1. Introduction

Demolition of old and deteriorated buildings and traffic infrastructure, and their substitution with new ones, is a frequent phenomenon today in a large part of the world. The main reasons for this situation are changes of purpose, structural deterioration, rearrangement of a city, expansion of traffic directions and increasing traffic load, natural disasters (earthquake, fire and flood),

etc. For example, about 850 millions tones of construction and demolition waste are generated in the EU per year, which represent 31% of the total waste generation [

1]. In the USA, the construction waste produced from building demolition alone is estimated to be 123 million tons per year [

2]. The most common method of managing this material has been through its disposal in landfills. In this way, huge deposits of construction waste are created, consequently becoming a special problem of human environment pollution. For this reason, in developed countries, laws have been brought into practice to restrict this waste: in the form of prohibitions or special taxes existing for creating waste areas.

On the other hand, production and utilization of concrete is rapidly increasing, which results in increased consumption of natural aggregate as the largest concrete component. For example, two billion tons of aggregate are produced each year in the United States. Production is expected to increase to more than 2.5 billion tons per year by the year 2020 [

2]. This situation leads to a question about the preservation of natural aggregates sources; many European countries have placed taxes on the use of virgin aggregates.

A possible solution to these problems is to recycle demolished concrete and produce an alternative aggregate for structural concrete in this way. Recycled concrete aggregate (RCA) is generally produced by two-stage crushing of demolished concrete, and screening and removal of contaminants such as reinforcement, paper, wood, plastics and gypsum. Concrete made with such recycled concrete aggregate is called recycled aggregate concrete (RAC). The main purpose of this work is to determine the basic properties of RAC depending on the coarse recycled aggregate content, and to compare them to the properties of concrete made with natural aggregate (NAC)—control concrete. Fine recycled aggregate was not considered for RAC production because its application in structural concrete is generally not recommended [

3,

4,

5,

6].

2. Basic Properties of Concrete with Recycled Concrete Aggregate

Based on available experimental evidence, the most important properties of recycled concrete aggregate (RCA) and concrete made with recycled aggregate (RAC) are briefly presented in this chapter. Recommendations for production of RAC are also presented.

When demolished concrete is crushed, a certain amount of mortar and cement paste from the original concrete remains attached to stone particles in recycled aggregate. This attached mortar is the main reason for the lower quality of RCA compared to natural aggregate (NA).

RCA compared to NA has following properties:

- -

increased water absorption [

7,

8,

9],

- -

decreased bulk density [

3,

10],

- -

decreased specific gravity [

3],

- -

increased abrasion loss [

3,

11,

12],

- -

increased crushability [

3],

- -

increased quantity of dust particles [

3],

- -

increased quantity of organic impurities if concrete is mixed with earth during building demolition [

3], and

- -

possible content of chemically harmful substances, depending on service conditions in building from which the demolition and crushing recycled aggregate is obtained [

3].

Available test results of recycled aggregate concrete vary in wide limits, sometimes are even opposite, but general conclusions about the properties of concrete with recycled coarse aggregate compared to concrete with natural aggregate are:

- -

increased drying shrinkage up to 50% [

13,

14],

- -

increased creep up to 50% [

13,

15],

- -

water absorption increased up to 50% [

3,

16],

- -

decreased compressive strength up to 25% [

3,

7,

8,

10,

17],

- -

decreased splitting and flexural tensile strength up to 10% [

3,

8,

17],

- -

decreased modulus of elasticity up to 45% [

7,

8,

17],

- -

same or decreased frost resistance [

3,

18,

19].

Technology of RAC production is different from the production procedure for concrete with natural aggregate. Because of the attached mortar, recycled aggregate has significantly higher water absorption than natural aggregate. Therefore, to obtain the desired workability of RAC it is necessary to add a certain amount of water to saturate recycled aggregate before or during mixing, if no water-reducing admixture is applied. One option is to first saturate recycled aggregate to the condition “water saturated surface dry”, and the other is to use dried recycled aggregate and to add the additional water quantity during mixing. The additional water quantity is calculated on the basis of recycled aggregate water absorption in prescribed time.

3. Experimental Investigation

The aim of this investigation is to compare the basic properties of control concrete (concrete made with natural aggregate) and the properties of concrete made with different contents of recycled aggregate.

Three concrete types were tested within the research program [

20]. Mixture proportions of the tested concrete types were determined in accordance to the following conditions:

- -

same cement content,

- -

same workability after 30 min,

- -

same maximum grain size (32 mm),

- -

same grain size distribution for aggregate mixture,

- -

same type and quantity of fine aggregate,

- -

variable type and quantity of coarse aggregate.

The type and quantity of coarse aggregate were varied in the following way:

- -

the first concrete mix had 100% of natural river coarse aggregate (R0), control mixture,

- -

the second concrete mix had 50% of natural river coarse aggregate and 50% of recycled coarse aggregate (R50),

- -

the third concrete mix had 100% of recycled coarse aggregate (R100).

As all the other variables were kept constant, this research enabled us to determine the influence of the coarse recycled aggregate amount (0%, 50% and 100%) on tested concrete properties. The following properties of concrete were selected for testing:

- -

workability (slump test) immediately after mixing and 30 minutes after mixing,

- -

bulk density of fresh concrete,

- -

air content,

- -

bulk density of hardened concrete,

- -

water absorption (at age of 28 days),

- -

wear resistance (at age of 28 days),

- -

compressive strength fc (at age of 2, 7 and 28 days),

- -

splitting tensile strength (at age of 28 days),

- -

flexural strength (at age of 28 days),

- -

modulus of elasticity (at age of 28 days),

- -

drying shrinkage (at age of 3, 4, 7, 14, 21 and 28 days),

- -

bond between ribbed and mild reinforcement and concrete.

Ninety nine specimens were made for testing of the listed properties of hardened concrete.

3.1. Component Materials

Component materials for concrete mixtures were:

- -

Portland-composite cement CEM II/A-M(S-L) 42.5R, (Lafarge-BFC),

- -

fine aggregate (river aggregate, separation Luka Leget, grain size 0/4 mm),

- -

two types of coarse aggregate: river aggregate, separation Luka Leget, and recycled concrete aggregate, grain sizes 4/8, 8/16 and 16/31.5 mm,

- -

water.

Fine and coarse natural aggregates were derived from River Sava and dominantly consist of quartz grains.

Recycled concrete aggregate was produced by crushing of “old” concrete cubes used for compressive strength testing and one precast reinforced concrete column, which had inappropriate dimensions (

Figure 1). The strength class of old concrete cubes was C30/37 and the corresponding value of compressive strength for precast column was C40/50, nomenclature according to Eurocode 2 [

21]. The primary crushing was done with a pneumatic hammer (

Figure 1) and the secondary crushing was performed in a rotating crusher. The obtained material after the primary and secondary crushing is shown in

Figure 2.

Figure 1.

Waste concrete for recycling: concrete cubes and precast column.

Figure 1.

Waste concrete for recycling: concrete cubes and precast column.

Figure 2.

Recycled material after (a) primary and (b) secondary crushing.

Figure 2.

Recycled material after (a) primary and (b) secondary crushing.

Crushed concrete particles were separated into standard fractions of coarse aggregate (4–8 mm, 8–16 mm and 16–31.5 mm), as seen in

Figure 3.

Figure 3.

Recycled concrete aggregate fractions. From left to right; 4–8 mm, 8–16 mm and 16–31.5 mm coarse aggregates.

Figure 3.

Recycled concrete aggregate fractions. From left to right; 4–8 mm, 8–16 mm and 16–31.5 mm coarse aggregates.

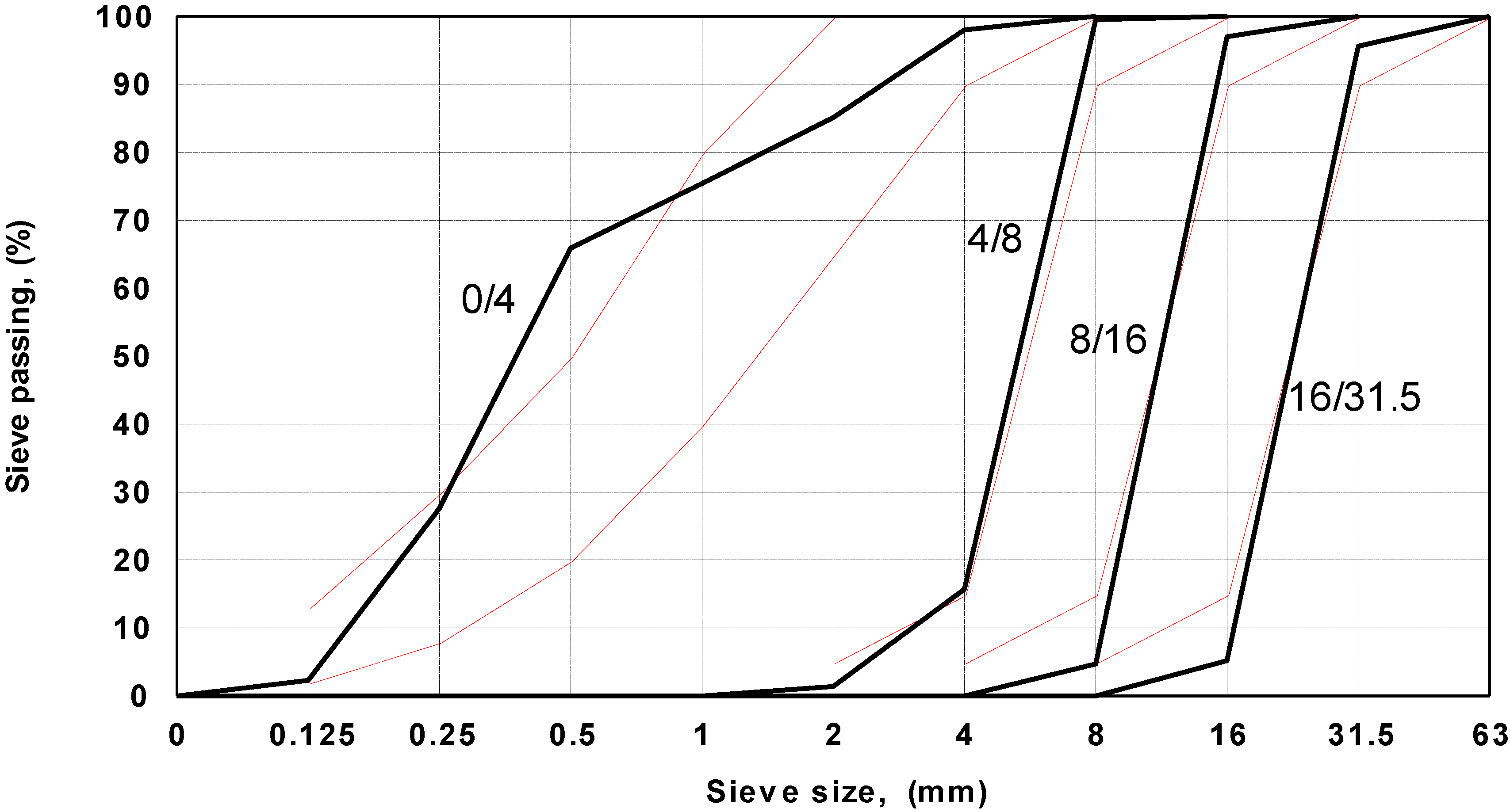

All component materials were tested prior to mix proportion design. The results of natural aggregate testing are shown in

Table 1 and grading curves are shown in

Figure 4.

Table 1.

Results of natural aggregate testing.

Table 1.

Results of natural aggregate testing.

| Tested property | Measured value | Grain size | Quality requirement |

| 0/4 | 4/8 | 8/16 | 16/32 |

Crushing resistance

(in cylinder) | mass loss (%) | - | 14.0 | 18.6 | 23.8 | <30 |

| Freezing resistance test | mass loss (%) | 1.8 | 1.6 | 1.4 | 1.5 | <12 |

| Content of weak grains | (%) | - | 0 | 0 | 0 | <3 (4) |

Crushing resistance

(Los Angeles test) | mass loss (%) | - | 26.3 | 29.0 | 29.2 | <30 |

| Water absorption after 30 minutes | (%) | 0.7 | 0.4 | 0.4 | 0.3 | - |

| Fines content | (%) | 1.6 | 0.23 | 0.15 | 0.12 | <5 (<1) |

| Specific gravity | kg/m3 | 2,655 | 2,666 | 2,669 | 2,671 | 2,000–3,000 |

| Bulk density, uncompacted | kg/m3 | 1,611 | 1,490 | 1,470 | 1,460 | - |

| Bulk density, compacted | kg/m3 | 1,729 | 1,590 | 1,570 | 1,560 | - |

Figure 4.

Grading curves of natural aggregate.

Figure 4.

Grading curves of natural aggregate.

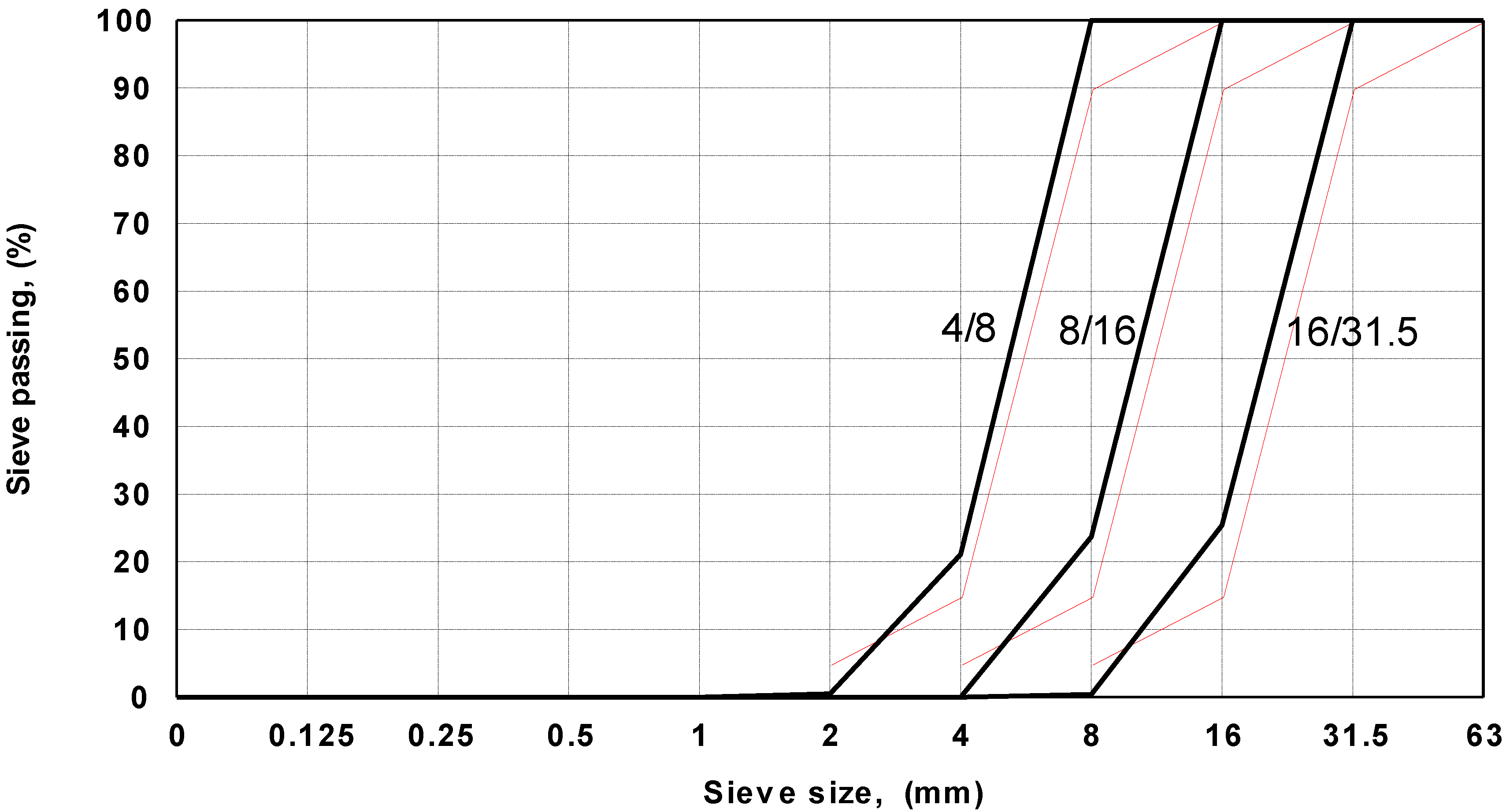

The results of recycled concrete aggregate testing are shown in

Table 2 and grading curves in

Figure 5.

Properties of natural and recycled concrete aggregate were tested according to Serbian standards for natural aggregates and quality requirements given in

Table 1 and

Table 2 are also according to Serbian standard for natural aggregates: SRPS B.B2.010:1986 [

22]. As it can be seen from

Table 2, recycled aggregate with grain sizes of 8/16 and 16/32 don’t satisfy the weak grains content and crushing resistance quality requirements for natural aggregates. This was expected because of the mortar and cement paste attached to the stone particles in the recycled aggregate.

Table 2.

Results of recycled concrete aggregate testing.

Table 2.

Results of recycled concrete aggregate testing.

| Tested property | Measured value | Grain size | Quality requirement |

| 4/8 | 8/16 | 16/32 |

Crushing resistance

(in cylinder) | mass loss (%) | 18.3 | 26.7 | 30.7 | <30 |

| Freezing resistance test | mass loss (%) | 2.0 | 1.4 | 1.0 | <12 |

| Chemical testing (mortar part of recycled aggregate) | chloride content | 0 | 0 | 0 | <0.1 |

| sulfate content | in traces | in traces | in traces | <1.0 |

| pH | 9.85 | 9.85 | 9.85 | - |

| Content of weak grains | (%) | 0 | 3.7 | 7.1 | <3 (4) |

Crushing resistance

(Los Angeles test) | mass loss (%) | 29.6 | 33.7 | 34.0 | <30 |

| Water absorption after 30 minutes | (%) | 4.59 | 2.87 | 2.44 | - |

| Fines content | (%) | 0.45 | 0.23 | 0.36 | <1.0 |

| Specific gravity | kg/m3 | 2,346 | 2,458 | 2,489 | 2,000–3,000 |

| Bulk density, uncompacted | kg/m3 | 1,275 | 1,239 | 1,236 | - |

| Bulk density, compacted | kg/m3 | 1,388 | 1,323 | 1,325 | - |

Figure 5.

Grading curves of recycled concrete aggregate.

Figure 5.

Grading curves of recycled concrete aggregate.

According to test results, natural river aggregate satisfies quality requirements given in [

22] and cement satisfies prescribed quality requirements given in EN 197-1:2,000 [

23].

3.2. Mix Proportion Design

Concrete mix proportions were calculated according to above listed conditions and are shown in

Table 3. Dried recycled aggregate, basic water content and additional water quantity were used to achieve the required workability of RAC.

Table 3.

Design quantities of component materials.

Table 3.

Design quantities of component materials.

| Concrete mixture | Cement

(kg/m³) | Effective water

(kg/m³) | Aggregate

(kg/m³) | Additional water (kg/m³) | Effective water-cement ratio | Total water-cement ratio | Bulk density (kg/m³) |

|---|

| R0 | 350 | 180 | 1857 | 0 | 0.514 | 0.514 | 2,387 |

| R50 | 350 | 180 | 1816 | 19 | 0.514 | 0.569 | 2,365 |

| R100 | 350 | 180 | 1776 | 37 | 0.514 | 0.620 | 2,343 |

Water absorption of recycled aggregates was studied in time intervals for a total of 24 hours. By analyzing the results, it was found that the major changes in the quantity of absorbed water occur in the first 30 minutes. On the other hand, it is known that the major change in the consistency of “ordinary concrete” (without chemical admixtures) occurs in the first 20–30 minutes. Also, after production, concrete must be transported to the site. Taking into account the underlying attitudes, 30 minutes from the moment of adding water to the concrete mixer was adopted as the reference time for the required workability.

Additional water quantity was calculated on the basis of water absorption of recycled aggregate after 30 minutes,

Table 2.

The substitution of natural coarse aggregate with recycled aggregate is made by weight, provided that all mixtures have the same granulometric composition, corresponding to the Fuller’s curve (Dmax = 31.5 mm). Percentage participation of each aggregate fraction in aggregate mixture is given in

Table 4 and corresponding quantity of each aggregate fraction is given in

Table 5.

Table 4.

Percentage participation of each aggregate fraction in aggregate mixture.

Table 4.

Percentage participation of each aggregate fraction in aggregate mixture.

| Concrete type | Natural river aggregate | Recycled concrete aggregate |

|---|

| 0/4 | 4/8 | 8/16 | 16/32 | 4/8 | 8/16 | 16/32 |

|---|

| R0 | 33 | 16 | 21 | 30 | 0 | 0 | 0 |

| R50 | 33 | 8 | 10.5 | 15 | 6.5 | 7.5 | 19.5 |

| R100 | 33 | 0 | 0 | 0 | 13 | 15 | 39 |

Table 5.

Design amounts of different aggregate fractions.

Table 5.

Design amounts of different aggregate fractions.

| Concrete mixture | Content of natural river aggregate (kg/m³) | Content of recycled aggregate (kg/m³) |

| 0/4 | 4/8 | 8/16 | 16/32 | 4/8 | 8/16 | 16/32 |

| R0 | 612 | 298 | 390 | 556 | 0 | 0 | 0 |

| R50 | 600 | 145 | 191 | 272 | 118 | 136 | 354 |

| R100 | 586 | 0 | 0 | 0 | 231 | 266 | 693 |

3.3. Results of Fresh Concrete Testing

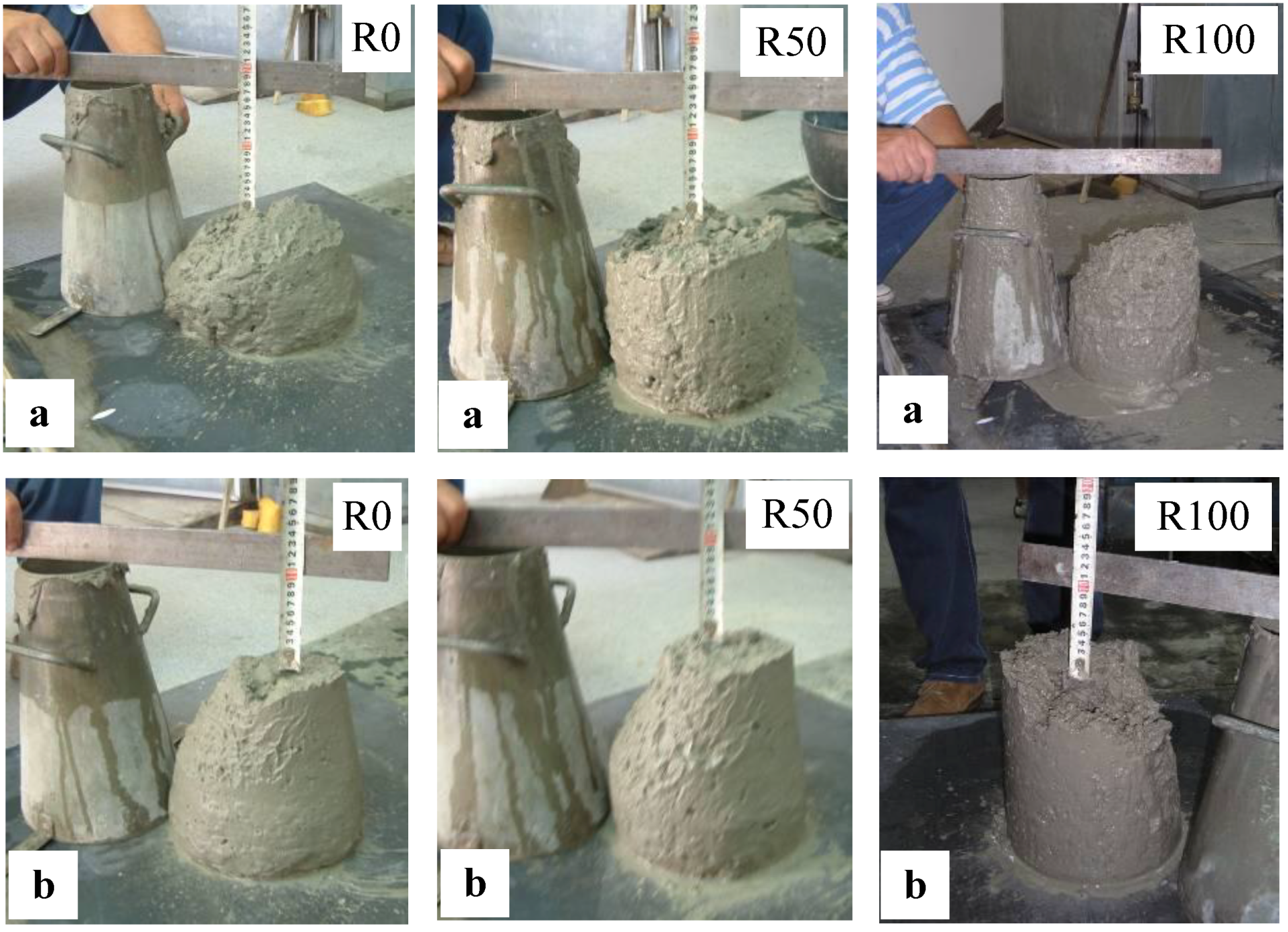

Calculated real amounts of component materials and test results of workability (

Figure 6), air content and bulk density for all three concrete types are presented in

Table 6.

Figure 6.

Slump test (a) after mixing and (b) after 30 minutes.

Figure 6.

Slump test (a) after mixing and (b) after 30 minutes.

Table 6.

Results of fresh concrete testing.

Table 6.

Results of fresh concrete testing.

| Concrete mixture | Cement

(kg/m³) | Total water

(kg/m³) | Aggregate (kg/m³) | Water/cement ratio1 | Aggregate/cement ratio | Slump2

(cm) | Slump3

(cm) | Air content

(%) | Bulk density

(kg/m³) |

|---|

| R0 | 352 | 181 | 1866 | 0.514 | 5.306 | 16 | 10 | 1.5 | 2,399 |

| R50 | 352 | 200 | 1826 | 0.568 | 5.188 | 14.5 | 8.5 | 1.4 | 2,378 |

| R100 | 348 | 216 | 1765 | 0.620 | 5.074 | 11 | 9 | 1.3 | 2,329 |

By analyzing the results of fresh concrete, shown in

Table 6, it was concluded that:

- -

Approximately the same workability after 30 minutes was achieved for all three concrete types using the additional water for concrete R50 and R100 (

Figure 6b).

- -

Concrete mixture R50 requires about 10% more total water quantity in comparison to mixture R0, and the corresponding value for concrete mixture R100 is about 20%.

- -

Differences in air content (Δp) are insignificant. Air content in fresh concrete was determined by standard test method that is based on Boyle-Mariotte’s Law. In [

26] was concluded that the air content of the RAC is higher than concrete made with NA at 100% replacement. However, the author used a gravimetric method for calculation of total air content, including aggregate porosity.

- -

Bulk density of concrete depends on aggregate type and quantity. The highest bulk density has concrete with natural aggregate (R0) and the lowest concrete with maximum content of recycled aggregate (R100). The bulk density decrease is about 3%.

3.4. Results of Hardened Concrete Testing

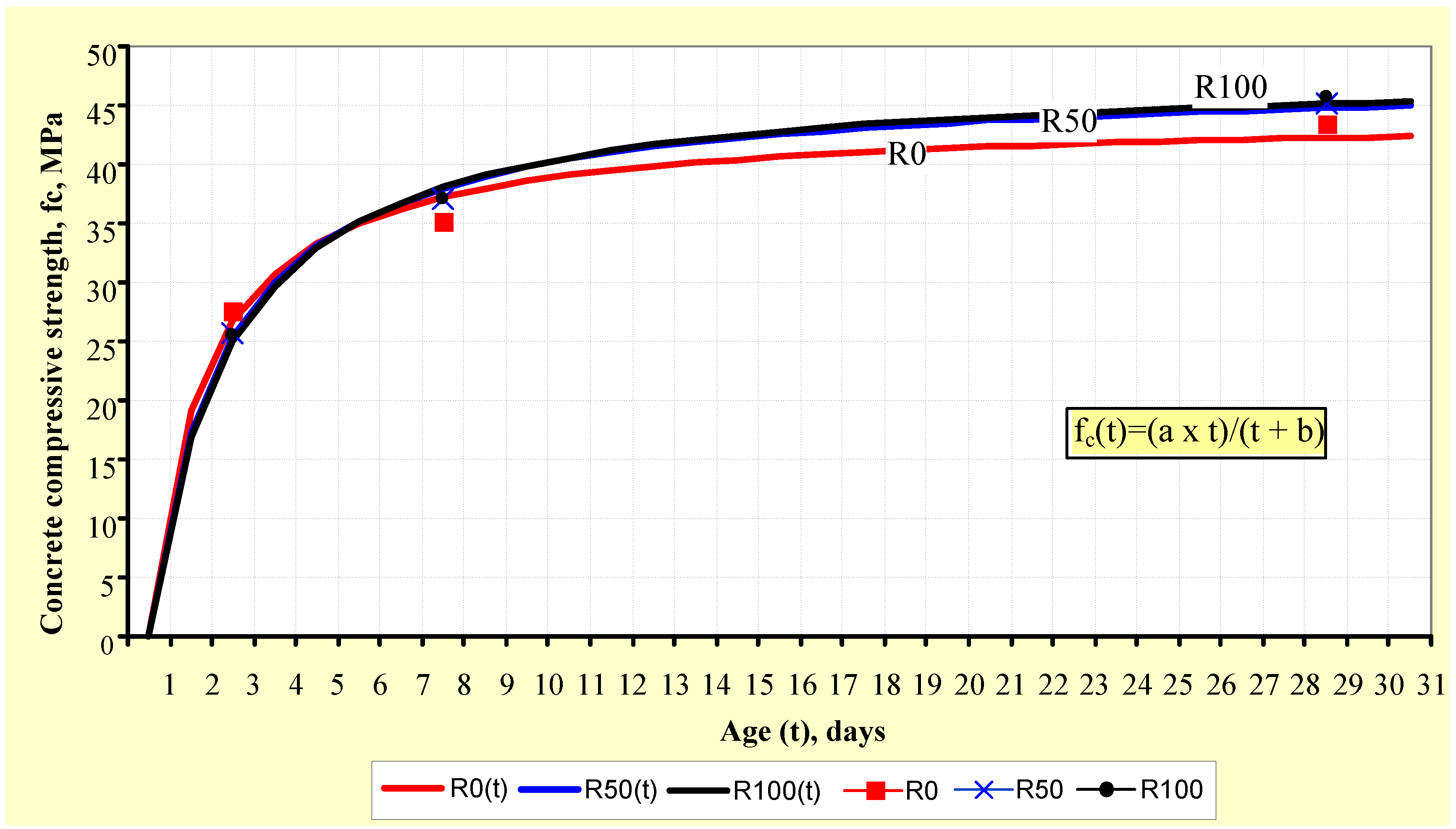

Measured compressive strengths of concrete R0, R50 and R100 at age of 2, 7 and 28 days [

24], are shown in

Table 7 and they represent average values. For each concrete type the following number of specimens (15 cm cubes) were used: three specimens/age 2 days, three specimens/age 7 days and six specimens/age 28 days. Standard deviation for the compressive strength results at age of 28 days is also shown in

Table 7.

Table 7.

Concrete compressive strength and relative compressive strength at different ages.

Table 7.

Concrete compressive strength and relative compressive strength at different ages.

| Concrete type | Concrete age (days) | Standard deviation (MPa) |

|---|

| 2 | 7 | 28 |

|---|

| R0 (MPa) | 27.55 | 35.23 | 43.44 | 1.5769 |

| R50 (MPa) | 25.74 | 37.14 | 45.22 | 1.2089 |

| R100 (MPa) | 25.48 | 37.05 | 45.66 | 3.5016 |

| R50/R0 (%) | 93 | 105 | 104 | |

| R100/R0 (%) | 92 | 105 | 105 | |

Measured values of drying shrinkage of concrete R0, R50 and R100 are shown in

Table 8. The specimens were three prisms (10 × 10 × 40 cm) for each concrete type. An extensometer with 25 cm base was used for measuring.

Table 8.

Drying shrinkage at different concrete ages.

Table 8.

Drying shrinkage at different concrete ages.

| Concrete type | 4 days

(mm/m) | 7 days

(mm/m) | 14 days

(mm/m) | 21 days

(mm/m) | 28 days

(mm/m) | Relative drying shrinkage*, % |

| R0 | 0.017 | 0.124 | 0.203 | 0.277 | 0.339 | 100 |

| R50 | 0.036 | 0.086 | 0.176 | 0.254 | 0.306 | 90 |

| R100 | 0.091 | 0.204 | 0.251 | 0.335 | 0.407 | 120 |

Results of the testing of other properties of the hardened concrete are presented in

Table 9. Each property of hardened concrete was tested on a group of three appropriate specimens at the age of 28 days. Water absorption of concretes R0, R50 and R100 was tested on 15 cm cubes. Splitting tensile strength of concrete was tested on 15 cm cubes, and flexural strength on 10 × 10 × 40 cm prisms. All tests were performed according to Serbian standards for testing the hardened natural aggregate concrete properties.

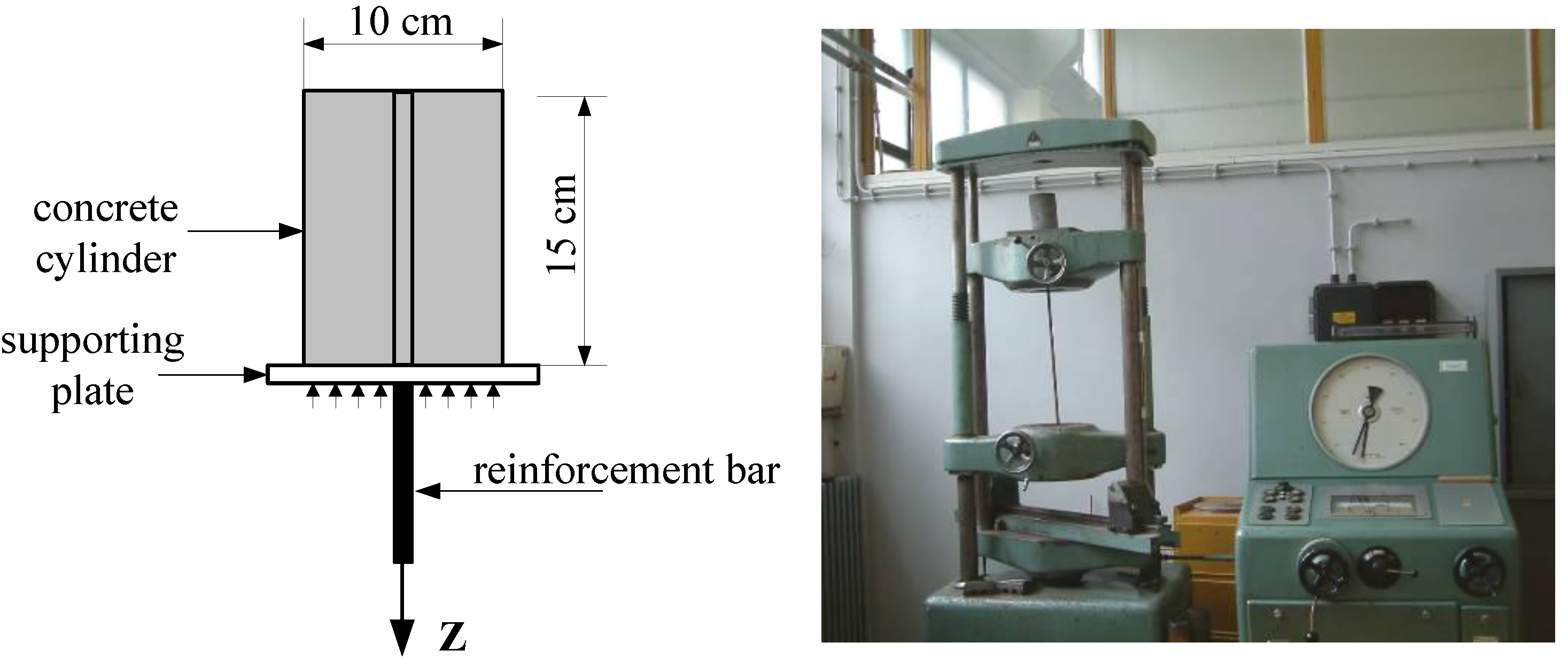

Cylindrical specimens with a diameter of 10 cm and height of 15 cm and with embedded ribbed and mild reinforcement (12 mm diameter) were used for testing the bond between reinforcement and concrete R0, R50 and R100. The length of the embedded part of reinforcement was 15 cm. For this testing, an axial tension procedure and tearing device were used (

Figure 7).

Table 9.

Other properties of hardened concrete at age of 28 days.

Table 9.

Other properties of hardened concrete at age of 28 days.

| Concrete type | R0 | R50 | R100 |

|---|

| Water absorption, (%) | 5.61 | 6.87 | 8.05 |

| Splitting tensile strength, (MPa) | 2.66 | 3.20 | 2.78 |

| Flexural strength, (MPa) | 5.4 | 5.7 | 5.2 |

| Wear resistance, (cm³/50 cm) | 13.40 | 15.58 | 17.18 |

| Modulus of elasticity (GPa) | 35.55 | 32.25 | 29.10 |

| Bond between mild reinforcement and concrete, MPa | 6.48 | 5.87 | 6.76 |

| Bond between ribbed reinforcement and concrete, MPa | 8.22 | 7.50 | 7.75 |

Figure 7.

Testing of bond between concrete and reinforcement.

Figure 7.

Testing of bond between concrete and reinforcement.

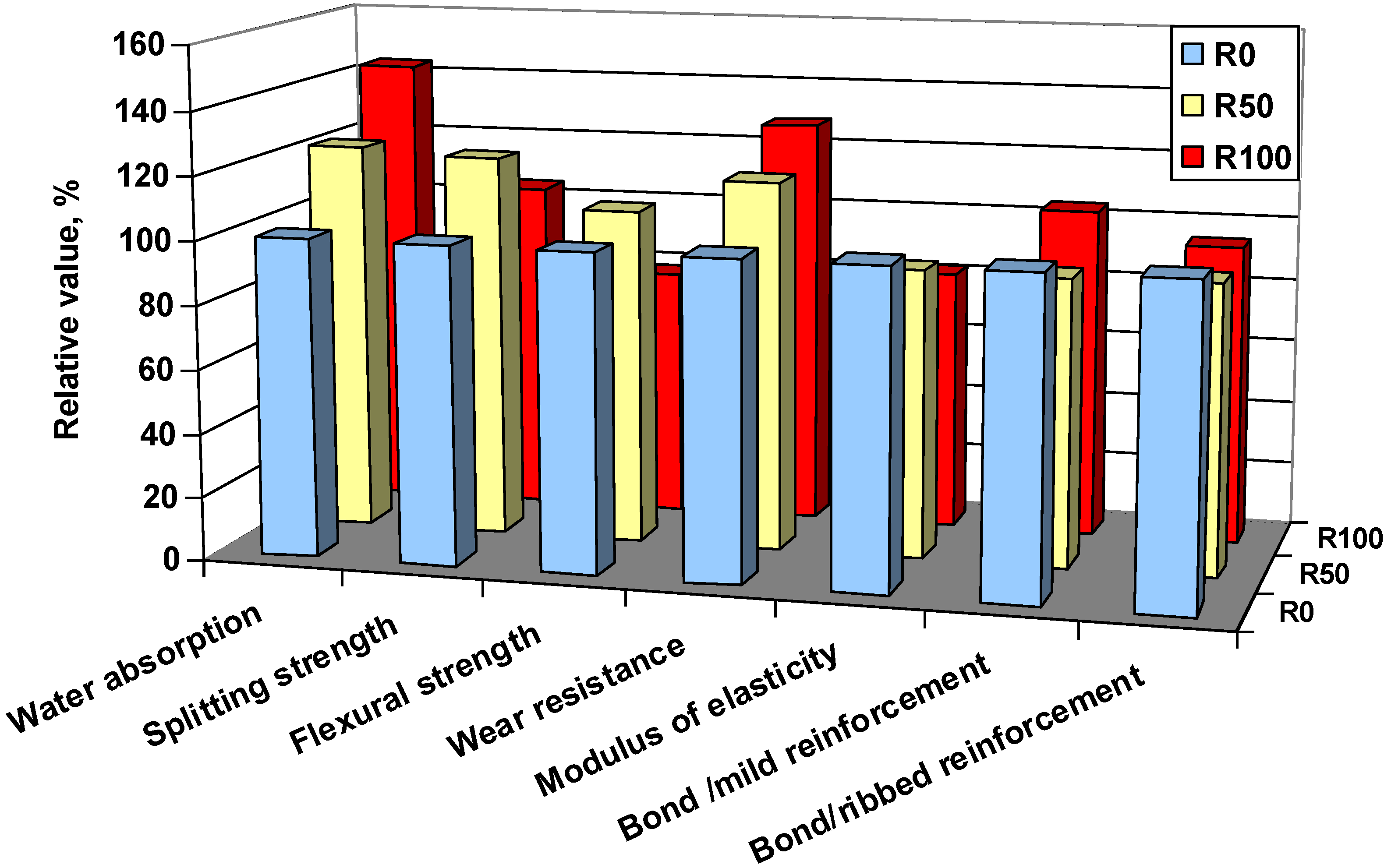

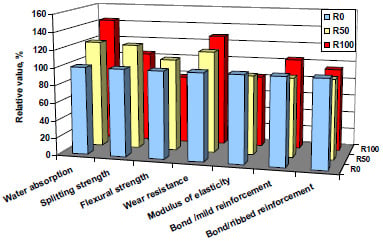

Relative values R50/R0 and R100/R0 for properties presented in

Table 9 are shown graphically in

Figure 8.

Figure 8.

Relative values R50/R0 and R100/R0 for properties of hardened concrete.

Figure 8.

Relative values R50/R0 and R100/R0 for properties of hardened concrete.

3.5. Discussion of Hardened Concrete Properties

To describe the development of concrete compressive strength f

c with time (t), a fraction Function (1) was adopted:

Calculated parameters of this functional relation (“a” and “b”) for concrete R0, R50 and R100, together with correlation coefficient (“r”), are presented in

Table 10. Values of correlation coefficients point to the fact that the chosen fraction function realistically represents the development of compressive strength with time for all three tested concrete types.

Table 10.

Parameters of functional relationship between the compressive strength and age of the concrete.

Table 10.

Parameters of functional relationship between the compressive strength and age of the concrete.

| Concrete type | a | b | r |

|---|

| R0 | 44.242 | 1.320 | 0.976 |

| R50 | 47.556 | 1.761 | 0.997 |

| R100 | 48.116 | 1.856 | 0.996 |

The test results of concrete compressive strength at age of 2, 7 and 28 days (

Table 7) and established functional relations f

c(t) for concrete R0, R50 and R100 are illustrated in

Figure 9.

Figure 9.

The compressive strength of concrete at various ages.

Figure 9.

The compressive strength of concrete at various ages.

Analysis of the concrete compressive strength values points to the following:

- -

all three concrete types have approximately the same compressive strength development with time,

- -

all three concrete types have 28-day compressive strength that is larger than 40 MPa,

- -

differences between compressive strengths of concrete R0, R50 and R100 are negligible for the same concrete age.

To find out if differences between obtained compressive strengths of concrete R0, R50 and R100 at age of 28 days are significant or not, differences between their mean values were statistically tested according to method in [

25]. For that purpose, pairs of corresponding 28-day strength were formed (R0–R50, R0–R100 and R50–R100). Tested value is defined with expression:

where:

t0 = quintile of Student distribution for number of degree of freedom ν = n1 + n2 − 2

xav,1 = average value (set I)

xav,2 = average value (set II)

n1 = number of test results (set I)

n2 = number of test results (set II)

tα = critical value of Student distribution for number of degree of freedom ν = n1 + n2 − 2

σ1 = standard deviation (set I)

σ2 = standard deviation (set II)

Results of this statistical test are shown in

Table 11.

Table 11.

Testing of difference significance for concrete compressive strength.

Table 11.

Testing of difference significance for concrete compressive strength.

| Test pairs | n1 | n2 | s | t0 | tα, for α = 0.05 |

|---|

| (R0 and R50) | 6 | 6 | 1.406523 | 2.189924 | 2.2281 |

| (R0 and R100) | 6 | 6 | 2.7163 | 1.417718 |

| (R50 and R100) | 6 | 6 | 2.61943 | 0.29425 |

On the basis of the results presented in

Table 11 and Criterion (4), it was concluded that differences between measured compressive strengths of concrete R0, R50 and R100 are insignificant (all results belong to the same set of results). This conclusion led to the fact that coarse aggregate type didn’t influence the concrete compressive strength value in this experimental research. This conclusion is opposite to results of other authors [

8,

31,

33], who found that compressive strength decreases with increasing quantity of recycled aggregates in concrete with the same effective water-cement ratio. However, in these experiments, recycled aggregate was obtained from demolished concrete structures of unknown compressive strength. Hansen [

3] find out that substitution of natural aggregate with recycled concrete aggregate up to 30% has no significant influence on concrete compressive strength. Our results confirm the statement that compressive strength of RAC depends more on the quality of recycled aggregate than on the quantity.

According to the analysis of the 28-day drying shrinkage values (

Table 8), it is concluded that:

- -

the lowest shrinkage rate was for concrete R50 (0.3 mm/m), and the highest for R100 (0.4 mm/m),

- -

drying shrinkage of concrete R100 is 20% higher than shrinkage of concrete R0,

- -

difference between 28-day shrinkage of concrete R0 and R50 is less than 10%.

The obtained results for drying shrinkage of RAC correspond to results of other authors, who found larger or smaller values for drying shrinkage compared to NAC [

10,

14,

29].

The test results of wear resistance are shown in

Figure 10. It is concluded that the highest material loss occurs for concrete R100 and the lowest for concrete R0.

Figure 10.

Test results of concrete wear resistance.

Figure 10.

Test results of concrete wear resistance.

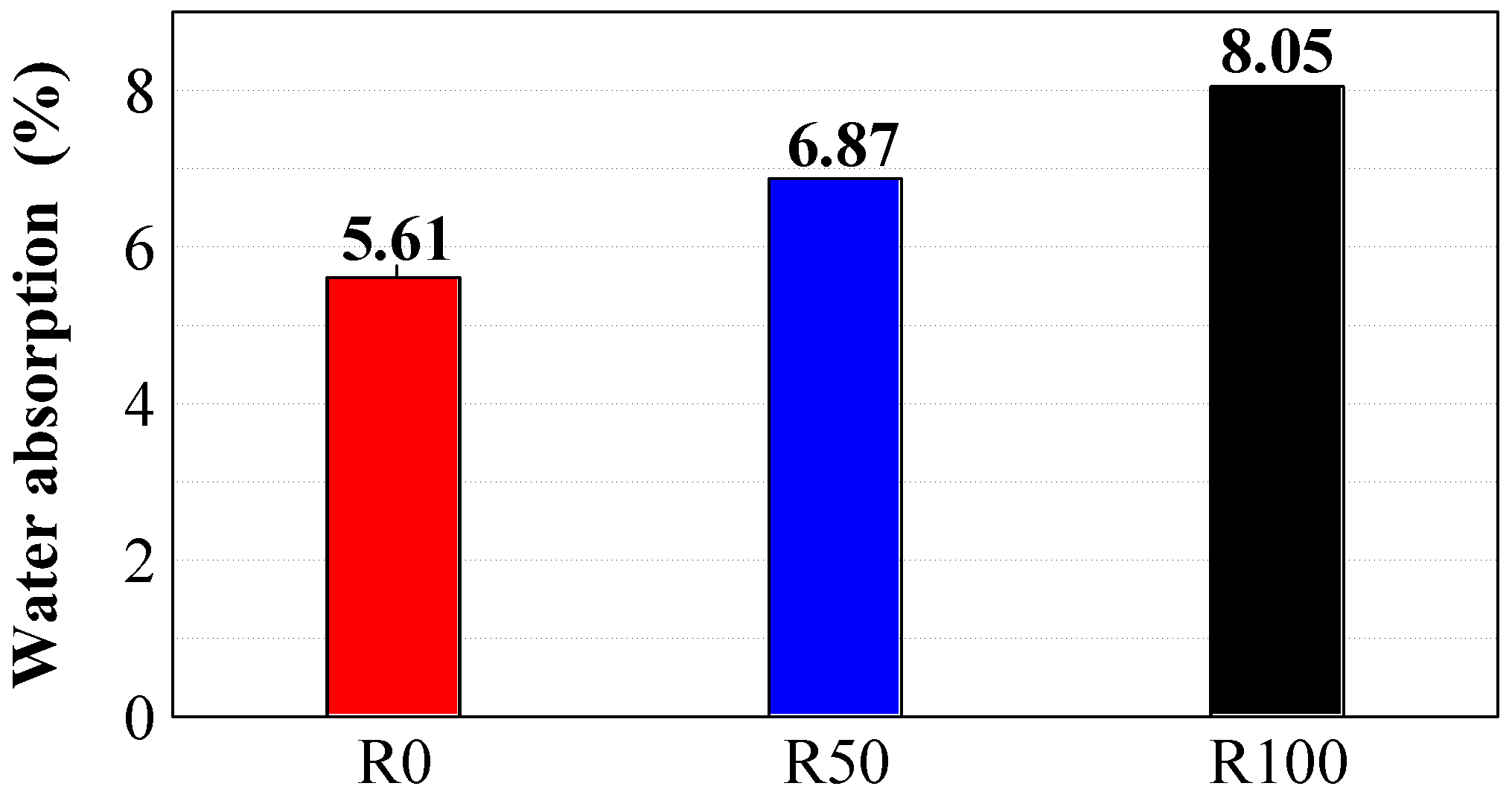

The analysis of water absorption values (shown in

Figure 11), points to the following:

- -

the lowest water absorption was registered in concrete R0 and the highest in R100,

- -

concrete R50 has 22% higher absorption, while concrete R100 has 44% higher absorption than control concrete R0.

Figure 11.

Test results of concrete water absorption.

Figure 11.

Test results of concrete water absorption.

By using the same statistical method as for the analysis of measured values of splitting tensile strengths (

Table 9), it was concluded that differences between measured splitting tensile strengths are insignificant (all results belong to the same set of results). The same conclusion is drawn for flexural strength results (

Table 9). Hansen [

3] states that both tensile strengths of RAC are maximum 10% less than the tensile strength of NAC. Other papers [

27,

28] and [

29] also confirmed that RAC tensile strength is not significantly affected by the amount of recycled coarse aggregate.

Our analysis of the obtained values of bond between mild and ribbed reinforcement and concrete R0, R50 and R100 (

Table 9) shows that:

- -

difference between lowest and highest bond for both reinforcement types is about 10%,

- -

bond between tested concretes and ribbed reinforcement is higher at least 15% than bond between tested concretes and mild reinforcement.

Although all three concrete types have similar compressive strength, the modulus of elasticity is lower for the concrete with recycled aggregate,

Table 9. This decrease depends on the content of the recycled aggregate and maximum decrease is for the concrete with maximum recycled aggregate content. The modulus of elasticity of concrete R100 is lower than the modulus of elasticity of control concrete R0 by about 18%. The same decreasing of modulus of elasticity was found in research [

14].

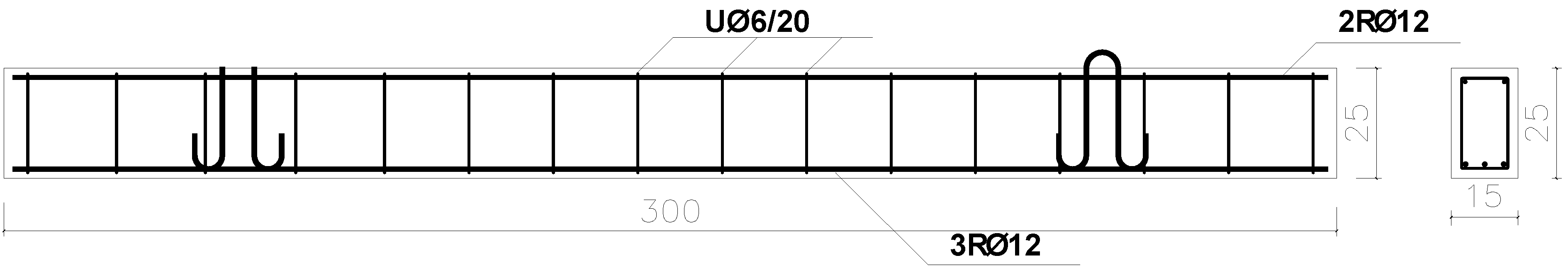

3.6. Load Testing of Reinforced Concrete (RC) Beams

Tested concrete types (R0, R50 and R100) were used for producing RC beams (beams “R0”, “R50” and “R100”). Three beams with a length of 3.0 m and rectangular cross section of 15/25 cm were prepared for flexural testing. Beams were reinforced with ribbed reinforcement 3R∅12 in the lower zone, 2R∅10 in the upper zone and with stirrups ∅6/20 (

Figure 12).

Figure 12.

Characteristic dimensions of RC beams and arrangement of reinforcement.

Figure 12.

Characteristic dimensions of RC beams and arrangement of reinforcement.

Details of the production of the beams for experimental testing is shown in

Figure 13 and

Figure 14.

Figure 13.

Moulds with placed reinforcement.

Figure 13.

Moulds with placed reinforcement.

Figure 14.

Finishing of the beams concrete surface.

Figure 14.

Finishing of the beams concrete surface.

The maximum (failure) load was calculated for the “RO” beam. Stresses in concrete and reinforcement, deflections and characteristic cracks width were calculated using the program CREEP (authors M. Tatomirovic, P. Pavlovic). Calculated values for the beam with referent concrete R0—beam “R0” are shown in

Table 12.

Table 12.

Calculated values for cross-section in the middle of the span (beam “R0”).

Table 12.

Calculated values for cross-section in the middle of the span (beam “R0”).

| Phase | Load (kN) | Beam edge | Stress in concrete

(MPa) | Stress in reinforcement

(MPa) | Deflection

(mm) | Crack width

(mm) |

|---|

| I | 5 | upper | 4.075 | | 0.46 | 0.017 |

| lower | | 65.569 |

| II | 10 | upper | 7.278 | | 1.54 | 0.062 |

| lower | | 117.092 |

| III | 20 | upper | 13.683 | | 3.87 | 0.137 |

| lower | | 220.139 |

| IV | 30 | upper | 20.087 | | 6.10 | 0.207 |

| lower | | 323.186 |

| V | 40 | upper | 26.492 | | 8.33 | 0.276 |

| lower | | 426.233 | | |

| VI | 50 | upper | 32.897 | | failure |

| | | lower | | 529.279 | |

At the age of 28 days, the beams were subjected to load testing (bending with concentrated force in the middle of the span). The arrangement of measuring spots for registering deflections and strains in the concrete and reinforcement is shown in

Figure 15. The load was increased in six phases until failure of the beams. During load testing, the following data were registered: deflections, reinforcement strains, concrete strains, arrangement and width and length of cracks.

Figure 15.

Arrangement of measuring spots throughout the beam. (U—deflection; T—strain in reinforcement; D—strain in concrete).

Figure 15.

Arrangement of measuring spots throughout the beam. (U—deflection; T—strain in reinforcement; D—strain in concrete).

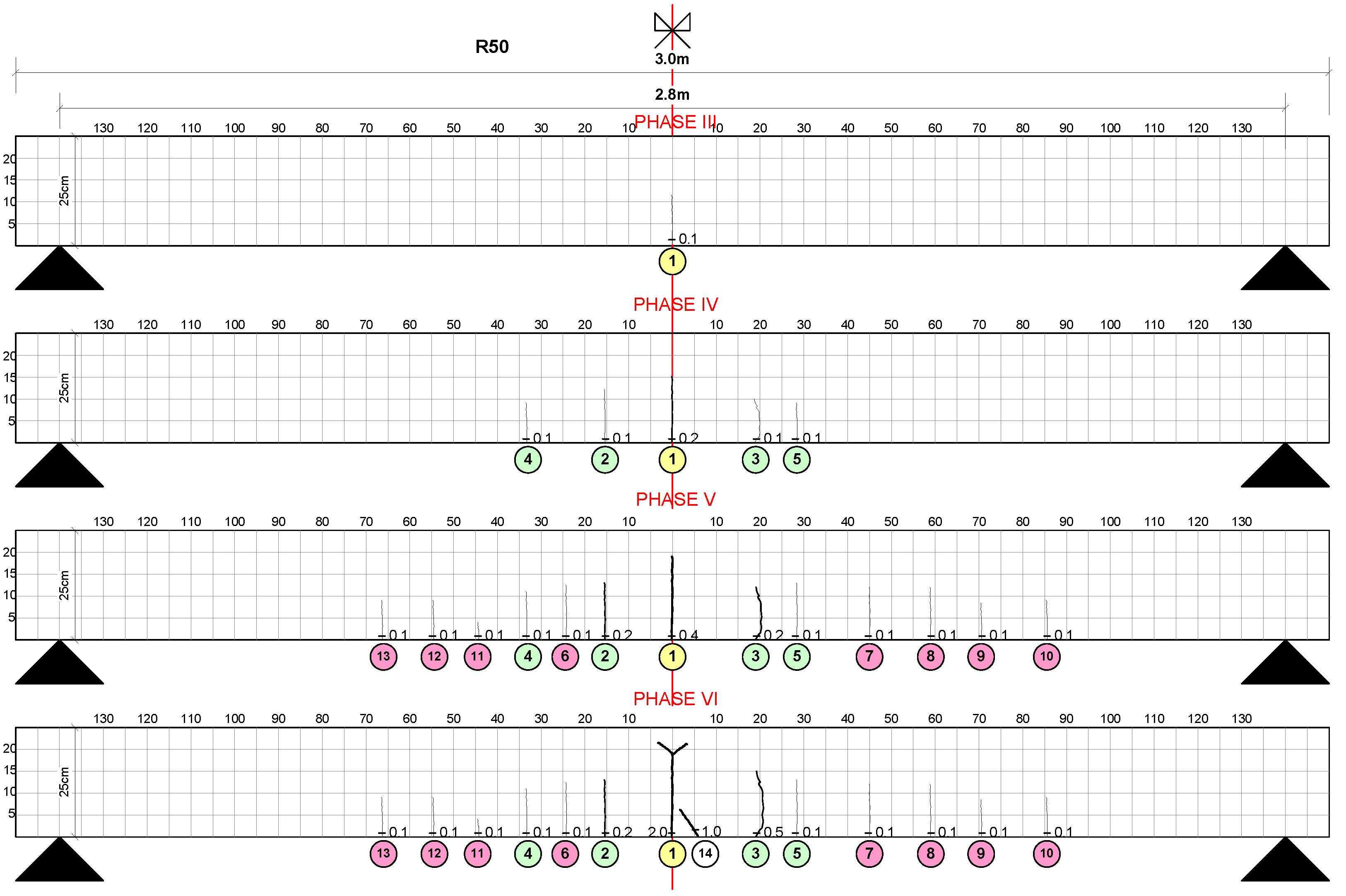

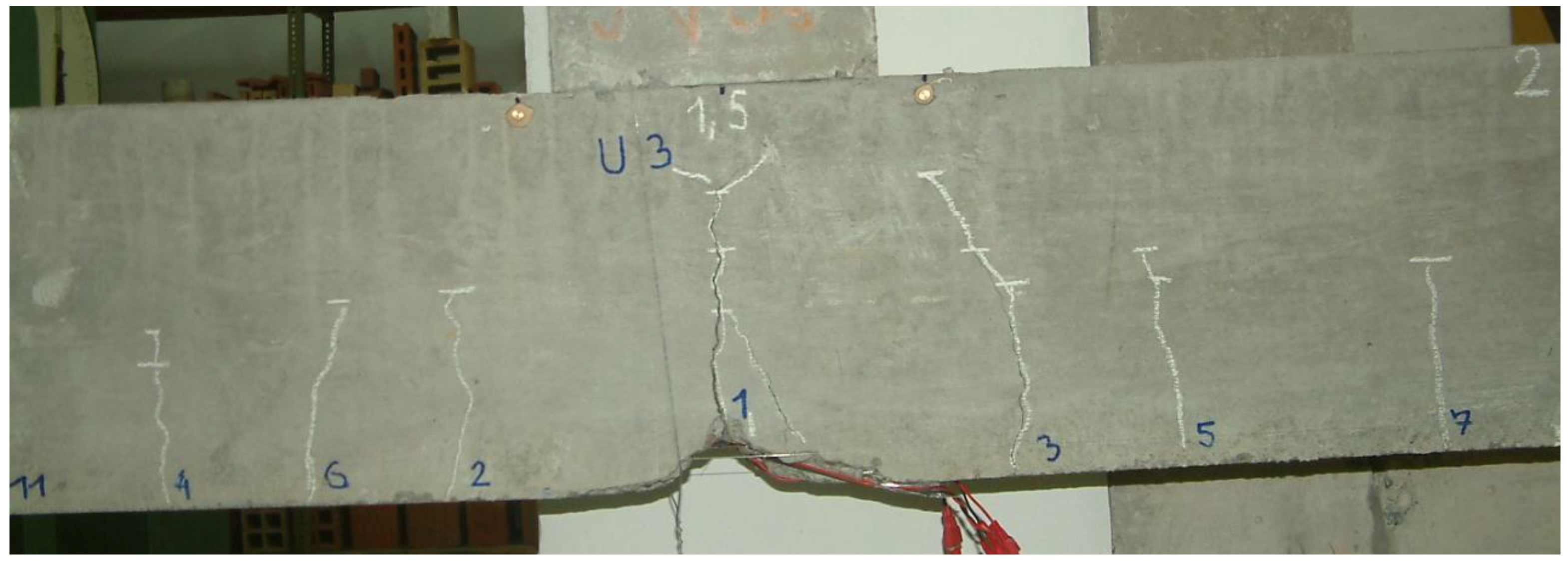

An example of the appearance and development of cracks during the load testing of beam R50 is presented graphically in

Figure 16. The photo of a crack pattern in the middle part of the span, after failure, is shown in

Figure 17.

Figure 16.

Development of cracks during load testing of beam R50.

Figure 16.

Development of cracks during load testing of beam R50.

Figure 17.

Crack pattern after collapse of beam R50.

Figure 17.

Crack pattern after collapse of beam R50.

By analysis of registered cracks on all tested RC beams, it was concluded:

- -

First crack appears in the middle of the span in the third load phase (P = 20 kN).

- -

The maximum width of cracks after collapse is between 2.0 and 2.7 mm.

- -

Similar disposition and width of cracks was registered on all tested RC beams.

The measured deflections and stresses in concrete in the middle of the span are presented in

Table 13. Measured stresses in the concrete are based on measured concrete strains.

Table 13.

Measured deflections and stresses in concrete in the middle of the span.

Table 13.

Measured deflections and stresses in concrete in the middle of the span.

| Phase | Load kN | Deflection, (mm) | Concrete compressive stress, (MPa) |

| R0 | R50 | R100 | R0 | R50 | R100 |

| I | 5 | 0.55 | 0.67 | 0.73 | - | - | - |

| II | 10 | 0.89 | 1.21 | 1.37 | 1.32 | 2.64 | 3.04 |

| III | 20 | 2.68 | 2.78 | 2.94 | 7.00 | 8.05 | 8.71 |

| IV | 30 | 4.66 | 5.97 | 6.89 | 12.80 | 10.96 | 14.78 |

| V | 40 | 7.43 | 10.52 | 11.78 | 20.20 | 21.12 | 24.02 |

| VI | 50 | failure |

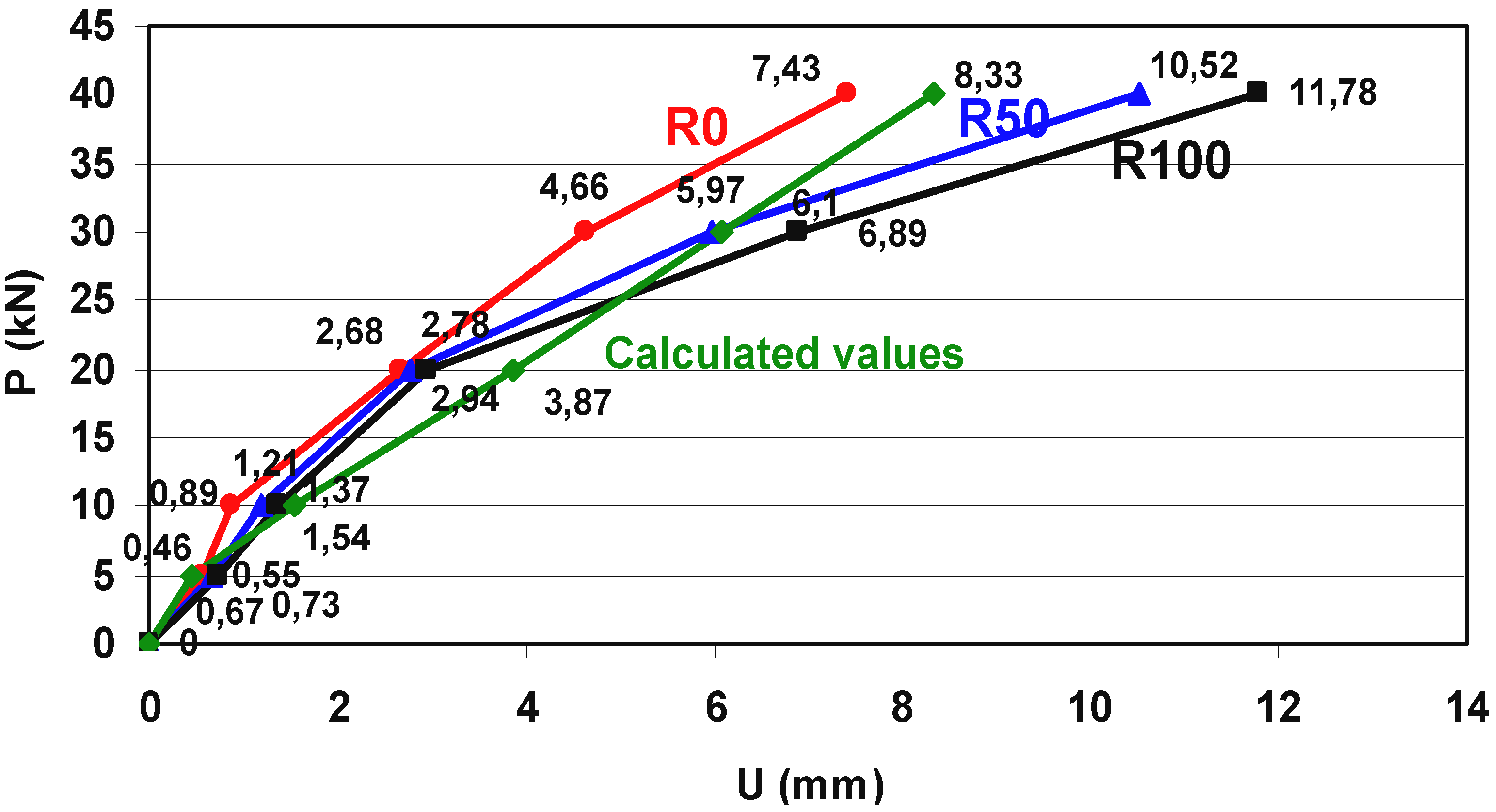

For the purpose of comparing beam behavior during loading, the calculated deflections of beam “R0” and measured deflections of all three beam types are presented in

Figure 18.

Figure 18.

Calculated and measured values of deflection of all tested beams.

Figure 18.

Calculated and measured values of deflection of all tested beams.

In the elastic area all tested beams have similar deflection, which means that for appropriate load level the quantity of coarse recycled concrete aggregate has no significant influence on the beam behavior. Fanthifazl [

34] had the similar conclusion in regard to the behavior of beams exposed to bending.

At the higher values of the test load, deflection depends on the type and quantity of used aggregate (with increasing quantity of recycled aggregate, the deflection value is increasing also). The different values of modulus of elasticity of used concrete types are the main cause for recorded behavior of tested beams in the post elastic area.

According to these test results, concrete compressive stresses depend on the type and quantity of used aggregate. With increasing of recycled aggregate content up to 100%, concrete compressive strength is increasing up to 25%.

4. Conclusions

On the basis of our comparative analysis of test results of the basic properties of concrete with three different percentages of coarse recycled aggregate content (0%, 50% and 100%), the following conclusions are made.

The way of preparing recycled aggregate for concrete mixtures influences the concrete workability: workability of concrete with natural and recycled aggregate is almost the same if “water saturated—surface dry” recycled aggregate is used. Also, if dried recycled aggregate is used and additional water quantity is added during mixing, the same workability can be achieved after a prescribed time. Additional water quantity depends on the time for which the same workability has to be achieved. It is determined as water quantity for which the recycled aggregate absorbs for the same period of time.

Bulk density of fresh concrete is slightly decreased with increasing quantity of recycled aggregate.

The type of coarse aggregate has no influence on the air content in concrete.

Concrete compressive strength mainly depends on the quality of recycled aggregate. If good quality aggregate (obtained by crushing higher strength class concrete as in this case) is used for the production of new concrete, the recycled aggregate has no influence on the compressive strength, regardless of the replacement ratio of natural coarse aggregate with recycled aggregate. The same conclusion is valid for concrete tensile strength (splitting and flexural).

The water absorption of concrete depends on the quantity of recycled aggregate. The amount of absorbed water is proportionally increased with increasing recycled aggregate content. Water absorption depends on the porosity of cement matrix in the new concrete and porosity of cement matrix of the recycled concrete: if recycled aggregate is produced from low porosity waste concrete, water absorption of the new concrete depends on the achieved structure of the new cement matrix.

Wear resistance of the concrete depends on the amount of recycled aggregate. Concrete wear resistance decreases with increasing recycled aggregate content, due to the increased quantity of hardened cement paste, which wears easier than grains of natural aggregate.

The modulus of elasticity of concrete also decreases with increasing recycled aggregate content as a consequence of lower modulus of elasticity of recycled aggregate compared to natural aggregate.

Shrinkage of concrete depends on the amount of recycled concrete aggregate. Concrete with more than 50% of recycled coarse aggregate has significantly more shrinkage compared to concrete with natural aggregate. Increased shrinkage is a result of the attached mortar and cement paste in the recycled aggregate grains.

The bond between recycled aggregate concrete and reinforcement is not significantly influenced by recycled concrete aggregate, because it is realized through new cement paste.

According to these test results, the performance of recycled aggregate concrete, even with the total replacement of coarse natural with coarse recycled aggregate, is mainly satisfactory, not only in terms of the mechanical properties, but also the other requirements related to mixture proportion design and production of this concrete type. The only two properties those are lower than for the natural aggregate concrete properties are the modulus of elasticity and shrinkage deformation. Because of that, it is not recommended to apply this type of concrete for structural elements for which large deformations can be expected. Also, this type of concrete shouldn’t be used for structures exposed to aggressive environment conditions without appropriate previous testing, as there are opposing conclusions about durability-related properties of RAC in existing literature [

3,

16,

30,

32].

Based on the results of the load tests on the reinforced concrete beams, it is concluded that used coarse aggregate type and quantity has no significant influence on the pattern and width of cracks. First, crack appears in the middle of the span at a load level equal to about one third of the ultimate load regardless of the concrete type. The measured crack widths were approximately the same for all three tested beams.

On the other hand, concrete compressive stresses depend on the quantity of recycled concrete aggregate for all load phases. Increasing the quantity of coarse RCA up to 100% increased the concrete compressive stress up to 25% in these tests.

Deflections of tested beams do not depend on the type and quantity of used aggregate in the elastic area—similar deflections were registered regardless of the concrete type. However, in the post elastic area, with increasing quantity of coarse recycled aggregate the deflection value increased. The deflection increase compared to deflection of the “R0” beam is 4% for the “R50” beam and 10% for the “R100” beam for the service load level. The main reason for such behavior of the tested beams is a lower modulus of elasticity of concrete types R100 and R50 in comparison to referent concrete R0.

All the conclusions made in this work about the tested properties of fresh and hardened concrete and consequently, about the behavior of beams subjected to bending, are valid for recycled aggregate concrete produced with quality recycled aggregate, obtained from demolished concrete with good mechanical properties, as it was the case in this experimental research.