1. Introduction

Along with the rapid industrialization and urbanization, China’s high greenhouse gas emissions have become an important issue both domestically and internationally [

1,

2]. China’s total CO

2 emissions by fossil fuel consumption were estimated to be 2.63 billion tons in 2012, which ranked China first in the world [

3]. Hence, China faces increasing international pressure to curb its CO

2 emissions. The government has made the commitment of reducing CO

2 emissions per unit of GDP by 40%–45% in 2020 compared with 2005 [

4], and the industries sector especially the heavy industries such as steel, cement, and chemicals production, contribute most of the GHG emissions [

5].

Till now, by employing various approaches, few studies have examined sources and reduction potentials of industrial GHG emissions. For example, Liaskas

et al., used the algebraic disaggregation method to identify the factors influencing CO

2 emissions generated in the industrial sector of European Union countries [

6], Zhou

et al., estimated the carbon footprint of China’s Ammonia production and analyzed the potential for carbon mitigation in the industry [

7], Sheinbaum

et al., analyzed Energy and CO

2 emission trends of Mexico’s iron and steel industry during the period 1970–2006, examining CO

2 emissions related to energy use and production process [

8]. Kim and Worrell [

9], and Kirschen

et al. [

10] present the analysis on energy-related carbon footprint in the iron and steel industrial sector of seven countries and electric arc furnace, respectively. With regard to the energy efficiency sector, Lee

et al., decomposed the changes of CO

2 emissions into eight factors from Taiwan’s petrochemical industries during 1984 and 1994 [

11], Lin

et al., identified the key factors which affecting CO

2 emission changes of industrial sectors in Taiwan by using the divisia index approach [

12], Hendriks

et al. [

13] and Van Puyvelde

et al. [

14] produced papers investigating emissions and reductions from the cement sector. However, most of the studies related to industrial GHG emission mainly focuses on GHG emissions from energy consumption. Put forward by the Intergovernmental Panel on Climate Change (IPCC), GHG emission of industrial process is usually discussed as one of the main components in the greenhouse gas emission inventory of different countries or regions, but seldom has intensive studies on its reduction potentials and relative countermeasures. A comprehensive study on industrial process GHG emission is necessary and is a new point of view that can contribute in a certain degree to the climate change.

Industrial process GHG emission refers to the greenhouse gas emissions from industrial processes that chemically or physically transform materials [

15]. According to the report of the National Development and Reform Commission (NDRC) of China, industrial process emissions contributed about 9% of total CO

2 emissions in 1994 [

16]. Though relatively small at the total level, GHG emission of industrial process, characterized by its important, un-negligible and fast growth in emissions, has naturally become the research focus in this field. Ever since 1996, iron and steel output has firmly held the first place [

17]. China’s steel industry has grown rapidly on the back of a huge growth in domestic demand. Crude steel production in China reached 273 million tons in 2004, about three times the figure for 1994, and accounted for around 25.8% of global steel production [

18]. In addition, China was the biggest cement producing and consumption country in this world [

19]. Cement output increased from 209.7 to 1868 million tonnes of cement between 1990 and 2010 in China, and now represents over half of the world’s total cement production [

20].These dramatic increases in steel and cement production are consistent with the trends in energy consumption and CO

2 emission. It should be mentioned that the amount of GHG emission from process-related accounted for growing larger portion in total GHG emission in China. In the year 2009, the process-related GHG emission from cement industry accounted for 54.1% of total cement industry in China [

21]. The GHG emission of industrial process from iron and steel industry contributed more than 60% of the total GHG emissions in steel industry [

22]. Therefore, it is crucial for researchers to focus on the study of GHG emission of the industrial process, including cement, steel and other industries.

The purpose of this study is to estimate the GHG emission of the industrial process and predict its reduction potentials with scenario analysis, so as to give some policy implications to local government. Thus, this study selects a city scale as a case study to study the GHG emission of industrial process, which is more accessible and representative to make scenario analysis. The paper is structured as follows: first, we give a brief description of the background information of Shenyang city and the industrial process GHG emission; then, we present the method used to assess the GHG emission of the industrial process; third, we introduce results for the case study of Shenyang city and make a general understanding of current state of industrial process GHG emission from year 2004 to 2009; fourth, we present scenario analysis based on business as usual(BAU) scenario and scenario with countermeasures to predict future industrial process GHG emission of 2020, so that proper scenarios and feasible GHG abating measures could be obtained; and finally, conclusions are drawn.

6. Conclusions

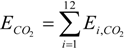

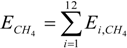

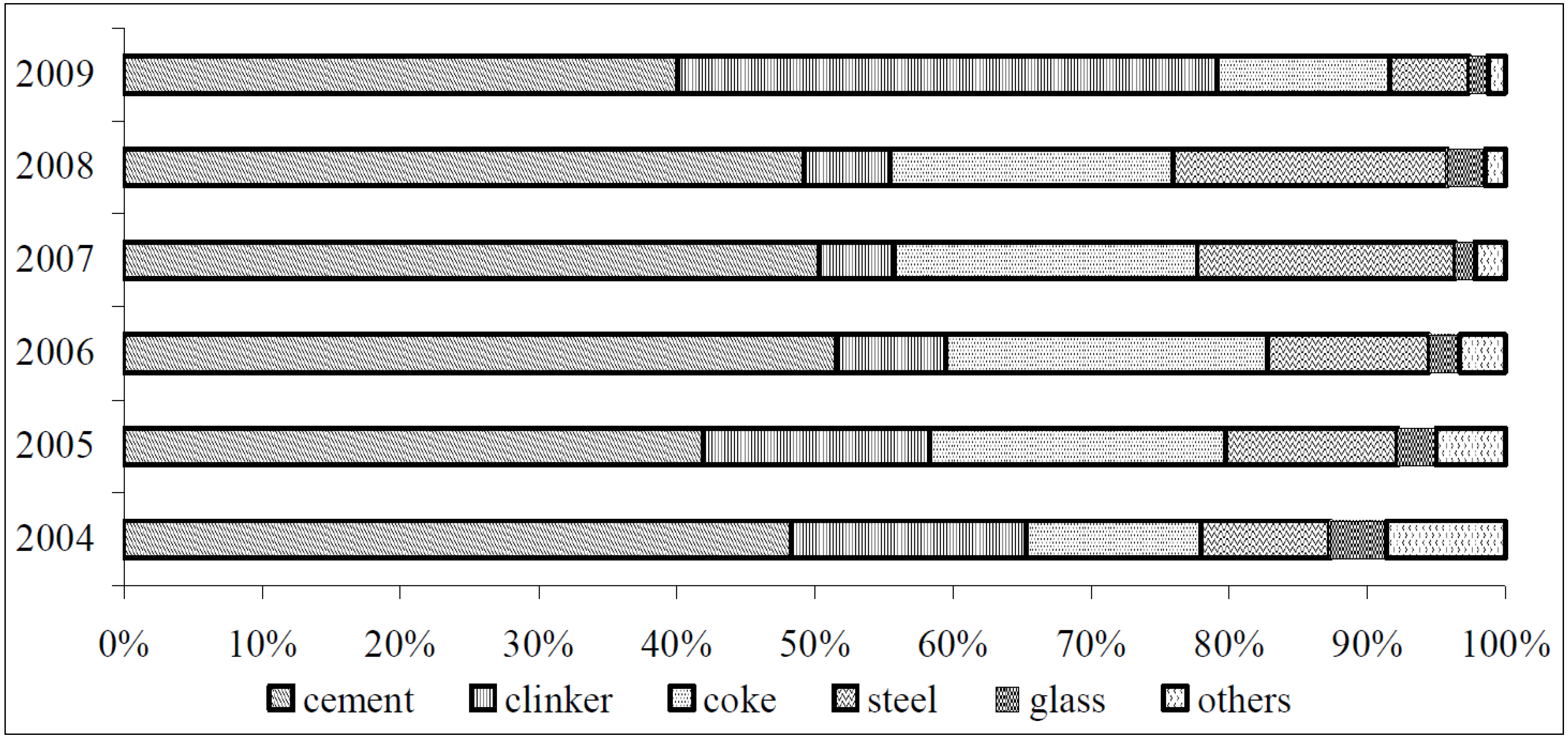

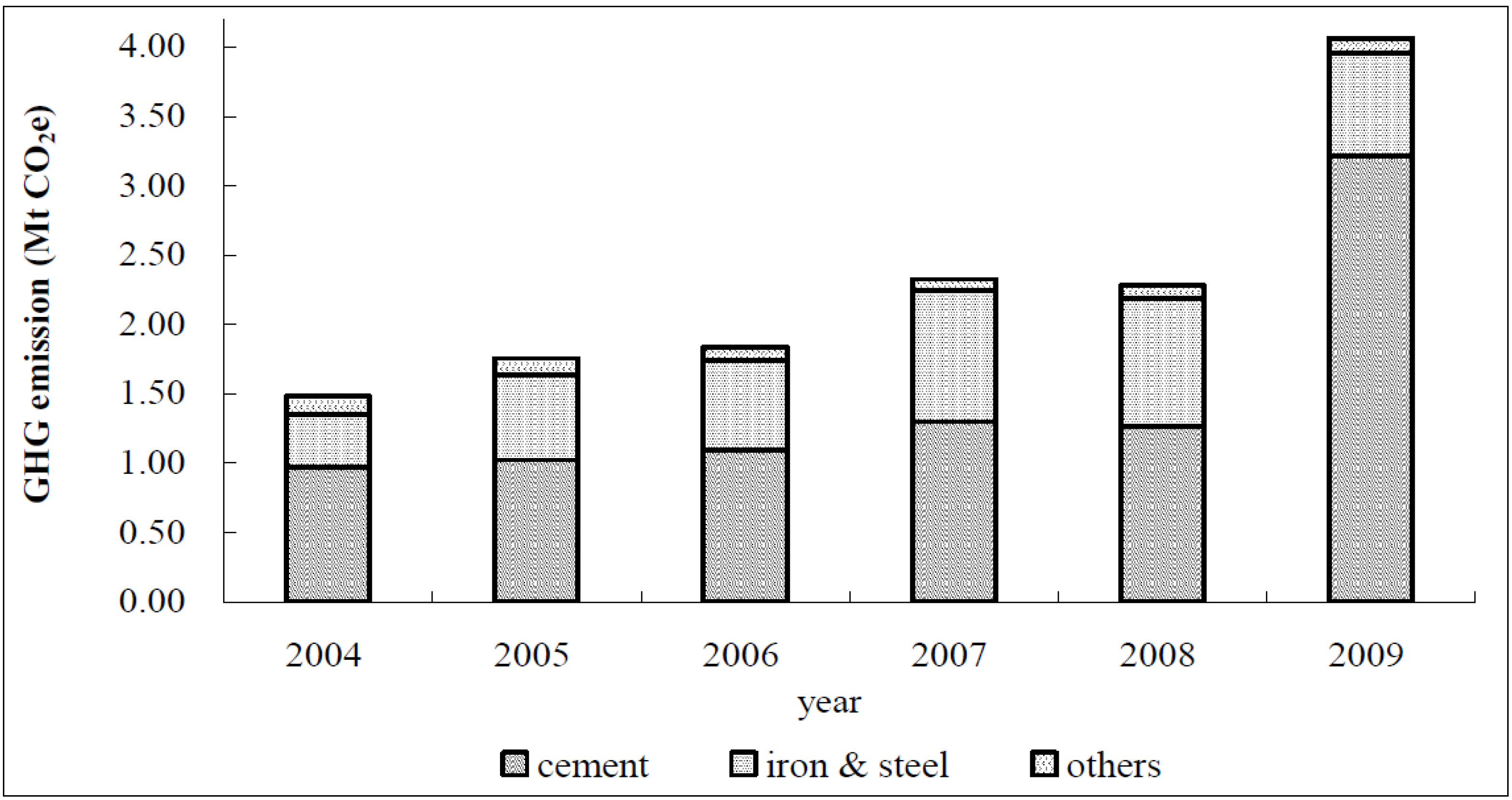

Industrial process GHG emissions increase quickly with fast urbanization and industrialization. Intensive study of the industrial process GHG emission should be investigated to respond to climate change. This paper simulates industrial process GHG emission and its reduction potentials by taking feasible technological measures, taking Shenyang as a case. Twelve industrial sectors that cause industrial process emissions are selected for study. Results indicate that industrial process GHG emission shows an increasing trend from year 2004 to 2009, although decreasing a little in 2008. The cement, iron the steel sectors are the main sources of industrial process GHG emission, occupying more than 90 percent.

Based on scenario analysis, one BAU and four with different countermeasures, the industrial process GHG emission of Shenyang in 2020 is predicted. The results show that if the industrial sectors go under current trend (BAU scenario), the total GHG emissions will reach 8.28 Mt in 2020, about two times of that of 2009. However, the four other scenarios with countermeasures prove to be effective in reducing industrial process GHG emission. And scenario 4 is the best one. It can almost keep the GHG emission at the same level as that of 2009. It can be demonstrated from scenario analysis that using clinker substitute for blended cement and increasing the ratio of DRI process and recycled steel will be efficient measures for Shenyang.