Production of Biodiesel Using Immobilized Lipase and the Characterization of Different Co-Immobilizing Agents and Immobilization Methods

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Immobilization Procedures

2.2.1. Adsorption Process (Immobilization by Adsorption)

2.2.2. Entrapment Process (Immobilization by Entrapment)

2.2.3. Adsorption Followed by Entrapment

2.3. Measurement of Immobilized Lipase Activity

2.4. Biodiesel Production from Waste Cooking Oil

2.5. Analytical Procedure

2.6. Operational Stability of Immobilized Lipase

2.7. Characterization with Scanning Electron Microscopy (SEM) and Atom Force Microscopy (AFM)

3. Results and Discussion

3.1. Effects of Co-Immobilized Agent in the Immobilized Process

3.1.1. Effects of Co-Immobilized Agent in the Adsorption Process of Immobilization

3.1.2. The Optimized Concentration of Co-Immobilizing Agents

3.2. Biodiesel Production Using Immobilized Lipase as Biocatalyst

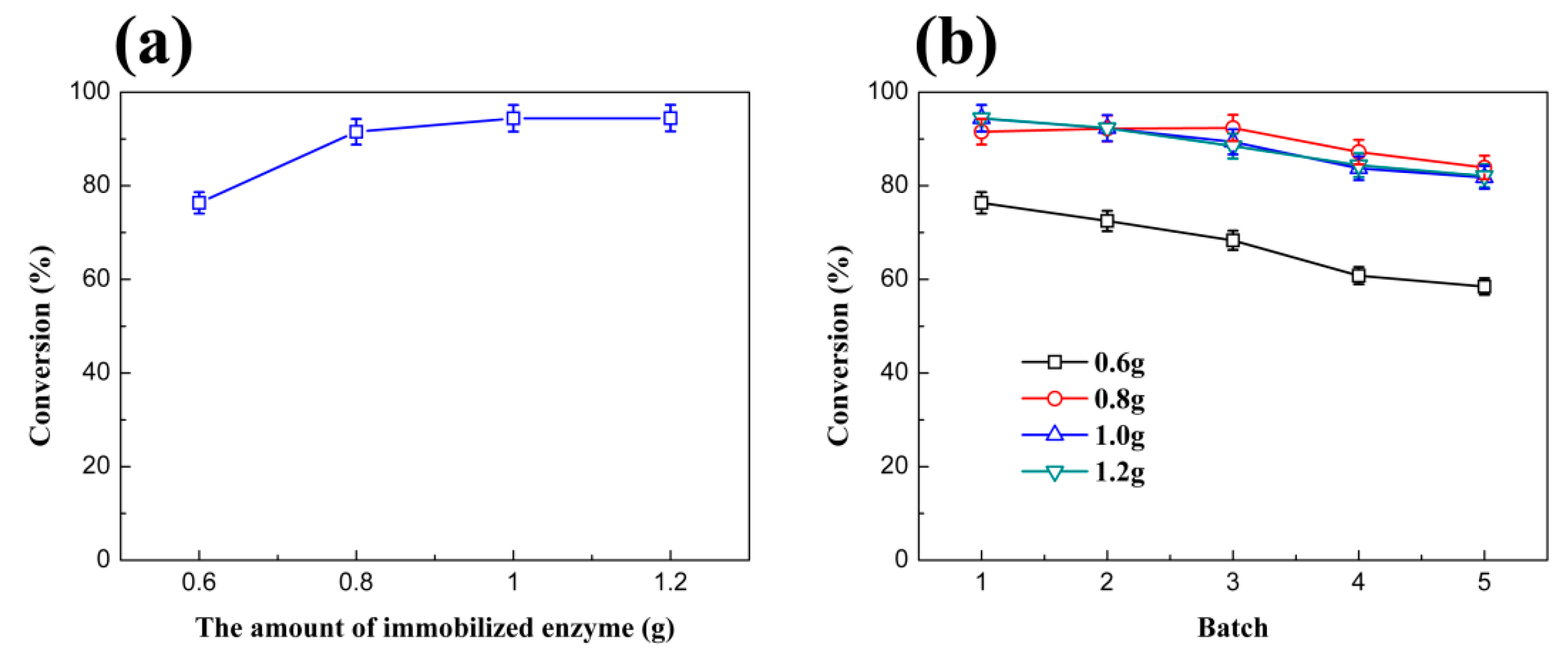

3.2.1. The Amount of Immobilized Lipase

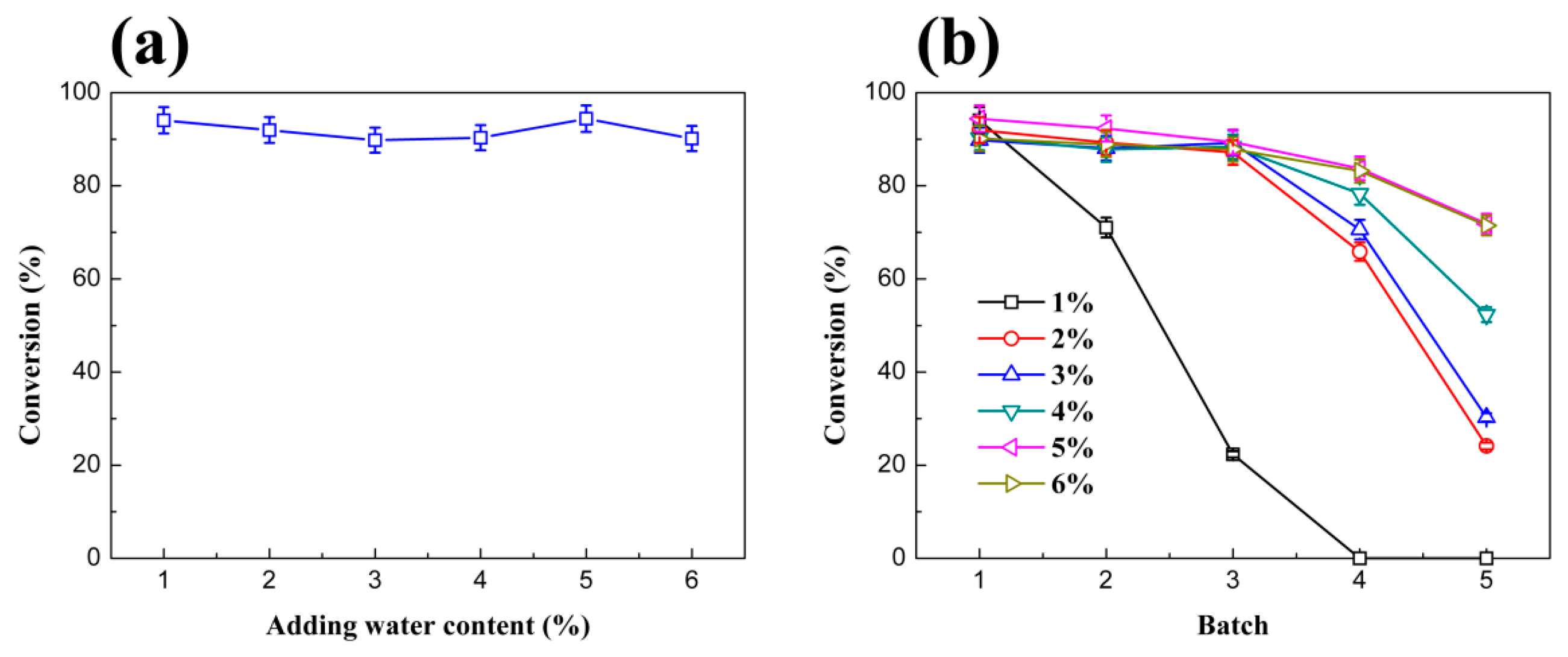

3.2.2. The Amount of the Water Content

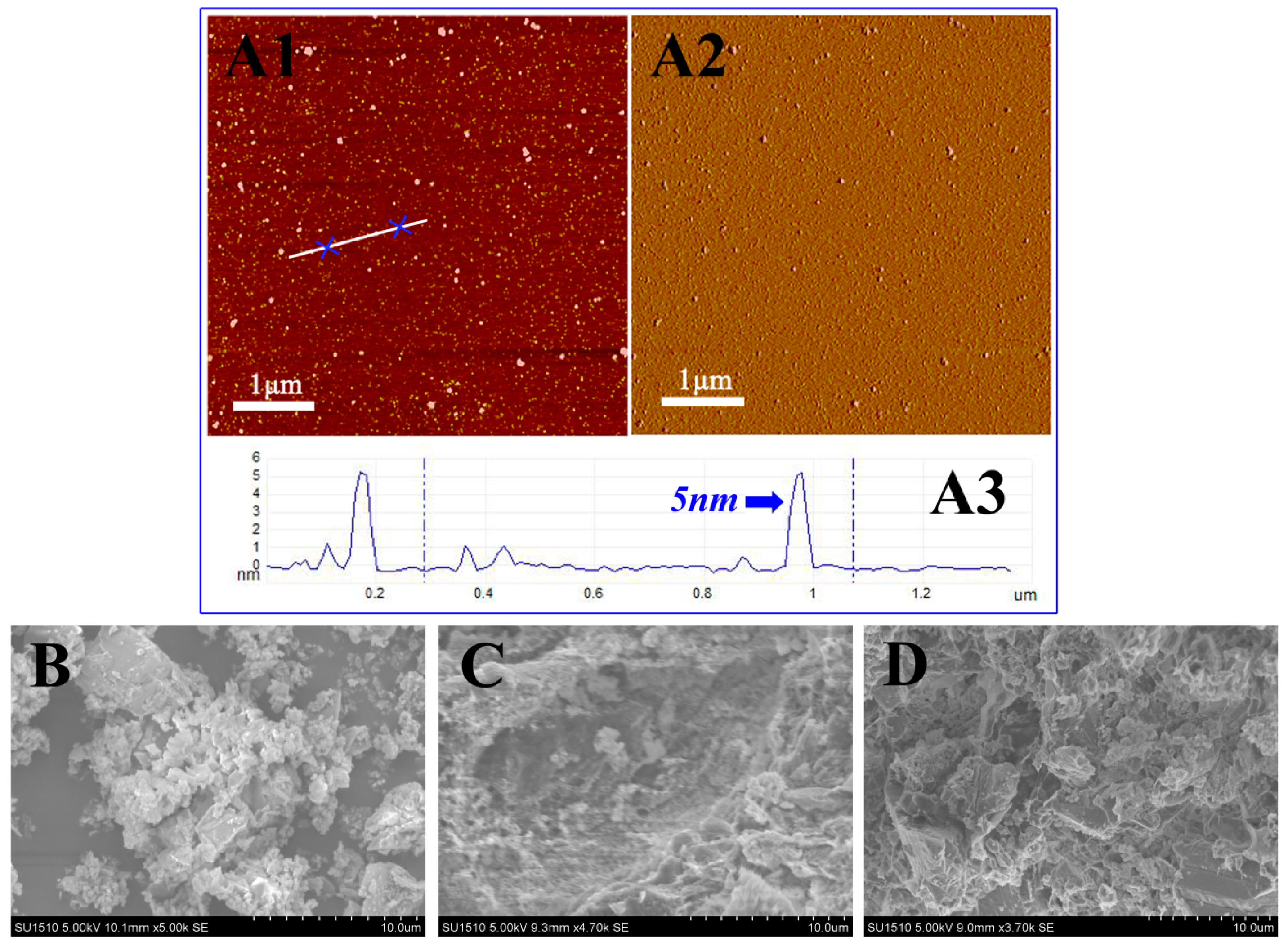

3.2.3. The Comparison of Different Immobilized Methods

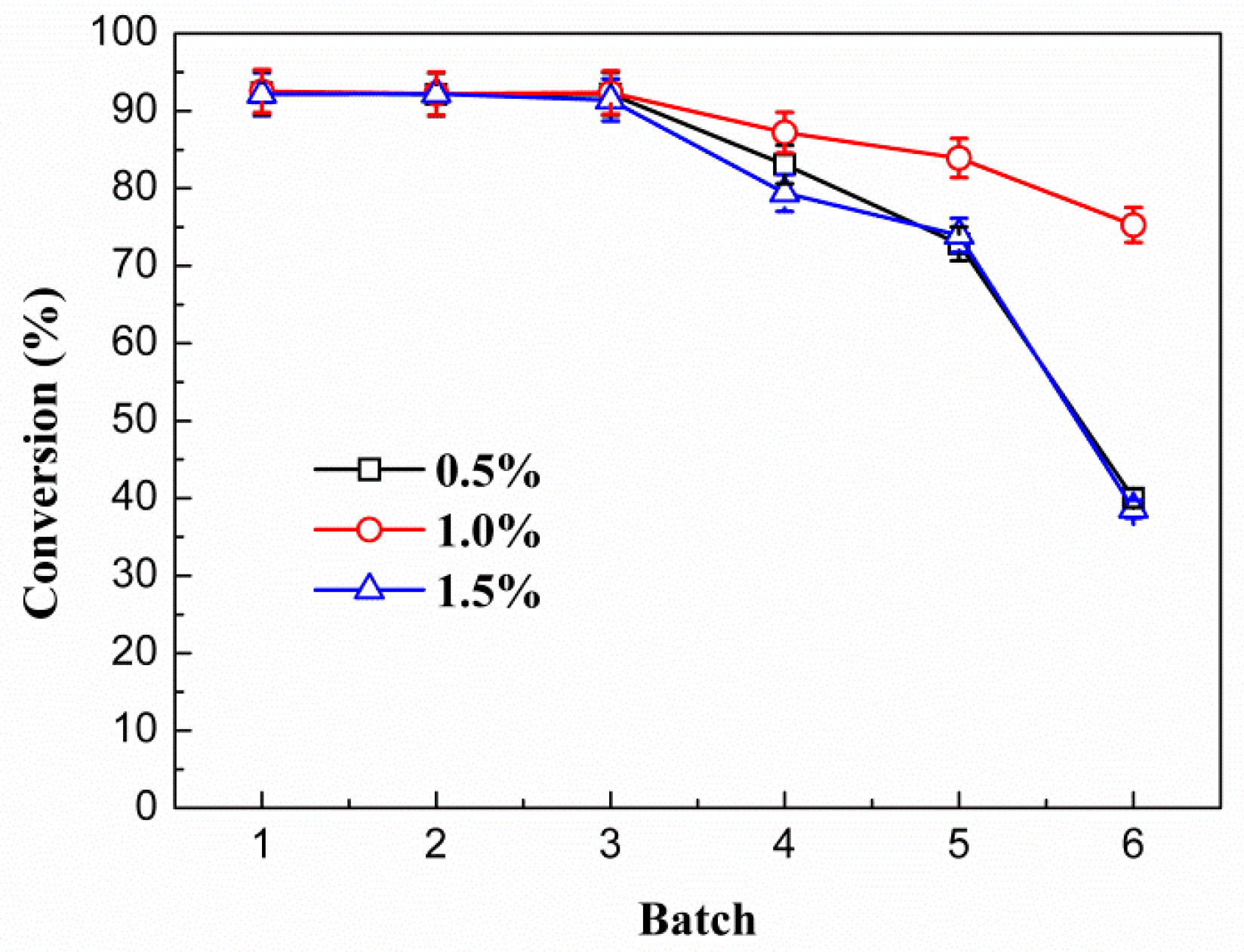

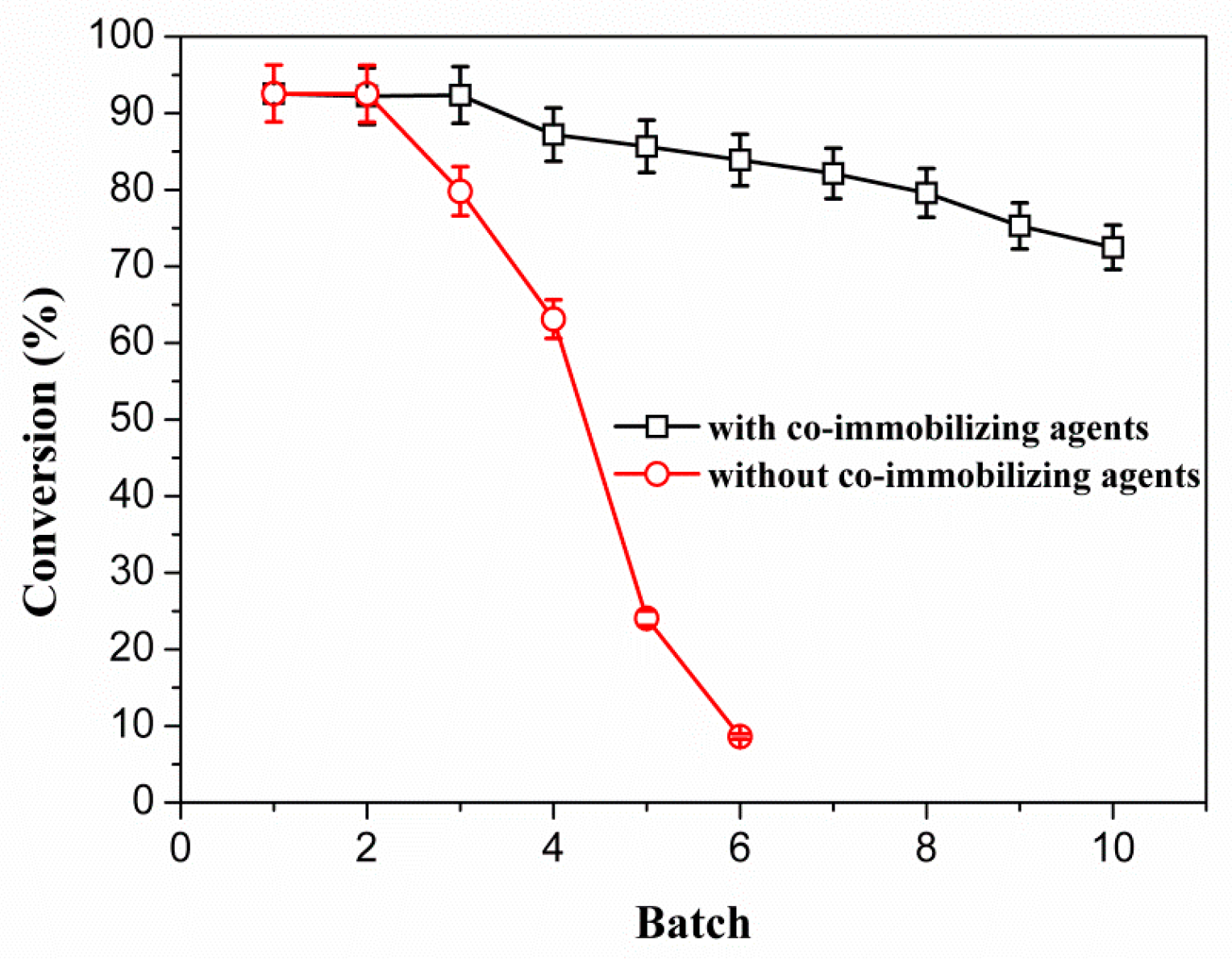

3.3. The Operational Stability of Immobilized Enzyme

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Demirbas, A. Political, economic and environmental impacts of biofuels: A review. Appl. Energy 2009, 86, S108–S117. [Google Scholar]

- Narwal, S.K.; Gupta, R. Biodiesel production by transesterification using immobilized lipase. Biotechnol. Lett. 2013, 35, 479–490. [Google Scholar] [CrossRef]

- Gog, A.; Roman, M.; Toşa, M.; Paizs, C.; Irimie, F.D. Biodiesel production using enzymatic transesterification–current state and perspectives. Renew. Energy 2012, 39, 10–16. [Google Scholar] [CrossRef]

- Xie, W.; Wang, J. Immobilized lipase on magnetic chitosan microspheres for transesterification of soybean oil. Biomass Bioenergy 2012, 36, 373–380. [Google Scholar] [CrossRef]

- Bajaj, A.; Lohan, P.; Jha, P.N.; Mehrotra, R. Biodiesel production through lipase catalyzed transesterification: An overview. J. Mol. Catal. B Enzym. 2010, 62, 9–14. [Google Scholar] [CrossRef]

- Sun, J.; Jiang, Y.; Zhou, L.; Gao, J. Immobilization of candida antarctica lipase b by adsorption in organic medium. New Biotechnol. 2010, 27, 53–58. [Google Scholar] [CrossRef] [PubMed]

- Gao, J.; Shi, L.; Jiang, Y.; Zhou, L.; He, Y. Formation of lipase candida sp. 99–125 cleas in mesoporous silica: Characterization and catalytic properties. Catal. Sci. Technol. 2013, 3, 3353–3359. [Google Scholar] [CrossRef]

- Ertan, F.; Yagar, H.; Balkan, B. Optimization of α-amylase immobilization in calcium alginate beads. Prep. Biochem. Biotechnol. 2007, 37, 195–204. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.C.; Selvam, V.; Hui, H.T.; Chow, Y.; Talukder, M.M.R.; Choi, W.J. Immobilization of candida rugosa lipase by cross-linking with glutaraldehyde followed by entrapment in alginate beads. Biocatal. Biotransform. 2009, 24, 352–357. [Google Scholar]

- Akoz, E.; Sayin, S.; Kaplan, S.; Yilmaz, M. Improvement of catalytic activity of lipase in the presence of calix arene valeric acid or hydrazine derivative. Bioprocess Biosyst. Eng. 2015, 38, 595–604. [Google Scholar] [CrossRef] [PubMed]

- Cabrera-Padilla, R.Y.; Melo, E.B.; Pereira, M.M.; Figueiredo, R.T.; Fricks, A.T.; Franceschi, E.; Lima, Á.S.; Silva, D.P.; Soares, C.M. Use of ionic liquids as additives for the immobilization of lipase from bacillus sp. J. Chem. Technol. Biotechnol. 2015, 90, 1308–1316. [Google Scholar] [CrossRef]

- Li, W.; Chen, B.; Tan, T. Comparative study of the properties of lipase immobilized on nonwoven fabric membranes by six methods. Process Biochem. 2011, 46, 1358–1365. [Google Scholar] [CrossRef]

- Zhang, J.; Xu, J. Oleyl oleate synthesis by immobilized lipase from candida sp. 1619. Chin. J. Biotechnol. 1995, 11, 325–331. [Google Scholar]

- He, X.-L.; Chen, B.-Q.; Tan, T.-W. Enzymatic synthesis of 2-ethylhexyl esters of fatty acids by immobilized lipase from candida sp. 99–125. J. Mol. Catal. B Enzym. 2002, 18, 333–339. [Google Scholar] [CrossRef]

- Yu, M.; Qin, S.; Tan, T. Purification and characterization of the extracellular lipase lip2 from yarrowia lipolytica. Process Biochem. 2007, 42, 384–391. [Google Scholar] [CrossRef]

- Lu, J.; Nie, K.; Xie, F.; Wang, F.; Tan, T. Enzymatic synthesis of fatty acid methyl esters from lard with immobilized candida sp. 99–125. Process Biochem. 2007, 42, 1367–1370. [Google Scholar] [CrossRef]

- Secundo, F.; Carrea, G. Mono- and disaccharides enhance the activity and enantioselectivity of burkholderia cepacia lipase in organic solvent but do not significantly affect its conformation. Biotechnol. Bioeng. 2005, 92, 438–446. [Google Scholar] [CrossRef] [PubMed]

- Rathod, V.K.; Pandit, A.B. Effect of various additives on enzymatic hydrolysis of castor oil. Biochem. Eng. J. 2009, 47, 93–99. [Google Scholar] [CrossRef]

- Su, F.; Li, G.-L.; Fan, Y.-L.; Yan, Y.-J. Enhancing biodiesel production via a synergic effect between immobilized rhizopus oryzae lipase and novozym 435. Fuel Process. Technol. 2015, 137, 298–304. [Google Scholar] [CrossRef]

- Aguieiras, E.C.; Cavalcanti-Oliveira, E.D.; Freire, D.M. Current status and new developments of biodiesel production using fungal lipases. Fuel 2015, 159, 52–67. [Google Scholar] [CrossRef]

- Ondul, E.; Dizge, N.; Keskinler, B.; Albayrak, N. Biocatalytic Production of Biodiesel from Vegetable Oils; InTech: Rijeka, Croatia, 2015. [Google Scholar]

- Tan, T.; Lu, J.; Nie, K.; Deng, L.; Wang, F. Biodiesel production with immobilized lipase: A review. Biotechnol. Adv. 2010, 28, 628–634. [Google Scholar] [CrossRef] [PubMed]

- Simpliciano, C.; Clark, L.; Asi, B.; Chu, N.; Mercado, M.; Diaz, S.; Goedert, M.; Mobed-Miremadi, M. Cross-linked alginate film pore size determination using atomic force microscopy and validation using diffusivity determinations. J. Surf. Eng. Mater. Adv. Technol. 2013, 3, 1. [Google Scholar] [CrossRef]

- Zhang, G.; Ma, J.; Wang, J.; Li, Y.; Zhang, G.; Zhang, F.; Fan, X. Lipase immobilized on graphene oxide as reusable biocatalyst. Ind. Eng. Chem. Res. 2014, 53, 19878–19883. [Google Scholar] [CrossRef]

- Lu, J.; Deng, L.; Zhao, R.; Zhang, R.; Wang, F.; Tan, T. Pretreatment of immobilized candida sp. 99–125 lipase to improve its methanol tolerance for biodiesel production. J. Mol. Catal. B Enzym. 2010, 62, 15–18. [Google Scholar] [CrossRef]

- Tan, T.; Nie, K.; Wang, F. Production of biodiesel by immobilized candida sp. Lipase at high water content. Appl. Biochem. Biotechnol. 2006, 128, 109–116. [Google Scholar] [CrossRef]

- Liu, Y.; Yan, Y.; Hu, F.; Yao, A.; Wang, Z.; Wei, F. Transesterification for biodiesel production catalyzed by combined lipases: Optimization and kinetics. AIChE J. 2010, 56, 1659–1665. [Google Scholar] [CrossRef]

- Huang, Y.; Zheng, H.; Yan, Y. Optimization of lipase-catalyzed transesterification of lard for biodiesel production using response surface methodology. Appl. Biochem. Biotechnol. 2010, 160, 504–515. [Google Scholar] [CrossRef] [PubMed]

| Lipase | Carried Used | Other Details | Oil | Percentage of Lipase Used (w/w of Oil) | Temperature (℃) | Maximum Yield (%) | Duration (h) | Batch | Ultimate Yield (%) | Reference |

|---|---|---|---|---|---|---|---|---|---|---|

| Candida sp. 99–125 | Diatomite | With co-immobilizing agents | Waste cooking oil | 1 | 40 | >90 | 24 | 10 | >70 | This work |

| Candida sp. 99–125 | Textile | Immobilized lipase immersed in organic solvents and salts | Soybean oil | 10 | 40 | >80 | 12 | 9 | >50 | [16] |

| Candida sp. 99–125 | Textile | Textile pre-soaked with co-immobilization solution | Lard | 20 | 40 | >80 | 30 | 7 | >70 | [25] |

| Candida sp. 99–125 | Cotton membrane | Membrane stirred with solutions containing gelatin, Tween-80, and PEG6000 | Vegetable oil | 15 | 40 | >90 | 30 | 6 | >90 | [26] |

| Combined Novozym435 and TLIM | Acrylic resin and Silica gel | In tert-butanol medium | Waste cooking oil | 4 | 50 | >80 | 10 | 30 | >70 | [27] |

| Combined Novozym435 and TLIM | Acrylic resin and Silica gel | In tert-butanol medium | Lard | 4 | 50 | >90 | 20 | 20 | >90 | [28] |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, K.; Di, Q.; Cao, X.; Wang, M.; Deng, L.; Wang, F. Production of Biodiesel Using Immobilized Lipase and the Characterization of Different Co-Immobilizing Agents and Immobilization Methods. Sustainability 2016, 8, 764. https://doi.org/10.3390/su8090764

Zhao K, Di Q, Cao X, Wang M, Deng L, Wang F. Production of Biodiesel Using Immobilized Lipase and the Characterization of Different Co-Immobilizing Agents and Immobilization Methods. Sustainability. 2016; 8(9):764. https://doi.org/10.3390/su8090764

Chicago/Turabian StyleZhao, Kang, Qinjian Di, Xi Cao, Meng Wang, Li Deng, and Fang Wang. 2016. "Production of Biodiesel Using Immobilized Lipase and the Characterization of Different Co-Immobilizing Agents and Immobilization Methods" Sustainability 8, no. 9: 764. https://doi.org/10.3390/su8090764