Thermoeconomic Analysis of Subcritical and Supercritical Isobutane Cycles for Geothermal Power Generation

Abstract

:1. Introduction

2. Materials and Methods

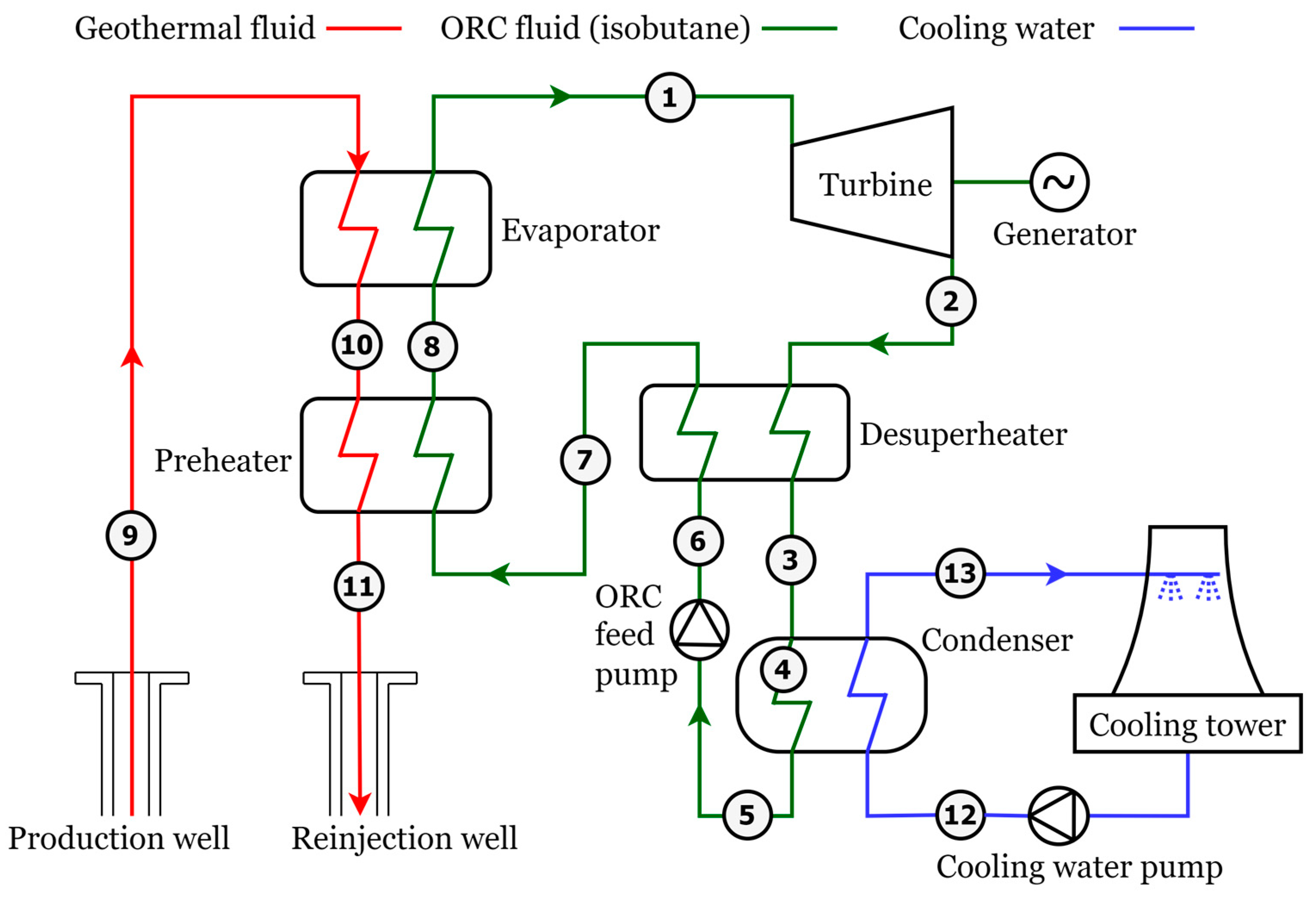

2.1. The Rankine Cycle Configuration

2.2. The Thermodynamic Model

2.3. The Heat Transfer Model

2.4. The Economic Model

3. Results and Discussion

3.1. Validation of the Thermodynamic Model

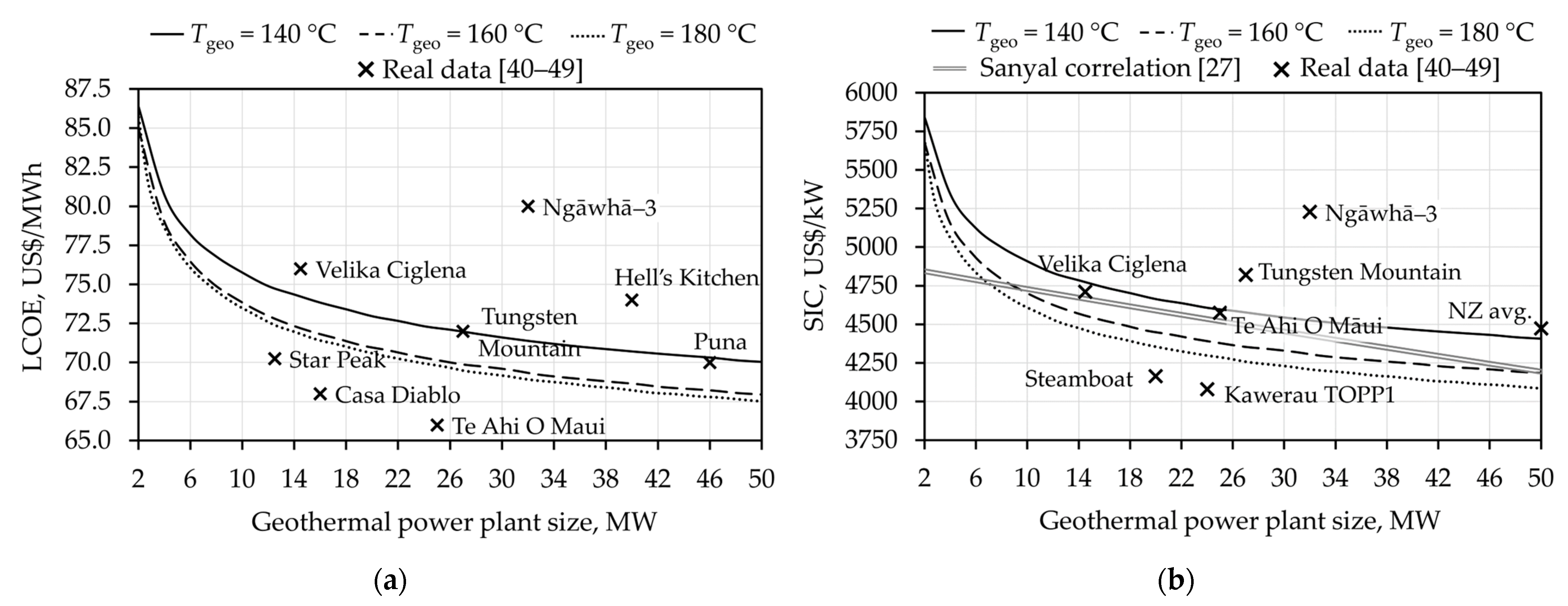

3.2. Validation of the Economic Model

3.3. Thermoeconomic Analysis

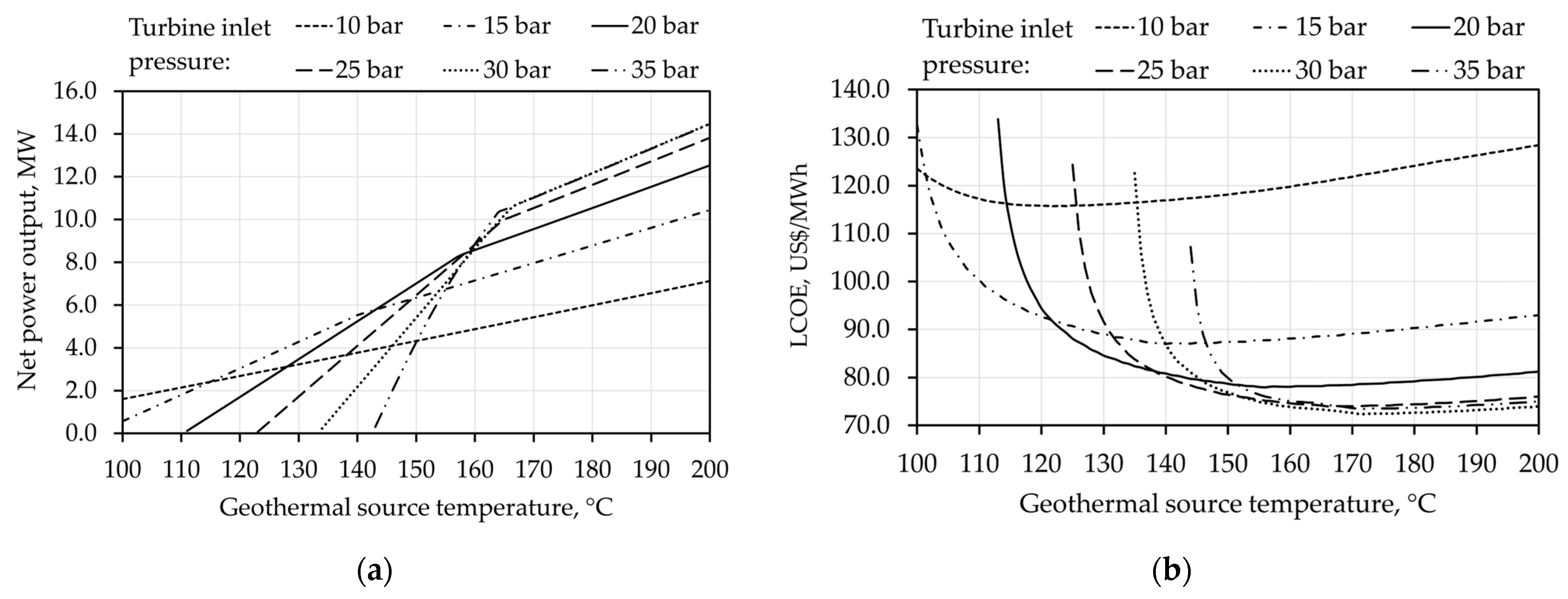

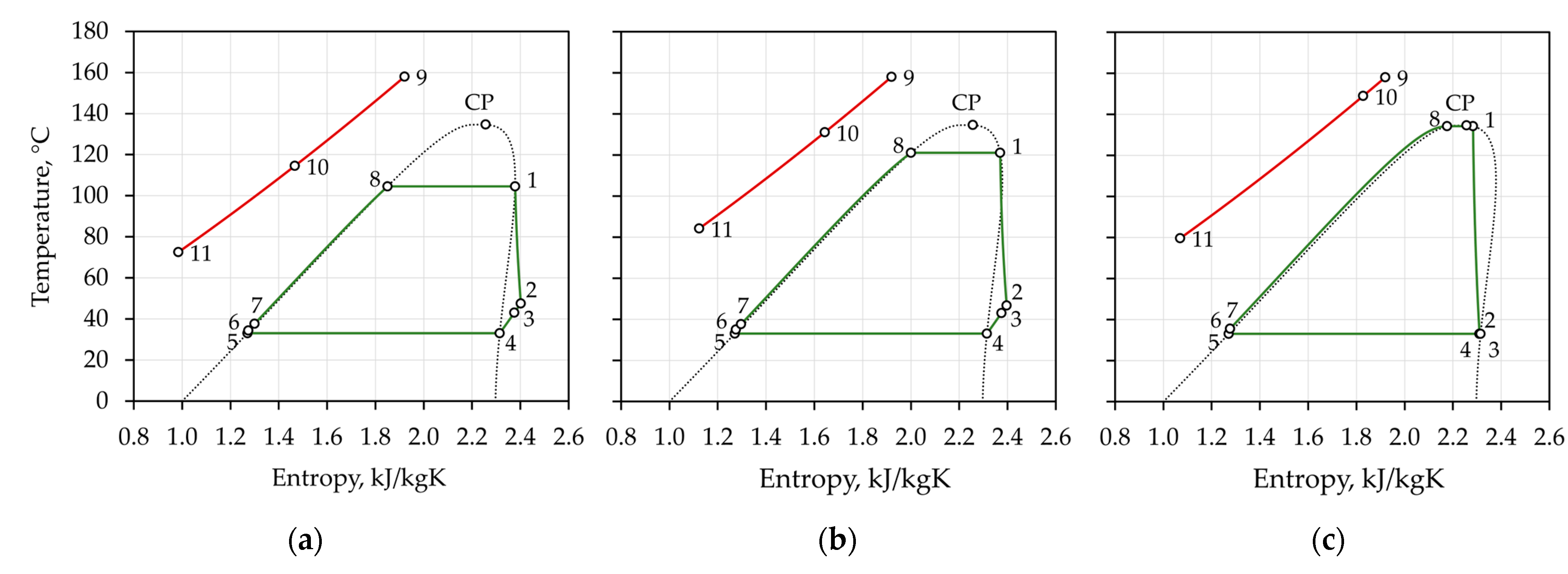

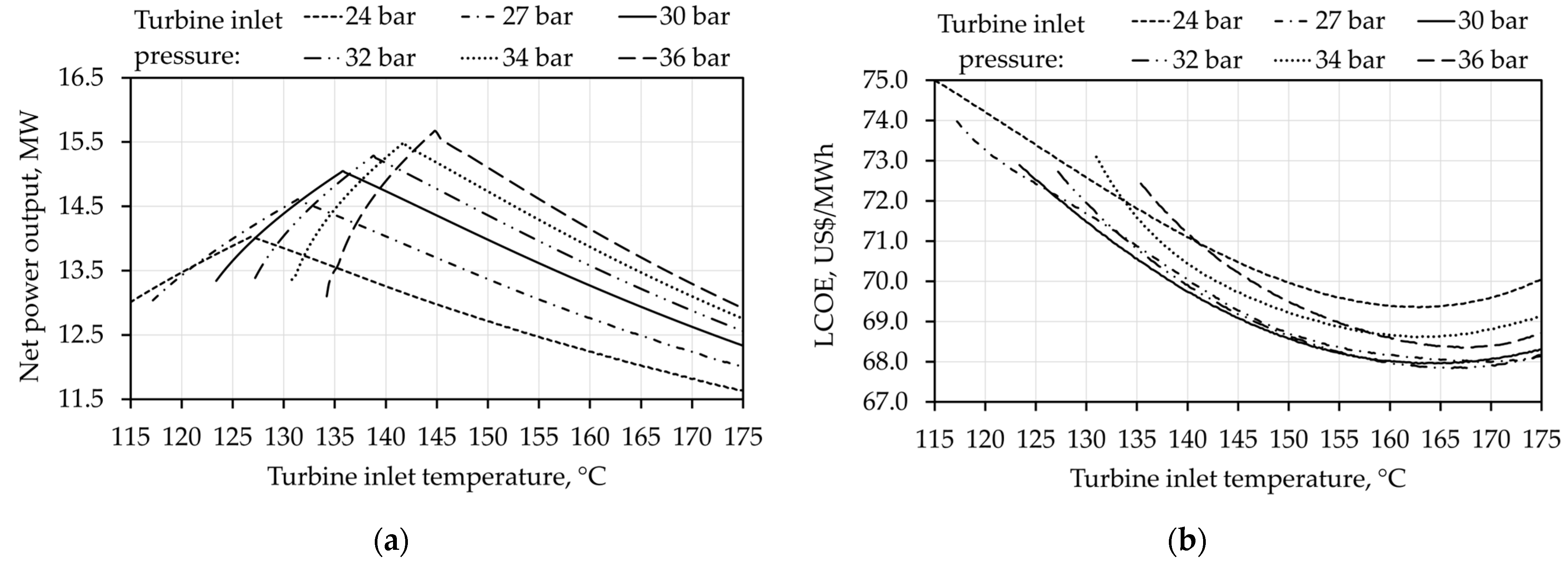

3.3.1. Subcritical Saturated Isobutane Cycles

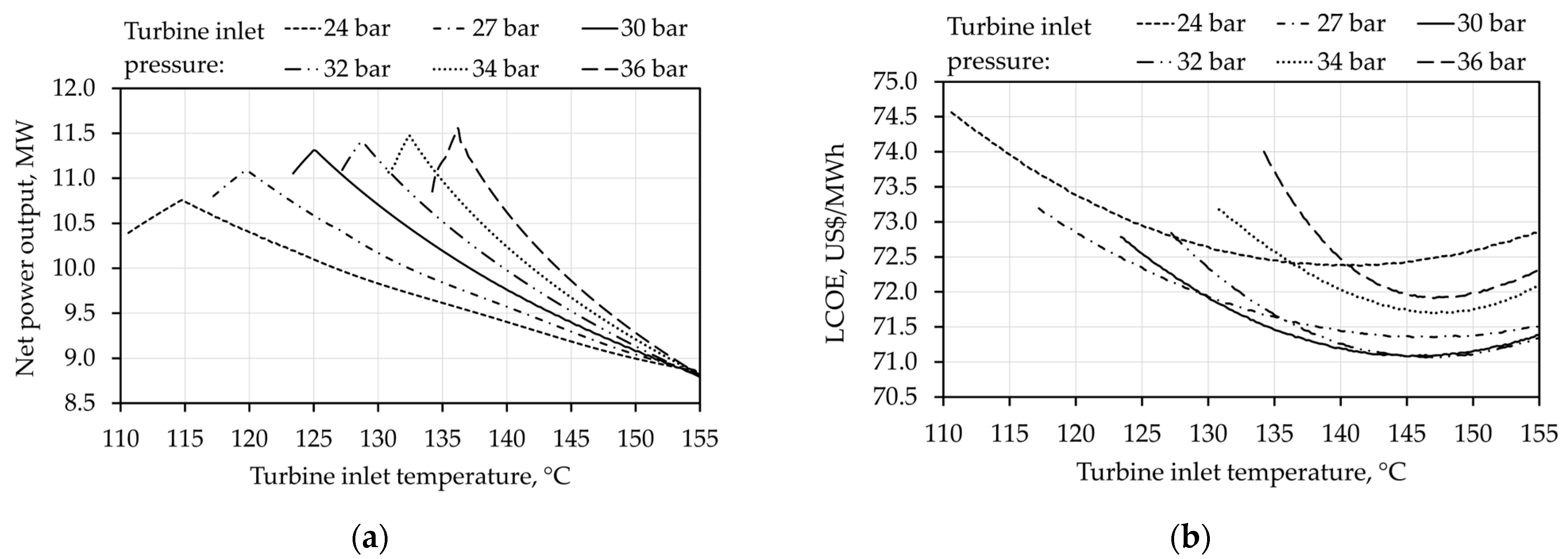

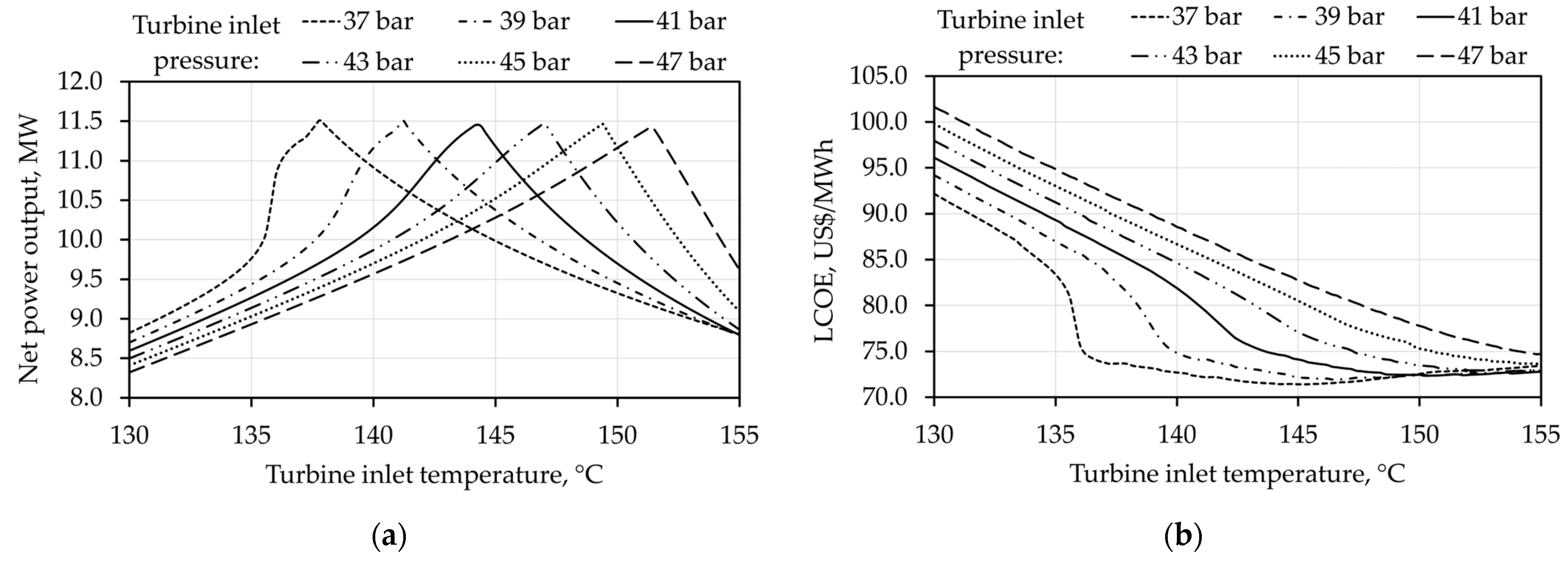

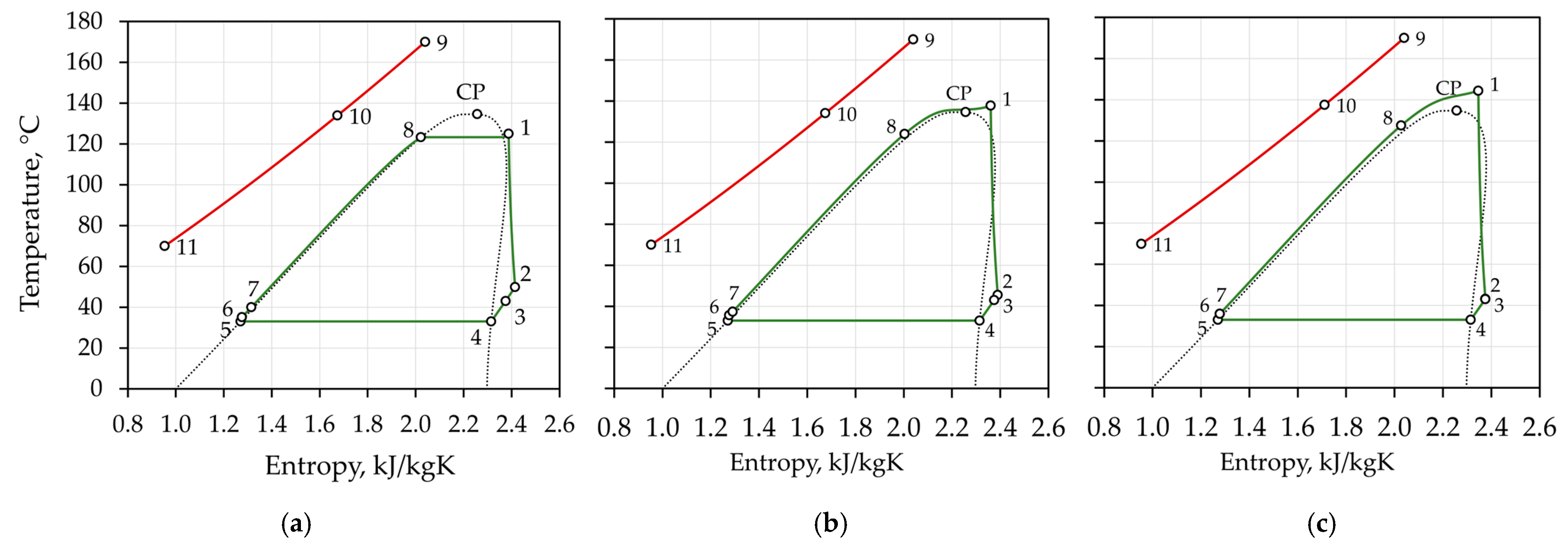

3.3.2. Subcritical Superheated Isobutane Cycles

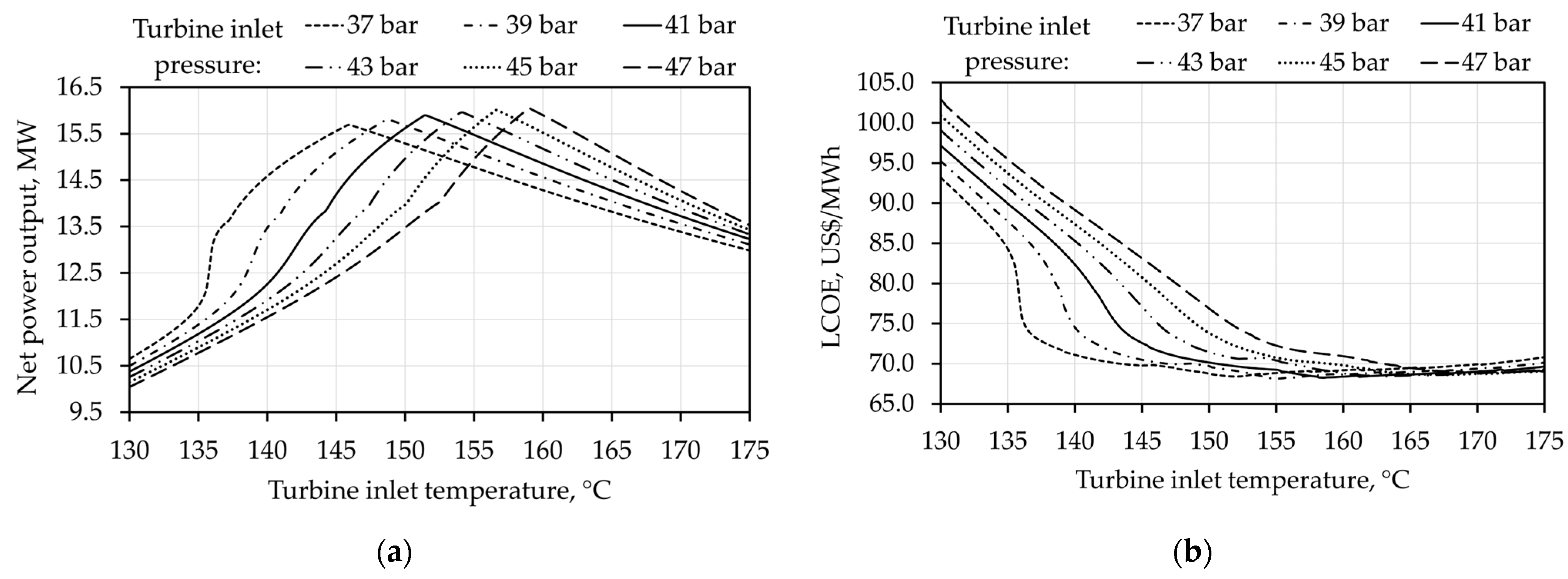

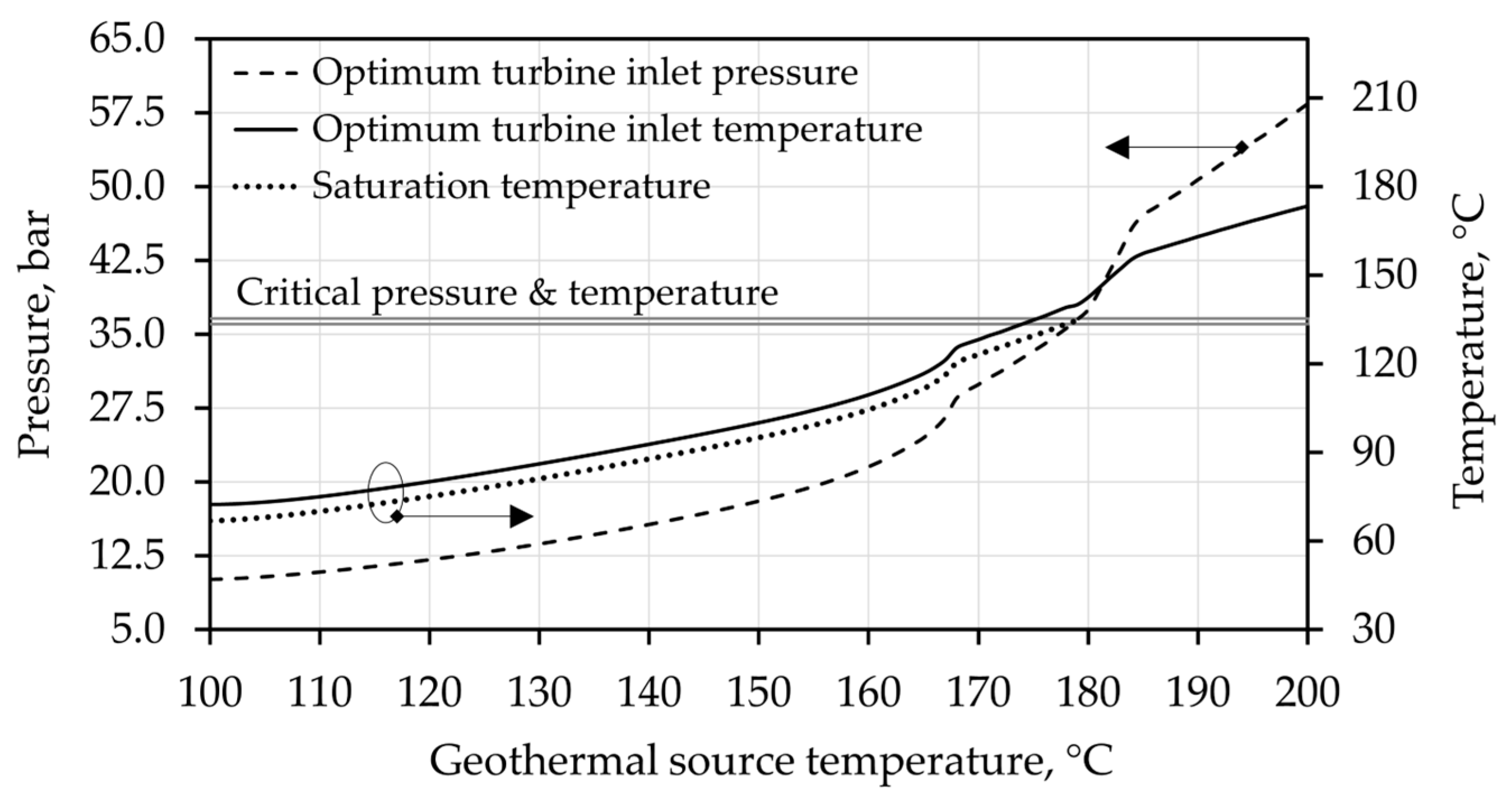

3.3.3. Supercritical Cycles

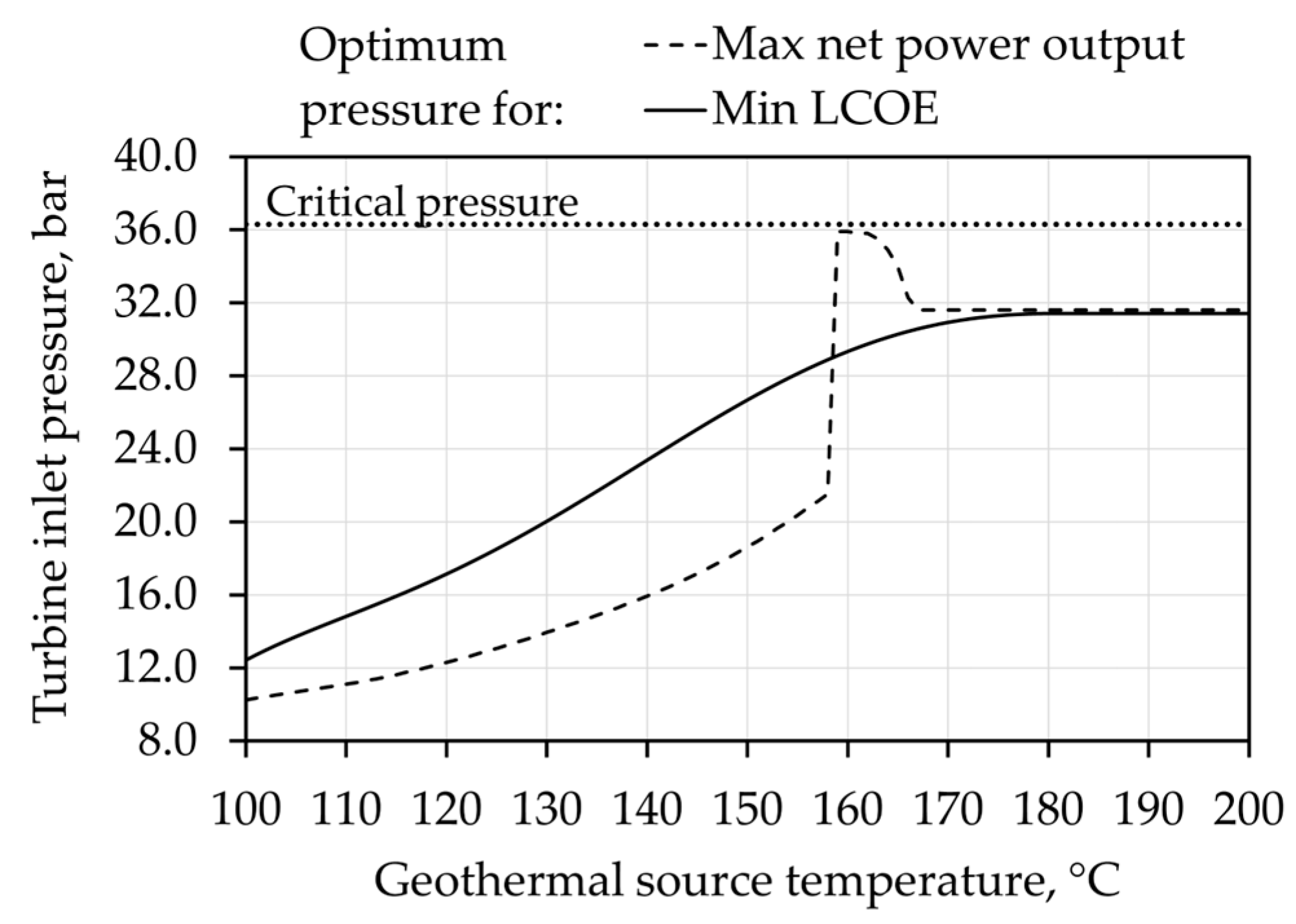

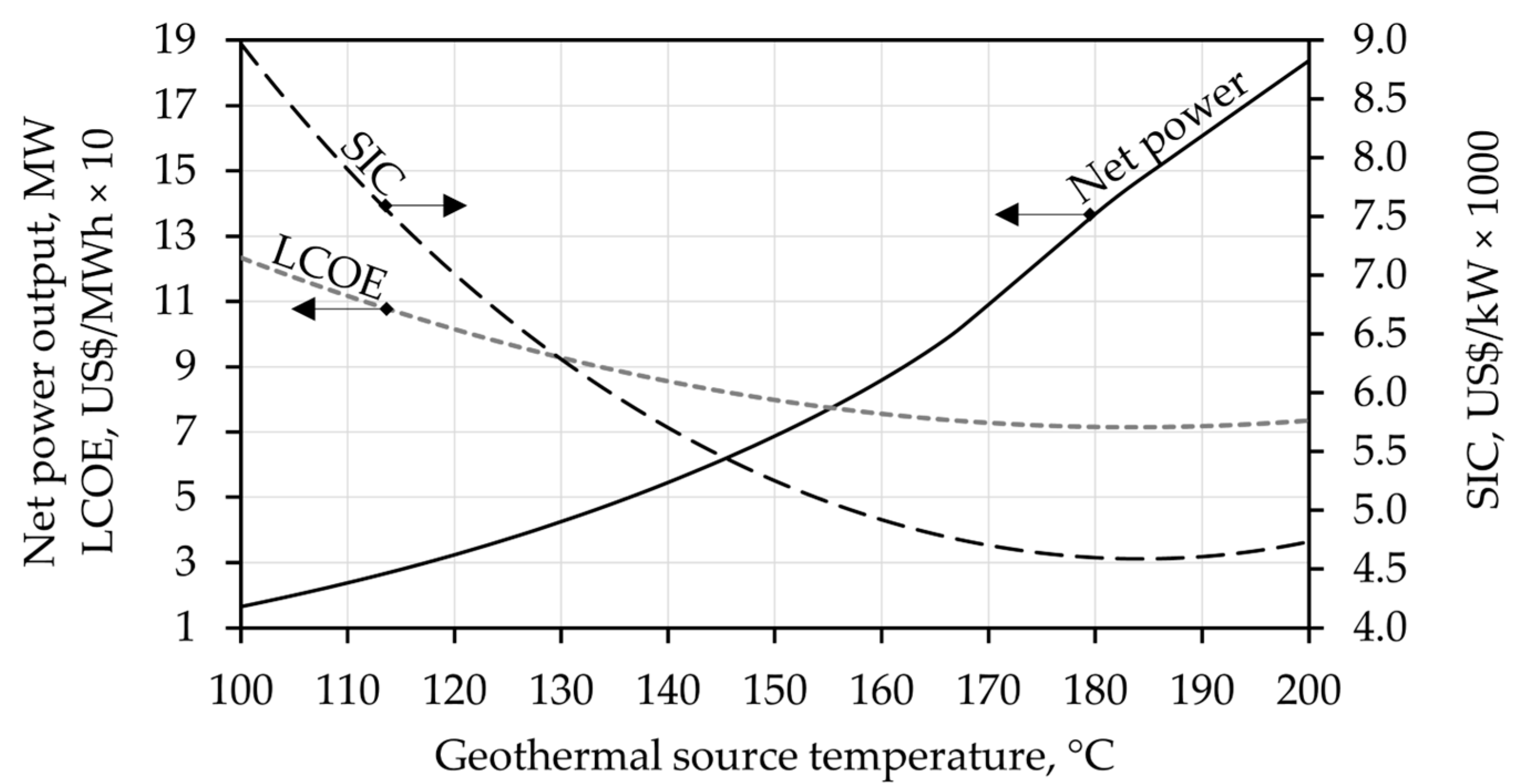

3.3.4. Subcritical vs. Supercritical Isobutane Cycles

4. Conclusions

- The thermal optimum point (maximum net power output) is different from the economic optimum point (minimum LCOE);

- For geothermal source temperatures of 100–158 °C, the thermal optimum points are found on the dry saturated curve of subcritical isobutane cycles;

- For geothermal source temperatures of 158–179 °C, the thermal optimum points are obtained with slightly superheated subcritical cycles’ vapor (ΔTsup < 5 °C);

- Only for higher geothermal source temperatures (above 179 °C) do supercritical isobutane cycles achieve a better thermal performance (higher net power output) than subcritical cycles while the economic performance (LCOE and SIC) is comparable;

- Binary cycles with near-critical pressures at the turbine inlet expand through the wet vapor region. While vapor superheating eliminates the risk of droplet formation and turbine blade erosion, it also causes departure from the thermal optimum point;

- For subcritical superheated isobutane cycles, the economic optimum point is found further in the superheated region relative to the thermal optimum point;

- Internal heat recuperation offers an improved thermoeconomic performance over non-recuperated cycles: the net power increases and the LCOE decreases, although installation costs (SIC) increase because of the costs of the additional heat exchanger;

- The estimated LCOE and SIC of isobutane binary cycles depend on the geothermal source temperature (Tgeo) and mass flow rate (geo), i.e., the power plant size;

- For a geothermal source with geo = 225 kg/s and 120 < Tgeo < 150 °C, the estimated costs are 100 > LCOE > 80 USD/MWh and 7000 > SIC > 5250 USD/kW, while for medium–high geothermal temperatures of 150 < Tgeo < 200 °C, the estimated costs are 80 > LCOE > 70 USD/MWh and 5250 > SIC > 4600 USD/kW.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Huttrer, G.W. Geothermal Power Generation in the World 2015-2020 Update Report. In Proceedings of the World Geothermal Congress 2020, Reykjavik, Iceland, 26 April–2 May 2020; Available online: https://www.geothermal-energy.org/pdf/IGAstandard/WGC/2020/01017.pdf (accessed on 10 April 2023).

- Krieger, M.; Kurek, K.A.; Brommer, M. Global Geothermal Industry Data Collection: A Systematic Review. Geothermics 2022, 104, 102457. [Google Scholar] [CrossRef]

- International Renewable Energy Agency. Renewable Power Generation Costs in 2021; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2022; Available online: https://www.irena.org/publications/2022/Jul/Renewable-Power-Generation-Costs-in-2021 (accessed on 10 April 2023).

- BP. Statistical Review of World Energy 2020, 69th ed.; BP p.l.c.: London, UK, 2020; Available online: https://www.bp.com/en/global/corporate/energy-economics/statistical-review-of-world-energy.html (accessed on 10 April 2023).

- Alsaleh, M.; Wang, X. How Does Information and Communication Technology Affect Geothermal Energy Sustainability? Sustainability 2023, 15, 1071. [Google Scholar] [CrossRef]

- DiPippo, R. Geothermal Power Plants: Principles, Applications, Case Studies and Environmental Impact, 4th ed.; Butterworth-Heinemann: Waltham, MA, USA, 2016. [Google Scholar]

- Kumar, L.; Hossain, M.S.; Assad, M.E.H.; Manoo, M.U. Technological Advancements and Challenges of Geothermal Energy Systems: A Comprehensive Review. Energies 2022, 15, 9058. [Google Scholar] [CrossRef]

- Ambriz-Díaz, V.M.; Rosas, I.Y.; Chávez, O.; Rubio-Maya, C. 4E Assessment of an Organic Rankine Cycle (ORC) Activated with Waste Heat of a Flash–Binary Geothermal Power Plant. Entropy 2022, 24, 1832. [Google Scholar] [CrossRef] [PubMed]

- Song, J.; Loo, P.; Teo, J.; Markides, C.N. Thermo-Economic Optimization of Organic Rankine Cycle (ORC) Systems for Geothermal Power Generation: A Comparative Study of System Configurations. Front. Energy Res. 2020, 8, 6. [Google Scholar] [CrossRef]

- Putera, A.D.P.; Hidayah, A.N.; Subiantoro, A. Thermo-Economic Analysis of A Geothermal Binary Power Plant in Indonesia—A Pre-Feasibility Case Study of the Wayang Windu Site. Energies 2019, 12, 4269. [Google Scholar] [CrossRef]

- Javanshir, N.; Seyed Mahmoudi, S.M.; Rosen, M.A. Thermodynamic and Exergoeconomic Analyses of a Novel Combined Cycle Comprised of Vapor-Compression Refrigeration and Organic Rankine Cycles. Sustainability 2019, 11, 3374. [Google Scholar] [CrossRef]

- Javanshir, N.; Mahmoudi, S.M.S.; Kordlar, M.A.; Rosen, M.A. Energy and Cost Analysis and Optimization of a Geothermal-Based Cogeneration Cycle Using an Ammonia-Water Solution: Thermodynamic and Thermoeconomic Viewpoints. Sustainability 2020, 12, 484. [Google Scholar] [CrossRef]

- Güler, O.V.; Gürbüz, E.Y.; Georgiev, A.G.; Keçebaş, A. Advanced Exergoeconomic Assessment of CO2 Emissions, Geo-Fluid and Electricity in Dual Loop Geothermal Power Plant. Energies 2023, 16, 3466. [Google Scholar] [CrossRef]

- Tagliaferri, M.; Gładysz, P.; Ungar, P.; Strojny, M.; Talluri, L.; Fiaschi, D.; Manfrida, G.; Andresen, T.; Sowiżdżał, A. Techno-Economic Assessment of the Supercritical Carbon Dioxide Enhanced Geothermal Systems. Sustainability 2022, 14, 16580. [Google Scholar] [CrossRef]

- Toffolo, A.; Lazzaretto, A.; Manente, G.; Paci, M.A. Multi-criteria Approach for the Optimal Selection of Working Fluid and Design Parameters in Organic Rankine Cycle systems. Appl. Energy 2014, 121, 219–232. [Google Scholar] [CrossRef]

- Wang, D.; Ling, X.; Peng, H.; Liu, L.; Tao, L. Efficiency and Optimal Performance Evaluation of Organic Rankine Cycle for Low Grade Waste Heat Power Generation. Energy 2013, 50, 343–352. [Google Scholar] [CrossRef]

- Mustapić, N.; Brkić, V.; Duić, Ž.; Kralj, T. Thermodynamic Optimization of Advanced Organic Rankine Cycle Configurations for Geothermal Energy Applications. Energies 2022, 15, 6990. [Google Scholar] [CrossRef]

- Prasetyo, T.; Surindra, M.D.; Caesarendra, W.; Taufik; Glowacz, A.; Irfan, M.; Glowacz, W. Influence of Superheated Vapour in Organic Rankine Cycles with Working Fluid R123 Utilizing Low-Temperature Geothermal Resources. Symmetry 2020, 12, 1463. [Google Scholar] [CrossRef]

- Algieri, A. Energy Exploitation of High-Temperature Geothermal Sources in Volcanic Areas: A Possible ORC Application in Phlegraean Fields (Southern Italy). Energies 2018, 11, 618. [Google Scholar] [CrossRef]

- Alghamdi, M.; Al-Kharsan, I.; Shahab, S.; Albaker, A.; Alayi, R.; Kumar, L.; El Haj Assad, M. Investigation of Energy and Exergy of Geothermal Organic Rankine Cycle. Energies 2023, 16, 2222. [Google Scholar] [CrossRef]

- Bell, I.H.; Wronski, J.; Quoilin, S.; Lemort, V. Pure and Pseudo-pure Fluid Thermophysical Property Evaluation and the Open-Source Thermophysical Property Library CoolProp. Ind. Eng. Chem. Res. 2014, 53, 2498–2508. Available online: http://www.coolprop.org/ (accessed on 10 April 2023). [CrossRef] [PubMed]

- Tramošljika, B.; Blecich, P.; Bonefačić, I.; Glažar, V. Advanced Ultra-Supercritical Coal-Fired Power Plant with Post-Combustion Carbon Capture: Analysis of Electricity Penalty and CO2 Emission Reduction. Sustainability 2021, 13, 801. [Google Scholar] [CrossRef]

- Yunus, A.C.; Afshin, J.G. Heat and Mass Transfer: Fundamentals and Applications, 6th ed.; McGraw-Hill Education: New York, NY, USA, 2020. [Google Scholar]

- Serth, R.W.; Lestina, T. Process Heat Transfer: Principles, Applications and Rules of Thumb, 2nd ed.; Academic Press: Cambridge, MA, USA, 2014. [Google Scholar]

- Clotworthy, A. Response of Wairakei Geothermal Reservoir to 40 years of Production. In Proceedings of the World Geothermal Congress 2000, Kyushu-Tohoku, Japan, 28 May–10 June 2000; Available online: https://www.geothermal-energy.org/pdf/IGAstandard/WGC/2000/R0080.PDF (accessed on 10 April 2023).

- Budisulistyo, D.; Wong, C.S.; Krumdieck, S. Lifetime Design Strategy for Binary Geothermal Plants Considering Degradation of Geothermal Resource Productivity. Energy Convers. Manag. 2017, 132, 1–13. [Google Scholar] [CrossRef]

- Sanyal, S.K. Cost of Geothermal Power and Factors That Affect it. In Proceedings of the 29th Workshop on Geothermal Reservoir Engineering, Stanford, CA, USA, 26–28 January 2004; Available online: https://pangea.stanford.edu/ERE/pdf/IGAstandard/SGW/2004/Sanyal.pdf (accessed on 10 April 2023).

- Jardas, D.; Arbula Blecich, A.; Blecich, P. Factors Affecting the Cost of Electricity from Geothermal Power Plants. Innovations 2021, 9, 137–140. Available online: https://stumejournals.com/journals/innovations/2021/4/137 (accessed on 10 April 2023).

- Turton, G.; Shaeiwitz, J.A.; Bhattacharya, D.; Whiting, W.B. Analysis, Synthesis and Design of Chemical Processes, 5th ed.; Pearson Education: New York, NJ, USA, 2018. [Google Scholar]

- Brennan, D.J.; Golonka, K.A. New Factors for Capital Cost Estimation in Evolving Process Designs. Chem. Eng. Res. Des. 2002, 80, 579–586. [Google Scholar] [CrossRef]

- Wain, Y.A. Updating the Lang Factor and Testing its Accuracy, Reliability and Precision as a Stochastic Cost Estimating Method. PM World J. 2014, 3, 1–17. Available online: https://pmworldlibrary.net/wp-content/uploads/2014/10/pmwj27-oct2014-Wain-updating-the-lang-factor-Featured-Paper.pdf (accessed on 10 April 2023).

- Lemmens, S. Cost Engineering Techniques and Their Applicability for Cost Estimation of Organic Rankine Cycle Systems. Energies 2016, 9, 485. [Google Scholar] [CrossRef]

- Heberle, F.; Brüggemann, D. Thermo-Economic Evaluation of Organic Rankine Cycles for Geothermal Power Generation Using Zeotropic Mixtures. Energies 2015, 8, 2097–2124. [Google Scholar] [CrossRef]

- Chemical Engineering: Essentials for the CPI Professional (www.chemengonline.com). Available online: https://www.nxtbook.com/accessintelligence/ChemicalEngineering/chemical-engineering-april-2023/index.php (accessed on 10 April 2023).

- Towler, G.; Sinnott, R. Chemical Engineering Design: Principles, Practice and Economics of Plant and Process Design, 3rd ed.; Butterworth-Heinemann (Elsevier): Oxford, UK, 2021. [Google Scholar]

- Shamoushaki, M.; Niknam, P.H.; Talluri, L.; Manfrida, G.; Fiaschi, D. Development of Cost Correlations for the Economic Assessment of Power Plant Equipment. Energies 2021, 14, 2665. [Google Scholar] [CrossRef]

- Ekonerg—Energy Research and Environmental Protection Institute: Environmental Impact for the Geothermal Power Plant Legrad. 2019. Available online: https://mingor.gov.hr/UserDocsImages/UPRAVA-ZA-PROCJENU-UTJECAJA-NA-OKOLIS-ODRZIVO-GOSPODARENJE-OTPADOM/Opuo/31_10_2019_Elaborat_Geotermalna_elektrana_Legrad_1.pdf (accessed on 10 April 2023).

- Nasday Historical Data: Mont Belvieu LDH Isobutane (OPIS) Swap. Available online: https://www.nasdaq.com/market-activity/commodities/mbl:nmx/historical (accessed on 10 April 2023).

- Vengateson, U. Cooling Towers: Estimate Evaporation Loss and Makeup Water Requirements, Chemical Engineering Online. Available online: https://www.chemengonline.com/cooling-towers-estimate-evaporation-loss-and-makeup-water-requirements/?printmode=1 (accessed on 10 April 2023).

- Adams, B.M.; Ogland-Hand, J.D.; Bielicki, J.M.; Schädle, P.; Saar, M.O. Estimating the Geothermal Electricity Generation Potential of Sedimentary Basins Using genGEO (The Generalizable GEOthermal Techno-Economic Simulator); ChemRxiv: Cambridge, UK, 2021. [Google Scholar] [CrossRef]

- DiMarzio, G.; Angelini, L.; Price, W.; Chin, C.; Harris, S. The Stillwater Triple Hybrid Power Plant: Integrating Geothermal, Solar Photovoltaic and Solar Thermal Power Generation. In Proceedings of the World Geothermal Congress, Melbourne, Australia, 19–25 April 2015; Available online: https://pangea.stanford.edu/ERE/db/WGC/papers/WGC/2015/38001.pdf (accessed on 10 April 2023).

- Bokelman, B.; Michaelides, E.E.; Michaelides, D.N. A Geothermal-Solar Hybrid Power Plant with Thermal Energy Storage. Energies 2020, 13, 1018. [Google Scholar] [CrossRef]

- Lazard’s Levelized Cost Of Energy Analysis—Version 16.0. 2023. Available online: https://www.lazard.com/media/typdgxmm/lazards-lcoeplus-april-2023.pdf (accessed on 16 May 2023).

- Lawless, J.; van Campen, B.; Randle, J. Future Geothermal Generation Stack, A Report for the Ministry of Business, Innovation and Employment; Ministry of Business, Innovation and Employment (MBIE): Wellington, New Zealand, 2020. Available online: https://www.mbie.govt.nz/assets/future-geothermal-generation-stack.pdf (accessed on 16 May 2023).

- Robins, J.C.; Kolker, A.; Flores-Espino, F.; Pettitt, W.; Schmidt, B.; Beckers, K.; Pauling, H.; Anderson, B. 2021 U.S. Geothermal Power Production and District Heating Market Report; National Renewable Energy Laboratory: Golden, CO, USA, 2021. Available online: https://www.nrel.gov/docs/fy21osti/78291.pdf (accessed on 16 May 2023).

- Eastland Group Annual Report. 2019. Available online: https://www.eastland.nz/wp-content/uploads/2019/06/ELG_Annual-Report_2019.pdf (accessed on 16 May 2023).

- Eastland Group Annual Report. 2022. Available online: https://www.eastland.nz/wp-content/uploads/2022/08/Eastland-Group-annual-report-2022.pdf (accessed on 16 May 2023).

- De Graaf, P. (The Northern Advocate): Ngāwhā Power Station Opening Heralds New Era of Far North Self-Reliance. Available online: https://www.nzherald.co.nz/northern-advocate/news/ngawha-power-station-opening-heralds-new-era-of-far-north-self-reliance/ZN5YOOHU4GAA2MXL2ICKDXSBJM/ (accessed on 16 May 2023).

- ThinkGeoEnergy. Croatia’s First Geothermal Plant Officially Inaugurated. Available online: https://www.thinkgeoenergy.com/croatias-first-geothermal-plant-officially-inaugurated/ (accessed on 16 May 2023).

- Mohammadzadeh, A.; Sabzalian, M.H.; Zhang, C.; Castillo, O.; Sakthivel, R.; El-Sousy, F.F.M. Modern Adaptive Fuzzy Control Systems; Springer: Cham, Switzerland, 2023. [Google Scholar]

- Mohammadzadeh, A.; Sabzalian, M.H.; Castillo, O.; Sakthivel, R.; El-Sousy, F.F.M.; Mobayen, S. Neural Networks and Learning Algorithms in MATLAB; Springer: Cham, Switzerland, 2022. [Google Scholar]

- Imre, A.R.; Kustán, R.; Groniewsky, A. Thermodynamic Selection of the Optimal Working Fluid for Organic Rankine Cycles. Energies 2019, 12, 2028. [Google Scholar] [CrossRef]

- Györke, G.; Groniewsky, A.; Imre, A.R. A Simple Method of Finding New Dry and Isentropic Working Fluids for Organic Rankine Cycle. Energies 2019, 12, 480. [Google Scholar] [CrossRef]

- White, M.T. Cycle and Turbine Optimization for an ORC Operating with Two-Phase Expansion. Appl. Therm. Eng. 2021, 192, 116852. [Google Scholar] [CrossRef]

- Li, H.; Rane, S.; Yu, Z.; Yu, G. An Inverse Mean-Line Design Method for Optimizing Radial Outflow Two-Phase Turbines in Geothermal Systems. Renew. Energy 2021, 168, 463–490. [Google Scholar] [CrossRef]

- Li, H.; Rane, S.; Yu, Z. Investigation of the Performance and Flow Characteristics of Two-Phase Reaction Turbines in Total Flow Geothermal Systems. Renew. Energy 2021, 175, 345–372. [Google Scholar] [CrossRef]

- Sun, J.; Liu, Q.; Duan, Y. Effects of Evaporator Pinch Point Temperature Difference on Thermo-Economic Performance of Geothermal Organic Rankine Cycle Systems. Geothermics 2018, 75, 249–258. [Google Scholar] [CrossRef]

| Reynolds Number Range | Constant C | Exponent x |

|---|---|---|

| 0–500 | 1.04 | 0.4 |

| 500–1000 | 0.71 | 0.5 |

| 1000–2 × 105 | 0.35 (XT/XL)0.2 | 0.6 |

| 2 × 105–2 × 106 | 0.031 (XT/XL)0.2 | 0.8 |

| Cost Parameter | Value | Ref. |

|---|---|---|

| Discount rate (real value), r | 5.0% | [3] |

| Price escalation rate, e | 2% | [26,27] |

| Capacity degradation rate, d | 1% | [25] |

| Project lifetime, T | 25 years | [3] |

| Contingencies and fees, fTM | 18% | [29] |

| Auxiliary costs, fAUX | 50% | [29] |

| Annual O&M costs | 135 USD/kW | [3] |

| Equipment Type | Size Unit | Cost Correlation (CEQ, i in USD) and Literature Source | Reference Cost Index (CIref) |

|---|---|---|---|

| Turbine | Power (kW) | [35] | 631.8 (CE: equipment, 2010) |

| Shell-and-tube heat exchanger | Heat transfer area, A (m2) | [36] | 614.5 (CE: heat exchangers, 2020) |

| Centrifugal pump | Power (kW) | [36] | 1084.3 (CE: pumps, 2020) |

| Generator | Power (kW) | [15] | 511.3 (CE: electrical equipment, 2012) |

| Cooling tower | Water flow rate (l/s) | [35] | 631.8 (CE: equipment, 2010) |

| Isobutane | Mass (kg): 7 kg/kWG | [37] | 1036.9: (CE: equipment, 2022) |

| Correction Factor | Range/Type | Value |

|---|---|---|

| Material type, fM | Stainless steel (SS) | 1.5 |

| Pressure factor constants for heat exchangers, fP (20) | p < 5 bar | C1 = C2 = C3 = 0 |

| 5 < p < 140 bar | C1 = 0.03881 C2 = −0.11272 C3 = 0.08183 | |

| Pressure factor constants for centrifugal pumps, fP (20) | p < 10 bar | C1 = C2 = C3 = 0 |

| 10 < p < 100 bar | C1 = –0.3935 | |

| C2 = 0.3957 | ||

| C3 = –0.00226 | ||

| Contingencies and fees, fTM | Greenfield projects | 1.18 |

| Auxiliary costs, fAUX | 0.5 |

| Decision Variable | Value | |||||

|---|---|---|---|---|---|---|

| Geothermal fluid inlet temperature, °C | 130 | 170 | ||||

| Geothermal fluid return temperature, °C | >70 | >70 | ||||

| Geothermal fluid mass flow rate, kg/s | 100 | 100 | ||||

| Turbine inlet temperature, °C | 84.4 | 135.1 | ||||

| Maximum ORC cycle pressure, bar | 14.3 | 35.2 | ||||

| Condenser saturation temperature, °C | 32.8 °C | 33 °C | ||||

| Pinch point temperature difference, °C | 10 | 10 | ||||

| Efficiency: turbine/pumps/generator, - | 0.85/0.70/0.96 | 0.85/0.70/0.96 | ||||

| Results comparison | Present model | Reference data [15] | % diff. | Present model | Reference data [15] | % diff. |

| ORC fluid mass flow rate | 63.3 kg/s | 62.4 kg/s | 1.44 | 104.17 kg/s | 105.6 kg/s | −1.35 |

| Gross power output | 2.36 MW | 2.39 MW | −1.26 | 6.53 MW | 6.61 MW | −1.21 |

| Net power output | 1.77 MW | 1.81 MW | −2.21 | 5.02 MW | 5.08 MW | −1.18 |

| Auxiliary power (feed pump, fans) | 0.59 MW | 0.58 MW | 1.72 | 1.51 MW | 1.53 MW | −1.31 |

| Net thermal efficiency | 7.24% | 7.48% | −3.21 | 11.80% | 11.94% | −1.17 |

| Cost Type | Present Model USD2022 | Reference Data [15] | Difference | |

|---|---|---|---|---|

| USD2009 | USD2022 | |||

| Equipment costs, ×106 | 83.48 | 44.75 | 75.63 | 10.38% |

| Total module costs, ×106 | 124.19 | 72.67 | 122.82 | 1.11% |

| Greenfield project costs, ×106 | 165.93 | 132.88 | 224.57 | –26.11% |

| Specific installation costs, USD/kW | 4938 | 3955 | 6684 | –26.11% |

| Value | Turbine Inlet Pressure | ||

|---|---|---|---|

| 21.6 bar | 28.9 bar | 36.0 bar | |

| Turbine inlet temperature, °C | 104.55 | 121.09 | 134.18 |

| Condenser saturation pressure, bar | 4.41 | 4.41 | 4.41 |

| Isobutane mass flow rate, kg/s | 198.97 | 169.22 | 190.03 |

| Reinjection temperature, °C | 72.50 | 84.34 | 79.87 |

| Pinch point temperature difference, °C | 10.0 | 10.0 | 10.0 |

| Evaporator heat flow rate, MW | 41.80 | 25.96 | 8.81 |

| Preheater heat flow rate, MW | 39.73 | 44.41 | 62.68 |

| Desuperheater heat flow rate, MW | 1.69 | 1.15 | 0 |

| Condenser heat flow rate, MW | 67.36 | 57.28 | 61.03 |

| Turbine gross power, MW | 10.85 | 10.52 | 11.51 |

| Gross power output, MW | 10.42 | 10.11 | 11.05 |

| Feed pump power, MW | 0.84 | 1.02 | 1.49 |

| Cooling pump power, MW | 0.60 | 0.51 | 0.55 |

| Auxiliary power, MW | 0.52 | 0.51 | 0.55 |

| Net power output, MW | 8.46 | 8.07 | 8.46 |

| Gross thermal efficiency, % | 12.78 | 14.36 | 14.78 |

| Net thermal efficiency, % | 10.37 | 11.47 | 11.32 |

| Absolute net efficiency, % | 10.08 | 9.62 | 10.08 |

| Cost of equipment, ×106 USD2022 | 22.61 | 20.47 | 22.13 |

| Total module costs, ×106 USD2022 | 30.60 | 28.44 | 31.42 |

| Initial investment, ×106 USD2022 | 41.91 | 38.71 | 42.48 |

| SIC, USD2022/kW | 4955.10 | 4795.27 | 5017.36 |

| LCOE, USD2022/MWh | 76.39 | 74.30 | 76.86 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arbula Blecich, A.; Blecich, P. Thermoeconomic Analysis of Subcritical and Supercritical Isobutane Cycles for Geothermal Power Generation. Sustainability 2023, 15, 8624. https://doi.org/10.3390/su15118624

Arbula Blecich A, Blecich P. Thermoeconomic Analysis of Subcritical and Supercritical Isobutane Cycles for Geothermal Power Generation. Sustainability. 2023; 15(11):8624. https://doi.org/10.3390/su15118624

Chicago/Turabian StyleArbula Blecich, Andrea, and Paolo Blecich. 2023. "Thermoeconomic Analysis of Subcritical and Supercritical Isobutane Cycles for Geothermal Power Generation" Sustainability 15, no. 11: 8624. https://doi.org/10.3390/su15118624