Food Plastic Packaging Transition towards Circular Bioeconomy: A Systematic Review of Literature

Abstract

:1. Introduction

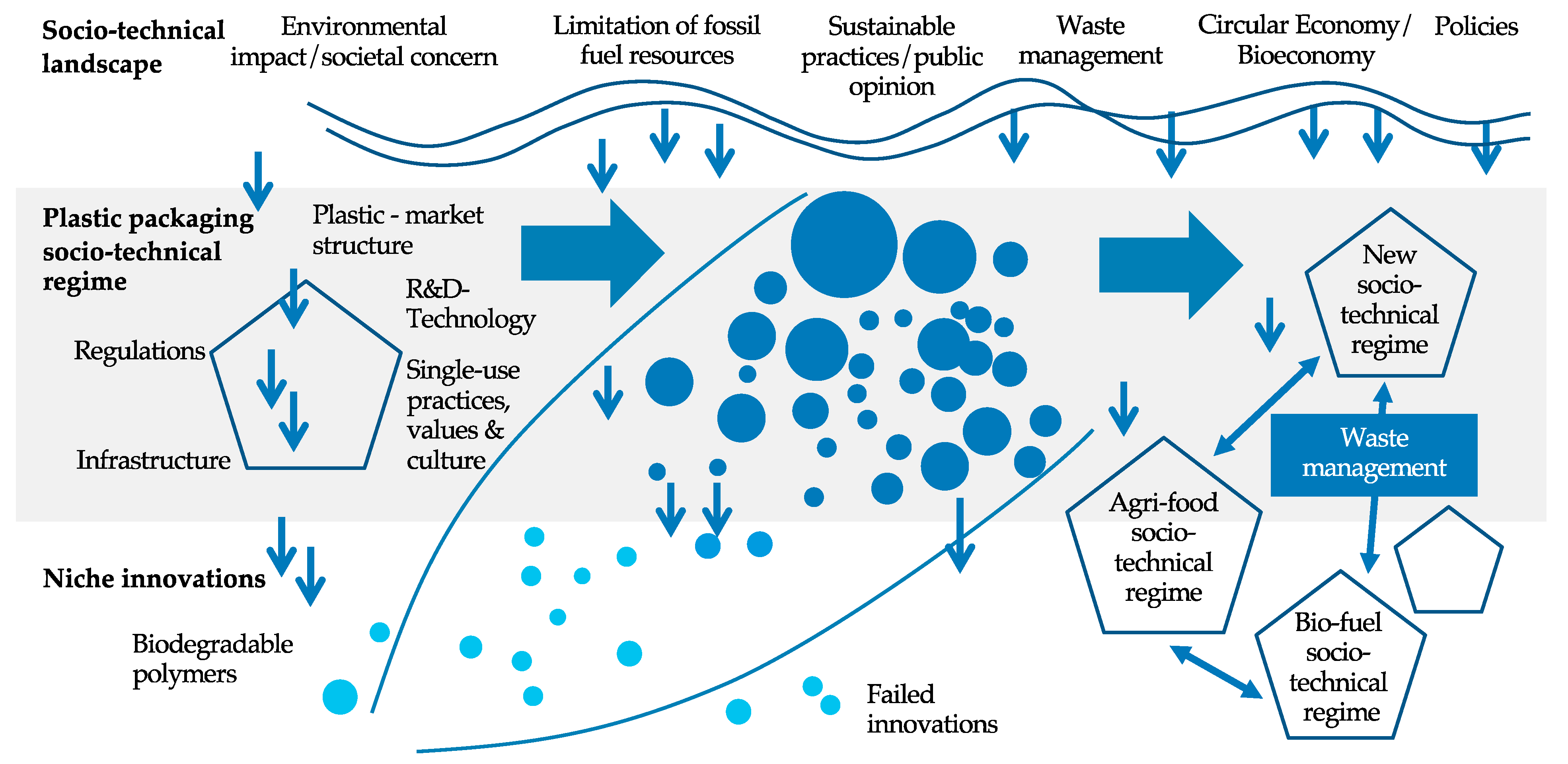

- How does the broader contextual development (landscape) influence the food packaging sector’s transition towards a circular bioeconomy?

- What is the potential of the socio-technical configurations (niche innovations) to change the existing food plastic packaging regime towards a circular bioeconomy?

2. Conceptual Background

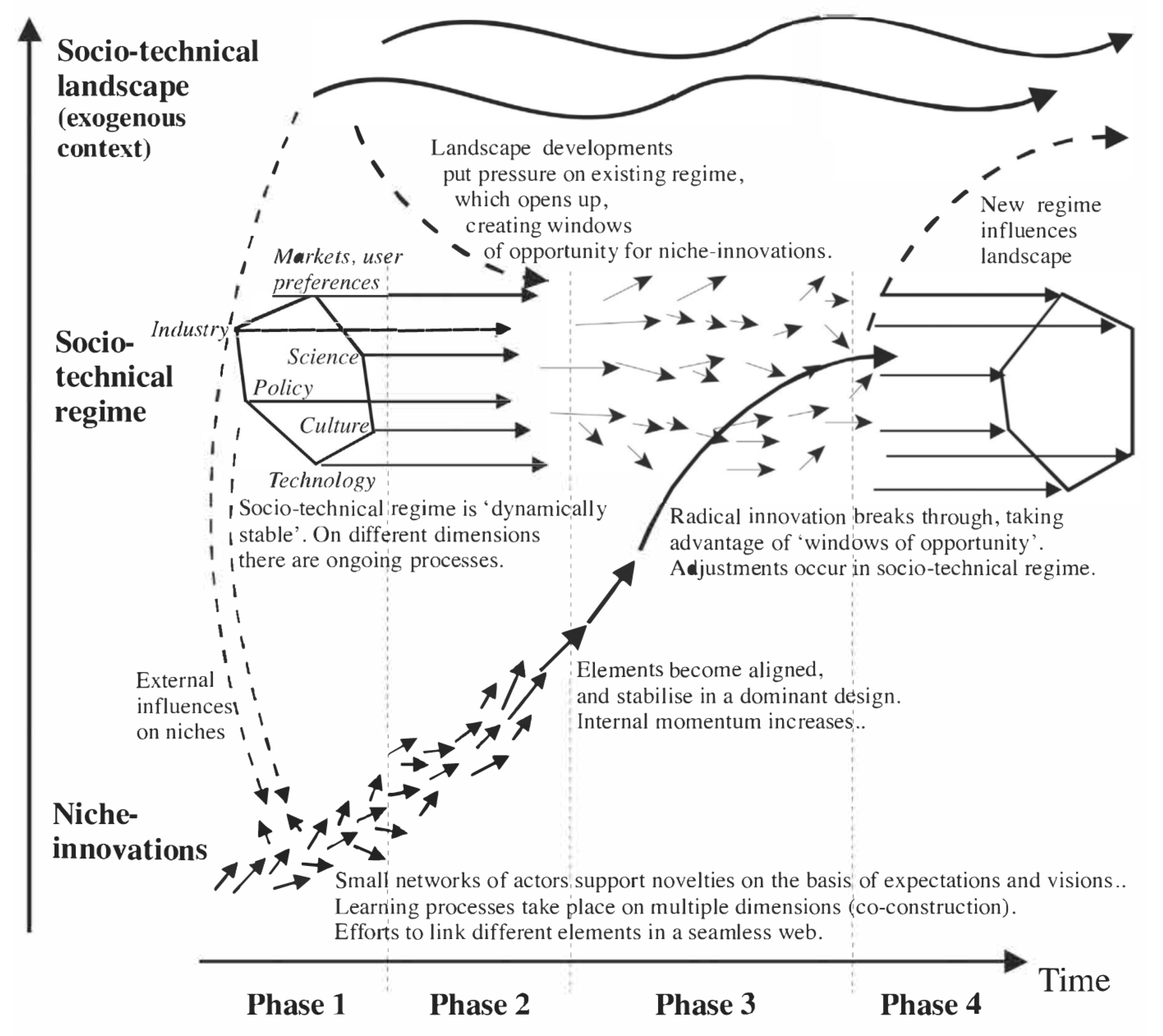

2.1. Socio-Technical System: The Multi-Level Perspective (MLP)

2.2. Bioplastic Materials

- Fossil-based plastics that can biodegrade, such as poly-(butylene adipate-co-terephthalate) (PBAT) and polycaprolactone (PCL);

- Biobased (or partially biobased) and non-biodegradable, such as bio-polyethylene (bio-PE), bio-poly-(ethylene terephthalate) (bio-PET);

- Biobased and biodegradable plastics, such as poly-(lactic acid) (PLA) and PHA.

- Polymers from biomass resources (i.e., polysaccharides, proteins and lipids);

- Polymers obtained by microbial production (e.g., PHA);

- Polymers chemically synthesized using monomers obtained from agro-resources (e.g., PLA);

- Polymers are produced by chemical synthesis from fossil resources (e.g., PCL, polyesteramides (PEA), aliphatic copolyesters (PBSA)).

3. Methods

3.1. Systematic Literature Review (SLR)

- The study reported niche innovations (social or technical) in the food packaging system;

- The study reported stakeholder relationship within niches of food packaging;

- The study explains the transition of food packaging towards a circular bioeconomy;

- The study is interested in at least one part of the supply chain from food packaging production to consumption;

- The study describes the current plastic packaging regime;

- The study is interested in broader contextual developments (external landscape pressure) that influence the food packaging system, such as policies, regulations, environmental issues, etc.; or

- The study reviews other actors’ influence (consumers, policymakers, NGOs, etc.) in the food packaging system.

3.2. Results of the Systematic Literature Review

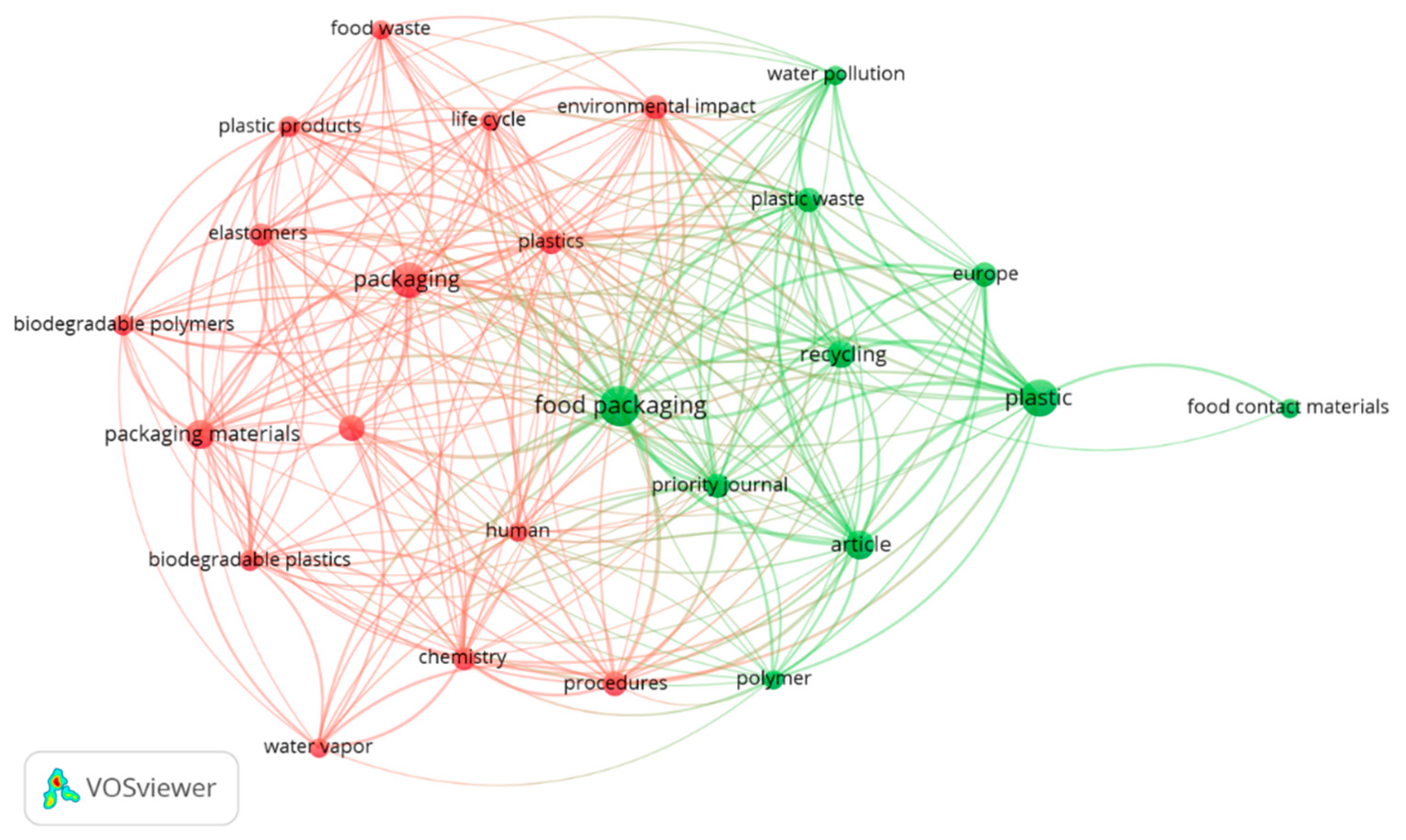

3.3. Bibliometric Analysis

4. The Conceptualization of the MLP Elements for the Food Packaging Socio-Technical System

4.1. Food Packaging Niches

4.2. Food Packaging Regime

4.3. The Landscape of Food Plastic Packaging

5. Discussion and Synthesis

6. Conclusions

6.1. Implications for Theory

6.2. Implications for Practice

6.3. Limitations and Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Section/Topic | # | Checklist Item | Reported on Section |

|---|---|---|---|

| Title | |||

| Title | 1 | Identify the report as a systematic review, meta-analysis, or both. | Title |

| Abstract | |||

| Structured summary | 2 | Provide a structured summary including, as applicable: background; objectives; data sources; study eligibility criteria, participants, and interventions; study appraisal and synthesis methods; results; limitations; conclusions and implications of key findings; systematic review registration number. | Abstract |

| Introduction | |||

| Rationale | 3 | Describe the rationale for the review in the context of what is already known. | 1 |

| Objectives | 4 | Provide an explicit statement of questions being addressed with reference to participants, interventions, comparisons, outcomes, and study design (PICOS). | 1 |

| Methods | |||

| Protocol and registration | 5 | Indicate if a review protocol exists, if and where it can be accessed (e.g., Web address), and, if available, provide registration information including registration number. | 3 |

| Eligibility criteria | 6 | Specify study characteristics (e.g., PICOS, length of follow-up) and report characteristics (e.g., years considered, language, publication status) used as criteria for eligibility, giving rationale. | 3 |

| Information sources | 7 | Describe all information sources (e.g., databases with dates of coverage, contact with study authors to identify additional studies) in the search and date last searched. | 3 |

| Search | 8 | Present full electronic search strategy for at least one database, including any limits used, such that it could be repeated. | 3 |

| Study selection | 9 | State the process for selecting studies (i.e., screening, eligibility, included in systematic review, and, if applicable, included in the meta-analysis). | 3 |

| Data collection process | 10 | Describe method of data extraction from reports (e.g., piloted forms, independently, in duplicate) and any processes for obtaining and confirming data from investigators. | 3 |

| Data items | 11 | List and define all variables for which data were sought (e.g., PICOS, funding sources) and any assumptions and simplifications made. | 3 |

| Risk of bias in individual studies | 12 | Describe methods used for assessing risk of bias of individual studies (including specification of whether this was done at the study or outcome level), and how this information is to be used in any data synthesis. | 3 |

| Summary measures | 13 | State the principal summary measures (e.g., risk ratio, difference in means). | N/A |

| Synthesis of results | 14 | Describe the methods of handling data and combining results of studies, if done, including measures of consistency (e.g., I2) for each meta-analysis. | N/A |

| Section/topic | # | Checklist item | Reported on page # |

| Risk of bias across studies | 15 | Specify any assessment of risk of bias that may affect the cumulative evidence (e.g., publication bias, selective reporting within studies). | 3 |

| Additional analyses | 16 | Describe methods of additional analyses (e.g., sensitivity or subgroup analyses, meta-regression), if done, indicating which were pre-specified. | N/A |

| Results | |||

| Study selection | 17 | Give numbers of studies screened, assessed for eligibility, and included in the review, with reasons for exclusions at each stage, ideally with a flow diagram. | 3.2 |

| Study characteristics | 18 | For each study, present characteristics for which data were extracted (e.g., study size, PICOS, follow-up period) and provide the citations. | Appendix A. Table A2 |

| Risk of bias within studies | 19 | Present data on risk of bias of each study and, if available, any outcome level assessment (see item 12). | N/A |

| Results of individual studies | 20 | For all outcomes considered (benefits or harms), present, for each study: (a) simple summary data for each intervention group (b) effect estimates and confidence intervals, ideally with a forest plot. | N/A |

| Synthesis of results | 21 | Present results of each meta-analysis done, including confidence intervals and measures of consistency. | N/A |

| Risk of bias across studies | 22 | Present results of any assessment of risk of bias across studies (see Item 15). | N/A |

| Additional analysis | 23 | Give results of additional analyses, if done (e.g., sensitivity or subgroup analyses, meta-regression [see Item 16]). | N/A |

| Discussion | |||

| Summary of evidence | 24 | Summarise the main findings including the strength of evidence for each main outcome; consider their relevance to key groups (e.g., healthcare providers, users, and policy makers). | 5 |

| Limitations | 25 | Discuss limitations at study and outcome level (e.g., risk of bias), and at review-level (e.g., incomplete retrieval of identified research, reporting bias). | 6.3 |

| Conclusions | 26 | Provide a general interpretation of the results in the context of other evidence, and implications for future research. | 6 |

| Funding | |||

| Funding | 27 | Describe sources of funding for the systematic review and other support (e.g., supply of data); role of funders for the systematic review. | N/A |

| ID | Item Type | Year | Author | Title | Journal/Publisher | Source |

|---|---|---|---|---|---|---|

| 1 | Book | 2011 | [65] | Industrial end-use applications | SpringerBriefs in Applied Sciences and Technology | Scopus |

| 2 | Journal article | 2012 | [77] | Going through the barrier | Food Science and Technology (London) | Scopus |

| 3 | Journal article | 2013 | [73] | An extended life cycle analysis of packaging systems for fruit and vegetable transport in Europe | International Journal of Life Cycle Assessment | Scopus |

| 4 | Journal article | 2013 | [78] | Is PET bottle-to-bottle recycling safe? Evaluation of post-consumer recycling processes according to the EFSA guidelines | Resources, Conservation and Recycling | Scopus |

| 5 | Journal article | 2014 | [52] | Extruded polymer films for optimal enzyme-catalysed oxygen scavenging | Chemical Engineering Science | Scopus |

| 6 | Journal article | 2015 | [55] | Effect of protein and glycerol concentration on the mechanical, optical, and water vapor barrier properties of canola protein isolate-based edible films | Food Science and Technology International | Scopus |

| 7 | Report | 2015 | COST | A position paper from the cost action FP1003 Biomatpack | Cellulose Chemistry and Technology | Scopus |

| 8 | Journal article | 2015 | [82] | Scientific opinion on the safety assessment of the process ‘PET-M’ used to recycle post-consumer PET into food contact materials | EFSA Journal | Scopus |

| 9 | Journal article | 2015 | [60] | Life cycle assessment of end-of-life options for two biodegradable packaging materials: Sound application of the European waste hierarchy | Journal of Cleaner Production | Scopus |

| 10 | Journal article | 2015 | [54] | Characterisation of multilayered and composite edible films from chitosan and beeswax | Food Science and Technology International | Scopus |

| 11 | Journal article | 2016 | [74] | Comparative Life Cycle Assessment of Packaging Systems for Extended Shelf Life Milk | Packaging Technology and Science | Scopus |

| 12 | Journal article | 2016 | [70] | Updating and testing of a Finnish method for mixed municipal solid waste composition studies | Waste Management | ScienceDirect |

| 13 | Journal article | 2016 | [49] | Palm oil deodoriser distillate as toughening agent in polylactide packaging films | Polymer International | Scopus |

| 14 | Journal article | 2016 | [63] | Methane generation from anaerobic digestion of biodegradable plastics—a review | International Journal of Environmental Studies | Scopus |

| 15 | Journal article | 2017 | [53] | Recent advances in food packaging with a focus on nanotechnology | Recent Patents on Engineering | Scopus |

| 16 | Journal article | 2017 | [92] | The prospects of zero-packaging grocery stores to improve the social and environmental impacts of the food supply chain | Journal of Cleaner Production | Scopus |

| 17 | Journal article | 2017 | [50] | Post-processing optimisation of electrospun submicron poly(3-hydroxybutyrate) fibers to obtain continuous films of interest in food packaging applications | Food Additives and Contaminants—Part A Chemistry, Analysis, Control, Exposure and Risk Assessment | Scopus |

| 18 | Journal article | 2017 | [72] | Separate collection of plastic waste, better than technical sorting from municipal solid waste? | Waste Management and Research | Scopus |

| 19 | Journal article | 2017 | [48] | Performance properties, lactic acid specific migration and swelling by simulant of biodegradable poly(lactic acid)/nanoclay multilayer films for food packaging | Food Additives and Contaminants—Part A Chemistry, Analysis, Control, Exposure and Risk Assessment | Scopus |

| 20 | Journal article | 2017 | [47] | New PLA/ZnO:Cu/Ag bionanocomposites for food packaging | Express Polymer Letters | Scopus |

| 21 | Journal article | 2018 | [75] | Improving the environmental sustainability of reusable food containers in Europe | Science of the Total Environment | Scopus |

| 22 | Journal article | 2018 | [67] | The skin of commerce: governing through plastic food packaging | Journal of Cultural Economy | Scopus |

| 23 | Journal article | 2018 | [93] | Greenhouse gas emission reduction in frozen food packaging | Environmental Engineering and Management Journal | Scopus |

| 24 | Journal article | 2018 | [57] | Plastic pollution and potential solutions | Science progress | Scopus |

| 25 | Journal article | 2018 | [81] | Safety assessment of the process ‘Concept Plastic Packaging’, based on Starlinger Decon technology, used to recycle post-consumer PET into food contact materials | EFSA Journal | Scopus |

| 26 | Journal article | 2018 | [85] | Beach litter along various sand dune habitats in the southern Adriatic (E Mediterranean) | Marine Pollution Bulletin | ScienceDirect |

| 27 | Journal article | 2018 | [76] | Black plastics: Linear and circular economies, hazardous additives and marine pollution | Environment International | Scopus |

| 28 | Journal article | 2018 | [62] | Degradation of some EN13432 compliant plastics in simulated mesophilic anaerobic digestion of food waste | Polymer Degradation and Stability | Scopus |

| 29 | Journal article | 2019 | [45] | End-of-waste life: Inventory of alternative end-of-use recirculation routes of bio-based plastics in the European Union context | Technology Analysis & Strategic Management | Author |

| 30 | Journal article | 2019 | [87] | A harmonised and coordinated assessment of the abundance and composition of seafloor litter in the Adriatic-Ionian macroregion (Mediterranean Sea) | Marine Pollution Bulletin | Scopus |

| 31 | Journal article | 2019 | [61] | A comparative life cycle assessment of meat trays made of various packaging materials | Sustainability (Switzerland) | Scopus |

| 32 | Journal article | 2019 | [68] | Ethics and responsibilisation in agri-food governance: the single-use plastics debate and strategies to introduce reusable coffee cups in UK retail chains | Agriculture and Human Values | Scopus |

| 33 | Journal article | 2019 | [86] | Baseline and power analyses for the assessment of beach litter reductions in the European OSPAR region | Environmental Pollution | Scopus |

| 34 | Journal article | 2019 | [89] | Detection of various microplastics in human stool: A prospective case series | Annals of Internal Medicine | Scopus |

| 35 | Journal article | 2019 | [80] | Safety assessment of the process Quinn Packaging, based on Erema Basic technology, used to recycle post-consumer PET into food contact materials | EFSA Journal | Scopus |

| 36 | Journal article | 2020 | [83] | Risk Assessment of Food Contact Materials | EFSA Journal | Scopus |

| 37 | Journal article | 2020 | [56] | Reinforced non-conventional material composites: a comprehensive review | Advances in Materials and Processing Technologies | Scopus |

| 38 | Journal article | 2020 | [69] | Technical limits in circularity for plastic packages | Sustainability (Switzerland) | Scopus |

| 39 | Journal article | 2020 | [91] | Incorporating consumer insights into the UK food packaging supply chain in the transition to a circular economy | Sustainability (Switzerland) | Scopus |

| 40 | Journal article | 2020 | [88] | Efficiency of wastewater treatment plants (Wwtps) for microplastic removal: A systematic review | International Journal of Environmental Research and Public Health | Scopus |

| 41 | Journal article | 2020 | [59] | Plastic packaging goes sustainable: An analysis of consumer preferences for plastic water bottles | Environmental Science & Policy | ScienceDirect |

| 42 | Journal article | 2020 | [66] | The true revolution of 1968: Mineral water trade and the early proliferation of plastic, 1960s–1970s | Business History Review | Scopus |

| 43 | Journal article | 2020 | [64] | Polyethylene terephthalate (PET) in the packaging industry | Polymer Testing | ScienceDirect |

| 44 | Journal article | 2020 | [51] | Sustainable tetra pak recycled cellulose/Poly(Butylene succinate) based woody-like composites for a circular economy | Journal of Cleaner Production | ScienceDirect |

| 45 | Journal article | 2020 | [79] | Safety assessment of the process Veolia URRC used to recycle post-consumer PET into food contact materials | EFSA Journal | Scopus |

| 46 | Journal article | 2020 | [94] | Removing plastic packaging from fresh produce—what’s the impact? | Nutrition Bulletin | Scopus |

| 47 | Journal article | 2020 | [84] | Macroplastic pollution in freshwater environments: Focusing public and policy action | Science of the Total Environment | Scopus |

| 48 | Journal article | 2021 | [90] | Collaborations for circular food packaging: The set-up and partner selection process | Sustainable Production and Consumption | ScienceDirect |

| 49 | Journal article | 2021 | [6] | A review on European Union’s strategy for plastics in a circular economy and its impact on food safety | Journal of Cleaner Production | Scopus |

| 50 | Journal article | 2021 | [71] | Lead in plastics—Recycling of legacy material and appropriateness of current regulations | Journal of Hazardous Materials | Scopus |

| 51 | Report | 2016 | Ellen MacArthur Foundation | The New Plastics Economy, Rethinking the Future of Plastics | Ellen MacArthur Foundation | Reference |

| 52 | Report | 2018 | European Commission | A European Strategy for Plastics in a Circular Economy. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions. | European Commission | Reference |

| 53 | Report | 2019 | PlasticEurope | Plastics—the Facts 2019. An analysis of European plastics production, demand and waste data | PlasticEurope | Author |

| 54 | Report | 2019 | DEFRA | Consultation on reforming the UK packaging producer responsibility system. Summary of consultation responses and next steps. July 2019 | Department of Environment Food and Rural Affairs | Author |

| 55 | Report | 2019 | DEFRA | Consultation on introducing a Deposit Return Scheme in England, Wales and Northern Ireland. Summary of responses. July 2019 | Department of Environment Food and Rural Affairs | Author |

| 56 | Report | 2019 | DEFRA | Consultation on consistency in household and business recycling collections in England. Part 1: analysis of responses from members of the public and householders. July 2019 | Department of Environment Food and Rural Affairs | Author |

| 57 | Report | 2019 | House of Commons | Plastic Food and Drink Packaging. Sixteenth Report of Session 2017–19. Printed 9th September 2019 | Stationery Office | Author |

| 58 | Report | 2020 | HMRC | Plastic Packaging Tax: Summary of Responses to the Policy Design Consultation. November 2020 | HM Revenue & Customs | Author |

References

- FAO. The State of Food and Agriculture 2019; Food and Agriculture Organisation of the United Nations: Rome, Italy, 2019. [Google Scholar]

- Corrado, S.; Sala, S. Food waste accounting along global and European food supply chains: State of the art and outlook. Waste Manag. 2018, 79, 120–131. [Google Scholar] [CrossRef] [PubMed]

- WRAP. UK Progress against Courtauld 2025 Targets and UN Sustainable Development Goal 12.3; WRAP: Banbury, UK, 2020. [Google Scholar]

- Ellen MacArthur Foundation. The New Plastics Economy, Rethinking the Future of Plastics; Ellen MacArthur Foundation: Cowes, UK, 2016. [Google Scholar]

- European Commission. A European Strategy for Plastics in a Circular Economy. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions; European Commission: Brussels, Belgium, 2018. [Google Scholar]

- Matthews, C.; Moran, F.; Jaiswal, A.K. A review on European Union’s strategy for plastics in a circular economy and its impact on food safety. J. Clean. Prod. 2021, 283, 125263. [Google Scholar] [CrossRef]

- Massey, S.; Pitcairn, J.; Minty, N. Plastics in the Bioeconomy; Report for the Biomass Biorefinery Network ED12430; Ricardo Energy Environment: Glasgow, UK, 2019. [Google Scholar]

- BEIS. Growing the Bioeconomy—Improving Lives and Strengthening our Economy: A National Bioeconomy Strategy to 2030; Department for Business, Energy & Industrial Strategy: London, UK, 2018.

- Falcone, P.M.; Tani, A.; Tartiu, V.E.; Imbriani, C. Towards a sustainable forest-based bioeconomy in Italy: Findings from a SWOT analysis. For. Policy Econ. 2020, 110, 101910. [Google Scholar] [CrossRef]

- Giurca, A.; Späth, P. A forest-based bioeconomy for Germany? Strengths, weaknesses and policy options for lignocellulosic biorefineries. J. Clean. Prod. 2017, 153, 51–62. [Google Scholar] [CrossRef]

- Wydra, S.; Hüsing, B.; Köhler, J.; Schwarz, A.; Schirrmeister, E.; Voglhuber-Slavinsky, A. Transition to the bioeconomy—Analysis and scenarios for selected niches. J. Clean. Prod. 2021, 294, 126092. [Google Scholar] [CrossRef]

- Keränen, O.; Komulainen, H.; Lehtimäki, T.; Ulkuniemi, P. Restructuring existing value networks to diffuse sustainable innovations in food packaging. Ind. Mark. Manag. 2021, 93, 509–519. [Google Scholar] [CrossRef]

- Donner, M.; De Vries, H. How to innovate business models for a circular bio-economy? Bus. Strateg. Environ. 2021, 1–16. [Google Scholar] [CrossRef]

- Perey, R.; Benn, S.; Agarwal, R.; Edwards, M. The place of waste: Changing business value for the circular economy. Bus. Strat. Environ. 2018, 27, 631–642. [Google Scholar] [CrossRef]

- Puntillo, P.; Gulluscio, C.; Huisingh, D.; Veltri, S. Reevaluating waste as a resource under a circular economy approach from a system perspective: Findings from a case study. Bus. Strateg. Environ. 2021, 30, 968–984. [Google Scholar] [CrossRef]

- Liliani, L.; Tjahjono, B.; Cao, D. Advancing bioplastic packaging products through co-innovation: A conceptual framework for supplier-customer collaboration. J. Clean. Prod. 2020, 252, 119861. [Google Scholar] [CrossRef]

- Gottinger, A.; Ladu, L.; Quitzow, R. Studying the Transition towards a Circular Bioeconomy—A Systematic Literature Review on Transition Studies and Existing Barriers. Sustainability 2020, 12, 8990. [Google Scholar] [CrossRef]

- Markard, J.; Raven, R.; Truffer, B. Sustainability transitions: An emerging field of research and its prospects. Res. Policy 2012, 41, 955–967. [Google Scholar] [CrossRef]

- Geels, F.W. Technological transitions as evolutionary reconfiguration processes: A multi-level perspective and a case-study. Res. Policy 2002, 31, 1257–1274. [Google Scholar] [CrossRef] [Green Version]

- Köhler, J.; Geels, F.W.; Kern, F.; Markard, J.; Onsongo, E.; Wieczorek, A.; Alkemade, F.; Avelino, F.; Bergek, A.; Boons, F.; et al. An agenda for sustainability transitions research: State of the art and future directions. Environ. Innov. Soc. Transit. 2019, 31, 1–32. [Google Scholar] [CrossRef] [Green Version]

- Geels, F.W. Socio-technical transitions to sustainability: A review of criticisms and elaborations of the Multi-Level Perspective. Curr. Opin. Environ. Sustain. 2019, 39, 187–201. [Google Scholar] [CrossRef]

- Geels, F.W.; Schot, J. Typology of sociotechnical transition pathways. Res. Policy 2007, 36, 399–417. [Google Scholar] [CrossRef]

- Geels, F.W.; Sovacool, B.K.; Schwanen, T.; Sorrell, S. The Socio-Technical Dynamics of Low-Carbon Transitions. Joule 2017, 1, 463–479. [Google Scholar] [CrossRef] [Green Version]

- Geels, F.W. The multi-level perspective on sustainability transitions: Responses to seven criticisms. Environ. Innov. Soc. Transit. 2011, 1, 24–40. [Google Scholar] [CrossRef]

- Geels, F.W. The dynamics of transitions in socio-technical systems: A multi-level analysis of the transition pathway from horse-drawn carriages to automobiles (1860–1930). Technol. Anal. Strateg. Manag. 2005, 17, 445–476. [Google Scholar] [CrossRef]

- Geels, F.W. Ontologies, socio-technical transitions (to sustainability) and the multi-level perspective. Res. Policy 2010, 39, 495–510. [Google Scholar] [CrossRef]

- Schot, J.; Geels, F.W. Strategic niche management and sustainable innovation journeys: Theory, findings, research agenda and policy. Technol. Anal. Strateg. Manag. 2008, 20, 537–554. [Google Scholar] [CrossRef]

- Kemp, R.; Schot, J.J.; Hoogma, R. Regime shifts to sustainability through processes of niche formation: The approach of strategic niche management. Technol. Anal. Strateg. Manag. 1998, 10, 175–198. [Google Scholar] [CrossRef]

- Geels, F.W. Disruption and low-carbon system transformation: Progress and new challenges in socio-technical transitions research and the Multi-Level Perspective. Energy Res. Soc. Sci. 2018, 37, 224–231. [Google Scholar] [CrossRef]

- European Bioplastics. Bioplastics Market Data 2019. Global Production Capacities of Bioplastics 2019–2024; European Bioplastics: Berlin, Germany, 2019. [Google Scholar]

- Bröring, S.; Laibach, N.; Wustmans, M. Innovation types in the bioeconomy. J. Clean. Prod. 2020, 266, 121939. [Google Scholar] [CrossRef]

- Vert, M.; Doi, Y.; Hellwich, K.-H.; Hess, M.; Hodge, P.; Kubisa, P.; Rinaudo, M.; Schué, F. Terminology for biorelated polymers and applications (IUPAC Recommendations 2012). Pure Appl. Chem. 2012, 84, 377–410. [Google Scholar] [CrossRef]

- European Bioplastics. Fact Sheet. What Are Bioplastics? Material Types, Terminology and Labels—An Introduction; European Bioplastics: Berlin, Germany, 2018. [Google Scholar]

- De Paula, F.C.; De Paula, C.B.; Contiero, J. Prospective biodegradable plastics from biomass conversion processes. In Biofuels: State of Development; IntechOpen: London, UK, 2018; pp. 245–271. [Google Scholar]

- Vieira, M.G.A.; Da Silva, M.A.; Dos Santos, L.O.; Beppu, M.M.J.E.P.J. Natural-based plasticizers and biopolymer films: A review. Eur. Polym. J. 2011, 47, 254–263. [Google Scholar] [CrossRef] [Green Version]

- Yadav, B.; Pandey, A.; Kumar, L.R.; Tyagi, R. Bioconversion of waste (water)/residues to bioplastics—A circular bioeconomy approach. Bioresour. Technol. 2020, 298, 122584. [Google Scholar] [CrossRef]

- Liberati, A.; Altman, D.G.; Tetzlaff, J.; Mulrow, C.; Gøtzsche, P.C.; Ioannidis, J.P.A.; Clarke, M.; Devereaux, P.J.; Kleijnen, J.; Moher, D. The PRISMA statement for reporting systematic reviews and meta-analyses of studies that evaluate health care interventions: Explanation and elaboration. J. Clin. Epidemiol. 2009, 62, e1–e34. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G. The PRISMA Group. Preferred reporting items for systematic reviews and meta-analyses: The PRISMA statement. PLoS Med. 2009, 6, e1000097. [Google Scholar] [CrossRef] [Green Version]

- HMRC. Plastic Packaging Tax: Summary of Responses to the Policy Design Consultation; HM Revenue & Customs: London, UK, 2020.

- DEFRA. Consultation on Consistency in Household and Business Recycling Collections in England. Part 1: Analysis of Responses from Members of the Public and Householders; Department for Environment Food and Rural Affairs: London, UK, 2019.

- DEFRA. Consultation on Introducing a Deposit Return Scheme in England, Wales and Northern Ireland. Summary of Responses; Department for Environment Food and Rural Affairs: London, UK, 2019.

- DEFRA. Consultation on Reforming the UK Packaging Producer Responsibility System. Summary of Consultation Responses and Next Steps; Department for Environment Food and Rural Affairs: London, UK, 2019.

- PlasticsEurope. Plastics—The Facts 2019. An Analysis of European Plastics Production, Demand and Waste Data; PlasticsEurope: Brussels, Belgium, 2019. [Google Scholar]

- House of Commons. Plastic Food and Drink Packaging; Sixteenth Report of Session 2017–2019; House of Commons: London, UK, 2019.

- Briassoulis, D.; Pikasi, A.; Hiskakis, M. End-of-waste life: Inventory of alternative end-of-use recirculation routes of bio-based plastics in the European Union context. Crit. Rev. Environ. Sci. Technol. 2019, 49, 1835–1892. [Google Scholar] [CrossRef]

- Van Eck, N.J.; Waltman, L. VOSviewer Manual; Manual for VOSviewer Version 1.6.16; Univeristeit Leiden: Leiden, The Netherlands, 2020; Volume 1, pp. 1–52. [Google Scholar]

- Vasile, C.; Râpă, M.; Ștefan, M.; Stan, M.; Macavei, S.; Darie-Niță, R.N.; Barbu-Tudoran, L.; Vodnar, D.C.; Popa, E.E.; Ștefan, R.; et al. New PLA/ZnO:Cu/Ag bionanocomposites for food packaging. Express Polym. Lett. 2017, 11, 531–544. [Google Scholar] [CrossRef]

- Scarfato, P.; Di Maio, L.; Milana, M.R.; Giamberardini, S.; Denaro, M.; Incarnato, L. Study of performance properties, lactic acid specific migration and swelling by simulant of biodegradable poly (lactic acid)/nanoclay multilayer films for food packaging. Food Addit. Contam. Part A 2017, 34, 1730–1742. [Google Scholar] [CrossRef] [PubMed]

- Ruellan, A.; Ducruet, V.; Gratia, A.; Jimenez, L.S.; Guinault, A.; Sollogoub, C.; Chollet, G.; Domenek, S. Palm oil deodorizer distillate as toughening agent in polylactide packaging films. Polym. Int. 2016, 65, 683–690. [Google Scholar] [CrossRef] [Green Version]

- Cherpinski, A.; Torres-Giner, S.; Cabedo, L.; Lagaron, J.M. Post-processing optimization of electrospun submicron poly (3-hydroxybutyrate) fibers to obtain continuous films of interest in food packaging applications. Food Addit. Contam. Part A 2017, 34, 1817–1830. [Google Scholar] [CrossRef] [PubMed]

- Platnieks, O.; Barkane, A.; Ijudina, N.; Gaidukova, G.; Thakur, V.K.; Gaidukovs, S. Sustainable tetra pak recycled cellulose/Poly (Butylene succinate) based woody-like composites for a circular economy. J. Clean. Prod. 2020, 270, 122321. [Google Scholar] [CrossRef]

- Johansson, K.; Kotkamo, S.; Rotabakk, B.T.; Johansson, C.; Kuusipalo, J.; Jönsson, L.J.; Järnström, L. Extruded polymer films for optimal enzyme-catalyzed oxygen scavenging. Chem. Eng. Sci. 2014, 108, 1–8. [Google Scholar] [CrossRef]

- Angiolillo, L.; Spinelli, S.; Conte, A.; Del Nobile, M.A. Recent advances in food packaging with a focus on nanotechnology. Recent Pat. Eng. 2017, 11, 174–187. [Google Scholar] [CrossRef]

- Velickova, E.; Winkelhausen, E.; Kuzmanova, S.; Moldão-Martins, M.; Alves, V.D. Characterization of multilayered and composite edible films from chitosan and beeswax. Food Sci. Technol. Int. 2013, 21, 83–93. [Google Scholar] [CrossRef] [PubMed]

- Chang, C.; Nickerson, M.T. Effect of protein and glycerol concentration on the mechanical, optical, and water vapor barrier properties of canola protein isolate-based edible films. Food Sci. Technol. Int. 2013, 21, 33–44. [Google Scholar] [CrossRef]

- Boparai, K.S.; Singh, R.; Hashmi, M.S.J. Reinforced non-conventional material composites: A comprehensive review. Adv. Mater. Process. Technol. 2020, 1–10. [Google Scholar] [CrossRef]

- Rhodes, C.J. Plastic Pollution and Potential Solutions. Sci. Prog. 2018, 101, 207–260. [Google Scholar] [CrossRef] [PubMed]

- COST. Position paper from the cost action FP1003 Biomatpack. Cellul. Chem. Technol. 2015, 49, 565–572. [Google Scholar]

- De Marchi, E.; Pigliafreddo, S.; Banterle, A.; Parolini, M.; Cavaliere, A. Plastic packaging goes sustainable: An analysis of consumer preferences for plastic water bottles. Environ. Sci. Policy 2020, 114, 305–311. [Google Scholar] [CrossRef]

- Rossi, V.; Cleeve-Edwards, N.; Lundquist, L.; Schenker, U.; Dubois, C.; Humbert, S.; Jolliet, O. Life cycle assessment of end-of-life options for two biodegradable packaging materials: Sound application of the European waste hierarchy. J. Clean. Prod. 2015, 86, 132–145. [Google Scholar] [CrossRef]

- Maga, D.; Hiebel, M.; Aryan, V. A Comparative Life Cycle Assessment of Meat Trays Made of Various Packaging Materials. Sustainability 2019, 11, 5324. [Google Scholar] [CrossRef] [Green Version]

- Zhang, W.; Heaven, S.; Banks, C.J. Degradation of some EN13432 compliant plastics in simulated mesophilic anaerobic digestion of food waste. Polym. Degrad. Stab. 2018, 147, 76–88. [Google Scholar] [CrossRef] [Green Version]

- Stagner, J. Methane generation from anaerobic digestion of biodegradable plastics—A review. Int. J. Environ. Stud. 2015, 73, 1–7. [Google Scholar] [CrossRef]

- Nisticò, R. Polyethylene terephthalate (PET) in the packaging industry. Polym. Test. 2020, 90, 106707. [Google Scholar] [CrossRef]

- Rosato, D.V. Industrial End Use Applications; Springer: Berlin/Heidelberg, Germany, 2011; pp. 33–48. [Google Scholar]

- Marty, N. The True Revolution of 1968: Mineral Water Trade and the Early Proliferation of Plastic, 1960s–1970s. Bus. Hist. Rev. 2020, 94, 483–505. [Google Scholar] [CrossRef]

- Hawkins, G. The skin of commerce: Governing through plastic food packaging. J. Cult. Econ. 2018, 11, 386–403. [Google Scholar] [CrossRef]

- Maye, D.; Kirwan, J.; Brunori, G. Ethics and responsibilisation in agri-food governance: The single-use plastics debate and strategies to introduce reusable coffee cups in UK retail chains. Agric. Hum. Values 2019, 36, 301–312. [Google Scholar] [CrossRef]

- Brouwer, M.; Van Velzen, E.T.; Ragaert, K.; Klooster, R.T. Technical Limits in Circularity for Plastic Packages. Sustainability 2020, 12, 21. [Google Scholar] [CrossRef]

- Liikanen, M.; Sahimaa, O.; Hupponen, M.; Havukainen, J.; Sorvari, J.; Horttanainen, M. Updating and testing of a Finnish method for mixed municipal solid waste composition studies. Waste Manag. 2016, 52, 25–33. [Google Scholar] [CrossRef] [PubMed]

- Turner, A.; Filella, M. Lead in plastics—Recycling of legacy material and appropriateness of current regulations. J. Hazard. Mater. 2021, 404, 124131. [Google Scholar] [CrossRef] [PubMed]

- Feil, A.; Pretz, T.; Jansen, M.; Thoden Van Velzen, E.U. Separate collection of plastic waste, better than technical sorting from municipal solid waste? Waste Manag. Res. 2017, 35, 172–180. [Google Scholar] [CrossRef]

- Albrecht, S.; Brandstetter, P.; Beck, T.; Fullana-i-Palmer, P.; Grönman, K.; Baitz, M.; Deimling, S.; Sandilands, J.; Fischer, M. An extended life cycle analysis of packaging systems for fruit and vegetable transport in Europe. Int. J. Life Cycle Assess. 2013, 18, 1549–1567. [Google Scholar] [CrossRef]

- Bertolini, M.; Bottani, E.; Vignali, G.; Volpi, A. Comparative Life Cycle Assessment of Packaging Systems for Extended Shelf Life Milk. Packag. Technol. Sci. 2016, 29, 525–546. [Google Scholar] [CrossRef]

- Gallego-Schmid, A.; Mendoza, J.M.F.; Azapagic, A. Improving the environmental sustainability of reusable food containers in Europe. Sci. Total. Environ. 2018, 628, 979–989. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Turner, A. Black plastics: Linear and circular economies, hazardous additives and marine pollution. Environ. Int. 2018, 117, 308–318. [Google Scholar] [CrossRef]

- Johansson, C. Going through the barrier. Food Sci. Technol. 2012, 26, 32–34. [Google Scholar]

- Welle, F. Is PET bottle-to-bottle recycling safe? Evaluation of post-consumer recycling processes according to the EFSA guidelines. Resour. Conserv. Recycl. 2013, 73, 41–45. [Google Scholar] [CrossRef]

- Silano, V.; Baviera, J.M.B.; Bolognesi, C.; Chesson, A.; Cocconcelli, P.S.; Crebelli, R.; Gott, D.M.; Grob, K.; Lambré, C.; Mengelers, M.; et al. Safety assessment of the process Veolia URRC used to recycle post-consumer PET into food contact materials. EFSA J. 2020, 18, 5. [Google Scholar] [CrossRef]

- Silano, V.; Baviera, J.M.B.; Bolognesi, C.; Chesson, A.; Cocconcelli, P.S.; Crebelli, R.; Gott, D.M.; Grob, K.; Mortensen, A.; Mengelers, M.; et al. Safety assessment of the process Quinn Packaging, based on Erema Basic technology, used to recycle post-consumer PET into food contact materials. EFSA J. 2019, 17, e05771. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Silano, V.; Bolognesi, C.; Castle, L.; Chipman, K.; Cravedi, J.; Engel, K.; Fowler, P.; Grob, K.; Gürtler, R.; Riviere, G.; et al. Safety assessment of the process ‘Concept Plastic Packaging’, based on Starlinger Decon technology, used to recycle post-consumer PET into food contact materials. EFSA J. 2018, 16, 2. [Google Scholar] [CrossRef] [Green Version]

- European Food Safety Authority. Scientific Opinion on the safety assessment of the process ‘PET-M’ used to recycle post-consumer PET into food contact materials. EFSA J. 2015, 13, 4046. [Google Scholar]

- Beneventi, E.; Tietz, T.; Merkel, S. Risk Assessment of Food Contact Materials. EFSA J. 2020, 18, 1–11. [Google Scholar] [CrossRef]

- Winton, D.J.; Anderson, L.G.; Rocliffe, S.; Loiselle, S. Macroplastic pollution in freshwater environments: Focusing public and policy action. Sci. Total Environ. 2020, 704, 135242. [Google Scholar] [CrossRef]

- Šilc, U.; Küzmič, F.; Caković, D.; Stešević, D. Beach litter along various sand dune habitats in the southern Adriatic (E Mediterranean). Mar. Pollut. Bull. 2018, 128, 353–360. [Google Scholar] [CrossRef]

- Schulz, M.; Walvoort, D.J.; Barry, J.; Fleet, D.M.; Van Loon, W.M. Baseline and power analyses for the assessment of beach litter reductions in the European OSPAR region. Environ. Pollut. 2019, 248, 555–564. [Google Scholar] [CrossRef]

- Fortibuoni, T.; Ronchi, F.; Mačić, V.; Mandić, M.; Mazziotti, C.; Peterlin, M.; Prevenios, M.; Prvan, M.; Somarakis, S.; Tutman, P.; et al. A harmonized and coordinated assessment of the abundance and composition of seafloor litter in the Adriatic-Ionian macroregion (Mediterranean Sea). Mar. Pollut. Bull. 2019, 139, 412–426. [Google Scholar] [CrossRef]

- Cristaldi, A.; Fiore, M.; Zuccarello, P.; Conti, G.O.; Grasso, A.; Nicolosi, I.; Copat, C.; Ferrante, M. Efficiency of Wastewater Treatment Plants (WWTPs) for Microplastic Removal: A Systematic Review. Int. J. Environ. Res. Public Health 2020, 17, 8014. [Google Scholar] [CrossRef] [PubMed]

- Schwabl, P.; Koppel, S.; Konigshofer, P.; Bucsics, T.; Trauner, M.; Reiberger, T.; Liebmann, B. Detection of various microplastics in human stool: A prospective case series. Ann. Intern. Med. 2019, 171, 453–457. [Google Scholar] [CrossRef] [PubMed]

- Jäger, J.K.; Piscicelli, L. Collaborations for circular food packaging: The set-up and partner selection process. Sustain. Prod. Consum. 2021, 26, 733–740. [Google Scholar] [CrossRef]

- Clark, N.; Trimingham, R.; Wilson, G.T. Incorporating Consumer Insights into the UK Food Packaging Supply Chain in the Transition to a Circular Economy. Sustainability 2020, 12, 6106. [Google Scholar] [CrossRef]

- Beitzen-Heineke, E.F.; Balta-Ozkan, N.; Reefke, H. The prospects of zero-packaging grocery stores to improve the social and environmental impacts of the food supply chain. J. Clean. Prod. 2017, 140, 1528–1541. [Google Scholar] [CrossRef] [Green Version]

- Kliaugaite, D.; Varzinskas, V.; Baikauskiene, A.; Miliunas, V.; Stasiskiene, Z. Greenhouse gas emission reduction in frozen food packaging. Environ. Eng. Manag. J. 2018, 17, 2977–2990. [Google Scholar] [CrossRef]

- White, A.; Lockyer, S. Removing plastic packaging from fresh produce—What’s the impact? Nutr. Bull. 2020, 45, 35–50. [Google Scholar] [CrossRef]

- Smith, A.; Raven, R. What is protective space? Reconsidering niches in transitions to sustainability. Res. Policy 2012, 41, 1025–1036. [Google Scholar] [CrossRef] [Green Version]

- Shove, E.; Pantzar, M.; Watson, M. The Dynamics of Social Practice: Everyday Life and How It Changes; SAGE: London, UK, 2012. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Beltran, M.; Tjahjono, B.; Bogush, A.; Julião, J.; Teixeira, E.L.S. Food Plastic Packaging Transition towards Circular Bioeconomy: A Systematic Review of Literature. Sustainability 2021, 13, 3896. https://doi.org/10.3390/su13073896

Beltran M, Tjahjono B, Bogush A, Julião J, Teixeira ELS. Food Plastic Packaging Transition towards Circular Bioeconomy: A Systematic Review of Literature. Sustainability. 2021; 13(7):3896. https://doi.org/10.3390/su13073896

Chicago/Turabian StyleBeltran, Macarena, Benny Tjahjono, Anna Bogush, Jorge Julião, and Evandro L. S. Teixeira. 2021. "Food Plastic Packaging Transition towards Circular Bioeconomy: A Systematic Review of Literature" Sustainability 13, no. 7: 3896. https://doi.org/10.3390/su13073896