Process Parameter Optimization of Additively Manufactured Parts Using Intelligent Manufacturing

Abstract

:1. Introduction

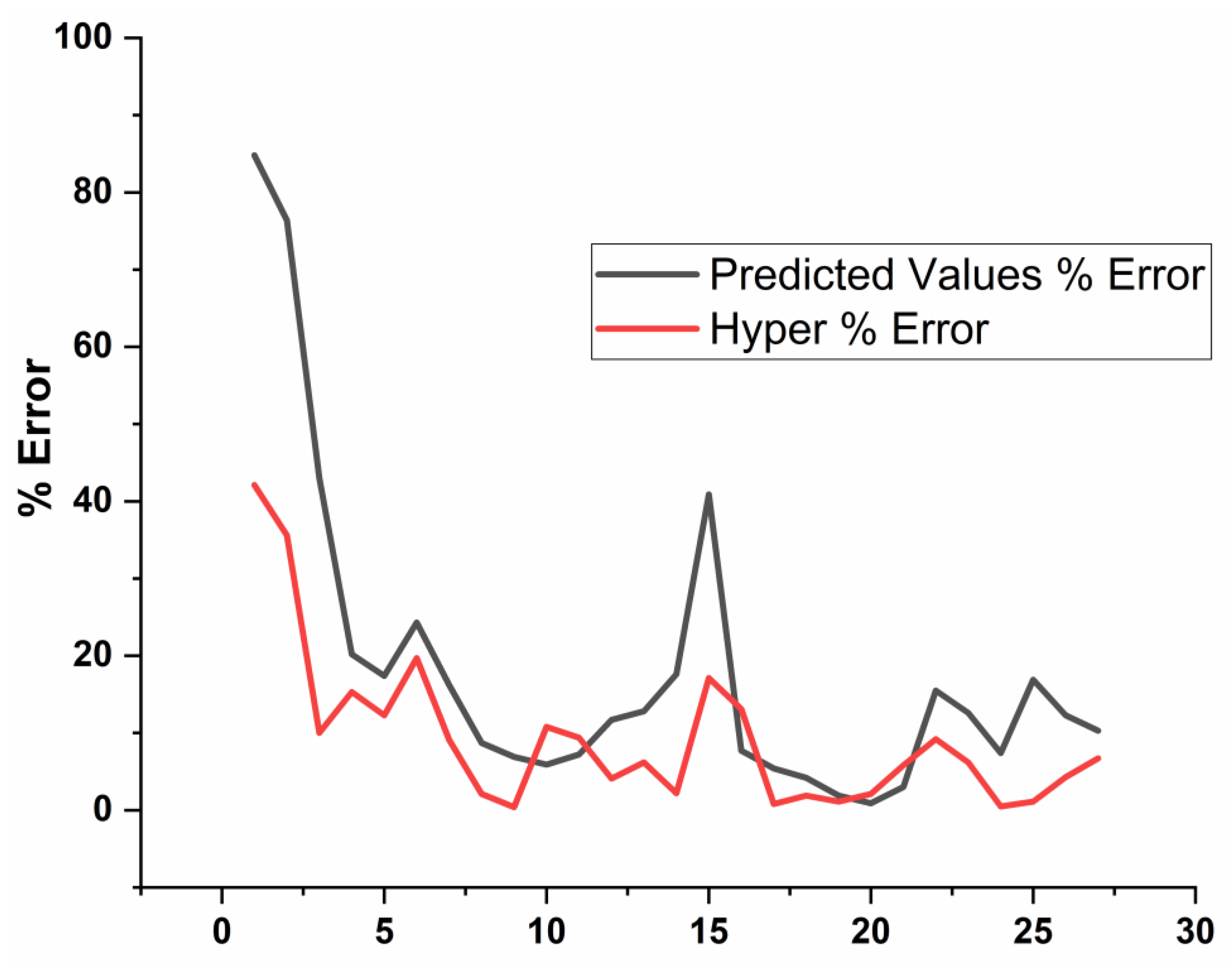

2. Methodology and Experimental Procedure

2.1. FDM Process Parameters’ Selection

2.2. Materials and Geometry of the Part

2.3. Selection of Orthogonal Array (OA) and Experiments

3. Database on Microsoft Azure

3.1. Edit Metadata and Filter Based Feature Selection

| Layer Height (mm) | Infill Density (%) | Infill Pattern | Number of Perimeter Walls | Tensile Strength (MPa) |

|---|---|---|---|---|

| 0.140533 | 0.539466 | 0.012817 | 0.661683 | 1 |

3.2. Data Segmentation and Algorithm for Regression

3.3. Tune Model Hyperparameters

3.4. Score and Evaluate Model

3.5. Web Service

3.6. Relationship of Input Parameters with Tensile Strength

3.7. Optimal Conditions

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ystems, S. A Dditive M Anufacturing for I Ntegrated S Pacecraft P Ropulsion. J. Manuf. Technol. Res. 2016, 5, 75–96. [Google Scholar]

- ISO/ASTM52900-15; Standard Terminology for Additive Manufacturing—General Principles—Terminology (ASTM52900). International Organization: Geneva, Switzerland, 2015; pp. 1–9.

- Li, J.H.; Huang, X.D.; Durandet, Y.; Ruan, D. A review of the mechanical properties of additively manufactured fiber reinforced composites. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1067, 012105. [Google Scholar] [CrossRef]

- Adefuye, O.A.; Raji, N.A.; Adedeji, K.A.; Fadipe, O.L.; Olowu, B. Additive Manufacturing and Sand-Casting Foundries Practices in Nigeria. Eng. Technol. Res. J. 2019, 4, 55–63. [Google Scholar] [CrossRef]

- Doshi, M.; Mahale, A.; Singh, S.K.; Deshmukh, S. Printing Parameters and Materials Affecting Mechanical Properties of FDM-3D Printed Parts: Perspective and Prospects. Mater. Today Proc. 2021, 50, 2269–2275. [Google Scholar] [CrossRef]

- Ghabezi, P.; Flanagan, T.; Harrison, N. Short Basalt Fibre Reinforced Recycled Polypropylene Filaments for 3D Printing. Mater. Lett. 2022, 326, 132942. [Google Scholar] [CrossRef]

- Srinivasan, R.; Pridhar, T.; Ramprasath, L.S.; Sree Charan, N.; Ruban, W. Prediction of Tensile Strength in FDM Printed ABS Parts Using Response Surface Methodology (RSM). Mater. Today Proc. 2020, 27, 1827–1832. [Google Scholar] [CrossRef]

- Sumalatha, M.; Malleswara Rao, J.N.; Supraja Reddy, B. Optimization Of Process Parameters In 3d Printing-Fused Deposition Modeling Using Taguchi Method. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1112, 012009. [Google Scholar] [CrossRef]

- Zhong, R.Y.; Xu, X.; Klotz, E.; Newman, S.T. Intelligent Manufacturing in the Context of Industry 4.0: A Review. Engineering 2017, 3, 616–630. [Google Scholar] [CrossRef]

- Dilberoglu, U.M.; Gharehpapagh, B.; Yaman, U.; Dolen, M. The Role of Additive Manufacturing in the Era of Industry 4.0. Procedia Manuf. 2017, 11, 545–554. [Google Scholar] [CrossRef]

- Yun Yee, W.; Chang Choon, C.; Chee Siong, T.; Ambar, R.; Helmy Abd Wahab, M. IoT-Based Production Output Monitoring System for Plastic Packaging Manufacturing Process. IOP Conf. Ser. Mater. Sci. Eng. 2020, 864, 012087. [Google Scholar] [CrossRef]

- Majeed, A.; Zhang, Y.; Ren, S.; Lv, J.; Peng, T.; Waqar, S.; Yin, E. A Big Data-Driven Framework for Sustainable and Smart Additive Manufacturing. Robot. Comput. Integr. Manuf. 2021, 67, 102026. [Google Scholar] [CrossRef]

- Wenzel, S.; Slomski-Vetter, E.; Melz, T. Optimizing System Reliability in Additive Manufacturing Using Physics-Informed Machine Learning. Machines 2022, 10, 525. [Google Scholar] [CrossRef]

- Meng, L.; McWilliams, B.; Jarosinski, W.; Park, H.Y.; Jung, Y.G.; Lee, J.; Zhang, J. Machine Learning in Additive Manufacturing: A Review. Jom 2020, 72, 2363–2377. [Google Scholar] [CrossRef]

- Gogtay, N.J.; Deshpande, S.P.; Thatte, U.M. Principles of Regression Analysis. J. Assoc. Physicians India 2017, 65, 48–52. [Google Scholar] [CrossRef]

- Jo, B.W.; Khan, R.M.A. An Internet of Things System for Underground Mine Air Quality Pollutant Prediction Based on Azure Machine Learning. Sensors 2018, 18, 930. [Google Scholar] [CrossRef] [Green Version]

- Milad, A.; Yusoff, N.I.M.; Majeed, S.A.; Ibrahim, A.N.H.; Hassan, M.A.; Ali, A.S.B. Using an Azure Machine Learning Approach for Flexible Pavement Maintenance. In Proceedings of the 2020 16th IEEE International Colloquium on Signal Processing & Its Application (CSPA 2020), Langkawi, Malaysia, 28–29 February 2020; pp. 146–150. [Google Scholar] [CrossRef]

- Zaman, U.K.; Rivette, M.; Siadat, A.; Mousavi, S.M. Integrated Product-Process Design: Material and Manufacturing Process Selection for Additive Manufacturing Using Multi-Criteria Decision Making. Robot. Comput. Integr. Manuf. 2018, 51, 169–180. [Google Scholar] [CrossRef]

- Which Layer Height is Best for 3D Printing? Available online: https://3dprinterly.com/which-layer-height-is-best-for-3d-printing/#:~:text=The%20best%20layer%20height%20for%20an%20Ender%203%20is%20between,height%20that%20balances%20out%20well (accessed on 11 February 2022).

| Ser No. | Control Parameter | Unit |

|---|---|---|

| 1 | Layer height | mm |

| 2 | Infill density | % |

| 3 | Infill pattern | Grid/honeycomb/triangle |

| 4 | Number of perimeter walls | - |

| FDM Process Parameters | Unit | Level 1 | Level 2 | Level 3 |

|---|---|---|---|---|

| Layer height | mm | 0.16 | 0.20 | 0.28 |

| Infill density | % | 10 | 30 | 70 |

| Infill pattern | - | Grid | Honeycomb | Triangle |

| No. of perimeter walls | - | 01 | 02 | 04 |

| Ser | Layer Height (mm) | Infill Density (%) | Infill Pattern | Number of Perimeter Walls | Tensile Strength (MPa) |

|---|---|---|---|---|---|

| 1 | 0.16 | 10 | Grid | 1 | 5.65 |

| 2 | 0.16 | 10 | Grid | 1 | 5.92 |

| 3 | 0.16 | 10 | Grid | 1 | 7.3 |

| 4 | 0.16 | 30 | Honeycomb | 2 | 14.09 |

| 5 | 0.16 | 30 | Honeycomb | 2 | 13.61 |

| 6 | 0.16 | 30 | Honeycomb | 2 | 14.85 |

| 7 | 0.16 | 70 | Triangle | 4 | 16.98 |

| 8 | 0.16 | 70 | Triangle | 4 | 18.15 |

| 9 | 0.16 | 70 | Triangle | 4 | 18.45 |

| 10 | 0.2 | 10 | Honeycomb | 4 | 13.06 |

| 11 | 0.2 | 10 | Honeycomb | 4 | 13.23 |

| 12 | 0.2 | 10 | Honeycomb | 4 | 13.91 |

| 13 | 0.2 | 30 | Triangle | 1 | 10.97 |

| 14 | 0.2 | 30 | Triangle | 1 | 10.52 |

| 15 | 0.2 | 30 | Triangle | 1 | 8.78 |

| 16 | 0.2 | 70 | Grid | 2 | 17.48 |

| 17 | 0.2 | 70 | Grid | 2 | 15.31 |

| 18 | 0.2 | 70 | Grid | 2 | 15.48 |

| 19 | 0.28 | 10 | Triangle | 2 | 11.61 |

| 20 | 0.28 | 10 | Triangle | 2 | 11.73 |

| 21 | 0.28 | 10 | Triangle | 2 | 12.19 |

| 22 | 0.28 | 30 | Grid | 4 | 18.29 |

| 23 | 0.28 | 30 | Grid | 4 | 17.69 |

| 24 | 0.28 | 30 | Grid | 4 | 16.69 |

| 25 | 0.28 | 70 | Honeycomb | 1 | 13.09 |

| 26 | 0.28 | 70 | Honeycomb | 1 | 12.41 |

| 27 | 0.28 | 70 | Honeycomb | 1 | 12.13 |

| Setting | Value |

|---|---|

| Normalize Features | True |

| Averaged | True |

| Learning Rate | 0.27507 |

| Num Iterations | 1 |

| Decrease Learning Rate | True |

| L2 Regularizer Weight | 0 |

| Allow Unknown Levels | False |

| Random Number Seed | 0 |

| Learning Rate | Number of Iterations | L2 Regularizer Weight | Mean Absolute Error | Root Mean Absolute Error | Relative Absolute Error | Relative Squared Error | Coefficient of Determination |

|---|---|---|---|---|---|---|---|

| 0.425057 | 34 | 0 | 1.451801 | 1.716379 | 0.48902 | 0.191385 | 0.808615 |

| Feature | Weight before Tune Model Hyperparameters | Weight after Tune Model Hyperparameters |

|---|---|---|

| Layer Height (mm) | −0.621489 | 1.45757 |

| Bias | 6.43571 | 4.79949 |

| Perimeter Walls | 5.50991 | 7.3376 |

| Infill Pattern_Honeycomb_1 | 0.545529 | 1.85053 |

| Infill Pattern_Grid_0 | 2.62925 | 1.39499 |

| Infill Pattern_Triangle_2 | 3.26093 | 1.55398 |

| Infill Density (%) | 4.5205 | 4.83268 |

| Metrics | Value before Tune Model Hyperparameters | Value after Tune Model Hyperparameters |

|---|---|---|

| Mean Absolute Error | 2.233084 | 1.451801 |

| Root Mean Absolute Error | 2.595885 | 1.716379 |

| Relative Absolute Error | 0.752184 | 0.48902 |

| Relative Squared Error | 0.437776 | 0.191385 |

| Coefficient of Determination | 0.562224 | 0.808615 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rehman, R.U.; Zaman, U.K.u.; Aziz, S.; Jabbar, H.; Shujah, A.; Khaleequzzaman, S.; Hamza, A.; Qamar, U.; Jung, D.-W. Process Parameter Optimization of Additively Manufactured Parts Using Intelligent Manufacturing. Sustainability 2022, 14, 15475. https://doi.org/10.3390/su142215475

Rehman RU, Zaman UKu, Aziz S, Jabbar H, Shujah A, Khaleequzzaman S, Hamza A, Qamar U, Jung D-W. Process Parameter Optimization of Additively Manufactured Parts Using Intelligent Manufacturing. Sustainability. 2022; 14(22):15475. https://doi.org/10.3390/su142215475

Chicago/Turabian StyleRehman, Rizwan Ur, Uzair Khaleeq uz Zaman, Shahid Aziz, Hamid Jabbar, Adnan Shujah, Shaheer Khaleequzzaman, Amir Hamza, Usman Qamar, and Dong-Won Jung. 2022. "Process Parameter Optimization of Additively Manufactured Parts Using Intelligent Manufacturing" Sustainability 14, no. 22: 15475. https://doi.org/10.3390/su142215475