Environmental and Economic Assessment of Eco-Concrete for Residential Buildings: A Case Study of Santiago de Cali (Colombia)

Abstract

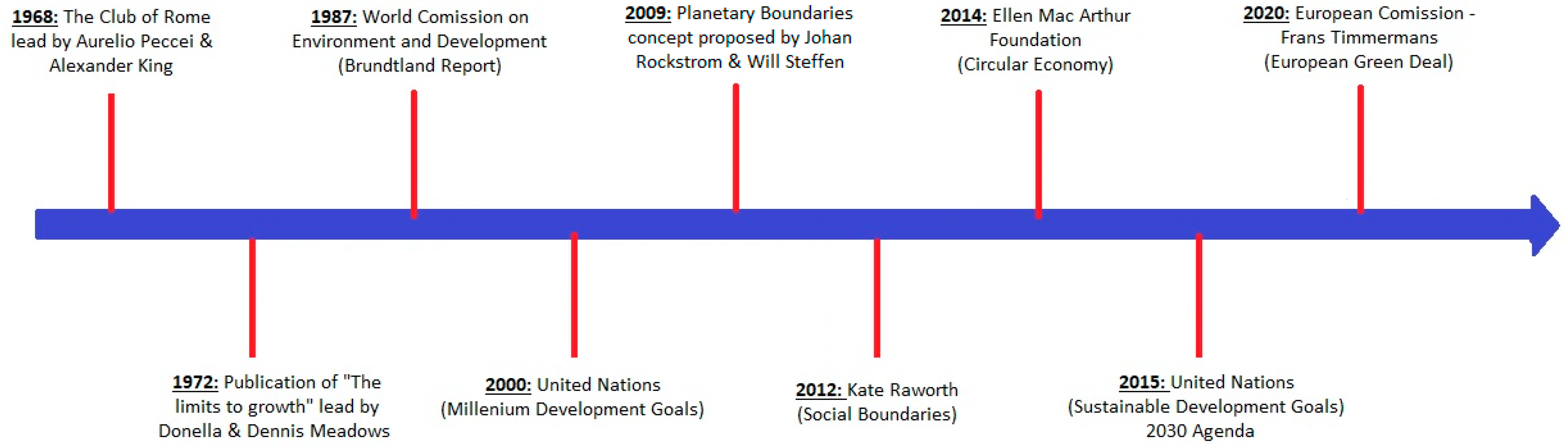

:1. Introduction

- (a)

- Design of a system to generate air purification and self-cleaning on the surfaces of the tunnel of Colombia Avenue (Cali) using a photocatalytic mortar and UV-A lighting. This design project includes economic and environmental performances [7].

- (b)

- Evaluation of semi-intensive green roofs with drainage layers made out of recycled and reused materials. Recycled rubber, recycled polyethylene (PET) bottles and recycled high-density polyethylene (HDPE) trays were evaluated as drainage layers regarding their hydraulic, thermal and mechanical performances in prototyped green roofs [8,9].

- (c)

- Evaluation of the mechanical properties of concrete using recycled aggregates obtained from old paving stones coming from Almaguer (Cauca, Colombia). The results showed promising results with a mix replacing 50% of the natural fine aggregate with recycled ones [10].

- (d)

- Evaluation of the effect in mortars of the partial replacement of Portland cement by ash from the paper industry. In particular, the fly ash was coming from the coal combustion in the manufacturing process of a local paper company [11].

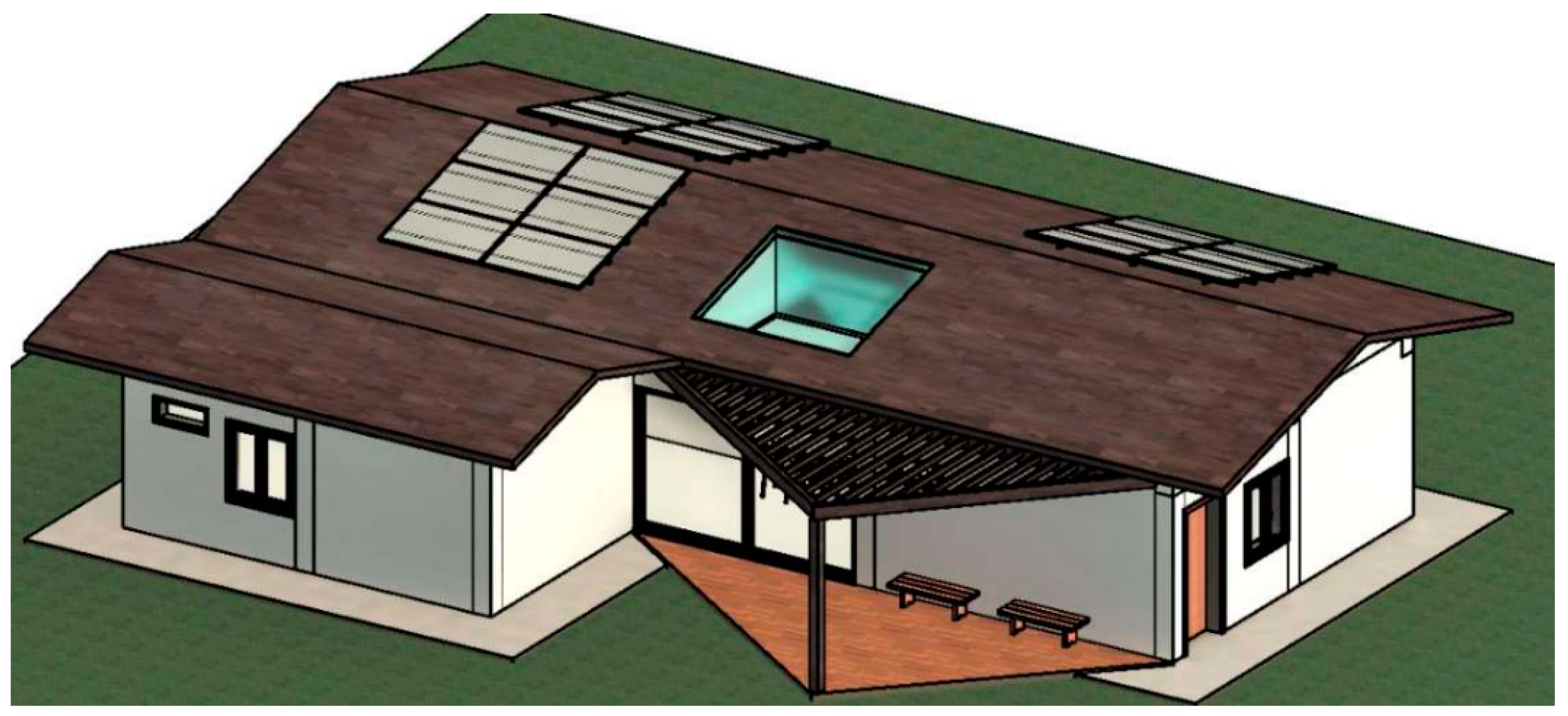

2. Case Study

3. Methodology

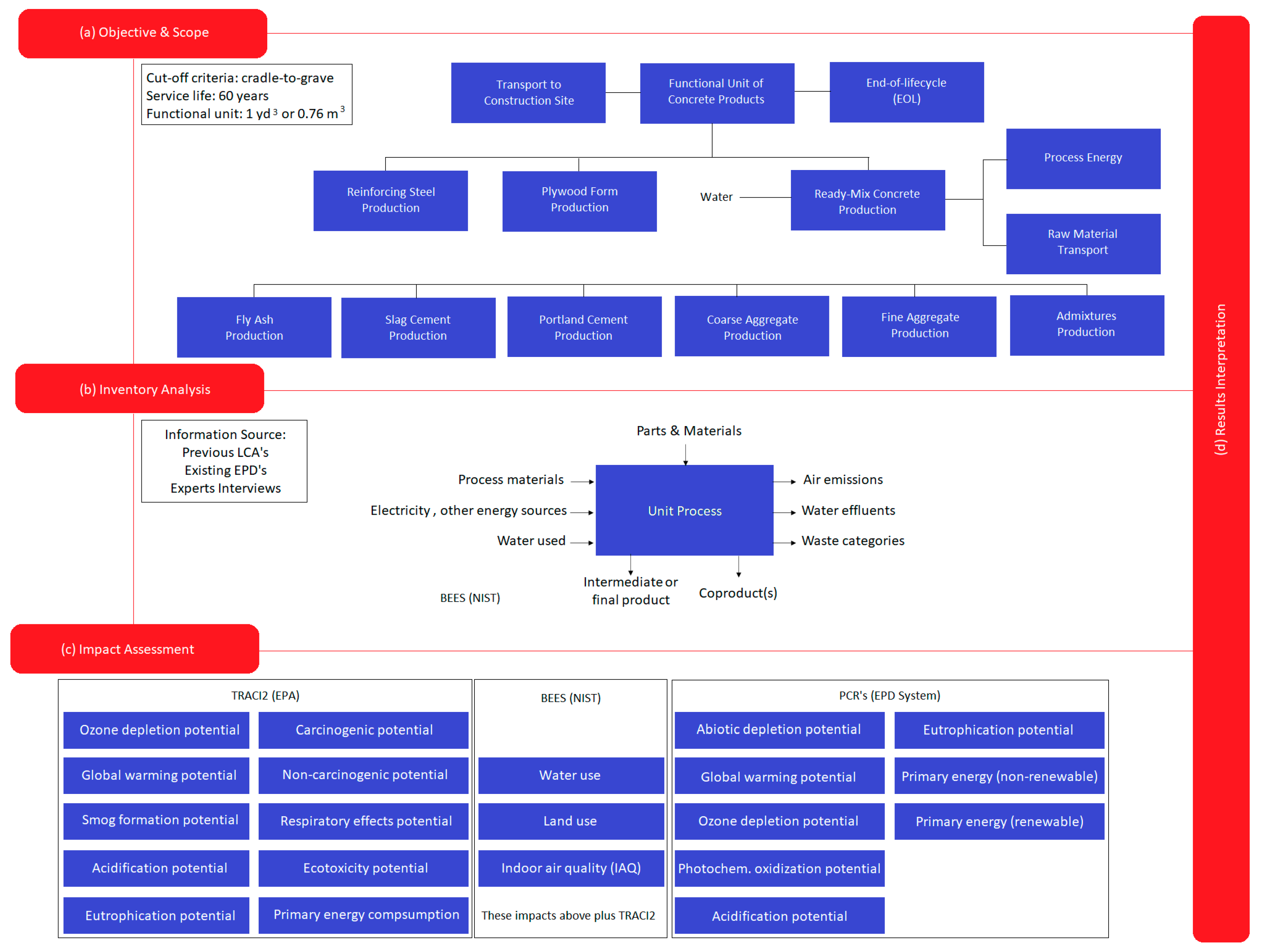

3.1. Life Cycle Assessment (LCA)

3.2. Life Cycle Costing (LCC)

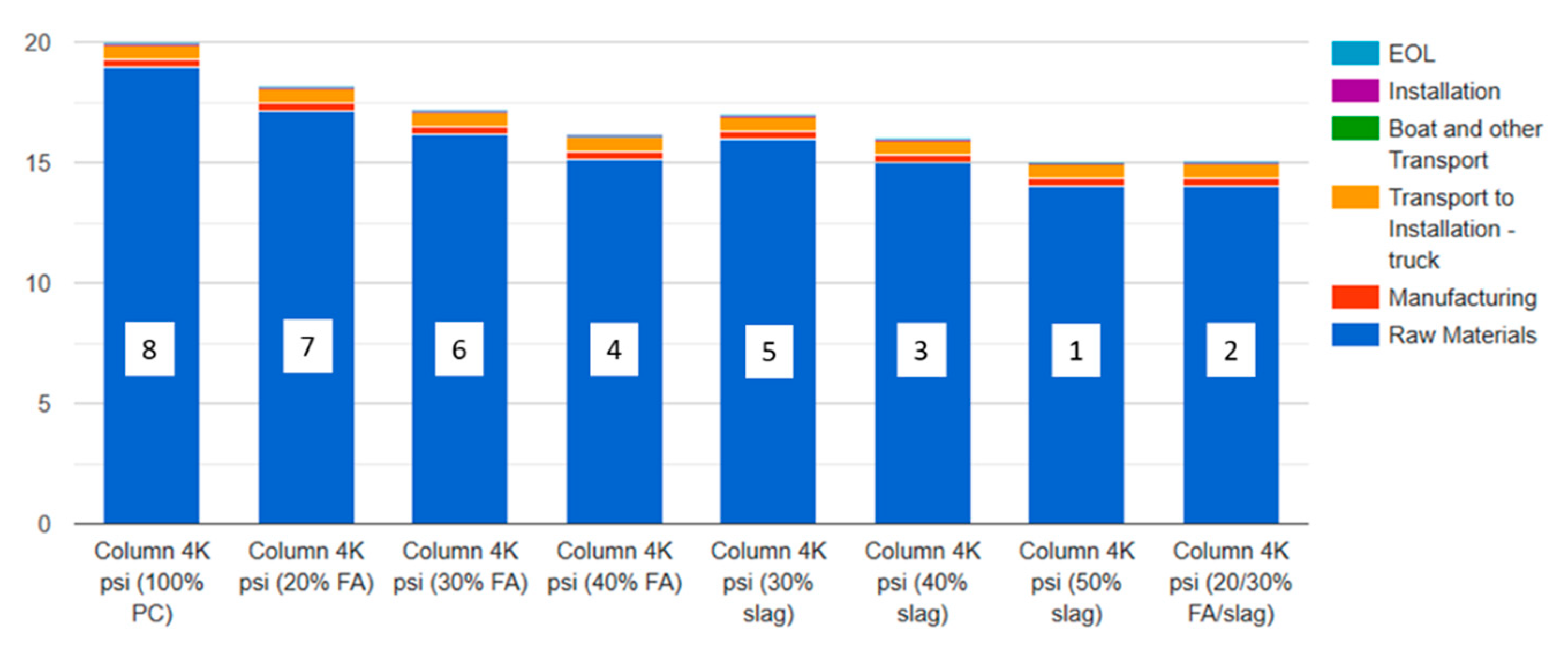

4. Results

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- La Economía Circular y su Papel en el Cambio Climático. Available online: https://www.elespectador.com/actualidad/la-economia-circular-y-su-papel-en-el-cambio-climatico/ (accessed on 6 April 2023).

- Rockström, J.; Steffen, W.; Noone, K.; Persson, Å.; Chapin, F.S., III; Lambin, E.; Lenton, T.M.; Scheffer, M.; Folke, C.; Schellnhuber, H.J.; et al. Planetary boundaries: Exploring the safe operating space for humanity. Ecol. Soc. 2009, 14, 32. [Google Scholar] [CrossRef]

- Raworth, K. A Safe and Just Space for Humanity: Can We Live within the Doughnut? Oxfam Discussion Papers; Oxfam International: Oxford, UK, 2012; ISBN 978-1-78077-059-8. [Google Scholar]

- Osuna Motta, I.; Villa Franco, J.F.; Maury-Ramírez, A.; Valencia Ojeda, L.A.; Giraldo Yepes, C.M.; Colonia Restrepo, A.F.; Galarza, S.; Carmona Ceballos, J.I.; Rincón Laverde, E.J.; Gutiérrez Robledo, A.; et al. Manual de Construcción Sostenible de Santiago de Cali. Alcaldía de Santiago de Cali, 2022 (Under City Hall Revision for Approval). Available online: https://www.concejodecali.gov.co/documentos/?genPag=3 (accessed on 26 May 2023).

- Economía Circular—DANE. Available online: http://www.andi.com.co/Uploads/economia-circular-1-reporte.pdf (accessed on 6 April 2023).

- Maury-Ramírez, A.; Illera-Perozo, D.; Mesa, J.A. Circular economy in the construction sector: A case study of Santiago de Cali (Colombia). Sustainability 2022, 14, 1923. [Google Scholar] [CrossRef]

- Medina Medina, A.F.; Torres Rojas, D.F.; Meza Girón, G.; Villota Grisales, R.A. Diseño de un Sistema Para Generar Purificación del Aire y Auto-Limpieza en las Superficies del Túnel de la Avenida Colombia (Cali). Ph.D. Thesis, Pontificia Universidad Javeriana Cali, Santiago de Cali, Colombia, May 2016. [Google Scholar]

- Naranjo, A.; Colonia, A.; Mesa, J.; Maury-Ramírez, A. Evaluation of Semi-Intensive Green Roofs with Drainage Layers Made Out of Recycled and Reused Materials. Coatings 2020, 10, 525. [Google Scholar] [CrossRef]

- Naranjo, A.; Colonia, A.; Mesa, J.; Maury, H.; Maury-Ramírez, A. State-of-the-art green roofs: Technical performance and certifications for sustainable construction. Coatings 2020, 10, 69. [Google Scholar] [CrossRef] [Green Version]

- Bravo-German, A.M.; Bravo-Gómez, I.D.; Mesa, J.A.; Maury-Ramírez, A. Mechanical Properties of Concrete Using Recycled Aggregates Obtained from Old Paving Stones. Sustainability 2021, 13, 3044. [Google Scholar] [CrossRef]

- Hurtado Portocarrero, I.A. Evaluación del Efecto del Reemplazo Parcial del Cemento Portland por Ceniza de la Industria del Papel en Morteros y Muretes. Master′s Thesis, Pontificia Universidad Javeriana Cali, Santiago de Cali, Colombia, September 2019. [Google Scholar]

- Shobeiri, V.; Bennett, B.; Xie, T.; Visintin, P. Mix design optimization of concrete containing fly ash and slag for global warming potential and cost reduction. Case Stud. Constr. Mater. 2023, 18, e01832. [Google Scholar] [CrossRef]

- Das, P.; Sankar Cheela, V.R.; Mistri, A.; Chakraborty, S.; Dubey, S.; Barai, S.V. Performance assessment and life cycle analysis of concrete containing ferrochrome slag and fly ash as replacement materials—A circular approach. Constr. Build. Mater. 2022, 347, 128609. [Google Scholar] [CrossRef]

- Chen, X.; Wang, H.; Najm, H.; Venkiteela, G.; Hencken, J. Evaluating engineering properties and environmental impact of pervious concrete with fly ash and slag. J. Clean. Prod. 2019, 237, 117714. [Google Scholar] [CrossRef]

- van den Heede, P.; de Belie, N. Environmental impact and life cycle assessment (LCA) of traditional and ‘green’ concretes: Literature review and theoretical calculations. Cem. Concr. Compos. 2012, 34, 431. [Google Scholar] [CrossRef]

- Kara, S.; Herrmann, C.; Hauschild, M. Operationalization of life cycle engineering, Resources. Conserv. Recycl. 2023, 190, 106836. [Google Scholar] [CrossRef]

- de Pedro, J.P.Q.; Lagao, J.A.T.; Ongpeng, J.M.C. Life Cycle Assessment of Concrete Using Copper Slag as a Partial Cement Substitute in Reinforced Concrete Buildings. Buildings 2023, 13, 746. [Google Scholar] [CrossRef]

- Orozco, C.R.; Babel, S.; Tangtermsirikul, S.; Sugiyama, T. Understanding the environmental, economic, and social impact of fly ash utilization on early-age high-strength mass concrete using life cycle analysis. Mater. Today Proc. 2023, in press. [CrossRef]

- De Lassio, J.; França, J.; Espirito Santo, K.; Haddad, A. Case Study: LCA Methodology Applied to Materials Management in a Brazilian Residential Construction Site. J. Eng. 2016, 2016, 8513293. [Google Scholar] [CrossRef] [Green Version]

- Global Consensus on Sustainability in the Built Environment—GLOBE. Decarbonising Global Construction. Available online: 221109-GlobePolicyAdviceDocument-revised-new-1.pdf (accessed on 6 April 2023).

- Lombardi, D.R.; Laybourn, P. Redefining Industrial Symbiosis, Crossing Academic–Practitioner Boundaries. J. Ind. Ecol. 2012, 16, 28. [Google Scholar] [CrossRef]

- Cagno, E.; Negri, A.M.; Neri, A.; Giambone, M. One Framework to Rule Them All: An Integrated, Multi-level and Scalable Performance Measurement Framework of Sustainability, Circular Economy and Industrial Symbiosis. Sustain. Prod. Consum. 2023, 35, 55. [Google Scholar] [CrossRef]

- Mesa, J.A.; Fúquene-Retamoso, C.; Maury-Ramírez, A. Life cycle assessment on construction and demolition waste: A systematic literature review. Sustainability 2021, 13, 7676. [Google Scholar] [CrossRef]

- Ruiz-Izquierdo, J.; Valencia-Chavez, D.; Salas-Nuñez, J.L.; Maldonado, J.F.; Yama, C.E. Edificación Sostenible, Proyecto Final Curso Sostenibilidad en la Construcción; Pontificia Universidad Javeriana Cali: Santiago de Cali, Colombia, 2022. [Google Scholar]

- National Institute of Standards—NIST. Building for Environmental and Economic Sustainability (BEES) Online 2.1 Technical Manual. Available online: https://ws680.nist.gov/BEES2/Home/UserManual/ (accessed on 6 April 2023).

- De Belie, N.; Gruyaert, E.; Soutsos, M. (Eds.) Properties of Fresh and Hardened Concrete Containing Supplementary Cementitious Materials, State-of-the-Art Report of the RILEM Technical Committee 238-SCM, Working Group 4; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar] [CrossRef]

- Villagrán-Zaccardi, Y.; Pareja, R.; Rojas, L.; Irassar, E.; Torres-Acosta, A.; Tobón, J.; Vanderley, J. Overview of cement and concrete production in Latin America and the Caribbean with a focus on the goals of reaching carbon neutrality. RILEM Tech. Lett. 2022, 7, 30. [Google Scholar] [CrossRef]

- American Standard of Testing Materials—ASTM. Standard Practice for Measuring Life-Cycle Costs of Buildings and Building Systems; ASTM: Conshohocken, PA, USA, 2017. [Google Scholar]

- World Green Building Council—WGBC. Policy Pathway Santiago de Cali, Colombia. Available online: https://worldgbc.org/signatory/santiago-de-cali-colombia/ (accessed on 6 April 2023).

- Tecnalia, Diagnóstico de Eficiencia en el Uso de Materiales y Cierre de Ciclos en los Sectores Manufacturero y de Construcción en Colombia: Contraste Frente a Experiencias Internacionales. Available online: https://bibliotecadigital.ccb.org.co/bitstream/handle/11520/21034/Diagn%c3%b3stico%20Tecnalia.pdf?sequence=1&isAllowed=y (accessed on 6 April 2023).

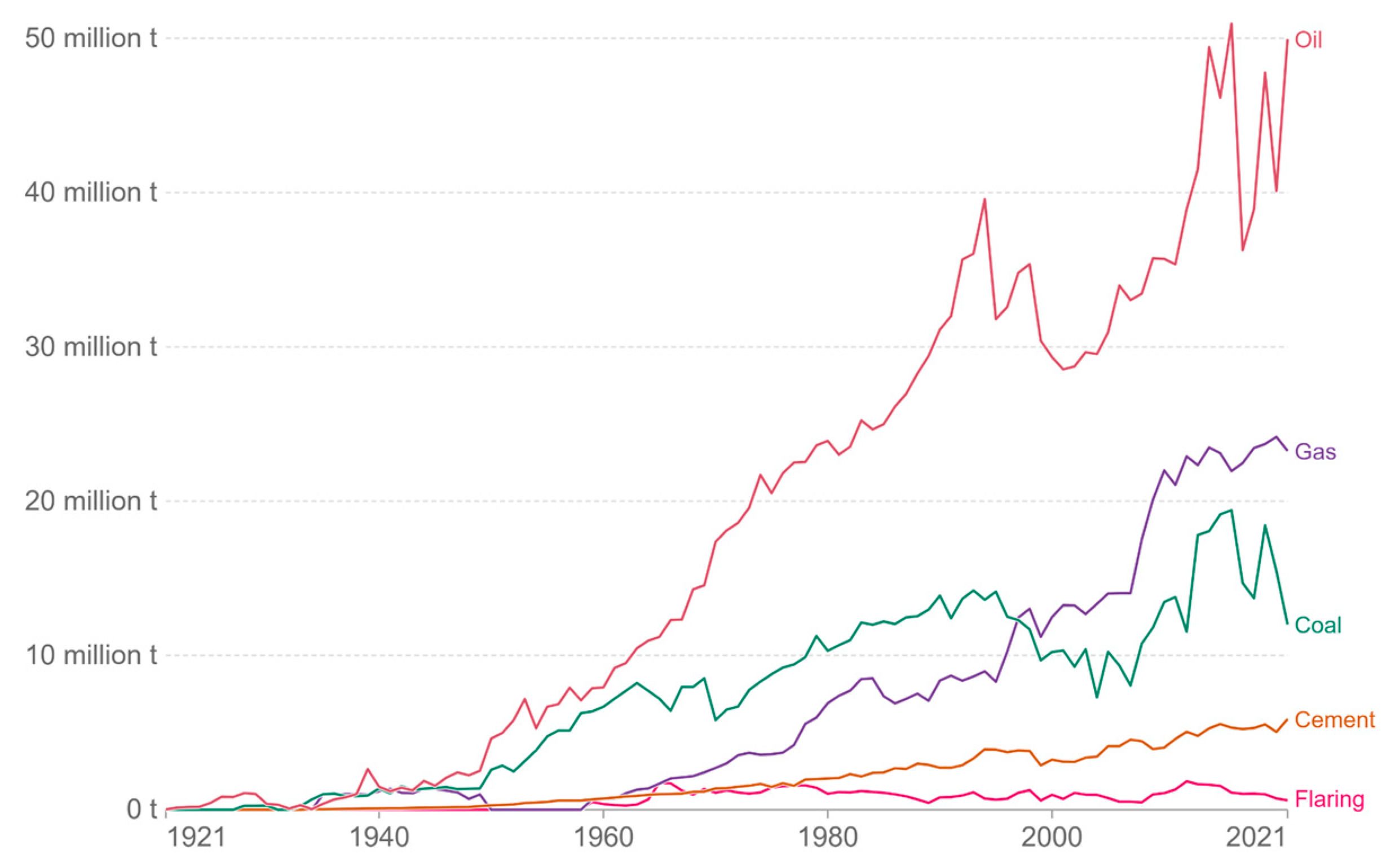

- Ritchie, H.; Roser, M.; Rosado, P. CO2 and Greenhouse Gas Emissions. Our World in Data. 2023. Available online: https://ourworldindata.org/co2/country/colombia#citation (accessed on 6 April 2023).

| Material | No Fly Ash or Slag | 20% Fly Ash | 30% Fly Ash | 40% Fly Ash |

|---|---|---|---|---|

| (Kg/m3) | (Kg/m3) | (Kg/m3) | (Kg/m3) | |

| Portland cement | 365.2 | 307.3 | 276.5 | 243.2 |

| Slag cement | 0 | 0 | 0 | 0 |

| Fly ash | 0 | 77.1 | 118.7 | 162.6 |

| Crushed coarse aggregate | 678.6 | 678.6 | 678.6 | 678.6 |

| Natural coarse aggregate | 316.2 | 316.2 | 316.2 | 316.2 |

| Crushed fine aggregate | 87.4 | 87.4 | 87.4 | 87.4 |

| Natural fine aggregate | 656.4 | 656.4 | 656.4 | 656.4 |

| Light weight aggregate | 0 | 0 | 0 | 0 |

| Accelerator (accel.) | 0.37 | 0.56 | 0.56 | 0.93 |

| Air entrainer | 0.04 | 0.04 | 0.06 | 0.06 |

| Water reducer and accel. | 0.11 | 0.11 | 0.11 | 0.11 |

| High range water red. and accel. | 0 | 0 | 0 | 0 |

| Water | 154.8 | 154.8 | 154.8 | 154.8 |

| Material | 30% Slag | 40% Slag | 50% Slag | 20% FA, 30% Slag |

|---|---|---|---|---|

| (Kg/m3) | (Kg/m3) | (Kg/m3) | (Kg/m3) | |

| Portland cement | 255.6 | 219.1 | 182.6 | 192.2 |

| Slag cement | 109.6 | 146.1 | 182.6 | 115.1 |

| Fly ash | 0 | 0 | 0 | 77.1 |

| Crushed coarse aggregate | 678.6 | 678.6 | 678.6 | 678.6 |

| Natural coarse aggregate | 316.2 | 316.2 | 316.2 | 316.2 |

| Crushed fine aggregate | 87.4 | 87.4 | 87.4 | 87.4 |

| Natural fine aggregate | 656.4 | 656.4 | 656.4 | 656.4 |

| Light weight aggregate | 0 | 0 | 0 | 0 |

| Accelerator (accel.) | 0.56 | 0.93 | 1.11 | 1.11 |

| Air entrainer | 0.04 | 0.04 | 0.04 | 0.04 |

| Water reducer and accel. | 0.11 | 0.11 | 0.11 | 0.11 |

| High range water red. and accel. | 0 | 0 | 0 | 0 |

| Water | 154.8 | 154.8 | 154.8 | 154.8 |

| Impact Category | Relative Importance Weight (%) |

|---|---|

| Climate change | 29 |

| Primary energy consumption | 10 |

| Human health criteria air | 9 |

| Human health cancer | 8 |

| Water consumption | 8 |

| Ecological toxicity | 7 |

| Eutrophication | 6 |

| Land use | 6 |

| Human health non-cancer | 5 |

| Smog formation | 4 |

| Acidification | 3 |

| Indoor air quality | 3 |

| Ozone depletion | 2 |

| Time (Year) | Cost (USD) |

|---|---|

| 2010 | 12 |

| 2015 | 13 |

| 2020 | 15 |

| 2025 | 17 |

| 2030 | 19 |

| 2035 | 22 |

| 2040 | 26 |

| 2045 | 28 |

| 2050 | 32 |

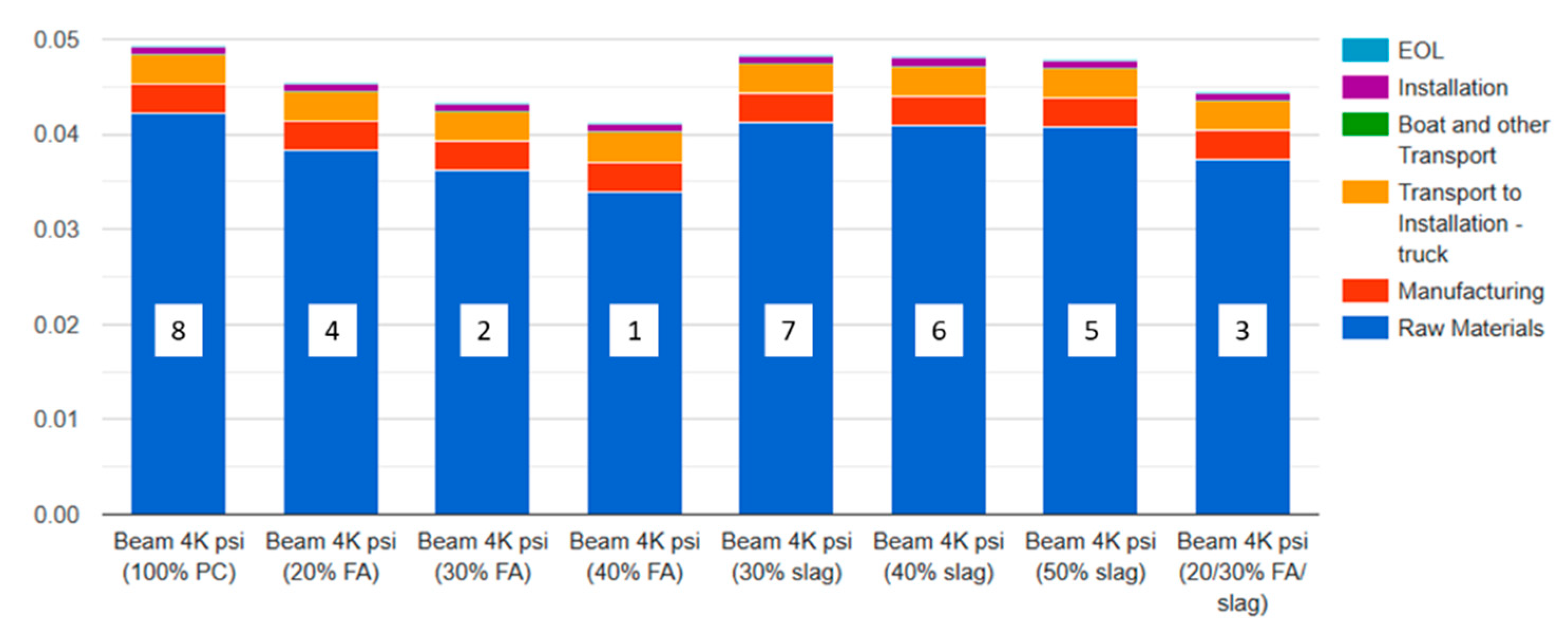

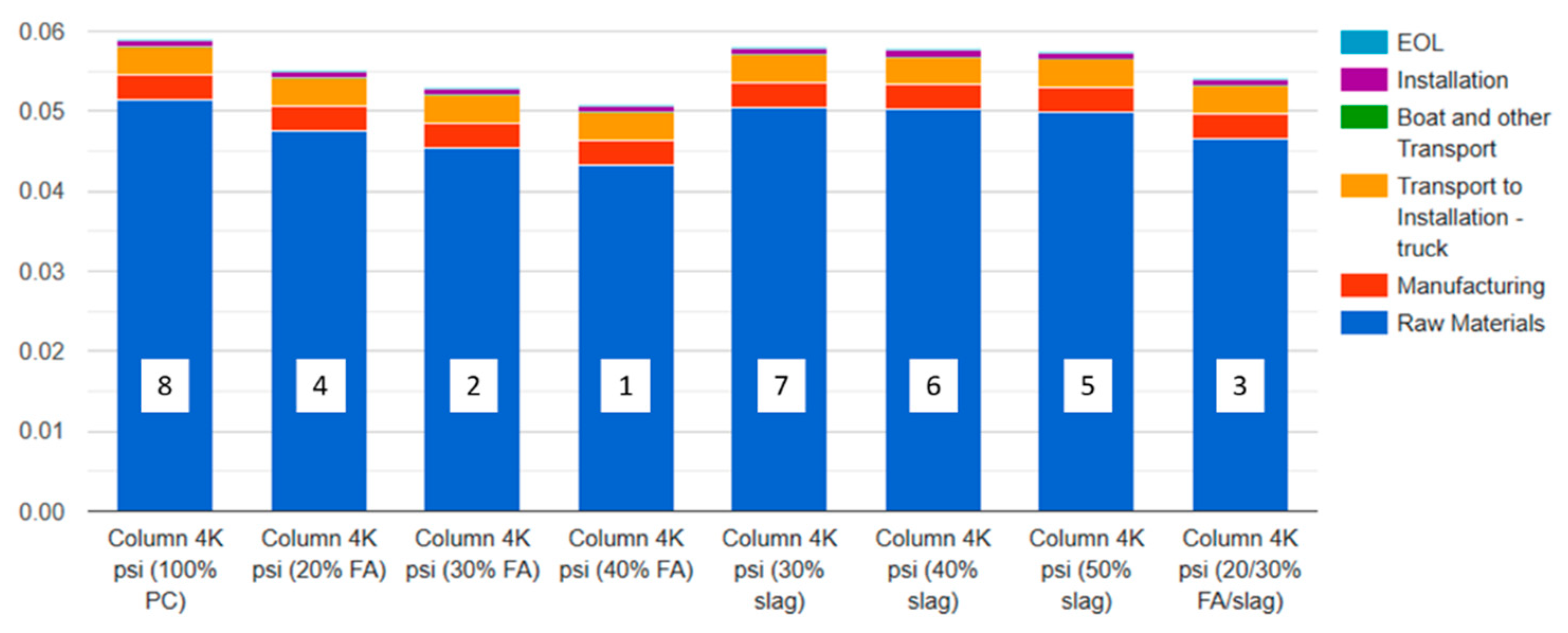

| Impact Category | 100% PC | 20% FA | 30% FA | 40% FA | 30% Slag | 40% Slag | 50% Slag | 20% FA, 30% Slag |

|---|---|---|---|---|---|---|---|---|

| Global warming | 8 | 7 | 6 | 4 | 5 | 3 | 1 | 2 |

| Primary energy consumption (nr)1 | 8 | 7 | 6 | 4 | 5 | 3 | 1 | 2 |

| Primary energy consumption (r)2 | 8 | 7 | 6 | 4 | 5 | 3 | 1 | 2 |

| Human health criteria air | 8 | 7 | 6 | 4 | 5 | 3 | 1 | 2 |

| Human health cancer | 8 | 7 | 6 | 4 | 5 | 3 | 1 | 2 |

| Water consumption | 8 | 7 | 6 | 4 | 5 | 3 | 1 | 2 |

| Ecological toxicity | 8 | 7 | 6 | 4 | 5 | 3 | 1 | 2 |

| Eutrophication | 8 | 7 | 6 | 4 | 5 | 3 | 1 | 2 |

| Land use | 8 | 7 | 6 | 4 | 5 | 3 | 1 | 2 |

| Human health non-cancer | 8 | 7 | 6 | 4 | 5 | 3 | 1 | 2 |

| Smog formation | 8 | 7 | 6 | 4 | 5 | 3 | 1 | 2 |

| Acidification | 8 | 4 | 2 | 1 | 7 | 6 | 5 | 3 |

| Ozone depletion | 8 | 7 | 6 | 4 | 5 | 3 | 1 | 2 |

| Indoor air quality | 8 | 7 | 6 | 4 | 5 | 3 | 1 | 2 |

| EP3: beams and columns | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Element | kg CO2/yd3 | kg CO2/m3 | Concrete (m3) | kgCO2/House |

|---|---|---|---|---|

| Beams 50% slag concrete (aerial) | 12 | 15.8 | 7.88 | 124.5 |

| Beams 50% slag concrete (foundation) | 12 | 15.8 | 9.00 | 142.2 |

| Columns 50% slag concrete | 15.3 | 20.1 | 5.60 | 112.6 |

| Total | 379.3 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maury-Ramírez, A.; De Belie, N. Environmental and Economic Assessment of Eco-Concrete for Residential Buildings: A Case Study of Santiago de Cali (Colombia). Sustainability 2023, 15, 12032. https://doi.org/10.3390/su151512032

Maury-Ramírez A, De Belie N. Environmental and Economic Assessment of Eco-Concrete for Residential Buildings: A Case Study of Santiago de Cali (Colombia). Sustainability. 2023; 15(15):12032. https://doi.org/10.3390/su151512032

Chicago/Turabian StyleMaury-Ramírez, Aníbal, and Nele De Belie. 2023. "Environmental and Economic Assessment of Eco-Concrete for Residential Buildings: A Case Study of Santiago de Cali (Colombia)" Sustainability 15, no. 15: 12032. https://doi.org/10.3390/su151512032