Fiber-Reinforced Polymer Nets for Strengthening Lava Stone Masonries in Historical Buildings

Abstract

:1. Introduction

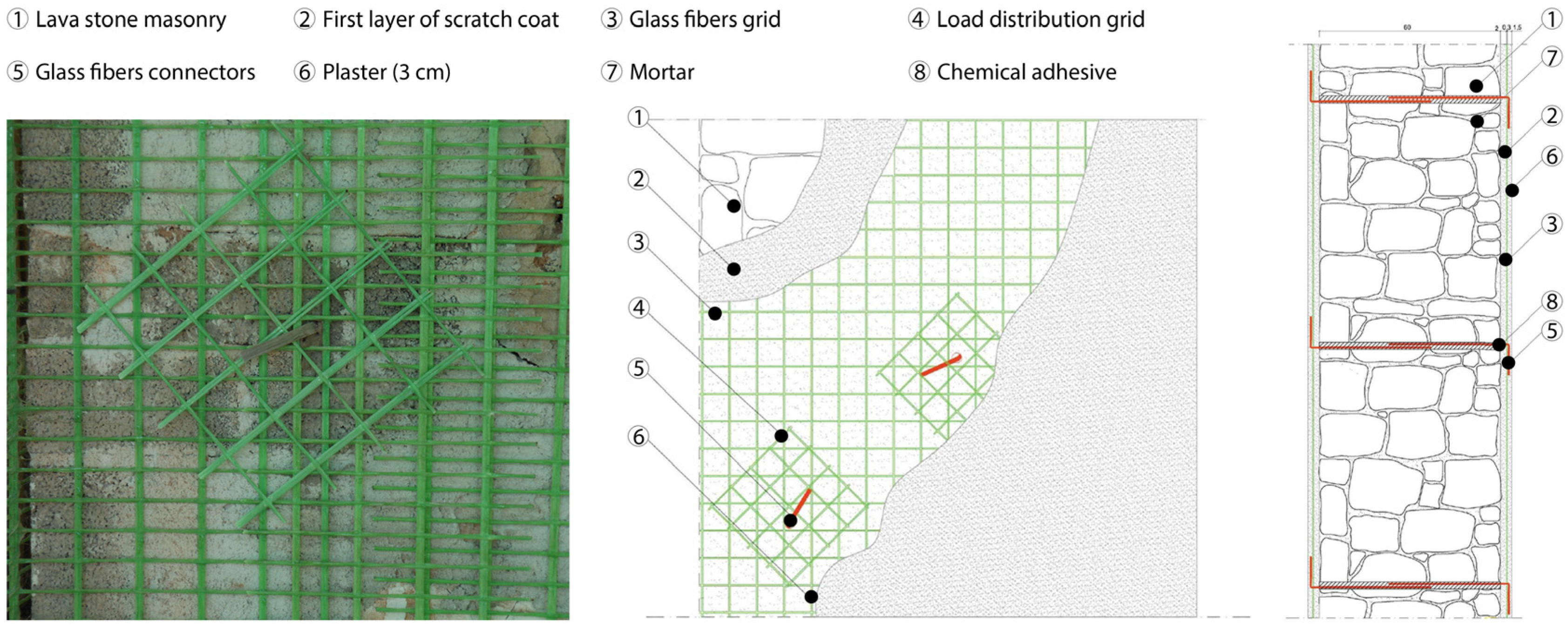

2. The Consolidation Intervention by Using Glass Fiber

- oxidation resistance of glass fibers;

- compatibility of the lime mortars with the historical walls;

- reduced thickness of the mesh, which allows the optimal positioning of the net in the original structures;

- non-magnetic property which avoids any interference problems with electro-magnetic fields;

- low maintenance requirements.

3. Materials and Methods

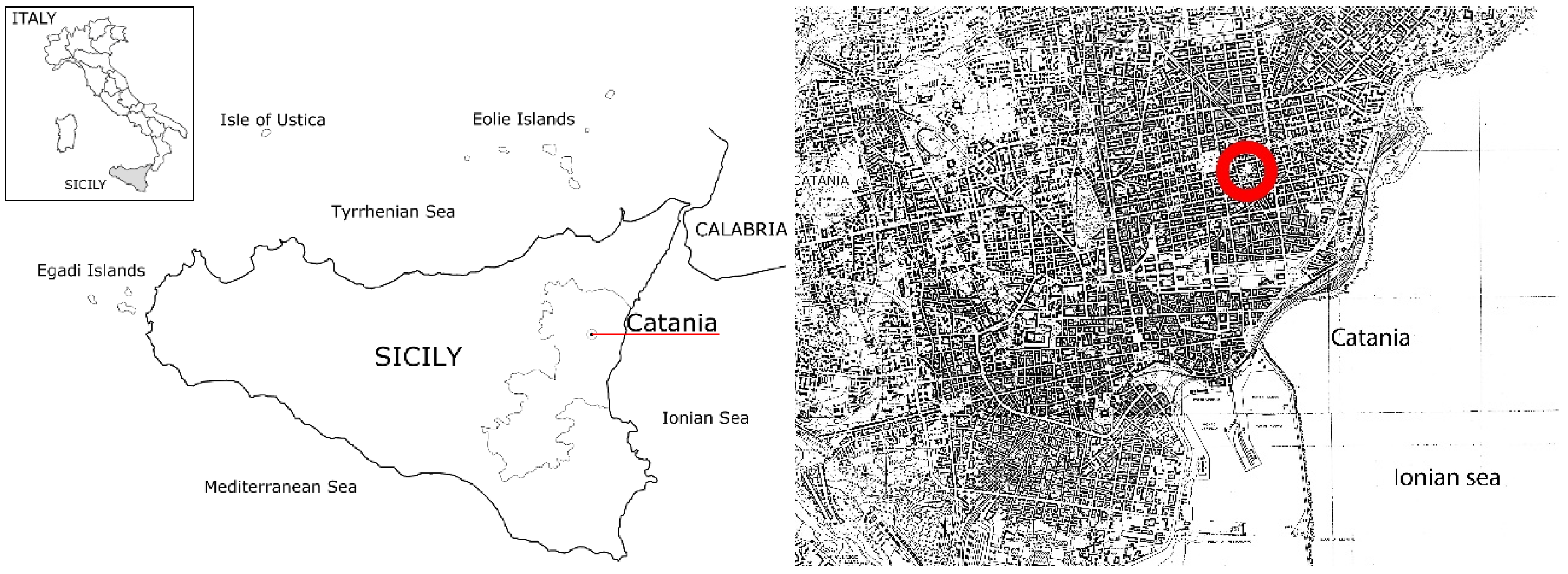

3.1. The Historical Building Object of the Research Study

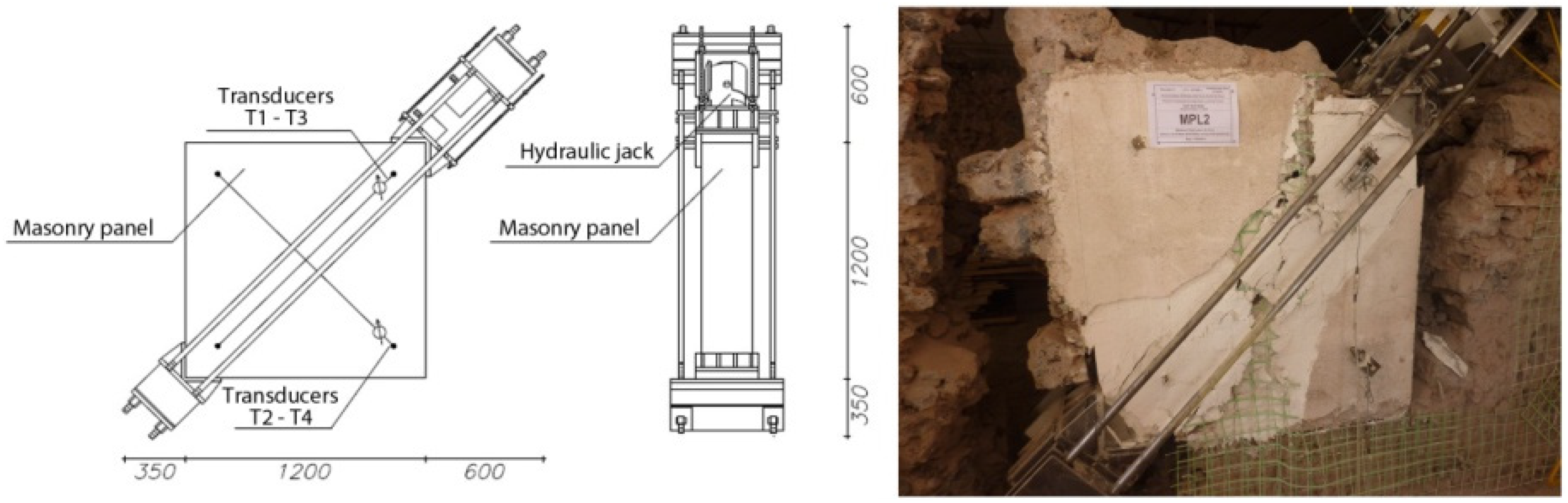

3.2. Test Methodology

4. Results and Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Porto, S.M.C.; Leanza, P.M.; Cascone, G. Developing interpretation plans to promote traditional rural buildings as Built Heritage Attractions. Int. J. Tour. Res. 2011, 14, 421–436. [Google Scholar] [CrossRef]

- Porto, S.M.C.; Cascone, G. A building characterization-based method for the advancement of knowledge on external architectural features of traditional rural buildings. Inf. Constr. 2013, 65, 481–496. [Google Scholar]

- Borri, A.; De Maria, A. Eurocode 8 and Italian Code. A comparison about safety levels and classification of interventions on masonry existing buildings. In Eurocode 8 Perspectives from the Italian Standpoint Workshop; Doppiavoce: Neaples, Italy, 2009; pp. 237–246. [Google Scholar]

- Giuffrè, A. Monumenti e Terremoti; Multigrafica Editrice: Rome, Italy, 1988. [Google Scholar]

- Giuffrè, A. Studi e interventi sull’edilizia storica. In Ingegneria Antisismica; Gavarini, C., Giuffrè, A., Longhi, G., Eds.; ESA: Milan, Italy, 1991. [Google Scholar]

- Giuffrè, A. Sicurezza e Conservazione dei Centri Storici; Laterza: Rome, Italy, 1993. [Google Scholar]

- Arcidiacono, C.; Porto, S.M.C.; Cascone, G. Seismic Analysis of Traditional Stone Rural Buildings: Case study of a one-storey building. Inf. Constr. 2015, 67, 481–496. [Google Scholar] [CrossRef]

- Doglioni, F.; Petrini, V.; Moretti, A. Le Chiese e Il Terremoto; LINT: Trieste, Italy, 1994. [Google Scholar]

- Doglioni, F. Codice di Pratica (Linee Guida) per la progettazione degli interventi di riparazione, miglioramento sismico e restauro dei Beni Architettonici danneggiati dal terremoto umbro-marchigiano del 1997; Bollettino Ufficiale Regione Marche: Ancona, Italy, 2000. [Google Scholar]

- Ministry of Heritage and Cultural Activities and Tourism. Linee Guida per la Valutazione e Riduzione del Rischio Sismico del Patrimonio Culturale Allineate alle Nuove Norme Tecniche per le Costruzioni (d.m. 14 Gennaio 2008); Ministry of Heritage and Cultural Activities and Tourism: Rome, Italy, 2008. [Google Scholar]

- Zanello, E. Rinforzo Strutturale e Principi Della Conservazione: Un Esempio Applicativo su Edifici in Tufo Soggetti a Vincolo. Available online: http://www.ingenio-web.it/Notizia/4821/Rinforzo_strutturale:_un_esempio_applicativo_su_edifici_in_tufo_soggetti_a_vincolo.html (accessed on 12 April 2016).

- Borri, A.; Corradi, M.; Vignoli, A. Seismic upgrading of masonry structures with FRP. In Proceedings of the 7th International Conference on “Inspection Appraisal Repairs and Maintenance of Buildings and Structures”, Nottingham, UK, 11–13 September 2001.

- Pearson, M.; Donchev, T.; Limbachiya, M. An investigation into the sustainability of FRP reinforcement bars. In Proceedings of the Fourth International Conference on Durability and Sustainability of Fiber-Reinforced Polymer (FRP) Composites for Construction and Rehabilitation, Quebec, QC, Canada, 20–22 July 2011.

- GangaRao, H.; Ruifeng, L. Advanced fiber reinforced polymer composites for sustainable civil infrastructures. Available online: http://www.civil.ist.utl.pt/~cristina/RREst/Aulas_Apresentacoes/07_Bibliografia/construcao%20terra%20%28earth%20construction%29/5%20FINAL%20hota_paper_keynote.pdf (accessed on 12 April 2016).

- Liberatore, D. Progetto Catania: Indagine Sulla Risposta Sismica di Due Edifici in Muratura; CNR—Gruppo Nazionale per la Difesa dai Terremoti: Rome, Italy, 2000. [Google Scholar]

- Leanza, P.; Porto, S.; Sapienza, V.; Cascone, S. A heritage interpretation-based itinerary to enhance tourist use of traditional rural buildings. Sustainability 2016, 8, 1–19. [Google Scholar] [CrossRef]

- Lee, L.; Estrada, H. Composite primer. In The International Handbook of FRP Composites in Civil Engineering; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar]

- Credali, L. L’impiego Delle Tecnologie FRP Nel Recupero Strutturale di Edifici Storici. Available online: http://www.betontex.it/wp-content/uploads/2015/01/Articolo-Convegno-Alba_20.02.08.pdf (accessed on 12 April 2016).

- Keller, T. Utilizzo Mirato di Compositi in FRP in Edilizia e Nella Costruzione di Ponti; Istituto Federale Svizzero di Tecnologia: Losanna, Italy, 2014; Available online: http://www.betontex.it/wp-content/uploads/2015/01/Articolo-Convegno-Alba_20.02.08.pdf (accessed on 12 April 2016).

- Jain, R.; Lee, L. Fiber reinforced polymer (FRP) composites for infrastructure applications: Focusing on innovation. In Technology Implementation and Sustainability; Springer Science & Business Media: New York, NY, USA, 2012. [Google Scholar]

- AVK–Federation of Reinforced Plastics. Sustainability of Fibre-Reinforced Plastics: An Assessment Based on Selected Examples of Application; AVK Report; AVK: Frankfurt am Main, Germany, 2010. [Google Scholar]

- Motavalli, M. Externally bonded FRP composite system for rehabilitation. In The International Handbook of FRP Composites in Civil Engineering; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar]

- Bakis, C.; Bank, L.; Brown, V.; Cosenza, E.; Davalos, J.; Lesko, J.; Machida, A.; Rizkalla, S.; Triantafillou, T. Fiber-reinforced polymer composites for construction—State-of-the-art review. J. Compos. Constr. 2012, 6, 73–87. [Google Scholar] [CrossRef]

- Hamed, E.; Chang, Z.; Rabinovitch, O. Strengthening of reinforced concrete arches with externally bonded composite materials: Testing and analysis. J. Compos. Constr. 2014, 6, 73–87. [Google Scholar] [CrossRef]

- Carmelo e Salvatore Sciuto-Patti, Archivi di Architettura Tra ’800 e ’900, Exhibition, Cured by Cultural Heritage of Catania. 2015. Available online: http://www.regione.sicilia.it/beniculturali/dirbenicult/areariservata/eventi/eventipubblicati/reportEventi.asp?cod=2779 (accessed on 12 April 2016).

- Sapienza, V. Residenze in Villa a Catania, tra Ottocento e Novecento; Il Lunario: Enna, Italy, 2004. [Google Scholar]

- Comite Europeen de Normalisation (CEN). ENV 1998-1 Eurocode 8: Design of Structures for Earthquake Resistance. Part 1: General Rules, Seismic Actions and Rules for Buildings; Comite Europeen de Normalisation: Brussels, Belgium, 2004. [Google Scholar]

- Binda, L.; Penazzi, D.; Mirabella Roberti, G.; Baronio, G.; Tedeschi, C.; Tiraboschi, C. Indagini per la caratterizzazione dei materiali. In Proceedings of the 9th National Congress on “L’ingegneria sismica in Italia”, Turin, Italy, 20–23 October 1999.

- Borri, A.; Corradi, M.; Vignoli, A. Il problema della valutazione della resistenza a taglio della muratura mediante prove sperimentali. In Proceedings of the X National Congress “L’Ingegneria Sismica in Italia”, Potenza-Matera, Italy, 9–13 September 2001.

- Sapienza, V. Le murature tradizionali nell’area etnea: Modi costruttivi e consistenza materica. Recuper. Conserv. 2008, 84, 46–51. [Google Scholar]

- Margani, L. Le Murature Antiche e Principi di Forma, Geometria, Decorazione, Costruzione, Stabilità; Lussografica: Caltanissetta, Italy, 2013. (In Italian) [Google Scholar]

- Mas Guindal, A. La concepción estructural de la fábrica en la arquitectura. Inf. Constr. 2005, 56, 3–12. [Google Scholar] [CrossRef]

- De Maria, A.; Donà, C.; Borri, A. Manuale delle Murature Storiche; DEI: Rome, Italy, 2011. (In Italian) [Google Scholar]

| Condition | Results | |||

|---|---|---|---|---|

| Pmax (kN) | σl,max (Mpa) | τ0 (Mpa) | ||

| Lava stone masonry | Unreinforced | 83.10 | 0.056 | 0.037 |

| Reinforced with FRP | 239.46 | 0.162 | 0.108 | |

| Results of Tests | σc (N/mm2) | fct (N/mm2) | Em (N/mm2) | Coeff. Poisson |

|---|---|---|---|---|

| 5.2 | 0.64 | 5332 | 0.17 | |

| TYPE | Fiber-reinforced, thixotropic, shrinkage compensated, hydraulic lime mortar with pozzolanic aggregates, conforming to the standards UNI EN 480-5 and UNI EN 459-1 | |||

| COMPOSITION | 20% Silica, alumina (SxAyHz); 10% Calcium silicate (Ca2SiO4) 42% Calcium hydroxide (Ca(OH)2); 28% Calcium carbonate (CaCO3) | |||

| Building | Masonry Type | Condition | Results | Reinforce Technology Type | ||

|---|---|---|---|---|---|---|

| Pmax (kN) | σl,max (Mpa) | τ0 (Mpa) | ||||

| Aquila, Italy. Location: Porta Napoli | White compact and just hewn stones | Unreinforced | 44.51 | 0.039 | 0.026 | - |

| Reinforced | 200.81 | 0.152 | 0.102 | 2 | ||

| Reinforced | 184.47 | 0.139 | 0.092 | 3 | ||

| Montefalco, Italy. Location: Turrita | Double layer masonry of just hewn stones (pink limestone) | Unreinforced | - | 0.029 | 0.019 | - |

| Reinforced | - | 0.066 | 0.044 | 4 | ||

| Foligno, Italy. Location: Pale | Double layer masonry of just hewn stones (white limestone) | Unreinforced | - | 0.017 | 0.011 | - |

| Reinforced | - | 0.044 | 0.029 | 5 | ||

| Reinforced | - | 0.027 | 0.018 | 6 | ||

| Trevi, Italy. Location: Trevi’s Shop | Double layer masonry of just hewn stones (pink limestone) | Unreinforced | - | 0.035 | 0.023 | - |

| Reinforced | - | 0.063 | 0.042 | 1 | ||

| Reinforced | - | 0.071 | 0.047 | 4 | ||

| Reinforced | - | 0.039 | 0.026 | 6 | ||

| Foligno, Italy. Location: ex-Hospital | Double layer masonry of just hewn stones (pink limestone) | Unreinforced | - | 0.033 | 0.022 | - |

| Reinforced | - | 0.089 | 0.059 | 5 | ||

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cascone, S.M.; Sapienza, V.; Lionti, I.; Porto, S.M.C. Fiber-Reinforced Polymer Nets for Strengthening Lava Stone Masonries in Historical Buildings. Sustainability 2016, 8, 394. https://doi.org/10.3390/su8040394

Cascone SM, Sapienza V, Lionti I, Porto SMC. Fiber-Reinforced Polymer Nets for Strengthening Lava Stone Masonries in Historical Buildings. Sustainability. 2016; 8(4):394. https://doi.org/10.3390/su8040394

Chicago/Turabian StyleCascone, Santi Maria, Vincenzo Sapienza, Irene Lionti, and Simona Maria Carmela Porto. 2016. "Fiber-Reinforced Polymer Nets for Strengthening Lava Stone Masonries in Historical Buildings" Sustainability 8, no. 4: 394. https://doi.org/10.3390/su8040394