Numerical and Experimental Analysis of a Low-GWP Heat Pump Coupled to Electrical and Thermal Energy Storage to Increase the Share of Renewables across Europe

Abstract

:1. Introduction

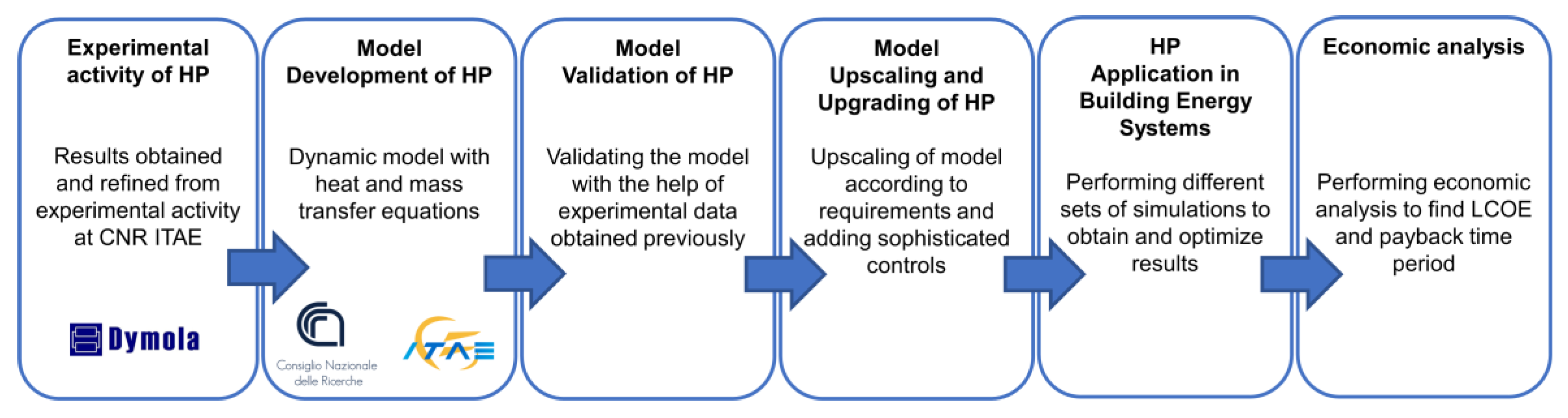

Paper Positioning and Methodology

2. Experimental Activity

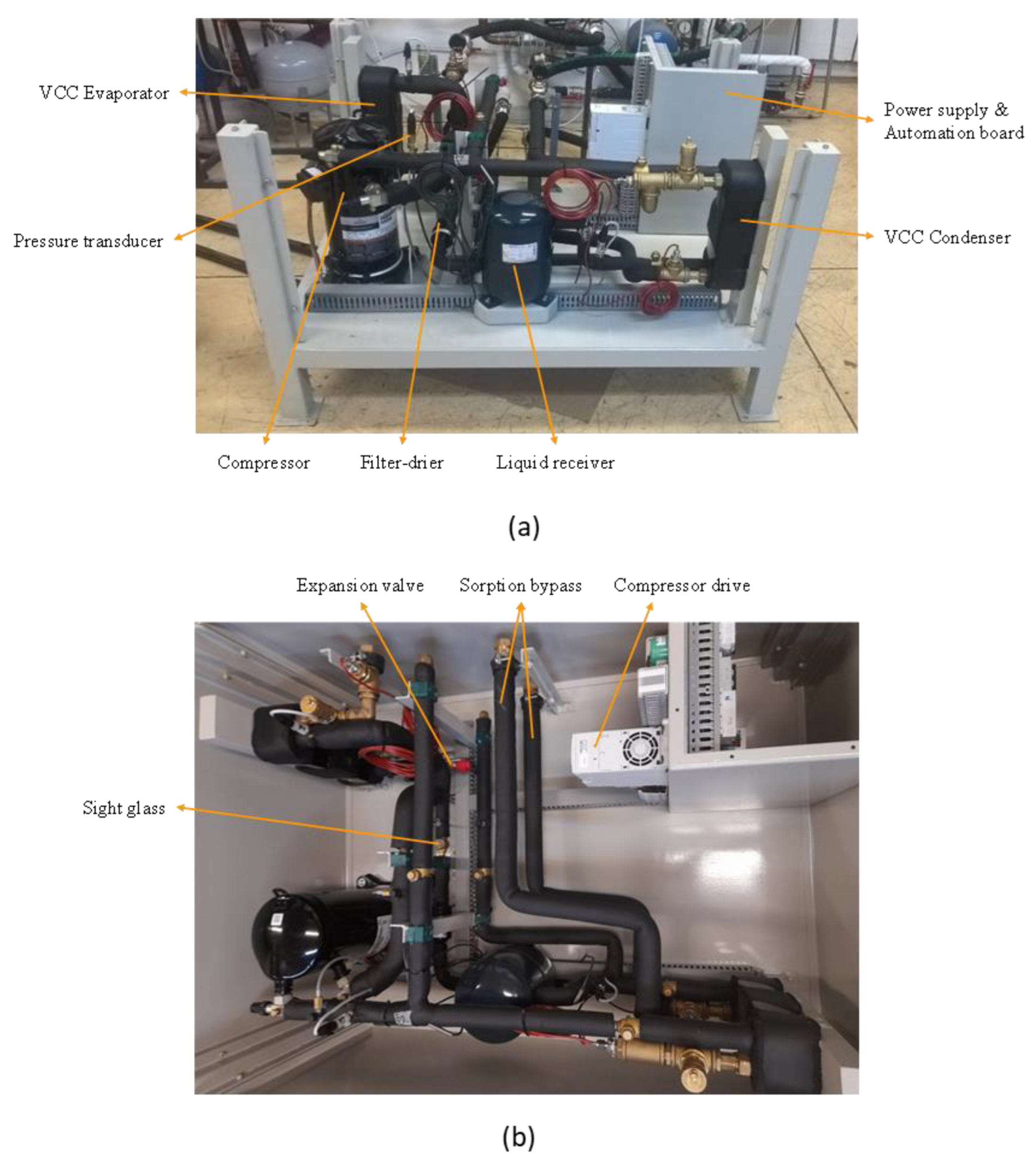

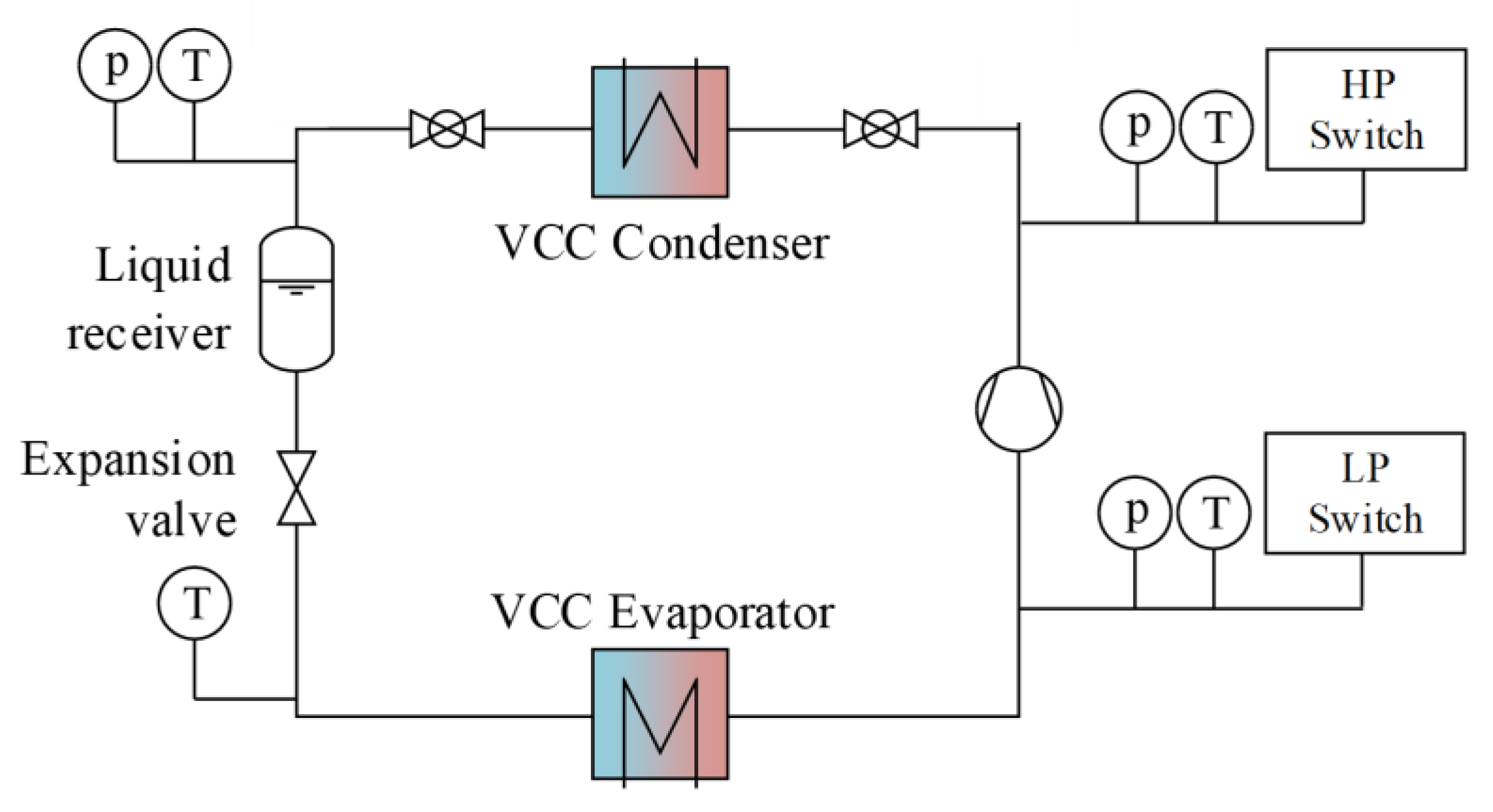

2.1. The Investigated System

2.2. Description of Testing Rig

2.3. Testing Procedure

- All electrical circuits are turned on. Pumps for the circulation of heat transfer fluid (HTF) in the condenser and evaporator reach the desired speeds, while the desired temperature for the condenser and evaporator inlet is set.

- The compressor is turned on and its speed is controlled from a control panel realized in LabVIEW. Superheating is set to 6 K.

- The test is started with a data acquisition rate of 1 s. Once a steady state is achieved, at least 1000 s of acquisition time for each condition is recorded. All values from the sensors are stored in a Notepad file.

2.4. Data Analysis

3. Modeling Activity

3.1. Model Description

3.2. Main Assumptions and Methodology

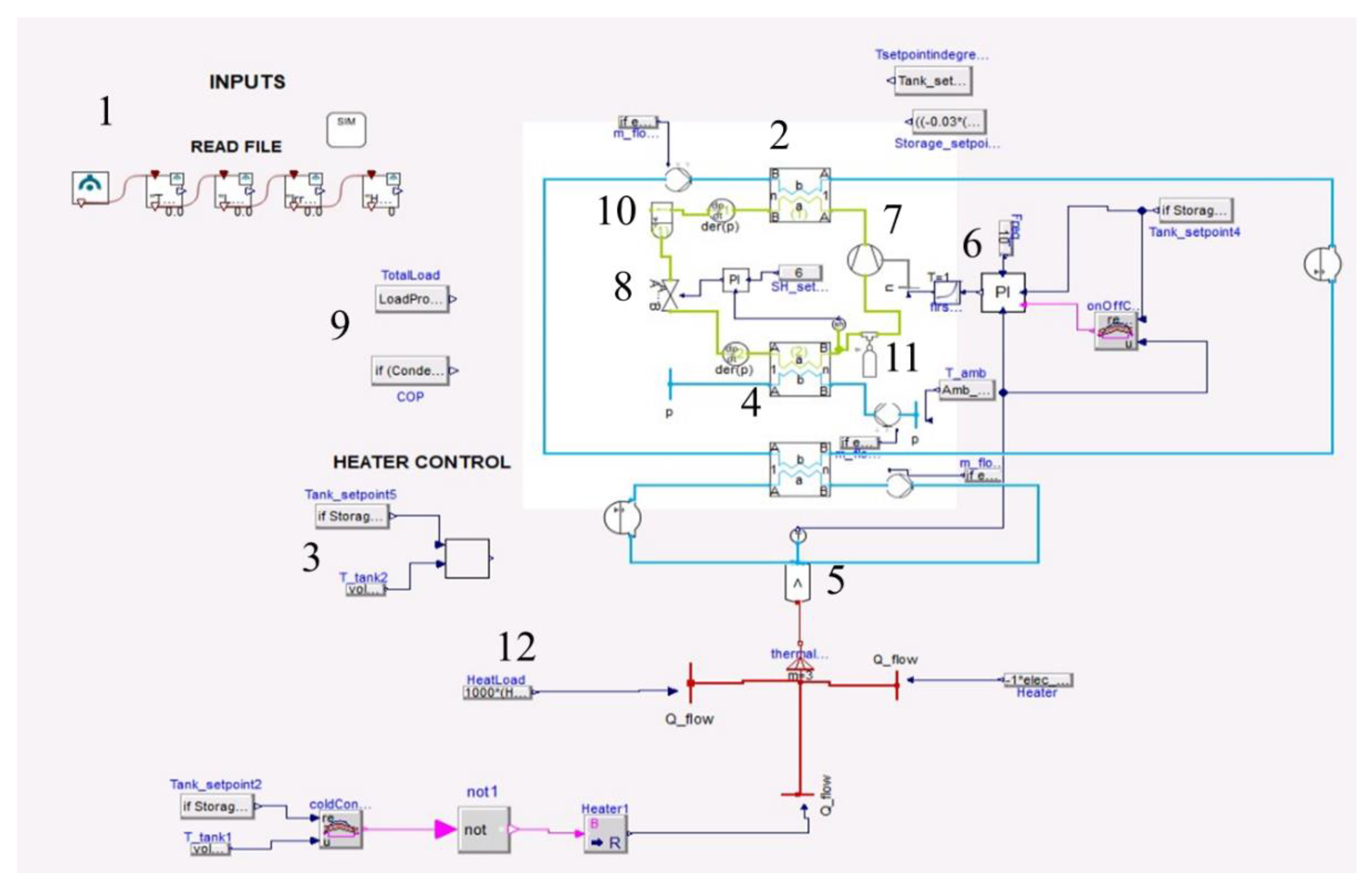

3.3. Thermal Sub-System Model

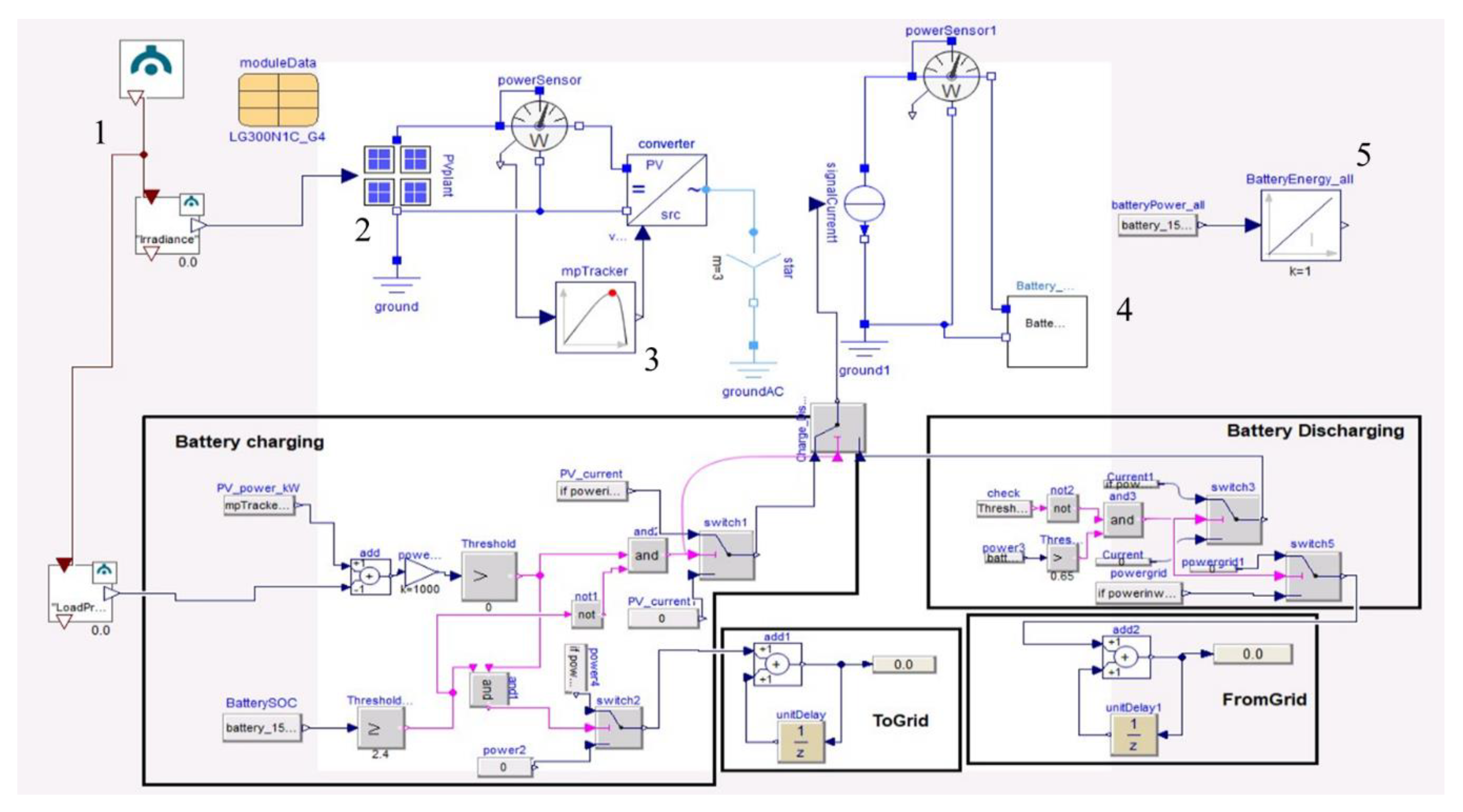

3.4. Electric Sub-System Model

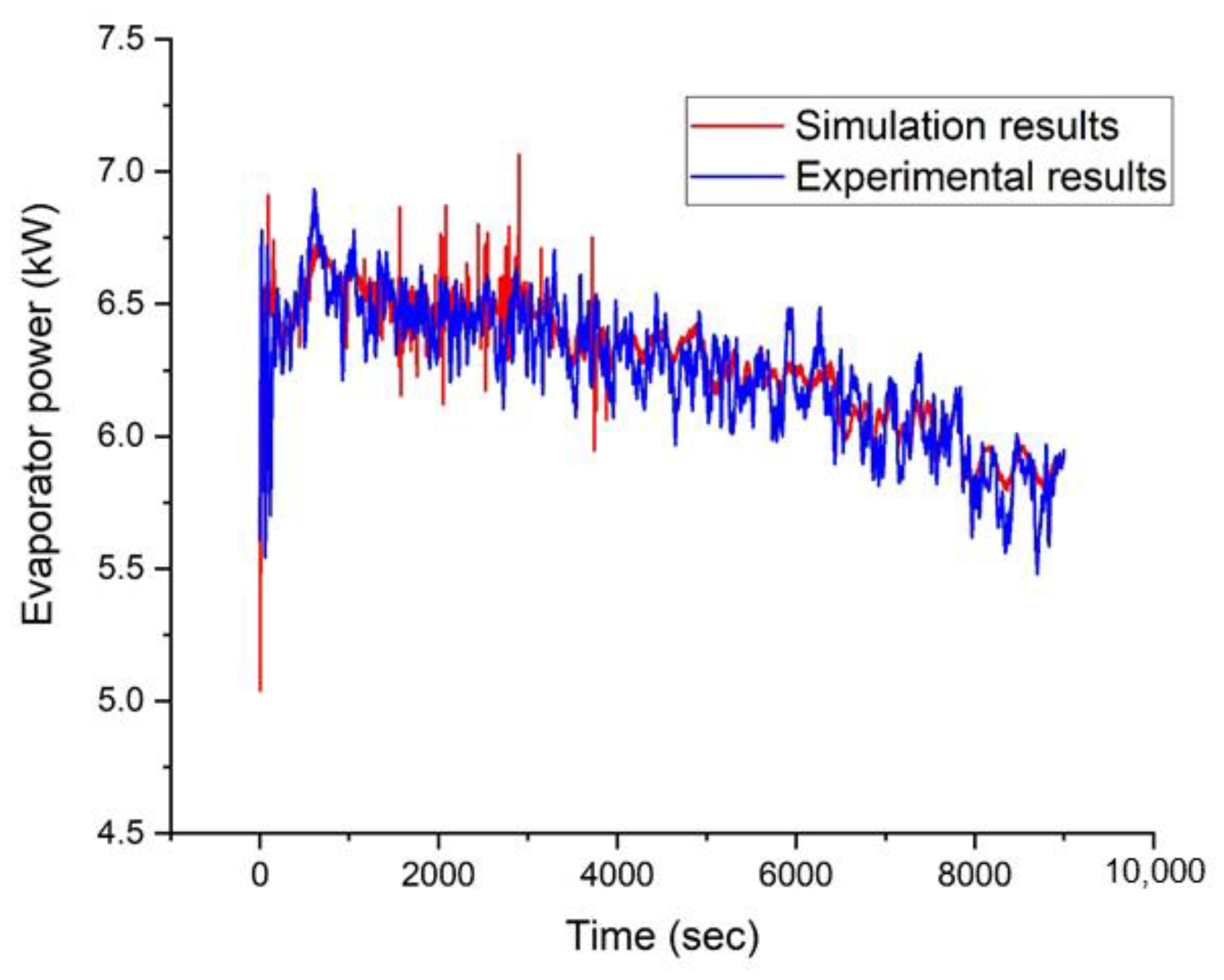

4. Reversible HP Model Validation

5. Results and Discussion

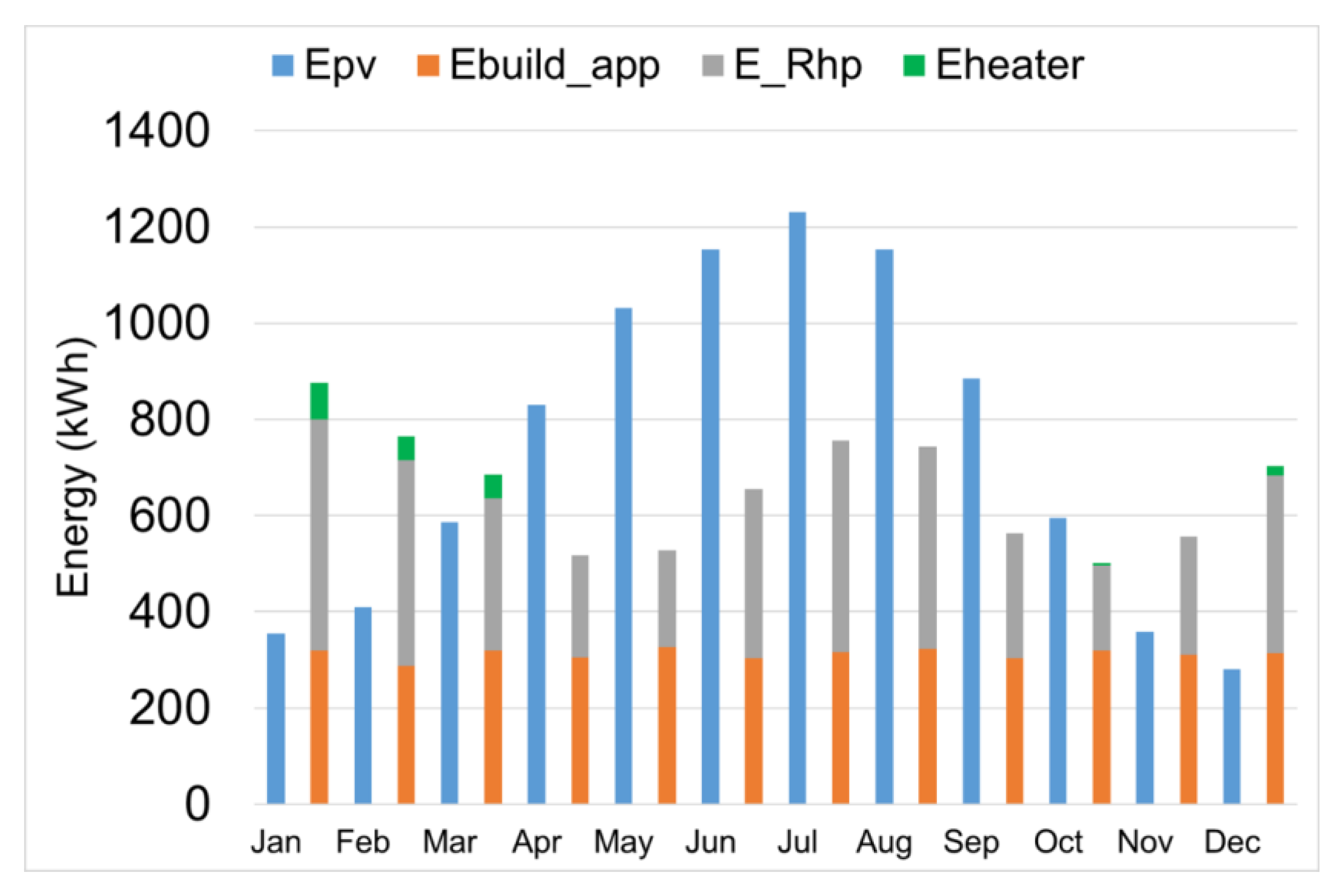

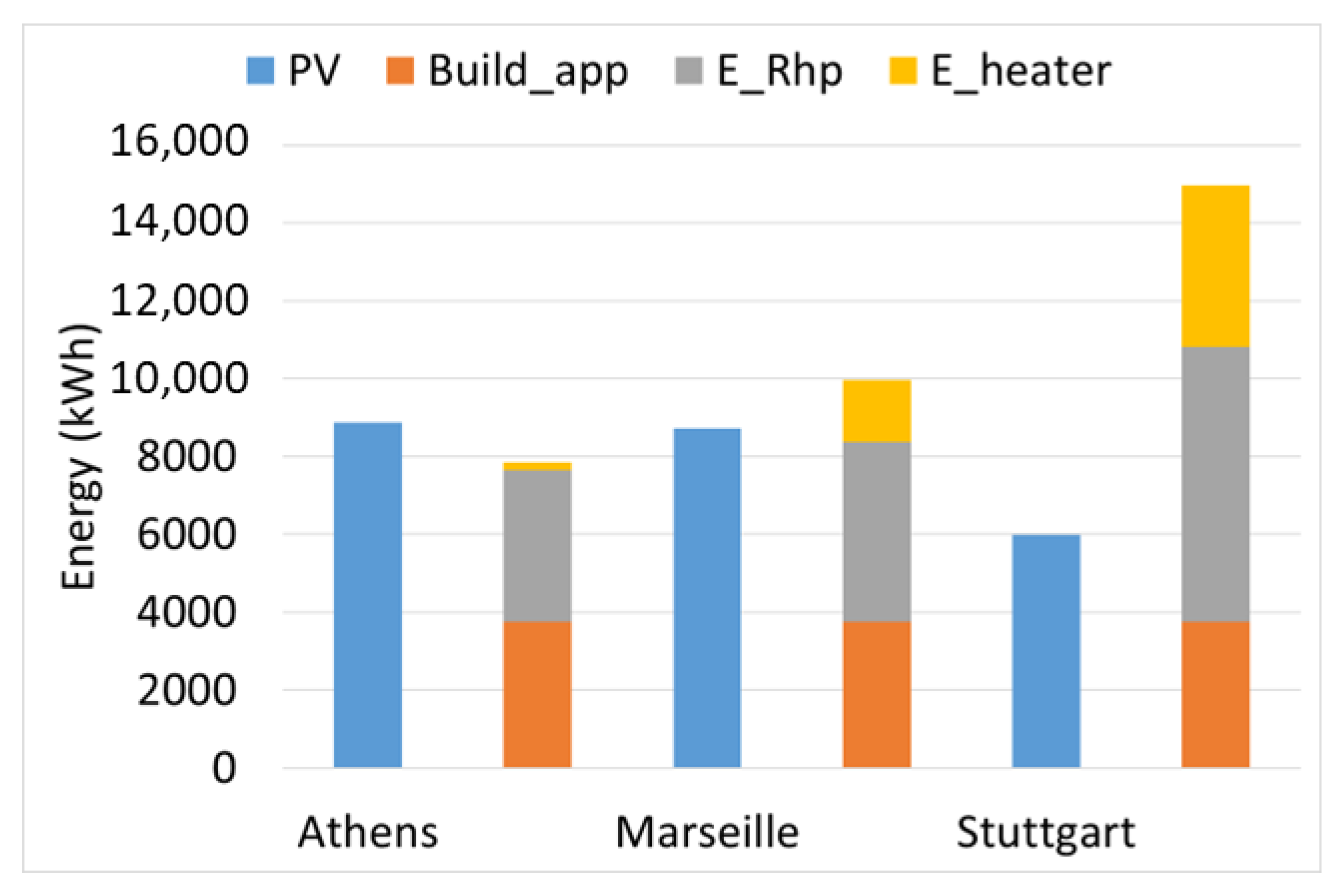

5.1. Results of Energy Analysis

5.1.1. Electricity Consumption

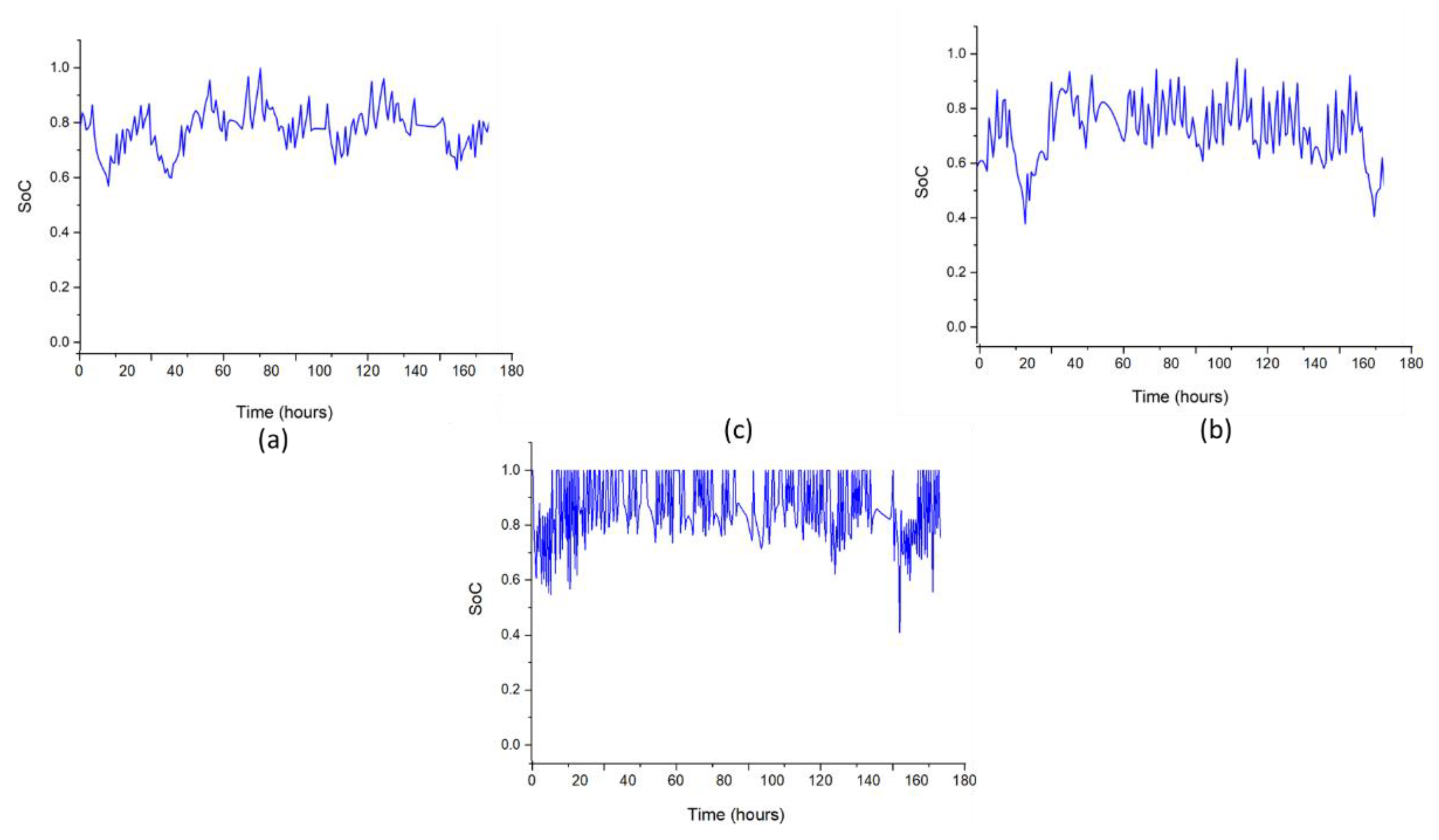

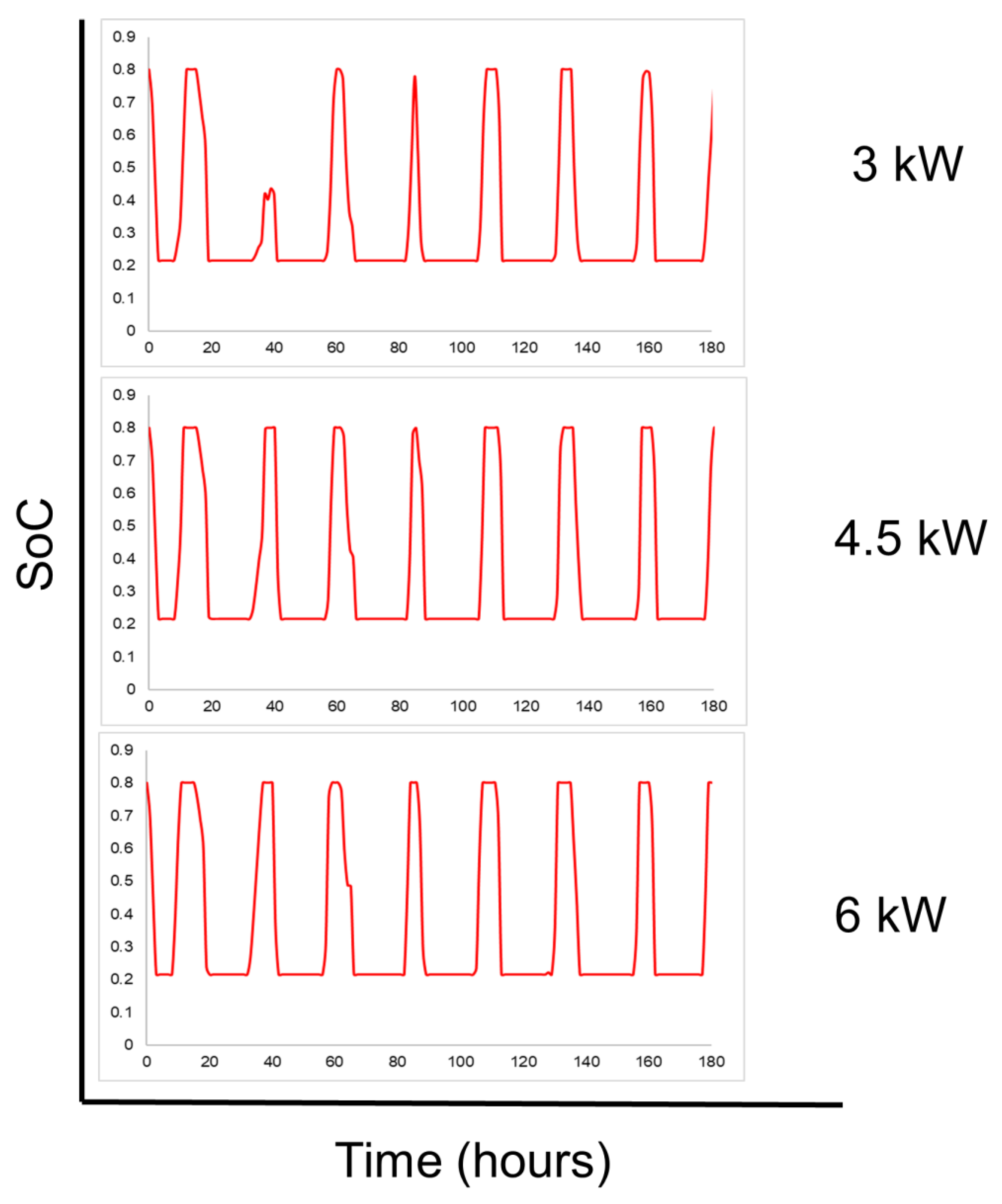

5.1.2. The Role of Energy Storage

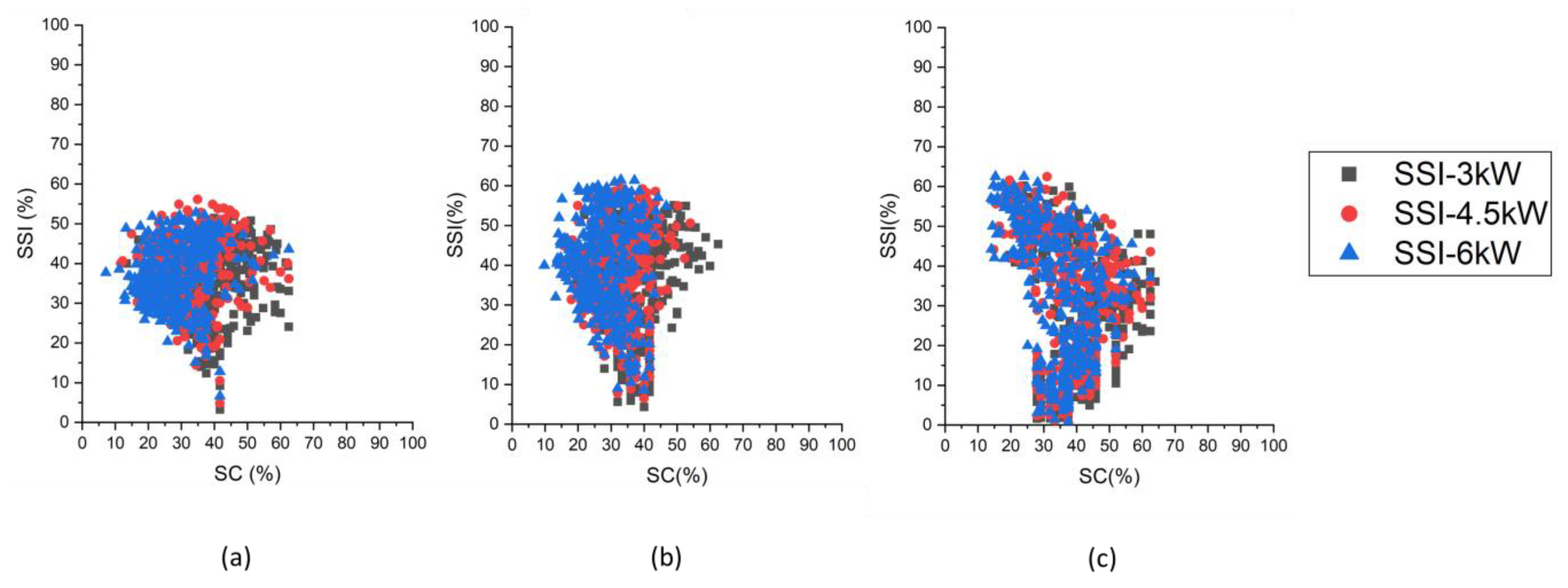

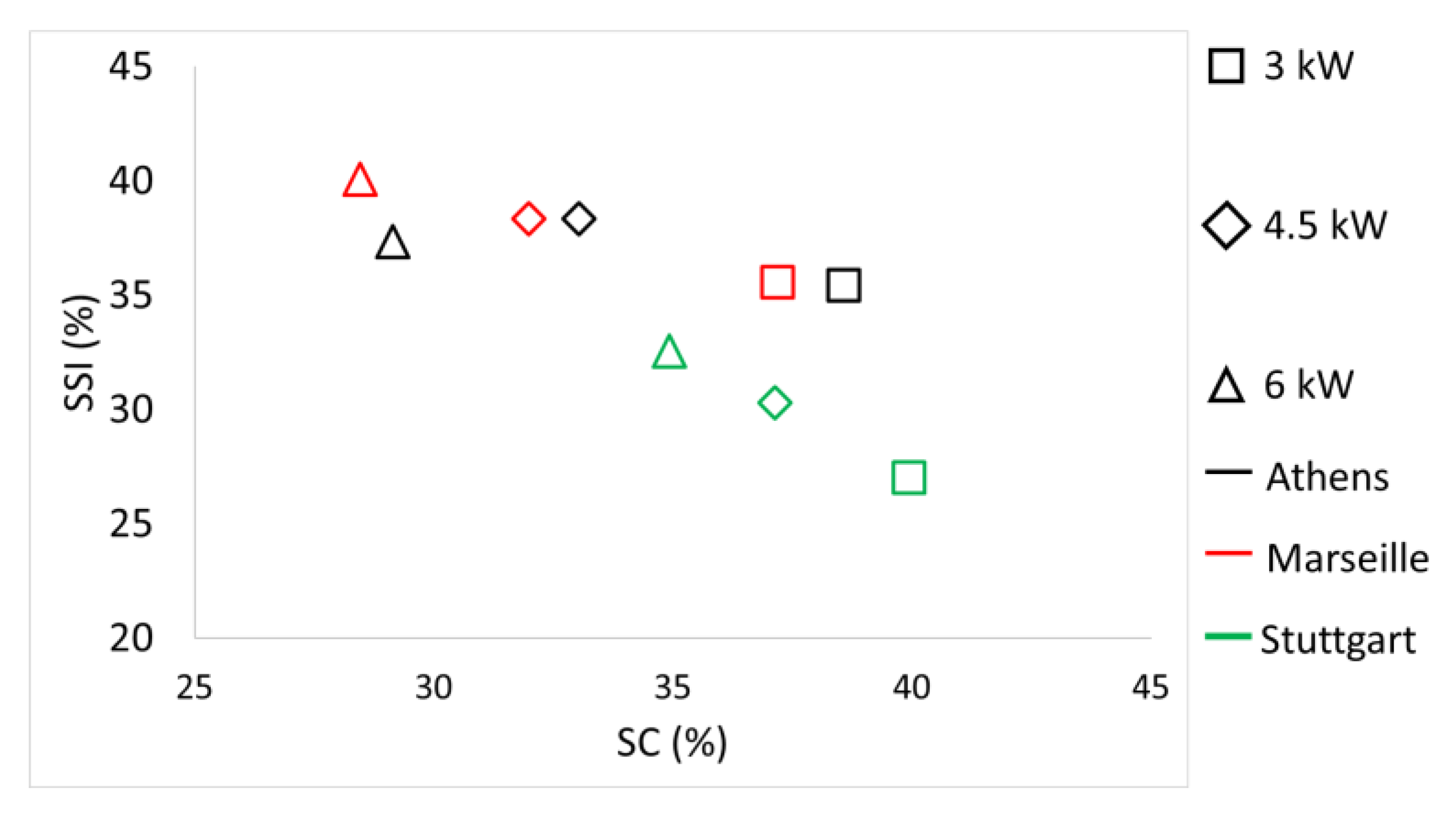

5.1.3. Self-Sufficiency and Energy Exchange with the Grid

5.2. Economic Analysis

5.2.1. Main Assumptions

5.2.2. Energy Policies and Subsidies for HP

- Working under a “feed-in-tariff” model, where all generated electricity, such as that from a PV system, is supplied to the grid.

- Installing an autonomous off-grid system with storage batteries (e.g., utilizing PVs, wind turbines, etc.) that is independent of the grid, where all the energy from the RES is consumed.

- Installing a renewable energy system that consumes as much energy as it produces, while remaining connected to the grid. When the energy demand is higher than the produced amount, energy is drawn from the grid. This is the concept of net metering.

Greece

Germany

France

5.2.3. Main Results

5.2.4. Levelized Cost of Electricity

6. Conclusions and Future Perspectives

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Acronyms

| European Union | EU |

| heating, ventilation, and air-conditioning | HVAC |

| global warming potential | GWP |

| nearly zero-energy buildings | nZEB |

| renewable energy sources | RES |

| seasonal coefficient of performance | SCOP |

| self-sufficiency index | SSI |

| heat pump | HP |

| levelized cost of energy | LCOE |

| high temperature | HT |

| low temperature | LT |

| medium temperature | MT |

| heat transfer fluid | HTF |

| logarithmic mean temperature difference | LMTD |

| energy efficiency ratio | EER |

| functional mock-up interface | FMI |

| maximum power point tracker | MPPT |

| open circuit voltage | OCV |

| state of charge | SoC |

Appendix A

Appendix A.1. Thermal Sub-System Model Components

Appendix A.1.1. Condenser and Evaporator

| Heat Exchangers (HX) | |

|---|---|

| Type | Plate Heat Exchanger |

| UA Condenser (W/K) | 7132 |

| UA Evaporator (W/K) | 11,379 |

| Condenser heat transfer area (m2) | 1.06 |

| Evaporator heat transfer area (m2) | 1.18 |

| Refrigerant | R1234ze(E) |

| Heat transfer fluid | Water |

Appendix A.1.2. Compressor

Appendix A.1.3. Expansion Valve

Appendix A.1.4. Liquid Separator

Appendix A.1.5. Thermal Energy Storage Tank

Appendix A.2. Thermal Sub-System Control and Management

Appendix A.2.1. Heater Control

Appendix A.2.2. Expansion Valve Control

Appendix A.2.3. HTF Mass Flow Control

Appendix A.3. Electric Sub-System Model Components

PV and Auxiliaries

| Electrical Properties (STC) | |

|---|---|

| Power Output (W) | 300 |

| Cells | 6 × 10 |

| Cell vendor | LG |

| Cell type | Monocrystalline/N-type |

| MPP voltage (Vmpp) (V) | 32.2 |

| MPP current (Impp) (A) | 9.34 |

| Open circuit voltage (V) | 39.8 |

| Short circuit current (A) | 9.9 |

| Module efficiency (%) | 18.3 |

References

- Archive: Consumption of Energy-Statistics Explained. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Archive:Consumption_of_energy (accessed on 16 November 2022).

- Economidou, M.; Atanasiu, B.; Despret, C.; Maio, J.; Nolte, I.; Rapf, O.; Laustsen, J.; Ruyssevelt, P.; Staniaszek, D.; Strong, D.; et al. Europe’s Buildings under the Microscope. A Country-by-Country Review of the Energy Performance of Buildings. Buildings Performance Institute Europe (BPIE). 2011. Available online: https://bpie.eu/wp-content/uploads/2015/10/HR_EU_B_under_microscope_study.pdf (accessed on 16 November 2022).

- Di Perna, C.; Magri, G.; Giuliani, G.; Serenelli, G. Experimental Assessment and Dynamic Analysis of a Hybrid Generator Composed of an Air Source Heat Pump Coupled with a Condensing Gas Boiler in a Residential Building. Appl. Therm. Eng. 2015, 76, 86–97. [Google Scholar] [CrossRef]

- Rehman, O.A.; Palomba, V.; Frazzica, A.; Cabeza, L.F. Enabling Technologies for Sector Coupling: A Review on the Role of Heat Pumps and Thermal Energy Storage. Energies 2021, 14, 8195. [Google Scholar] [CrossRef]

- Kolokotsa, D.; Rovas, D.; Kosmatopoulos, E.; Kalaitzakis, K. A Roadmap towards Intelligent Net Zero- and Positive-Energy Buildings. Sol. Energy 2011, 85, 3067–3084. [Google Scholar] [CrossRef]

- Kapsalaki, M.; Leal, V.; Santamouris, M. A Methodology for Economic Efficient Design of Net Zero Energy Buildings. Energy Build. 2012, 55, 765–778. [Google Scholar] [CrossRef]

- Apache, P. EN Horizon 2020 Work Programme 2018–2020 10. Secure, Clean and Efficient Energy. 2020. Available online: https://policycommons.net/artifacts/2024173/en-horizon-2020-work-programme-2018-2020-10/2776616/ (accessed on 16 November 2022).

- D’Agostino, D.; Zangheri, P.; Castellazzi, L. Towards Nearly Zero Energy Buildings in Europe: A Focus on Retrofit in Non-Residential Buildings. Energies 2017, 10, 117. [Google Scholar] [CrossRef]

- Zanetti, E.; Aprile, M.; Kum, D.; Scoccia, R.; Motta, M. Energy Saving Potentials of a Photovoltaic Assisted Heat Pump for Hybrid Building Heating System via Optimal Control. J. Build. Eng. 2020, 27, 100854. [Google Scholar] [CrossRef]

- Li, G. Parallel Loop Configuration for Hybrid Heat Pump–Gas Fired Water Heater System with Smart Control Strategy. Appl. Therm. Eng. 2018, 138, 807–818. [Google Scholar] [CrossRef]

- Thieblemont, H.; Haghighat, F.; Ooka, R.; Moreau, A. Predictive Control Strategies Based on Weather Forecast in Buildings with Energy Storage System: A Review of the State-of-the Art. Energy Build. 2017, 153, 485–500. [Google Scholar] [CrossRef] [Green Version]

- Bagarella, G.; Lazzarin, R.; Noro, M. Annual Simulation, Energy and Economic Analysis of Hybrid Heat Pump Systems for Residential Buildings. Appl. Therm. Eng. 2016, 99, 485–494. [Google Scholar] [CrossRef]

- Chen, Y.; Chen, Z.; Chen, Z.; Yuan, X. Dynamic Modeling of Solar-Assisted Ground Source Heat Pump Using Modelica. Appl. Therm. Eng. 2021, 196, 117324. [Google Scholar] [CrossRef]

- Beccali, M.; Finocchiaro, P.; Ippolito, M.G.; Leone, G.; Panno, D.; Zizzo, G. Analysis of Some Renewable Energy Uses and Demand Side Measures for Hotels on Small Mediterranean Islands: A Case Study. Energy 2018, 157, 106–114. [Google Scholar] [CrossRef]

- Eslami, S.; Gholami, A.; Bakhtiari, A.; Zandi, M.; Noorollahi, Y. Experimental Investigation of a Multi-Generation Energy System for a Nearly Zero-Energy Park: A Solution toward Sustainable Future. Energy Convers. Manag. 2019, 200, 112107. [Google Scholar] [CrossRef]

- Ciriminna, R.; Pagliaro, M.; Meneguzzo, F.; Pecoraino, M. Solar Energy for Sicily’s Remote Islands: On the Route from Fossil to Renewable Energy. Int. J. Sustain. Built Environ. 2016, 5, 132–140. [Google Scholar] [CrossRef] [Green Version]

- Calise, F.; Dentice d’Accadia, M.; Figaj, R.D.; Vanoli, L. Thermoeconomic Optimization of a Solar-Assisted Heat Pump Based on Transient Simulations and Computer Design of Experiments. Energy Convers. Manag. 2016, 125, 166–184. [Google Scholar] [CrossRef]

- Calise, F.; Cappiello, F.L.; Dentice d’Accadia, M.; Vicidomini, M. Dynamic Modelling and Thermoeconomic Analysis of Micro Wind Turbines and Building Integrated Photovoltaic Panels. Renew. Energy 2020, 160, 633–652. [Google Scholar] [CrossRef]

- Roselli, C.; Tariello, F.; Sasso, M. Integration of a Photovoltaic System with an Electric Heat Pump and Electrical Energy Storage Serving an Office Building. J. Sustain. Dev. Energy Water Environ. Syst. 2019, 7, 213–228. [Google Scholar] [CrossRef] [Green Version]

- Ma, R.; Qiao, H.; Yu, X.; Yang, B.; Yang, H. Thermo-Economic Analysis and Multi-Objective Optimization of a Reversible Heat Pump-Organic Rankine Cycle Power System for Energy Storage. Appl. Therm. Eng. 2023, 220, 119658. [Google Scholar] [CrossRef]

- Cirone, D.; Bruno, R.; Bevilacqua, P.; Perrella, S.; Arcuri, N. Techno-Economic Analysis of an Energy Community Based on PV and Electric Storage Systems in a Small Mountain Locality of South Italy: A Case Study. Sustainability 2022, 14, 13877. [Google Scholar] [CrossRef]

- Global Warming Potential Values of Hydrofluorocarbon Refrigerants-DCCEEW. Available online: https://www.dcceew.gov.au/environment/protection/ozone/rac/global-warming-potential-values-hfc-refrigerants (accessed on 17 December 2022).

- Alabdulkarem, A.; Eldeeb, R.; Hwang, Y.; Aute, V.; Radermacher, R. Testing, Simulation and Soft-Optimization of R410A Low-GWP Alternatives in Heat Pump System. Int. J. Refrig. 2015, 60, 106–117. [Google Scholar] [CrossRef]

- Palomba, V.; Dino, G.E.; Frazzica, A. Coupling Sorption and Compression Chillers in Hybrid Cascade Layout for Efficient Exploitation of Renewables: Sizing, Design and Optimization. Renew. Energy 2020, 154, 11–28. [Google Scholar] [CrossRef]

- Dino, G.E.; Palomba, V.; Nowak, E.; Frazzica, A. Experimental Characterization of an Innovative Hybrid Thermal-Electric Chiller for Industrial Cooling and Refrigeration Application. Appl. Energy 2021, 281, 116098. [Google Scholar] [CrossRef]

- Application Note Thermal Energy Storage Strategies for Commercial HVAC Systems. 1997. Available online: https://www.pge.com/includes/docs/pdfs/about/edusafety/training/pec/inforesource/thrmstor.pdf (accessed on 17 December 2022).

- Residential Geothermal Water Source Chiller and Heat Pump of 10 kw-Buy Residential Heat Pump, Domestic Heat Pump, Ground Source Heat Pump Product on Alibaba.Com. Available online: https://www.alibaba.com/product-detail/Residential-Geothermal-Water-Source-Chiller-And_1600744659947.html?s=p (accessed on 17 December 2022).

- Daikin Applied EWAQ010ACV3P Air Cooled Mini Inverter Water Chiller 10 Kw/34000Btu 240 V 50 Hz. Available online: https://www.orionairsales.co.uk/daikin-applied-ewaq010acv3p-air-cooled-mini-inverter-water-chiller-10kw34000btu-240v50hz-10472-p.asp (accessed on 17 December 2022).

- Daikin Scroll Chiller EWWQ-KC-Daikin Applied Europe. Available online: https://www.daikinapplied.eu/products/daikin-scroll-chiller-ewwq-kc/ (accessed on 17 December 2022).

- Dymola-Dassault Systèmes®. Available online: https://www.3ds.com/products-services/catia/products/dymola/ (accessed on 25 November 2022).

- TIL Suite. Available online: https://www.tlk-thermo.com/index.php/en/software/38-til-suite (accessed on 17 December 2022).

- Brkic, J.; Ceran, M.; Elmoghazy, M.; Kavlak, R.; Kral, C. PhotoVoltaics Library. Available online: https://build.openmodelica.org/Documentation/PhotoVoltaics.html (accessed on 17 December 2022).

- Vasta, S.; Palomba, V.; Frazzica, A.; Di Bella, G.; Freni, A. Techno-Economic Analysis of Solar Cooling Systems for Residential Buildings in Italy. J. Sol. Energy Eng. Trans. ASME 2016, 138, 031005. [Google Scholar] [CrossRef]

- Longo, S.; Palomba, V.; Beccali, M.; Cellura, M.; Vasta, S. Energy Balance and Life Cycle Assessment of Small Size Residential Solar Heating and Cooling Systems Equipped with Adsorption Chillers. Sol. Energy 2017, 158, 543–558. [Google Scholar] [CrossRef]

- Richardson, I.; Thomson, M. Accredited PV Measurement and Calibration Lab|CREST|Loughborough University. Available online: https://www.lboro.ac.uk/research/crest/working-with-us/lab/ (accessed on 21 April 2021).

- Interactive Europe Koppen-Geiger Climate Classification Map. Available online: https://www.plantmaps.com/koppen-climate-classification-map-europe.php (accessed on 11 December 2022).

- Palomba, V.; Bonanno, A.; Brunaccini, G.; Aloisio, D.; Sergi, F.; Dino, G.E.; Varvaggiannis, E.; Karellas, S.; Nitsch, B.; Strehlow, A.; et al. Hybrid Cascade Heat Pump and Thermal-Electric Energy Storage System for Residential Buildings: Experimental Testing and Performance Analysis. Energies 2021, 14, 2580. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Palomba, V. The Role of Thermal Energy Storage in the Energy System. In Reference Module in Earth Systems and Environmental Sciences; Elsevier: Amsterdam, The Netherlands, 2020. [Google Scholar]

- Keinath, C.M.; Garimella, S. An Energy and Cost Comparison of Residential Water Heating Technologies. Energy 2017, 128, 626–633. [Google Scholar] [CrossRef]

- Ferreira, A.C.; Silva, A.; Teixeira, J.C.; Teixeira, S. Multi-Objective Optimization of Solar Thermal Systems Applied to Portuguese Dwellings. Energies 2020, 13, 6739. [Google Scholar] [CrossRef]

- 220 v 500 w 800 w 1500 w 2 kw 3 kw 4000 w 4 kw 6 kw 9 kw 12 kw 15 kw 20 kw 30 kw Electric Resistance Flange Immersion Water Heater Element-Buy 110 v Immersion Heater, 240 v Immersion Heater, 6 kw Stainless Steel Immersion Heater Product on Alibaba.Com. Available online: https://www.alibaba.com/product-detail/Water-Immersion-Flange-Heater-220v-500w_1881524500.html?s=p (accessed on 10 December 2022).

- LG300N1C-G4 NeON2. Available online: https://www.europe-solarstore.com/lg300n1c-g4-neon2-174.html (accessed on 10 December 2022).

- Innovative Compact HYbrid Electrical/Thermal Energy Storage Systems for Low Energy BUILDings Life Cycle Cost Assessment Studies. Available online: http://www.hybuild.eu/wp-content/uploads/2022/12/HYBUILD-D5.3.pdf (accessed on 10 December 2022).

- Baxi 615 Gas System Condensing Boiler|Boilers|Screwfix.Com. Available online: https://www.screwfix.com/p/baxi-615-gas-system-condensing-boiler/563hg (accessed on 15 December 2022).

- Worcester Greenstar Ri 24 kW Heat Only Gas Boiler ERP 7733600311|Travis Perkins. Available online: https://www.travisperkins.co.uk/regular-gas-boilers/worcester-greenstar-ri-24kw-heat-only-gas-boiler-erp-7733600311/p/263628 (accessed on 10 December 2022).

- 5 kW LG Standard Wall Mounted Unit. Available online: https://cooleasy.co.uk/lg-standard-3-5kw-air-con-heat-pump-system.html (accessed on 16 December 2022).

- Natural Gas Price Statistics-Statistics Explained. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Natural_gas_price_statistics (accessed on 12 December 2022).

- Electricity Price Statistics-Statistics Explained. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Electricity_price_statistics (accessed on 12 December 2022).

- Key ECB Interest Rates. Available online: https://www.ecb.europa.eu/stats/policy_and_exchange_rates/key_ecb_interest_rates/html/index.en.html (accessed on 17 December 2022).

- Net Metering. Available online: https://www.c2h.gr/en/renewable-energy/net-metering (accessed on 11 December 2022).

- Renewable Energy Policy Database and Support: Single. Available online: http://www.res-legal.eu/en/search-by-country/greece/single/s/res-hc/t/promotion/aid/subsidy-ii-combined-with-loan-energy-saving-at-home-ii/lastp/139/ (accessed on 12 December 2022).

- Ministry of Environment and Energy, Greece. Oδηγός Eφαρμογής Προγράμματος «EΞOIKONOMΩ 2021» [Application Guide of “TO SAVE ENERGY 2021” Program]. 2021. Available online: https://exoikonomo2021.gov.gr/odegos (accessed on 16 December 2022).

- Government Gazette Greece 3971/Β/30-08-2021, Amendment of the Ministry of Environment and Energy/15084/382/19.02.2019 Ministerial Decision Installation of Power Plants by Self-Producers with the Application of Net-Metering or Virtual Net-Metering Accordi. 2021. Available online: https://exoikonomo2021.gov.gr/opheloumenoi (accessed on 17 December 2022).

- Renewable Energy Policy Database and Support: Single. Available online: http://www.res-legal.eu/en/search-by-country/germany/single/s/res-hc/t/promotion/aid/subsidy-investment-support/lastp/135/ (accessed on 10 December 2022).

- Marian Willhun Germany Raises Feed-In Tariffs for Solar up to 750 KW–Pv Magazine International. Available online: https://www.pv-magazine.com/2022/07/07/germany-raises-feed-in-tariffs-for-solar-up-to-750-kw/ (accessed on 10 December 2022).

- Geert de Clerq France Ends Gas Heaters Subsidies, Boosts Heat Pumps in Bid to Cut Russia Reliance|Reuters. Available online: https://www.reuters.com/world/europe/france-ends-gas-heaters-subsidies-boosts-heat-pumps-bid-cut-russia-reliance-2022-03-16/ (accessed on 10 December 2022).

- Renewable Energy Policy Database and Support: Tools List. Available online: http://www.res-legal.eu/en/search-by-country/france/tools-list/c/france/s/res-hc/t/promotion/sum/132/lpid/131/ (accessed on 12 December 2022).

- Home Energy Conservation Tax Credits in France (Crédit d’impot Développement Durable). Available online: https://www.french-property.com/guides/france/building/renovation/energy-conservation (accessed on 10 December 2022).

- Does the Installation of Solar Panels in France Make Sense?|French-Property.Com. Available online: https://www.french-property.com/news/money_france/installation_solar_panels (accessed on 10 December 2022).

- LG LG300N1K-G4: High Efficiency LG NeON® 2 Black Module Cells: 6 × 10 Module Efficiency 18.3% Connector Type: MC4, MC4 Compatible, IP67|LG USA Business. Available online: https://www.lg.com/us/business/solar-panels/lg-LG300N1K-G4 (accessed on 29 November 2022).

| Component | Model | Specifications |

|---|---|---|

| Compressor | Copeland ZB29KCE-TFD | 3-phase, 400 VAC, 2.2 kW, 16 A circuit breaker 2940 rpm @ 50 Hz |

| Expansion valve | Carel E2V24ZWF | Kv = 0.20 m3/h |

| Expansion valve controller | Carel EVD evolution Universal-Modbus | Modbus communication for superheating, pressure, and temperature measurements Automatic or manual (with 4–20 mA signal) control Regulation start/stop capability Manually full opening capability Alarm signal |

| Compressor drive | ABB ACS355 4 kW | Remote start/stop 4–20 mA signal for speed modulation |

| Condenser | Alfa Laval AC30EQ | Brazed plate heat exchanger 36 plates |

| Evaporator | Alfa Laval AC30EQ | Brazed plate heat exchanger 40 plates |

| Experimental Conditions | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Compressor speed (RPM) | 1500 | 2100 | 2400 | 2800 | ||||||||||||||||

| Condenser inlet temperature (°C) | 26 | 29 | 32 | 35 | 40 | 26 | 29 | 32 | 35 | 40 | 26 | 29 | 32 | 35 | 40 | 26 | 29 | 32 | 35 | 40 |

| Module Electrical Characteristics | |

|---|---|

| Nominal voltage (V) | 27.6 |

| Rated capacity (Ah) | 45 |

| Rated energy (kWh) | 1.2 |

| Upper cut-off voltage (V) | 32.4 |

| Lower cut-off voltage (V) | 18 |

| Nominal current (A) | 45 |

| Cities | PV Power (kW) | |||||

|---|---|---|---|---|---|---|

| 3 | 4.5 | 6 | ||||

| Athens | PV production (kWh) | |||||

| 4435 | 6653 | 8870 | ||||

| To grid * | From grid | To grid | From grid | To grid | From grid | |

| 1532 | 4753 | 3379 | 4403 | 5408 | 4176 | |

| Marseille | PV production (kWh) | |||||

| 4352 | 6258 | 8704 | ||||

| To grid | From grid | To grid | From grid | To grid | From grid | |

| 1751 | 6783 | 3587 | 6443 | 5549 | 6235 | |

| Stuttgart | PV production (kWh) | |||||

| 2996 | 4494 | 5992 | ||||

| To grid | From grid | To grid | From grid | To grid | From grid | |

| 1251 | 9064 | 2362 | 8677 | 3577 | 8394 | |

| Components | Specifications | Price per Item | Total Cost (EUR) |

|---|---|---|---|

| Reversible HP | 10 kW | --- | 7000 |

| 15 kW | --- | 8000 | |

| Storage tank | 700 L | --- | 1454 [40] |

| 900 L | --- | 1570 [40] | |

| Electric heater | 3 kW | --- | 7 [41] |

| 5 kW | --- | 10 [41] | |

| Solar PV panels | 3 kW | 268 [42] | 2680 |

| 4.5 kW | 4020 | ||

| 6 kW | 5360 | ||

| Batteries | 5 kWh | 1400/kWh [43] | 7000 |

| 10 kWh | 14,000 | ||

| 15 kWh | 21,000 | ||

| Dry cooler | 15 kW | --- | 1500 |

| Gas boiler | 15 kW | --- | 1219 [44] |

| 24 kW | --- | 1433 [45] | |

| Split AC | 3 kW | 657 [46] | 1970 |

| Cities | Electricity Prices (EUR/kWh) | Gas Prices (EUR/kWh) |

|---|---|---|

| Athens | 0.2305 | 0.0888 |

| Marseille | 0.2086 | 0.085 |

| Stuttgart | 0.3279 | 0.0806 |

| Cities | PV Power (kW) | |||

|---|---|---|---|---|

| 3 | 4.5 | 6 | ||

| Athens | Capital cost (EUR) | 21,605 | 23,079 | 24,553 |

| Subsidy (EUR) | 6112 | |||

| Discounted payback time (y) | 3.8 | 3.8 | 3.9 | |

| Marseille | Capital cost (EUR) | 21,608 | 23,082 | 24,556 |

| Subsidy (EUR) | 4000 | |||

| Discounted payback time (y) | 5.8 | 6.1 | 6.6 | |

| Stuttgart | Capital cost (EUR) | 24,166 | 25,640 | 27,114 |

| Subsidy (EUR) | 2800 | |||

| Discounted payback time (y) | 8.1 | 8.9 | 9.9 | |

| Cities | PV Power (kW) | |||

|---|---|---|---|---|

| 3 | 4.5 | 6 | ||

| Athens | Capital cost | 6084 | 7424 | 8764 |

| Discounted payback time (years) | 7.5 | 8.7 | 9.9 | |

| Marseille | Capital cost | 6084 | 7424 | 8764 |

| Discounted payback time (years) | 8.7 | 10.3 | 11.8 | |

| Stuttgart | Capital cost | 6084 | 7424 | 8764 |

| Discounted payback time (years) | 7.9 | 9.2 | 10.5 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rehman, O.A.; Palomba, V.; Frazzica, A.; Charalampidis, A.; Karellas, S.; Cabeza, L.F. Numerical and Experimental Analysis of a Low-GWP Heat Pump Coupled to Electrical and Thermal Energy Storage to Increase the Share of Renewables across Europe. Sustainability 2023, 15, 4973. https://doi.org/10.3390/su15064973

Rehman OA, Palomba V, Frazzica A, Charalampidis A, Karellas S, Cabeza LF. Numerical and Experimental Analysis of a Low-GWP Heat Pump Coupled to Electrical and Thermal Energy Storage to Increase the Share of Renewables across Europe. Sustainability. 2023; 15(6):4973. https://doi.org/10.3390/su15064973

Chicago/Turabian StyleRehman, Omais Abdur, Valeria Palomba, Andrea Frazzica, Antonios Charalampidis, Sotirios Karellas, and Luisa F. Cabeza. 2023. "Numerical and Experimental Analysis of a Low-GWP Heat Pump Coupled to Electrical and Thermal Energy Storage to Increase the Share of Renewables across Europe" Sustainability 15, no. 6: 4973. https://doi.org/10.3390/su15064973