Applying a Hybrid MCDM Model to Evaluate Green Supply Chain Management Practices

Abstract

:1. Introduction

- The effectiveness of different GSCM strategies and practices. Few studies discuss which strategies and practices are most effective for reducing supply chains’ environmental impacts and improving business operations’ sustainability;

- The costs and benefits of GSCM. Existing studies do not investigate the financial implications of implementing GSCM practices, and the costs and benefits of these practices compared with those of other business strategies;

- The potential barriers and challenges to implementing GSCM. Few studies explore the obstacles and challenges that organizations face when trying to implement GSCM practices, and how these challenges can be overcome;

- The role of government and other external stakeholders in promoting GSCM. Few studies explain the ways in which governments and other stakeholders can support and incentivize the adoption of GSCM practices.

2. Literature Review

2.1. Evaluation of GSCM Practices

- Identify the goals and objectives of the corporation’s GSCM efforts. This is based on the triple bottom line theory that organizations have three bottom lines: financial, social, and environmental. According to this theory, organizations should strive to balance their performance across these three dimensions in order to be truly sustainable and successful [29]. This could include reducing the supply chain’s environmental impact, improving its operations’ sustainability, or achieving other goals related to environmental responsibility;

- Develop metrics and benchmarks for evaluating the corporation’s GSCM practices. These metrics could include the corporation’s carbon footprint, waste reduction, water use, energy consumption, and other environmental performance indicators;

- Collect and analyze data on the corporation’s GSCM practices. This could involve conducting surveys, interviews, and other research to gather information on the corporation’s current practices and environmental impact;

- Compare the corporation’s performance on the selected metrics and benchmarks with those of other organizations in the same industry or with predetermined goals. The resource-based view theory proposes that organizations should focus on managing and leveraging their internal resources, such as their knowledge, skills, and capabilities, in order to create a competitive advantage and improve their performance. In the context of GSCM, this could mean building expertise and capabilities in areas such as waste reduction, energy efficiency, and sustainable sourcing [30]. This could involve using data envelopment analysis (DEA) or other performance evaluation methods to assess the corporation’s efficiency and identify areas for improvement;

- Develop and implement strategies for improving the corporation’s GSCM practices. The sustainability theory suggests that organizations should strive to achieve long-term sustainability by balancing the economic, social, and environmental dimensions of their activities. In the context of GSCM, this could mean considering the long-term impact of the organization’s practices on the environment and finding ways to reduce that impact [31]. This could include identifying and addressing inefficiencies, reducing waste and emissions, and implementing other strategies to enhance the environmental performance of the corporation’s supply chain.

2.2. Environmental Dimension

- Green design (A11) refers to a company’s consideration of a product’s potential harm to humans, spanning from conception to preliminary design, to final design. It also takes into account any possible effects on the environment and the level of resource wastage [43];

- Green production (A13) relates to the requirement for companies to respect and protect the natural environment in their production process, creating a GSC system [34]. Green production focuses on how the integration of green resources in the supply chain can effectively enhance corporate image and implement environmental protection policies [34];

- Optimal resource allocation (A14) assesses whether a company utilizes resources effectively, which would help them avoid or reduce waste to maximize profits [33].

2.3. Social Dimension

- Compliance with regulations (A21) means investing in green manufacturing processes to reduce the use and production of hazardous substances, while simultaneously reducing water, land, and air pollution to comply with various laws and regulations [2];

- Liability risk (A22) involves the use of hazardous substances or processes that cause harm to people or the environment, which in turn makes the company bear liability and damage its reputation [37];

- CRM capability (A23) is the process by which consumer trust is strengthened through green manufacturing. It can also enhance customer loyalty, because of cost reduction and quality improvement [36];

- Social requirements (A24) refer to the requirements placed on companies by society to fulfill their responsibilities in product safety and environmental protection [38].

2.4. Economic Dimension

- Supply chain requirements (A31) are based on green manufacturing requirements. Upstream manufacturers must pay attention to environmental protection throughout the production process, including when acquiring raw materials, processing, packaging, storage, transportation, use, and disposal of products [39];

- Market expansion (A33) assesses a company’s ability to obtain international certification for its green manufacturing processes, which is helpful for corporate developments and new market expansions [40];

- Cost reduction (A34) assesses how companies maximize resource utilization, reduce resource consumption, and directly cut costs through process-based improvements, innovative designs, or new technologies [12].

2.5. Organization Dimension

- Stakeholders (A41) refer to stakeholder participation, including shareholders and their views on environmental protection [41];

- Corporate image (A42) refers to the WCI’s corporate image, which is an important asset of any modern company. Through the promotion of green manufacturing and an emphasis on environmental protection, a high-quality corporate image can be created [42];

- Supervisor support (A43) refers to the degree of support provided by supervisors in the concept of green manufacturing and related initiatives [12];

- Employee motivation (A44) refers to employees’ awareness and understanding of green manufacturing and their ability to cooperate with relevant corporate policies and regulations actively [43].

3. Methods

4. Results

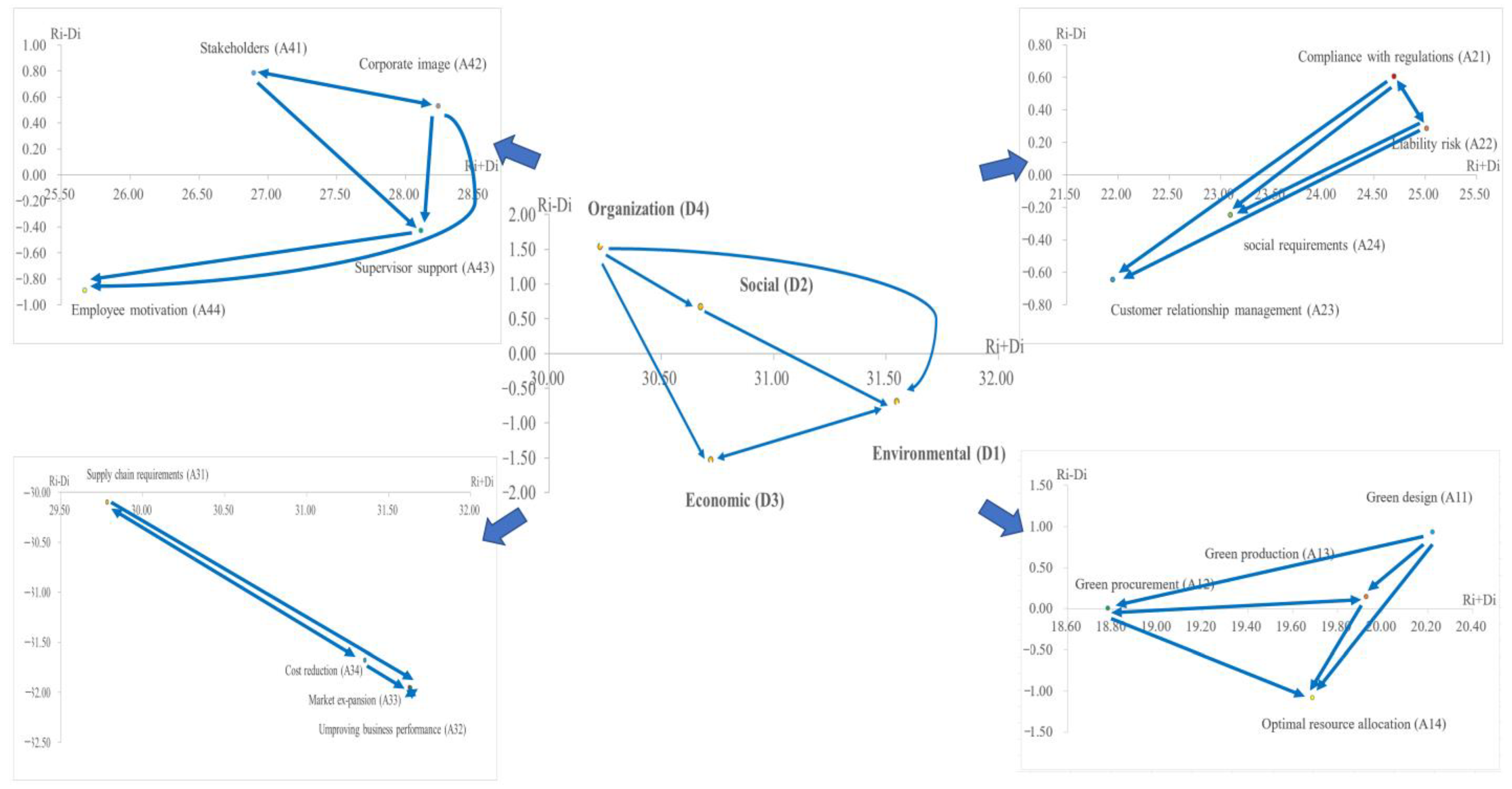

4.1. Dimension Relevance

4.2. Data Analysis of Dimension and Criterion Weights

5. Discussion

- Financial barriers: Implementing GSCM practices may require a significant investment of time and resources, which can be a barrier for organizations facing financial constraints or not willing to make the necessary investment;

- Cultural barriers: Organizations may face resistance from employees or other stakeholders who are not supportive of green initiatives, or who may be skeptical about the benefits of GSCM. Overcoming this resistance and building support for green initiatives can be challenging;

- Technical barriers: Implementing GSCM practices may require organizations to invest in new technologies and systems, and to develop new skills and expertise. This can be a barrier for organizations that do not have the necessary technical resources or capabilities;

- Regulatory barriers: Organizations may face barriers in the form of regulations or other legal requirements that limit their ability to implement GSCM practices. For example, some countries may have regulations that restrict the use of certain materials or technologies or require organizations to meet certain environmental standards. For GSM, and organizations may need to overcome these barriers to successfully implement these practices.

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statements

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bhatia, M.S.; Gangwani, K.K. Green supply chain management: Scientometric review and analysis of empirical research. J. Clean. Prod. 2021, 284, 124722. [Google Scholar] [CrossRef]

- Lo, H.-W.; Liou, J.J.; Wang, H.-S.; Tsai, Y.-S. An integrated model for solving problems in green supplier selection and order allocation. J. Clean. Prod. 2018, 190, 339–352. [Google Scholar] [CrossRef]

- Ma, S.; Zhang, Y.; Liu, Y.; Yang, H.; Lv, J.; Ren, S. Data-driven sustainable intelligent manufacturing based on demand response for energy-intensive industries. J. Clean. Prod. 2020, 274, 123155. [Google Scholar] [CrossRef]

- Chatterjee, S.; Chaudhuri, R.; Shah, M.; Maheshwari, P. Big data driven innovation for sustaining SME supply chain operation in post COVID-19 scenario: Moderating role of SME technology leadership. Comput. Ind. Eng. 2022, 168, 108058. [Google Scholar] [CrossRef] [PubMed]

- Raj, A.; Mukherjee, A.A.; de Sousa Jabbour, A.B.L.; Srivastava, S.K. Supply chain management during and post-COVID-19 pandemic: Mitigation strategies and practical lessons learned. J. Bus. Res. 2022, 142, 1125–1139. [Google Scholar] [CrossRef]

- Hajiagha, S.H.R.; Mahdiraji, H.A.; Behnam, M.; Nekoughadirli, B.; Joshi, R. A scenario-based robust time–cost tradeoff model to handle the effect of COVID-19 on supply chains project management. Oper. Manag. Res. 2022, 15, 357–377. [Google Scholar] [CrossRef]

- Weber, C.A.; Current, J.R.; Benton, W. Vendor selection criteria and methods. Eur. J. Oper. Res. 1991, 50, 2–18. [Google Scholar] [CrossRef]

- Afrasiabi, A.; Tavana, M.; Di Caprio, D. An extended hybrid fuzzy multi-criteria decision model for sustainable and resilient supplier selection. Environ. Sci. Pollut. Res. 2022, 29, 37291–37314. [Google Scholar] [CrossRef]

- Verma, M.; Prem, P.R.; Ren, P.; Liao, H.; Xu, Z. Green supplier selection with a multiple criteria decision-making method based on thermodynamic features. Environ. Dev. Sustain. 2022, 1–33. [Google Scholar] [CrossRef]

- Ghosh, S.; Mandal, M.C.; Ray, A. Green supply chain management framework for supplier selection: An integrated multi-criteria decision-making approach. Int. J. Manag. Sci. Eng. Manag. 2021, 17, 205–219. [Google Scholar] [CrossRef]

- Quan, M.-Y.; Wang, Z.-L.; Liu, H.-C.; Shi, H. A hybrid MCDM approach for large group green supplier selection with uncertain linguistic information. IEEE Access 2018, 6, 50372–50383. [Google Scholar] [CrossRef]

- Rouyendegh, B.D.; Yildizbasi, A.; Üstünyer, P. Intuitionistic fuzzy TOPSIS method for green supplier selection problem. Soft Comput. 2020, 24, 2215–2228. [Google Scholar] [CrossRef]

- Rye, S.; Aktas, E. A Multi-Attribute Decision Support System for Allocation of Humanitarian Cluster Resources Based on Decision Makers’ Perspective. Sustainability 2022, 14, 13423. [Google Scholar] [CrossRef]

- Wu, Y.-C.; Lin, S.-W. Integrated approach for exploring critical elements that affect sustainable development of cultural and creative industries. J. Bus. Econ. Manag. 2021, 22, 596–615. [Google Scholar] [CrossRef]

- Sotoudeh-Anvari, A. The applications of MCDM methods in COVID-19 pandemic: A state of the art review. Appl. Soft Comput. 2022, 126, 109238. [Google Scholar] [CrossRef]

- Fontela, E.; Gabus, A. The DEMATEL Observer; Battelle Geneva Research Center: Geneva, Switzerland, 1976. [Google Scholar]

- Chang, B.; Chang, C.-W.; Wu, C.-H. Fuzzy DEMATEL method for developing supplier selection criteria. Expert Syst. Appl. 2011, 38, 1850–1858. [Google Scholar] [CrossRef]

- Chang, D.-S.; Wu, W.-D. Impact of the COVID-19 pandemic on the tourism industry: Applying TRIZ and DEMATEL to construct a decision-making model. Sustainability 2021, 13, 7610. [Google Scholar] [CrossRef]

- Lin, H.-F. IT resources and quality attributes: The impact on electronic green supply chain management implementation and performance. Technol. Soc. 2022, 68, 101833. [Google Scholar] [CrossRef]

- Birasnav, M.; Chaudhary, R.; Dunne, J.H.; Bienstock, J.; Seaman, C. Green Supply Chain Management: A Theoretical Framework and Research Directions. Comput. Ind. Eng. 2022, 172, 108441. [Google Scholar] [CrossRef]

- Shetty, S.K.; Bhat, K.S. Green supply chain management practices implementation and sustainability–A review. Mater. Today Proc. 2022, 52, 735–740. [Google Scholar] [CrossRef]

- Habib, M.A.; Bao, Y.; Nabi, N.; Dulal, M.; Asha, A.A.; Islam, M. Impact of strategic orientations on the implementation of green supply chain management practices and sustainable firm performance. Sustainability 2021, 13, 340. [Google Scholar] [CrossRef]

- Yildizbasi, A.; Arioz, Y. Green supplier selection in new era for sustainability: A novel method for integrating big data analytics and a hybrid fuzzy multi-criteria decision making. Soft Comput. 2022, 26, 253–270. [Google Scholar] [CrossRef]

- Nguyen, N.B.T.; Lin, G.-H.; Dang, T.-T. A Two phase integrated fuzzy decision-making framework for green supplier selection in the coffee bean supply chain. Mathematics 2021, 9, 1923. [Google Scholar] [CrossRef]

- Celik, E.; Yucesan, M.; Gul, M. Green supplier selection for textile industry: A case study using BWM-TODIM integration under interval type-2 fuzzy sets. Environ. Sci. Pollut. Res. 2021, 28, 64793–64817. [Google Scholar] [CrossRef] [PubMed]

- Kazemitash, N.; Fazlollahtabar, H.; Abbaspour, M. Rough best-worst method for supplier selection in biofuel companies based on green criteria. Oper. Res. Eng. Sci. Theory Appl. 2021, 4, 1–12. [Google Scholar] [CrossRef]

- Shi, H.; Quan, M.-Y.; Liu, H.-C.; Duan, C.-Y. A novel integrated approach for green supplier selection with interval-valued intuitionistic uncertain linguistic information: A case study in the agri-food industry. Sustainability 2018, 10, 733. [Google Scholar] [CrossRef] [Green Version]

- Konys, A. Green supplier selection criteria: From a literature review to a comprehensive knowledge base. Sustainability 2019, 11, 4208. [Google Scholar] [CrossRef] [Green Version]

- Abdala, E.C.; de Oliveira, E.J.; Cezarino, L.O. Triple bottom line in Green Supply Chain Management: A chemical industry study. Braz. J. Oper. Prod. Manag. 2018, 15, 162–172. [Google Scholar] [CrossRef]

- Yu, W.; Chavez, R.; Feng, M. Green supply management and performance: A resource-based view. Prod. Plan. Control 2017, 28, 659–670. [Google Scholar] [CrossRef]

- Zaid, A.A.; Jaaron, A.A.; Bon, A.T. The impact of green human resource management and green supply chain management practices on sustainable performance: An empirical study. J. Clean. Prod. 2018, 204, 965–979. [Google Scholar] [CrossRef]

- Javad, M.O.M.; Darvishi, M.; Javad, A.O.M. Green supplier selection for the steel industry using BWM and fuzzy TOPSIS: A case study of Khouzestan steel company. Sustain. Futur. 2020, 2, 100012. [Google Scholar] [CrossRef]

- Kilic, H.S.; Yalcin, A.S. Modified two-phase fuzzy goal programming integrated with IF-TOPSIS for green supplier selection. Appl. Soft Comput. 2020, 93, 106371. [Google Scholar] [CrossRef]

- Jiang, P.; Hu, Y.C.; Yen, G.F.; Tsao, S.J. Green supplier selection for sustainable development of the automotive industry using grey decision-making. Sustain. Dev. 2018, 26, 890–903. [Google Scholar] [CrossRef]

- Lu, M.-T.; Tsai, J.-F.; Shen, S.-P.; Lin, M.-H.; Hu, Y.-C. Estimating sustainable development performance in the electrical wire and cable industry: Applying the integrated fuzzy MADM approach. J. Clean. Prod. 2020, 277, 122440. [Google Scholar] [CrossRef]

- Parkouhi, S.V.; Ghadikolaei, A.S.; Lajimi, H.F. Resilient supplier selection and segmentation in grey environment. J. Clean. Prod. 2019, 207, 1123–1137. [Google Scholar] [CrossRef]

- Li, F.; Wu, C.-H.; Zhou, L.; Xu, G.; Liu, Y.; Tsai, S.-B. A model integrating environmental concerns and supply risks for dynamic sustainable supplier selection and order allocation. Soft Comput. 2021, 25, 535–549. [Google Scholar] [CrossRef]

- Guarnieri, P.; Trojan, F. Decision making on supplier selection based on social, ethical, and environmental criteria: A study in the textile industry. Resour. Conserv. Recycl. 2019, 141, 347–361. [Google Scholar] [CrossRef]

- Dobos, I.; Vörösmarty, G. Inventory-related costs in green supplier selection problems with Data Envelopment Analysis (DEA). Int. J. Prod. Econ. 2019, 209, 374–380. [Google Scholar] [CrossRef] [Green Version]

- Krishankumar, R.; Gowtham, Y.; Ahmed, I.; Ravichandran, K.; Kar, S. Solving green supplier selection problem using q-rung orthopair fuzzy-based decision framework with unknown weight information. Appl. Soft Comput. 2020, 94, 106431. [Google Scholar] [CrossRef]

- Song, Y.; Li, G. A large-scale group decision-making with incomplete multi-granular probabilistic linguistic term sets and its application in sustainable supplier selection. J. Oper. Res. Soc. 2019, 70, 827–841. [Google Scholar] [CrossRef]

- Lu, J.; Zhang, S.; Wu, J.; Wei, Y. COPRAS method for multiple attribute group decision making under picture fuzzy environment and their application to green supplier selection. Technol. Econ. Dev. Econ. 2021, 27, 369–385. [Google Scholar] [CrossRef]

- Ecer, F. Multi-criteria decision making for green supplier selection using interval type-2 fuzzy AHP: A case study of a home appliance manufacturer. Oper. Res. 2022, 22, 199–233. [Google Scholar] [CrossRef]

- Lin, F.; Lin, S.-W.; Lu, W.-M. Sustainability assessment of Taiwan’s semiconductor industry: A new hybrid model using combined analytic hierarchy process and two-stage additive network data envelopment analysis. Sustainability 2018, 10, 4070. [Google Scholar] [CrossRef] [Green Version]

- Lin, S.-W.; Lu, W.-M.; Lin, F. Entrusting decisions to the public service pension fund: An integrated predictive model with additive network DEA approach. J. Oper. Res. Soc. 2021, 72, 1015–1032. [Google Scholar] [CrossRef]

- Saaty, T.L. On polynomials and crossing numbers of complete graphs. J. Comb. Theory Ser. A 1971, 10, 183–184. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Eckert, C.M.; Earl, C. A review of fuzzy AHP methods for decision-making with subjective judgements. Expert Syst. Appl. 2020, 161, 113738. [Google Scholar] [CrossRef]

- Saaty, T.L. Decision Making with Dependence and Feedback: The Analytic Network Process; RWS Publications: Pittsburgh, PA, USA, 1996; Volume 4922. [Google Scholar]

- Alkan, N.; Kahraman, C. Evaluation of government strategies against COVID-19 pandemic using q-rung orthopair fuzzy TOPSIS method. Appl. Soft Comput. 2021, 110, 107653. [Google Scholar] [CrossRef]

- Ghosh, S.; Chatterjee, N.D.; Dinda, S. Urban ecological security assessment and forecasting using integrated DEMATEL-ANP and CA-Markov models: A case study on Kolkata Metropolitan Area, India. Sustain. Cities Soc. 2021, 68, 102773. [Google Scholar] [CrossRef]

- Esfandi, S.; Rahmdel, L.; Nourian, F.; Sharifi, A. The role of urban spatial structure in energy resilience: An integrated assessment framework using a hybrid factor analysis and analytic network process model. Sustain. Cities Soc. 2022, 76, 103458. [Google Scholar] [CrossRef]

- Moktadir, M.A.; Kumar, A.; Ali, S.M.; Paul, S.K.; Sultana, R.; Rezaei, J. Critical success factors for a circular economy: Implications for business strategy and the environment. Bus. Strategy Environ. 2020, 29, 3611–3635. [Google Scholar] [CrossRef]

- Sabokro, M.; Masud, M.M.; Kayedian, A. The effect of green human resources management on corporate social responsibility, green psychological climate and employees’ green behavior. J. Clean. Prod. 2021, 313, 127963. [Google Scholar] [CrossRef]

- Sharma, M.; Luthra, S.; Joshi, S.; Kumar, A. Developing a framework for enhancing survivability of sustainable supply chains during and post-COVID-19 pandemic. Int. J. Logist. Res. Appl. 2022, 25, 433–453. [Google Scholar] [CrossRef]

- Foerstl, K.; Reuter, C.; Hartmann, E.; Blome, C. Managing supplier sustainability risks in a dynamically changing environment—Sustainable supplier management in the chemical industry. J. Purch. Supply Manag. 2010, 16, 118–130. [Google Scholar] [CrossRef]

- Lo, H.-W.; Liaw, C.-F.; Gul, M.; Lin, K.-Y. Sustainable supplier evaluation and transportation planning in multi-level supply chain networks using multi-attribute-and multi-objective decision making. Comput. Ind. Eng. 2021, 162, 107756. [Google Scholar] [CrossRef]

| Dimension | Criteria | References |

|---|---|---|

| Environmental (D1) | Green design (A11) | [32,33] |

| Green procurement (A12) | [34,33] | |

| Green production (A13) | [32,34] | |

| Optimal resource allocation (A14) | [35,33] | |

| Social (D2) | Compliance with regulations (A21) | [2,36] |

| Liability risk (A22) | [37] | |

| Customer relationship management (A23) | [35,36] | |

| Social requirements (A24) | [37,38] | |

| Economic (D3) | Supply chain requirements (A31) | [39,40] |

| Improving business performance (A32) | [32] | |

| Market expansion (A33) | [40] | |

| Cost reduction (A34) | [12,32] | |

| Organization (D4) | Stakeholders (A41) | [12,41] |

| Corporate image (A42) | [12,42] | |

| Supervisor support (A43) | [12,35] | |

| Employee motivation (A44) | [43,35] |

| Expertise | Specialist Background | Number of Specialists |

|---|---|---|

| Practical Experience(years) | 1–10 11–20 21–30 | 2 6 6 |

| Field | Academia Manufacturing industry | 4 10 |

| D1 | D2 | D3 | D4 | |

|---|---|---|---|---|

| D1 | 0.00 | 2.77 | 2.62 | 2.23 |

| D2 | 2.85 | 0.00 | 2.54 | 2.38 |

| D3 | 2.46 | 2.31 | 0.00 | 2.31 |

| D4 | 2.77 | 2.23 | 2.92 | 0.00 |

| D1 | D2 | D3 | D4 | |

|---|---|---|---|---|

| D1 | 0.00 | 0.34 | 0.32 | 0.28 |

| D2 | 0.35 | 0.00 | 0.31 | 0.30 |

| D3 | 0.30 | 0.29 | 0.00 | 0.29 |

| D4 | 0.34 | 0.28 | 0.36 | 0.00 |

| D1 | D2 | D3 | D4 | r | |

|---|---|---|---|---|---|

| D1 | 3.85 | 3.84 | 4.10 | 3.64 | 15.43 |

| D2 | 4.17 | 3.64 | 4.15 | 3.71 | 15.68 |

| D3 | 3.88 | 3.61 | 3.64 | 3.46 | 14.60 |

| D4 | 4.22 | 3.91 | 4.23 | 3.53 | 15.88 |

| d | 16.12 | 15.00 | 16.12 | 14.34 |

| r | d | r + d | r-d | |

|---|---|---|---|---|

| D1 | 15.43 | 16.12 | 31.55 | −0.69 |

| D2 | 15.68 | 15.00 | 30.67 | 0.68 |

| D3 | 14.60 | 16.12 | 30.72 | −1.53 |

| D4 | 15.88 | 14.34 | 30.23 | 1.54 |

| Dimension | Criteria | Global Weight | Rank | Dimension Local Weight | Criteria Local Weight |

|---|---|---|---|---|---|

| Environmental | Green design | 0.0645 | 6 | 0.262 | 0.2460 |

| Green procurement | 0.0626 | 8 | 0.2388 | ||

| Green production | 0.0659 | 3 | 0.2517 | ||

| Optimal resource allocation | 0.0690 | 1 | 0.2635 | ||

| Social | Compliance with regulations | 0.0621 | 9 | 0.244 | 0.2545 |

| Liability risk | 0.0637 | 7 | 0.2610 | ||

| Customer relationship management | 0.0581 | 14 | 0.2382 | ||

| Social requirements | 0.0601 | 11 | 0.2463 | ||

| Economic | Supply chain requirements | 0.0637 | 7 | 0.261 | 0.2442 |

| Improving business performance | 0.0653 | 5 | 0.2503 | ||

| Market expansion | 0.0664 | 2 | 0.2544 | ||

| Cost reduction | 0.0655 | 4 | 0.2510 | ||

| Organization | Stakeholders | 0.0559 | 13 | 0.233 | 0.2399 |

| Corporate image | 0.0593 | 12 | 0.2546 | ||

| Supervisor support | 0.0610 | 10 | 0.2619 | ||

| Employee motivation | 0.0568 | 15 | 0.2436 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tsai, J.-F.; Shen, S.-P.; Lin, M.-H. Applying a Hybrid MCDM Model to Evaluate Green Supply Chain Management Practices. Sustainability 2023, 15, 2148. https://doi.org/10.3390/su15032148

Tsai J-F, Shen S-P, Lin M-H. Applying a Hybrid MCDM Model to Evaluate Green Supply Chain Management Practices. Sustainability. 2023; 15(3):2148. https://doi.org/10.3390/su15032148

Chicago/Turabian StyleTsai, Jung-Fa, Shih-Ping Shen, and Ming-Hua Lin. 2023. "Applying a Hybrid MCDM Model to Evaluate Green Supply Chain Management Practices" Sustainability 15, no. 3: 2148. https://doi.org/10.3390/su15032148