Liner Shipping Fleet Deployment with Sustainable Collaborative Transportation

Abstract

:1. Introduction

2. Literature Review

3. Problem Description

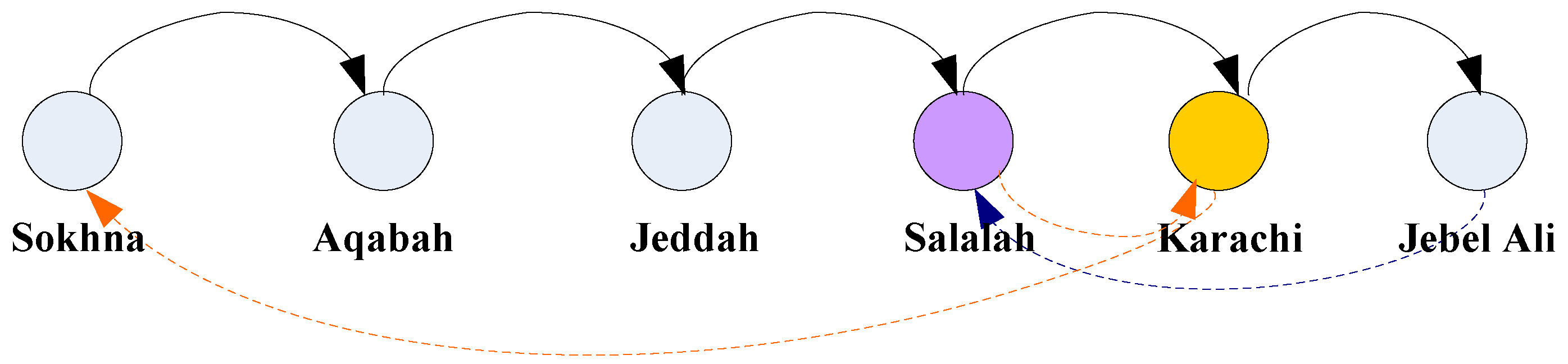

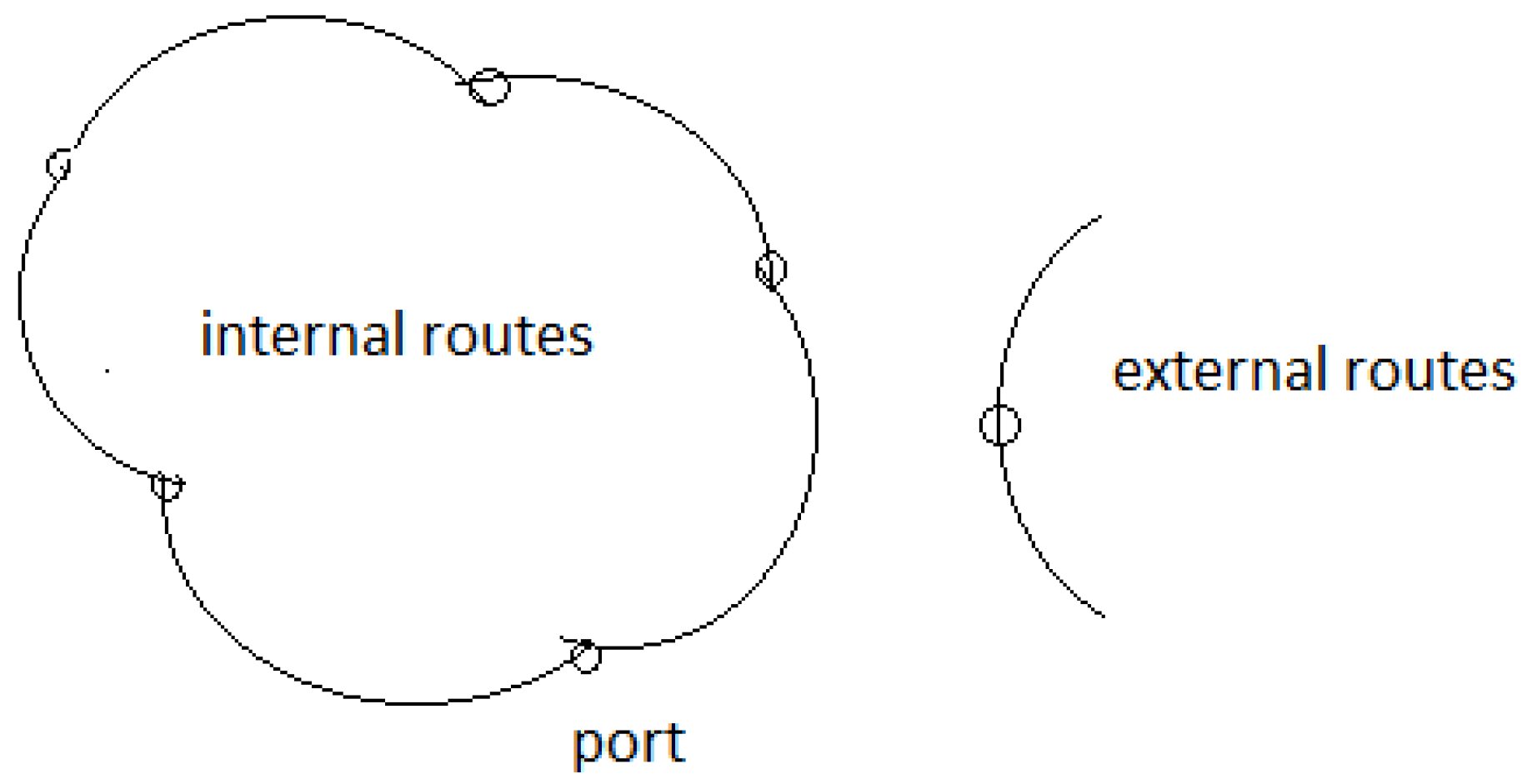

3.1. Liner Shipping Route of Traditional Transportation

3.2. Liner Shipping Route with Collaborative Transportation

4. Model Formulation

4.1. Assumptions

- (1)

- We assume that the hub ports and the ship routes are given in advance.

- (2)

- We suppose that the demand is fixed.

- (3)

- In order to take collaborative transportation into consideration, we assume that ships can be transported at any ports.

- (4)

- In collaborative transportation, we assume that there would be no empty containers.

- (5)

- Finally, we make a selection between the internal routes and the external routes to serve each task by comparing the distances, as well as costs between the above routes in collaborative transportation.

4.2 Decision Variables

4.3. Parameters

4.4. Objective Function

4.5. Constraints

4.6. Input and Output Parameters

5. Numerical Experimentation and Analysis

5.1. The Data Description

| Type of the Ship (Twenty Feet Equivalent Units, TEUs) | 3000 | 5000 | 10,000 |

|---|---|---|---|

| Fixed operating cost (1,000USDs/week) | 76.9 | 115.3 | 173.1 |

| Productivity (moves/hour) | 70 | 95 | |

| Fixed charge ($) | 12,000 | 20,000 | |

| Speed (knots) | 18.9 | 22.5 | 26 |

| Bunker cost (USDs/n mile) | 72 | 78 | 100 |

| Berth occupancy charge (USDs) | 1000 | 1666 | 3333 |

| Fixed cost for calling at a port (USDs/h) | 5477 | 7071 | 10,000 |

| Fixed time when calling at a port (h) | 4 | 4 | 4 |

| Container handling time (h/TEU) | 1/85 | 1/95 | 1/120 |

| Company | Shipping Routes |

|---|---|

| A | 1. Chittagong—Chennai—Colombo—Cochin—Nhava Sheva—Cochin—Colombo—Chennai—Chittagong 2. Southampton—Thamesport—Hamburg—Bremerhaven—Rotterdam—Antwerp—Zeebrugge—Le Havre—Southampton 3. Sokhna—Aqabah—Jeddah—Salalah—Karachi—Jebel Ali—Salalah—Sokhna 4. Southampton—Sokhna—Salalah—Colombo—Singapore—Hong Kong—Xiamen—Shanghai—Busan—Dalian—Xingang—Qingdao—Shanghai—Hong Kong—Singapore |

| B | 5. Yokohama—Tokyo—Nagoya—Kobe—Shanghai—Hong Kong—Singapore—Hong Kong—Yokohama 6. Manila—Kaohsiung—Xiamen—Hong Kong—Yantian—Chiwan—Hong Kong—Manila 7. Yantian—Hamburg—Sokhna—Jeddah—Port Klang—Singapore—Manila—Shanghai—Yantian 8. Dalian—Hong Kong—Shanghai—Qingdao—Ningbo—Shanghai—Kwangyang—Busan—Dalian |

| C | 9. Ho Chi Minh—Laem Chabang—Singapore—Port Klang—Ho Chi Minh 10. Brisbane—Sydney—Melbourne—Adelaide—Fremantle—Colombo—Salalah—Rotterdam—Salalah—Colombo—Brisbane 11. Port Klang—Singapore—Jakarta—Kaohsiung—Busan—Kaohsiung—HongKong—Chiwan—Xingang—Port Klang—Colombo —Salalah—Southampton |

5.2. The Numerical Results

| Asia-Europe Shipping Line | Number of Shipping Routes | 3000TEUs | 5000TEUs | 10,000TEUs |

|---|---|---|---|---|

| Company A | 4 | 6 | 4 | 25 |

| Company B | 8 | 5 | 5 | 20 |

| Company C | 3 | 3 | 6 | 13 |

| Total | 11 | 14 | 15 | 58 |

| Place of Departure | Destination | Transportation Demand (Ten Thousand TEUs) | The Actual Volume (Ten Thousand TEUs) |

|---|---|---|---|

| Dalian | Hong Kong | 82 | 24 |

| Hong Kong | Qingdao | 1 | 0 |

| Shanghai | Singapore | 39 | 11 |

| Singapore | Shanghai | 1 | 0 |

| Hong Kong | Xingang | 3 | 2 |

| Xingang | Singapore | 3 | 0 |

| The Total Cost (Ten Thousand U.S. Dollars) | Total No. of Transshipment Containers | Container Transportation Volume (Million TEUs) | |

|---|---|---|---|

| Quantity | 2733.63 | 19 | 20.50 |

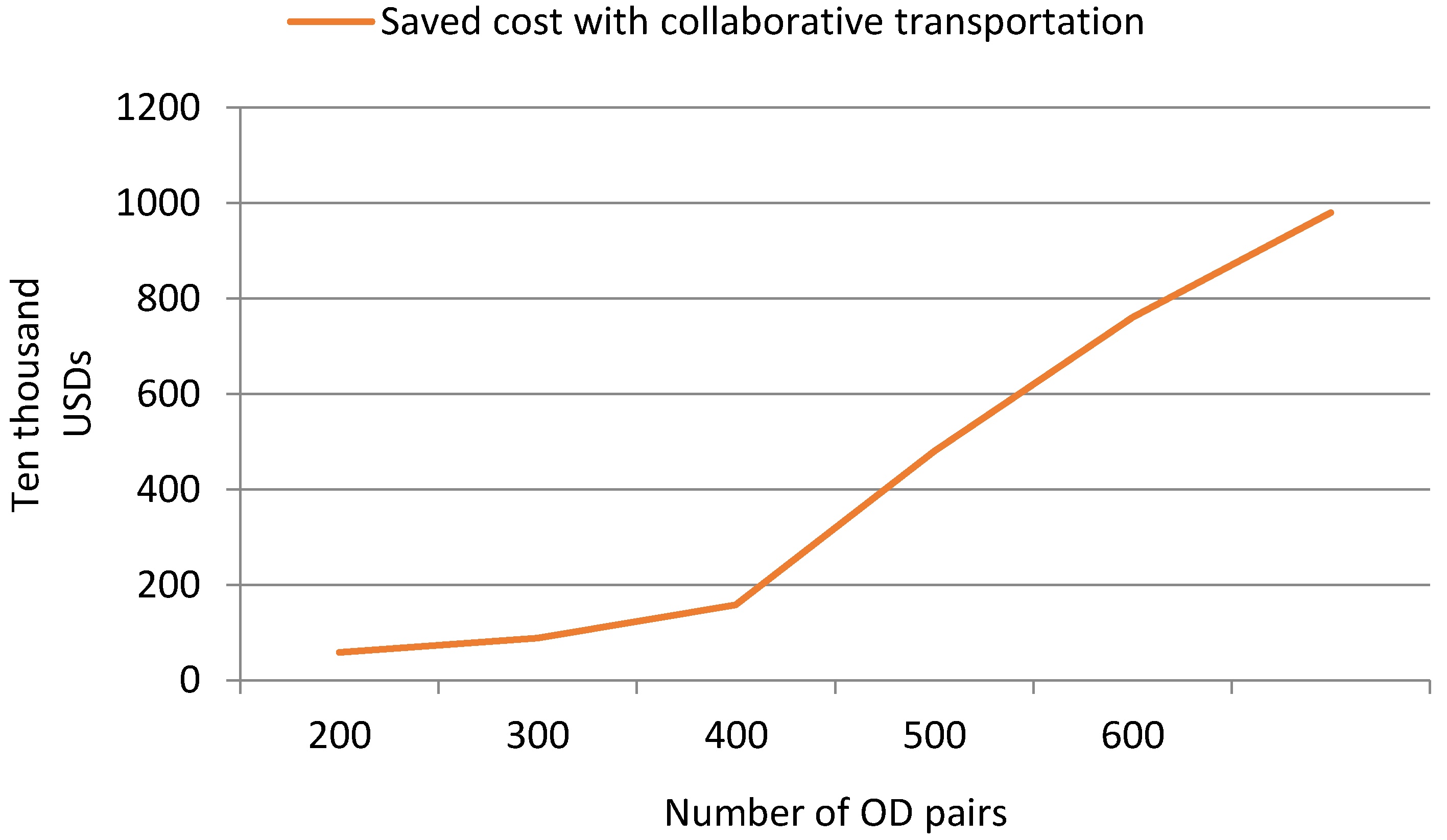

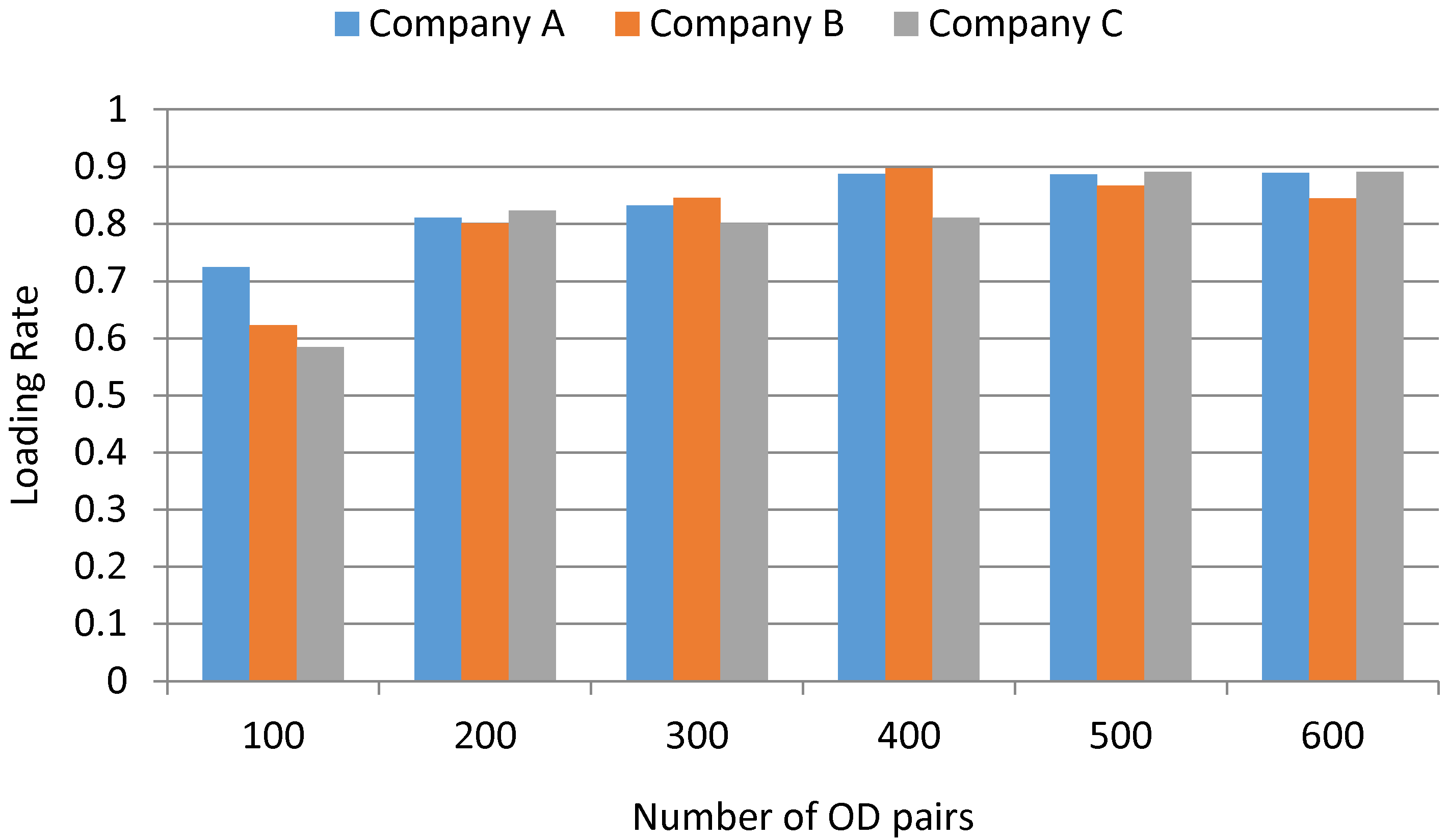

5.3. Different Container Transportation Demand Analysis

6. Conclusions and Implications

Acknowledgments

Author Contributions

Conflicts of Interest

References

- UNCTAD. Review of Maritime Transportation. In Paper Presented at the United Nations Conference on Trade and Development, New York and Geneva; Available online: http://unctad.org/en/publicationslibrary/rmt2013_en.pdf (accessed on 2 February 2016).

- Christiansen, M.; Fagerholt, K.; Nygreen, B.; Ronen, D. Ship routing and scheduling in the new millennium. Eur. J. Oper. Res. 2013, 228, 467–483. [Google Scholar] [CrossRef]

- Rana, K.; Vickson, R.G. Routing container ships using Lagrangean relaxation and decomposition. Transp. Sci. 1991, 25, 201–204. [Google Scholar] [CrossRef]

- Perakis, A.N.; Jaramillo, D.I. Fleet deployment optimization for liner shipping, Part 1: Background, problem formulation and solution approaches. Marit. Policy Manag. 1991, 18, 183–200. [Google Scholar] [CrossRef]

- Jaramillo, D.I.; Perakis, A.N. Fleet deployment optimization for liner shipping, Part 2: Implementation and results. Marit. Policy Manag. 1991, 18, 235–262. [Google Scholar] [CrossRef]

- Cho, S.C.; Perakis, A.N. Optimal liner fleet routing strategies. Marit. Policy Manag. 1996, 23, 249–259. [Google Scholar] [CrossRef]

- Agarwal, R.; Ergun, Ö. Mechanism design for a multicommodity flow game in service network alliances. Oper. Res. Lett. 2008, 36, 520–524. [Google Scholar] [CrossRef]

- Agarwal, R.; Ergun, Ö. Ship scheduling and network design for cargo routing in liner shipping. Transp. Sci. 2008, 42, 175–196. [Google Scholar] [CrossRef]

- Alvarez, J.F. Joint routing and deployment of a fleet of container vessels. Marit. Econ. Logist. 2009, 11, 186–208. [Google Scholar] [CrossRef]

- Meng, Q.; Wang, T. A chance constrained programming model for short-term liner ship fleet planning problem. OR Spectr. 2010, 37, 327–446. [Google Scholar] [CrossRef]

- Wang, S.; Meng, Q. Liner ship fleet deployment with container transshipment operations. Transp. Res. Part E Logist. Transp. Rev. 2012, 48, 470–484. [Google Scholar] [CrossRef]

- Wang, S.; Meng, Q. Schedule design and container routing in liner shipping. Transp. Res. Rec. 2011, 2222, 25–33. [Google Scholar] [CrossRef]

- Gelareh, S.; Nickel, S.; Pisinger, D. Liner shipping hub network design in a competitive environment. Transp. Res. Part E Logist. Transp. Rev. 2010, 46, 991–1004. [Google Scholar] [CrossRef]

- Gelareh, S.; Pisinger, D. Fleet deployment, network design and hub location of liner shipping companies. Transp. Res. Part E Logist. Transp. Rev. 2011, 47, 947–964. [Google Scholar] [CrossRef]

- Gelareh, S.; Maculan, N.; Mahey, P.; Monemi, R.N. Hub-and-spoke network design and fleet deployment for string planning of liner shipping. Appl. Math. Model. 2013, 37, 3307–3321. [Google Scholar] [CrossRef]

- Brouer, B.D.; Desaulniers, G.; Pisinger, D. A matheuristic for the liner shipping network design problem. Transp. Res. Part E Logist. Transp. Rev. 2014, 72, 42–59. [Google Scholar] [CrossRef]

- Brouer, B.; Alvarez, J.F.; Plum, C.; Pisinger, D.; Sigurd, M. A base integer programming model and benchmark suite for liner shipping network design. Transp. Sci. 2014, 48, 281–312. [Google Scholar] [CrossRef] [Green Version]

- Plum, C.E.M.; Pisinger, D.; Sigurd, M.M. A service flow model for the liner shipping network design problem. Eur. J. Oper. Res. 2014, 235, 378–386. [Google Scholar] [CrossRef]

- Zheng, J.; Meng, Q.; Sun, Z. Impact analysis of maritime cabotage legislations on liner hub-and-spoke shipping network design. Eur. J. Oper. Res. 2014, 234, 874–884. [Google Scholar] [CrossRef]

- Mulder, J.; Dekker, R. Methods for strategic liner shipping network design. Eur. J. Oper. Res. 2014, 235, 367–377. [Google Scholar] [CrossRef] [Green Version]

- Lin, D.Y.; Tsai, Y.Y. The ship routing and freight assignment problem for daily frequency operation of maritime liner shipping. Transp. Res. Part E Logist. Transp. Rev. 2014, 67, 52–70. [Google Scholar] [CrossRef]

- Wang, S.; Liu, Z.; Meng, Q. Segment-based alteration for container liner shipping network design. Transp. Res. Part B Methodol. 2015, 72, 128–145. [Google Scholar] [CrossRef]

- Song, D.P.; Li, D.; Drake, P. Multi-objective optimization for planning liner shipping service with uncertain port time. Transp. Res. Part E: Logist. Transp. Rev. 2015, 84, 1–22. [Google Scholar] [CrossRef]

- Wang, S.; Meng, Q. Robust bunker management for liner shipping networks. Eur. J. Oper. Res. 2015, 243, 789–797. [Google Scholar] [CrossRef]

- Karsten, C.V.; Pisinger, D.; Ropke, S.; Brouer, B. The time constrained multi-commodity network flow problem and its application to liner shipping network design. Transp. Res. Part E Logist. Transp. Rev. 2015, 76, 122–138. [Google Scholar] [CrossRef] [Green Version]

- Meng, Q.; Wang, S. Liner shipping service network design with empty container repositioning. Transp. Res. Part E 2011, 47, 695–708. [Google Scholar] [CrossRef]

- Meng, Q.; Wang, S.; Andersson, H.; Thun, K. Containership routing and scheduling in liner shipping: Overview and future research directions. Transp. Sci. 2014, 48, 265–280. [Google Scholar] [CrossRef]

- Wang, S.; Wang, T.; Meng, Q. A note on liner ship fleet deployment. Flex. Serv. Manuf. J. 2011, 23, 422–430. [Google Scholar] [CrossRef]

- Meng, Q.; Wang, T.; Wang, S. Multi-period liner ship fleet planning with dependent uncertain container shipment demand. Marit. Policy Manag. 2015, 42, 43–67. [Google Scholar] [CrossRef]

- Ergun, O.; Kuyzu, G.; Savelsbergh, M. Reducing truckload transportation costs through collaboration. Transp. Sci. 2007, 41, 206–221. [Google Scholar] [CrossRef]

- Asawasakulsorn, A. Transportation collaboration: Partner selection criteria and interorganizational system design issues for supporting trust. Int. J. Bus. Inf. 2009, 4, 199–220. [Google Scholar]

- Audy, J.F.; D’Amours, S.; Rousseau, L.M. Cost allocation in the establishment of a collaborative transportation agreement—An application in the furniture industry. J. Oper. Res. Soc. 2011, 62, 960–970. [Google Scholar] [CrossRef]

- Yilmaz, O.; Savasaneril, S. Collaboration among small shippers in a transportation market. Eur. J. Oper. Res. 2012, 218, 408–415. [Google Scholar] [CrossRef]

- Guajardo, M.; Ronnqvist, M. Operations research models for coalition structure in collaborative logistics. Eur. J. Oper. Res. 2015, 240, 147–159. [Google Scholar] [CrossRef]

- Ergun, O.; Kuyzu, G.; Savelsbergh, M. Shipper collaboration. Comput. Oper. Res. 2007, 34, 1551–1560. [Google Scholar] [CrossRef]

- Houghtalen, L.M. Designing allocation mechanisms for carrier alliances. Georgia Institute of Technology 2007. [Google Scholar]

- Meyer, M.; Campbell, S.; Leach, D.; Coogan, M. Collaboration: The key to success in transportation. Transp. Res. Rec. J. Transp. Res. Board 2005, 1924, 153–162. [Google Scholar]

- Agarwal, R.; Ergun, Ö. Network design and allocation mechanisms for carrier alliances in liner shipping. Oper. Res. 2010, 58, 1726–1742. [Google Scholar] [CrossRef]

- Liu, R.; Jiang, Z.; Fung, R.Y.K.; Chen, F.; Liu, X. Two-phase Heuristic Algorithms for Full Truckloads Multi-depot Capacitated Vehicle Routing Problem in Carrier Collaboration. Comput. Oper. Res. 2010, 37, 950–959. [Google Scholar] [CrossRef]

- Hernández, S.; Peeta, S.; Kalafatas, G. A less-than-truckload carrier collaboration planning problem under dynamic capacities. Transp. Res. Part E Logist. Transp. Rev. 2011, 47, 933–946. [Google Scholar] [CrossRef]

- Hernández, S.; Unnikrishnan, A.; Awale, S. Centralized Carrier Collaboration Multihub Location Problem for Less-Than-Truckload Industry: Hybrid Hub-and-Spoke Network. Transp. Res. Rec. J. Transp. Res. Board 2012, 2269, 20–28. [Google Scholar] [CrossRef]

- Özener, O.Ö.; Ergun, Ö. Allocating costs in a collaborative transportation procurement network. Transp. Sci. 2008, 42, 146–165. [Google Scholar] [CrossRef]

- Lim, A.; Rodrigues, B.; Xu, Z. Transportation procurement with seasonally varying shipper demand and volume guarantees. Operat. Res. 2008, 56, 758–771. [Google Scholar] [CrossRef]

- Audy, J.F.; D’Amours, S. Impact of Benefit Sharing among Companies in the Implantation of A Collaborative Transportation System—An Application in the Furniture Industry. In Pervasive Collaborative Networks; Springer: New York, NY, USA, 2008; pp. 519–532. [Google Scholar]

- Chan, F.T.S.; Zhang, T. The impact of Collaborative Transportation Management on supply chain performance: A simulation approach. Expert Syst. Appl. 2011, 38, 2319–2329. [Google Scholar] [CrossRef]

- Dai, B.; Chen, H. Profit allocation mechanisms for carrier collaboration in pickup and delivery service. Comput. Ind. Eng. 2012, 62, 633–643. [Google Scholar] [CrossRef]

- Lozano, S.; Moreno, P.; Adenso-Díaz, B.; Algaba, E. Cooperative game theory approach to allocating benefits of horizontal cooperation. Eur. J. Oper. Res. 2013, 229, 444–452. [Google Scholar] [CrossRef]

- Wang, X.; Kopfer, H. Collaborative transportation planning of less-than-truckload freight. OR Spectr. 2014, 36, 357–380. [Google Scholar] [CrossRef]

- Dao, S.D.; Abhary, K.; Marian, R. Optimisation of partner selection and collaborative transportation scheduling in Virtual Enterprises using GA. Expert Syst. Appl. 2014, 41, 6701–6717. [Google Scholar] [CrossRef]

- Li, J.; Rong, G.; Feng, Y. Request selection and exchange approach for carrier collaboration based on auction of a single request. Transp. Res. Part E Logist. Transp. Rev. 2015, 84, 23–39. [Google Scholar]

- Zhou, G.; Van Hui, Y.; Liang, L. Strategic alliance in freight consolidation. Transp. Res. Part E Logist. Transp. Rev. 2011, 47, 18–29. [Google Scholar] [CrossRef]

- Ryoo, D.K.; Thanopoulou, H.A. Liner alliances in the globalization era: a strategic tool for Asian container carriers. Marit. Policy Manag. 1999, 26, 349–367. [Google Scholar] [CrossRef]

- Slack, B.; Comtois, C.; McCalla, R. Strategic alliances in the container shipping industry: a global perspective. Marit. Policy Manag. 2002, 29, 65–76. [Google Scholar] [CrossRef]

- Song, D.W.; Panayides, P.M. A conceptual application of cooperative game theory to liner shipping strategic alliances. Marit. Policy Manag. 2002, 29, 285–301. [Google Scholar] [CrossRef]

- Yang, D.; Liu, M.; Shi, X. Verifying liner shipping alliance’s stability by applying core theory. Res. Transp. Econ. 2011, 32, 15–24. [Google Scholar] [CrossRef]

- Hwang, T.; Ouyang, Y. Urban Freight Truck Routing under Stochastic Congestion and Emission Considerations. Sustainability 2015, 7, 6610–6625. [Google Scholar] [CrossRef]

- Staš, D.; Lenort, R.; Wicher, P.; Holman, D. Green Transport Balanced Scorecard Model with Analytic Network Process Support. Sustainability 2015, 7, 15243–15261. [Google Scholar] [CrossRef]

- Agarwal, R.; Ergun, Ö.; Houghtalen, L. Collaboration in Cargo Transportation. In Optimization and Logistics Challenges in the Enterprise; Springer: Berlin, Germany, 2009; pp. 373–409. [Google Scholar]

- Fugate, B.S.; Davis-Sramek, B.; Goldsby, T.J. Operational collaboration between shippers and carriers in the transportation industry. Int. J. Logist. Manag. 2009, 20, 425–447. [Google Scholar] [CrossRef]

- Zheng, J.; Gao, Z.; Yang, D.; Sun, Z. Network design and capacity exchange for liner alliances with fixed and variable container demands. Transp. Sci. 2015, 49, 886–899. [Google Scholar] [CrossRef]

- Zhang, W.; Lu, J.; Xu, P.; Zhang, Y. Moving towards Sustainability: Road Grades and On-Road Emissions of Heavy-Duty Vehicles—A Case Study. Sustainability 2015, 7, 12644–12671. [Google Scholar] [CrossRef]

- López-Navarro, M.Á. Environmental Factors and Intermodal Freight Transportation: Analysis of the Decision Bases in the Case of Spanish Motorways of the Sea. Sustainability 2014, 6, 1544–1566. [Google Scholar] [CrossRef]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, G.; Sun, C.; Weng, J. Liner Shipping Fleet Deployment with Sustainable Collaborative Transportation. Sustainability 2016, 8, 165. https://doi.org/10.3390/su8020165

Du G, Sun C, Weng J. Liner Shipping Fleet Deployment with Sustainable Collaborative Transportation. Sustainability. 2016; 8(2):165. https://doi.org/10.3390/su8020165

Chicago/Turabian StyleDu, Gang, Chuanwang Sun, and Jinxian Weng. 2016. "Liner Shipping Fleet Deployment with Sustainable Collaborative Transportation" Sustainability 8, no. 2: 165. https://doi.org/10.3390/su8020165