Research on Power Battery Recycling in the Green Closed-Loop Supply Chain: An Evolutionary Game-Theoretic Analysis

Abstract

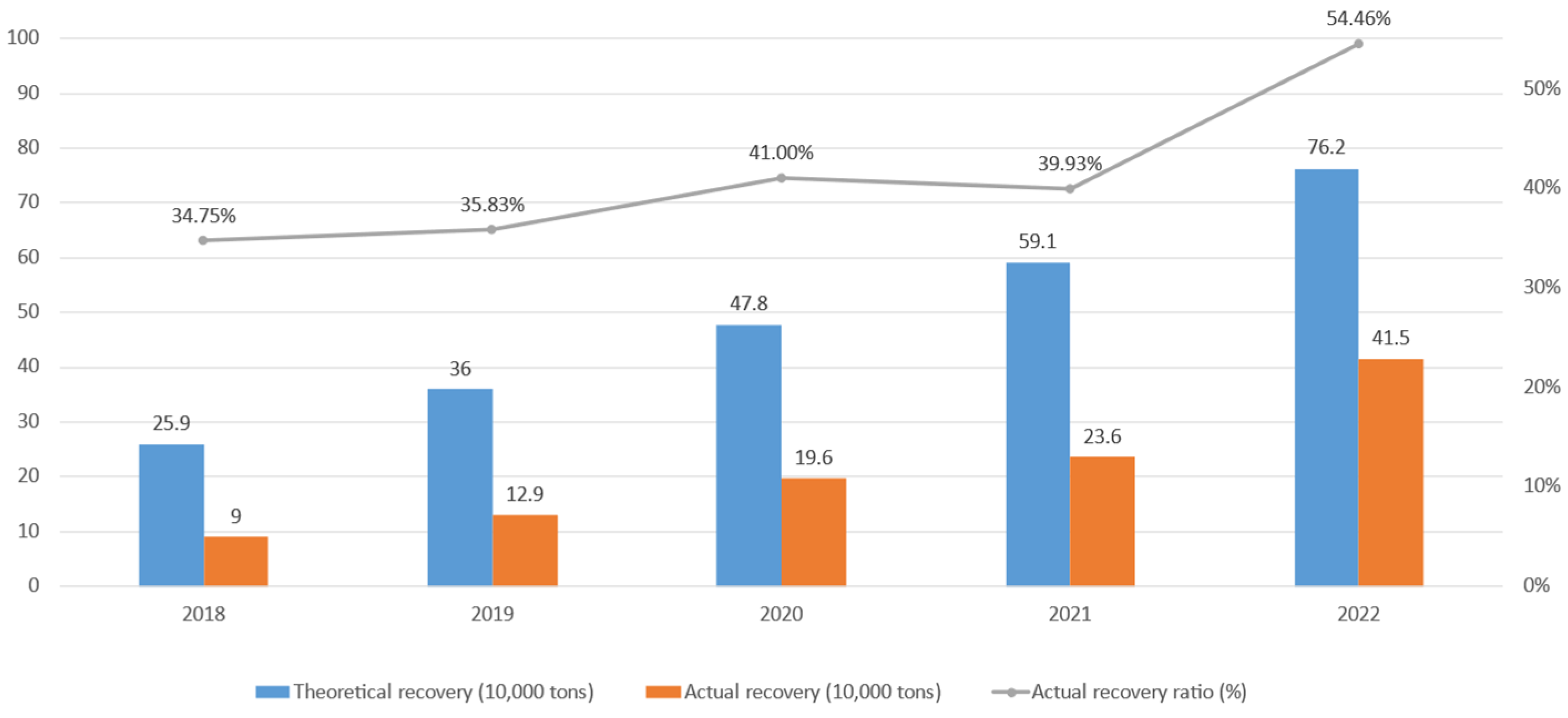

:1. Introduction

2. Literature Review

2.1. Power Battery Recycling

2.2. Green Closed-Loop Supply Chain and Its Influencing Factors

2.3. Theoretic Models of Power Battery Recycling

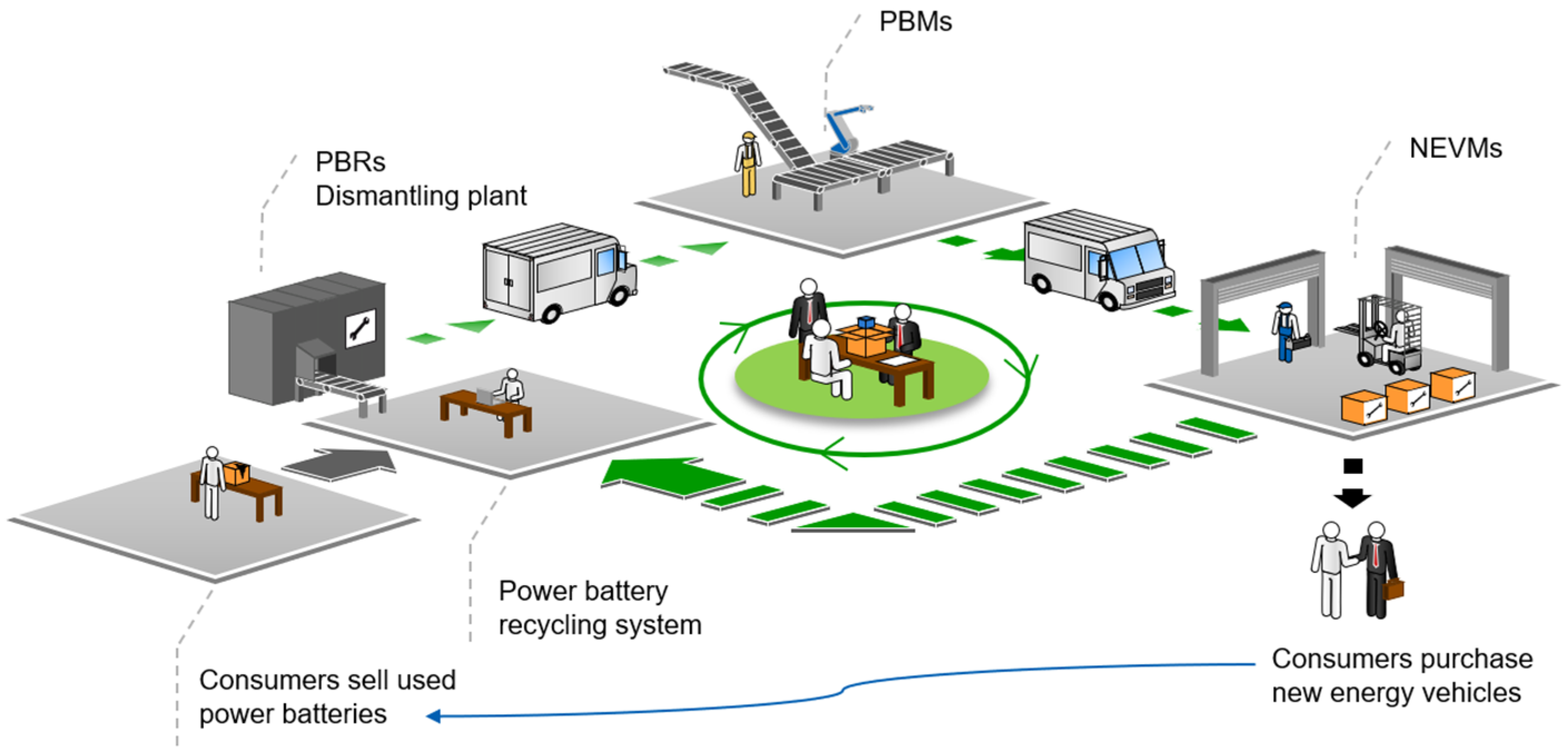

3. Evolutionary Game Model Building

3.1. Game Model Assumptions

- (a)

- NEVMs

- (b)

- PBMs

- (c)

- PBRs

- (d)

- We posit that the level of digital transformation for NEVMs, PBMs, and PBRs are , , and , and their fundamental benefits are , and , respectively.

- (e)

- Assume that the strategic risk cost of choosing green strategies for NEVMs, PBMs and PBRs, respectively, are , and . When both NEVMs and PBMs choose the green strategies, NEVMs pay assistance cost and PBMs pay technology cost . When both NEVMs and PBRs choose the green strategies, NEVMs pay assistance cost and PBRs pay technology cost .

- (f)

- When all three subjects choose green strategies, the supply chain generates additional benefits . The coefficients of benefits for each of the three are , , and , respectively. When only two subjects choose the green strategies, we consider the synergistic benefits generated and the distribution coefficient , as shown in Table 2.

3.2. Strategy Combinations and Payment Matrix

3.3. Replicator Dynamics Equations

3.4. Tripartite Stability Analysis

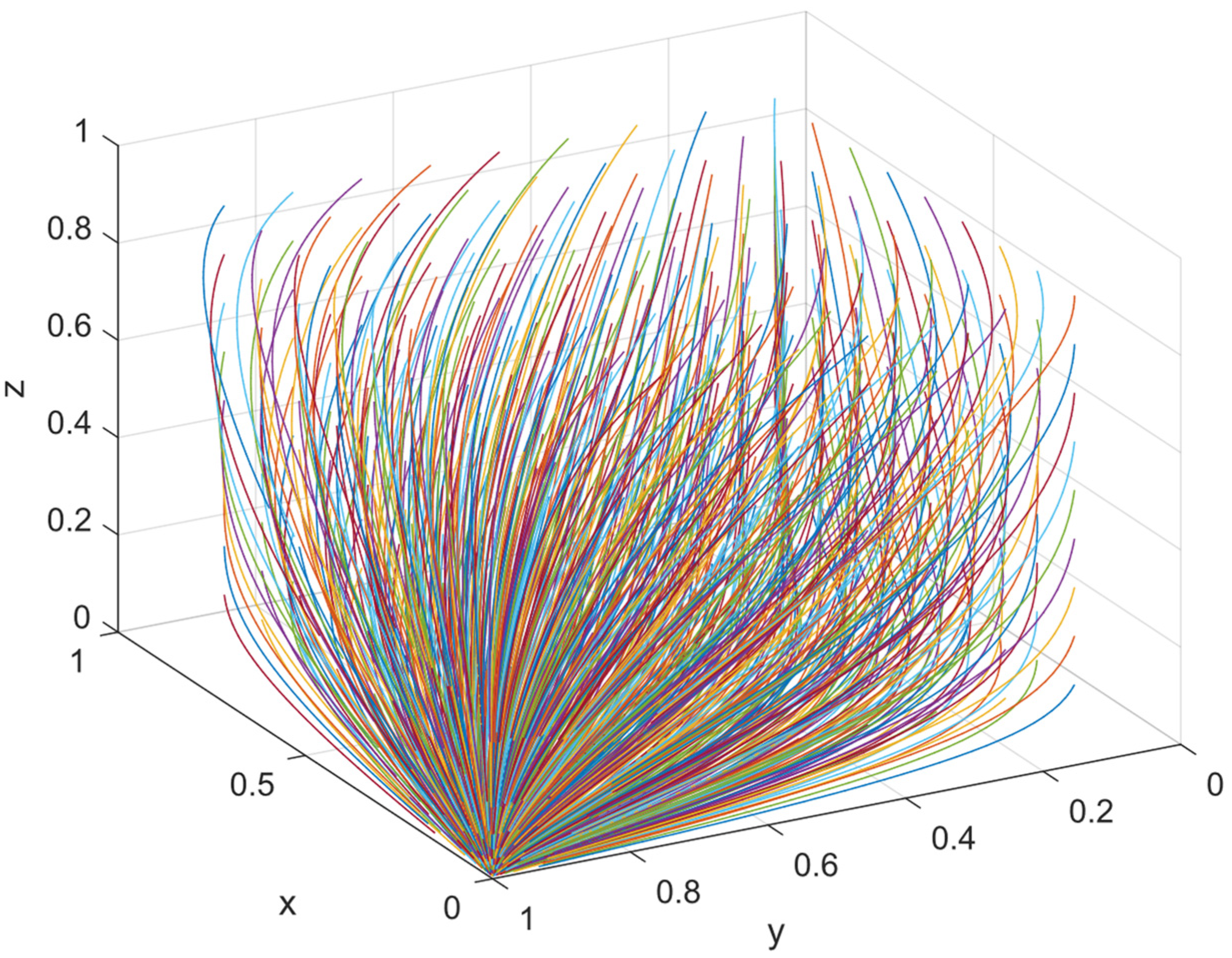

4. Simulation and Analysis

4.1. Initial Evolutionary Paths Analysis

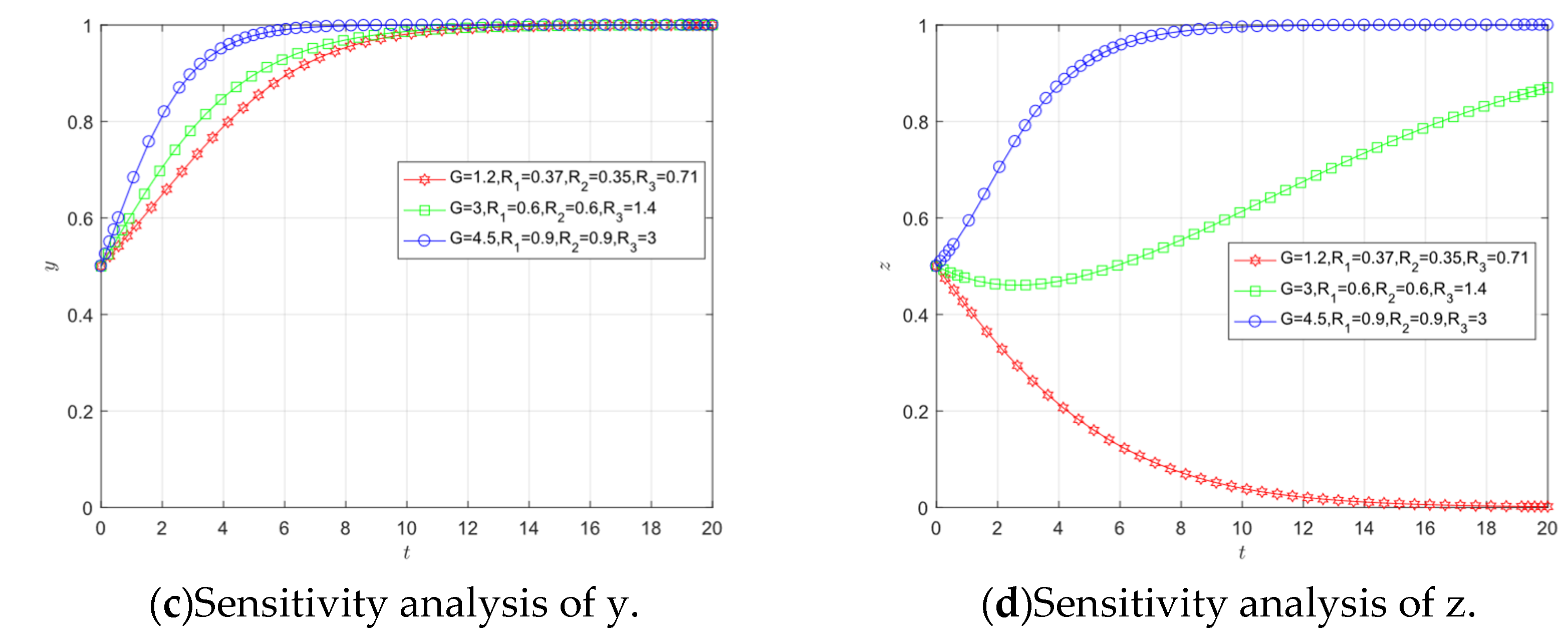

4.2. Sensitivity Analysis

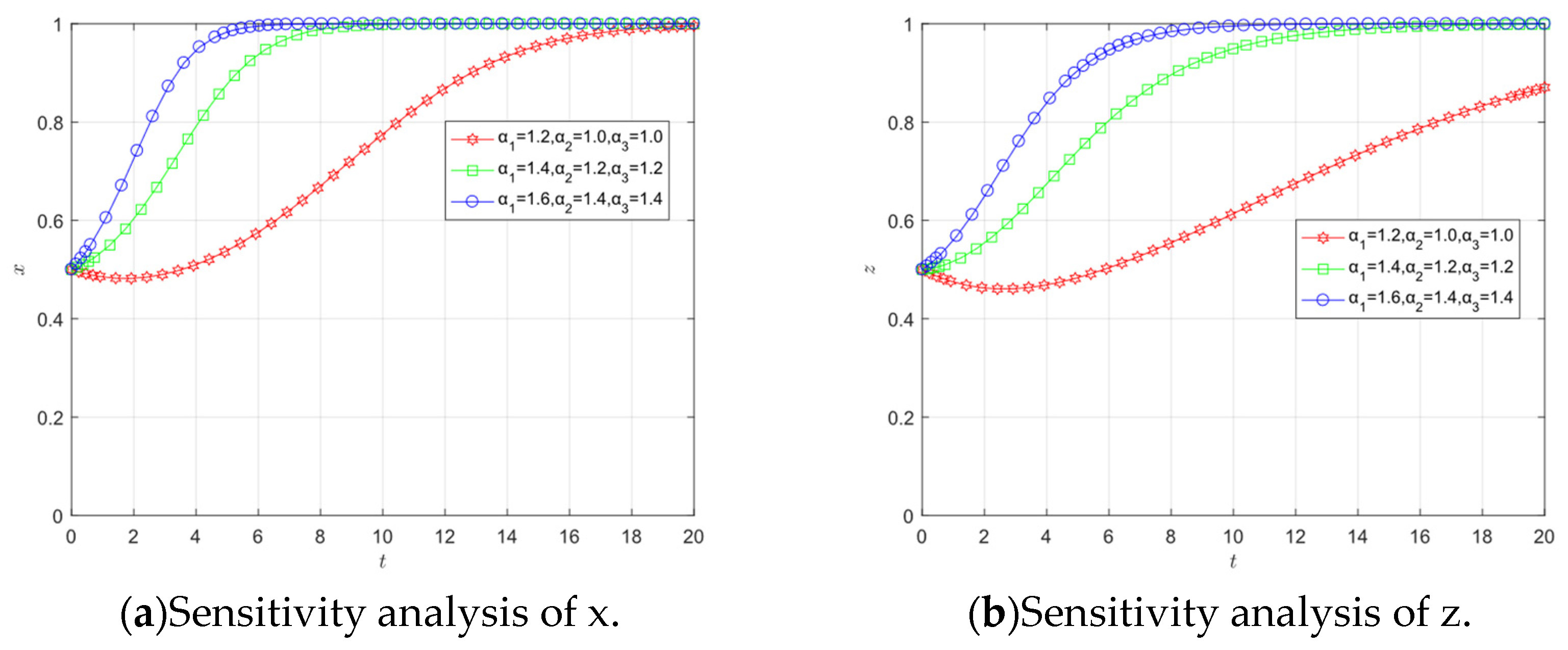

- (1)

- Sensitivity analysis of digital transformation degree

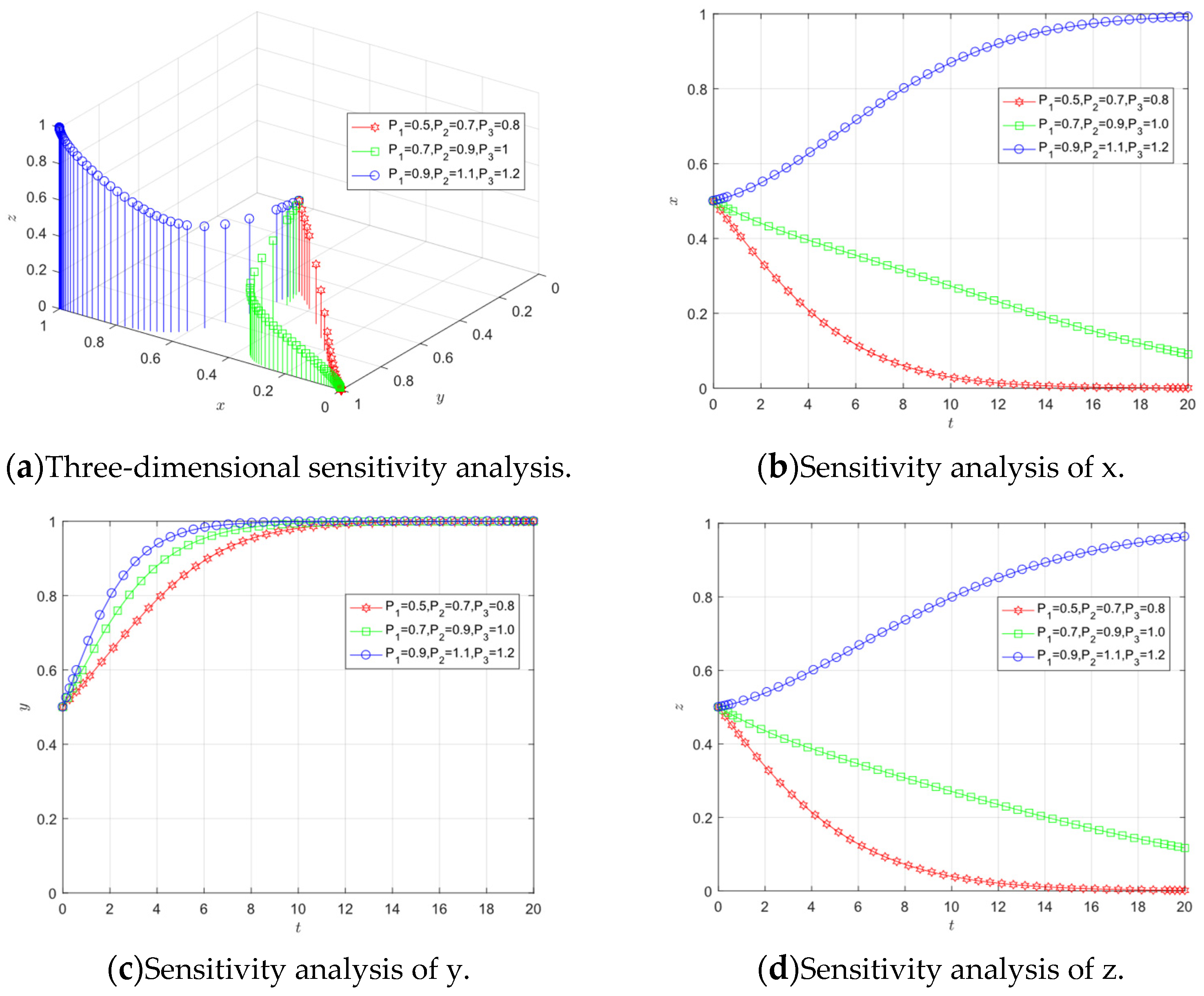

- (2)

- Sensitivity analysis of additional benefits.

- (3)

- Sensitivity analysis of government rewards and penalties.

- (4)

- Other Parameters Simulation

5. Conclusions and Implications

5.1. Conclusions

5.2. Implications

5.3. Limitations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- China’s New Energy Vehicle Holdings Reached 13.1 Million Units, Showing Rapid Growth. Available online: https://www.gov.cn/xinwen/2023-01/11/content_5736281.htm (accessed on 11 January 2023).

- Dqa, B.; Gw, B.; Tg, B.; Bw, B.; Tao, D.B. Potential impact of the end-of-life batteries recycling of electric vehicles on lithium demand in China: 2010–2050. Sci. Total Environ. 2020, 764, 142835. [Google Scholar] [CrossRef]

- Richa, K.; Babbitt, C.W.; Gaustad, G.; Xue, W. A future perspective on lithium-ion battery waste flows from electric vehicles. Resour. Conserv. Recycl. 2014, 83, 63–76. [Google Scholar] [CrossRef]

- Huang, Z.; Zhu, J.; Qiu, R.; Ruan, J.; Qiu, R. A cleaner and energy-saving technology of vacuum step-by-step reduction for recovering cobalt and nickel from spent lithium-ion batteries. J. Clean. Prod. 2019, 229, 1148–1157. [Google Scholar] [CrossRef]

- Zhu, J.; Mathews, I.; Ren, D.; Li, W.; Bazant, M.Z. End-of-life or second-life options for retired electric vehicle batteries. Cell Rep. Phys. Sci. 2021, 2, 100537. [Google Scholar] [CrossRef]

- Meng, K.; Xu, G.; Peng, X.; Youcef-Toumi, K.; Li, J. Intelligent disassembly of electric-vehicle batteries: A forward-looking overview. Resour. Conserv. Recycl. 2022, 182, 106207. [Google Scholar] [CrossRef]

- Berman, S.J. Digital transformation: Opportunities to create new business models. Strategy Leadersh. 2012, 40, 16–24. [Google Scholar] [CrossRef]

- Zhu, G.; He, X. Disassembly and Step Utilization of Waste Lithium Ion Power Battery. Adv. Mater. Ind. 2017, 9, 43–46. [Google Scholar] [CrossRef]

- Wei, M. Consider Reverse Recovery of Power Battery for Step Utilization. China Storage Transp. 2021, 6, 178–179. [Google Scholar] [CrossRef]

- Li, J.; Wang, Z.; Xu, D.; Liu, D. A Comparative Analysis of Relevant Policies is Made on Retired Power Batteries. Mod. Electr. Power 2021, 38, 316–324. [Google Scholar] [CrossRef]

- Li, Y.; Lan, T. Research on vehicle power battery recovery and step utilization. Stand. Qual. Light Ind. 2020, 2, 116–119. [Google Scholar] [CrossRef]

- Li, Y.; Zhou, W.; Huang, Y. The ldea of Establishment New Energy Automotive Battery Recycling System. Resour. Recycl. 2012, 1, 28–30. [Google Scholar]

- Jiao, N.; Evans, S. Business Models for Sustainability: The Case of Second-life Electric Vehicle Batteries. Procedia CIRP 2016, 40, 250–255. [Google Scholar] [CrossRef] [Green Version]

- Ma, Y. EPR Government Power Battery Manufacturer and Consumer Three Party Evolutionary Game Analysis. Logist. Eng. Manag. 2018, 40, 132–135. [Google Scholar]

- Zhang, S.; Zhang, M.; Yu, X.; Hao, R. What keeps Chinese from recycling: Accessibility of recycling facilities and the behavior. Resour. Conserv. Recycl. 2016, 109, 176–186. [Google Scholar] [CrossRef]

- Shen, Y.; Song, Z.; Gao, T.; Ma, J. Research on Closed-Loop Supply Chain Decision Making of Power Battery Considering Subsidy Transfer under EPR System. Sustainability 2022, 14, 2488. [Google Scholar] [CrossRef]

- Mitra, S.; Webster, S. Competition in remanufacturing and the effects of government subsidies. Int. J. Prod. Econ. 2008, 111, 287–298. [Google Scholar] [CrossRef]

- Ravi, V.; Shankar, R.; Tiwari, M.K. Analyzing alternatives in reverse logistics for end-of-life computers: ANP and balanced scorecard approach. Comput. Ind. Eng. 2005, 48, 327–356. [Google Scholar] [CrossRef]

- Tang, Y.; Zhang, Q.; Liu, B.; Li, Y.; Ni, R.; Wang, Y. What influences residents’ intention to participate in the electric vehicle battery recycling? Evidence from China. Energy 2023, 276, 127563. [Google Scholar] [CrossRef]

- Wang, X.; Li, J. Endogenous Selection of Enterprise Waste Treatment Model under EPR System. Chin. J. Manag. 2019, 16, 728–735. [Google Scholar]

- Qiao, F. Recycle Mode Choice of Waste Pure Electric Vehicle Power Battery Based On Game Theory. Master’s Thesis, Beijing Jiaotong University, Beijing, China, 2015. [Google Scholar]

- Tang, Y.; Zhang, Q.; Li, Y.; Wang, G.; Li, Y. Recycling Mechanisms and Policy Suggestions for Spent Electric Vehicles’ Power Battery -A Case of Beijing. J. Clean. Prod. 2018, 186, 388–406. [Google Scholar] [CrossRef]

- Zheng, C.; Zhang, H.; Guo, D.; Wang, J.; Li, C. AnyLogic—Based simulation of recovery model for lithium battery of the electric vehicle. J. Shandong Univ. Technol. (Nat. Sci. Ed.) 2019, 33, 25–28. [Google Scholar] [CrossRef]

- Liu, J.; Ma, J. Research on Reverse Subsidy Mechanism of Power Battery Closed-loop Supply Chain Considering Cascade Utilization. Ind. Eng. Manag. 2021, 26, 80–88. [Google Scholar] [CrossRef]

- Wieland, A. Dancing the Supply Chain: Toward Transformative Supply Chain Management. J. Supply Chain Manag. 2021, 57, 58–73. [Google Scholar] [CrossRef]

- Savaskan, R.C. Management of closed-loop supply chains for recoverable products. Northwestern University: Evanston, IL, USA, 2000. [Google Scholar]

- Rybaczewska-Baejowska, M.; Masternak-Janus, A. Assessing and Improving the Eco-Efficiency of Manufacturing: Learning and Challenges from a Polish Case Study. Energies 2021, 14, 8125. [Google Scholar] [CrossRef]

- Handfield, R.B.; Walton, S.V.; Goizueta, R.C.; Seegers, L.K.; Melnyk, S.A. ‘Green’ supply chain: Best practices from the furniture industry. J. Oper. Manag. 1997, 15, 293–315. [Google Scholar] [CrossRef]

- Savaskan, R.C.; Bhattacharya, S.; Wassenhove, L. Closed-Loop Supply Chain Models with Product Remanufacturing. Manag. Sci. 2004, 50, 239–252. [Google Scholar] [CrossRef] [Green Version]

- Yao, M.; Teng, C. Decision models for closed-loop supply chain with two competingretailers considering fairness concerns. Comput. Integr. Manuf. Syst. 2017, 23, 1731–1738. [Google Scholar] [CrossRef]

- YU, Y. Comparative Study on E-waste Recycling Model Based on System Dynamics. Master’s Thesis, Beijing Jiaotong University, Beijing, China, 2019. [Google Scholar]

- Huang, Z.; Nei, J.; Zhao, Y. The cooperation recovery strategies across the closed-loop supply chain. J. Ind. Eng. Eng. Manag. 2019, 33, 147–152. [Google Scholar] [CrossRef]

- Zu-Jun, M.; Zhang, N.; Dai, Y.; Hu, S. Managing channel profits of different cooperative models in closed-loop supply chains. Omega 2016, 59, 251–262. [Google Scholar] [CrossRef]

- Zhang, P.; Yu, L.; Xiong, Z. Designing Contracts for A Closed-loop Supply Chain with Information Asymmetry under the Government’s Reward-penalty Mechanism. Chin. J. Manag. Sci. 2020, 28, 89–100. [Google Scholar] [CrossRef]

- Heydari, J.; Govindan, K.; Jafari, A. Reverse and closed loop supply chain coordination by considering government role. Transp. Res. Part D Transp. Environ. 2017, 52, 379–398. [Google Scholar] [CrossRef]

- Zhang, Z.; Guo, M.; Yang, W. Analysis of NEV Power Battery Recycling under Different Government Reward-Penalty. Sustainability 2022, 14, 538. [Google Scholar] [CrossRef]

- Li, X.; Du, J.; Cheng, Y.; Hanif, S.; Mu, D.; Cui, Y. Electric vehicle battery recycling: System dynamics game based analysis for the influencing factors. Environ. Eng. Manag. J. 2019, 18, 1123–1136. [Google Scholar] [CrossRef]

- Wang, W.; Da, Q. The Decision-Making Model of the Electronic Product Manufacturer about Collection and Remanufacturing based on Premium and Penalty Mechanism. Chin. J. Manag. Sci. 2008, 16, 57–63. [Google Scholar]

- Stank, T.; Esper, T.; Goldsby, T.J.; Zinn, W.; Autry, C. Toward a Digitally Dominant Paradigm for twenty-first century supply chain scholarship. Int. J. Phys. Distrib. Logist. Manag. 2019, 49, 917–956. [Google Scholar] [CrossRef]

- Fitzgerald, M.; Kruschwitz, N.; Bonnet, D.; Welch, M. Embracing Digital Technology: A New Strategic Imperative. MIT Sloan Manag. Rev. 2014, 55, 1. [Google Scholar]

- Reis, J.C.G.d.; Amorim, M.P.C.; Melão, N.F.R.; Matos, P.S.L. Digital Transformation: A Literature Review and Guidelines for Future Research. In Proceedings of the Trends and Advances in Information Systems and Technologies, Naples, Italy, 27–29 March 2018; pp. 411–421. [Google Scholar]

- Bai, P.; Yu, L. Digital Economy Development and Firms’ Markup: Theoretical Mechanisms and Empirical Facts. China Ind. Econ. 2021, 11, 59–77. [Google Scholar] [CrossRef]

- Wena, H.; Wen, C.; Leea, C.-C. Impact of digitalization and environmental regulation on total factor productivity. Inf. Econ. Policy 2022, 61, 101007. [Google Scholar] [CrossRef]

- Gaglio, C.; Kraemer-Mbula, E.; Lorenz, E. The effects of digital transformation on innovation and productivity: Firm-level evidence of South African manufacturing micro and small enterprises. Technol. Forecast. Soc. Change 2022, 182, 121785. [Google Scholar] [CrossRef]

- Kim, D.H.; Kim, D.H. A system dynamics model for a mixed-strategy game between police and driver. Syst. Dyn. Rev. 1997, 13, 33–52. [Google Scholar] [CrossRef]

- Xu, L.; Li, S.; Zheng, J. Cooperation Mechanism of E-waste Recycling in “nternet + Recycling Environment Based on Evolutionary Game. Oper. Res. Manag. Sci. 2018, 27, 87–98. [Google Scholar]

- Wang, Z.; Wang, Q.; Chen, B.; Wang, Y. Evolutionary game analysis on behavioral strategies of multiple stakeholders in E-waste recycling industry. Resour. Conserv. Recycl. 2020, 155, 104618. [Google Scholar] [CrossRef]

- Li, B.; Wang, Q.; Chen, B.; Sun, T.; Wang, Z.; Cheng, Y. Tripartite evolutionary game analysis of governance mechanism in Chinese WEEE recycling industry. Comput. Ind. Eng. 2022, 167, 108045. [Google Scholar] [CrossRef]

- Wang, M.; Liu, C.; Zhong, Y. Research on Investment Model Selection of Power Battery Recyclers Based on Evolutionary Game. Ind. Eng. Manag. 2021, 26, 161–170. [Google Scholar] [CrossRef]

- Zhang, H.M.; Zhu, K.X.; Hang, Z.X.; Zhou, D.; Zhou, Y.; Xu, Z. Waste battery-to-reutilization decisions under government subsidies: An evolutionary game approach. Energy 2022, 259, 124835. [Google Scholar] [CrossRef]

- He, L.; Sun, B. Exploring the EPR system for power battery recycling from a supply-side perspective: An evolutionary game analysis. Waste Manag. 2022, 140, 204–212. [Google Scholar] [CrossRef] [PubMed]

- Huo, L.; Shao, Y.; Lin, X. Research on recovery strategies in remanufaction close-oop supply chain based on evolutionary game perspective. Appl. Res. Comput. 2018, 35, 727–732. [Google Scholar]

- Zhang, J.; Wen, S.; Lv, X.; Sun, T. Evolutionary Game Analysis of Closed-Loop Supply Chain under the Background of Low-Carbon Economy. Ind. Eng. Manag. 2023, 3, 1–14. Available online: https://kns.cnki.net/kcms/detail/31.1738.T.20230324.1009.002.html (accessed on 1 May 2023).

- Smith, J.; Price, G.R. The logic of animal conflict. Nature 1973, 246, 15–18. [Google Scholar] [CrossRef]

- Easley, D.; Kleinberg, J. Networks, Crowds, and Markets: Reasoning about a Highly Connected World; Cambridge University Press: Cambridge, UK, 2010. [Google Scholar]

- Chen, C.K.; ‘Ulya, M.A. Analyses of the reward-penalty mechanism in green closed-loop supply chains with product remanufacturing. Int. J. Prod. Econ. 2019, 210, 211–223. [Google Scholar] [CrossRef]

- Cressman, R.; Tao, Y. The replicator equation and other game dynamics. Proc. Natl. Acad. Sci. USA 2014, 111, 10810–10817. [Google Scholar] [CrossRef]

- Waldner, F.; Klages, R. Symmetric Jacobian for local Lyapunov exponents and Lyapunov stability analysis revisited. Chaos Solitons Fractals 2012, 45, 325–340. [Google Scholar] [CrossRef] [Green Version]

- Yang, Y.; Yang, W.; Chen, H.; Li, Y. China’s energy whistleblowing and energy supervision policy: An evolutionary game perspective. Energy 2020, 213, 118774. [Google Scholar] [CrossRef]

- Ma, B.; Jiang, X. Stability analysis of the three-group 2 × 2 × 2 asymmetric evolutionary game. Oper. Res. Manag. Sci. 2022, 31, 38–45. [Google Scholar]

- Weibull, J.W. Evolutionary Game Theory; MIT Press: Cambridge, MA, USA, 1997. [Google Scholar]

- He, X. Evolutionary Game Study of Power Battery Recycling Decision Based on Closed-loop Supply Chain. Master’s Thesis, Jiangxi University of Science and Technology, Ganzhou, China, 2021. [Google Scholar]

- Wei, L.; Wang, C. Regulatory Strategies of New Energy Vehicle Powzer Battery Recycling Based on SD Evolutionary Game. J. Syst. Sci. Math. Sci. 2023, 5, 1–17. Available online: https://kns.cnki.net/kcms/detail//11.2019.o1.20230111.1326.010.html (accessed on 31 May 2023).

- Zhang, Y.; Ma, X.; Pang, J.; Xing, H.; Wang, J. The impact of digital transformation of manufacturing on corporate performance —The mediating effect of business model innovation and the moderating effect of innovation capability. Res. Int. Bus. Financ. 2023, 64, 101890. [Google Scholar] [CrossRef]

- Pedro, F.; Arnaldo, C. How to boost green innovation and performance through collaboration in the supply chain: Insights into a more sustainable economy. J. Clean. Prod. 2022, 359, 132005. [Google Scholar] [CrossRef]

- Zhang, M.; Wu, W.; Song, Y. Study on the impact of government policies on power battery recycling under different recycling models. J. Clean. Prod. 2023, 413, 137492. [Google Scholar] [CrossRef]

| Probability | Implication | Range |

|---|---|---|

| Probability of NEVMs choosing green strategies | ||

| Probability of NEVMs choosing non-green strategies | ||

| Probability of PBMs choosing green strategies | ||

| Probability of PBMs choosing non-green strategies | ||

| Probability of PBRs choosing green strategies | ||

| Probability of PBRs choosing non-green strategies |

| Parameters | Implication | Range |

|---|---|---|

| NEVMs’ digital transformation degree | ||

| PBMs’ digital transformation degree | ||

| PBRs’ digital transformation degree | ||

| The fundamental benefits of NEVMs | ||

| The fundamental benefits of PBMs | ||

| The fundamental benefits of PBRs | ||

| The strategic risk cost of NEVMs | ||

| The strategic risk cost of PBMs | ||

| The strategic risk cost of PBRs | ||

| Cost of NEVMs assistance to PBMs | ||

| Cost of NEVMs assistance to PBRs | ||

| PBMs’ technology input | ||

| PBRs’ technology input | ||

| Additional benefits when all three subjects choose green strategies | ||

| Additional earnings distribution factor for NEVMs | ||

| Additional earnings distribution factor for PBMs | ||

| Additional earnings distribution factor for PBRs | ||

| Benefits of collaboration between NEVMs and PBMs | ||

| Benefits of collaboration between NEVMs and PBRs | ||

| Benefits of collaboration between PBMs and PBRs | ||

| Gain factor when NEVMs and PBMs collaborate | ||

| Gain factor when NEVMs and PBRs collaborate | ||

| Gain factor when PBMs and PBRs collaborate |

| Parameters | Implication | Range |

|---|---|---|

| Government rewards for NEVMs choosing green strategies | ||

| Government rewards for PBMs choosing green strategies | ||

| Government rewards for PBRs choosing green strategies | ||

| Government penalties for NEVMs choosing non-green strategies | ||

| Government penalties for PBMs choosing non-green strategies | ||

| Government penalties for PBRs choosing non-green strategies |

| Strategies | NEVMs | PBMs | PBRs |

|---|---|---|---|

| Equilibrium Points | Eigenvalues | ||

|---|---|---|---|

| Parameters | Initial Value | Parameters | Initial Value | Parameters | Initial Value |

|---|---|---|---|---|---|

| 1.2 | 0.5 | 0.6 | |||

| 1 | 0.55 | 0.5 | |||

| 1 | 0.45 | 0.4 | |||

| 0.45 | 1.82 | 0.6 | |||

| 0.26 | 0.5 | 0.3 | |||

| 0.3 | 0.2 | 0.7 | |||

| 1.45 | 0.3 | 0.5 | |||

| 0.5 | 0.37 | 0.7 | |||

| 1.8 | 0.35 | 0.8 | |||

| 0.4 | 0.71 | - | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, G.; Lu, M.; Lai, S.; Li, Y. Research on Power Battery Recycling in the Green Closed-Loop Supply Chain: An Evolutionary Game-Theoretic Analysis. Sustainability 2023, 15, 10425. https://doi.org/10.3390/su151310425

Li G, Lu M, Lai S, Li Y. Research on Power Battery Recycling in the Green Closed-Loop Supply Chain: An Evolutionary Game-Theoretic Analysis. Sustainability. 2023; 15(13):10425. https://doi.org/10.3390/su151310425

Chicago/Turabian StyleLi, Gang, Mengyu Lu, Sen Lai, and Yonghong Li. 2023. "Research on Power Battery Recycling in the Green Closed-Loop Supply Chain: An Evolutionary Game-Theoretic Analysis" Sustainability 15, no. 13: 10425. https://doi.org/10.3390/su151310425