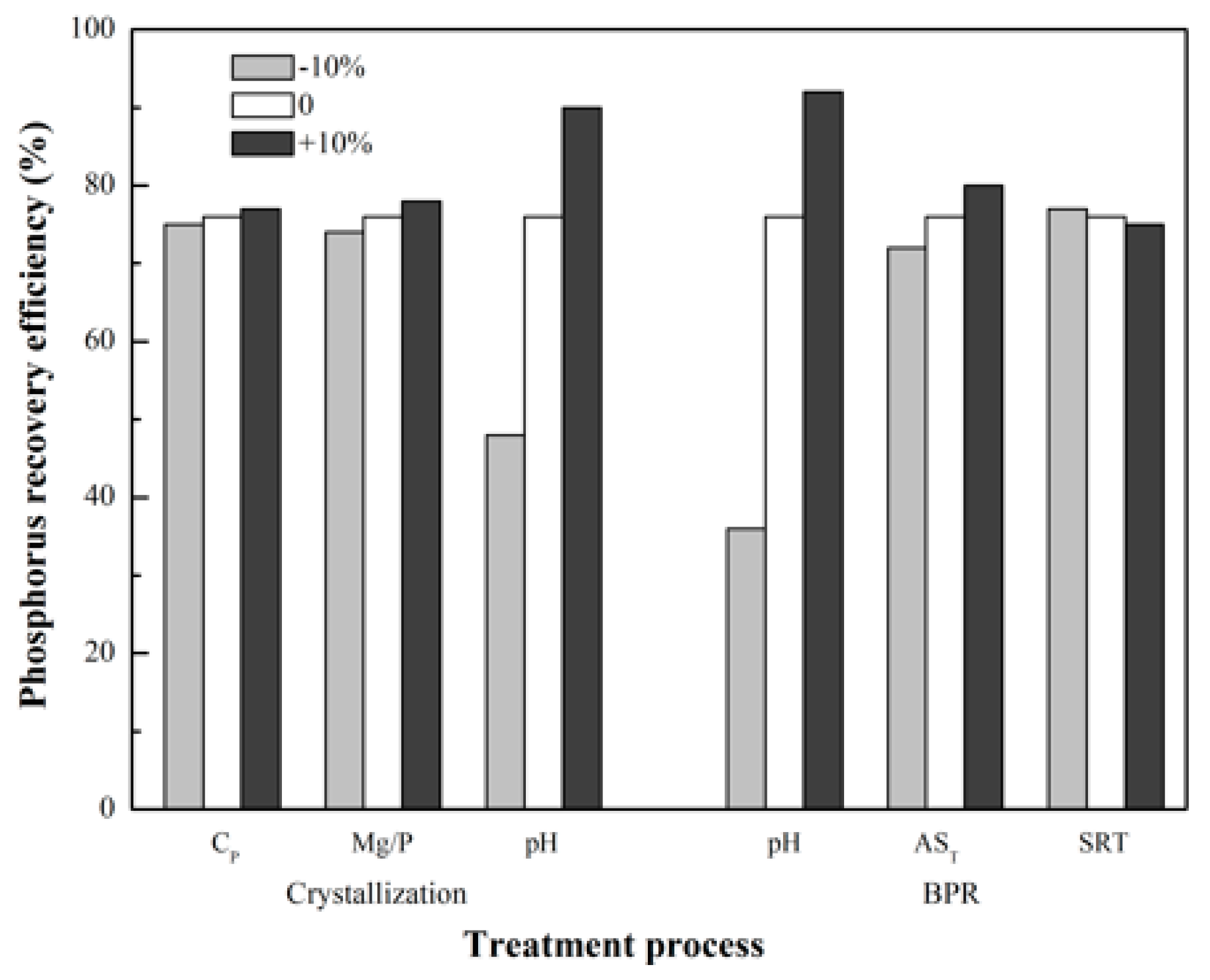

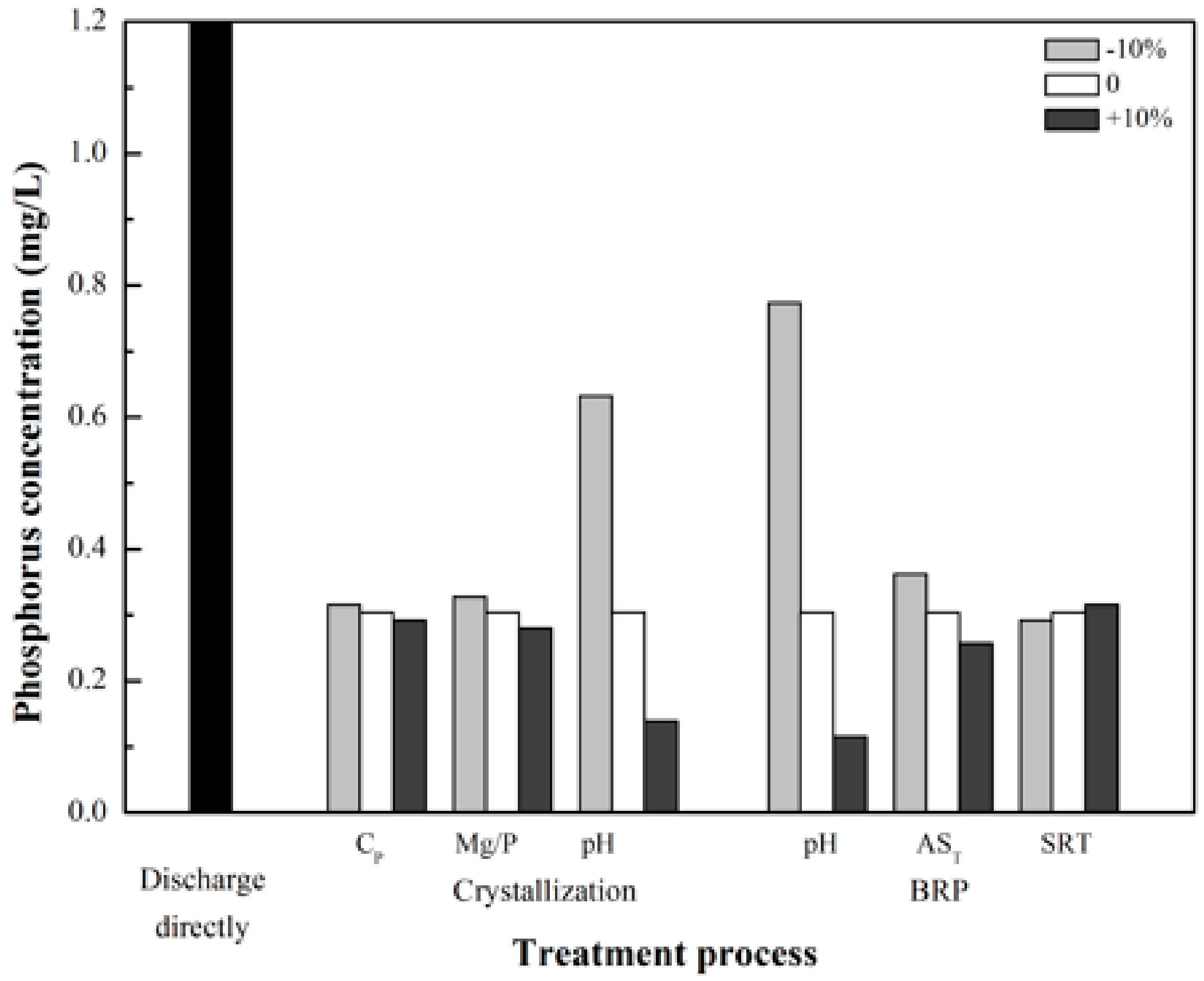

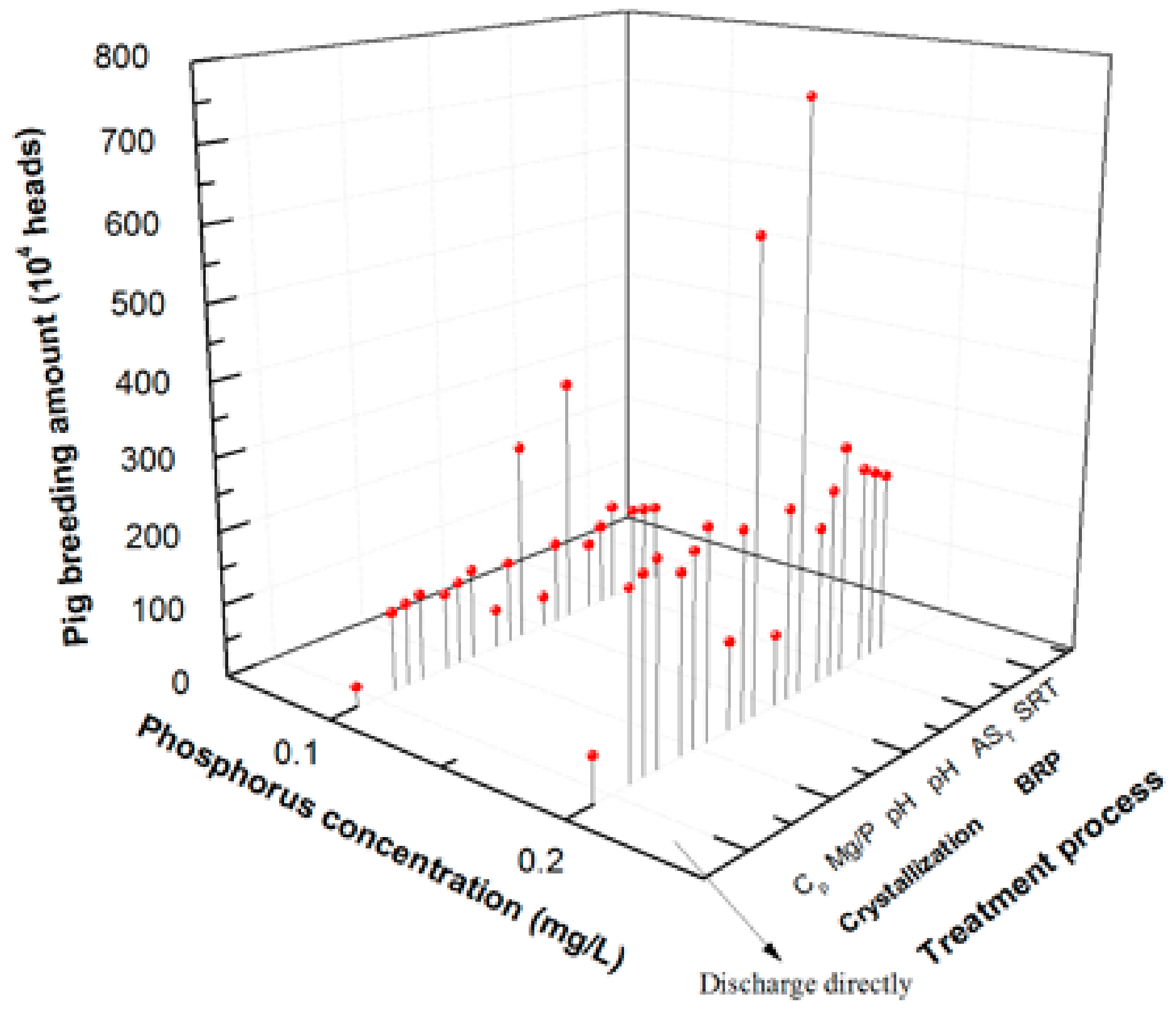

3.2. P Recovery Potential

3.3. Water Environment Capacity Calculation

3.4. Treatment Cost

4. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Huang, H.M.; Zhang, P.; Zhang, Z.; Liu, J.H.; Xiao, J.; Gao, F.M. Simultaneous removal of ammonia nitrogen and recovery of phosphate from swine wastewater by struvite electrochemical precipitation and recycling technology. J. Clean. Prod. 2016, 127, 302–310. [Google Scholar] [CrossRef]

- Elser, J.; Bennett, E. Phosphorus cycle: A broken biogeochemical cycle. Nature 2011, 478, 29–31. [Google Scholar] [CrossRef] [PubMed]

- Withers, P.J.A.; Elser, J.J.; Julian, H.; Hisao, O.; Schipper, W.J.; Van, D.K.C. Greening the global phosphorus cycle: How green chemistry can help achieve planetary P sustainability. Green Chem. 2015, 17, 2087–2099. [Google Scholar] [CrossRef]

- Li, B.; Boiarkina, I.; Young, B.; Yu, W. Substance flow analysis of phosphorous in China. Int. J. Environ. Sci. Dev. 2015, 6, 9–13. [Google Scholar] [CrossRef]

- Kazuyo, M.Y.; Hironari, K.; Kenichi, N.; Tetsuya, N. A material flow analysis of phosphorus in Japan. J. Ind. Ecol. 2009, 13, 687–705. [Google Scholar]

- Cordell, D.; Jackson, M.; White, S. Phosphorus flows through the Australian food system: Identifying intervention points as a roadmap to phosphorus security. Environ. Sci. Policy 2013, 29, 87–102. [Google Scholar] [CrossRef]

- Sattari, S.Z.; Van Ittersum, M.K.; Giller, K.E.; Zhang, F.; Bouwman, A.F. Key role of China and its agriculture in global sustainable phosphorus management. Environ. Res. Lett. 2014, 9, 1–8. [Google Scholar] [CrossRef]

- Chadwick, D.; Jia, W.; Tong, Y.; Yu, G.; Shen, Q.; Chen, Q. Improving manure nutrient management towards sustainable agricultural intensification in China. Agric. Ecosyst. Environ. 2015, 209, 34–46. [Google Scholar] [CrossRef]

- Jin, Y.; Hu, Z.H.; Wen, Z.Y. Enhancing anaerobic digestibility and phosphorus recovery of dairy manure through microwave-based thermochemical pretreatment. Water Res. 2009, 43, 3493–3502. [Google Scholar] [CrossRef] [PubMed]

- Luo, P.; Liu, F.; Liu, X.L.; Wu, X.; Yao, R.; Chen, L.; Li, X.; Xiao, R.L.; Wu, J.S. Phosphorus removal from lagoon-pretreated swine wastewater by pilot-scale surface flow constructed wetlands planted with Myriophyllum aquaticum. Sci. Total Environ. 2017, 576, 490–497. [Google Scholar] [CrossRef] [PubMed]

- Vanotti, M.B.; Dube, P.J.; Szogi, A.A.; Garcíagonzález, M.C. Recovery of ammonia and phosphate minerals from swine wastewater using gas-permeable membranes. Water Res. 2017, 112, 137–146. [Google Scholar] [CrossRef] [PubMed]

- Ge, S.; Peng, Y.; Wang, S.; Guo, J.; Ma, B.; Zhang, L.; Cao, X. Enhanced nutrient removal in a modified step feed process treating municipal wastewater with different inflow distribution ratios and nutrient ratios. Bioresour. Technol. 2010, 101, 9012–9019. [Google Scholar] [CrossRef] [PubMed]

- Obaja, D.; Mace, S.; Costa, J.; Sans, C.; Mata-Alvarez, J. Nitrification, denitrification and biological phosphorus removal in piggery wastewater using a sequencing batch reactor. Bioresour. Technol. 2003, 87, 103–111. [Google Scholar] [CrossRef]

- Deng, L.W.; Zheng, P.; Chen, Z.A.; Mahmood, Q. Improvement in post-treatment of digested swine wastewater. Bioresour. Technol. 2008, 99, 3136–3145. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.H.; Kwag, J.H.; Kim, J.H.; Ra, C.S. Recovery of nitrogen and phosphorus by struvite crystallization from swine wastewater. Desalination 2011, 277, 364–369. [Google Scholar] [CrossRef]

- Iqbal, M.; Bhuiyan, H.; Mavinic, D.S. Assessing struvite precipitation in a pilot-scale fluidized bed crystallizer. Environ. Technol. 2008, 29, 1157–1167. [Google Scholar] [CrossRef] [PubMed]

- Munafò, M.; Cecchi, G.; Baiocco, F.; Mancini, L. River pollution from non-point sources: A new simplified method of assessment. J. Environ. Manag. 2005, 77, 93–98. [Google Scholar] [CrossRef] [PubMed]

- Bai, Z.H.; Ma, L.; Qin, W.; Chen, Q.; Oenema, O.; Zhang, F.S. Changes in pig production in China and their effects on nitrogen and phosphorus use and losses. Environ. Sci. Technol. 2014, 48, 12742–12749. [Google Scholar] [CrossRef] [PubMed]

- Wei, S.; Ma, L.; Jiang, R.F.; Bai, Z.H.; Wu, D.M.; Xia, L.J. Use efficiency and emission spatial-temporal variability of nitrogen and phosphorus for pig production in Beijing. Trans. Chin. Soc. Agric. Eng. 2016, 32, 190–196. (In Chinese) [Google Scholar]

- Zhang, B.; Wang, L.J.; Riddicka, B.; Li, R.; Justin, R.A.; Nana, A.B.; Abolghasem, S. Sustainable production of algal biomass and biofuels using swine wastewater in North Carolina, US. Sustainability 2016, 8, 477. [Google Scholar] [CrossRef]

- Jia, W. Studies on the Evaluation of Nutrient Resources Derived from Manure and Optimized Utilization in Arable Land of China. Ph.D. Thesis, China Agriculture University, Beijing, China, 2014. (In Chinese). [Google Scholar]

- Pérez-Sangrador, M.P.; León-Cófreces, M.C.; Acítores-Benavente, M.; García-González, M.C. Solids and nutrient removal from flushed swine manure using polyacrylamides. J. Environ. Manag. 2012, 93, 67–70. [Google Scholar] [CrossRef] [PubMed]

- Hjorth, M.; Christensen, K.V.; Christensen, M.L.; Sommer, S.G. Solid–liquid separation of animal slurry in theory and practice, a review. Agron. Sustain. Dev. 2010, 30, 153–180. [Google Scholar] [CrossRef]

- Riaño, B.; García-González, M.C. On-farm treatment of swine manure based on solid–liquid separation and biological nitrification-denitrification of the liquid fraction. J. Environ. Manag. 2014, 132, 87–93. [Google Scholar] [CrossRef] [PubMed]

- Doyle, J.D.; Parsons, S.A. Struvite formation, control and recovery. Water Res. 2002, 36, 3925–3940. [Google Scholar] [CrossRef]

- Singh, M.; Srivastava, R.K. Sequencing batch reactor technology for biological wastewater treatment: A review. Asia Pac. J. Chem. Eng. 2011, 6, 3–13. [Google Scholar] [CrossRef]

- Beijing Water Affairs Bureau. Beijing Water Resources Bulletin. 2012. Available online: http://www.bjwater.gov.cn/pub/bjwater/zfgk/tjxx/ndbg/201307/P020130731652249528239.doc (accessed on 1 July 2017).

- Gao, Y.T. Characteristic Indexes Analysis and Ecosystem Health Evaluation of the Typical Rivers in the Suburb of Beijing. Master’s Thesis, Beijing Forestry University, Beijing, China, 2014. (In Chinese). [Google Scholar]

- Feng, S.; Li, S.Y.; Deng, J.C. Pollutants degradation coefficients study of the Taihu Lake upstream rivers. Acta Sci. Circumst. 2016, 36, 3127–3136. (In Chinese) [Google Scholar]

- Xiao, H.B. Study on the Growth and Fluctuation of Hog Production in China. Master’s Thesis, Chinese Academy of Agricultural Sciences, Beijing, China, 2010. (In Chinese). [Google Scholar]

- Zhang, M.C.; Lawlor, P.G.; Wu, G.X.; Lynch, B.; Zhan, X.M. Partial nitrification and nutrient removal in intermittently aerated sequencing batch reactors treating separated digestate liquid after anaerobic digestion of pig manure. Bioprocess Biosyst. Eng. 2011, 34, 1049–1056. [Google Scholar] [CrossRef] [PubMed]

- Ermolieva, P.; Winiwarter, W.; Fischer, G.; Cao, G.-Y.; Klimont, Z.; Schoepp, W.; Li, Y.; Asman, W.A.H. Integrated Nitrogen Management in China (IR-09–005); Interim Report; International Institute for Applied Systems Analysis: Laxenburg, Austria, 2009; p. 54. [Google Scholar]

- Corre, K.S.L.; Valsamijones, E.; Hobbs, P.; Parsons, S.A. Phosphorus recovery from wastewater by struvite crystallization: A review. Crit. Rev. Environ. Sci. Technol. 2009, 39, 433–477. [Google Scholar] [CrossRef]

- Kuba, T.; Van Loosdrecht, M.C.M.; Heijnen, J.J. Biological dephosphatation by activated sludge under denitrifying conditions pH influence and occurrence of denitrifying dephosphatation in a full-scale waste water treatment plant. Water Sci. Technol. 1997, 36, 75–82. [Google Scholar]

- Kuba, T.; Van Loosdrecht, M.C.M.; Brandse, F.A.; Heijnen, J.J. Occurrence of denitrifying phosphorus removing bacteria in modified UCT-type wastewater treatment plants. Water Res. 1997, 31, 777–786. [Google Scholar] [CrossRef]

- State Environmental Protection Administration of the P.R. China (SEPA). Environmental Quality Standards for Surface Water GB3838-2002; China Environmental Science Press: Beijing, China, 2002. (In Chinese) [Google Scholar]

- State Environmental Protection Administration of the P.R. China (SEPA). Discharge Standard of Pollutants for Livestock and Poultry Breeding GB18596-2001. 2001. Available online: http://kjs.mep.gov.cn/hjbhbz/bzwb/shjbh/swrwpfbz/200301/t20030101_66550.htm (accessed on 1 July 2017).

- Su, S.Q.; Chuan, X.Y.; Ma, H.W. Recovery of nitrogen and phosphorus by struvite crystallization and its application as slow-release eco-friendly fertilizers. Inorg. Chem. Ind. 2016, 48, 58–63. (In Chinese) [Google Scholar]

| Breeding Cycle (day) | Phosphorus Concentration (%) | Phosphorus Discharge Coefficient (kg/head·Breeding Cycle) | ||

|---|---|---|---|---|

| Solid | Liquid | Solid | Liquid | |

| 180 | 5.44 | 0.46 | 23.89 | 2.66 |

| R2 | Deviation (%) | |

|---|---|---|

| average growth rate model | 18.61 | |

| linear fit model | 0.45 | 21.21 |

| G.M. (1.1) gray model | 22.88 | |

| logistic model | 0.57 | 18.23 |

| Parameters for Struvite Crystallization | Parameters for BPR | Total PRE (%) | P Concentration in Water Body (mg/L) | ||||

|---|---|---|---|---|---|---|---|

| Parameter | Condition | PRE (%) | Parameter | Condition | PRE (%) | ||

| Base case | 0 | 76 | Base case | 76 | 94.24 | 0.0895 | |

| pH | −10% | 36 | 84.64 | 0.2022 | |||

| +10% | 92 | 98.08 | 0.0444 | ||||

| AST | −10% | 71 | 93.04 | 0.1036 | |||

| +10% | 80 | 95.20 | 0.0782 | ||||

| SRT | −10% | 77 | 94.48 | 0.0867 | |||

| +10% | 75 | 94.00 | 0.0923 | ||||

| Cp | −10% | 83 | Base case | 76 | 95.92 | 0.0698 | |

| pH | −10% | 36 | 89.12 | 0.1496 | |||

| +10% | 92 | 98.64 | 0.0378 | ||||

| AST | −10% | 71 | 95.07 | 0.0797 | |||

| +10% | 80 | 96.60 | 0.0618 | ||||

| SRT | −10% | 77 | 96.09 | 0.0678 | |||

| +10% | 75 | 95.75 | 0.0718 | ||||

| +10% | 72 | Base case | 76 | 93.28 | 0.1008 | ||

| pH | −10% | 36 | 82.08 | 0.2323 | |||

| +10% | 92 | 97.76 | 0.0482 | ||||

| AST | −10% | 71 | 91.88 | 0.1172 | |||

| +10% | 80 | 94.40 | 0.0876 | ||||

| SRT | −10% | 77 | 93.56 | 0.0975 | |||

| +10% | 75 | 93.00 | 0.1041 | ||||

| Mg/P | −10% | 76 | Base case | 76 | 93.52 | 0.0979 | |

| pH | −10% | 36 | 82.72 | 0.2247 | |||

| +10% | 92 | 97.84 | 0.0472 | ||||

| AST | −10% | 71 | 92.17 | 0.1138 | |||

| +10% | 80 | 94.60 | 0.0853 | ||||

| SRT | −10% | 77 | 93.79 | 0.0948 | |||

| +10% | 75 | 93.25 | 0.1011 | ||||

| +10% | 73 | Base case | 76 | 94.96 | 0.0810 | ||

| pH | −10% | 36 | 86.56 | 0.1797 | |||

| +10% | 92 | 98.32 | 0.0416 | ||||

| AST | −10% | 71 | 93.91 | 0.0934 | |||

| +10% | 80 | 95.80 | 0.0712 | ||||

| SRT | −10% | 77 | 95.17 | 0.0786 | |||

| +10% | 75 | 94.75 | 0.0835 | ||||

| pH | −10% | 79 | Base case | 76 | 84.64 | 0.2022 | |

| pH | −10% | 36 | 59.04 | 0.5028 | |||

| +10% | 92 | 94.88 | 0.0820 | ||||

| AST | −10% | 71 | 81.44 | 0.2398 | |||

| +10% | 80 | 87.20 | 0.1721 | ||||

| SRT | −10% | 77 | 85.28 | 0.1947 | |||

| +10% | 75 | 84.00 | 0.2097 | ||||

| +10% | 76 | Base case | 76 | 98.08 | 0.0444 | ||

| pH | −10% | 36 | 94.88 | 0.0820 | |||

| +10% | 92 | 99.36 | 0.0294 | ||||

| AST | −10% | 71 | 97.68 | 0.0491 | |||

| +10% | 80 | 98.40 | 0.0406 | ||||

| SRT | −10% | 77 | 98.16 | 0.0435 | |||

| +10% | 75 | 98.00 | 0.0453 | ||||

| Process Unit | Construction Investment /104 Yuan | Running Cost/104 Yuan/Year | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Build | Facility | Installation | Sum | Management Cost/5% | Depreciation Cost/2.5% | Maintenance Cost/2.5% | Energy Charge | Chemical Cost | Sum | ||

| Storage Pool | 9 | 0 | 0 | 9 | |||||||

| Pre-Treatment | Grid | 3.375 | 6.75 | 1.125 | 11.25 | ||||||

| Adjustment Pool | 18 | 39.375 | 3.375 | 60.75 | |||||||

| BPR section | Sequencing batch Reactor | 140 | 7.0 | 3.5 | 3.5 | 1.205 | 15.205 | ||||

| Crystallization section | Fluidized Bed Reactor | 250 | 12.5 | 6.25 | 6.25 | 2.463 | 1.444 | 28.907 | |||

| Auxiliary building | Integrated Room | 36 | 40 | 4 | 80 | ||||||

| Crystallization 411 | 28.907 | ||||||||||

| BPR 301 | 15.205 | ||||||||||

| Coupled 551 | 44.112 | ||||||||||

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Q.; Zhang, T.; He, X.; Jiang, R. Assessment of Phosphorus Recovery from Swine Wastewater in Beijing, China. Sustainability 2017, 9, 1845. https://doi.org/10.3390/su9101845

Wang Q, Zhang T, He X, Jiang R. Assessment of Phosphorus Recovery from Swine Wastewater in Beijing, China. Sustainability. 2017; 9(10):1845. https://doi.org/10.3390/su9101845

Chicago/Turabian StyleWang, Qiming, Tao Zhang, Xinyue He, and Rongfeng Jiang. 2017. "Assessment of Phosphorus Recovery from Swine Wastewater in Beijing, China" Sustainability 9, no. 10: 1845. https://doi.org/10.3390/su9101845

APA StyleWang, Q., Zhang, T., He, X., & Jiang, R. (2017). Assessment of Phosphorus Recovery from Swine Wastewater in Beijing, China. Sustainability, 9(10), 1845. https://doi.org/10.3390/su9101845