1. Introduction

The transmission tower structure is important infrastructure for the electric power supply system, which consists of conductors, overhead power lines, steel-lattice tower and lower foundation parts. In particular, lower foundation parts are key component to guarantee the sustainability and continuous serviceability of the entire transmission system. Various types of transmission tower foundations have been used depending on load and soil conditions [

1,

2,

3,

4]. When design loads are relatively small and ground condition is sufficiently favorable, inverted T-foundations or embedded footings are preferred. Deep foundations, such as piers and piles, are used when the towers are constructed in steep slope and hill areas, or in soft soils such as clays and weak reclaimed deposits [

5].

Upon continuous and dramatic increases in electricity demand, it has been a critical issue to maintain more sustainable and resilient energy supply system against various unfavorable environments such as weak ground condition. A possible option to increase the sustainability of electric transmission tower system is the use of complementary structural components that connect individual foundations placed at each corner of the tower. The connected foundation does not alter the original foundation configuration with no additional environmental destruction. Introducing connected foundation, increases in the stability of the entire structure is expected with the effects of improved mechanical performance and more sustainable energy supply capability [

1,

6].

Design guidelines of connected foundations for transmission tower structures can be found in TEPCO [

6] and IEEE [

1]. In TEPCO [

6], connection beams that are placed between foundations are regarded as rigid components and mechanical properties of connection beams are not considered in the design. IEEE [

1] specified the use of connection beams for the same purpose of increasing foundation resistance and reducing differential settlement. As in TEPCO [

6], no specific, detailed design guideline or performance of connection components is included. To clarify and fully utilize the performance of connected foundations, further investigation is required in comparison to the performance of conventional unconnected foundations.

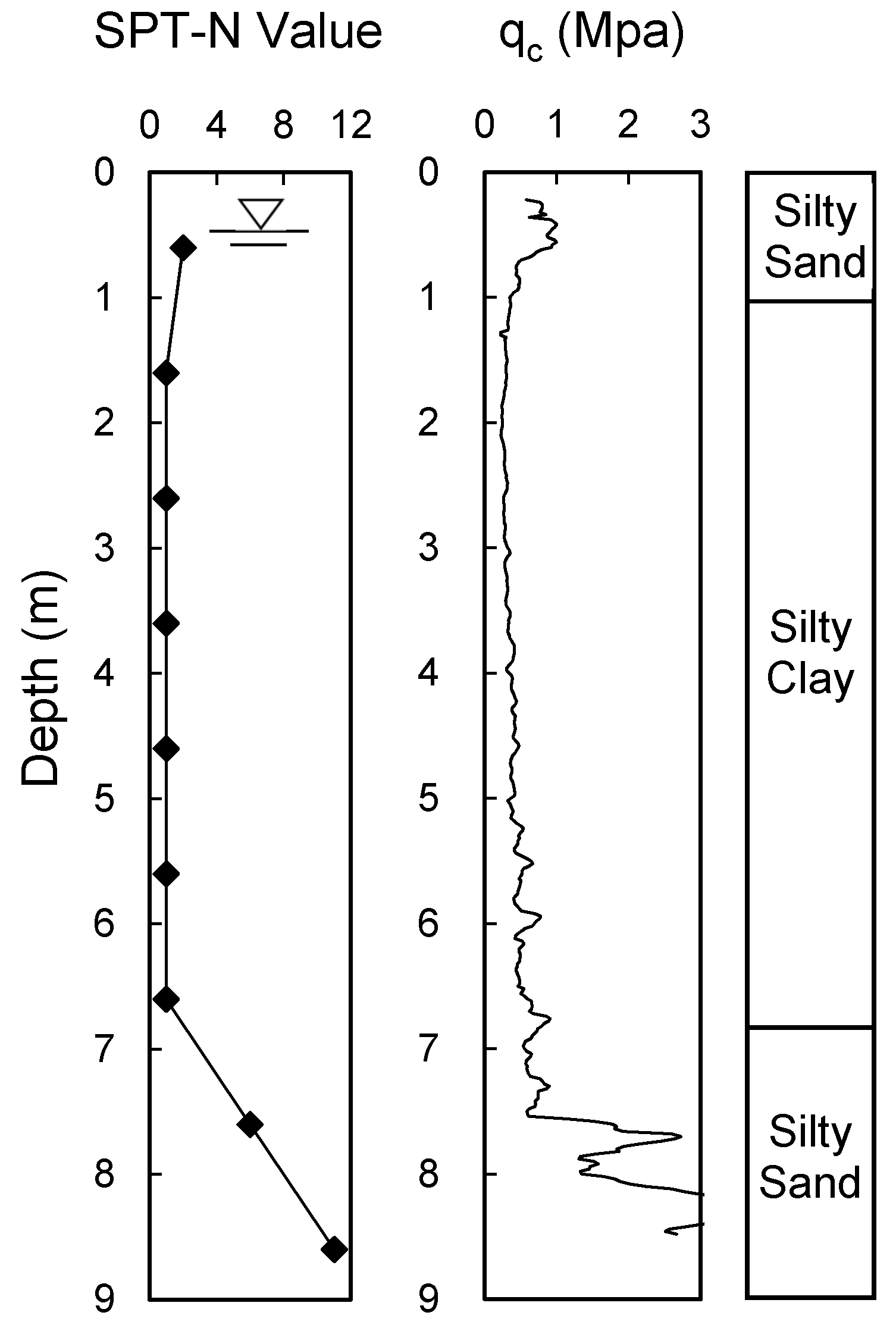

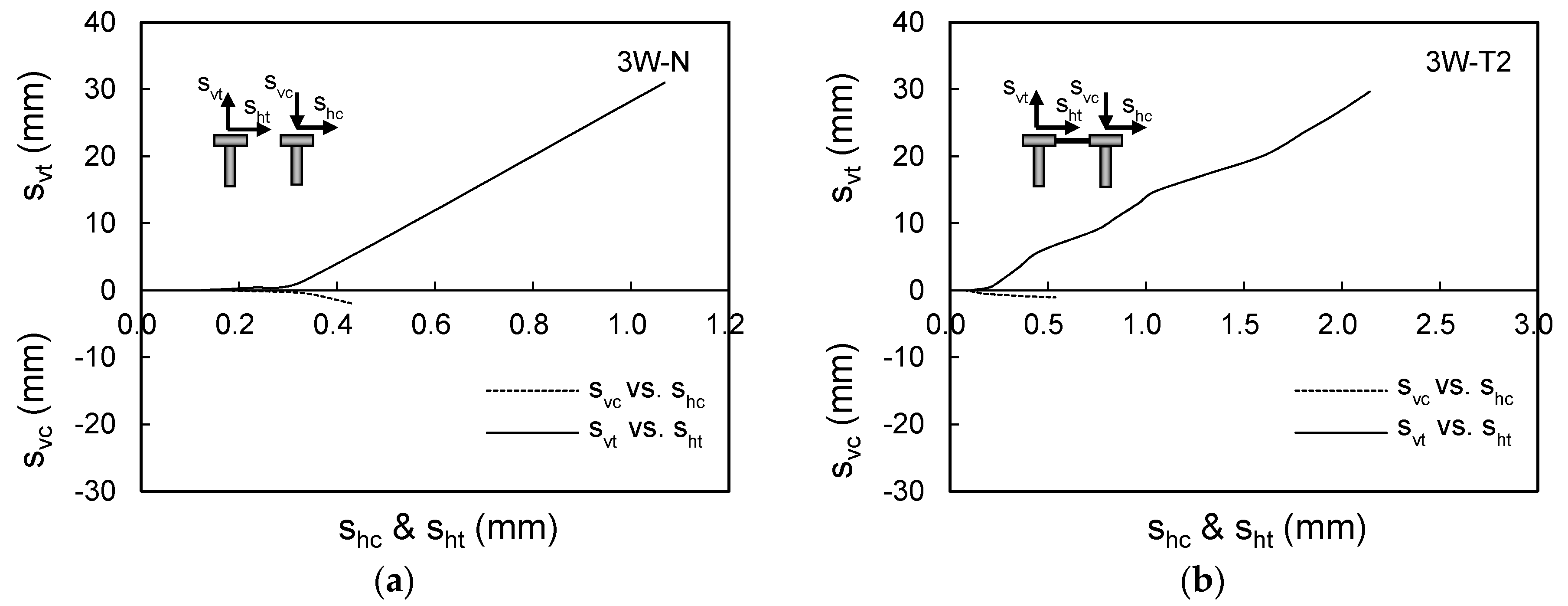

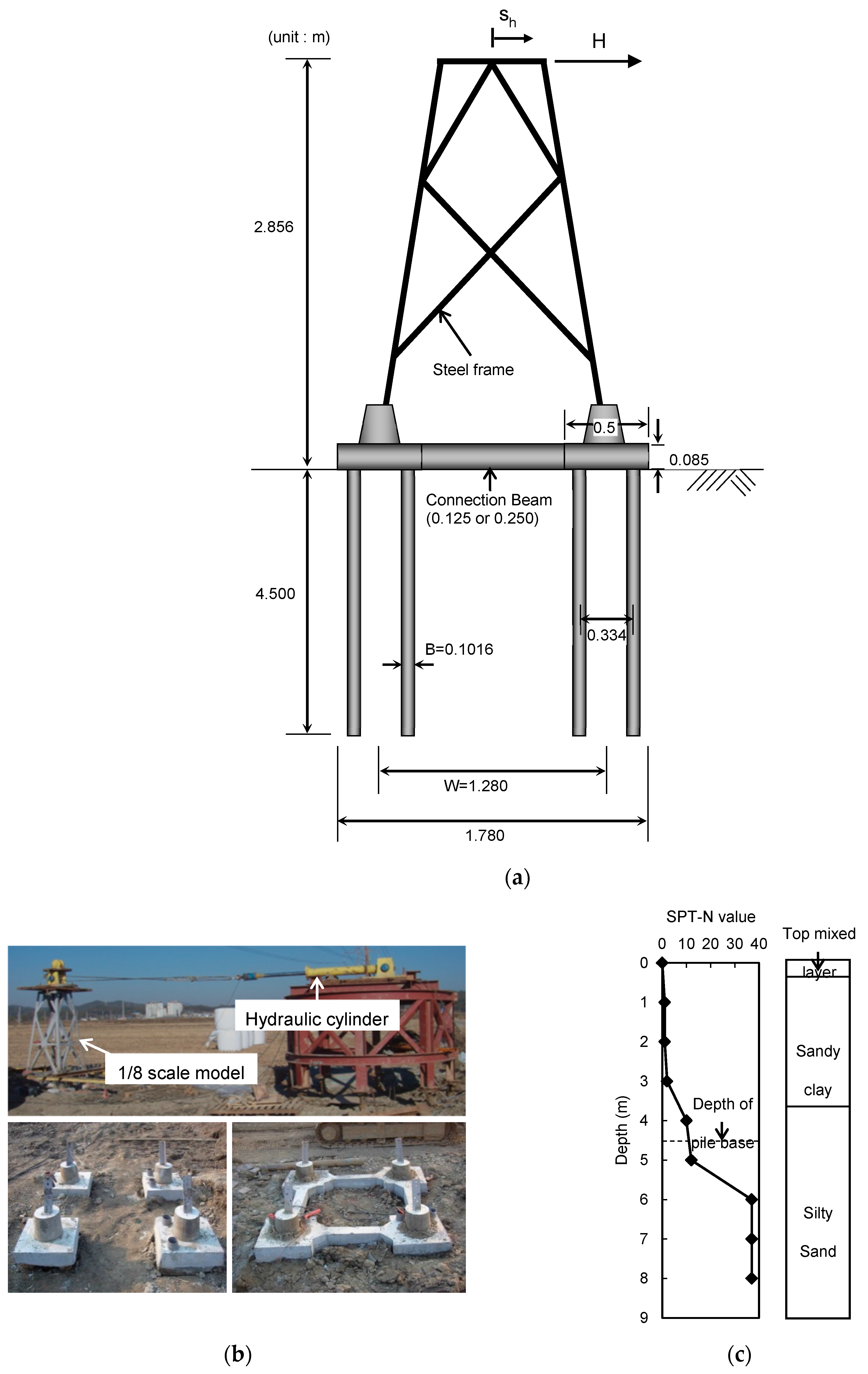

In this study, the performance of connected foundation for the electric transmission tower structures is investigated using a series of field load tests. For this purpose, model transmission tower structures using unconnected and connected foundations are manufactured and used in the field load testing program. For the model structures, connection beams with different stiffness are used to examine the effect of connection beams on overall performance of transmission tower foundations. Based on the test results, a design equation is proposed for the estimation of the load carrying capacity of connected foundations. Field load tests using the prototype models of transmission towers are also conducted to confirm the performance of connected foundations obtained from the model tests and to verify the proposed design method.

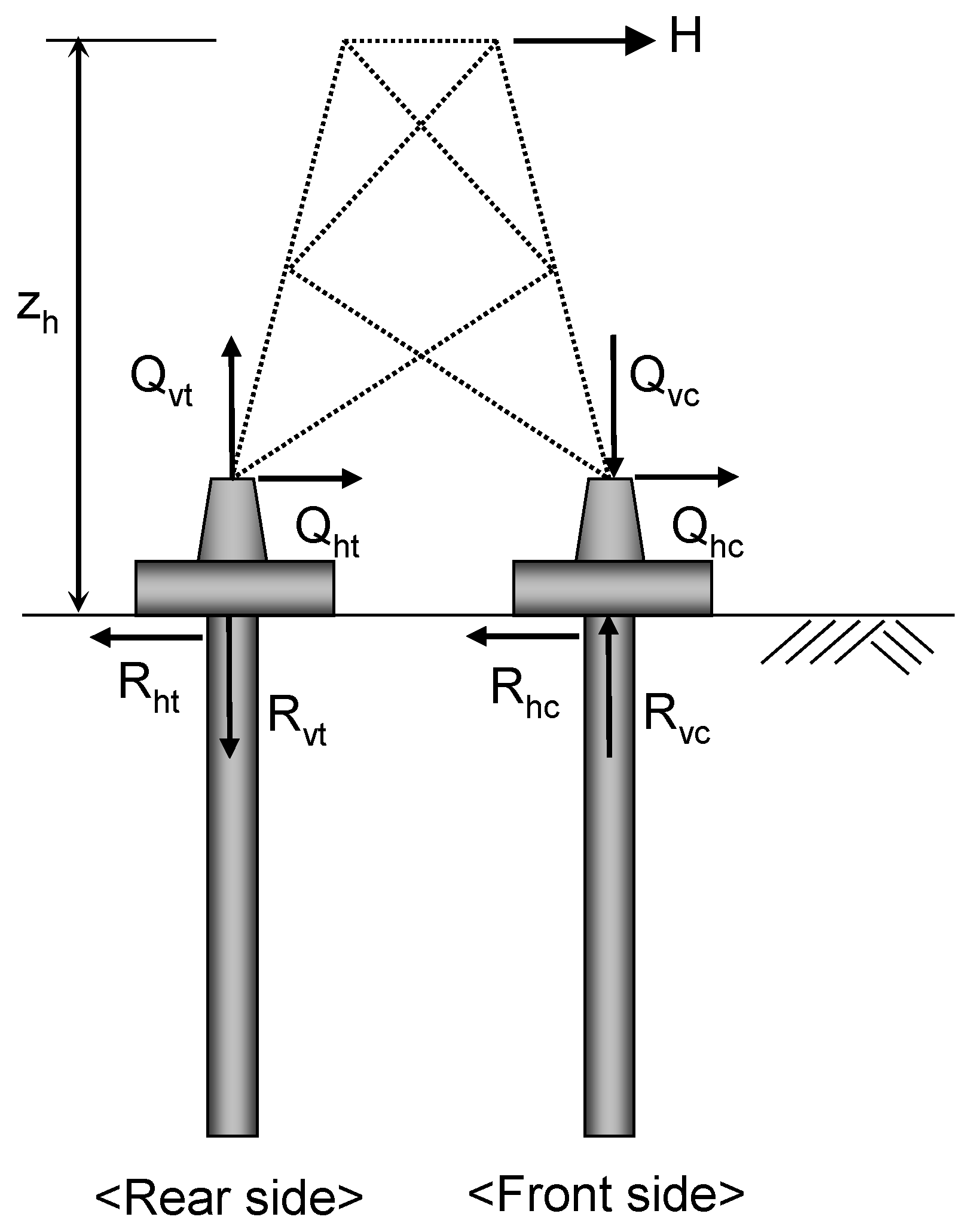

5. Design Application

As indicated in Equations (1) and (2), the maximum load (

Hu) applicable to the transmission tower is given as a function of the vertical or horizontal resistance (

Rv or

Rh) of the individual foundation components. Considering the equilibrium condition of entire structural system in

Figure 2,

Hu can be estimated as follows:

where

Rvc and

Rvt are compressive and uplift resistances, respectively;

Rhc and

Rht are horizontal resistances;

FS is factor of safety; and W and z

h are contiguous distance and load height, respectively. The smallest

Hu is determined from Equations (3)–(5), which would then control the design. For most cases of transmission tower structures,

Rvt is smallest and Equation (4) tends to control the design.

Connected foundations show higher load carrying capability due to additional resistances provided by connection beams. Increase in the uplift resistance (

Rvt) for connected foundations can then be expressed in terms of that for unconnected foundation as follows:

where

Rvt,c and

Rvt are uplift resistances of connected and unconnected foundations, respectively, and

CR is the resistance increase factor. Introducing the resistance increase factor

CR, the ultimate lateral load of Equation (4) can be rewritten as follows:

where

Hu,c is ultimate lateral load capacity for connected foundations;

Rvt is uplift resistance; and

CR is resistance increase factor.

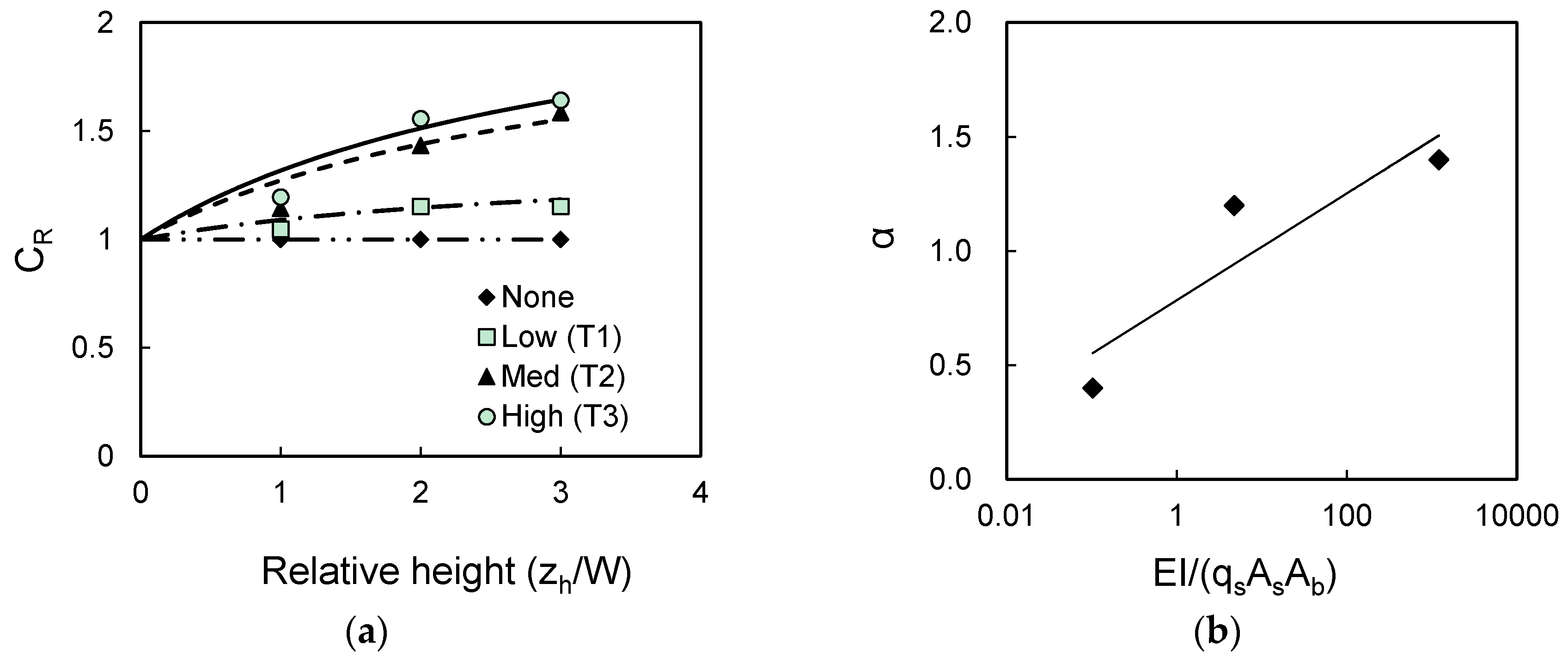

In order to evaluate the values of

CR, the correlation analysis was performed using the model load test results. Key variables adopted into the correlation analysis are load height, stiffness of connection beams, and soil condition, which were found as affecting the load carrying capability of connected foundations from the test results. The result of correlation analysis. given in

Figure 9a,b. shows the influence of load height and connection beam stiffness, respectively. From

Figure 9a, it is seen that

CR increases with connection beam stiffness and loading height. The correlation given in

Figure 9a is:

where

α is stiffness-related model parameter. The values of α were found to be 0.4, 1.2, and 1.4 for low (T1), medium (T2), and high (T3) stiffness cases, respectively, indicating variability with connection beam stiffness.

The effect of connection beam stiffness given in terms of

CR would change with soil condition as the load capacity of foundations depends on soil condition, which needs to be properly taken into account. The values of α in Equation (8) were therefore evaluated considering the connection beam stiffness (

EI) normalized with the uplift pile load capacity given by pile skin friction (

qs), pile shaft area (

As), and pile base area (

Ab). Note that

Ab and

As eventually represent the load capacity of foundation, while q

s reflect the local soil condition. The values of α were obtained from the model test results and plotted in

Figure 9b as a function of the normalized stiffness. The correlation given in

Figure 9b is:

where

EI is connection beam stiffness;

qs is pile skin friction; and

As and

Ab are pile shaft and base areas, respectively. The summation in Equation (9) represents the cases where multiple piles are used.

Ab was introduced to make

α as a dimensionless, normalized parameter. Using Equations (8) and (9), the values of

CR can be obtained and applied to estimate the load carrying capacity of connected foundations.

Figure 9.

Correlation for resistance increase factor: (a) Resistance increase factor (CR) versus relative height and (b) Correlation parameter versus normalized stiffness.

Figure 9.

Correlation for resistance increase factor: (a) Resistance increase factor (CR) versus relative height and (b) Correlation parameter versus normalized stiffness.

7. Summary and Conclusions

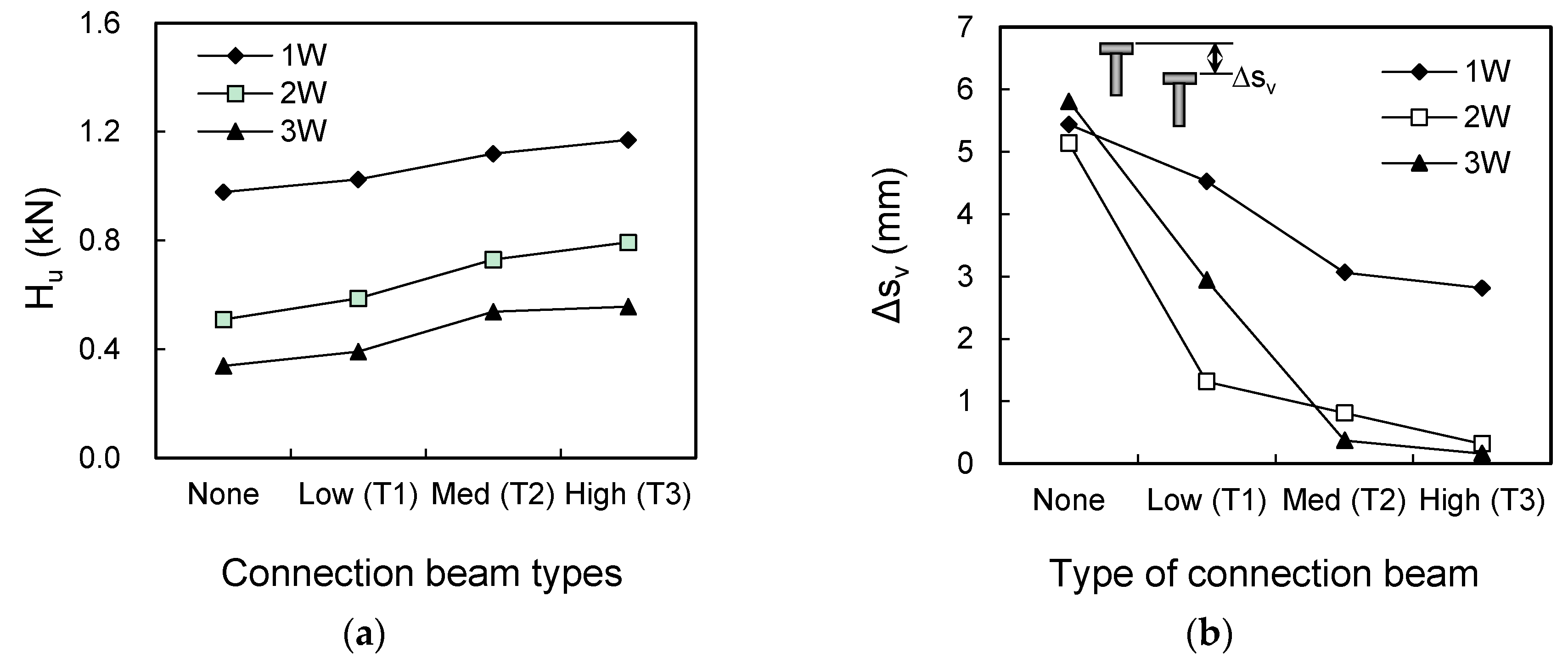

The sustainability of electrical energy supply system has become a critical issue as the demand for electricity has continuously increased. The connected foundation is an effective foundation type to increase the sustainability of electrical transmission tower system in soft soils without additional environmental destruction. In this study, the performance of connected foundation for transmission tower structures was investigated using a series of field load testing programs. For this purpose, model transmission tower structures were specifically manufactured and adopted into the field load tests. Variety of test conditions with different connection beam stiffness and load heights were considered in the model load tests. Based on the load-capacity mobilization mechanism, a criterion to define the ultimate load capacity (Hu) for connected foundations was proposed.

For all test conditions considered in this study, connected foundations produced better performance with higher load carrying capacities and smaller differential settlements than unconnected foundations. In particular, the use of connection beam was more effective for higher load heights. The load carrying capacity of connected foundation increased with increasing connection beam stiffness. Based on the test results, a design method to estimate the load capacity of connected foundation was proposed with the correlation of resistance increase factor. The effects of load height, connection beam stiffness, and soil condition were taken into account for the proposed design method. The proposed method can be effectively applied to improve the foundation stability of electrical transmission tower structures in soft soils.

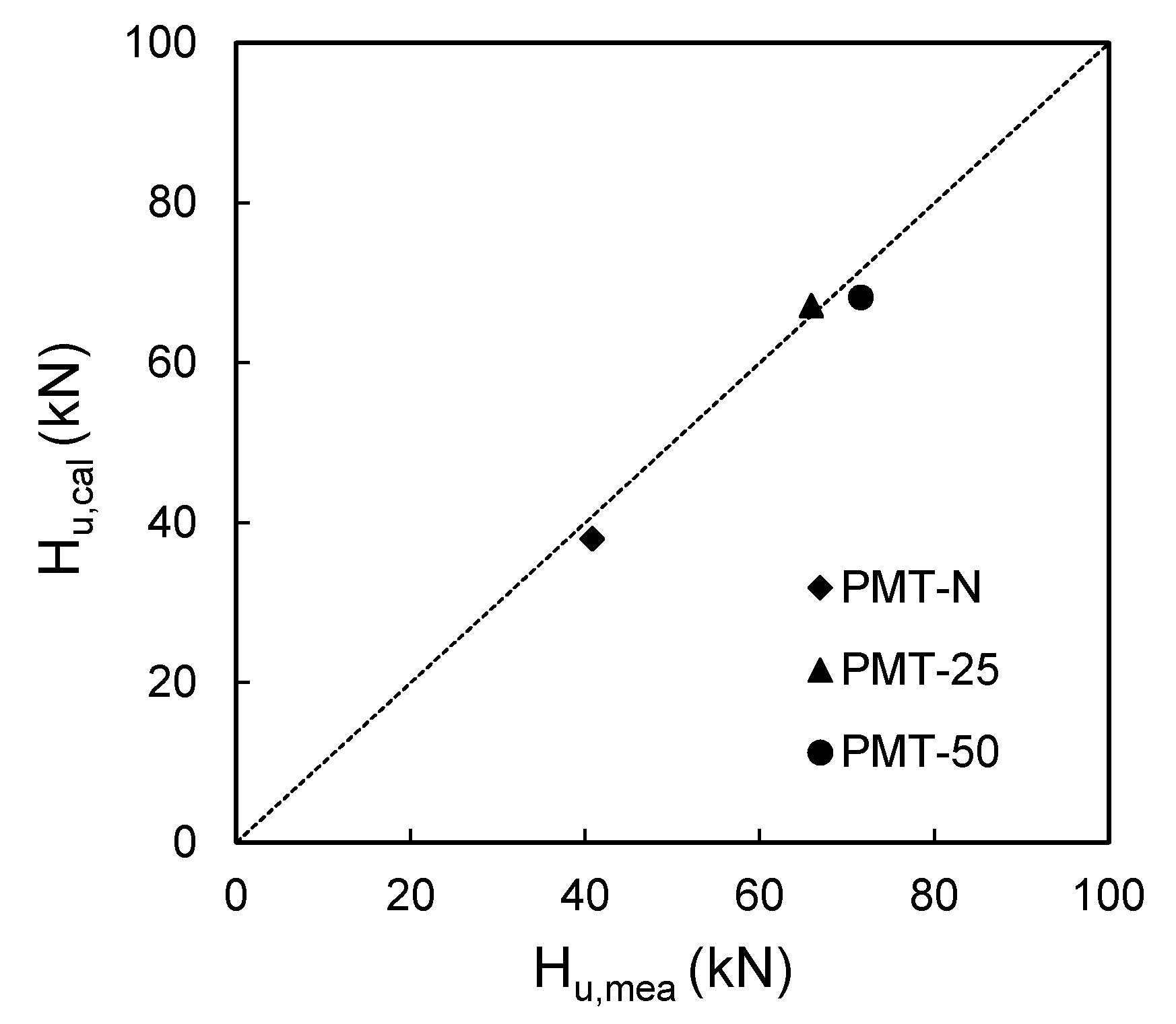

Field load tests using prototype models of transmission tower structure with reduced scale were conducted to check the performance of connected foundations and the validity of proposed design method. Two connection-beam stiffness of 25% and 50% mat stiffness were considered for the prototype model structures. Hu of connected foundations increased by 56.9% and 75.5% for 25% and 50% of stiffness connection beams, respectively. Differential settlements decreased by 88% and 94% for 25% and 50% of stiffness connection beams, respectively. The calculated load carrying capacity using the proposed design method showed good agreement with measured results confirming the validity of the proposed method.