Global Polyethylene Terephthalate (PET) Plastic Supply Chain Resource Metabolism Efficiency and Carbon Emissions Co-Reduction Strategies

Abstract

:1. Introduction

- Establishing the material flow baseline for the PET plastic supply chain in 2020 for major producing countries, divided into 12 regions (41 countries in total), and assessing the PET resource metabolism efficiency of each country;

- Calculating the annual greenhouse gas emissions of the PET supply chain in 12 countries and regions (covering 41 countries) in 2020, identifying emission hotspots;

- Assessing the potential for improving resource metabolism efficiency and the potential for reducing greenhouse gas emissions in the PET plastic industry under 13 scenarios from 2020 to 2030 (related to plastic demand, plastic waste exports, waste collection, and recycling technologies), providing scientific support for strategies aimed at reducing plastic waste generation and greenhouse gas emissions.

2. Materials and Methods

2.1. System Boundaries

2.2. Modeling Approach

2.3. Scenario Definition

2.3.1. Baseline Scenario (S0)

2.3.2. Improvement in Collection (S1)

2.3.3. Improvement in Sorting (S2)

2.3.4. Improvement in Recycling (S3)

2.3.5. Improvement in Incineration with Energy Recovery (S4)

2.3.6. Banning the Export of Waste (S5)

2.3.7. Committing 100% to Strict Closed-Loop (S6)

2.3.8. Recycling 100% to Fibers (S7)

2.3.9. Combined Scenarios (S8–S13)

2.4. Evaluation Indicators

2.5. Data Source

3. Results

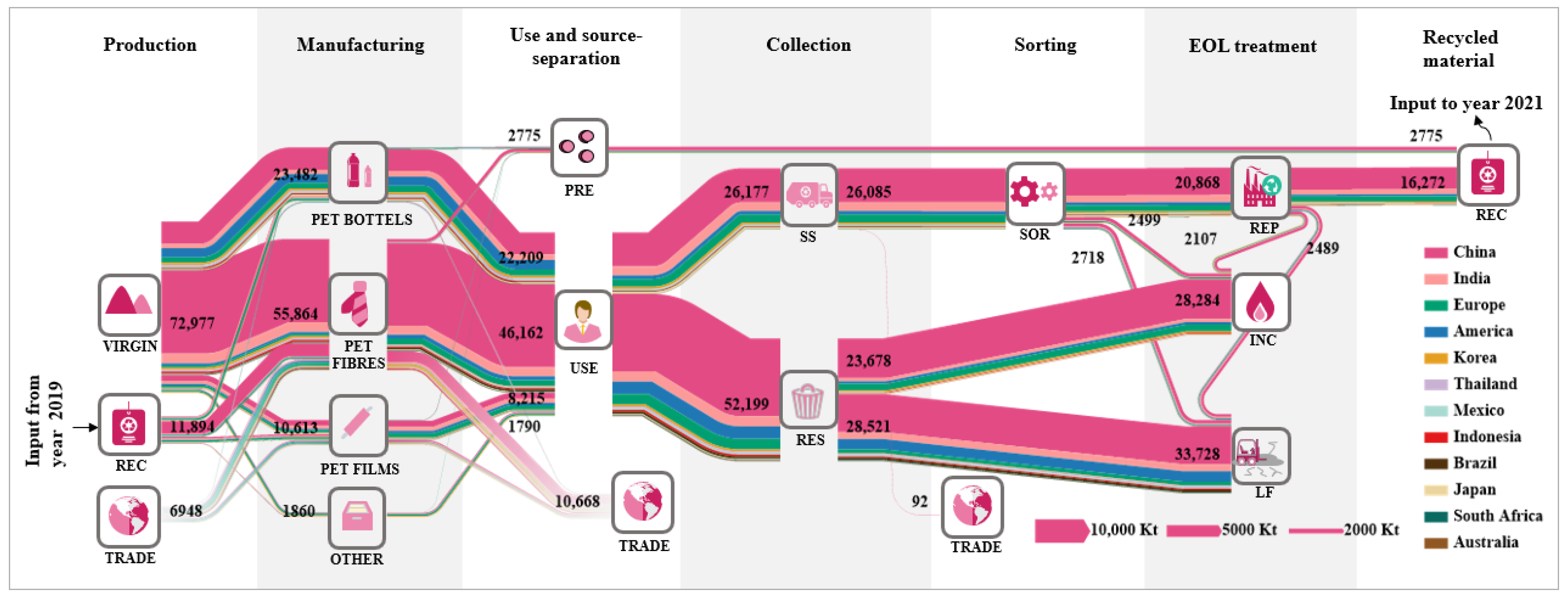

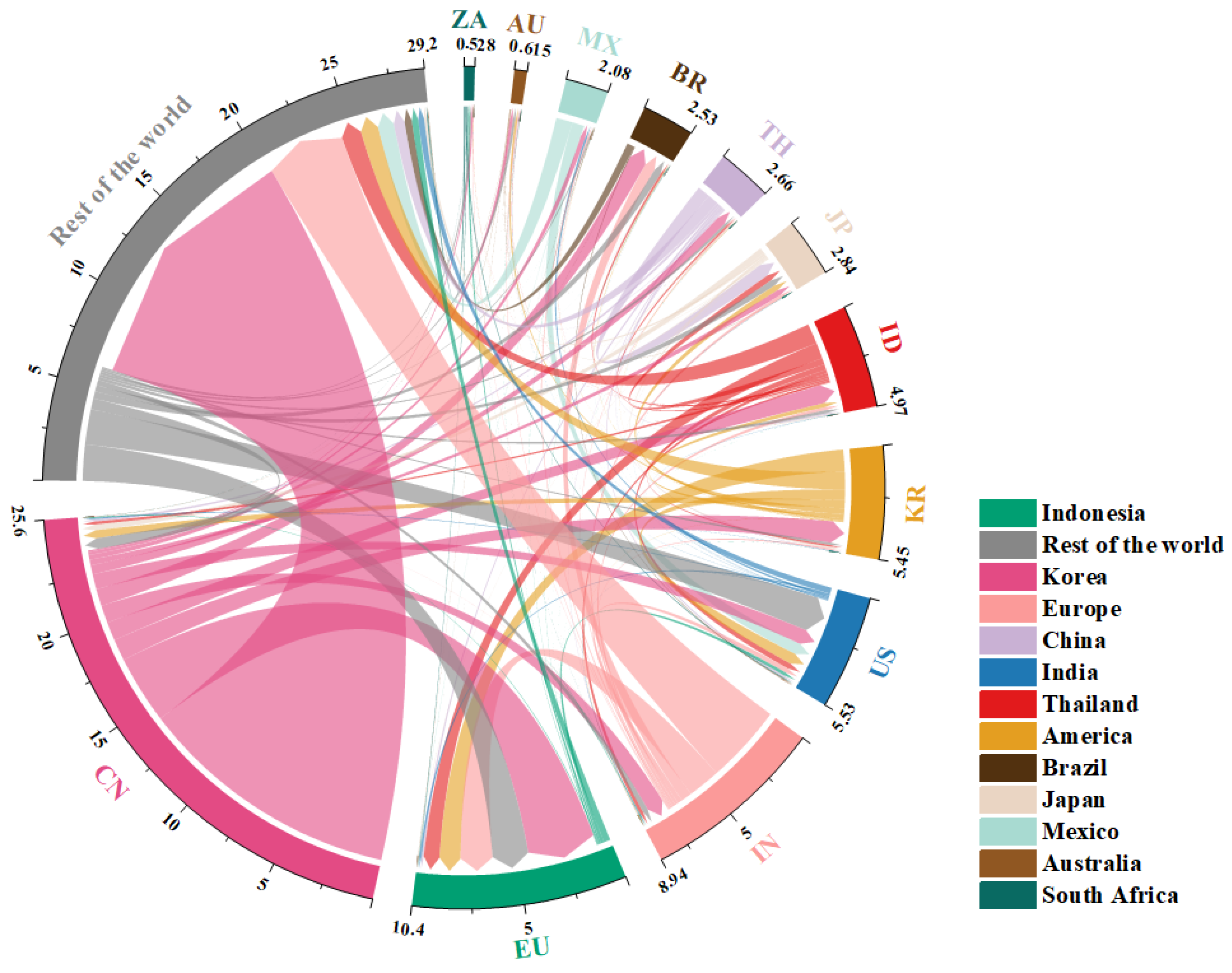

3.1. Baseline Material Flow System of PET

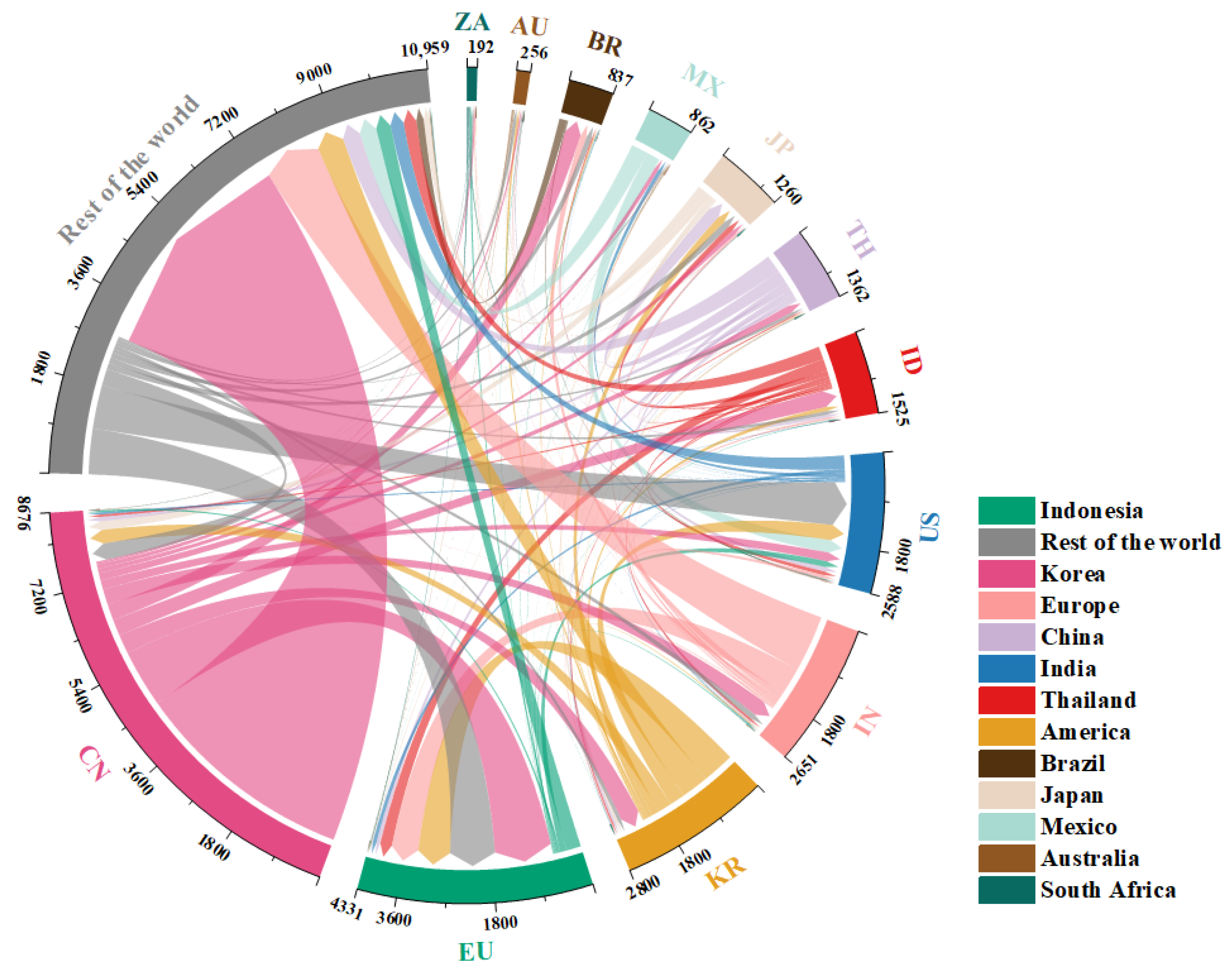

3.2. Resource Metabolism Efficiency across Countries

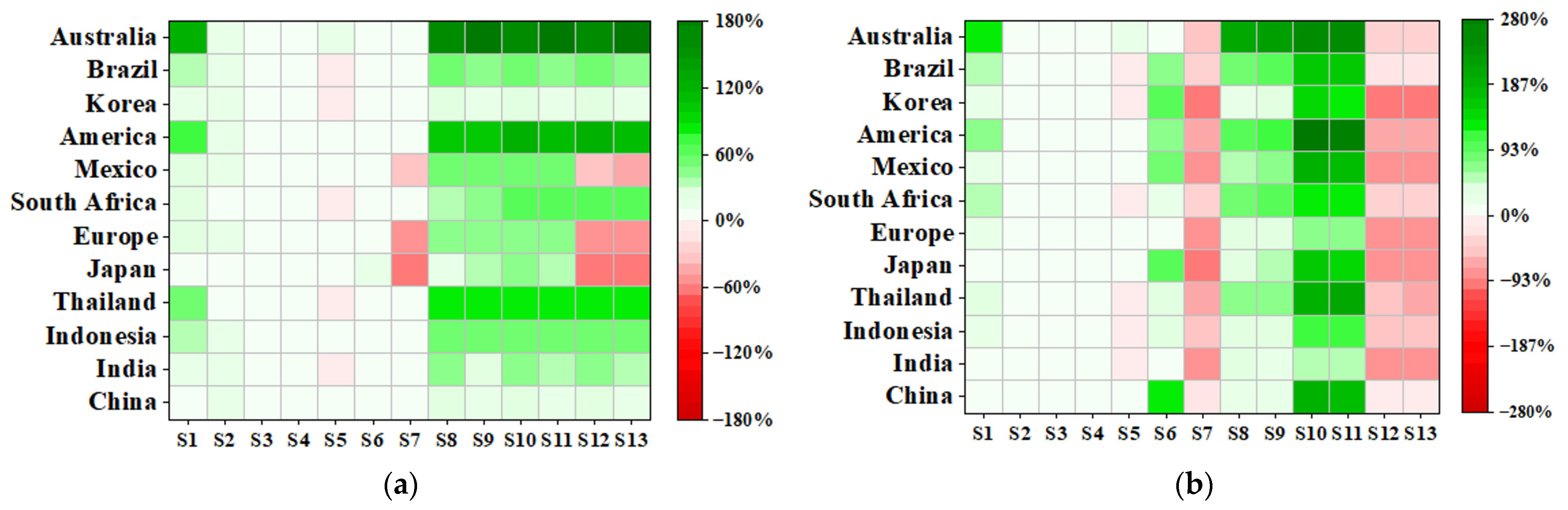

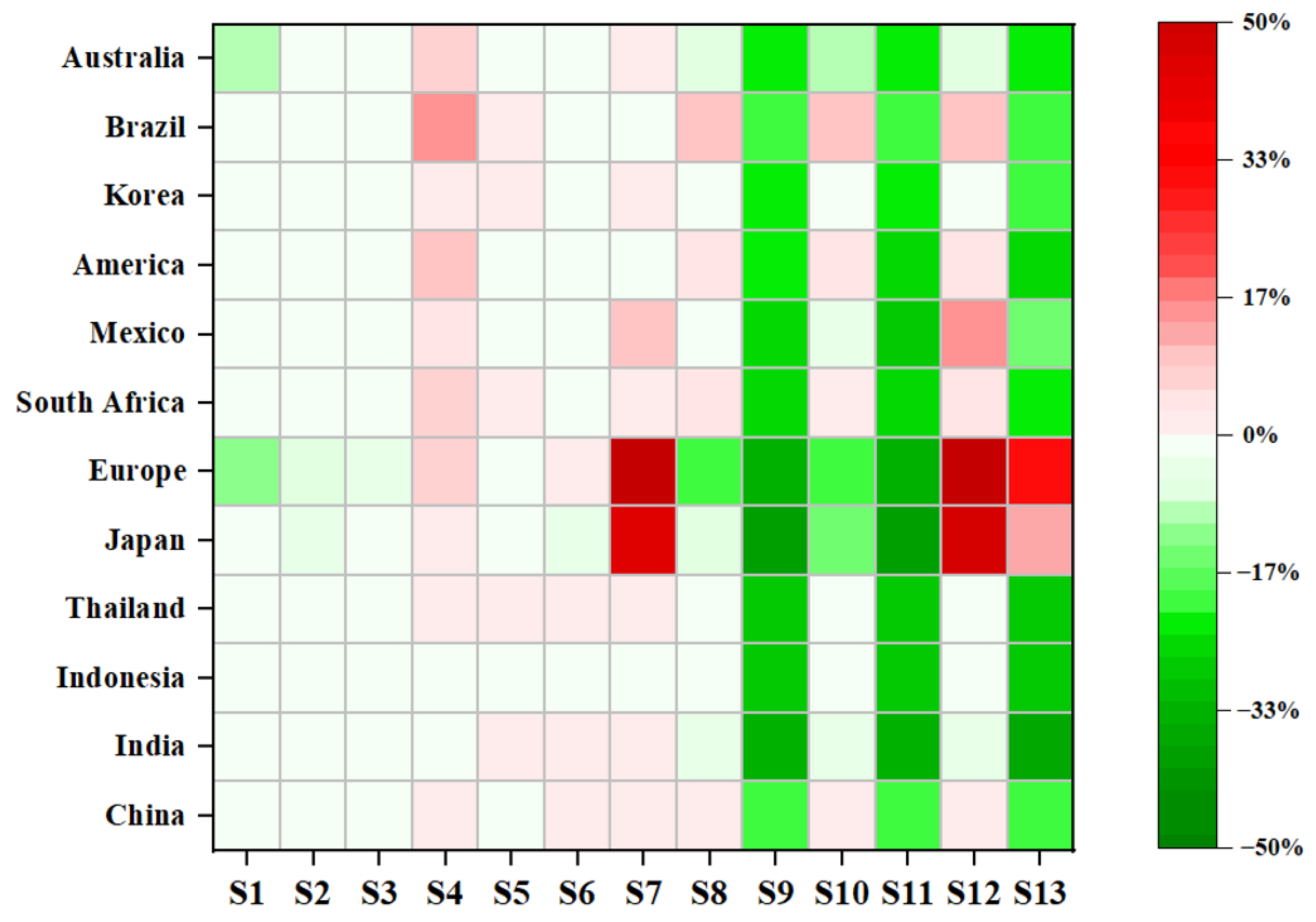

3.3. Variations in Metabolic Efficiency Indicators in Different Scenarios

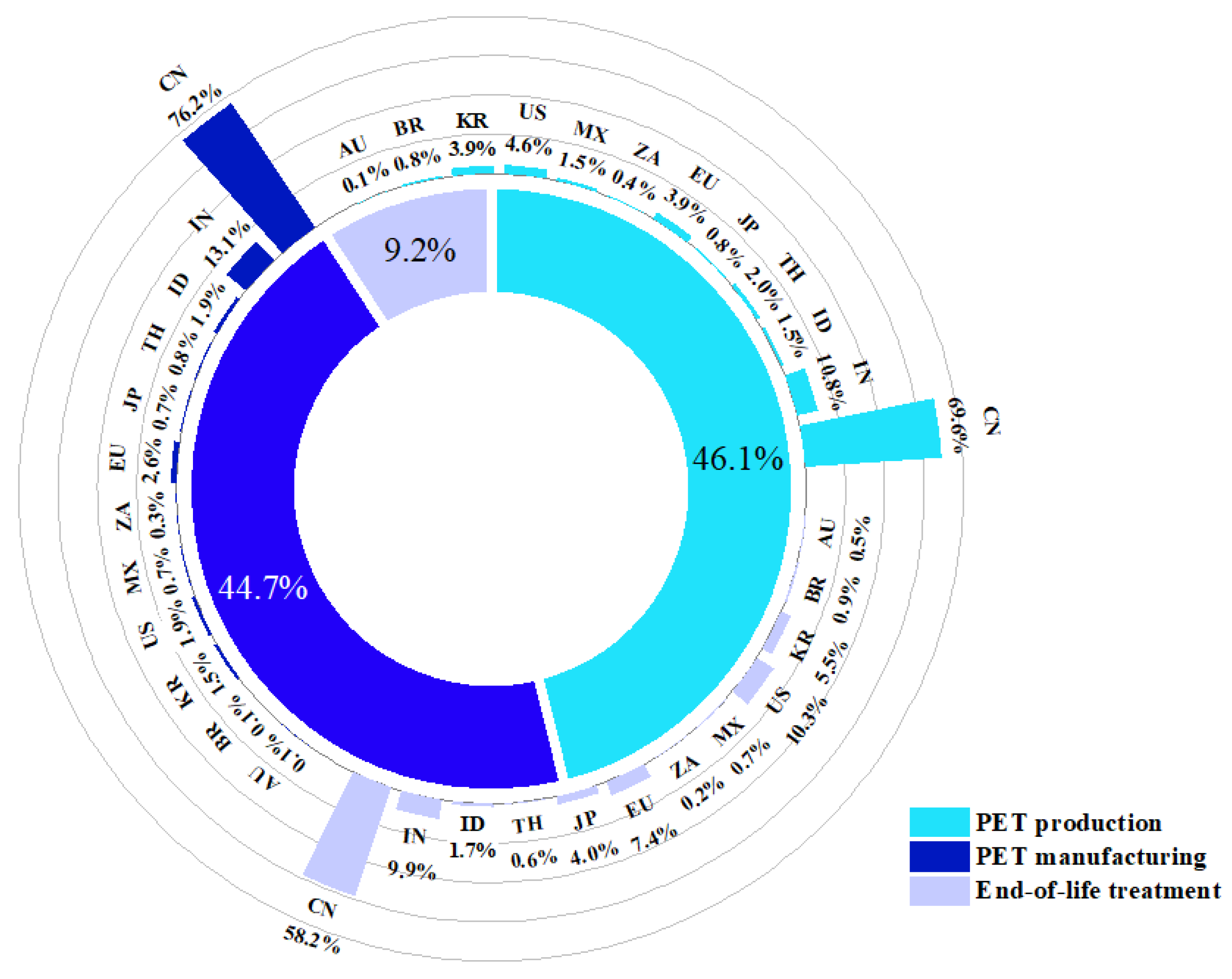

3.4. GHG Emissions of PET Plastic Supply Chains in 2020

3.5. Variations in Greenhouse Gas Emissions in Different Scenarios

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Levi, P.G.; Cullen, J.M. Mapping Global Flows of Chemicals: From Fossil Fuel Feedstocks to Chemical Products. Environ. Sci. Technol. 2018, 52, 1725–1734. [Google Scholar] [CrossRef] [PubMed]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, Use, and Fate of All Plastics Ever Made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef] [PubMed]

- Moore, C.J. Synthetic Polymers in the Marine Environment: A Rapidly Increasing, Long-Term Threat. Environ. Res. 2008, 108, 131–139. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Shan, Y.; Guan, D.; Liang, X.; Cai, Y.; Liu, J.; Xie, W.; Xue, J.; Ma, Z.; Yang, Z. Sharing Tableware Reduces Waste Generation, Emissions and Water Consumption in China’s Takeaway Packaging Waste Dilemma. Nat. Food 2020, 1, 552–561. [Google Scholar] [CrossRef] [PubMed]

- Rahmani, E.; Dehestani, M.; Beygi, M.H.A.; Allahyari, H.; Nikbin, I.M. On the Mechanical Properties of Concrete Containing Waste PET Particles. Constr. Build. Mater. 2013, 47, 1302–1308. [Google Scholar] [CrossRef]

- Awaja, F.; Pavel, D. Recycling of PET. Eur. Polym. J. 2005, 41, 1453–1477. [Google Scholar] [CrossRef]

- Ryberg, M.W.; Hauschild, M.Z.; Wang, F.; Averous-Monnery, S.; Laurent, A. Global Environmental Losses of Plastics across Their Value Chains. Resour. Conserv. Recycl. 2019, 151, 104459. [Google Scholar] [CrossRef]

- Ciacci, L.; Passarini, F.; Vassura, I. The European PVC Cycle: In-Use Stock and Flows. Resour. Conserv. Recycl. 2017, 123, 108–116. [Google Scholar] [CrossRef]

- Kawecki, D.; Scheeder, P.; Nowack, B. Probabilistic Material Flow Analysis of Seven Commodity Plastics in Europe. Environ. Sci. Technol. 2018, 52, 9874–9888. [Google Scholar] [CrossRef]

- Luan, X.; Kou, X.; Cui, X.; Chen, L.; Xue, W.; Liu, W.; Cui, Z. Greenhouse Gas Emissions Associated with Plastics in China from 1950 to 2060. Resour. Conserv. Recycl. 2023, 197, 107089. [Google Scholar] [CrossRef]

- Van Eygen, E.; Laner, D.; Fellner, J. Circular Economy of Plastic Packaging: Current Practice and Perspectives in Austria. Waste Manag. 2018, 72, 55–64. [Google Scholar] [CrossRef] [PubMed]

- Jang, Y.C.; Lee, G.; Kwon, Y.; Lim, J.H.; Jeong, J.H. Recycling and Management Practices of Plastic Packaging Waste towards a Circular Economy in South Korea. Resour. Conserv. Recycl. 2020, 158, 104798. [Google Scholar] [CrossRef]

- Bureecam, C.; Chaisomphob, T.; Sungsomboon, P.-Y. Material Flows Analysis of Plastic in Thailand. Therm. Sci. 2018, 22, 2379–2388. [Google Scholar] [CrossRef]

- Franklin Associates. Cradle-to-Resin Life Cycle Analysis of Polyethylene Terephthalate Resin; NAPCOR: Charlotte, NC, USA, 2020. [Google Scholar]

- Moretti, C.; Junginger, M.; Shen, L. Environmental Life Cycle Assessment of Polypropylene Made from Used Cooking Oil. Resour. Conserv. Recycl. 2020, 157, 104750. [Google Scholar] [CrossRef]

- Arijit, S.; Andreja, K. Carbon Footprint versus Performance of Aluminum, Plastic, and Wood Window Frames from Cradle to Gate. Buildings 2012, 2, 542–553. [Google Scholar] [CrossRef]

- Klemeš, J.J.; Fan, Y.V.; Tan, R.R.; Jiang, P. Minimising the Present and Future Plastic Waste, Energy and Environmental Footprints Related to COVID-19. Renew. Sustain. Energy Rev. 2020, 127, 109883. [Google Scholar] [CrossRef] [PubMed]

- Pasqualino, J.; Meneses, M.; Castells, F. The Carbon Footprint and Energy Consumption of Beverage Packaging Selection and Disposal. J. Food Eng. 2011, 103, 357–365. [Google Scholar] [CrossRef]

- Eriksen, M.K.; Pivnenko, K.; Faraca, G.; Boldrin, A.; Astrup, T.F. Dynamic Material Flow Analysis of PET, PE, and PP Flows in Europe: Evaluation of the Potential for Circular Economy. Environ. Sci. Technol. 2020, 54, 16166–16175. [Google Scholar] [CrossRef]

- Liang, H.; Dong, H.; Zhang, C.; Geng, Y.; Liu, X.; Liu, G.; Zhong, C. Combining LCA-MFA Models to Identify China’s Plastic Value Chain Environmental Impact Mitigation Pathways. iScience 2023, 26, 107701. [Google Scholar] [CrossRef]

- Chaudhari, U.S.; Lin, Y.; Thompson, V.S.; Handler, R.M.; Pearce, J.M.; Caneba, G.; Muhuri, P.; Watkins, D.; Shonnard, D.R. Systems Analysis Approach to Polyethylene Terephthalate and Olefin Plastics Supply Chains in the Circular Economy: A Review of Data Sets and Models. ACS Sustain. Chem. Eng. 2021, 9, 7403–7421. [Google Scholar] [CrossRef]

- Rosato, D.V.; Rosato, D.V.; Rosato, M.G. Plastics Design Handbook; Springer: Boston, MA, USA, 2001; ISBN 978-0-7923-7980-5. [Google Scholar]

- Chu, J.; Zhou, Y.; Cai, Y.; Wang, X.; Li, C.; Liu, Q. A Life-Cycle Perspective for Analyzing Carbon Neutrality Potential of Polyethylene Terephthalate (PET) Plastics in China. J. Clean. Prod. 2022, 330, 129872. [Google Scholar] [CrossRef]

- Gu, B.; Jiang, S.; Wang, H.; Wang, Z.; Jia, R.; Yang, J.; He, S.; Cheng, R. Characterization, Quantification and Management of China’s Municipal Solid Waste in Spatiotemporal Distributions: A Review. Waste Manag. 2017, 61, 67–77. [Google Scholar] [CrossRef]

- Achilias, D.S.; Karayannidis, G.P. The Chemical Recycling of PET in the Framework of Sustainable Development. ChemInform 2005, 36. [Google Scholar] [CrossRef]

- Textile Exchange. Preferred Fiber & Materials Market Report; Textile Exchange: Lamesa, TX, USA, 2020. [Google Scholar]

- Kuczenski, B.; Geyer, R. Material Flow Analysis of Polyethylene Terephthalate in the US, 1996–2007. Resour. Conserv. Recycl. 2010, 54, 1161–1169. [Google Scholar] [CrossRef]

- Zheng, J.; Suh, S. Strategies to Reduce the Global Carbon Footprint of Plastics. Nat. Clim. Chang. 2019, 9, 374–378. [Google Scholar] [CrossRef]

- Hestin, M.; Faninger, T.; Milios, L. Prepared for Plastic Recyclers Europe. Available online: https://www.plasticsrecyclers.eu/wp-content/uploads/2022/10/increased-eu-plastics-recycling-targets.pdf (accessed on 23 July 2023).

- Shen, L.; Worrell, E.; Patel, M.K. Open-Loop Recycling: A LCA Case Study of PET Bottle-to-Fibre Recycling. Resour. Conserv. Recycl. 2010, 55, 34–52. [Google Scholar] [CrossRef]

- Fazi, C. Valutazioni Economiche ed Ambientali del Riciclo Della Plastica. Master’s Thesis, University of Bologna, Bologna, Italy, 2015. [Google Scholar]

- Rigamonti, L. Valutazione dei Percorsi di Recupero di Materiali e di Energia in Sistemi Integrati di Gestione dei Rifiuti Urbani; it. 2007. Available online: https://opac.bncf.firenze.sbn.it/Record/GEA0123010?uri=GEA0123010 (accessed on 23 July 2023).

- Oikos Progetti. Adeguamento Del Piano Regionale Di Gestione Dei Rifiuti; Oikos Progetti: Milano, Italy, 2006. (In Italian) [Google Scholar]

- Institute for Prospective Technological Studies (Joint Research Centre); Villanueva, A.; Eder, P. End-of-Waste Criteria for Waste Plastic for Conversion: Technical Proposals: Final Report; Publications Office of the European Union: Luxembourg, 2014; ISBN 978-92-79-40944-8. [Google Scholar]

- European Commission; Nessi, S.; Sinkko, T.; Bulgheroni, C.; Garcia-Gutierrez, P.; Giuntoli, J.; Konti, A.; Sanye-Mengual, E.; Tonini, D.; Pant, R.; et al. Life Cycle Assessment (LCA) of Alternative Feedstocks for Plastics Production; Part 1, The Plastics LCA Method; Publications Office of the European Union: Luxembourg, 2021; ISBN 978-92-76-38145-7. [Google Scholar]

- Chaudhari, U.S.; Johnson, A.T.; Reck, B.K.; Handler, R.M.; Thompson, V.S.; Hartley, D.S.; Young, W.; Watkins, D.; Shonnard, D. Material Flow Analysis and Life Cycle Assessment of Polyethylene Terephthalate and Polyolefin Plastics Supply Chains in the United States. ACS Sustain. Chem. Eng. 2022, 10, 13145–13155. [Google Scholar] [CrossRef]

- Brunner, P.H.; Rechberger, H. Handbook of Material Flow Analysis: For Environmental, Resource, and Waste Engineers, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2016; ISBN 978-1-315-31345-0. [Google Scholar]

- Ragaert, K.; Delva, L.; Van Geem, K. Mechanical and Chemical Recycling of Solid Plastic Waste. Waste Manag. 2017, 69, 24–58. [Google Scholar] [CrossRef] [PubMed]

- Eriksen, M.K.; Christiansen, J.D.; Daugaard, A.E.; Astrup, T.F. Closing the Loop for PET, PE and PP Waste from Households: Influence of Material Properties and Product Design for Plastic Recycling. Waste Manag. 2019, 96, 75–85. [Google Scholar] [CrossRef]

- Welle, F. The Facts about PET. 2018. Available online: https://www.petcore-europe.org/images/news/pdf/factsheet_the_facts_about_pet_dr_frank_welle_2018.pdf (accessed on 23 July 2023).

- MOSCA. Sustainability & Resources: Strap Production. Available online: https://www.mosca.com/en-sg/company/strap-production/sustainability-resources-strap-production/ (accessed on 24 March 2024).

- Wang, P.; Ryberg, M.; Yang, Y.; Feng, K.; Kara, S.; Hauschild, M.; Chen, W.-Q. Efficiency Stagnation in Global Steel Production Urges Joint Supply- and Demand-Side Mitigation Efforts. Nat. Commun. 2021, 12, 2066. [Google Scholar] [CrossRef]

- Chu, J.; Hu, X.; Kong, L.; Wang, N.; Lin, C. Dynamic Flow and Pollution of Antimony from Polyethylene Terephthalate (PET) Fibers in China. Sci. Total Environ. 2021, 771, 144643. [Google Scholar] [CrossRef]

- Zhang, M. Study on the Recycling of Post-Consumer Polyester Textiles. 2011. Available online: https://scholar.google.com/scholar_lookup?title=Study%20on%20the%20Recycling%20of%20Post-consumer%20Polyester%20Textiles&author=M.%20Zhang&publication_year=2011 (accessed on 23 July 2023).

- Andreasi Bassi, S.; Tonini, D.; Saveyn, H.; Astrup, T.F. Environmental and Socioeconomic Impacts of Poly (Ethylene Terephthalate) (PET) Packaging Management Strategies in the EU. Environ. Sci. Technol. 2022, 56, 501–511. [Google Scholar] [CrossRef] [PubMed]

- European Commission. Landfill Directive (EU) 2018/850|Circular Cities and Regions Initiative. Available online: https://circular-cities-and-regions.ec.europa.eu/support-materials/eu-regulations-legislation/landfill-directive-directive-eu-2018850 (accessed on 24 March 2024).

- Sutter, K.M.; Sutherland, M.D. China’s 14th Five-Year Plan: A First Look; CRS Reports; Congressional Research Service: Washington, DC, USA, 2021.

- Borrelle, S.B.; Ringma, J.; Law, K.L.; Monnahan, C.C.; Lebreton, L.; McGivern, A.; Murphy, E.; Jambeck, J.; Leonard, G.H.; Hilleary, M.A.; et al. Predicted Growth in Plastic Waste Exceeds Efforts to Mitigate Plastic Pollution. Science 2020, 369, 1515–1518. [Google Scholar] [CrossRef]

- Petcore Europe. PET Market in Europe State of Play 2022; Petcore Europe: Brussels, Belgium, 2022. [Google Scholar]

- Petcore Europe. Petcore Europe 2025 Pledge for the PET Value Chain to Increase Circularity and Recycling; Petcore Europe: Brussels, Belgium, 2019. [Google Scholar]

- European Commission. European Reference Life Cycle Database; European Commission: Brussels, Belgium, 2014. [Google Scholar]

- CLCD. Chinese Life Cycle Database. Available online: https://www.ike-global.com/#/products-2/chinese-lca-database-clcd (accessed on 15 July 2023).

- Korea Institute of Industrial Technology; Ministry of Environment. Korea Life Cycle Inventory (LCI) Database. Available online: http://www.epd.or.kr (accessed on 5 July 2023).

- USLCI. US Life Cycle Inventory Database. Available online: https://www.nrel.gov/analysis/lci.html (accessed on 2 July 2023).

- Life Cycle Assessment Society of Japan. JLCA LCA Database. Available online: https://idea-lca.com/en/ (accessed on 10 April 2023).

- Ecoinvent, version 3.5; Ecoinvent: Zurich, Switzerland, 2018.

- Aizenshtein, E.M. Polyester Fibres Continue to Dominate on the World Textile Raw Materials Balance Sheet. Fibre Chem. 2009, 41, 1–8. [Google Scholar] [CrossRef]

- OECD. Global Plastics Outlook: Economic Drivers, Environmental Impacts and Policy Options; OECD: Paris, France, 2022; ISBN 978-92-64-65494-5. [Google Scholar]

- Andrew, C.; Enda, C.; Stephen, C. LCA of Kerbside Recycling in Victoria; Sustainability Victoria: Melbourne, VIC, Australia, 2015.

- Cáceres Ruiz, A.M.; Zaman, A. The Current State, Challenges, and Opportunities of Recycling Plastics in Western Australia. Recycling 2022, 7, 64. [Google Scholar] [CrossRef]

- Kawecki, D.; Wu, Q.; Gonçalves, J.S.V.; Nowack, B. Polymer-Specific Dynamic Probabilistic Material Flow Analysis of Seven Polymers in Europe from 1950 to 2016. Resour. Conserv. Recycl. 2021, 173, 105733. [Google Scholar] [CrossRef]

- Chen, C.; Jiang, Z.; Li, N.; Wang, H.; Wang, P.; Zhang, Z.; Zhang, C.; Ma, F.; Huang, Y.; Lu, X.; et al. Advancing UN Comtrade for Physical Trade Flow Analysis: Review of Data Quality Issues and Solutions. Resour. Conserv. Recycl. 2022, 186, 106526. [Google Scholar] [CrossRef]

- ISO 3166; Country Codes. ISO: Geneva, Switzerland, 2020. Available online: https://www.iso.org/iso-3166-country-codes.html (accessed on 1 October 2023).

- Ellen MacArchur Foundation. The New Plastics Economy: Catalysing Action; Ellen MacArchur Foundation: Isle of Wight, UK, 2016. [Google Scholar]

- Wu, H.; Shi, Y.; Xia, Q.; Zhu, W. Effectiveness of the Policy of Circular Economy in China: A DEA-Based Analysis for the Period of 11th Five-Year-Plan. Resour. Conserv. Recycl. 2014, 83, 163–175. [Google Scholar] [CrossRef]

- Jawahir, I.S.; Bradley, R. Technological Elements of Circular Economy and the Principles of 6R-Based Closed-Loop Material Flow in Sustainable Manufacturing. Procedia CIRP 2016, 40, 103–108. [Google Scholar] [CrossRef]

- Plastic Europe. Plastics—The Facts 2020; Plastic Europe: Brussels, Belgium, 2020. [Google Scholar]

- Ono, S.; Hewage, H.T.S.A.; Visvanathan, C. Towards Plastic Circularity: Current Practices in Plastic Waste Management in Japan and Sri Lanka. Sustainability 2023, 15, 7550. [Google Scholar] [CrossRef]

- Olatayo, K.I.; Mativenga, P.T.; Marnewick, A.L. Plastic Value Chain and Performance Metric Framework for Optimal Recycling. J. Ind. Ecol. 2023, 27, 601–623. [Google Scholar] [CrossRef]

- Neo, E.R.K.; Soo, G.C.Y.; Tan, D.Z.L.; Cady, K.; Tong, K.T.; Low, J.S.C. Life Cycle Assessment of Plastic Waste End-of-Life for India and Indonesia. Resour. Conserv. Recycl. 2021, 174, 105774. [Google Scholar] [CrossRef]

- Ministry of Statistics and Programme Implementation. EnviStats India 2022: Vol II Environment Accounts; Ministry of Statistics and Programme Implementation: New Delhi, India, 2020.

- Olatayo, K.I.; Mativenga, P.T.; Marnewick, A.L. Comprehensive Evaluation of Plastic Flows and Stocks in South Africa. Resour. Conserv. Recycl. 2021, 170, 105567. [Google Scholar] [CrossRef]

- Goga, T.; Harding, K.; Russo, V.; Von Blottnitz, H. What Material Flow Analysis and Life Cycle Assessment Reveal about Plastic Polymer Production and Recycling in South Africa. S. Afr. J. Sci. 2022, 118, 12522. [Google Scholar] [CrossRef] [PubMed]

- OECD. Municipal Waste, Generation and Treatment, Organization for Economic Co-Operation and Development; OECD: Paris, France, 2023. [Google Scholar]

- Kamsook, S.; Phongphiphat, A.; Towprayoon, S.; Vinitnantharat, S. Investigation of Plastic Waste Management in Thailand Using Material Flow Analysis. Waste Manag. Res. 2023, 41, 924–935. [Google Scholar] [CrossRef] [PubMed]

- Abrelpe. Panorama dos Resíduos Sólidos No Brasil; Abrelpe: São Paulo, Brazil, 2020. [Google Scholar]

- Lim, J.; Ahn, Y.; Kim, J. Optimal Sorting and Recycling of Plastic Waste as a Renewable Energy Resource Considering Economic Feasibility and Environmental Pollution. Process Saf. Environ. Prot. 2023, 169, 685–696. [Google Scholar] [CrossRef]

- Korea Ministry of Environment. Status of National Waste Generation and Treatment; Ministry of Environment and Korea Environment Corporation: Seoul, Republic of Korea, 2022. [Google Scholar]

- Arunan, I.; Crawford, R.H. Greenhouse Gas Emissions Associated with Food Packaging for Online Food Delivery Services in Australia. Resour. Conserv. Recycl. 2021, 168, 105299. [Google Scholar] [CrossRef]

- Damayanti, D.; Saputri, D.R.; Marpaung, D.S.S.; Yusupandi, F.; Sanjaya, A.; Simbolon, Y.M.; Asmarani, W.; Ulfa, M.; Wu, H.-S. Current Prospects for Plastic Waste Treatment. Polymers 2022, 14, 3133. [Google Scholar] [CrossRef] [PubMed]

- Hao, X.; An, H. Comparative Study on Transmission Mechanism of Supply Shortage Risk in the International Trade of Iron Ore, Pig Iron and Crude Steel. Resour. Policy 2022, 79, 103022. [Google Scholar] [CrossRef]

- Jeswani, H.K.; Smith, R.W.; Azapagic, A. Energy from Waste: Carbon Footprint of Incineration and Landfill Biogas in the UK. Int. J. Life Cycle Assess. 2013, 18, 218–229. [Google Scholar] [CrossRef]

- Cai, H.; Jang, Y. Material Flow Analysis for PET Bottles and Greenhouse Gas Reduction by Recycling Towards a Circular Economy. J. Korea Soc. Waste Manag. 2021, 38, 294–302. [Google Scholar] [CrossRef]

- Mu, B.; Shao, Y.; McBride, L.; Hidalgo, H.; Yang, Y. Rapid Fiber-to-Fiber Recycling of Poly (Ethylene Terephthalate) and Its Dye from Waste Textiles without Damaging Their Chemical Structures. Resour. Conserv. Recycl. 2023, 197, 107102. [Google Scholar] [CrossRef]

- Chen, L.; Liu, W.; Yang, T.; Nowack, B. Probabilistic Material Flow Analysis of Eight Commodity Plastics in China: Comparison between 2017 and 2020. Resour. Conserv. Recycl. 2023, 191, 106880. [Google Scholar] [CrossRef]

- Rafey, A.; Siddiqui, F.Z. A Review of Plastic Waste Management in India—Challenges and Opportunities. Int. J. Environ. Anal. Chem. 2023, 103, 3971–3987. [Google Scholar] [CrossRef]

- Nakatani, J.; Maruyama, T.; Moriguchi, Y. Revealing the Intersectoral Material Flow of Plastic Containers and Packaging in Japan. Proc. Natl. Acad. Sci. USA 2020, 117, 19844–19853. [Google Scholar] [CrossRef]

- Ackerman, J.; Levin, D.B. Rethinking Plastic Recycling: A Comparison between North America and Europe. J. Environ. Manag. 2023, 340, 117859. [Google Scholar] [CrossRef]

- Ángeles-Hurtado, L.A.; Rodríguez-Reséndiz, J.; Salazar-Colores, S.; Torres-Salinas, H.; Sevilla-Camacho, P.Y. Viable Disposal of Post-Consumer Polymers in Mexico: A Review. Front. Environ. Sci. 2021, 9, 749775. [Google Scholar] [CrossRef]

- Moyen Massa, G.; Archodoulaki, V.-M. An Imported Environmental Crisis: Plastic Mismanagement in Africa. Sustainability 2024, 16, 672. [Google Scholar] [CrossRef]

- Di, J.; Reck, B.K.; Miatto, A.; Graedel, T.E. United States Plastics: Large Flows, Short Lifetimes, and Negligible Recycling. Resour. Conserv. Recycl. 2021, 167, 105440. [Google Scholar] [CrossRef]

- Mederake, L. Without a Debate on Sufficiency, a Circular Plastics Economy Will Remain an Illusion. Circ. Econ. Sust. 2023, 3, 1425–1439. [Google Scholar] [CrossRef]

- Prata, J.C.; Silva, A.L.P.; da Costa, J.P.; Mouneyrac, C.; Walker, T.R.; Duarte, A.C.; Rocha-Santos, T. Solutions and Integrated Strategies for the Control and Mitigation of Plastic and Microplastic Pollution. Int. J. Environ. Res. Public Health 2019, 16, 2411. [Google Scholar] [CrossRef] [PubMed]

- Chu, J.; Zhou, Y.; Cai, Y.; Wang, X.; Li, C.; Liu, Q. Flows and Waste Reduction Strategies of PE, PP, and PET Plastics under Plastic Limit Order in China. Resour. Conserv. Recycl. 2023, 188, 106668. [Google Scholar] [CrossRef]

- Zhao, C.; Hou, Y.; Liu, M.; Gong, Y.; Wang, J. Research on the Cooperative Network Game Model of Marine Plastic Waste Management. Mar. Policy 2023, 149, 105504. [Google Scholar] [CrossRef]

- Liu, T.; Wang, Q.; Su, B. A Review of Carbon Labeling: Standards, Implementation, and Impact. Renew. Sustain. Energy Rev. 2016, 53, 68–79. [Google Scholar] [CrossRef]

- Zhao, R.; Wu, D.; Zhang, J. Policy Implications on Carbon Labeling Scheme Toward Carbon Neutrality in China. Front. Environ. Sci. 2021, 9, 739943. [Google Scholar] [CrossRef]

- Liu, C.; Xiong, K.; Chen, X.; Huang, X. Consumer Behavior Patterns of Carbon Neutral Label Using the Unified Theory of Acceptance and Use of Technology. Chin. J. Popul. Resour. Environ. 2023, 21, 137–144. [Google Scholar] [CrossRef]

- Zhang, H.; Wen, Z.-G. The Consumption and Recycling Collection System of PET Bottles: A Case Study of Beijing, China. Waste Manag. 2014, 34, 987–998. [Google Scholar] [CrossRef]

- Papong, S.; Malakul, P.; Trungkavashirakun, R.; Wenunun, P.; Chom-in, T.; Nithitanakul, M.; Sarobol, E. Comparative Assessment of the Environmental Profile of PLA and PET Drinking Water Bottles from a Life Cycle Perspective. J. Clean. Prod. 2014, 65, 539–550. [Google Scholar] [CrossRef]

- Jiao, H.; Ali, S.S.; Alsharbaty, M.H.M.; Elsamahy, T.; Abdelkarim, E.; Schagerl, M.; Al-Tohamy, R.; Sun, J. A Critical Review on Plastic Waste Life Cycle Assessment and Management: Challenges, Research Gaps, and Future Perspectives. Ecotoxicol. Environ. Saf. 2024, 271, 115942. [Google Scholar] [CrossRef]

- Wang, C.; Liu, Y.; Chen, W.; Zhu, B.; Qu, S.; Xu, M. Critical Review of Global Plastics Stock and Flow Data. J. Ind. Ecol. 2021, 25, 1300–1317. [Google Scholar] [CrossRef]

- Huajing Industry Research Institute. 2023–2028 China Polyethylene Terephthalate (PET) Industry Market Prospect and Investment Strategic Planning Analysis Report. 2022. Available online: https://www.huaon.com/channel/chemical/869808.html (accessed on 14 November 2023).

- Eurostat. Industry, Trade and Services-Statistics on the Production of Manufactured Goods. Available online: https://ec.europa.eu/eurostat/databrowser/view/ds-056121/legacyMultiFreq/table?lang=en&category=prom (accessed on 8 November 2023).

- METI. Ministry of Economy, Trade and Industry Home—Statistics—Ministry of Economy, Trade and Industry Dynamic Production Statistics—Overview. Available online: https://view.officeapps.live.com/op/view.aspx?src=https%3A%2F%2Fwww.meti.go.jp%2Fstatistics%2Ftyo%2Fseidou%2Fresult%2Fichiran%2FresourceData%2F08_seidou%2Fnenpo%2F2022%2Fh2daa2022k.xlsx&wdOrigin=BROWSELINK (accessed on 8 December 2023). (In Japanese).

- Martin, E.J.P.; Oliveira, D.S.B.L.; Oliveira, L.S.B.L.; Bezerra, B.S. Life Cycle Comparative Assessment of Pet Bottle Waste Management Options: A Case Study for the City of Bauru, Brazil. Waste Manag. 2021, 119, 226–234. [Google Scholar] [CrossRef] [PubMed]

- Markets and Markets. Purified Terephthalic Acid (PTA) Market—Global Forecast to 2023. 2018. Available online: https://www.marketsandmarkets.com/Market-Reports/purified-terephthalic-acid-market-150628286.html (accessed on 23 November 2023).

- Park, J.; Jang, Y.; Son, M. Dynamic Plastics Flow Analysis for Korea between 1982-2020. J. Korean Soc. Environ. Eng. 2022. [Google Scholar] [CrossRef]

- O’Farrell, K.; Harney, F.; Stovell, L. Australian Plastics Flows and Fates Study 2020-21—National Report. 2020. Available online: https://www.dcceew.gov.au/environment/protection/waste/publications/australian-plastic-flows-and-fates-report-2020-21 (accessed on 23 November 2023).

- ECOCE. Informe de 20 Aniversario. 2022. Available online: https://www.ecoce.mx/ (accessed on 2 November 2023). (In Spanish).

- Chu, J.; Cai, Y.; Li, C.; Wang, X.; Liu, Q.; He, M. Dynamic Flows of Polyethylene Terephthalate (PET) Plastic in China. Waste Manag. 2021, 124, 273–282. [Google Scholar] [CrossRef] [PubMed]

- Huajing Industry Research Institute. 2022–2027 China Bottle-Grade PET Industry Development Trend and Investment Strategy Consulting Report. 2023. Available online: https://www.huaon.com/channel/plastic/807186.html (accessed on 2 November 2023).

- China National Textile and Apparel Council. 2020–2021 China Textile Industry Development Report. 2021. Available online: https://cnki.nbsti.net/CSYDMirror/trade/Yearbook/Single/N2022060151?z=Z012 (accessed on 2 November 2023). (In Chinese).

- Nicholson, S.R.; Rorrer, N.A.; Carpenter, A.C.; Beckham, G.T. Manufacturing Energy and Greenhouse Gas Emissions Associated with Plastics Consumption. Joule 2021, 5, 673–686. [Google Scholar] [CrossRef]

- EURATEX. Facts & Key Figures 2022 of the European Textile and Clothing Industry. 2022. Available online: https://euratex.eu/facts-and-key-figures/ (accessed on 29 November 2023).

- Pet Bottle Recycling Association. Overview of Designated PET Bottle Recycling. Available online: https://www.petbottle-rec.gr.jp/data/general_situation.html (accessed on 29 November 2023). (In Japanese).

- WZAIR ADVISORS. Indian Textile & Apparel Industry 2022. 2022. Available online: https://www.ibef.org/industry/indian-textiles-and-apparel-industry-analysis-presentation (accessed on 9 November 2023).

- Korea Chemical Fibers Industry Association. The Korea Chemical Fiber Handbook 2020. 2020. Available online: http://kcfa.or.kr/bbs/board.php?bo_table=statistics (accessed on 18 November 2023).

- Mordor Intelligence. 2018–2028 Global Polyethylene Terephthalate (Pet) Resin Market. 2020. Available online: https://www.mordorintelligence.com/industry-reports/polyethylene-terephtalate-market/market-trends (accessed on 27 April 2023).

- de Oliveira, C.C.N.; Zotin, M.Z.; Rochedo, P.R.R.; Szklo, A. Achieving Negative Emissions in Plastics Life Cycles through the Conversion of Biomass Feedstock. Biofuels Bioprod. Biorefining 2021, 15, 430–453. [Google Scholar] [CrossRef]

- Zero Waste Europe. How Circular Is PET. 2022. Available online: https://zerowasteeurope.eu/library/how-circular-is-pet/ (accessed on 7 April 2023).

- China Petroleum and Petrochemical. PET Bottle Flakes: Downstream Demand Grows Steadily, Industry Concentration Increases. 2022. Available online: https://www.vzkoo.com/document/20220518e2a8f735a499e4cc6d88be06.html (accessed on 7 January 2024).

- Groot, J.; Bing, X.; Bos-Brouwers, H.; Bloemhof-Ruwaard, J. A Comprehensive Waste Collection Cost Model Applied to Post-Consumer Plastic Packaging Waste. Resour. Conserv. Recycl. 2014, 85, 79–87. [Google Scholar] [CrossRef]

- Indorama Ventures. A New Era of Growth and Value Creation. 2020. Available online: https://www.sambuz.com/doc/and-value-creation-ppt-presentation-259972 (accessed on 7 August 2023).

- Bozhang, Q. Current Situation of PET Production in China. Polyest. Ind. 2017, 30, 4. (In Chinese) [Google Scholar]

- National Association for PET Container Resources. 2020 Pet Recycling Report. 2021. Available online: https://napcor.com/reports-resources/ (accessed on 27 August 2023).

- US EPA. Advancing Sustainable Materials Management: Facts and Figures Report. 2015. Available online: https://www.epa.gov/facts-and-figures-about-materials-waste-and-recycling/advancing-sustainable-materials-management (accessed on 24 August 2023).

- Eriksen, M.K.; Damgaard, A.; Boldrin, A.; Astrup, T.F. Quality Assessment and Circularity Potential of Recovery Systems for Household Plastic Waste. J. Ind. Ecol. 2019, 23, 156–168. [Google Scholar] [CrossRef]

- Pimentel Pincelli, I.; Borges de Castilhos Júnior, A.; Seleme Matias, M.; Wanda Rutkowski, E. Post-Consumer Plastic Packaging Waste Flow Analysis for Brazil: The Challenges Moving towards a Circular Economy. Waste Manag. 2021, 126, 781–790. [Google Scholar] [CrossRef]

- Pollution Control Department of Thailand. Thailand State of Waste Disposal Site Report in 2020. 2020. Available online: https://www.pcd.go.th/publication/14745/ (accessed on 24 September 2023). (In Thai).

- Jang, Y.; Nam Kim, K.; Woo, J. Post-Consumer Plastic Packaging Waste from Online Food Delivery Services in South Korea. Waste Manag. 2023, 156, 177–186. [Google Scholar] [CrossRef]

- Wurm, F.R.; Spierling, S.; Endres, H.; Barner, L. Plastics and the Environment—Current Status and Challenges in Germany and Australia. Macromol. Rapid Commun. 2020, 41, 2000351. [Google Scholar] [CrossRef]

- ECOCE. El Reciclaje de PET En México Es Caso de Éxito. 2023. Available online: https://www.pt-mexico.com/articulos/el-reciclaje-de-pet-en-mexico-es-caso-de-exito (accessed on 19 September 2023). (In Spanish).

- Antonopoulos, I.; Faraca, G.; Tonini, D. Recycling of Post-Consumer Plastic Packaging Waste in the EU: Recovery Rates, Material Flows, and Barriers. Waste Manag. 2021, 126, 694–705. [Google Scholar] [CrossRef] [PubMed]

- Axion Consulting. A Financial Assessment of Recycling Mixed Plastics in the UK. 2009. Available online: https://www.yumpu.com/en/document/view/40248968/financial-assessment-of-mixed-plastics-recycling-in-the-uk-wrap (accessed on 9 September 2023).

- Enviros Consulting. MRF Quality Assessment Study. 2009. Available online: https://documents.pub/document/mrf-quality-assessment-study.html (accessed on 19 September 2023).

- Shonfield, P. LCA of Management Options for Mixed Waste Plastics. Available online: https://www.eco-conception.fr/data/sources/users/8/lca-of-management-options-for-mixed-waste-plastics.pdf (accessed on 12 September 2023).

- Turner, D.A.; Williams, I.D.; Kemp, S. Combined Material Flow Analysis and Life Cycle Assessment as a Support Tool for Solid Waste Management Decision Making. J. Clean. Prod. 2016, 129, 234–248. [Google Scholar] [CrossRef]

- Rigamonti, L.; Grosso, M.; Møller, J.; Martinez Sanchez, V.; Magnani, S.; Christensen, T.H. Environmental Evaluation of Plastic Waste Management Scenarios. Resour. Conserv. Recycl. 2014, 85, 42–53. [Google Scholar] [CrossRef]

- Pressley, P.N.; Levis, J.W.; Damgaard, A.; Barlaz, M.A.; DeCarolis, J.F. Analysis of Material Recovery Facilities for Use in Life-Cycle Assessment. Waste Manag. 2015, 35, 307–317. [Google Scholar] [CrossRef]

- Conte, C.; Navarotto, P.; Grosso, M. Analisi sperimentale di un impianto di selezione avanzata dei rifiuti plastici da raccolta differenziata. Ing. Dell’ambiente 2018, 5. [Google Scholar] [CrossRef]

- Moore, P. Life Cycle Impacts for Postconsumer Recycled Resins: PET, HDPE, and PP. PRCC. Available online: https://prcc.biz/2018/12/01/life-cycle-impacts-for-postconsumer-recycled-resins-pet-hdpe-and-pp/ (accessed on 16 September 2023).

- Van Eygen, E.; Laner, D.; Fellner, J. Integrating High-Resolution Material Flow Data into the Environmental Assessment of Waste Management System Scenarios: The Case of Plastic Packaging in Austria. Environ. Sci. Technol. 2018, 52, 10934–10945. [Google Scholar] [CrossRef] [PubMed]

- Zhang, R.; Ma, X.; Shen, X.; Zhai, Y.; Zhang, T.; Ji, C.; Hong, J. PET Bottles Recycling in China: An LCA Coupled with LCC Case Study of Blanket Production Made of Waste PET Bottles. J. Environ. Manag. 2020, 260, 110062. [Google Scholar] [CrossRef]

- Faraca, G.; Martinez-Sanchez, V.; Astrup, T.F. Environmental Life Cycle Cost Assessment: Recycling of Hard Plastic Waste Collected at Danish Recycling Centres. Resour. Conserv. Recycl. 2019, 143, 299–309. [Google Scholar] [CrossRef]

- Pet Bottle Recycling Association. Pet Bottle Recycling Annual Report 2022. Available online: https://www.petbottle-rec.gr.jp/ (accessed on 16 December 2023). (In Japanese).

- Gileno, L.A.; Turci, L.F.R. Life Cycle Assessment for PET-Bottle Recycling in Brazil: B2B and B2F Routes. Clean. Environ. Syst. 2021, 3, 100057. [Google Scholar] [CrossRef]

- Ministry of Environment of Korea. National Waste Generation and Disposal Status in 2020. Available online: https://www.recycling-info.or.kr/rrs/stat/envStatDetail.do?menuNo=M13020201&pageIndex=1&bbsId=BBSMSTR_000000000002&s_nttSj=KEC005&nttId=1200&searchBgnDe=&searchEndDe= (accessed on 6 December 2023). (In Korean).

- Recycled Plastics Branch of China Material Recycling Association. Report on the Development of China’s Recycled Plastics Industry. 2020. Available online: http://ltfzs.mofcom.gov.cn/article/ztzzn/202106/20210603171351.shtml (accessed on 22 December 2023). (In Chinese)

- The Wolrd Bank. Market Study for Malaysia: Plastics Circularity Opportunities and Barriers. 2021. Available online: https://www.worldbank.org/en/home (accessed on 21 December 2023).

- Plastic Waste Management Institute of Japan. Plastic Products, Plastic Waste and Resource Recovery. 2020. Available online: https://www.pwmi.or.jp/ (accessed on 16 October 2023).

- Lino, F.A.M.; Ismail, K.A.R.; Castañeda-Ayarza, J.A. Municipal Solid Waste Treatment in Brazil: A Comprehensive Review. Energy Nexus 2023, 11, 100232. [Google Scholar] [CrossRef]

- Rueda-Avellaneda, J.F.; Rivas-García, P.; Gomez-Gonzalez, R.; Benitez-Bravo, R.; Botello-Álvarez, J.E.; Tututi-Avila, S. Current and Prospective Situation of Municipal Solid Waste Final Disposal in Mexico: A Spatio-Temporal Evaluation. Renew. Sustain. Energy Transit. 2021, 1, 100007. [Google Scholar] [CrossRef]

- Minghui, X. Environmental Impact of the Derivative Fuel Method for Disposal of Low Quality Plastic Packaging in Beijing. Environ. Sci. Res. 2010, 7. (In Chinese) [Google Scholar] [CrossRef]

- Yano, J.; Sakai, S. Energy Recovery and Greenhouse Gas Reduction Potential from Food Waste in Japan. J. Mater. Cycles Waste Manag. 2016, 18, 631–645. [Google Scholar] [CrossRef]

- Dos Santos, R.E.; Dos Santos, I.F.S.; Barros, R.M.; Bernal, A.P.; Tiago Filho, G.L.; da Silva, F.D.G.B. Generating Electrical Energy through Urban Solid Waste in Brazil: An Economic and Energy Comparative Analysis. J. Environ. Manag. 2019, 231, 198–206. [Google Scholar] [CrossRef] [PubMed]

- Suryavanshi, A.V.; Ahammed, M.M.; Shaikh, I.N. Energy, Economic, and Environmental Analysis of Waste-to-Energy Technologies for Municipal Solid Waste Treatment: A Case Study of Surat, India. J. Hazard. Toxic Radioact. Waste 2023, 27, 04023005. [Google Scholar] [CrossRef]

- Intharathirat, R.; Abdul Salam, P. Valorization of MSW-to-Energy in Thailand: Status, Challenges and Prospects. Waste Biomass Valorization 2016, 7, 31–57. [Google Scholar] [CrossRef]

- Kwon, Y.-H.; Kang, J.-G.; Ko, Y.-J.; Yoo, H.-N.; Kwon, J.-H.; Park, H.-Y.; Jeon, T.-W.; Lee, Y.-K. Estimation of Energy Recovery Rate of Municipal Waste Incineration Facilities through Measuring Instruments. J. Korea Soc. Waste Manag. 2018, 35, 770–776. [Google Scholar] [CrossRef]

- Gunamantha, M. Sarto Life Cycle Assessment of Municipal Solid Waste Treatment to Energy Options: Case Study of KARTAMANTUL Region, Yogyakarta. Renew. Energy 2012, 41, 277–284. [Google Scholar] [CrossRef]

- Dastjerdi, B.; Strezov, V.; Kumar, R.; He, J.; Behnia, M. Comparative Life Cycle Assessment of System Solution Scenarios for Residual Municipal Solid Waste Management in NSW, Australia. Sci. Total Environ. 2021, 767, 144355. [Google Scholar] [CrossRef]

- Pablo Emilio, E.-G.; Fernández-Rodríguez, E.; Carrasco-Hernández, R.; Coria-Páez, A.L.; Gutiérrez-Galicia, F. A Comparison Assessment of Landfill Waste Incineration and Methane Capture in the Central Region of Mexico. Waste Manag. Res. 2022, 40, 1785–1793. [Google Scholar] [CrossRef] [PubMed]

- Scarlat, N.; Motola, V.; Dallemand, J.F.; Monforti-Ferrario, F.; Mofor, L. Evaluation of Energy Potential of Municipal Solid Waste from African Urban Areas. Renew. Sustain. Energy Rev. 2015, 50, 1269–1286. [Google Scholar] [CrossRef]

- European Commission. Global Energy and Climate Outlook 2018: Sectoral Mitigation Options towards a Low Emissions Economy: Global Context to the EU Strategy for Long Term Greenhouse Gas Emissions Reduction; Publications Office: Luxembourg, 2018; Available online: https://op.europa.eu/en/publication-detail/-/publication/edff2046-f2c1-11e8-9982-01aa75ed71a1/language-en (accessed on 26 October 2023).

- United Nations Statistics Division. United Nations Comtrade Database. Available online: https://comtradeplus.un.org/ (accessed on 1 October 2023).

- Chen, Y.; Cui, Z.; Cui, X.; Liu, W.; Wang, X.; Li, X.; Li, S. Life Cycle Assessment of End-of-Life Treatments of Waste Plastics in China. Resour. Conserv. Recycl. 2019, 146, 348–357. [Google Scholar] [CrossRef]

- The Japan Plastics Industry Federation. Production of Plastics Materials 2018 Japan. 2018. Available online: http://www.jpif.gr.jp/english/statistics/monthly/2018/2018_production_materials_e.htm (accessed on 16 August 2023).

- US EPA. Municipal Solid Waste in the United States: 2009 Facts and Figures. 2010. Available online: https://archive.epa.gov/epawaste/nonhaz/municipal/web/pdf/msw2009rpt.pdf (accessed on 16 October 2023).

- Benavides, P.T.; Dunn, J.B.; Han, J.; Biddy, M.; Markham, J. Exploring Comparative Energy and Environmental Benefits of Virgin, Recycled, and Bio-Derived PET Bottles. ACS Sustain. Chem. Eng. 2018, 6, 9725–9733. [Google Scholar] [CrossRef]

- Chu, J.; Zhou, Y.; Cai, Y.; Wang, X.; Li, C.; Liu, Q. Life-Cycle Greenhouse Gas Emissions and the Associated Carbon-Peak Strategies for PS, PVC, and ABS Plastics in China. Resour. Conserv. Recycl. 2022, 182, 106295. [Google Scholar] [CrossRef]

- Udaipurwala, M. Plastics Industry Status Report—India—2022. 2022. Available online: https://plastindia.org/plastic-industry-status-report/ (accessed on 22 December 2023).

| Scenario | Combination Methods | Plastic Demand |

|---|---|---|

| S8 | S1–S5 | increasing by growth rate |

| S9 | S1–S5 | zero growth rate, demand maintained at 2020 level |

| S10 | S1–S5 + S6 | increasing by growth rate |

| S11 | S1–S5 + S6 | zero growth rate, demand maintained at 2020 level |

| S12 | S1–S5 + S7 | increasing by growth rate |

| S13 | S1–S5 + S7 | zero growth rate, demand maintained at 2020 level |

| Type | Indicator | Formula |

|---|---|---|

| Recyclability | RR (%) | |

| CMUR (%) | ||

| CLCR (%) | ||

| Demand for virgin resin | VMC (kt) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duan, C.; Wang, Z.; Zhou, B.; Yao, X. Global Polyethylene Terephthalate (PET) Plastic Supply Chain Resource Metabolism Efficiency and Carbon Emissions Co-Reduction Strategies. Sustainability 2024, 16, 3926. https://doi.org/10.3390/su16103926

Duan C, Wang Z, Zhou B, Yao X. Global Polyethylene Terephthalate (PET) Plastic Supply Chain Resource Metabolism Efficiency and Carbon Emissions Co-Reduction Strategies. Sustainability. 2024; 16(10):3926. https://doi.org/10.3390/su16103926

Chicago/Turabian StyleDuan, Chenxingyu, Zhen Wang, Bingzheng Zhou, and Xiaolei Yao. 2024. "Global Polyethylene Terephthalate (PET) Plastic Supply Chain Resource Metabolism Efficiency and Carbon Emissions Co-Reduction Strategies" Sustainability 16, no. 10: 3926. https://doi.org/10.3390/su16103926