Optimizing the Physical, Mechanical and Hygrothermal Performance of Compressed Earth Bricks

Abstract

: The paper is based on findings from research that assesses the potential for enhancing the performance of compressed earth bricks. A set of experiments was carried out to assess the potential for enhancing the bricks' physical, mechanical and hygrothermal performance through the design of an optimal stabilization strategy. Three different types of bricks were fabricated: soil-cement, soil-cement-lime, and soil-cement-fiber. The different types of bricks did not exhibit significant differences in performances when assessed on the basis of porosity, density, water absorption, and compressive strength. However, upon exposure to elevated moisture and temperature conditions, the soil-cement-fiber bricks had the highest residual strength (87%). The soil-cement and soil-cement-lime bricks had residual strength values of 48.19 and 46.20% respectively. These results suggest that, like any other cement-based material, compressed earth brick properties are affected by hydration-triggered chemical and structural changes occurring in the matrix that would be difficult to isolate using tests that focus on “bulk” changes. The discussion in this paper presents findings from a research effort directed at quantifying the specific changes through an analysis of the microstructure.1. Introduction

This paper reports on the findings of research efforts directed at investigating adaptations that can be made to earth bricks to improve their hygrothermal performance in hot and humid climates such as Dar es Salaam, Tanzania. The overarching goals of the research are: (1) To quantify the moisture and thermal performance of walling systems for the selected earth bricks based on data collected from Dar es Salaam in Summer 2008; and; (2) To develop and calibrate a hygrothermal (moisture and temperature) computer model for the earth bricks that can be used to predict these materials performance in selected sites. With the exception of periods with more or less rain and the occurrence of gusty winds and electric storms, this region is characterized by very little seasonal variation throughout the year [1]. Air temperature is 27 and 32 degrees Celcius during the day; 21 to 27 degrees Celsius at night while the Relative Humidity is high (about 75% most of the time may vary from 55 to 100%). Precipitation is high throughout the year generally becoming more intense for several consecutive months. Annual rainfall can vary from 2,000 to 5,000 mm and may exceed 500 mm in one month. During severe storms rain may fall at the rate of 100mm for short periods. Although traditional building forms of the rural choice include sound solutions to climatic problems outlined here, they are not always suitable for the urban population. A key concern with their use is their susceptibility to moisture-related deterioration.

The main body of the paper focuses on the moisture dynamics [2]. Properties of cement-based materials are profoundly affected by hydration-triggered chemical and structural changes occurring in the matrix [3]. Despite the strides being made by different researchers in this area, there are still no robust quantitative models that can be used to predict these chemical and structural changes. Concerns raised in the U.S. Concrete Industry Technology Roadmap [4], were echoed in Mehta's [3] position that “without a measurement science tool that can test for chemical interactions and their effects on hydration mechanisms, potential chemical incompatibilities…can go undetected and lead to major performance problems in the field.” This gap in scientific knowledge impedes efforts directed at optimizing short term performance and extending the long term durability of concrete and “concrete-like” systems. Emerging data from research on the microstructure of concrete cannot be directly applied to all classes of cement-based composites. New classes of cement-based materials incorporate non-cementitious constituents which introduce chemical reactions that are difficult to isolate using tests that focus on “bulk” changes. There are also a number of potential incompatibilities among the various components that are difficult to capture without adequate data on changes at the microstructure level.

In a previous publication [5], the author presented preliminary data capturing changes in the earthen masonry microstructure that can be linked to exposure-related deterioration. The author tabulated chemical characterization quantifying changes after samples had been aged through being immersed in water and exposed to 100 °C temperatures in an oven for 7 days. This data was generated using Energy Dispersive X-Ray Spectroscopy (EDS) & Scanning Electron Microscopy (SEM). Based on this initial data, some key changes to the microstructure were identified. For example, focusing on the Carbon, Oxygen, Silica and Calcium, a few things were observed. The inclusion of lime triggered chemical reactions that increased Silica while decreasing Calcium. The chemical reactions that occurred when fiber was included in the mix increased the Carbon content while decreasing the Oxygen, Silica and Calcium content. The data from the preliminary analysis motivated the author to scale-up the exposure period. It was essential to track the observed chemical changes over a much longer period of time to generate additional empirical data that can be used to validate the initial findings and ultimately, to develop prediction models. This paper reports on findings from follow-up research undertaken to do just that.

2. Experimental Approach

The rationale behind the approach adopted for brick fabrication was reported in Obonyo et al. [5]. A flexible set of guidelines was used to select the mixing proportions for the different constituents (see Table 1). Cement, lime and natural fibers were identified as potential stabilizers for the soil in the research. Compaction was achieved using a manually-operated device, mirroring the fabrication process in Tanzania (the case study context).

Through experimenting with different recipes, it was established that the most ideal mix design for the soil in the study was as follows: (1) 45.35 kg of soil, 3.17 kg of cement, (2) 45.35 kg of soil, 2.27 kg of cement, 3.17 kg of lime (3) 45.35 kg of soil, 2.27 kg of cement, 0.45 kg of fiber, (4) 45.35 kg of soil, 2.27 kg of cement, 2.27 kg of lime, 1.13 kg of Aeonian brick Stabilizer (subsequently dropped for not having any noticeable impact). The fifth brick in the study were factory-produced interlocking bricks that were used in the study for benchmarking purposes. The fabricated bricks were for cured in room temperature settings for 28 days. The cured samples were then tested for physical and mechanical properties both in their virgin state and following exposure to weathering agents in elevated moisture and temperature conditions.

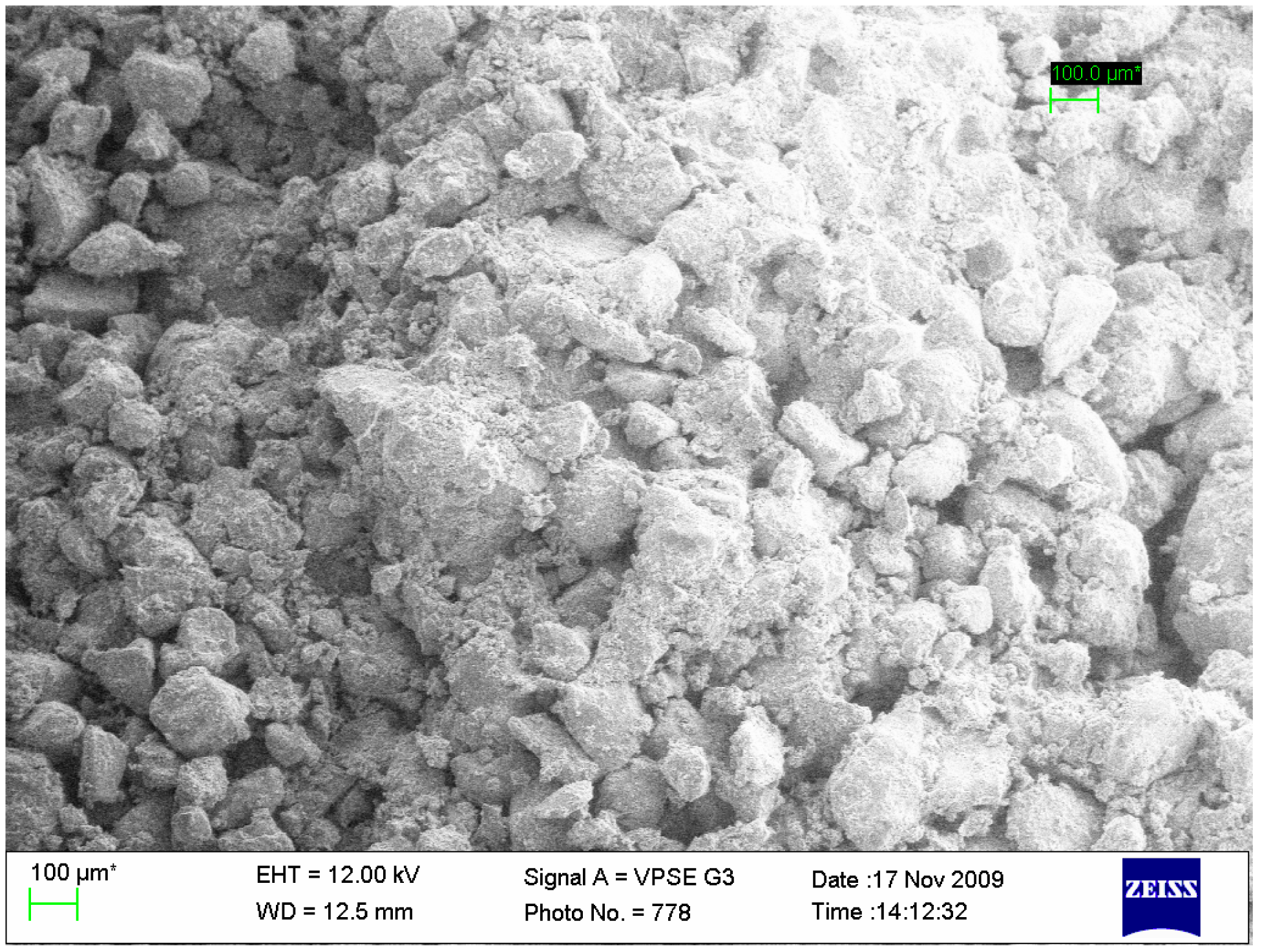

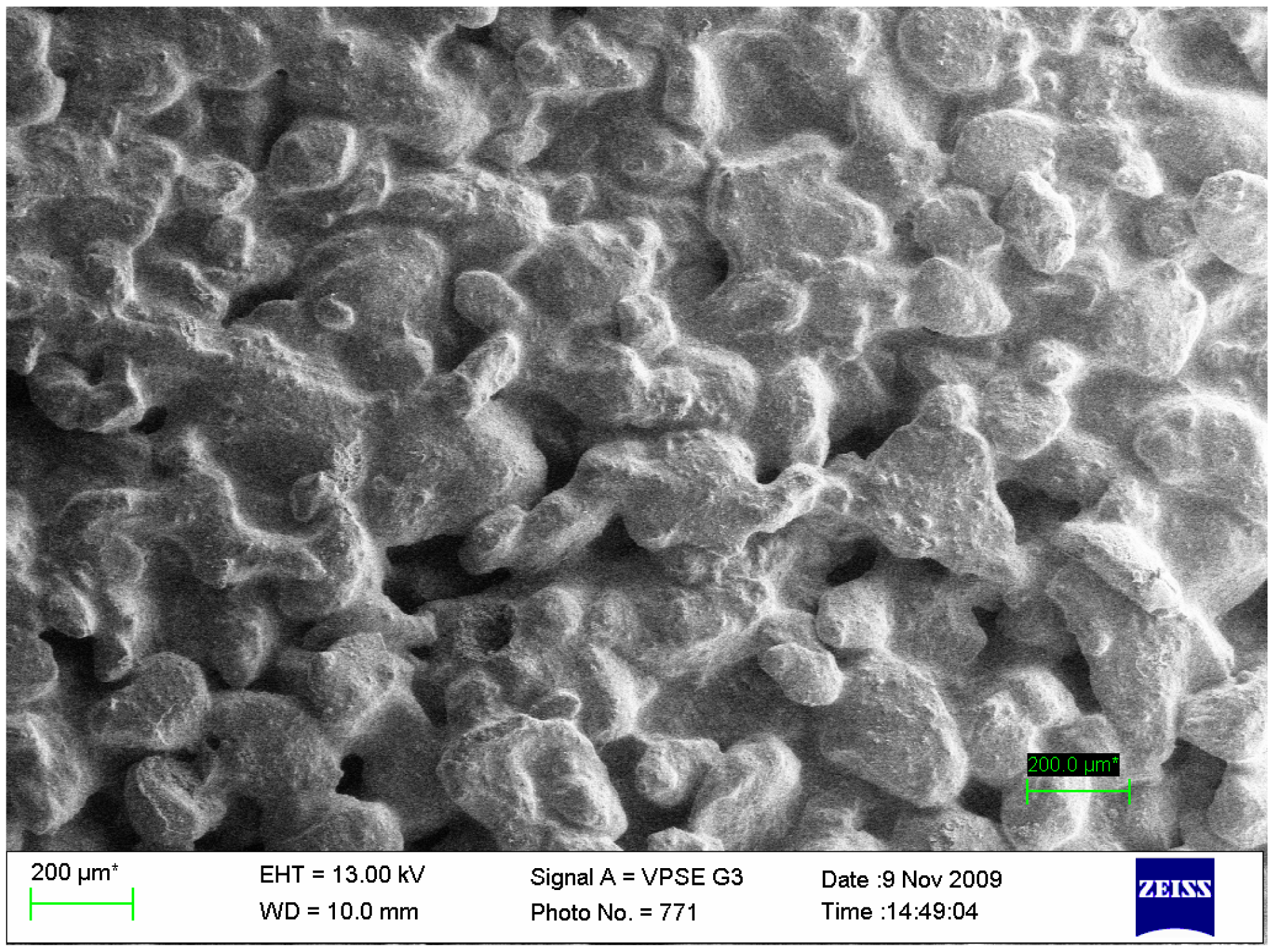

Specific physical and mechanical properties that were tested include porosity, bulk density, compressive strength and water absorption. The hygrothermal performance of different types of brick units was further assessed through placing them in a climate control chamber. The specimens were exposed to high temperature and humidity conditions based on 1 and 2 month exposure. Empirical data capturing changes to the microstructure were generated using EDS chemical micro-analysis and SEM at University of Florida's Major Analytical Instrumentation Center. Figures 1 and Figure 2 depict SEM analysis for the low cost cementitious composite studied in the preliminary research.

The equipment used for this comprises a detector and the system software. The detector is typically lithium-drifted silicon, solid-state device which measures the relative abundance of emitted x-rays versus their energy. It separates the characteristic x-rays of different elements into an energy spectrum. The EDS technique detects x-rays emitted from the material sample during bombardment by the electron beams to give out the different element chemical compositions of the analyzed material down to the smallest microns. The system software analyzes the energy spectrum to determine the abundance of specific elements contained in the analyzed material. All data for this study was captured at the K-Alpha line.

3. Results and Findings

The results from the different experiments have been summarized in Tables 2 to 5. From these results, it is clear that the use of the three different stabilization strategies did not results in any significant differences in the performance of the bricks as far as properties such as porosity, density and compressive strength is concerned.

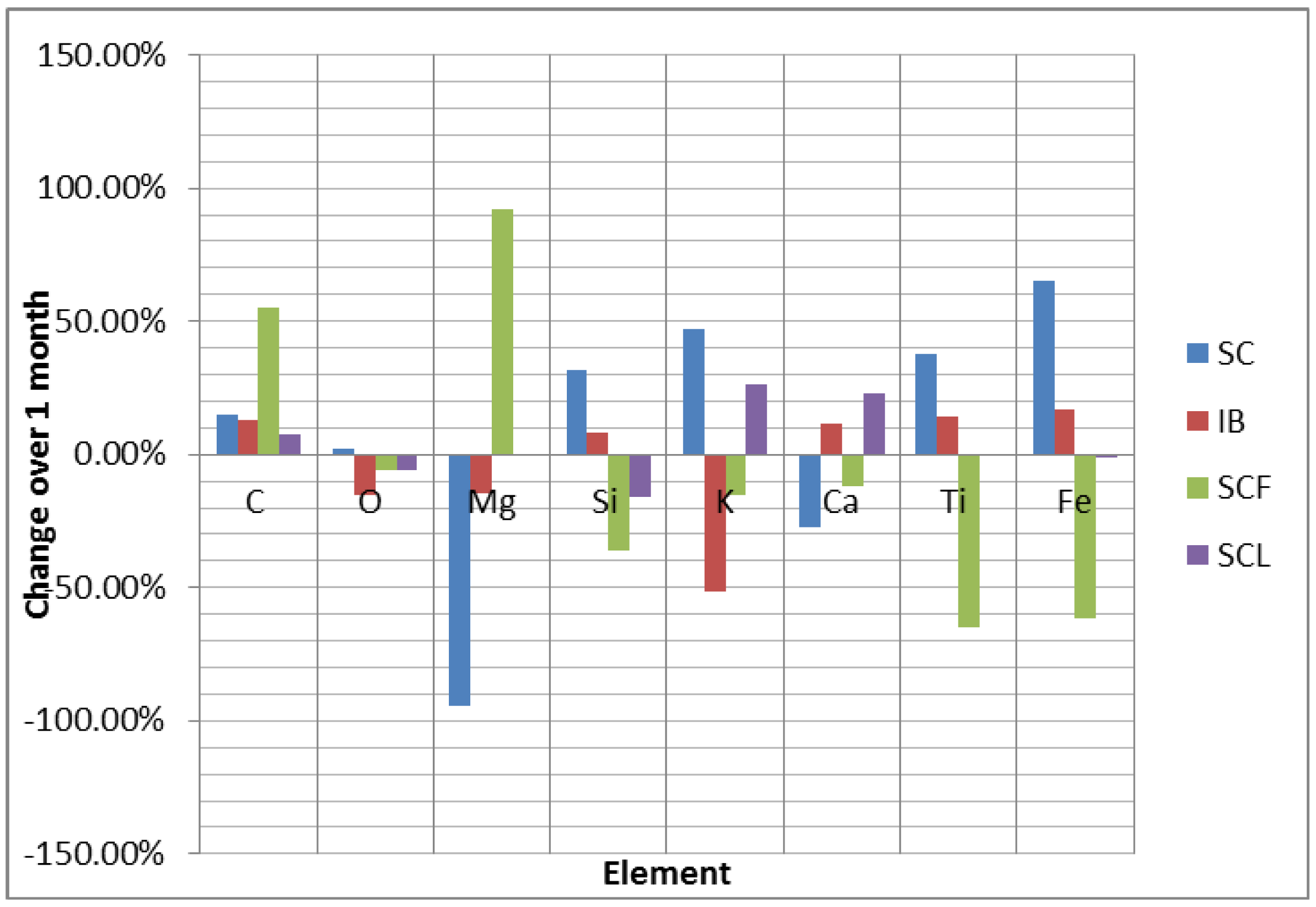

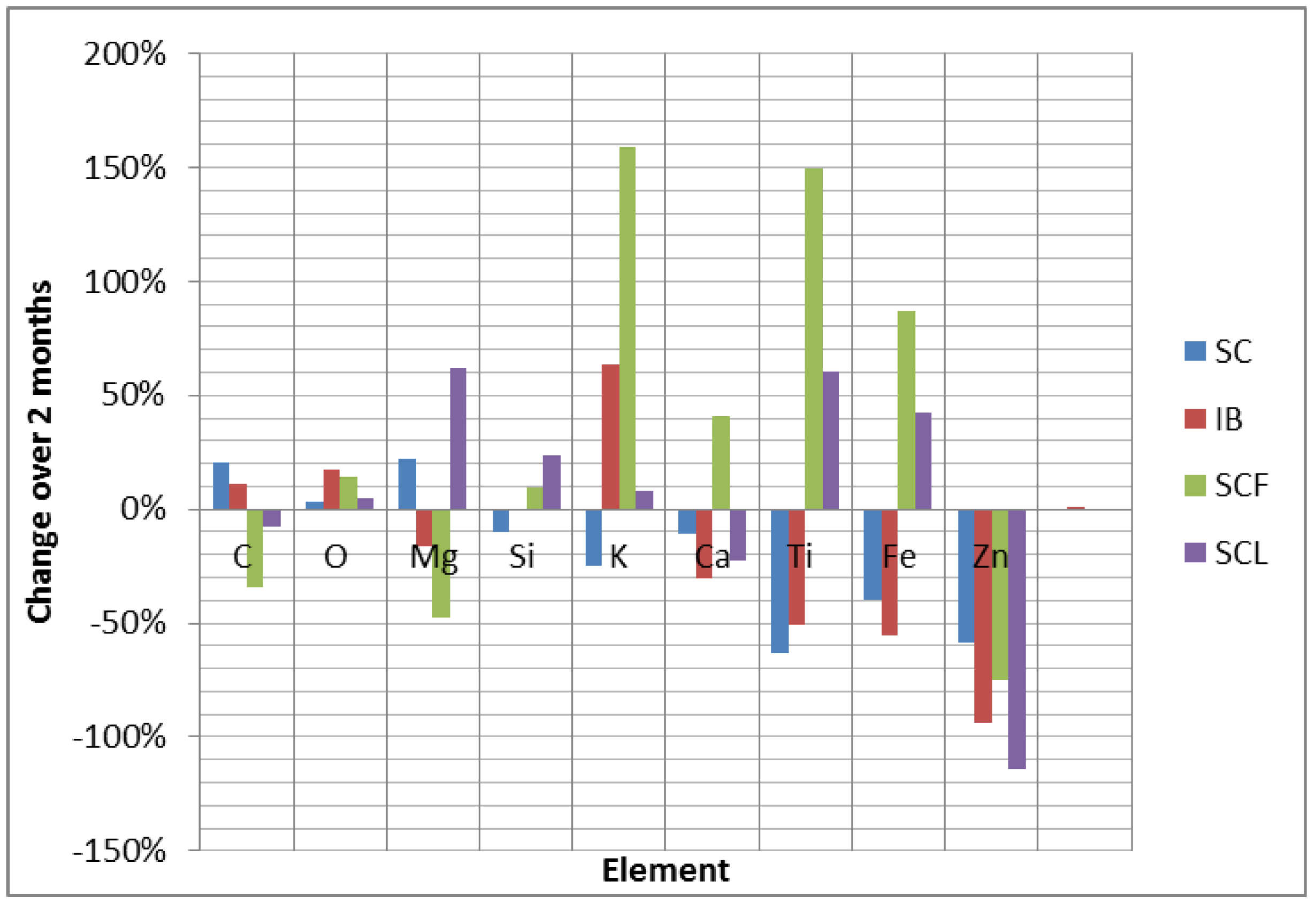

When the bricks were subjected to combined moisture and temperature stresses, the soil-cement-fiber bricks outperformed the other two types of bricks by a significant margin—the residual strength value for the soil-cement-fiber bricks was almost double that for the other two bricks (see Table 3). This suggests that the deterioration of compressed earth bricks due to moisture problems is compounded by heat. Tables 4 & 5 tabulate chemical characterization quantifying changes to the microstructure after the different samples had been aged through being immersed in water and exposed to 100 °C temperatures in an oven for 1 and 2 months. This data was generated through SEM & EDS analysis. Figures 1 and Figure 2 are visual representations of this information. Using the “Unexposed Samples” as the baseline, it is clear that changes in the microstructure are incremental in some cases while in others there are reductions. Some of the captured changes are minimal while others are significant.

Changes to the Carbon, Oxygen, Silica and Calcium content for all the samples have been presented in details in Table 4. The most dramatic changes were as follows:

For the Interlocking Bricks (IB), an increased Carbon content and a reduction in Oxygen after one month, and a reduced an increased Oxygen content after two months;

For Soil-Cement-Fiber (SCF), Carbon more than doubled after one month but after two months the largest change was an increased Oxygen content;

For Soil-Cement-Lime (SCL), after one month, Calcium decreased significantly; after two months the significant increase to Silica was coupled with a significant reduction of Calcium content.

Table 5 tabulates changes to the microstructure on elemental atomic basis. Using the factory produced Interlocking Bricks (IB) as an example, after a 1-month exposure, the biggest change was an increased Carbon content while after two months, the Calcium content decreases significantly.

Table 3 indicated that fiber had the highest residual strength when crushed after a 7-day exposure to hygrothermal loads. This information cannot be used to guarantee that the bricks will perform in a certain manner where the period of exposure is longer. From the SEM-EDS analysis it is clear that the chemical changes occurring within the microstructure can be directly linked to the existence of specific non-cementitious inclusions. For example, the inclusion of lime triggers chemical reactions that increase after one month of exposure increases Carbon and Calcium while decreasing Oxygen and Silica. Over the same time period, the chemical reactions that occur when fiber is included in the mix reduce Carbon content by over 1/3 while significantly increasing the Oxygen, Silica and Calcium content. Although previous research recommended the inclusion of both lime and Fiber for the case study context (see [5]), it is also clear that their use could result in both desirable and undesirable effects depending on how the mineralization of the organic inclusions affect hydration-based chemical reactions. The performance of compressed earth bricks can be optimized through establishing a direct link between these changes and desirable physical or mechanical properties. This will be the subject of a subsequent publication.

4. Discussion and Conclusions

From the findings, it is clear that with the right approach to stabilization, it is possible to fabricate different types of bricks that have more or less similar physical and mechanical properties such as porosity, density and compressive strength even when one uses different stabilizers. However, when moisture and temperature loads are applied to the different types of bricks concurrently, they register significant differences in residual strength. This type of testing being very time consuming is often overlooked suggesting some concerns over the decisions being made on the basis of what is available. A review of research has revealed that the problem of hygrothermal loads in masonry units such as brick remains as subject that is still not well understood. This notwithstanding, there have been some attempts to counter the damaging effects of hygothermal stresses. Many implemented solutions focus on surface strategies. As minimizing costs remains a primary driver for using bricks in developing countries such as Tanzania, strategies that are being developed to counter moisture-related failure must be easily accessible to low income communities. The author's research tries to make a contribution through quantifying changes in the microstructure and linking this to specific stabilization strategies.

As stated earlier, the research discussed in this paper is directed at improving the durability performance of an entire walling structure through developing a high quality material. The material used here is earthen masonry, a low cost, cementitious system that that can be best described as strongly heterogeneous and anisotropic materials, with random and irregular or regular internal arrangement of different phases. Similar to any other cement-based material, properties of compressed earth bricks are significantly affected by hydration-triggered chemical and structural changes occurring in the microstructure. In the introduction, the author pointed out complexities that make it difficult to directly use “bulk” properties to track the impact of these changes on the properties of cement-based materials. Earth-based bricks pose additional challenges as they belong to a new class of cement-based materials incorporate non-cementitious constituents which introduce chemical reactions that are difficult to isolate using tests that focus on “bulk” changes. There are also a number of potential incompatibilities among the various components that are difficult to capture without adequate data on changes at the microstructure level. All these factors compound the difficulties of understanding the mechanism of hydration.

Through quantifying changes in the microstructure, the research discussed in this paper makes a contribution to efforts directed at understanding deterioration triggered by hygrothermal loads. In follow up activities, the research will capture changes to the compressed earth bricks' microstructure following 3 and 6 month exposure to elevated temperature and moisture conditions. A robust understanding these chemical changes will provide empirical data that can be used to quantify how using different stabilizers affects the bricks' resistance to hygrothermal loads. The resulting data will be used to develop a modeling tool for designers seeking to optimize short term performance and extend the long term durability of “concrete and concrete-like” systems in buildings within the hot and humid climate.

| Type of Soil/conditions | Stabilizer |

|---|---|

| For nearly all types of soil | Portland cement |

| Medium, moderately fine and fine-grained soils | Hydrated lime |

| Coarse-grained soil with little if any fine grains | Fly ash |

| Cold climate applications | Calcium chloride |

| For increasing resistance to water and frost | Bitumen |

| Type of Brick | Porosity | Density (kg/m3) | 28 Day compressive strength (psi) |

|---|---|---|---|

| Soil-Cement | 0.14 | 1,054 | 1,100 |

| Soil-cement-lime | 0.12 | 1,144 | 1,200 |

| Soil-cement-fiber | 0.16 | 1,058 | 1,150 |

| Type of Brick | Original Compressive Strength (psi) | Residual Strength after 7-day exposure to elevated moisture and temperature conditions (%) |

|---|---|---|

| Soil-Cement | 1,100 | 48.19 |

| Soil-cement-lime | 1,200 | 46.20 |

| Soil-cement-fiber | 1,150 | 87.00 |

| Unexposed Samples Baseline Values | 1-Month Exposure % Change | 2-Month Exposure % Change from 1-Month Exposure | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Element | SC | IB | SCF | SCL | SC | IB | SCF | SCL | SC | IB | SCF | SCL |

| C | 14.84 | 13.19 | 55.28 | 7.84 | 14.84 | 13.19 | 55.28 | 7.84 | 20.10 | 11.39 | −34.08 | −7.90 |

| O | 2.23 | −15.61 | −5.60 | −5.58 | 2.23 | −15.61 | −5.60 | −5.58 | 3.07 | 17.55 | 13.93 | 4.46 |

| Mg | −94.25 | −14.29 | 92.31 | 0.00 | −94.25 | −14.29 | 92.31 | 0.00 | 22.22 | −16.67 | −48.00 | 61.90 |

| Si | 31.40 | 8.09 | −35.78 | −15.78 | 31.40 | 8.09 | −35.78 | −15.78 | −10.33 | −0.49 | 9.65 | 23.36 |

| S | −38.46 | −53.78 | 510.53 | −39.02 | −38.46 | −53.78 | 510.53 | −39.02 | 25.00 | 614.55 | −53.45 | −12.00 |

| K | 47.37 | −51.28 | −15.00 | 26.32 | 47.37 | −51.28 | −15.00 | 26.32 | −25.00 | 63.16 | 158.82 | 8.33 |

| Ca | −27.32 | 11.34 | −12.22 | 23.14 | −27.32 | 11.34 | −12.22 | 23.14 | −10.54 | −30.17 | 40.85 | −22.31 |

| Ti | 37.50 | 14.52 | −65.22 | 0.00 | 37.50 | 14.52 | −65.22 | 0.00 | −63.64 | −50.70 | 150.00 | 60.00 |

| Cr | −120.00 | 257.14 | −400.00 | 100.00 | −120.00 | 257.14 | −400.00 | 100.00 | 400.00 | −108.00 | 0.00 | −16.67 |

| Fe | 64.97 | 17.03 | −61.59 | −1.04 | 64.97 | 17.03 | −61.59 | −1.04 | −39.77 | −55.24 | 87.39 | 42.11 |

| Zn | −26.09 | 410.00 | −57.14 | 200.00 | −26.09 | 410.00 | −57.14 | 200.00 | −58.82 | −94.12 | −75.00 | −114.29 |

| Unexposed Samples Baseline Values | 1-Month Exposure % Change | 2-Month Exposure % Change from 1-Month Exposure | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Element | SC | IB | SCF | SCL | SC | IB | SCF | SCL | SC | IB | SCF | SCL |

| C | 24.87 | 27.21 | 31.96 | 25.14 | 12.18 | 15.84 | 38.67 | 8.95 | 14.59 | 3.05 | −27.17 | −8.36 |

| O | 52.42 | 50.22 | 46.62 | 54.48 | −1.01 | −0.14 | −0.13 | −0.05 | −1.56 | −6.37 | 5.88 | −0.84 |

| Mg | 2.52 | 0.11 | 0.10 | 0.16 | −94.44 | −0.09 | 0.70 | 0.00 | 14.29 | −36.36 | 0.00 | 68.75 |

| Si | 9.09 | 9.18 | 14.73 | 11.06 | 29.81 | 0.11 | −0.41 | −0.15 | −14.49 | 1.42 | −30.07 | 4.43 |

| S | 0.24 | 0.72 | 0.22 | 0.24 | −41.67 | −0.53 | 4.86 | −0.38 | 14.29 | 226.39 | 177.27 | −45.83 |

| K | 0.09 | 0.20 | 0.09 | 0.09 | 55.56 | −0.50 | −0.22 | 0.33 | −28.57 | −25.00 | 122.22 | 33.33 |

| Ca | 9.87 | 10.17 | 5.26 | 8.07 | −31.21 | 0.14 | −0.17 | 0.24 | −14.43 | −25.76 | 20.72 | −3.84 |

| Ti | 0.13 | 0.25 | 0.17 | 0.12 | 30.77 | 0.20 | −0.65 | 0.00 | −64.71 | −44.00 | −11.76 | 58.33 |

| Cr | −0.03 | 0.02 | 0.00 | −0.01 | −133.33 | 4.00 | 0.00 | 2.00 | 100.00 | −150.00 | 0.00 | 100.00 |

| Fe | 0.54 | 1.91 | 0.95 | 0.64 | 59.26 | 0.20 | −0.63 | −0.89 | −43.02 | −49.74 | −29.47 | 42.19 |

| Zn | 0.28 | 0.03 | 0.95 | 0.02 | −32.14 | 4.00 | −1.03 | 2.00 | −57.89 | −66.67 | −101.05 | −150.00 |

Acknowledgments

The work described in this paper is based on research supported by NSF Award No. 0844612: “SGER: Optimizing the Hygrothermal Performance of Earth Bricks in Hot and Humid Climates.” The author also acknowledges the contribution of her graduate research assistants (Joseph Exelbirt and Malarvizhi Baskaran), as well as members of staff at FDOT Material Testing Lab, NHBRA and Dar es Salaam Institute of Technology.

References

- Koenisgsberger, I.; Mayhew, S. Manual of Tropical Housing and Building, Part1 Climatic Design; Longman: New York, NY, USA, 1990. [Google Scholar]

- Adam, E.A.; Jones, P.J. Thermo physical properties of stabilized soil building blocks. Build. Environ. 1995, 30, 245–253. [Google Scholar]

- Mehta, K.P.; Monteiro, P.J.M. Concrete Microstructure, Properties, and Materials, 3rd ed.; McGraw-Hill: Columbus, OH, USA, 2005. [Google Scholar]

- Roadmap 2030. The US Concrete Industry Technology Roadmap (Version 1.0), Concrete Research and Education Foundation (ConREF)—ACI. American Concrete Institute: Farmington Hills, MI, USA,, 2002. Available oneline: http://www1.eere.energy.gov/industry/imf/pdfs/concrete_rdmap.pdf (accessed on 1 February 2011). [Google Scholar]

- Obonyo, E.; Exelbirt., J.; Baskaran, M. Durability of compressed earth bricks: Assessing erosion resistance using the modified spray testing. Sustainability 2010, 2, 3639–3649. [Google Scholar]

- Brandt, A.M. Cement Based Composites, Materials, Mechanical Properties and Performance; Polish Academy of Sciences: Warsaw, Poland, 2009. [Google Scholar]

© 2011 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Obonyo, E. Optimizing the Physical, Mechanical and Hygrothermal Performance of Compressed Earth Bricks. Sustainability 2011, 3, 596-604. https://doi.org/10.3390/su3040596

Obonyo E. Optimizing the Physical, Mechanical and Hygrothermal Performance of Compressed Earth Bricks. Sustainability. 2011; 3(4):596-604. https://doi.org/10.3390/su3040596

Chicago/Turabian StyleObonyo, Esther. 2011. "Optimizing the Physical, Mechanical and Hygrothermal Performance of Compressed Earth Bricks" Sustainability 3, no. 4: 596-604. https://doi.org/10.3390/su3040596