The Role of Green Supply Chain Management Practices on Environmental Performance of Firms: An Exploratory Survey in Brazil

Abstract

:1. Introduction

2. Theoretical Frameworks, Development of the Hypothesis, and Control Variables

2.1. Green Supply Chain Management

2.2. Environmental Performance

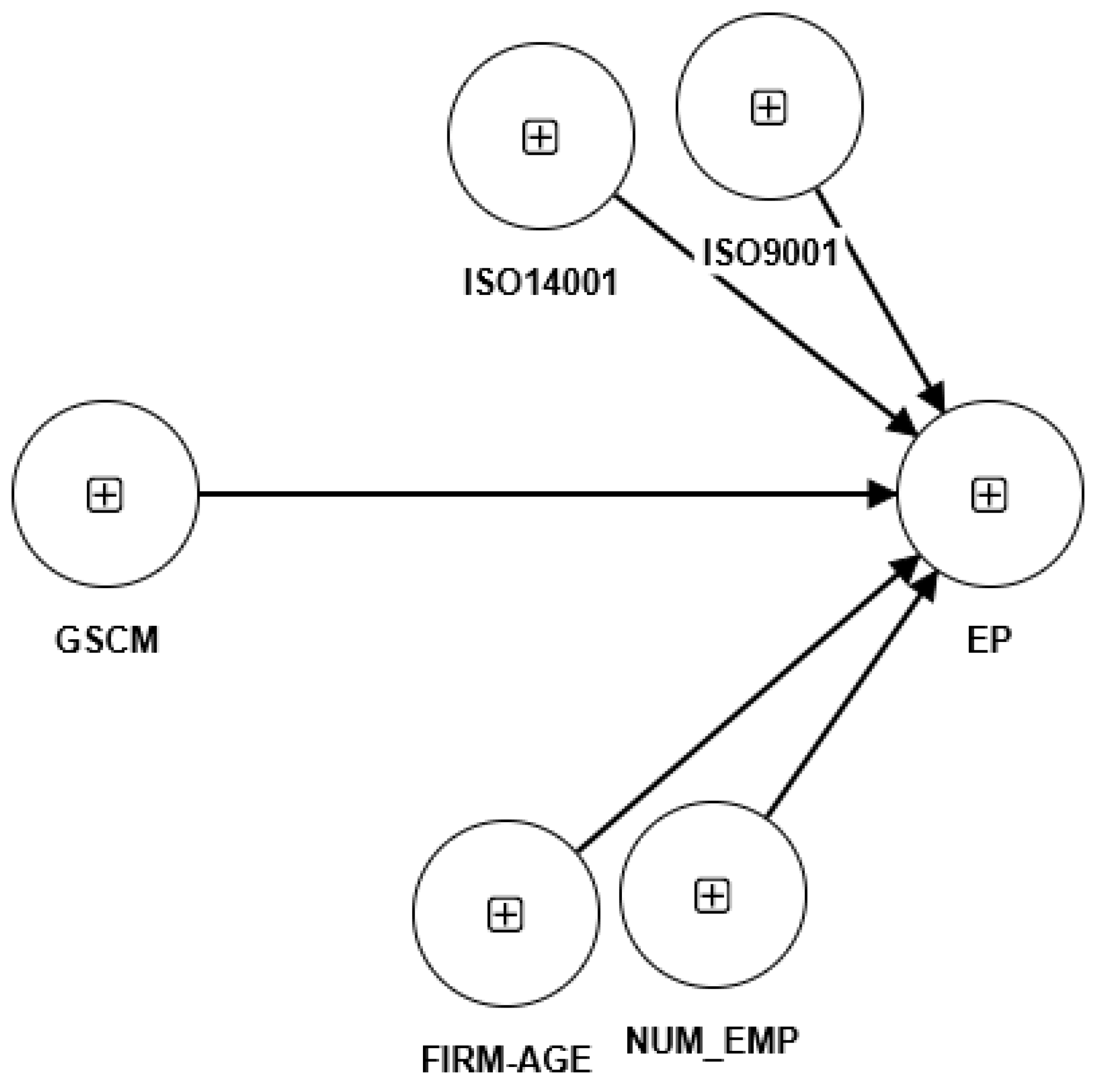

2.3. Theory, Hypothesis, and Control Variables of the Research

3. Materials and Methods

3.1. Research Method

3.2. Data Collection Instrument

3.3. Sample Composition and Respondents

3.4. Data Collection

3.5. Data Analysis

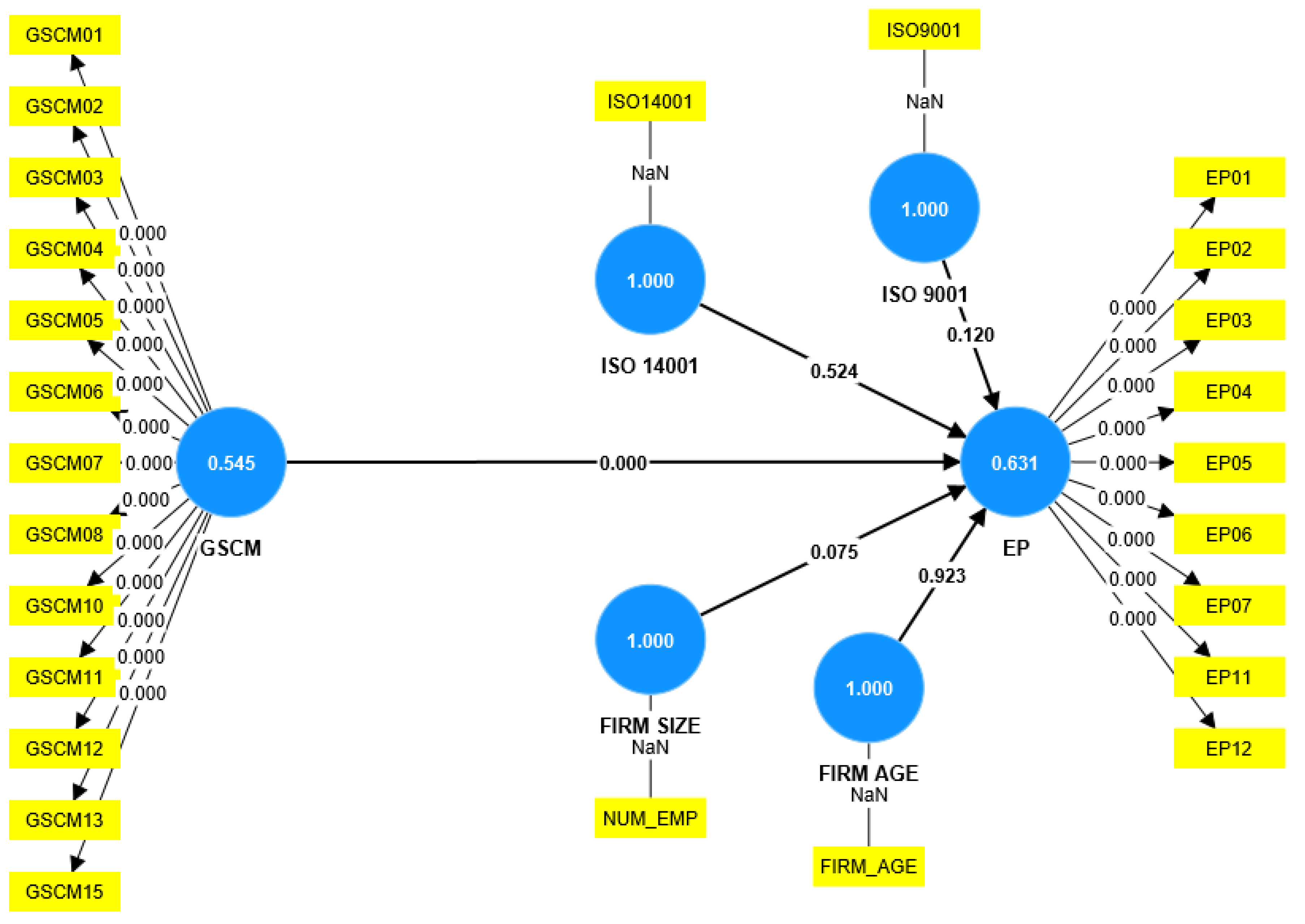

4. Data Analysis and Results Interpretations

5. Discussions and Conclusions

6. Implications and Future Research

6.1. Theoretical Implications

6.2. Practical Implications

6.3. Limitations and Suggestions for Future Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Al-Sheyadi, A.; Muyldermans, L.; Kauppi, K. The complementarity of green supply chain management practices and the impact on environmental performance. J. Environ. Manag. 2019, 242, 186–198. [Google Scholar] [CrossRef] [PubMed]

- Saeed, A.; Rasheed, F.; Waseem, M.; Tabash, M.I. Green human resource management and environmental performance: The role of green supply chain management practices. Benchmarking Int. J. 2021, 29, 2881–2899. [Google Scholar] [CrossRef]

- Sundram, V.P.K.; Bahrin, A.S.; Othman, A.A.; Munir, Z.A. Green supply chain management practices in Malaysia manufacturing industry. Int. J. Supply Chain. Manag. 2017, 6, 89–95. [Google Scholar]

- Khan, N.U.; Anwar, M.; Li, S.; Khattak, M.S. Intellectual capital, financial resources, and green supply chain management as predictors of financial and environmental performance. Environ. Sci. Pollut. Res. 2021, 28, 19755–19767. [Google Scholar] [CrossRef] [PubMed]

- Khan, S.A.R.; Yu, Z.; Sharif, A.; Golpîra, H. Determinants of economic growth and environmental sustainability in South Asian Association for Regional Cooperation: Evidence from panel ARDL. Environ. Sci. Pollut. Res. 2020, 27, 45675–45687. [Google Scholar] [CrossRef]

- Dong, Z.; Tan, Y.; Wang, L.; Zheng, J.; Hu, S. Green supply chain management and clean technology innovation: An empirical analysis of multinational enterprises in China. J. Clean. Prod. 2021, 310, 127377. [Google Scholar] [CrossRef]

- Zhou, H.; Yang, Y.; Chen, Y.; Zhu, J. Data envelopment analysis application in sustainability: The origins, development, and future directions. Eur. J. Oper. Res. 2018, 264, 1–16. [Google Scholar] [CrossRef]

- Gelderman, C.J.; Semeijn, J.; Vluggen, R. Development of sustainability in public sector procurement. Public Money Manag. 2017, 37, 435–442. [Google Scholar] [CrossRef]

- Dzikriansyah, M.A.; Masudin, I.; Zulfikarijah, F.; Jihadi, M.; Jatmiko, R.D. The role of green supply chain management practices on environmental performance: A case of Indonesian small and medium enterprises. Clean. Logist. Supply Chain. 2023, 6, 100100. [Google Scholar] [CrossRef]

- Amjad, A.; Abbass, K.; Hussain, Y.; Khan, F.; Sadiq, S. Effects of the green supply chain management practices on firm performance and sustainable development. Environ. Sci. Pollut. Res. 2022, 29, 66622–66639. [Google Scholar] [CrossRef]

- Meng, Q.; Li, M.; Liu, W.; Li, Z.; Zhang, J. Pricing policies of dual-channel green supply chain: Considering government subsidies and consumers’ dual preferences. Sustain. Prod. Consum. 2021, 26, 1021–1030. [Google Scholar] [CrossRef]

- Azadi, E.; Moghaddas, Z.; Saen, R.F.; Mardani, A.; Azadi, M. Green supply chains and performance evaluation: A multiplier network analytics model with common set of weights. J. Clean. Prod. 2023, 411, 137377. [Google Scholar] [CrossRef]

- AlZgool, M.; Ahmed, U.; Shah, S.; Alkadash, T.; AlMaamary, Q. Going green during COVID-19: Examining the links between green HRM, green supply chain and firm performance in food Industry of Bahrain: The moderating role of lockdown due to COVID-19. Uncertain Supply Chain. Manag. 2021, 9, 79–88. [Google Scholar] [CrossRef]

- Das, G.; Li, S.; Tunio, R.A.; Jamali, R.H.; Ullah, I.; Fernando, K.W.T.M. The implementation of green supply chain management (GSCM) and environmental management system (EMS) practices and its impact on market competitiveness during COVID-19. Environ. Sci. Pollut. Res. 2023, 30, 68387–68402. [Google Scholar] [CrossRef] [PubMed]

- Appiah, M.K.; Odei, S.A.; Kumi-Amoah, G.; Yeboah, S.A. Modeling the impact of green supply chain practices on environmental performance: The mediating role of ecocentricity. Afr. J. Econ. Manag. Stud. 2022; ahead-of-print. [Google Scholar] [CrossRef]

- Ma, X.; Akhtar, R.; Akhtar, A.; Hashim, R.A.; Sibt-e-Ali, M. Mediation effect of environmental performance in the relationship between green supply chain management practices, institutional pressures, and financial performance. Front. Environ. Sci. 2022, 1196, 972555. [Google Scholar] [CrossRef]

- Tariq, M.I.; Abbass, K.; Chebbi, K.; Hussain, Y. Assessing the role of green supply chain management in enhancing Pakistan manufacturers’ performances. Environ. Sci. Pollut. Res. 2023, 30, 78495–78506. [Google Scholar] [CrossRef]

- Kholaif, M.M.N.H.K.; Xiao, M.; Hamdy, A. COVID-19’s effect on green supply chains and environmental sustainability; innovative technologies moderation. J. Clean. Prod. 2023, 406, 137083. [Google Scholar] [CrossRef]

- Kazancoglu, Y.; Kazancoglu, I.; Sagnak, M. A new holistic conceptual framework for green supply chain management performance assessment based on circular economy. J. Clean. Prod. 2018, 195, 1282–1299. [Google Scholar] [CrossRef]

- Cousins, P.D.; Lawson, B.; Petersen, K.J.; Fugate, B. Investigating green supply chain management practices and performance: The moderating roles of supply chain ecocentricity and traceability. Int. J. Oper. Prod. Manag. 2019, 39, 767–786. [Google Scholar] [CrossRef]

- Bonera, M.; Corvi, E.; Codini, A.P.; Ma, R. Does nationality matter in eco-behaviour? Sustainability 2017, 9, 1694. [Google Scholar] [CrossRef] [Green Version]

- Lavuri, R.; Akram, U.; Akram, Z. Exploring the sustainable consumption behavior in emerging countries: The role of pro-environmental self-identity, attitude, and environmental protection emotion. Bus. Strategy Environ. 2023; early view. [Google Scholar] [CrossRef]

- Rahman, H.U.; Zahid, M.; Al-Faryan, M.A.S. ESG and firm performance: The rarely explored moderation of sustainability strategy and top management commitment. J. Clean. Prod. 2023, 404, 136859. [Google Scholar] [CrossRef]

- Bendul, J.C.; Rosca, E.; Pivovarova, D. Sustainable supply chain models for base of the pyramid. J. Clean. Prod. 2017, 162, S107–S120. [Google Scholar] [CrossRef]

- Jabbour, C.J.C.; Jabbour, A.B.L.D.S. Latin America: Research opportunities on management for sustainable development. Lat. Am. J. Manag. Sustain. Dev. 2014, 1, 1–6. [Google Scholar] [CrossRef]

- Pohlmann, C.R.; Scavarda, A.J.; Alves, M.B.; Korzenowski, A.L. The role of the focal company in sustainable development goals: A Brazilian food poultry supply chain case study. J. Clean. Prod. 2020, 245, 118798. [Google Scholar] [CrossRef]

- Murillo-Luna, J.L.; Garcés-Ayerbe, C.; Rivera-Torres, P. Barriers to the adoption of proactive environmental strategies. J. Clean. Prod. 2011, 19, 1417–1425. [Google Scholar] [CrossRef]

- Russo, A.; Pogutz, S.; Misani, N. Paving the road toward eco-effectiveness: Exploring the link between greenhouse gas emissions and firm performance. Bus. Strategy Environ. 2021, 30, 3065–3078. [Google Scholar] [CrossRef]

- de Sousa Jabbour, A.B.L.; Jabbour, C.J.C.; Latan, H.; Teixeira, A.A.; de Oliveira, J.H.C. Quality management, environmental management maturity, green supply chain practices and green performance of Brazilian companies with ISO 14001 certification: Direct and indirect effects. Transp. Res. Part E Logist. Transp. Rev. 2014, 67, 39–51. [Google Scholar] [CrossRef]

- González-Benito, J.; Lannelongue, G.; Queiruga, D. Stakeholders and environmental management systems: A synergistic influence on environmental imbalance. J. Clean. Prod. 2011, 19, 1622–1630. [Google Scholar] [CrossRef]

- Sørensen, J.B.; Stuart, T.E. Aging, obsolescence, and organizational innovation. Adm. Sci. Q. 2000, 45, 81–112. [Google Scholar] [CrossRef] [Green Version]

- Vanalle, R.M.; Ganga, G.M.D.; Godinho Filho, M.; Lucato, W.C. Green supply chain management: An investigation of pressures, practices, and performance within the Brazilian automotive supply chain. J. Clean. Prod. 2017, 151, 250–259. [Google Scholar] [CrossRef]

- Fu, L.; Yang, D.; Liu, S.; Mei, Q. The impact of green supply chain management on enterprise environmental performance: A meta-analysis. Chin. Manag. Stud. 2023, 17, 274–289. [Google Scholar] [CrossRef]

- Yildiz Çankaya, S.; Sezen, B. Effects of green supply chain management practices on sustainability performance. J. Manuf. Technol. Manag. 2019, 30, 98–121. [Google Scholar] [CrossRef]

- Shaikh, F.A.; Shahbaz, M.S.; Odhano, N. A short review on green supply chain management practices. Eng. Technol. Appl. Sci. Res. 2020, 10, 5367–5370. [Google Scholar] [CrossRef]

- Bag, S.; Gupta, S.; Kumar, S.; Sivarajah, U. Role of technological dimensions of green supply chain management practices on firm performance. J. Enterp. Inf. Manag. 2021, 34, 1–27. [Google Scholar] [CrossRef]

- Lopes, L.J.; Sacomano Neto, M.; Silva, E.M.D.; Lopes, F.C.D.C. Influência das Práticas do Green Supply Chain Management no Desempenho Ambiental das Empresas do Setor Automotivo Brasileiro; XXXVII Encontro da Associação Nacional de Pós-Graduação e Pesquisa em Administração: Rio de Janeiro, Brazil, 2013. [Google Scholar]

- Zhu, Q.; Sarkis, J.; Lai, K.H. Confirmation of a measurement model for green supply chain management practices implementation. Int. J. Prod. Econ. 2008, 111, 261–273. [Google Scholar] [CrossRef]

- ISO 14001; Criteria for Environmental Management System. The International Organization for Standardization: London, UK, 2015.

- Jin, X.; Wu, W.; Lei, X. Can digital investment improve corporate environmental performance?––Empirical evidence from China. J. Clean. Prod. 2023, 414, 137669. [Google Scholar] [CrossRef]

- Amirteimoori, A.; Allahviranloo, T.; Zadmirzaei, M.; Hasanzadeh, F. On the environmental performance analysis: A combined fuzzy data envelopment analysis and artificial intelligence algorithms. Expert Syst. Appl. 2023, 224, 119953. [Google Scholar] [CrossRef]

- Dung, M.D.; Mankilik, M.; Ozoji, B.E. Assessment of College Students’ Knowledge and Attitudes Towards Solid Waste Management in North Central Zone of Nigeria. Sci. Educ. Int. 2017, 28, 141–146. [Google Scholar] [CrossRef]

- Bakhsh Magsi, H.; Ong, T.S.; Ho, J.A.; Sheikh Hassan, A.F. Organizational culture and environmental performance. Sustainability 2018, 10, 2690. [Google Scholar] [CrossRef] [Green Version]

- Ansari, Z.N.; Kant, R. A state-of-art literature review reflecting 15 years of focus on sustainable supply chain management. J. Clean. Prod. 2017, 142, 2524–2543. [Google Scholar] [CrossRef]

- Dubey, R.; Gunasekaran, A.; Papadopoulos, T. Green supply chain management: Theoretical framework and further research directions. Benchmarking Int. J. 2017, 24, 184–218. [Google Scholar] [CrossRef]

- Hafezalkotob, A. Competition, cooperation, and coopetition of green supply chains under regulations on energy saving levels. Transp. Res. Part E Logist. Transp. Rev. 2017, 97, 228–250. [Google Scholar] [CrossRef]

- Jabbour, A.B.L.; Jabbour, C.J. Are supplier selection criteria going green? Case studies of companies in Brazil. Ind. Manag. Data Syst. 2009, 109, 477–495. [Google Scholar] [CrossRef]

- Wood, D.J.; Mitchell, R.K.; Agle, B.R.; Bryan, L.M. Stakeholder identification and salience after 20 years: Progress, problems, and prospects. Bus. Soc. 2021, 60, 196–245. [Google Scholar] [CrossRef]

- Pane Haden, S.S.; Oyler, J.D.; Humphreys, J.H. Historical, practical, and theoretical perspectives on green management: An exploratory analysis. Manag. Decis. 2009, 47, 1041–1055. [Google Scholar] [CrossRef]

- Montabon, F.; Sroufe, R.; Narasimhan, R. An examination of corporate reporting, environmental management practices and firm performance. J. Oper. Manag. 2007, 25, 998–1014. [Google Scholar] [CrossRef]

- Klassen, R.D.; McLaughlin, C.P. The impact of environmental management on firm performance. Manag. Sci. 1996, 42, 1199–1214. [Google Scholar] [CrossRef]

- Paillé, P.; Chen, Y.; Boiral, O.; Jin, J. The impact of human resource management on environmental performance: An employee-level study. J. Bus. Ethics 2014, 121, 451–466. [Google Scholar] [CrossRef]

- Boiral, O.; Guillaumie, L.; Heras-Saizarbitoria, I.; Tayo Tene, C.V. Adoption and outcomes of ISO 14001: A systematic review. Int. J. Manag. Rev. 2018, 20, 411–432. [Google Scholar] [CrossRef]

- Esfahbodi, A.; Zhang, Y.; Watson, G. Sustainable supply chain management in emerging economies: Trade-offs between environmental and cost performance. Int. J. Prod. Econ. 2016, 181, 350–366. [Google Scholar] [CrossRef] [Green Version]

- Cho, C.K.; Cho, T.S.; Lee, J. Managerial attributes, consumer proximity, and corporate environmental performance. Corp. Soc. Responsib. Environ. Manag. 2019, 26, 159–169. [Google Scholar] [CrossRef] [Green Version]

- Ramanathan, R. Understanding complexity: The curvilinear relationship between environmental performance and firm performance. J. Bus. Ethics 2018, 149, 383–393. [Google Scholar] [CrossRef] [Green Version]

- Hartmann, J.; Vachon, S. Linking environmental management to environmental performance: The interactive role of industry context. Bus. Strategy Environ. 2018, 27, 359–374. [Google Scholar] [CrossRef]

- Benkraiem, R.; Dubocage, E.; Lelong, Y.; Shuwaikh, F. The effects of environmental performance and green innovation on corporate venture capital. Ecol. Econ. 2023, 210, 107860. [Google Scholar] [CrossRef]

- Yadav, P.L.; Han, S.H.; Rho, J.J. Impact of environmental performance on firm value for sustainable investment: Evidence from large US firms. Bus. Strategy Environ. 2016, 25, 402–420. [Google Scholar] [CrossRef]

- Abdul Aziz, N.A.; Ong, T.S.; Foong, S.Y.; Senik, R.; Attan, H. Green initiatives adoption and environmental performance of public listed companies in Malaysia. Sustainability 2018, 10, 2003. [Google Scholar] [CrossRef] [Green Version]

- González-Blanco, J.; Coca-Pérez, J.L.; Guisado-González, M. The contribution of technological and non-technological innovation to environmental performance. An analysis with a complementary approach. Sustainability 2018, 10, 4014. [Google Scholar] [CrossRef] [Green Version]

- Chiou, T.Y.; Chan, H.K.; Lettice, F.; Chung, S.H. The influence of greening the suppliers and green innovation on environmental performance and competitive advantage in Taiwan. Transp. Res. Part E Logist. Transp. Rev. 2011, 47, 822–836. [Google Scholar] [CrossRef]

- Manrique, S.; Martí-Ballester, C.P. Analyzing the effect of corporate environmental performance on corporate financial performance in developed and developing countries. Sustainability 2017, 9, 1957. [Google Scholar] [CrossRef] [Green Version]

- Tan, L.P. Implementing ISO 14001: Is it beneficial for firms in newly industrialized Malaysia? J. Clean. Prod. 2005, 13, 397–404. [Google Scholar] [CrossRef]

- Machado Junior, C.; Mazzali, L.; Souza, M.T.S.D.; Furlaneto, C.J.; Prearo, L.C. A gestão dos recursos naturais nas organizações certificadas pela norma NBR ISO 14001. Production 2013, 23, 41–51. [Google Scholar] [CrossRef] [Green Version]

- González-Benito, J.; González-Benito, Ó. A review of determinant factors of environmental proactivity. Bus. Strategy Environ. 2006, 15, 87–102. [Google Scholar] [CrossRef]

- González, P.; Sarkis, J.; Adenso-Díaz, B. Environmental management system certification and its influence on corporate practices: Evidence from the automotive industry. Int. J. Oper. Prod. Manag. 2008, 28, 1021–1041. [Google Scholar] [CrossRef]

- Dawkins, C.; Fraas, J.W. Coming clean: The impact of environmental performance and visibility on corporate climate change disclosure. J. Bus. Ethics 2011, 100, 303–322. [Google Scholar] [CrossRef]

- Tung, A.; Baird, K.; Schoch, H. The effectiveness of using environmental performance measures. Australas. J. Environ. Manag. 2018, 25, 459–474. [Google Scholar] [CrossRef]

- Bach, V.; Minkov, N.; Finkbeiner, M. Assessing the ability of the Cradle to Cradle Certified™ Products Program to reliably determine the environmental performance of products. Sustainability 2018, 10, 1562. [Google Scholar] [CrossRef] [Green Version]

- Claver, E.; Lopez, M.D.; Molina, J.F.; Tari, J.J. Environmental management and firm performance: A case study. J. Environ. Manag. 2007, 84, 606–619. [Google Scholar] [CrossRef] [PubMed]

- Urban, B.; Govender, D.P. Empirical evidence on environmental management practices. Eng. Econ. 2012, 23, 209–215. [Google Scholar] [CrossRef] [Green Version]

- Comoglio, C.; Botta, S. The use of indicators and the role of environmental management systems for environmental performances improvement: A survey on ISO 14001 certified companies in the automotive sector. J. Clean. Prod. 2012, 20, 92–102. [Google Scholar] [CrossRef]

- Sehnem, S.; Lopes de Sousa Jabbour, A.B.; Conceição, D.A.D.; Weber, D.; Julkovski, D.J. The role of ecological modernization principles in advancing circular economy practices: Lessons from the brewery sector. Benchmarking Int. J. 2021, 28, 2786–2807. [Google Scholar] [CrossRef]

- Huang, Y.C.; Huang, C.H. Examining the antecedents and consequences of sustainable green supply chain management from the perspective of ecological modernization: Evidence from Taiwan’s high-tech sector. J. Environ. Plan. Manag. 2022, 65, 1579–1610. [Google Scholar] [CrossRef]

- Gunasekaran, A.; Jabbour, C.J.C.; Jabbour, A.B.L.D.S. Managing organizations for sustainable development in emerging countries: An introduction. Int. J. Sustain. Dev. World Ecol. 2014, 21, 195–197. [Google Scholar] [CrossRef]

- Surroca, J.; Tribó, J.A.; Waddock, S. Corporate responsibility and financial performance: The role of intangible resources. Strateg. Manag. J. 2010, 31, 463–490. [Google Scholar] [CrossRef]

- Synodinos, N.E. The “art” of questionnaire construction: Some important considerations for manufacturing studies. Integr. Manuf. Syst. 2003, 14, 221–237. [Google Scholar] [CrossRef]

- ISO 9001; Criteria for a Quality Management System. The International Organization for Standardization: London, UK, 2015.

- Hair, J.; Babin, B.; Money, A.; Samouel, P. Fundamentos de Métodos de Pesquisa em Administração; Bookman, C., Ed.; Bookman: Porto Alegre, RS, Brazil, 2005. [Google Scholar]

- Faul, F.; Erdfelder, E.; Lang, A.G.; Buchner, A. G* Power 3: A flexible statistical power analysis program for the social, behavioral, and biomedical sciences. Behav. Res. Methods 2007, 39, 175–191. [Google Scholar] [CrossRef] [PubMed]

- Cohen, J. Statistical Power Analysis for the Behavioral Sciences; Academic Press: Cambridge, MA, USA, 2013. [Google Scholar]

- Henseler, J.; Dijkstra, T.K.; Sarstedt, M.; Ringle, C.M.; Diamantopoulos, A.; Straub, D.W.; Ketchen, D.J., Jr.; Joseph, F.; Hair, G.; Hult, T.M.; et al. Common beliefs and reality about PLS: Comments on Rönkkö and Evermann (2013). Organ. Res. Methods 2014, 17, 182–209. [Google Scholar] [CrossRef] [Green Version]

- Willaby, H.W.; Costa, D.S.; Burns, B.D.; MacCann, C.; Roberts, R.D. Testing complex models with small sample sizes: A historical overview and empirical demonstration of what partial least squares (PLS) can offer differential psychology. Personal. Individ. Differ. 2015, 84, 73–78. [Google Scholar] [CrossRef]

- Hair, J.F.; Black, W.C.; Babin, B.J.; Anderson, R.E.; Tatham, R.L. Análise Multivariada de Dado; Bookman: Porto Alegre, RS, Brazil, 2009. [Google Scholar]

- Hair, J.F.; Ringle, C.M.; Sarstedt, M. PLS-SEM: Indeed, a silver bullet. J. Mark. Theory Pract. 2011, 19, 139–152. [Google Scholar] [CrossRef]

- Marôco, J. Análise de Equações Estruturais: Fundamentos Teóricos, Software & Aplicações; ReportNumber, Lda.: Pêro Pinheiro, Portugal, 2014. [Google Scholar]

- Monecke, A.; Leisch, F. semPLS: Structural Equation Modeling Using Partial Least Squares. J. Stat. Softw. 2012, 48, 1–32. [Google Scholar] [CrossRef] [Green Version]

- Ravand, H.; Baghaei, P. Partial least squares structural equation modeling with R. Pract. Assess. Res. Eval. 2016, 21, 11. [Google Scholar] [CrossRef]

- Raykov, T.; Marcoulides, G.A. A First Course in Structural Equation Modeling; Routledge: London, UK, 2012. [Google Scholar]

- Kline, R.B. Principles and Practice of Structural Equation Modeling; Guilford Publications: New York, NY, USA, 2023. [Google Scholar]

- Rodrigues, H.S.; Alves, W.; Silva, Â. The impact of lean and green practices on logistics performance: A structural equation modelling. Production 2020, 30. [Google Scholar] [CrossRef] [Green Version]

- Hair, J.F., Jr.; Hult, G.T.M.; Ringle, C.M.; Sarstedt, M. A Primer on Partial Least Squares Structural Equation Modeling (PLS-SEM); Sage Publications: Los Angeles, CA, USA, 2021. [Google Scholar]

- Anekawati, A.; Otok, B.W. Structural equation modelling with three schemes estimation of score factors on partial least square (Case study: The quality of education level SMA/MA in Sumenep Regency). J. Phys. Conf. Ser. 2017, 855, 012006. [Google Scholar] [CrossRef]

- Cohen, J. A Power Primer. Phychological Bull. 1992, 112, 155–159. [Google Scholar] [CrossRef] [PubMed]

- Hair, J.F., Jr.; Howard, M.C.; Nitzl, C. Assessing measurement model quality in PLS-SEM using confirmatory composite analysis. J. Bus. Res. 2020, 109, 101–110. [Google Scholar] [CrossRef]

- Benitez, J.; Henseler, J.; Castillo, A.; Schuberth, F. How to perform and report an impactful analysis using partial least squares: Guidelines for confirmatory and explanatory IS research. Inf. Manag. 2020, 57, 103168. [Google Scholar] [CrossRef]

- Kock, N. Common method bias: A full collinearity assessment method for PLS-SEM. In Partial Least Squares Path Modeling: Basic Concepts, Methodological Issues and Applications; Springer: Cham, Switerland, 2017; pp. 245–257. [Google Scholar] [CrossRef]

- Ringle, C.M.; Da Silva, D.; de Souza Bido, D. Modelagem de equações estruturais com utilização do SmartPLS. REMark-Rev. Bras. Mark. 2014, 13, 56–73. [Google Scholar] [CrossRef]

- Ghozali, I.; Latan, H. Partial Least Squares Konsep, Teknik dan Aplikasi Menggunakan Program Smartpls 3.0 Untuk Penelitian Empiris; Badan Penerbit UNDIP: Semarang, Indonesia, 2015. [Google Scholar]

- Teixeira, A.A.; Jabbour, C.J.C.; de Sousa Jabbour, A.B.L.; Latan, H.; De Oliveira, J.H.C. Green training and green supply chain management: Evidence from Brazilian firms. J. Clean. Prod. 2016, 116, 170–176. [Google Scholar] [CrossRef]

- Teixeira, A.A.; Moraes, T.E.D.C.; Stefanelli, N.O.; de Oliveira, J.H.C.; Teixeira, T.B.; de Souza Freitas, W.R. Green supply chain management in Latin America: Systematic literature review and future directions. Environ. Qual. Manag. 2020, 30, 47–73. [Google Scholar] [CrossRef]

- Fahimnia, B.; Sarkis, J.; Davarzani, H. Green supply chain management: A review and bibliometric analysis. Int. J. Prod. Econ. 2015, 162, 101–114. [Google Scholar] [CrossRef]

- Jabbour, C.J.C.; de Sousa Jabbour, A.B.L.; Govindan, K.; Teixeira, A.A.; de Souza Freitas, W.R. Environmental management and operational performance in automotive companies in Brazil: The role of human resource management and lean manufacturing. J. Clean. Prod. 2013, 47, 129–140. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J. An inter-sectoral comparison of green supply chain management in China: Drivers and practices. J. Clean. Prod. 2006, 14, 472–486. [Google Scholar] [CrossRef]

- Aftab, J.; Abid, N.; Cucari, N.; Savastano, M. Green human resource management and environmental performance: The role of green innovation and environmental strategy in a developing country. Bus. Strategy Environ. 2022, 32, 1782–1798. [Google Scholar] [CrossRef]

- Habidin, N.F.; Hibadullah, S.N.; Mohd Fuzi, N.; Salleh, M.I.; Md Latip, N.A. Lean manufacturing practices, ISO 14001, and environmental performance in Malaysian automotive suppliers. Int. J. Manag. Sci. Eng. Manag. 2018, 13, 45–53. [Google Scholar] [CrossRef]

| Practice Groups | Variables | Acronym |

|---|---|---|

| Internal environmental management (Internal practice) | Senior management’s commitment to GSCM | GSCM1 |

| Support offered by Middle management to GSCM | GSCM2 | |

| Cross-functional cooperation for environmental improvements | GSCM3 | |

| Environmental management with total quality | GSCM4 | |

| Programas de conformidade e auditoria ambiental | GSCM5 | |

| Green purchase (External practice) | Selection of certified suppliers ISO 14001 [39] | GSCM6 |

| Cooperação com fornecedores para atingir objetivos de gestão ambiental | GSCM7 | |

| Delivery to suppliers of environmental guidelines for each product to be purchased | GSCM8 | |

| Assessment of the environmental management of second-tier suppliers (suppliers of your suppliers) | GSCM9 | |

| Conducting environmental audits within the supplier companies | GSCM10 | |

| Cooperation with customers (External practice) | Cooperation with customers for cleaner production | GSCM11 |

| Cooperation with the customer for the development of an environmentally friendly packaging | GSCM12 | |

| Eco-design (Internal practice) | Design of products to reduce the use of materials and energy | GSCM13 |

| Design of products for reduction, reuse, recycling or recovery of materials and components | GSCM14 | |

| Product design to prevent or reduce the use of dangerous and toxic products | GSCM15 | |

| Return on investment. (Internal Practice) | Sale of excess materials/inventory | GSCM16 |

| Sale of scrap and used materials | GSCM17 | |

| Sale of equipment | GSCM18 |

| Variables | Authors | Acronym |

|---|---|---|

| We reduce the consumption of natural resources in production operations | [59,60,61,62,63,64,65] | EP1 |

| We reduce the consumption of raw materials in production operations. | [59,60,61,62,63,64,65,66,67] | EP2 |

| We reduce energy consumption in production operations | [59,60,61,62,63,64,65,68] | EP3 |

| We reduce the Generation of atmospheric emissions | [61,62,64,68,69,70,71] | EP4 |

| We reduce the generation and/or emission of effluents and waste | [65] | EP5 |

| We reduce the frequency of environmental accidents | [65] | EP6 |

| We reduce the consumption of oxide/hazardous/harmful materials | [64,65] | EP7 |

| We carry out an inventory of gas emissions | [66] | EP8 |

| We recycle solid waste | [59,60,62,63,68,70,71,72,73] | EP9 |

| We reduce the amount of solid waste | [59,62,63,69,71,72,73] | EP10 |

| Improved the company’s environmental reputation with stakeholders | [60,61,62,63,65,66,67,68] | EP11 |

| Improved the company’s compliance with environmental legislation | [65,66,67] | EP12 |

| Variables | Items | Quantity | Percentage |

|---|---|---|---|

| ISO 14001 | 46 | 58.23 | |

| ISO 9001 | 64 | 81.01 | |

| Number of employees | 0–19 | 4 | 5.06 |

| Firm age | 20–99 | 16 | 20.25 |

| 100–499 | 34 | 43.04 | |

| ≥500 | 25 | 31.65 | |

| 0–5 | 2 | 2.53 | |

| 6–10 | 3 | 3.80 | |

| 11–15 | 5 | 6.33 | |

| 16–20 | 8 | 10.13 | |

| 21–25 | 7 | 8.86 | |

| >25 | 54 | 68.35 | |

| Sector | Construction | 4 | 5.06 |

| Information Technology | 3 | 3.80 | |

| Metallurgical | 16 | 20.25 | |

| Electrical and Electronics | 4 | 5.06 | |

| Retail Trade | 2 | 2.53 | |

| Chemical Industry | 6 | 7.59 | |

| Auto Parts Industry | 15 | 18.99 | |

| Automotive Industry | 2 | 2.53 | |

| Services | 20 | 25.32 | |

| Vegetable Oil | 1 | 1.27 | |

| Food Industry | 2 | 2.53 | |

| Agriculture and Livestock | 1 | 1.27 | |

| Paper and Cellulose | 1 | 1.27 | |

| Textile | 1 | 1.27 | |

| Sugar and Alcohol | 1 | 1.27 |

| Variables | Items | External Loads | AVE | rho_C | rho_A |

|---|---|---|---|---|---|

| GSCM | GSCM1 | 0.758 | 0.545 | 0.939 | 0.931 |

| GSCM2 | 0.789 | ||||

| GSCM3 | 0.810 | ||||

| GSCM4 | 0.846 | ||||

| GSCM5 | 0.777 | ||||

| GSCM6 | 0.719 | ||||

| GSCM7 | 0.841 | ||||

| GSCM8 | 0.680 | ||||

| GSCM10 | 0.643 | ||||

| GSCM11 | 0.758 | ||||

| GSCM12 | 0.605 | ||||

| GSCM13 | 0.635 | ||||

| GSCM15 | 0.683 | ||||

| EP | EP1 | 0.826 | 0.631 | 0.939 | 0.933 |

| EP2 | 0.779 | ||||

| EP3 | 0.746 | ||||

| EP4 | 0.860 | ||||

| EP5 | 0.817 | ||||

| EP6 | 0.821 | ||||

| EP7 | 0.758 | ||||

| EP11 | 0.824 | ||||

| EP12 | 0.705 |

| Variables | EP | GSCM |

|---|---|---|

| EP | 0.794 | - |

| GSCM | 0.692 | 0.738 |

| V.L | EP | FIRM AGE | FIRM SIZE | GSCM | ISO 14001 |

|---|---|---|---|---|---|

| FIRM AGE | 0.155 | ||||

| FIRM SIZE | 0.350 | 0.224 | |||

| GSCM | 0.721 | 0.119 | 0.228 | ||

| ISO 14001 | 0.390 | 0.096 | 0.270 | 0.469 | |

| ISO 9001 | 0.113 | 0.010 | 0.045 | 0.161 | 0.344 |

| Items | EP | FIRM AGE | FIRM SIZE | GSCM | ISO 14001 | ISO 9001 |

|---|---|---|---|---|---|---|

| EP01 | 0.826 | −0.055 | 0.222 | 0.467 | −0.266 | 0.093 |

| EP02 | 0.779 | −0.122 | 0.185 | 0.435 | −0.181 | 0.036 |

| EP03 | 0.746 | −0.045 | 0.267 | 0.443 | −0.299 | 0.184 |

| EP04 | 0.860 | 0.122 | 0.277 | 0.606 | −0.348 | −0.011 |

| EP05 | 0.817 | 0.207 | 0.207 | 0.522 | −0.306 | −0.054 |

| EP06 | 0.821 | 0.101 | 0.209 | 0.642 | −0.460 | −0.198 |

| EP07 | 0.758 | 0.084 | 0.157 | 0.602 | −0.220 | −0.028 |

| EP11 | 0.824 | 0.148 | 0.472 | 0.580 | −0.318 | 0.162 |

| EP12 | 0.705 | 0.180 | 0.413 | 0.567 | −0.280 | −0.009 |

| FIRM_AGE | 0.099 | 1.000 | 0.224 | 0.084 | −0.096 | 0.010 |

| NUM_EMP | 0.348 | 0.224 | 1.000 | 0.218 | −0.270 | −0.045 |

| GSCM01 | 0.549 | 0.065 | 0.101 | 0.758 | −0.274 | −0.009 |

| GSCM02 | 0.548 | 0.122 | 0.132 | 0.789 | −0.306 | −0.055 |

| GSCM03 | 0.606 | 0.034 | 0.030 | 0.810 | −0.321 | −0.042 |

| GSCM04 | 0.493 | −0.043 | 0.104 | 0.846 | −0.503 | −0.209 |

| GSCM05 | 0.488 | 0.013 | 0.320 | 0.777 | −0.550 | −0.230 |

| GSCM06 | 0.393 | 0.159 | 0.190 | 0.719 | −0.371 | −0.172 |

| GSCM07 | 0.564 | 0.044 | 0.155 | 0.841 | −0.404 | −0.072 |

| GSCM08 | 0.524 | 0.067 | 0.262 | 0.680 | −0.424 | −0.116 |

| GSCM10 | 0.500 | 0.159 | 0.261 | 0.643 | −0.364 | −0.176 |

| GSCM11 | 0.395 | −0.054 | 0.157 | 0.758 | −0.222 | −0.185 |

| GSCM12 | 0.327 | 0.158 | 0.061 | 0.605 | −0.183 | −0.068 |

| GSCM13 | 0.542 | −0.031 | 0.065 | 0.635 | −0.182 | −0.040 |

| GSCM15 | 0.545 | 0.142 | 0.264 | 0.683 | −0.215 | −0.113 |

| ISO14001 | −0.382 | −0.096 | −0.270 | −0.453 | 1.000 | 0.344 |

| ISO9001 | 0.023 | 0.010 | −0.045 | −0.149 | 0.344 | 1.000 |

| Variables | R2 | R2 Adjusted | Effect Size (f2) | Q2 Predictive Validity | VIF |

|---|---|---|---|---|---|

| EP | 0.536 | 0.509 | - | 0.307 | - |

| GSCM | - | - | 0.669 | - | 1.275 |

| FIRM AGE | - | - | 0.000 | - | 1.056 |

| FIRM SIZE | - | - | 0.072 | - | 1.142 |

| ISO 14001 | - | - | 0.005 | - | 1.458 |

| ISO 9001 | - | - | 0.041 | - | 1.139 |

| Variables | Original Sample | Sample Mean | STDEV | t Statistics | p-Value | Decision |

|---|---|---|---|---|---|---|

| GSCM → DA | 0.626 | 0.642 | 0.074 | 8.444 | 0 | Accepted |

| FIRM SIZE → EP | −0.008 | −0.003 | 0.078 | 0.105 | 0.923 | Rejected |

| FIRM AGE → EP | 0.193 | 0.185 | 0.111 | 1.744 | 0.075 | Rejected |

| ISO 14001 → EP | −0.101 | −0.084 | 0.102 | 0.989 | 0.524 | Rejected |

| ISO 9001 → EP | 0.406 | 0.379 | 0.241 | 1.688 | 0.12 | Rejected |

| Regressions | Original Sample (O) | Sample Mean (M) | 2.5% | 97.5% |

|---|---|---|---|---|

| FIRM AGE → EP | −0.008 | −0.003 | −0.156 | 0.156 |

| FIRM SIZE → EP | 0.193 | 0.185 | −0.040 | 0.386 |

| GSCM → EP | 0.626 | 0.642 | 0.491 | 0.780 |

| ISO 14001 → EP | −0.101 | −0.084 | −0.262 | 0.131 |

| ISO 9001 → EP | 0.406 | 0.379 | −0.107 | 0.820 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Teixeira, A.A.; Moraes, T.E.C.; Teixeira, T.B.; Battistelle, R.A.G.; Araújo, E.G.; de Seabra, Q.A.C. The Role of Green Supply Chain Management Practices on Environmental Performance of Firms: An Exploratory Survey in Brazil. Sustainability 2023, 15, 11843. https://doi.org/10.3390/su151511843

Teixeira AA, Moraes TEC, Teixeira TB, Battistelle RAG, Araújo EG, de Seabra QAC. The Role of Green Supply Chain Management Practices on Environmental Performance of Firms: An Exploratory Survey in Brazil. Sustainability. 2023; 15(15):11843. https://doi.org/10.3390/su151511843

Chicago/Turabian StyleTeixeira, Adriano Alves, Tiago E. C. Moraes, Talita Borges Teixeira, Rosane A. G. Battistelle, Elton Gean Araújo, and Quintino Augusto Có de Seabra. 2023. "The Role of Green Supply Chain Management Practices on Environmental Performance of Firms: An Exploratory Survey in Brazil" Sustainability 15, no. 15: 11843. https://doi.org/10.3390/su151511843