Environmental Assessment of Integrated Food and Cooking Fuel Production for a Village in Ghana

Abstract

:1. Introduction

2. Materials and Methods

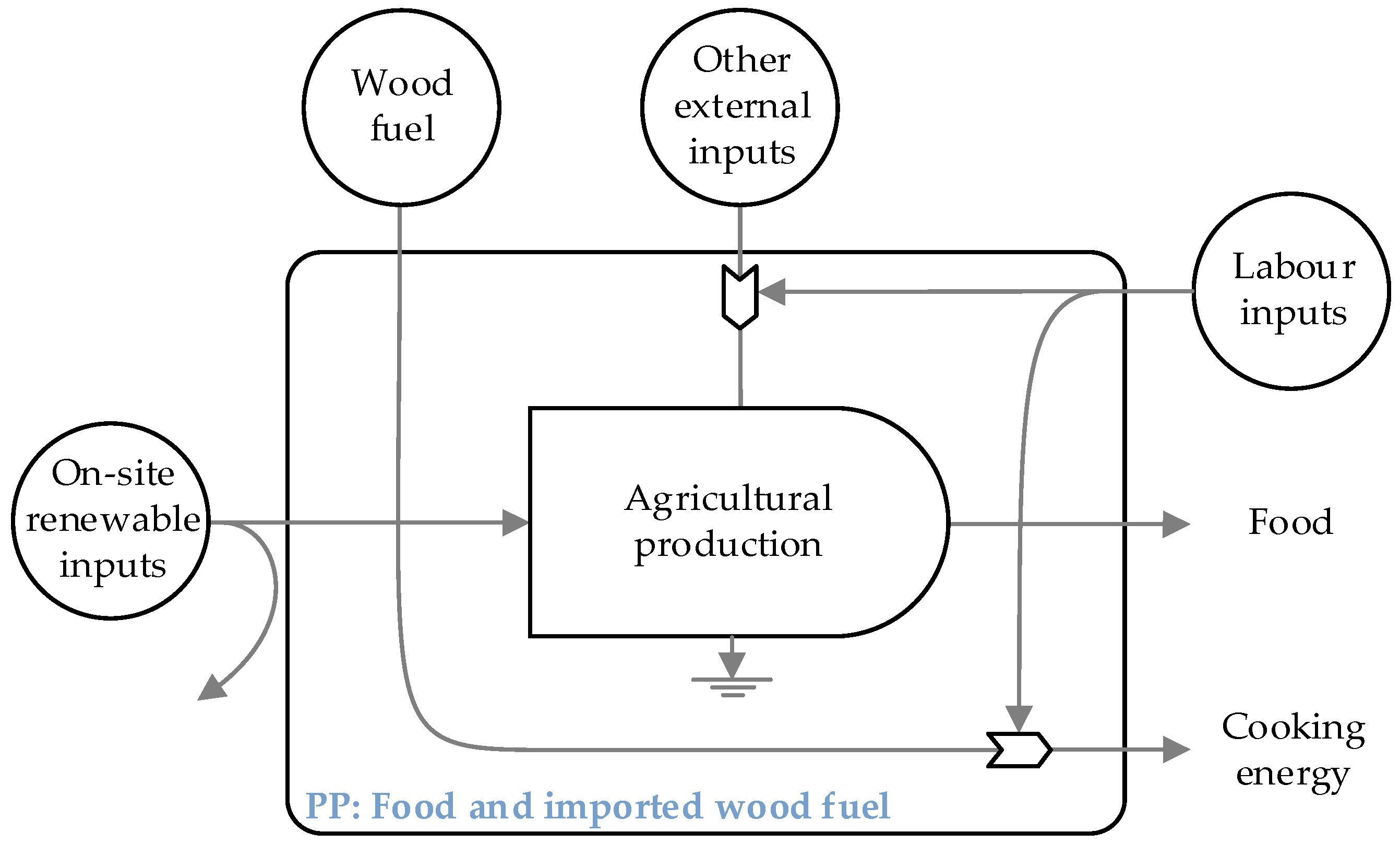

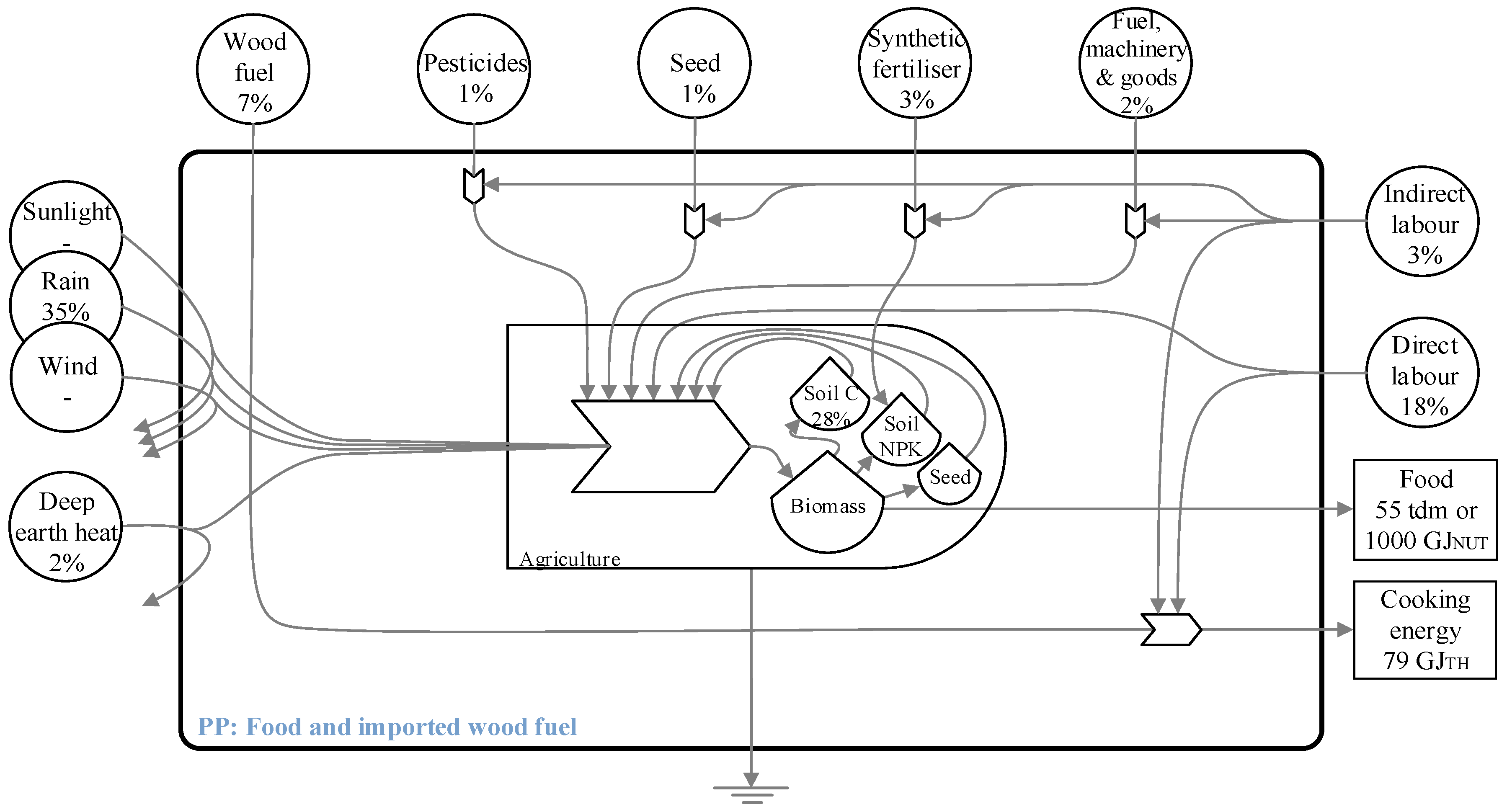

2.1. Present Practice Case Study

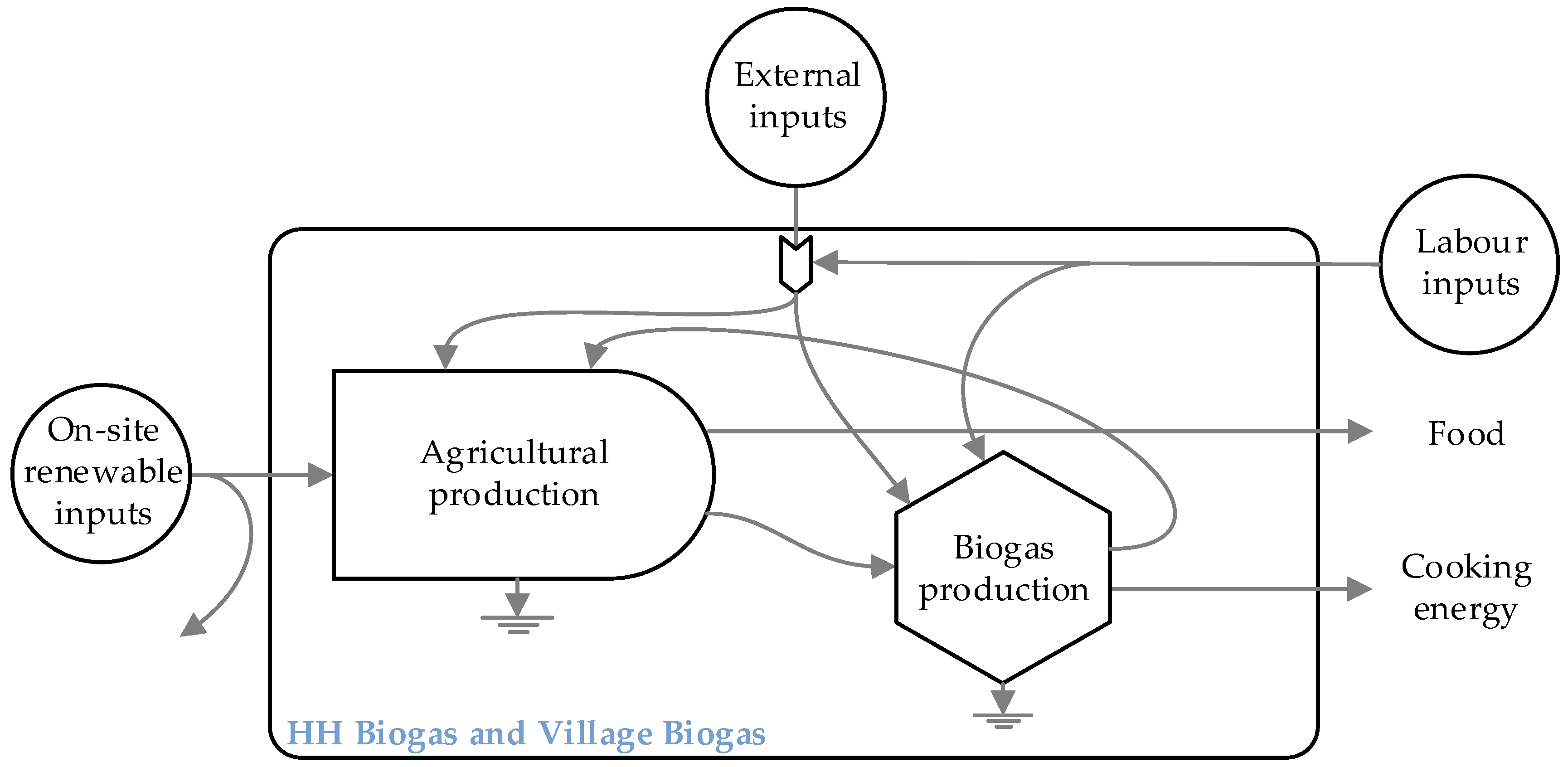

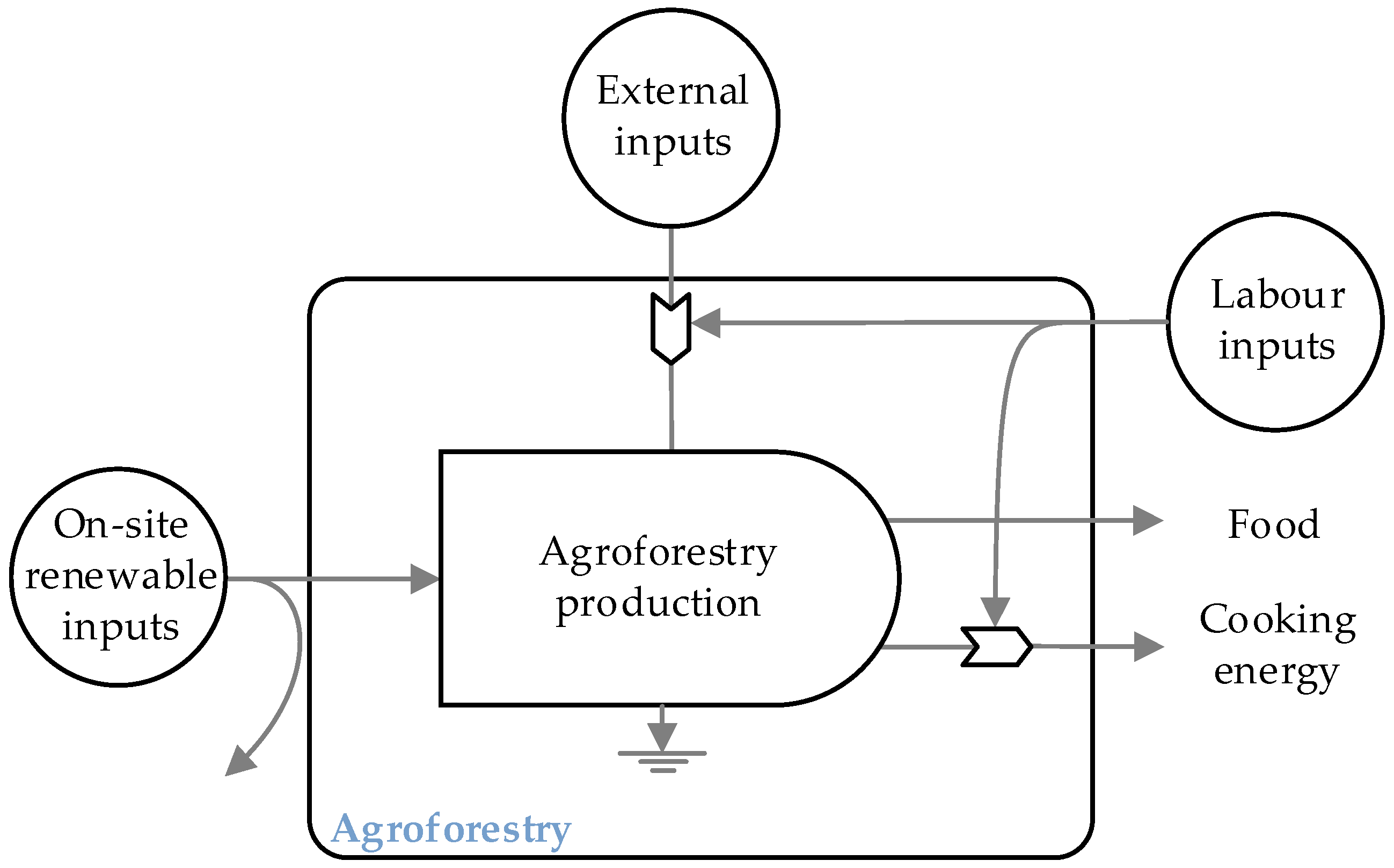

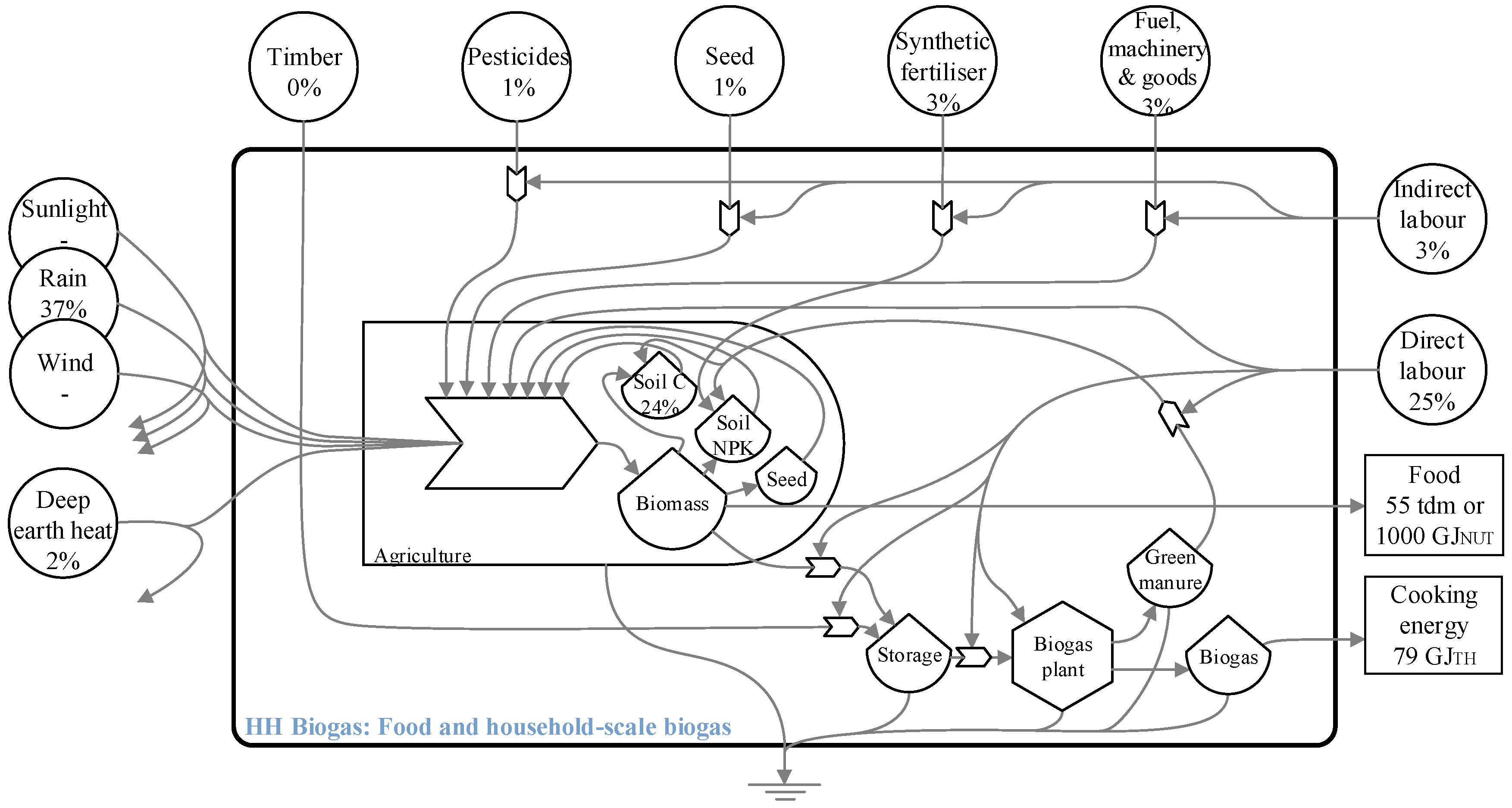

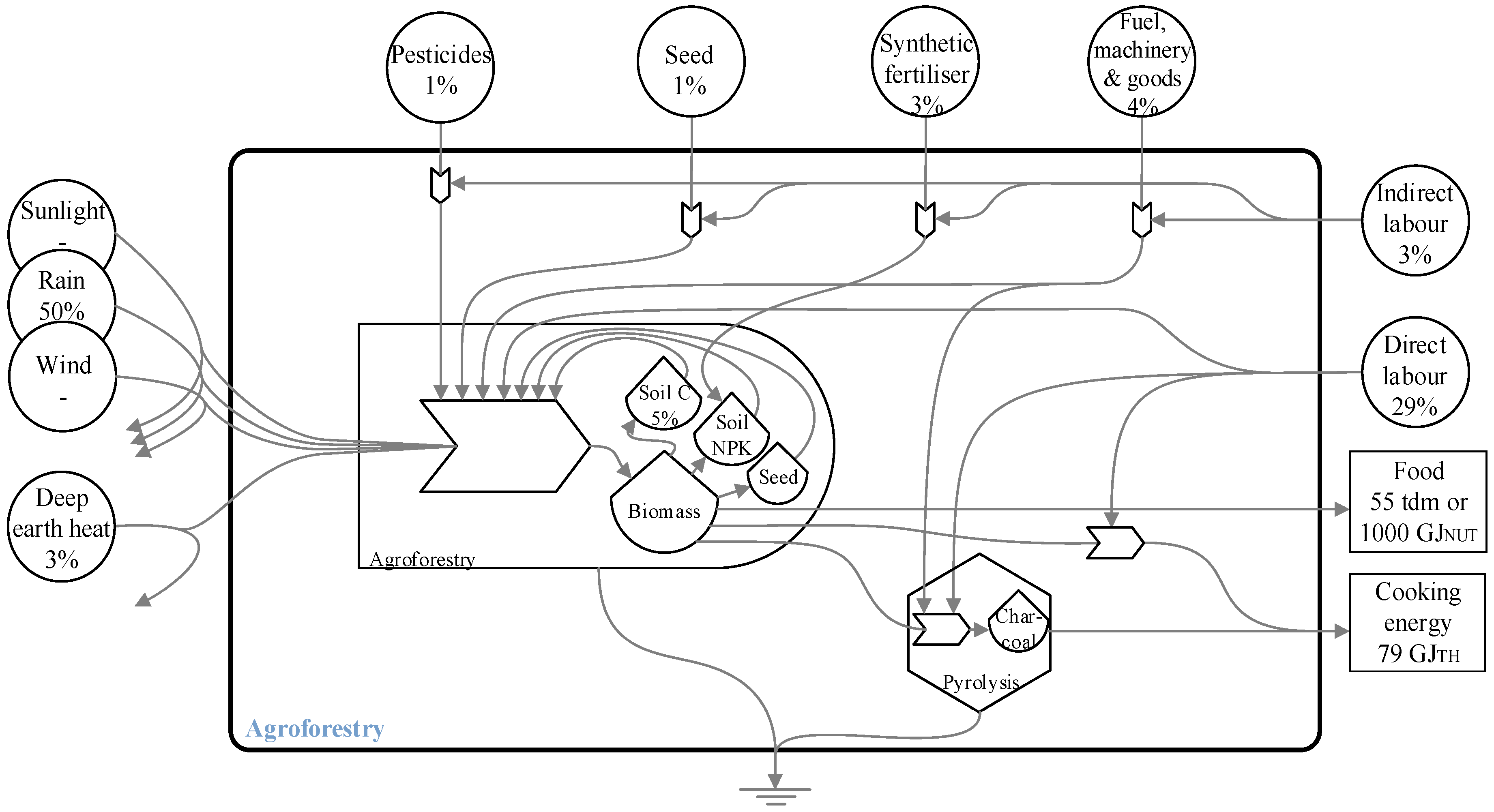

2.2. Integrated Food and Energy Systems

2.3. Emergy Assessment (EmA)

2.3.1. UEV Calculation

2.3.2. Renewability Fraction

2.3.3. Labor Accounting

2.3.4. UEVs of Firewood and Charcoal

2.4. Sensitivity Analysis

3. Results

3.1. Mass Balance and Labor Inputs

3.1.1. Present Practice

3.1.2. Integrated Food and Energy Systems

3.2. Emergy Analysis

3.2.1. Present Practice

3.2.2. Integrated Food and Energy Systems

3.3. Sensitivity Analysis

4. Discussion

4.1. Deforestation

4.2. Fossil-Fuel Independence

4.3. Soil Degradation

4.4. Resource Use

4.5. Accounting for Labor

5. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| PP | Present Practice |

| HH | Household |

| sej | solar emjoule |

| tdm | tonne dry matter |

| UEV | Unit Emergy Value |

| USD | United States Dollar |

| Global Ren. Fraction | Global Renewability Fraction |

References

- Hirsch, R. The Inevitable Peaking of World Oil Production; Atlantic Council: Washington, DC, USA, 2005; Volume XVI, pp. 1–10. [Google Scholar]

- Krausmann, F.; Gingrich, S.; Eisenmenger, N.; Erb, K.H.; Haberl, H.; Fischer-Kowalski, M. Growth in global materials use, GDP and population during the 20th century. Ecol. Econ. 2009, 68, 2696–2705. [Google Scholar] [CrossRef]

- UNEP. Decoupling Natural Resource Use and Environmental imPacts from Economic Growth. A Report of the Working Group on Decoupling to the International Resource Panel. 2011. Available online: http://www.unep.org/resourcepanel/decoupling/files/pdf/Decoupling_Report_English.pdf (accessed on 15 April 2016).

- International Assessment of Agricultural Knowledge, Science and Technology for Development (IAASTD). Agriculture at a Crossroads. Synthesis Report. 2009. Available online: http://www.unep.org/dewa/agassessment/reports/IAASTD/EN/Agriculture%20at%20a%20Crossroads_Synthesis%20Report%20%28English%29.pdf (accessed on 15 April 2016).

- UNEP. Assessing the Environmental Impacts of Consumption and Production. 2010. Available online: http://www.greeningtheblue.org/sites/default/files/Assessing%20the%20environmental%20impacts%20of%20consumption%20and%20production.pdf (accessed on 15 April 2016).

- Neff, R.A.; Parker, C.L.; Kirshenmann, F.L.; Tinch, J.; Lawrence, R.S. Peak oil, food systems and public health. Am. J. Public Health 2011, 101, 1587–1597. [Google Scholar] [CrossRef] [PubMed]

- Markussen, M.V. Sustainability Assessment of Food and Bioenergy Systems in a Societal Context—In a Time of Crisis. Ph.D. Thesis, Technical University of Denmark, DTU, Kongens Lyngby, Denmark, September 2013. [Google Scholar]

- Østergård, H.; Finckh, M.R.; Fontaine, L.; Goldringer, I.; Hoad, S.P.; Kristensen, K.; Lammerts van Bueren, E.T.; Mascher, F.; Munk, L.; Wolfe, M.S. Time for a shift in crop production: Embracing complexity through diversity at all levels. J. Sci. Food Agric. 2009, 89, 1439–1445. [Google Scholar] [CrossRef]

- Owusu, V.; Fosu, K.Y.; Burger, K. Intersectoral labor mobility and deforestation in Ghana. Environ. Dev. Econ. 2012, 17, 741–762. [Google Scholar] [CrossRef]

- Ministry of Lands and Natural Resources. Ghana Investment Plan for the Forest Investment Program. 2012. Available online: http://www.fcghana.org/assets/file/Programmes/Forest_Investment_Plan_fip/Ghana%20%20FIP%20Final.pdf (accessed on 15 April 2016).

- Boucher, D.; Elias, P.; Lininger, K.; May-Tobin, C.; Roquemore, S.; Saxon, E. The Root of the Problem. What’s Driving Tropical Deforestation Today? 2011. Available online: http://www.ucsusa.org/sites/default/files/legacy/assets/documents/global_warming/UCS_RootoftheProblem_DriversofDeforestation_FullReport.pdf (accessed on 15 April 2016).

- Agyeman, K.O.; Amponsah, O.; Braimah, I.; Lurumuah, S. Commercial charcoal production and sustainable community development of the Upper West Region, Ghana. J. Sustain. Dev. 2012, 5, 149–164. [Google Scholar] [CrossRef]

- Botchie, G.; Seini, W.; Asuming-Brempong, S. FAO Roles of Agriculture (ROA) project. Socio-Economic Analysis and the Roles of Agriculture in Developing Countries. 2003. Available online: ftp://ftp.fao.org/es/esa/roa/pdf/Brief3-e.pdf (accessed on 15 April 2016).

- Cobo, J.G.; Dercon, G.; Cadisch, G. Nutrient balances in African land use systems across different spatial scales: A review of approaches, challenges and progress. Agric. Ecosyst. Environ. 2010, 136, 1–15. [Google Scholar] [CrossRef]

- Ray, D.K.; Ramankutty, N.; Mueller, N.D.; West, P.C.; Foley, J.A.F. Recent patterns of crop yield growth and stagnation. Nat. Commun. 2012, 3, 1293. [Google Scholar] [CrossRef] [PubMed]

- Pittelkow, C.M.; Liang, X.; Linquist, B.A.; van Groenigen, K.J.; Lee, J.; Lundy, M.E.; van Gestel, N.; Six, J.; Venterea, R.T.; van Kessel, C. Productivity limits and potentials of the principles of conservation agriculture. Nature 2014, 517, 365–367. [Google Scholar] [CrossRef] [PubMed]

- Bond, T.; Templeton, M.R. History and future of domestic biogas plants in the developing world. Energy Sustain. Dev. 2011, 15, 347–354. [Google Scholar] [CrossRef]

- Amigun, B.; Parawira, W.; Musango, J.K. Anaerobic biogas generation for rural area energy provision in Africa. In Biogas; Kumar, S., Ed.; InTech: Rijeka, Croatia, 2012; pp. 35–62. [Google Scholar]

- Arthur, R.; Baidoo, M.F.; Antwi, E. Biogas as a potential renewable energy source: A Ghanaian case study. Renew. Energy 2011, 36, 1510–1516. [Google Scholar] [CrossRef]

- Chanakya, H.N.; Bhogle, S.; Arun, R.S. Field experience with leaf litter-based biogas plants. Energy Sustain. Dev. 2005, 9, 49–62. [Google Scholar] [CrossRef]

- Altieri, M.A.; Nicholls, C.I. Agroecology scaling up for food sovereignty and resiliency. Sustain. Agric. Rev. 2012, 11, 1–29. [Google Scholar]

- Akinnifesi, F.K.; Ajayi, O.C.; Sileshi, G.; Chirwa, P.W.; Chianu, J. Fertiliser trees for sustainable food security in the maize-based production systems of East and Southern Africa. Agron. Sustain. Dev. 2010, 30, 615–629. [Google Scholar] [CrossRef]

- Svensson, L.M.; Christensson, K.; Björnsson, L. Biogas production from crop residues on a farm-scale level in Sweden: Scale, choice of substrate and utilisation rate most important parameters for financial feasibility. Bioprocess Biosyst. Eng. 2006, 29, 137–142. [Google Scholar] [CrossRef] [PubMed]

- Bogdanski, A.; Ismail, M. NRC Integrated food energy systems (IFES). Environ. Nat. Resour. Manag. Work. Pap. 2012, 49, 1–10. [Google Scholar]

- Odum, H.T. Environmental Accounting: Emergy and Environmental Decision Making; Wiley and Sons: New York, NY, USA, 1996. [Google Scholar]

- Keita, J.D. Wood or charcoal—Which is better? Unasylva 1987, 39, 137–138. [Google Scholar]

- Lefroy, E.; Rydberg, T. Emergy evaluation of three cropping systems in southwestern Australia. Ecol. Model. 2003, 161, 195–211. [Google Scholar] [CrossRef]

- Cannon, K. Soil Organic Matter. Organic Carbon and Nitrogen. Available online: http://www1.agric.gov.ab.ca/$department/deptdocs.nsf/all/aesa1861/$file/organicmatter.pdf?OpenElement (accessed on 13 April 2016).

- Kemausuor, F.; Kamp, A.; Thomsen, S.T.; Bensah, E.C.; Østergård, H. Assessment of biomass residue availability and bioenergy yields in Ghana. Resour. Conserv. Recycl. 2014, 86, 28–37. [Google Scholar] [CrossRef]

- Thomsen, S.T.; Spliid, H.; Østergård, H. Statistical prediction of biomethane potentials based on the composition of lignocellulosic biomass. Bioresour. Technol. 2014, 154, 80–86. [Google Scholar] [CrossRef] [PubMed]

- Emery, I.R.; Mosier, N.S. The impact of dry matter loss during herbaceous biomass storage on net greenhouse gas emissions from biofuels production. Biomass Bioenergy 2012, 39, 237–246. [Google Scholar] [CrossRef]

- Heiske, S.; formerly Technical University of Denmark, Lyngby, Denmark; Londoño, J.; Technical University of Denmark. Personal communication, 2013.

- Bhattacharya, S.C.; Abdul Salam, P. Low greenhouse gas biomass options for cooking in the developing countries. Biomass Bioenergy 2002, 22, 305–317. [Google Scholar] [CrossRef]

- Thomsen, S.T.; formerly Technical University of Denmark; Heiske, S.; formerly Technical University of Denmark. Personal communication, 2013.

- Chanakya, H.N.; Ganguli, N.K.; Anand, V.; Jagadish, K.S. Performance characteristics of a solid-phase biogas fermentor. Energy Sustain. Dev. 1995, 1, 43–46. [Google Scholar] [CrossRef]

- Burri, M.; Martius, G. Conception and construction of a dry fermentation pilot plant for developing countries. In Biogas from Solid Waste; Swiss Federal Institute of Technology in Zürich (ETH): Zürich, Switzerland, 2011; Available online: https://www.eawag.ch/fileadmin/Domain1/Abteilungen/sandec/publikationen/SWM/Anaerobic_Digestion/Burri_2011.pdf (accessed on 15 April 2016).

- Kang, B.T.; Wilson, G.F.; Sipkens, L. Alley cropping maize (Zea mays L.) and leucaena (Leucaena leucocephala Lam) in southern Nigeria. Plant Soil 1981, 63, 165–179. [Google Scholar] [CrossRef]

- Cook, B.G.; Pengelly, B.C.; Brown, S.D.; Donnelly, J.L.; Eagles, D.A.; Franco, M.A.; Hanson, J.; Mullen, B.F.; Partridge, I.J.; Peters, M.; et al. Tropical Forages: An Interactive Selection Tool. 2016. Available online: http://www.tropicalforages.info/key/Forages/Media/Html/Leucaena_leucocephala.htm (accessed on 15 April 2016).

- Kang, B.T.; Grimme, H.; Lawson, T.L. Alleu cropping sequentially cropped maize and cowpea with Leucaena on a sandy soil in Southern Nigeria. Plant Soil 1985, 85, 267–277. [Google Scholar] [CrossRef]

- Lal, R. Agroforestry systems and soil surface management of a tropical alfisol: I: Soil moisture and crop yields. Agrofor. Syst. 1989, 8, 7–29. [Google Scholar] [CrossRef]

- Remington, T.; Eklou-Takpani, K. Alley farming in central Togo. In Alley Farming in the Humid and Subhumid Tropics, Proceedings of the International Workshop, Ibadan, Nigeria, 10–14 March 1986; International Development Research Centre: Ottawa, ON,Canada, 1989; pp. 137–138. [Google Scholar]

- Ngambeki, D.S. Economic evaluation of alley cropping leucaena with Maize-Maize and Maize-Cowpea in Southern Nigeria. Agric. Syst. 1985, 17, 243–258. [Google Scholar] [CrossRef]

- Brown, M.T.; Sweeney, S.; Campbell, D.E.; Huang, S.-L.; Rydberg, T.; Ulgiati, S. (Eds.) Emergy Synthesis 8: Theory and Applications of the Emergy Methodology; University of Florida: Gainesville, FL, USA, 2015.

- Odum, H.T.; Brown, M.T.; Brandt-Williams, S. Handbook of Emergy Evaluation Folio 1: Introduction and Global Budget; University of Florida: Gainesville, FL, USA, 2000. [Google Scholar]

- Bastianoni, S.; Marchettini, N. The problem of co-production in environmental accounting by emergy analysis. Ecol. Model. 2000, 129, 187–193. [Google Scholar] [CrossRef]

- Kamp, A.; Østergård, H. How to manage co-product inputs in emergy accounting exemplified by willow production for bioenergy. Ecol. Modell. 2013, 253, 70–78. [Google Scholar] [CrossRef]

- Wright, C.; Østergård, H. Scales of renewability exemplified by a case study of three Danish pig production systems. Ecol. Modell. 2015, 315, 28–36. [Google Scholar] [CrossRef]

- Cavalett, O.; de Queiroz, J.F.; Ortega, E. Emergy assessment of integrated production systems of grains, pig and fish in small farms in the South Brazil. Ecol. Modell. 2006, 193, 205–224. [Google Scholar] [CrossRef]

- Kamp, A.; Morandi, F.; Østergård, H. Development of concepts for human labor accounting in Emergy Assessment and other Environmental Sustainability Assessment methods. Ecol. Indic. 2016, 60, 884–892. [Google Scholar] [CrossRef]

- Brown, M.T.; Ulgiati, S. Understanding the global economic crisis: A biophysical perspective. Ecol. Modell. 2011, 223, 4–13. [Google Scholar] [CrossRef]

- World Bank. Labor Force, Total Datasheet. Available online: http://data.worldbank.org/indicator/SL.TLF.TOTL.IN (accessed on 15 April 2016).

- Robèrt, K.H.; Broman, G.I.; Basile, G. Analyzing the concept of planetary boundaries from a strategic sustainability perspective: How does humanity avoid tipping the planet? Ecol. Soc. 2013, 18. [Google Scholar] [CrossRef]

- Bationo, A.; Kihara, J.; Vanlauwe, B.; Waswa, B.; Kimetu, J. Soil organic carbon dynamics, functions and management in West African agro-ecosystems. Agric. Syst. 2007, 94, 13–25. [Google Scholar] [CrossRef]

- Agostinho, F.; Ortega, E. Integrated food, energy and environmental services production as an alternative for small rural properties in Brazil. Energy 2012, 37, 103–114. [Google Scholar] [CrossRef]

- Ikerd, J.E. The need for a system approach to sustainable agriculture. Agric. Ecosyst. Environ. 1993, 46, 147–160. [Google Scholar] [CrossRef]

| Technology Option a | Parameter | More Inputs, Non-Renewable Imported Wood | Reference Model Parameter Values | Less Inputs, Renewable Imported Wood |

|---|---|---|---|---|

| All | Labour inputs | 30% more | Present practice | 30% less |

| All | Global Ren. Fraction of wood | 0% | 50% | 100% |

| HH Biogas | Conversion efficiency | 30% | 43% | 52% |

| Village Biogas | Conversion efficiency | 35% | 50% | 55% |

| Agroforestry | Soil loss reduction | 61% | 87% | 100% |

| Technology Option a | |||||

|---|---|---|---|---|---|

| Unit | PP | HH Biogas | Village Biogas | Agroforestry | |

| Input | |||||

| Imported cooking fuel | tons | 67 | 0 | 0 | 0 |

| Synthetic fertilizer use | kg | 3200 | 2400 | 2100 | 1800 |

| Soil loss | tons soil organic carbon | 18 | 14 | 13 | 2.3 |

| Direct labor | man-hours | 18,000 | 23,000 | 22,000 | 20,000 |

| Indirect labor | global man-hours | 510 | 510 | 480 | 410 |

| Output | |||||

| Food | tdm | 55 | 55 | 55 | 55 |

| Useful cooking energy | GJ thermal energy | 79 | 79 | 79 | 79 |

| Technology Option a | |||||

|---|---|---|---|---|---|

| Unit | PP | HH Biogas | Village Biogas | Agro-forestry | |

| Unit Emergy Value, incl. labor | 105 sej/J | 2.8 | 2.7 | 2.6 | 2.0 |

| Unit Emergy Value, excl. labor | 105 sej/J | 2.2 | 1.9 | 1.8 | 1.3 |

| Global Ren. Fraction, incl. labor | % | 43 | 43 | 45 | 58 |

| Global Ren. Fraction, excl. labor | % | 51 | 56 | 58 | 80 |

| Technology Option a | |||||

|---|---|---|---|---|---|

| Unit | PP | HH Biogas | Village Biogas | Agro-forestry | |

| Unit Emergy Value, incl. labor | 105 sej/J | 2.6–3.0 | 2.5–2.8 | 2.4–2.6 | 1.7–2.4 |

| Unit Emergy Value, excl. labor | 105 sej/J | 2.2 | 1.8–1.9 | 1.6–1.9 | 1.2–1.5 |

| Global Ren. Fraction, incl. labor | % | 38–48 | 41–46 | 45–47 | 49–66 |

| Global Ren. Fraction, excl. labor | % | 48–55 | 55–60 | 66–70 | 69–87 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kamp, A.; Østergård, H.; Bolwig, S. Environmental Assessment of Integrated Food and Cooking Fuel Production for a Village in Ghana. Sustainability 2016, 8, 404. https://doi.org/10.3390/su8050404

Kamp A, Østergård H, Bolwig S. Environmental Assessment of Integrated Food and Cooking Fuel Production for a Village in Ghana. Sustainability. 2016; 8(5):404. https://doi.org/10.3390/su8050404

Chicago/Turabian StyleKamp, Andreas, Hanne Østergård, and Simon Bolwig. 2016. "Environmental Assessment of Integrated Food and Cooking Fuel Production for a Village in Ghana" Sustainability 8, no. 5: 404. https://doi.org/10.3390/su8050404