Design of Stirrer Impeller with Variable Operational Speed for a Food Waste Homogenizer

Abstract

:1. Introduction

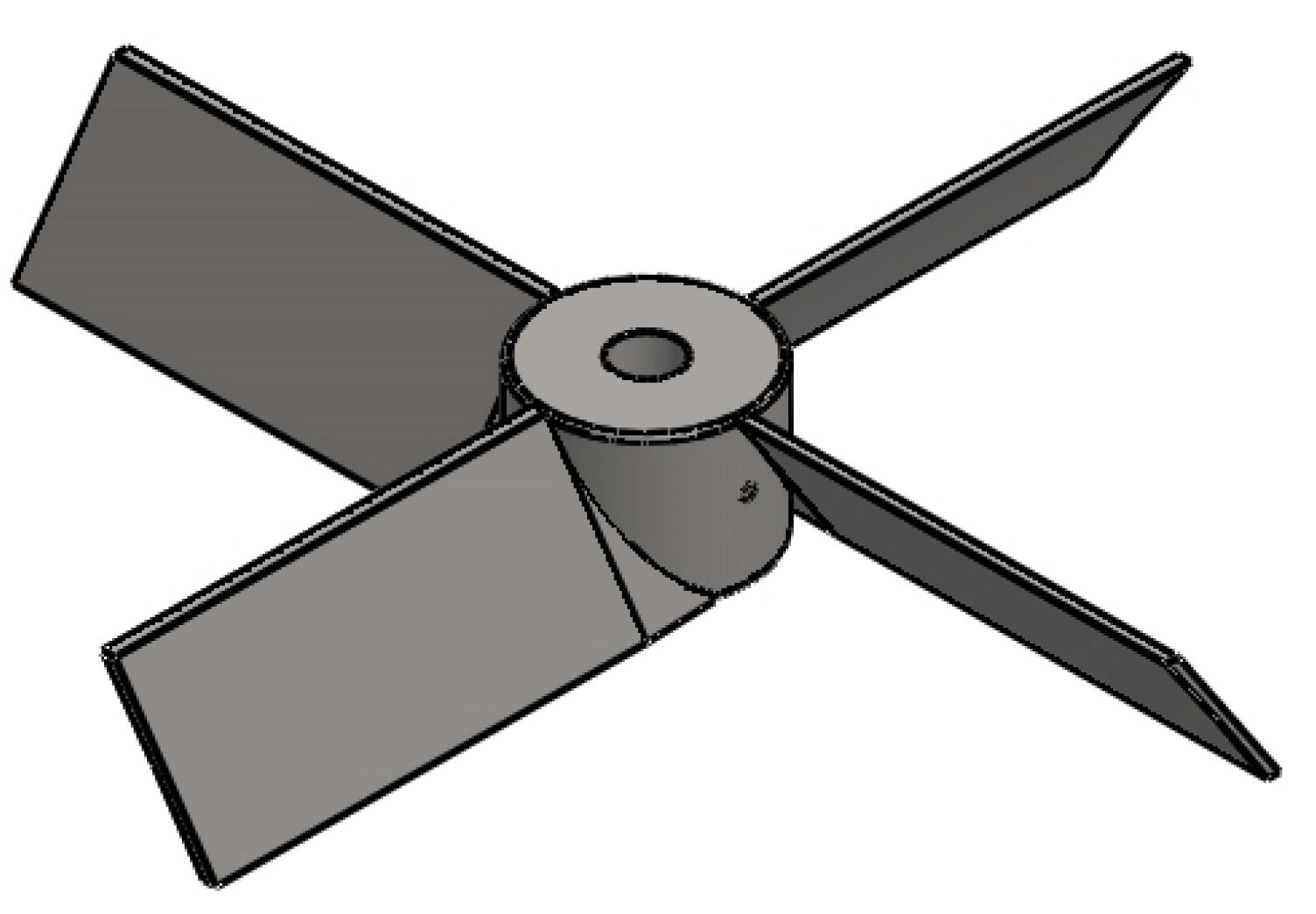

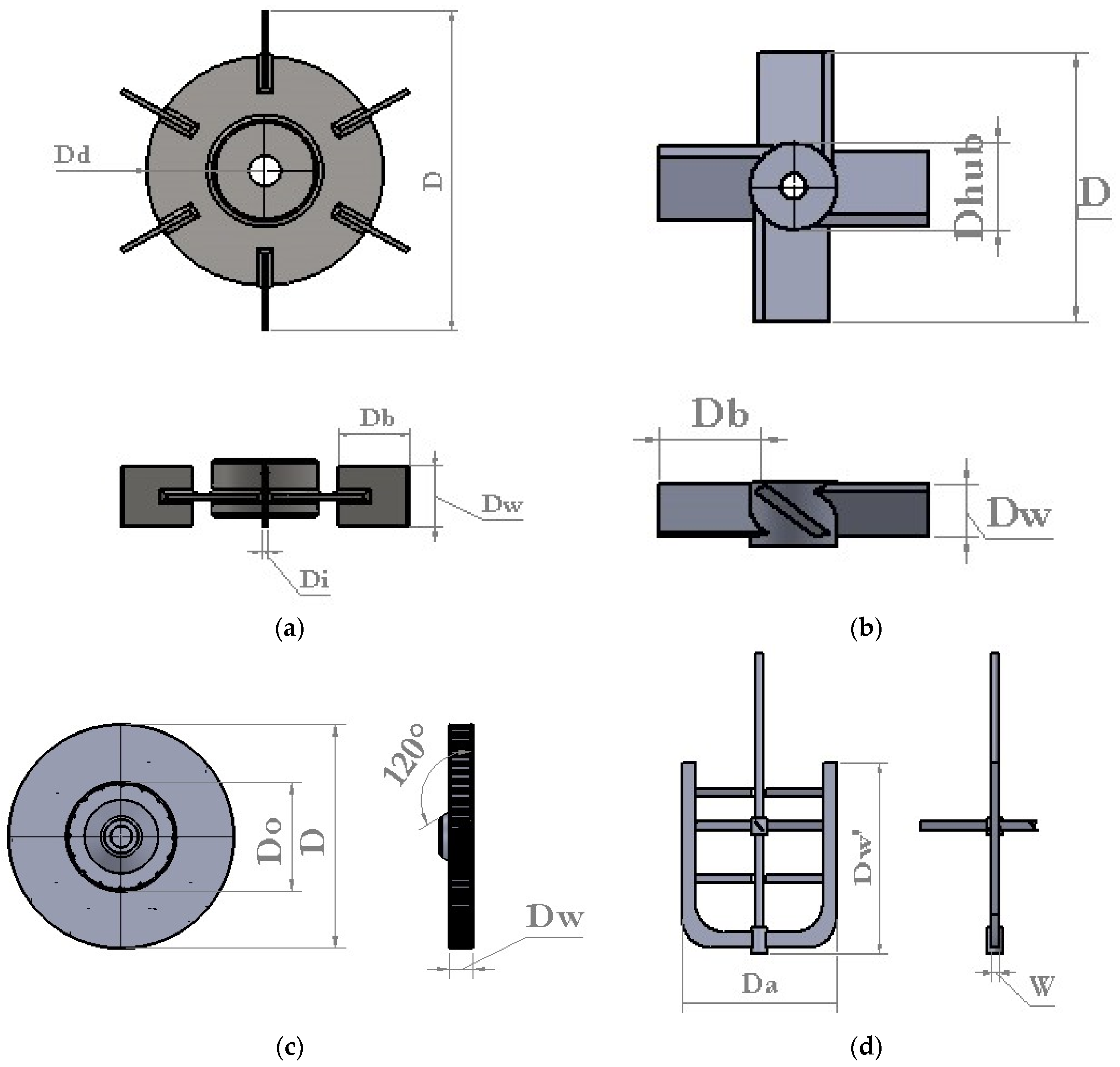

2. Methodology

2.1. Homogenizer Configuration

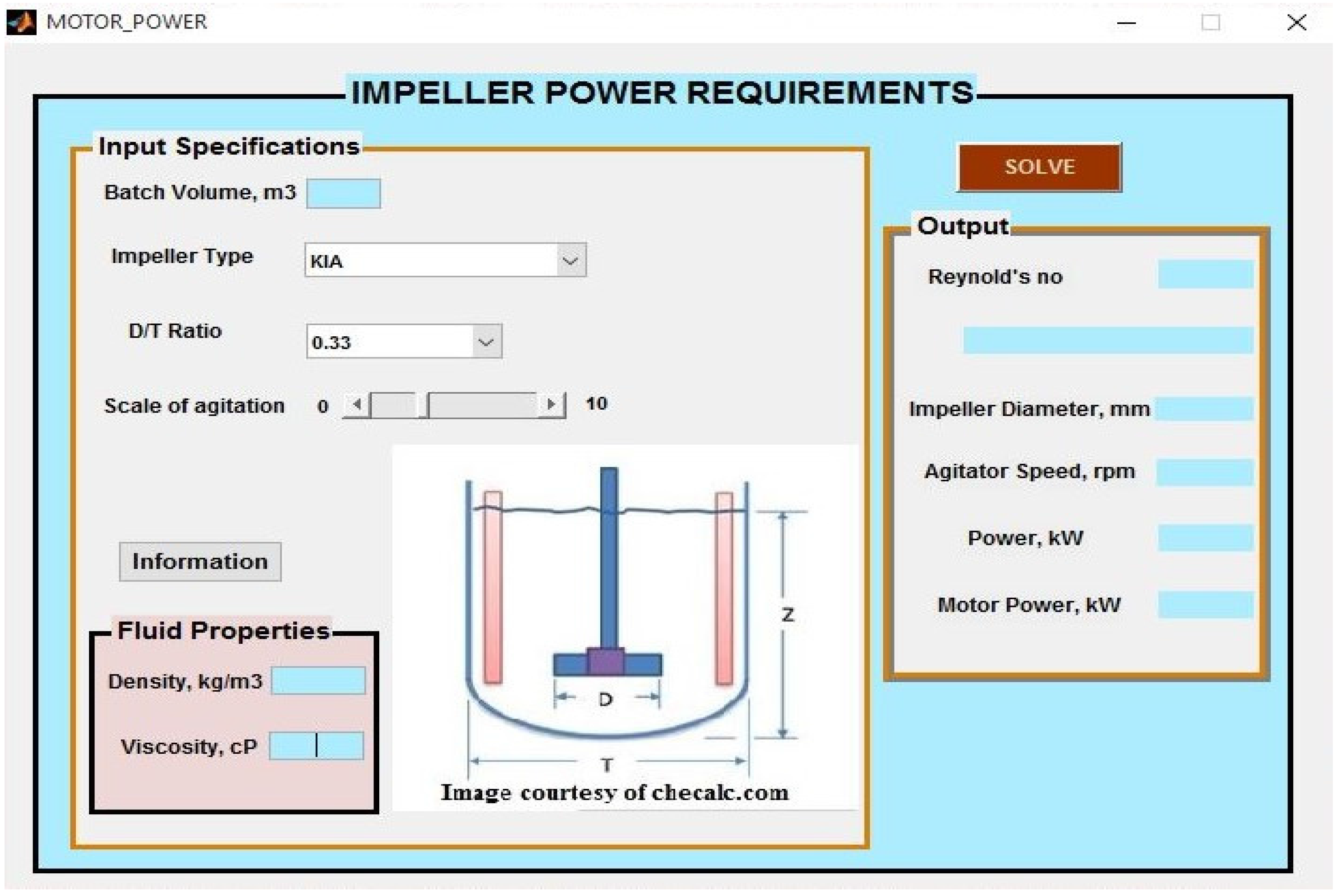

2.2. Computational Method

3. Results and Discussions

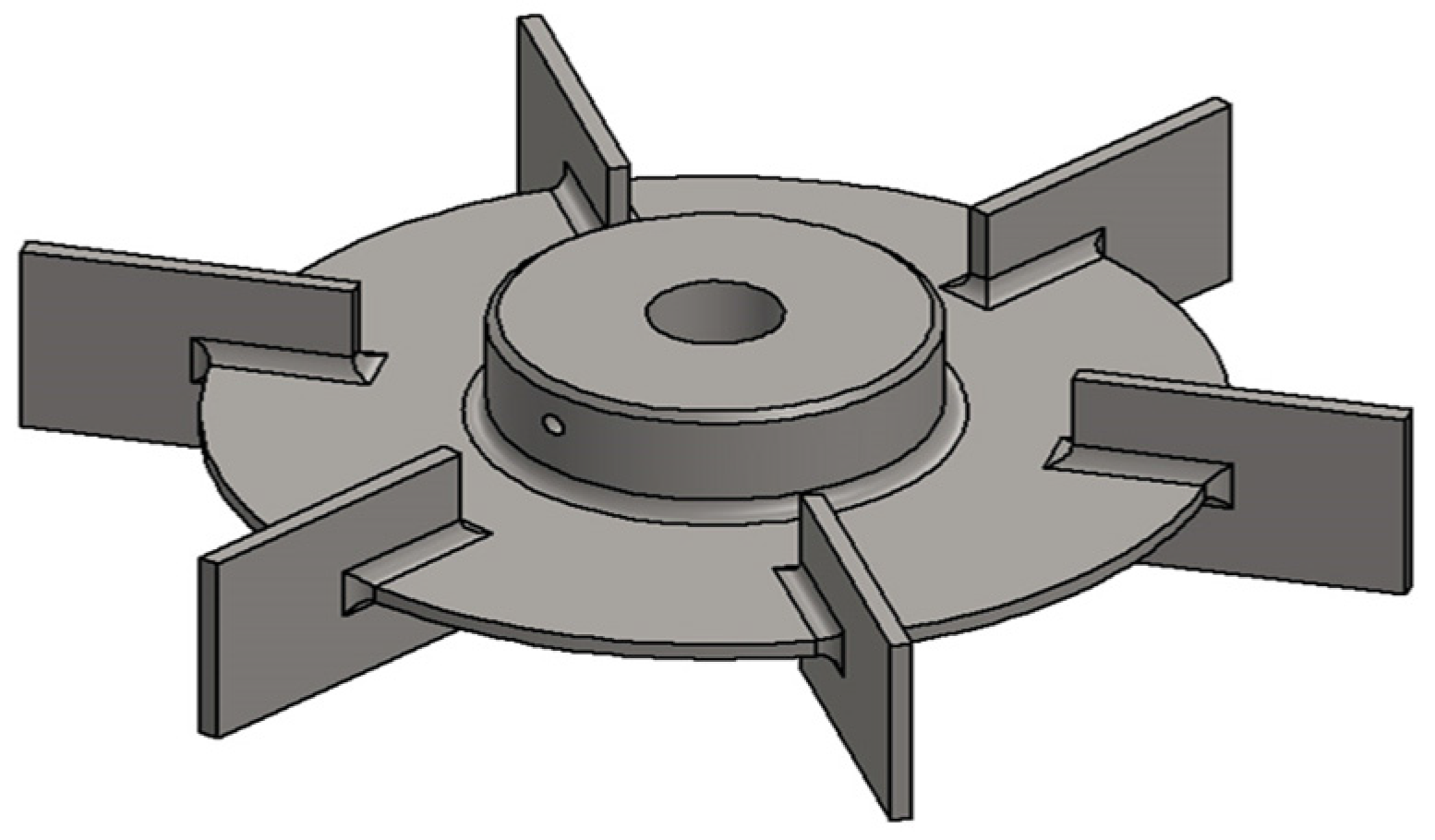

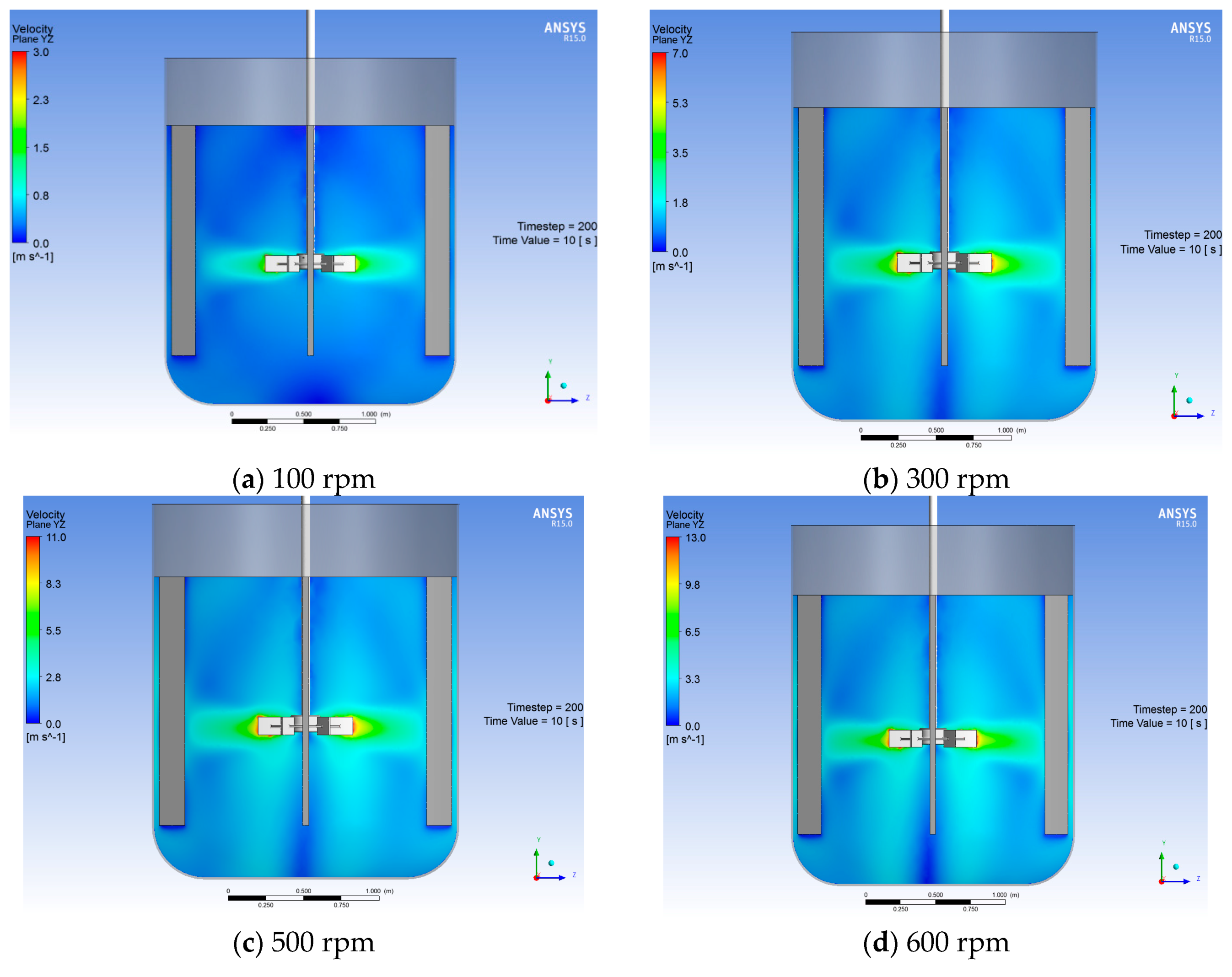

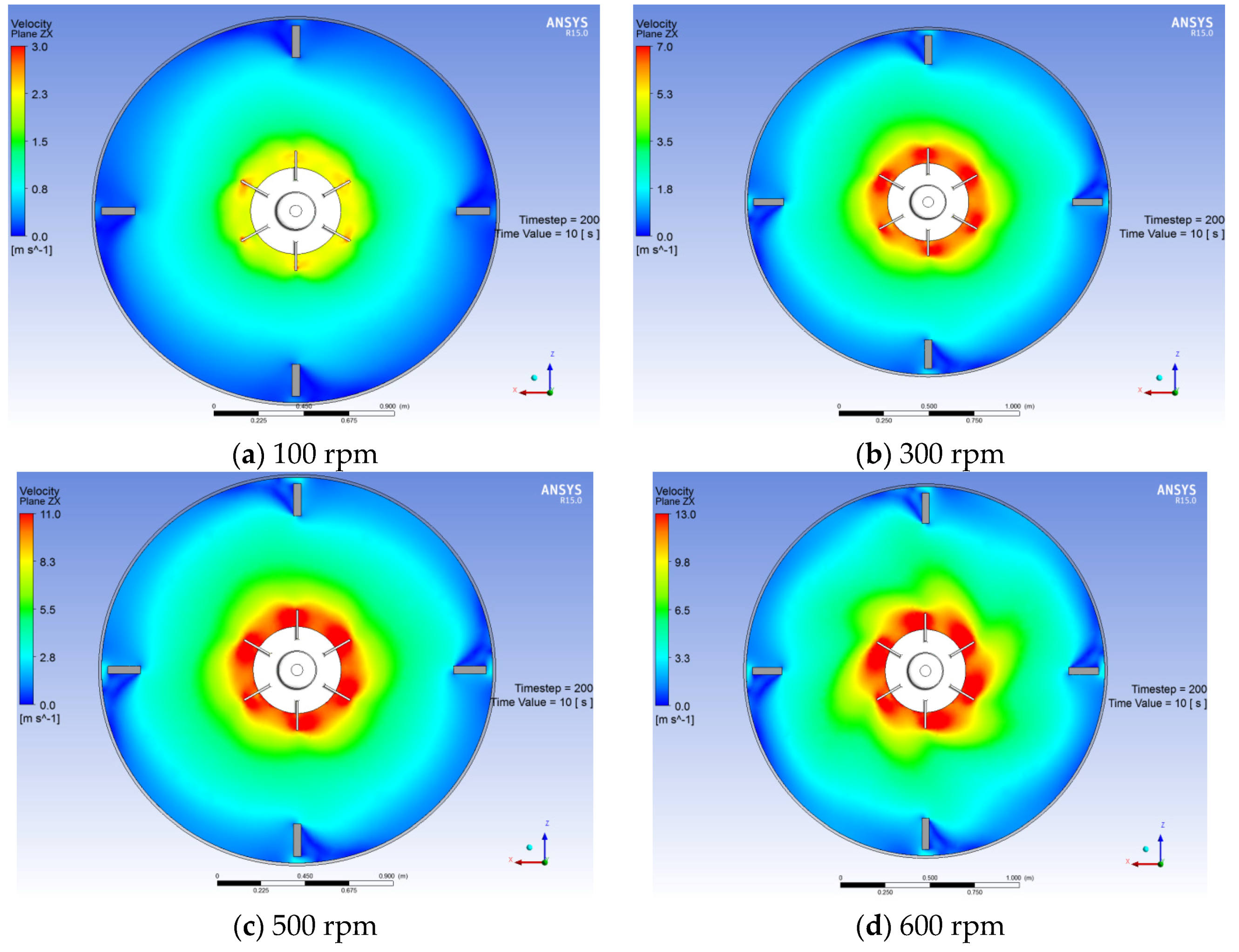

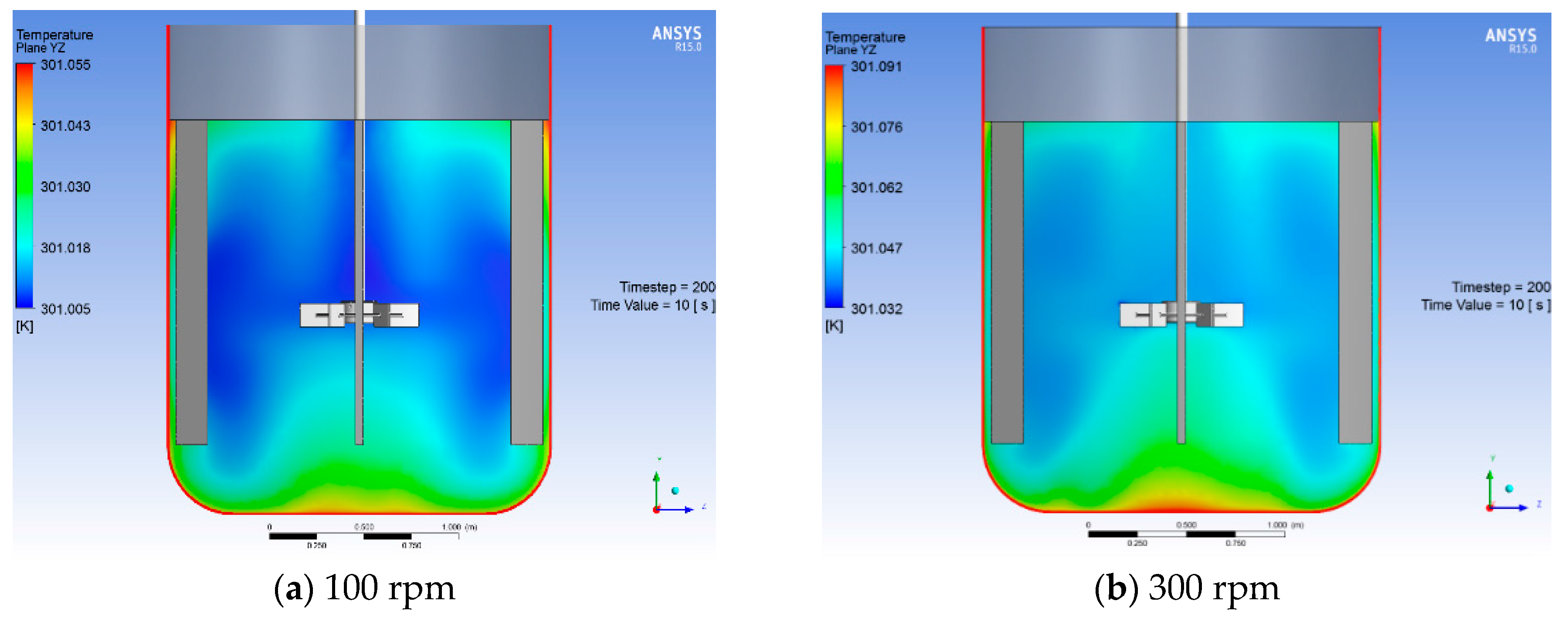

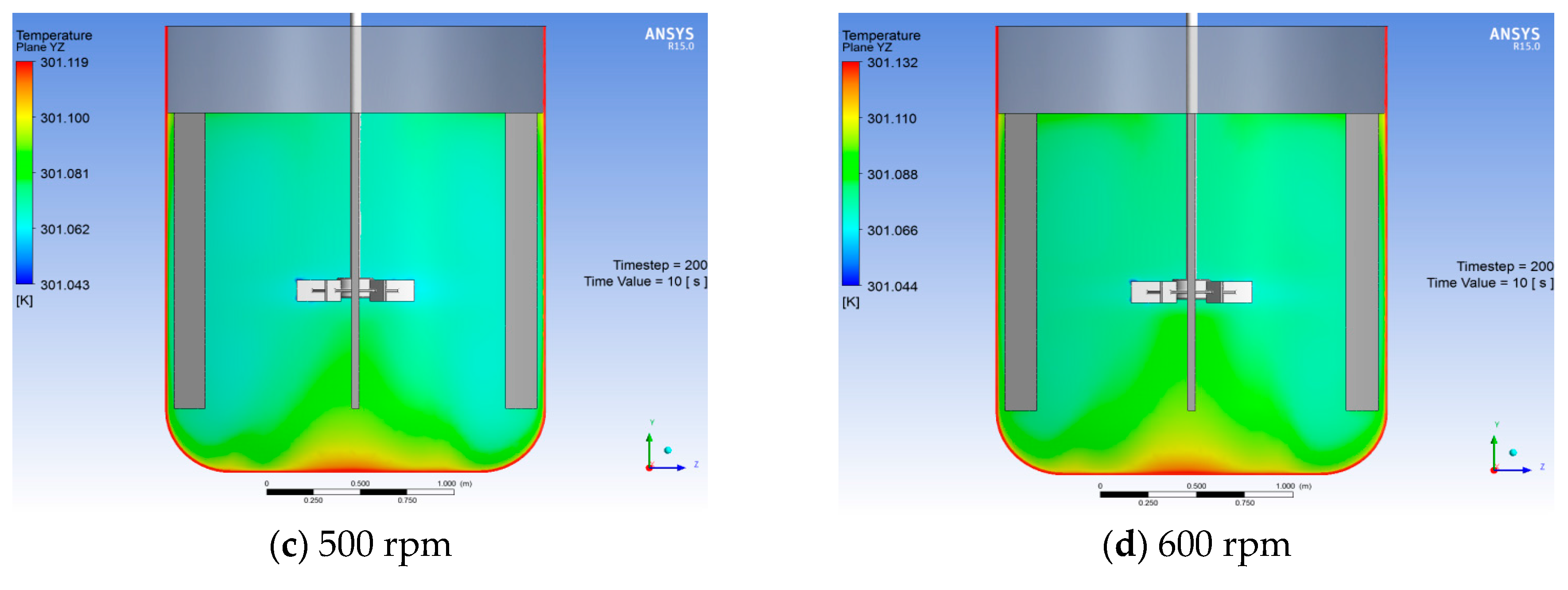

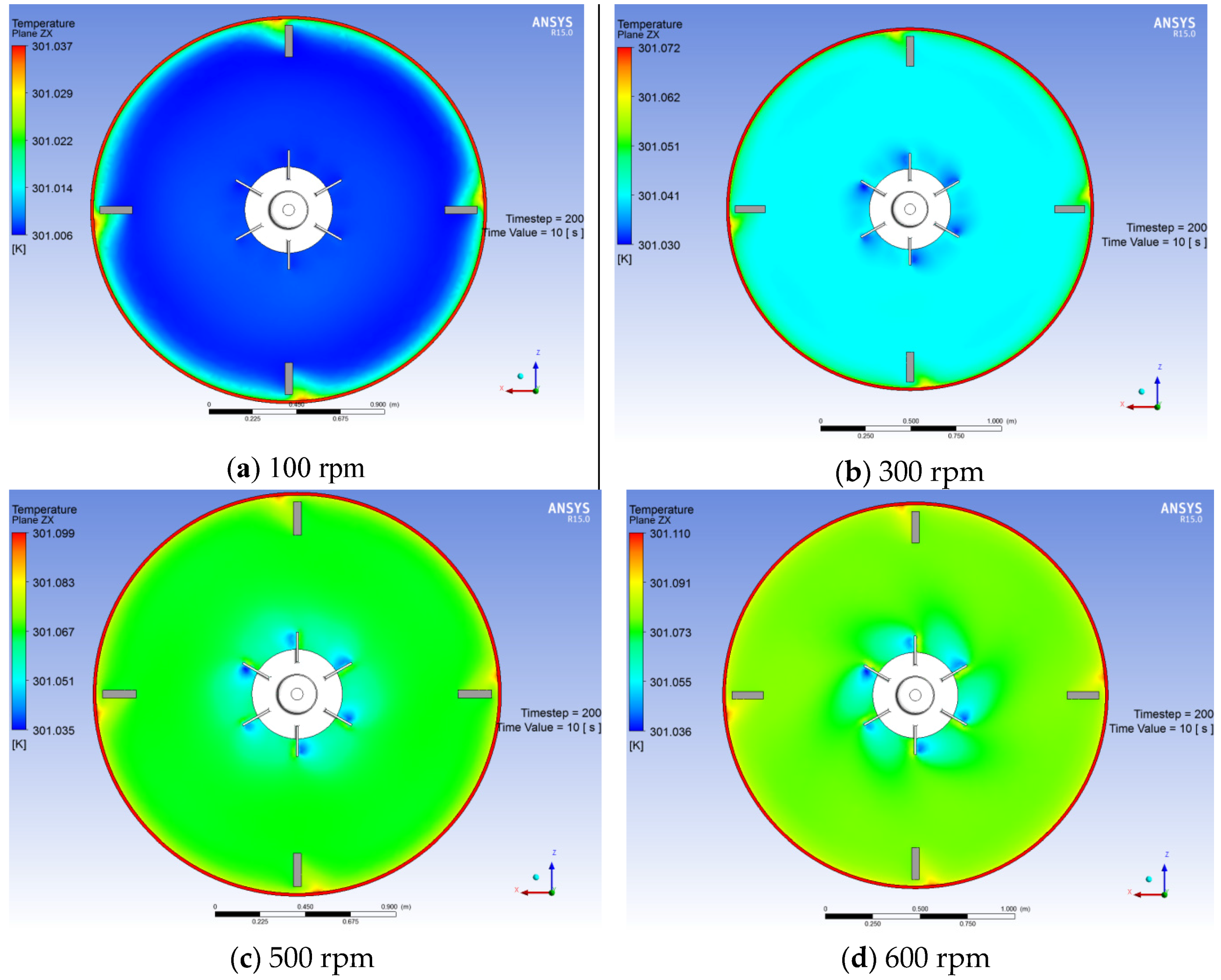

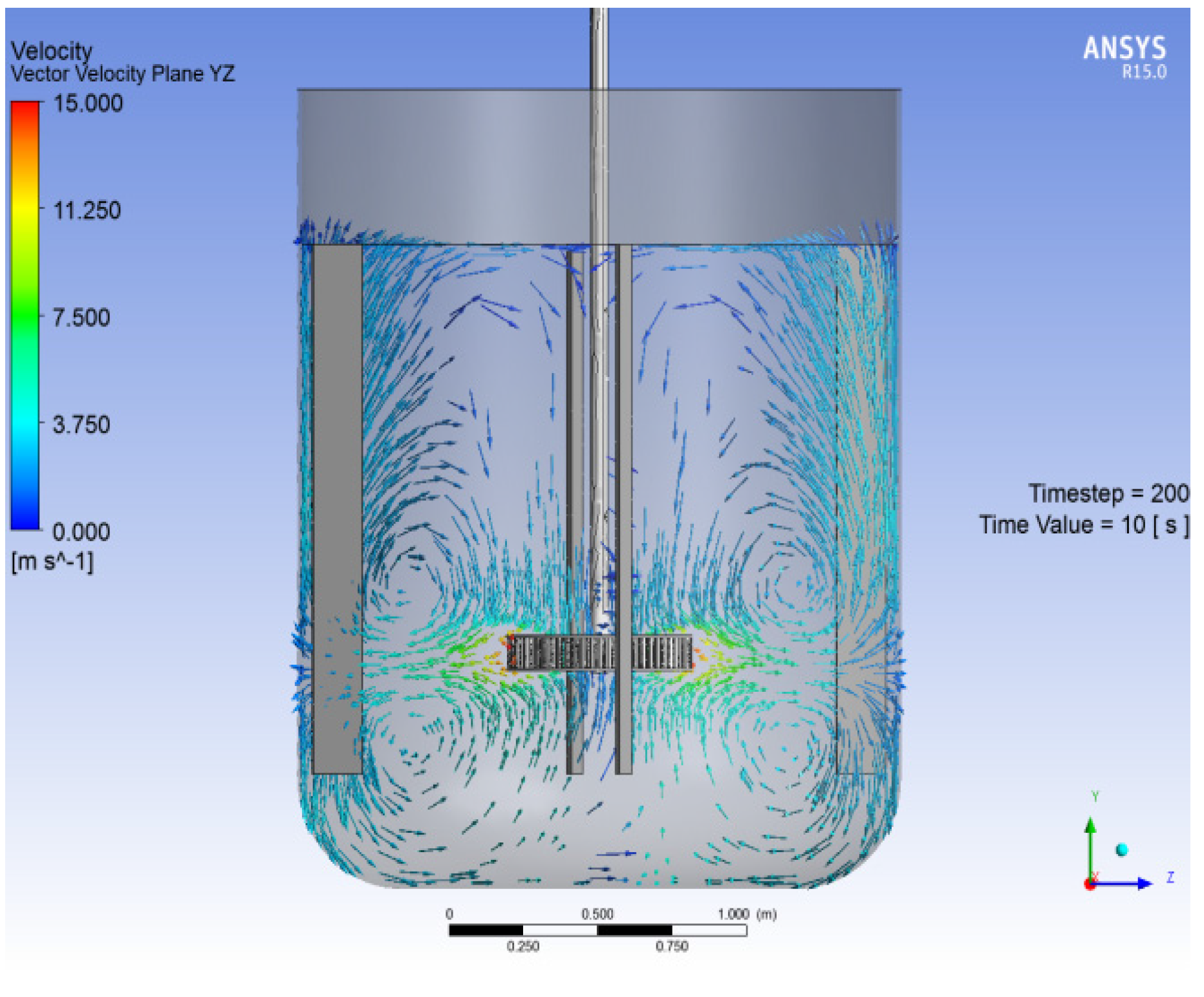

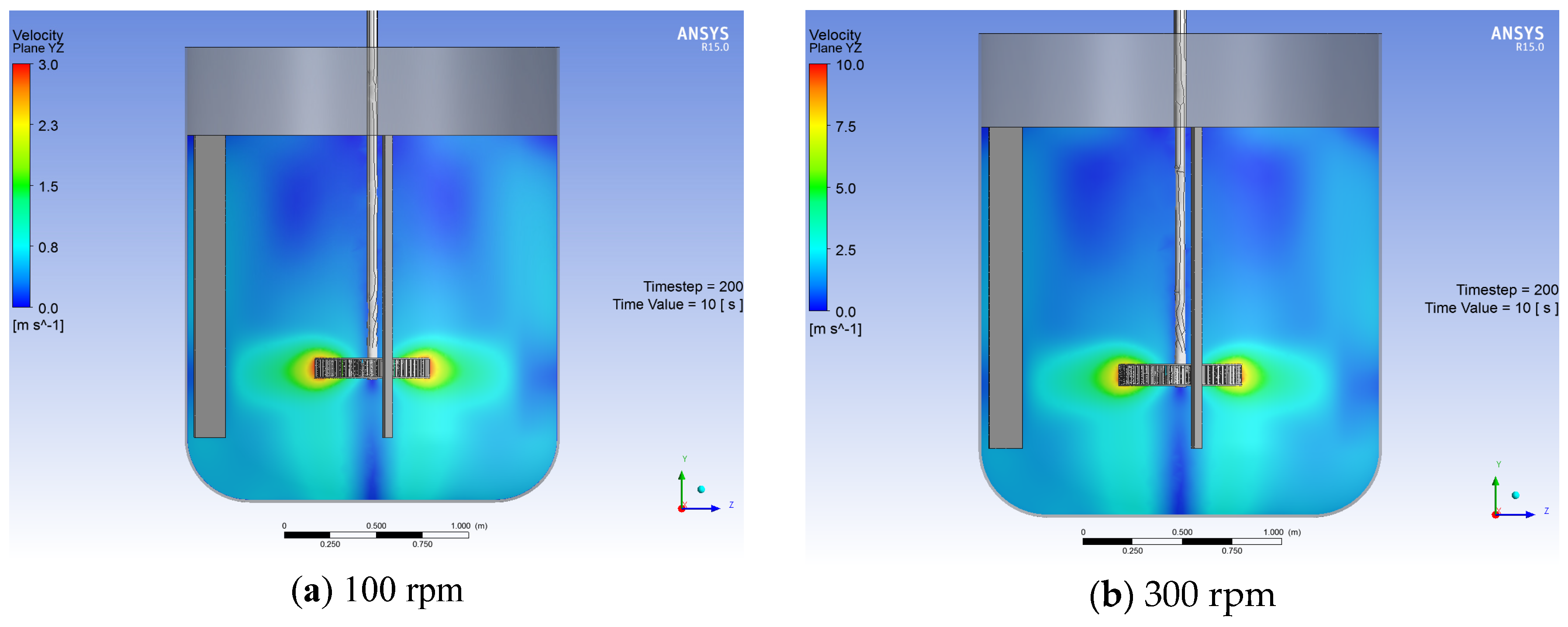

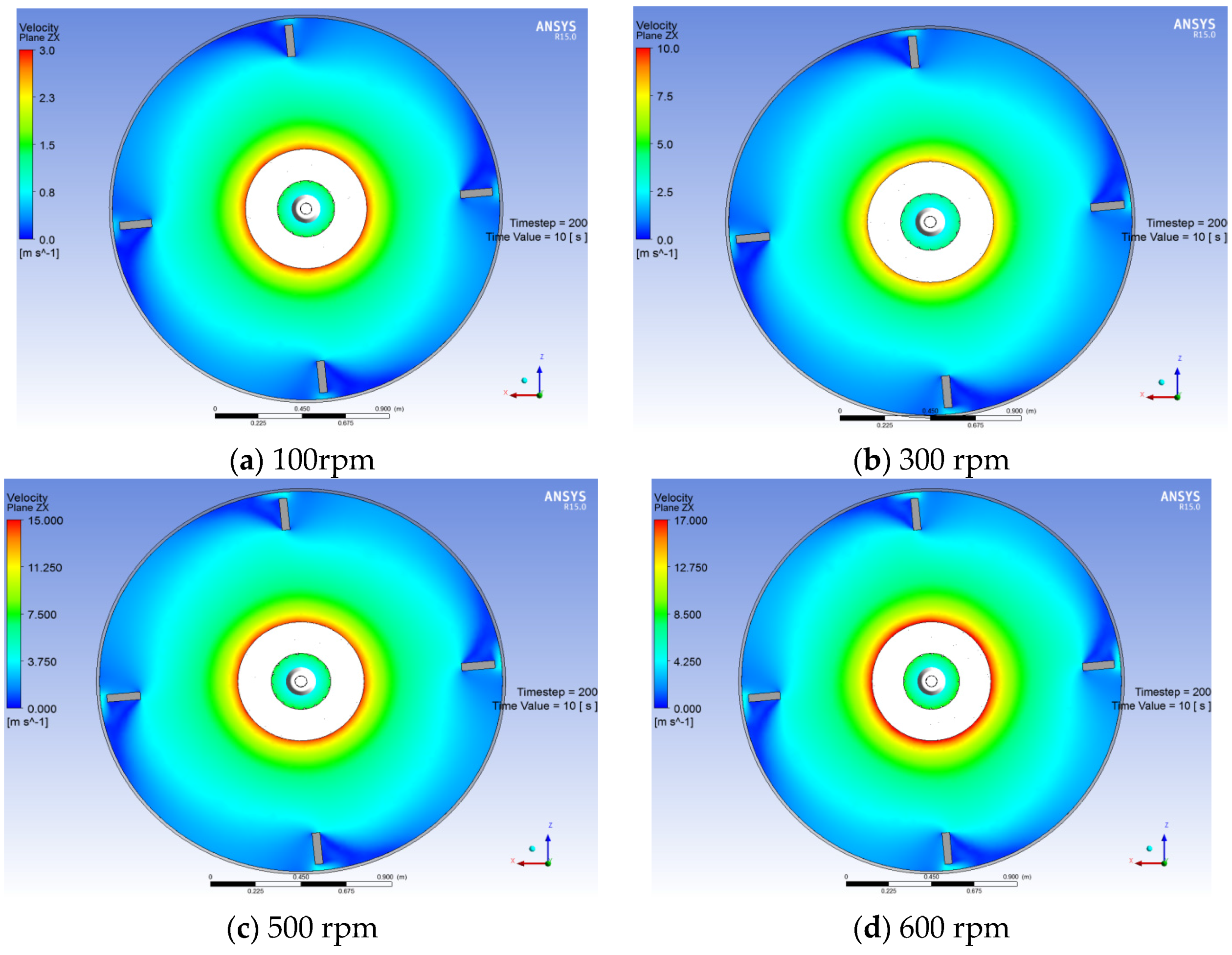

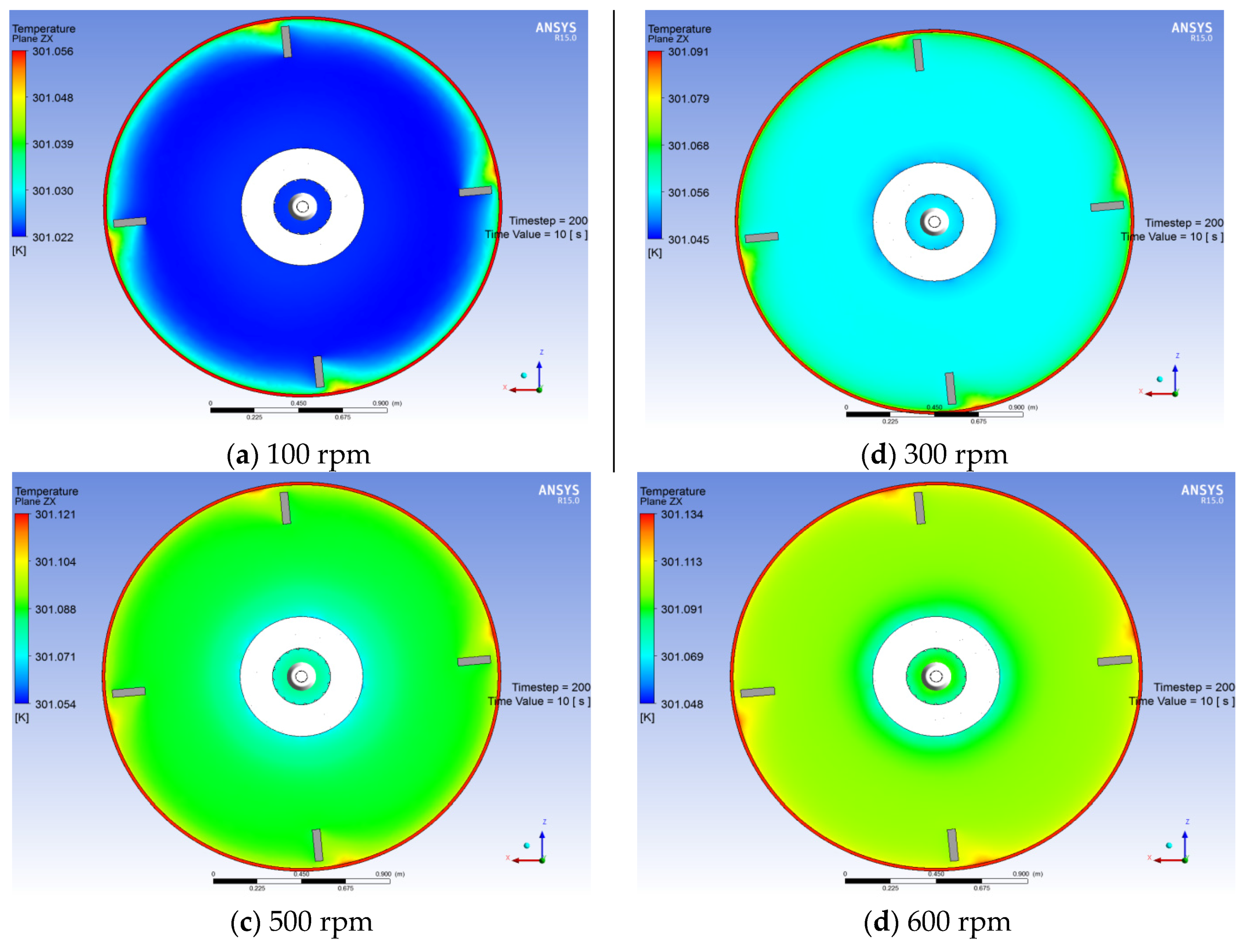

3.1. Homogenizer with Rushton Impeller

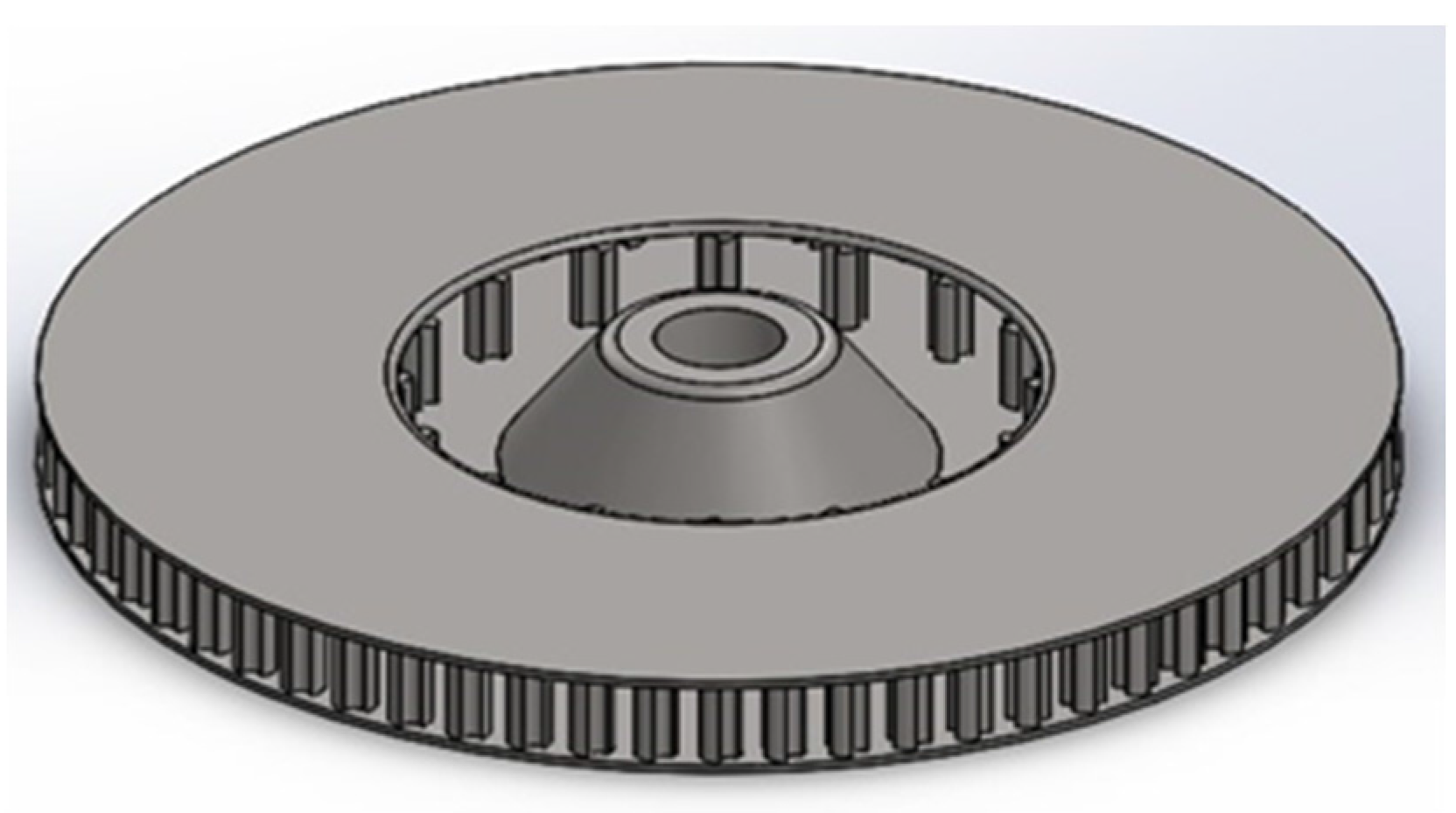

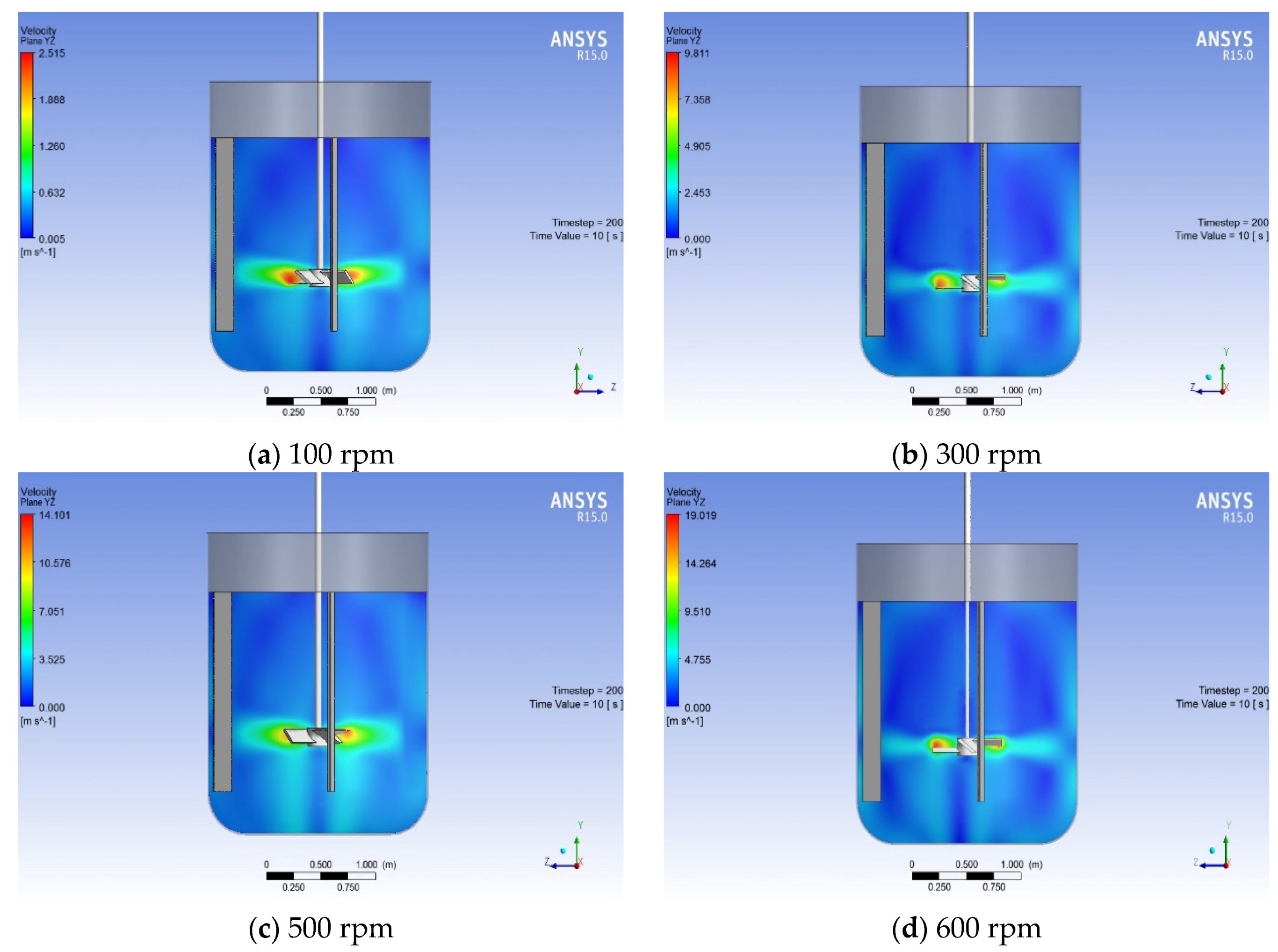

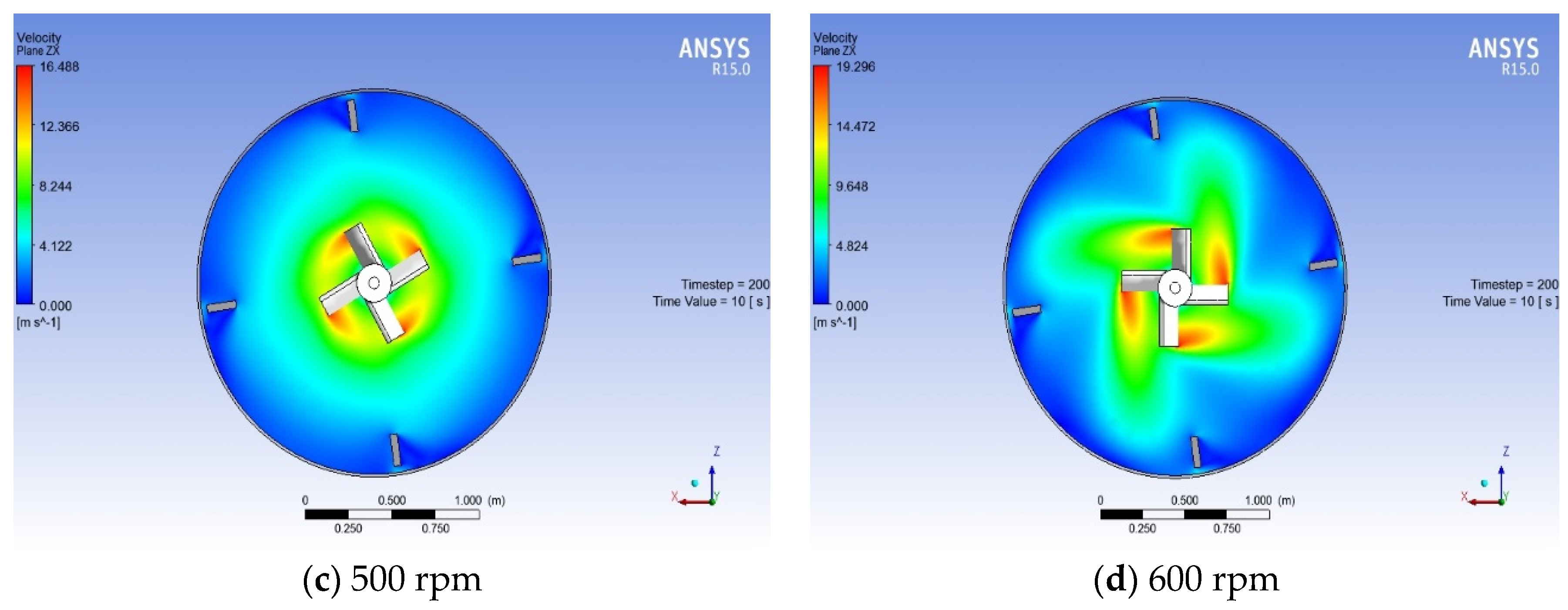

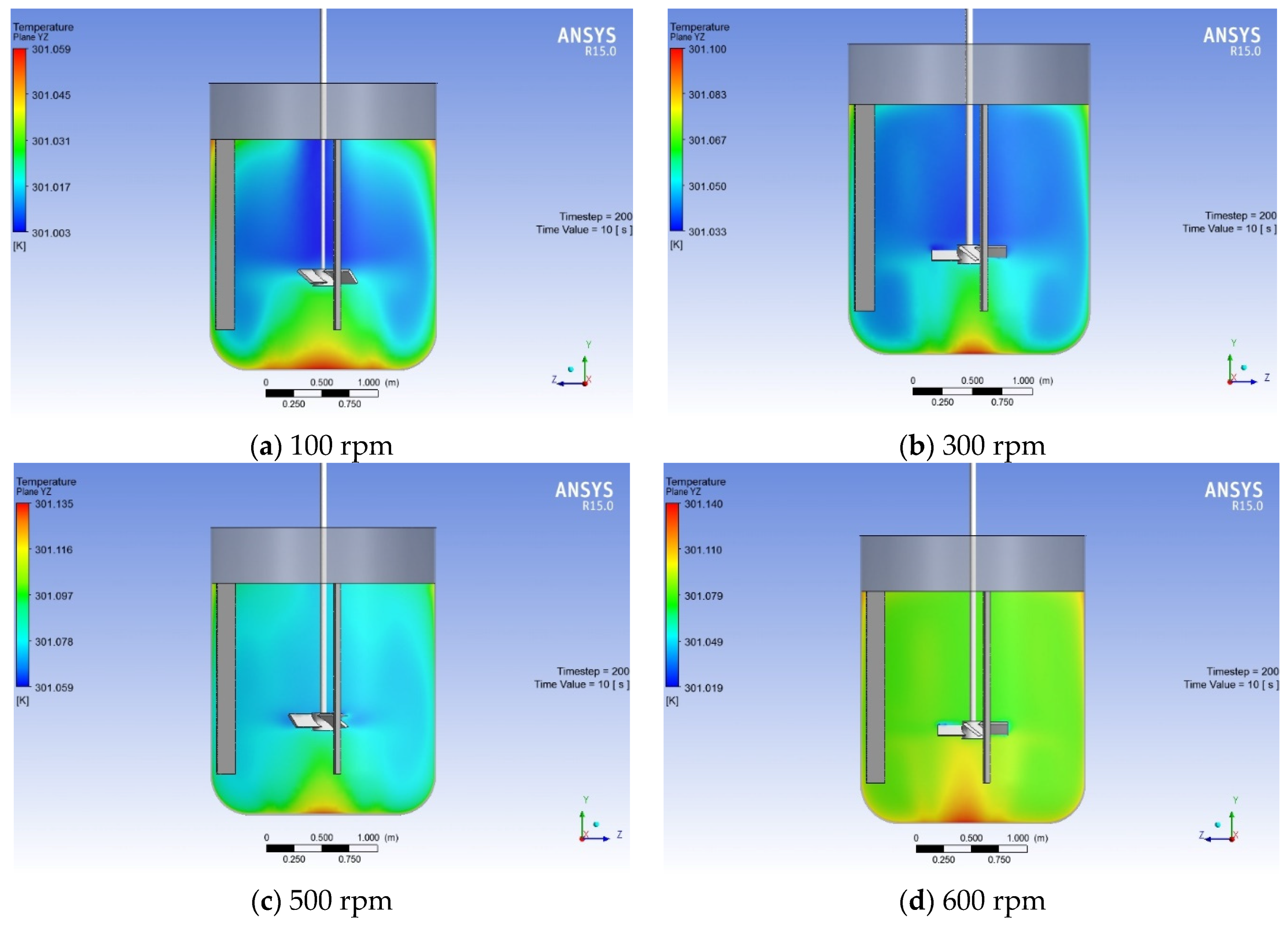

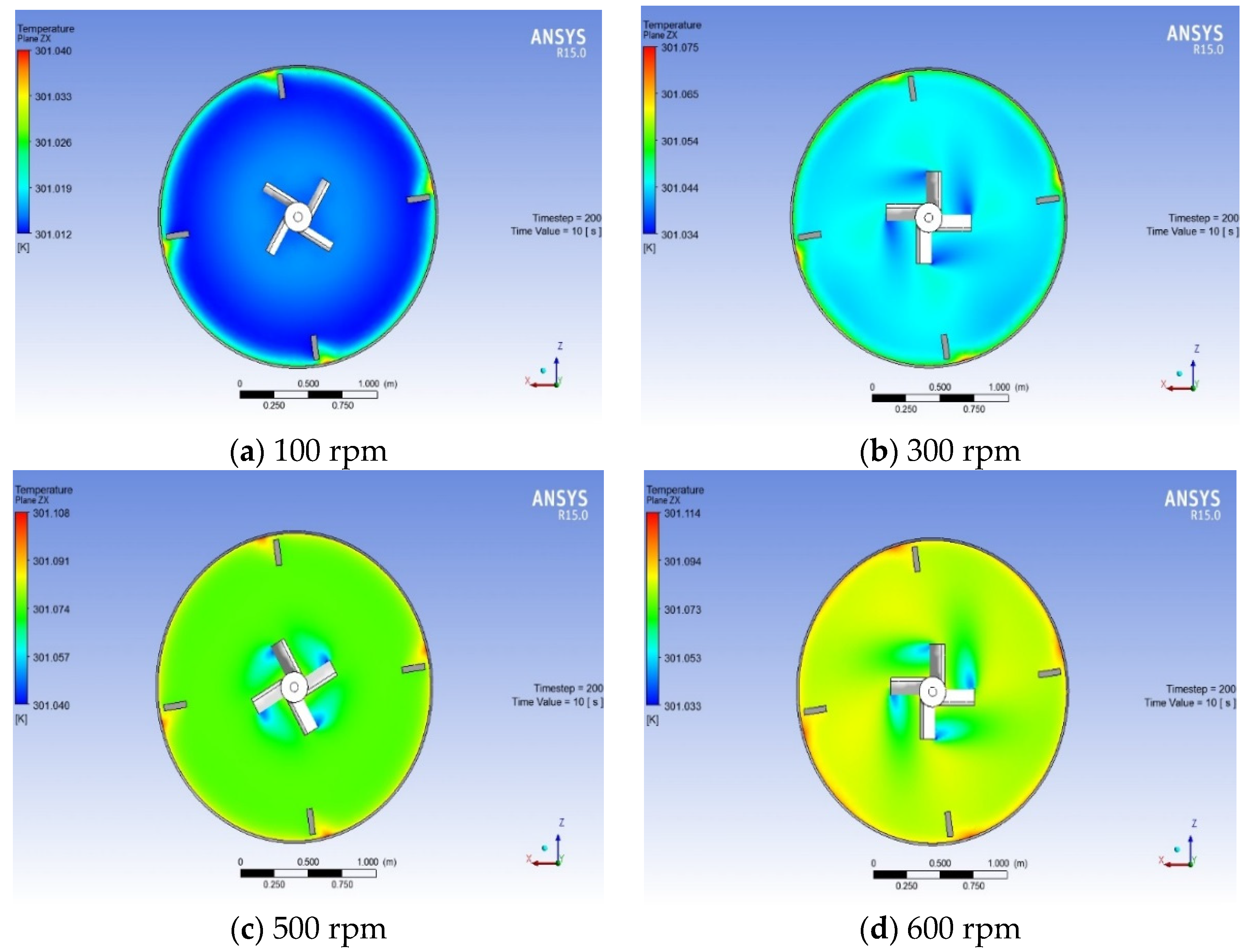

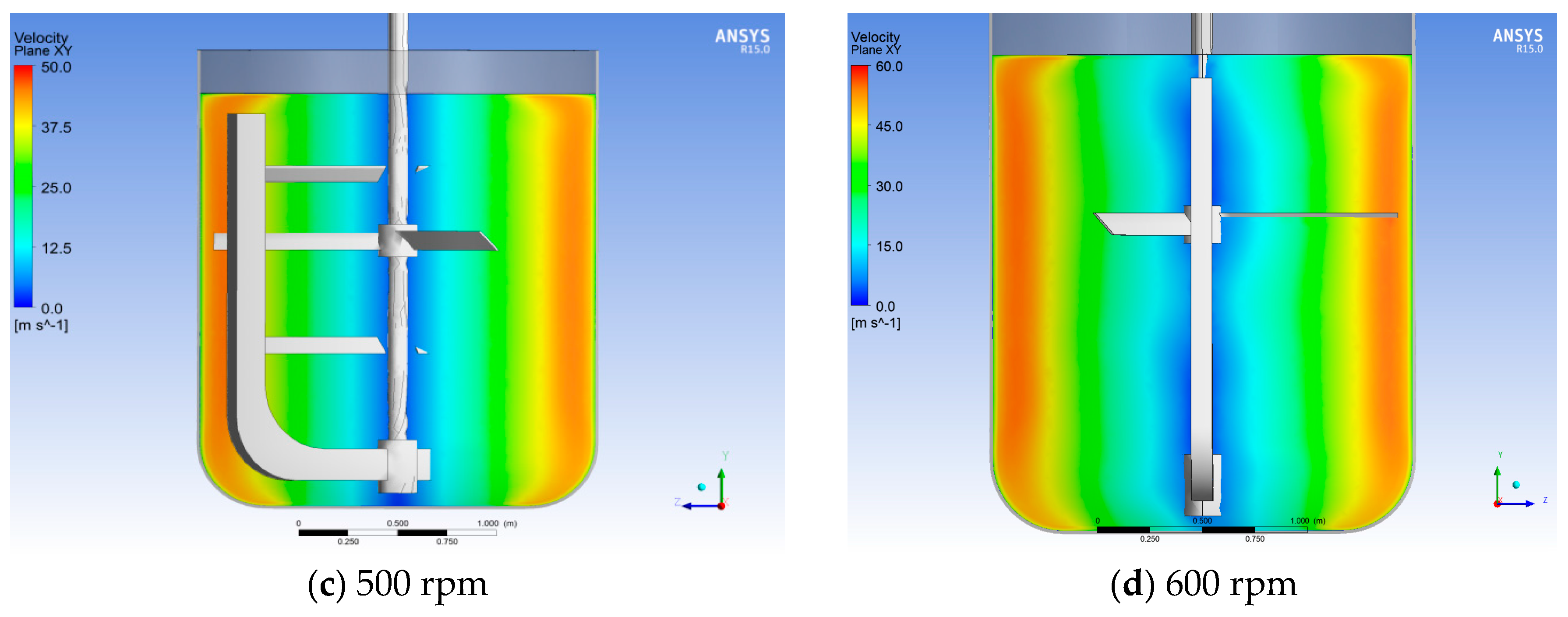

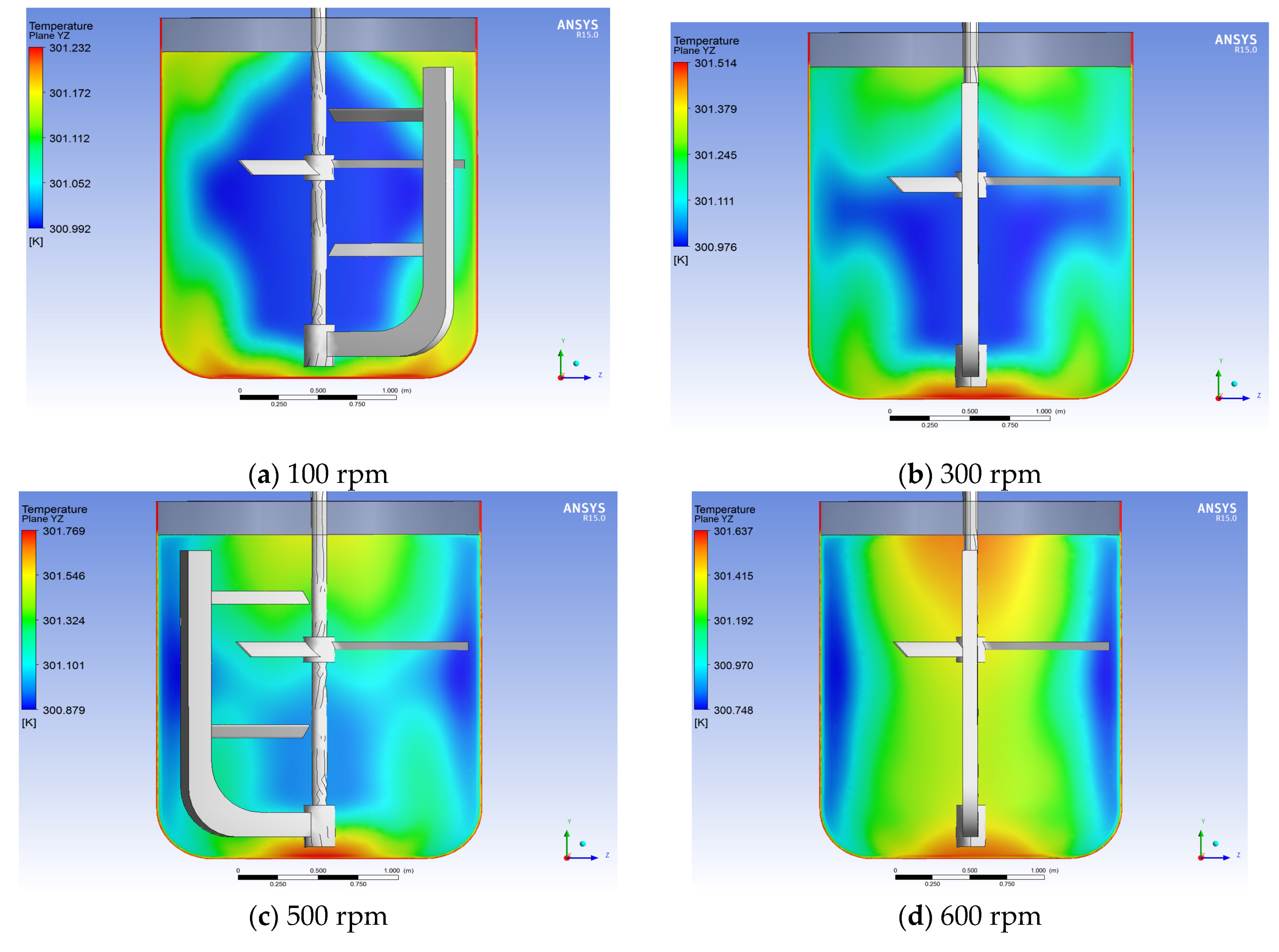

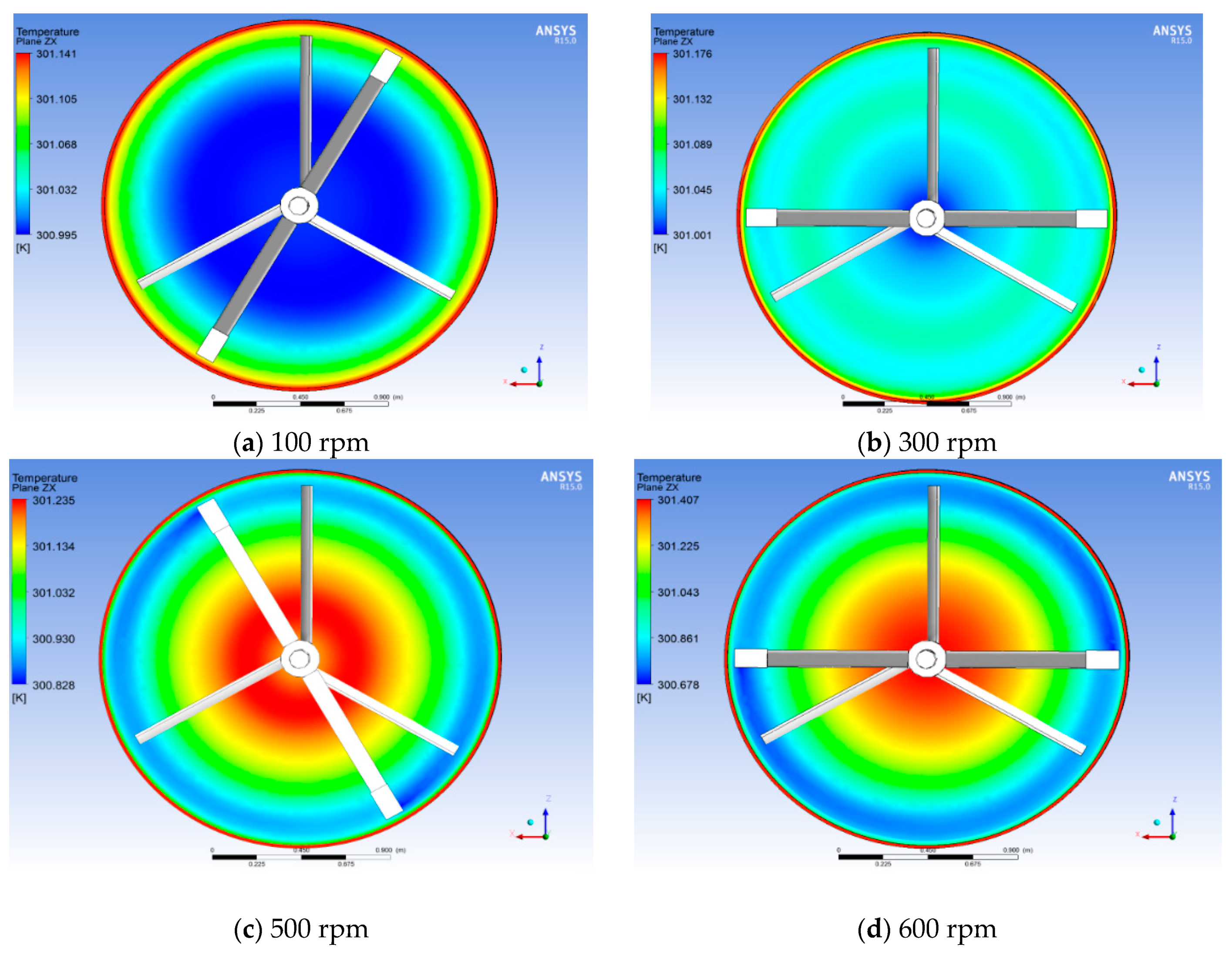

3.2. Homogenizer with KIA Impeller

3.3. Homogenizer with Pitched Blade Impeller

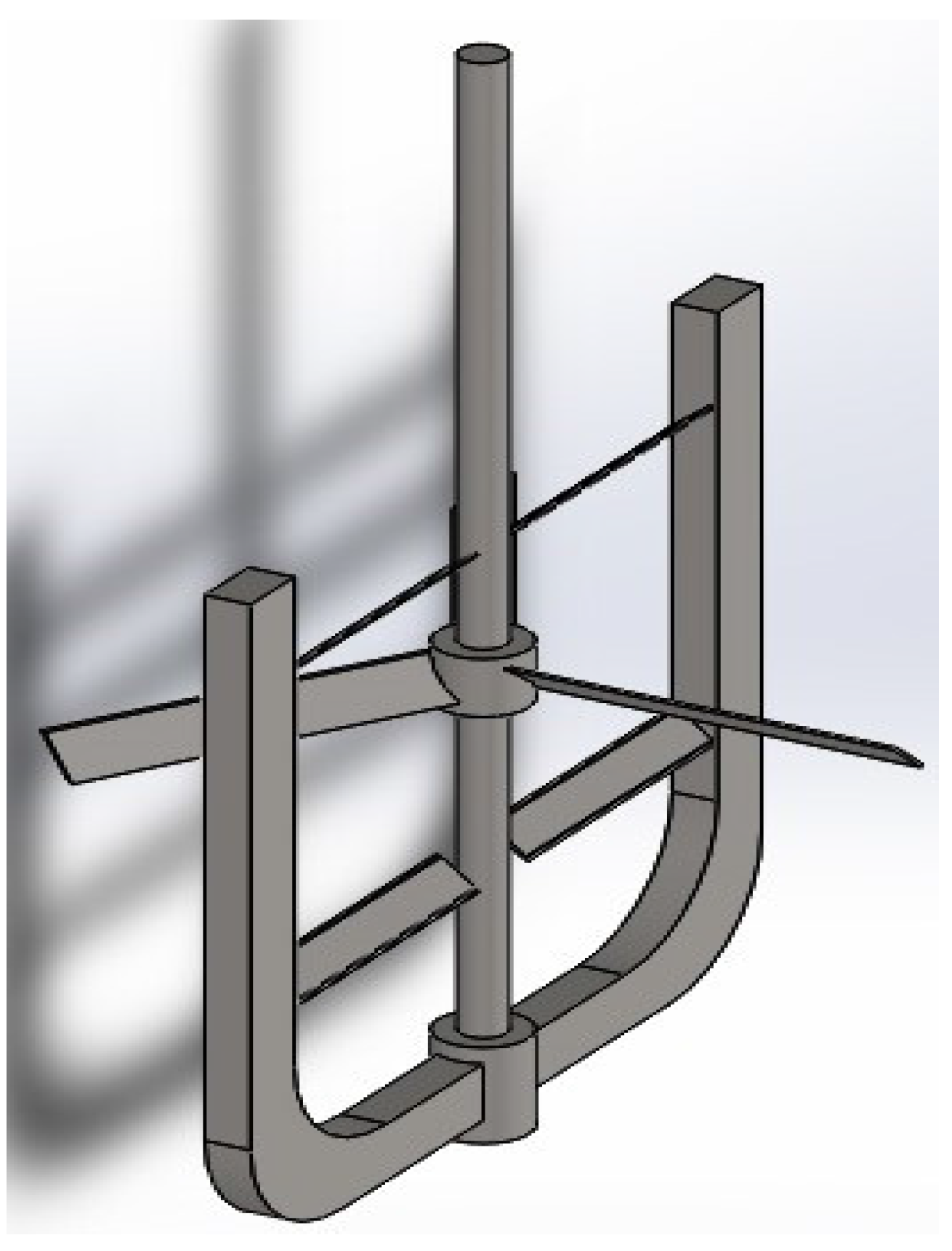

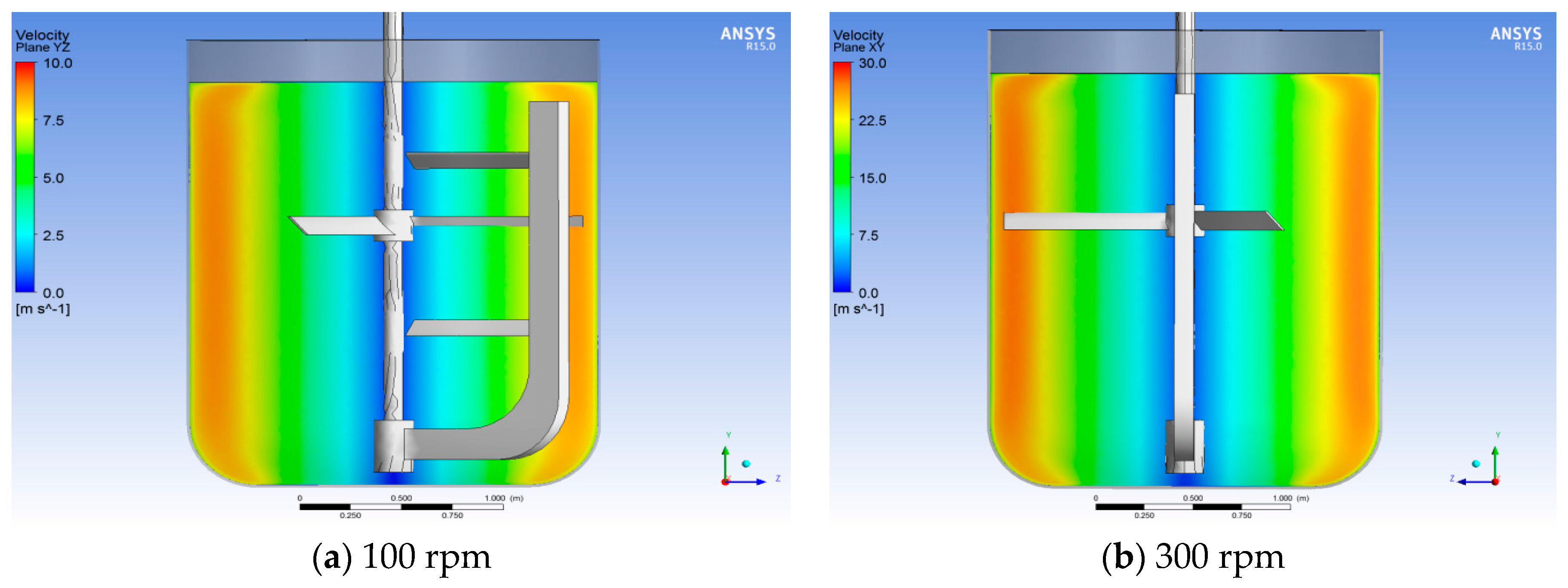

3.4. Homogenizer with Anchor Impeller

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Appendix A Municipal Solid Waste generated in five (5) districts in Abuja

| District names | ||||||

|---|---|---|---|---|---|---|

| Waste Type and % | Garki | Wuse | Maitama | Asokoro | Gwarimpa | Apo |

| Paper | 13 | 12 | 13 | 13.6 | 6.9 | 10.1 |

| Metal | 5.6 | 3.3 | 5.30 | 6.7 | 5.4 | 4.9 |

| Glass | 5.5 | 4.4 | 5.32 | 4.1 | 4.1 | - |

| Plastic | 16.2 | 17.3 | 20 | 15.1 | 21.3 | 18.7 |

| Food remnants | 52 | 54.3 | 54.80 | 53 | 61.2 | 65.3 |

| Textile | 2.2 | 4.7 | 0.10 | 3.1 | - | - |

| Rubber | 3.4 | 1.5 | 0.19 | 0.7 | - | 0.9 |

| Others | 1.8 | 2.4 | 0.60 | 2.8 | 1.1 | - |

| Person/household | 8 | 8 | 6 | 6 | 13 | 6 |

Appendix B

Nomenclature

| C − Impeller off bottom clearance (mm) |

| Cv − Volumetric concentrations (−) |

| ds − minimum shaft diameter (mm) |

| H − Height of homogenizer Vessel (mm) |

| ks − Effective shear rate estimate (s−1) |

| Nc − Critical speed of impeller shaft (rpm) |

| S − General source term (kgm−3s−1) |

| tcpu − computer simulation time (s) |

| T − Homogenizer vessel diameter (mm) |

| − Componenets of fluid velocity () |

| − Components of forcing velocity due to the immersed solid () |

| V − Volume of homogenizer vessel (mm3) |

| β − forcing function (m) |

References

- Ayuba, K.A.; Manaf, L.A.; Sabrina, A.H.; Azmin, S.W. Current Status of Municipal Solid Waste Practice in FCT Abuja. Res. J. Environ. Earth Sci. 2013, 5, 295–304. [Google Scholar]

- Environmental Protection Department. Monitoring of Solid Waste in Hong Kong: Waste Statistics for 2011. Available online: https://www.wastereduction.gov.hk/sites/default/files/msw2011.pdf (accessed on 2 July 2015).

- Lee, P.K.H.; Lin, C.S.K.; Chan, J.C.L. Turning Food Waste into Treasure. Available online: https://www.cityu.edu.hk/see/news/TurningFoodWasteIntoTreasure.pdf (accessed on 2 July 2015).

- Ogedengbe, E.O.B.; Kingsley, E.; Eteure, R.U.; Rosen, M.A. Feasibility Study of Cafeteria Energy Demand with Integration of a Downdraft Bio-digester System. In Proceedings of the 10th International Energy Conversion Engineering Conference, Atlanta, Georgia, 30 July–1 August 2012.

- Babarinsa, O.; Ogedengbe, E.O.B.; Rosen, M.A. Mixing Performance of a Suspended Stirrer for Homogenizing Biodegradable Food Waste from Eatery Centres. Sustainability 2014, 6, 5554–5565. [Google Scholar] [CrossRef]

- Akhilesh, K.; Basudeb, M. Numerical comparison of Rushton Turbine and CD-6 Impeller in Non-Newtonian Fluid Stirred Tank. Int. J. Electron. Commun. Eng. 2014, 1, 14–18. [Google Scholar]

- Ameur, H.; Bouzit, M.; Helmaoui, M. Numerical Study of Fluid and Power Consumption in a Stirred Vessel with a Scaba 6SRGT Impeller. Chem. Process Eng. 2011, 32, 351–366. [Google Scholar] [CrossRef]

- Jirout, T.; Reiger, F. Impeller Design for Mixing of Suspensions. Chem. Eng. Res. Des. 2011, 89, 1144–1151. [Google Scholar] [CrossRef]

- Thakur, R.K.; Vial, C.H.; Djelveh, G.; Labbafi, M. Mixing of Complex Fluids with Flat-Bladed Impellers: Effect of Impeller Geometry and Highly Shear Thinning Behavior. Chem. Eng. Process. Process Intensif. 2004, 43, 1211–1222. [Google Scholar] [CrossRef]

- Rieger, F.; Jirout, T.; Ceres, D.; Seichter, P. Effects of Impeller Shape on Solid Particle Suspension. Chem. Process Eng. 2013, 34, 139–152. [Google Scholar] [CrossRef]

- Monteith, H.D.; Stephenson, J.P. Mixing Efficiencies in Full-Scale Anaerobic Digesters by Tracer Methods. J. Water Pollut. Control Fed. 1981, 53, 78–84. [Google Scholar]

- Abbaszadeh, A.; Ghobadian, B.; Najafi, G.; Motevali, A. Analytical and FEM Design of Mixing Systems in STR Biodiesel Production. Adv. Environ. Biol. 2014, 8, 325–334. [Google Scholar]

- Asiri, S. Fluid Differential Agitators. Available online: http://waset.org/publications/6310/fluid-differential-agitators (accessed on 16 May 2106).

- Kaushal, P.; Sharma, H.K. Concept of Computational Fluid Dyanmics (CFD) and Its Application in Food Processing Equipment Design. J. Food Process Technol. J. Food Technol. 2011. [Google Scholar] [CrossRef]

- Guha, D. Hydrdynamics and Mixing in Single Phase and Liquid-Solid Tank Reactors. Ph.D. Thesis, Department of Energy, environmental and chemical Engineering, Washington University, St. Louis, MO, USA, 2007. [Google Scholar]

- Delaplace, G.; Torrez, C.; Andre, C.; Leuliet, J.C.; Belaubre, N. Experimental and CFD simulation of Heat Transfer to Highly Viscous Fluids in an Agitated Vessel Equipped With a Non Standard Helical Ribbon Impeller. Inst. Chem. Eng. Res. Des. 2001, 79, 927–937. [Google Scholar] [CrossRef]

- Ghani, A.G.; Farid, M.M.; Chen, X.D. Numerical Simulation of Transient Temperature and Velocity Profiles in a Horizontal Can during Sterilization using Computational Fluid Dynamics. J. Food Eng. 2002, 51, 77–83. [Google Scholar] [CrossRef]

- Maingonnat, J.F.; Doublier, J.L.; Lefebvre, J.; Delaplace, G. Power Consumption of a Double Ribbon Impeller with Newtonian and Shear thinning Fluids and during the Gelation of a Iota-Carrageenan Solution. J. Food Eng. 2008, 87, 82–90. [Google Scholar] [CrossRef]

- Abdul Ghani Al-Baali, A.G.; Farid, M.M. Sterilization of Food in Retort Pouches (Food Engineering Series); Springer: New York, NY, USA, 2006. [Google Scholar]

- Paul, E.L.; Atiemo-Obeng, V.A.; Kresta, S.M. Handbook of Industrial Mixing Science and Practice; Wiley-Interscience: Hoboken, NJ, USA, 2004; pp. 292–302. [Google Scholar]

- Kayode, I.A. Design of a Stirrer Impeller with Variable Speed for a Food Waste Homogenizer. Master’s Thesis, University of Lagos, Nigeria, 2016. [Google Scholar]

- Ranganathan, P.; Savithri, S. Computational Flow Modeling of Multiphase Mechanically Agitated Reactors. In Computational Fluid Dynamics, 1st ed.; Woo, H., Ed.; INTECH: Rijeka, Croatia, 2010. [Google Scholar]

- Chara, Z.; Kysela, B.; Konfrst, J.; Fort, I. Study of Fluid Flow in Baffled Vessels Stirred by a Rushton Standard Impeller. Appl. Math. Comput. 2016, 272, 614–628. [Google Scholar] [CrossRef]

- Gagnon, H.; Lounès, M.; Thibault, J. Power Consumption and Mass Transfer in Agitated Gas-Liquid Columns: A comparative Study. Can. J. Chem. Eng. 1998, 76, 379–389. [Google Scholar] [CrossRef]

| Fluid/Impeller Material | Density (kg/m3) | Specific Heat Capacity (J·kg−1·K−1) | Thermal Conductivity (W·m−1·K−1) |

|---|---|---|---|

| Carrot-Orange Soup | 1026 | 3880 | 0.596 |

| Stainless Steel | 8000 | 500 | 16.3 |

| Dimension | Symbol | Value (mm) |

|---|---|---|

| Impeller diameter | D | 625 |

| Blade length | Db | 145 |

| KIA impeller inner diameter | Do | 305 |

| Pitched Blade hub diameter | Dhub | 200 |

| Blade height | Dw | 30 |

| KIA impeller plate thickness | W | 65 |

| Impeller plate diameter | Dd | 450 |

| Anchor impeller diameter | Da | 1932 |

| Anchor impeller height | Dw’ | 2000 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kayode, I.A.; Ogedengbe, E.O.B.; Rosen, M.A. Design of Stirrer Impeller with Variable Operational Speed for a Food Waste Homogenizer. Sustainability 2016, 8, 489. https://doi.org/10.3390/su8050489

Kayode IA, Ogedengbe EOB, Rosen MA. Design of Stirrer Impeller with Variable Operational Speed for a Food Waste Homogenizer. Sustainability. 2016; 8(5):489. https://doi.org/10.3390/su8050489

Chicago/Turabian StyleKayode, Idris A., Emmanuel O. B. Ogedengbe, and Marc A. Rosen. 2016. "Design of Stirrer Impeller with Variable Operational Speed for a Food Waste Homogenizer" Sustainability 8, no. 5: 489. https://doi.org/10.3390/su8050489