Mechanisms of Environmental Regulation’s Impact on Green Technological Progress—Evidence from China’s Manufacturing Sector

Abstract

:1. Introduction

2. Literature Review

2.1. Related Research on the Environmental Regulation and Green Total Factor Productivity

2.2. Related Research on the Bias of Technological Change

2.3. Related Research on Manufacturing Sector Sustainability Measurement

3. Materials and Methods

3.1. The Model

3.2. Data and Sources

- Labor input. The labor force data is measured by using the average annual number of employees of enterprises above designated size in 27 subindustries of China’s manufacturing industry, which is taken from the “China Industrial Economic Statistics Yearbook.”

- Capital investment. The average annual balance of net fixed assets of enterprises above designated size in 27 subindustries in China’s manufacturing industry is used as an approximate estimate of the capital stock, and the fixed asset investment price index of each industry is converted into the constant price in 2000.

- Energy input. The total energy consumption of enterprises above designated size in 27 subindustries in China’s manufacturing industry is measured by the data from the “China Energy Statistical Yearbook,” which is converted into 10,000 tons of standard coal according to the conversion factor from the attached list in the “China Energy Statistical Yearbook.”

- Expected Output. The expected output is expressed using the main business income of above-scale enterprises in 27 subindustries of China’s manufacturing industry, with price index deflations using 2000 as the base period.

- Undesired Output. Using the calculation method of carbon emissions in the Guidelines for National Greenhouse Gas Inventories compiled by the Intergovernmental Panel on Climate Change (IPCC, 2016), the carbon emissions of enterprises above designated size by industry are obtained by summing the estimates using coal, coke, crude oil, gasoline, kerosene, diesel, fuel oil, and natural gas as benchmarks.

4. Empirical Results and Discussion

4.1. The Green TFP Growth and Technological Bias in China’s Manufacturing Sector

4.2. The Direction of the Green-Biased Technological Change

4.3. The Influencing Factors of Technological Bias and It’s Threshold Model

5. Conclusions and Policy Implications

- (1)

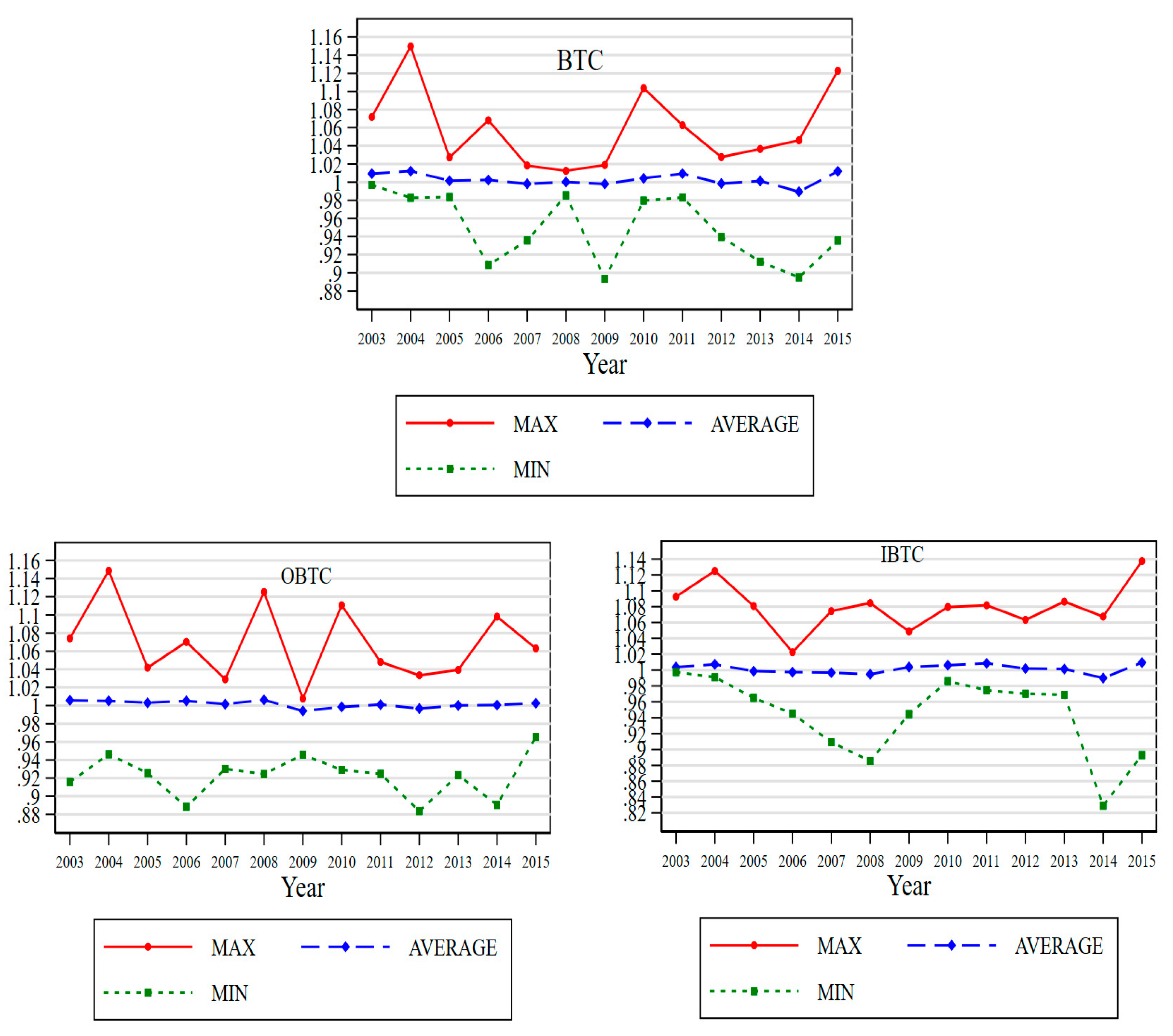

- During the study period, the growth rate of green total factor productivity in China’s manufacturing industry showed an overall downward trend, with an average annual growth rate of −0.622%. As for the decomposition, the average annual growth rate of technical efficiency EC was −0.105%. Technological progress TC is −0.497%. Compared with efficiency changes, technological changes are the main reason for the decline of green total factor productivity, which accounts for 79.9% of the decline in the growth rate of green total factor productivity. The average value of the BTC index is 1.003, which is very close to 1. This indicates that the overall technological progress of China’s manufacturing industry during the sample period is a neutral technological change, but the technological progress bias between industries is more obvious with significant differences.

- (2)

- By analyzing the elements of the Chinese manufacturing subsector combined with technical progress bias, we found that, in the input bias, the manufacturing sector showed significant L-Using/k-saving, L-using/E-saving, and K-using/E-saving are factor-biased characteristics. This shows that China’s manufacturing sector was mainly labor-intensive industries during the study period, with obvious labor input preferences, which benefited from China’s demographic dividend. In the output bias, the manufacturing industry has a clear bias toward the undesirable output CO2 characteristics, which indicates that the sector still uses fossil energy as the main energy consumer. The input of fossil energy has positive significance in promoting the technological progress of the sector. This also shows that green energy has not yet occupied China’s manufacturing industry’s main energy consumption, and the level of green technology innovation needs to be improved.

- (3)

- Through the analysis of the threshold model of environmental regulation on the technological progress of China’s manufacturing industry. Environmental regulation has obvious dual-threshold characteristics for biased technological change bias (BTC), input-biased and output-biased technological change, as well as obvious single threshold characteristics for technological progress, which shows that the relationship between environmental regulation and technological progress is not a simple linear relationship. For BTC, environmental regulation has a negative impact on BTC. As the intensity of environmental regulation increases, its impact on BTC first increases and then decreases. For IBTC, as the intensity of environmental regulations increases, its impact on IBTC has changed from positive to negative. For OBTC, as the intensity of environmental regulations increases, its impact on OBTC has changed from negative to positive and then to negative ultimately. For TC, as the intensity of environmental regulations increases, its impact on TC has changed from a positive impact to a negative impact. Regulating the intensity of environmental regulations can improve the technological progress of China’s manufacturing industry in a targeted manner. For example, for resource conservation requirements, more attention is paid to the intensity of IBTC’s environmental regulations; for pollution reduction requirements, more attention is paid to the intensity of OBTC’s environmental regulations.

- (4)

- In terms of other influencing factors, except for the property rights structure (PROP), the other influencing factors are all significant at the 1% level. Among them, R&D intensity, industry experts, and energy structure positively impact technological progress. The scale of the industry has a negative impact. This shows that R&D and foreign exports can effectively promote technological progress. At present, China’s manufacturing industry still uses fossil energy as the primary energy consumption, and all factor inputs are more biased towards labor factors. This analysis result is also consistent with the previous conclusion on technological progress biased factors.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhai, X.; An, Y. Analyzing influencing factors of green transformation in China’s manufacturing industry under environmental regulation: A structural equation model. J. Clean. Prod. 2020, 251, 119760. [Google Scholar] [CrossRef]

- Liu, J.; Xie, J. Environmental Regulation, Technological Innovation, and Export Competitiveness: An Empirical Study Based on China’s Manufacturing Industry. Int. J. Environ. Res. Public Health 2020, 17, 1427. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yuan, B.; Ren, S.; Chen, X. Can environmental regulation promote the coordinated development of economy and environment in China’s manufacturing industry?–A panel data analysis of 28 sub-sectors. J. Clean. Prod. 2017, 149, 11–24. [Google Scholar] [CrossRef]

- Shen, N.; Liao, H.; Deng, R.; Wang, Q. Different types of environmental regulations and the heterogeneous influence on the environmental total factor productivity: Empirical analysis of China’s industry. J. Clean. Prod. 2019, 211, 171–184. [Google Scholar] [CrossRef]

- Acemoglu, D. Why Do New Technologies Complement Skills? Directed Technical Change and Wage Inequality. Q. J. Econ. 1998, 113, 1055–1089. [Google Scholar] [CrossRef] [Green Version]

- Chen, P.-C.; Yu, M.-M. Total factor productivity growth and directions of technical change bias: Evidence from 99 OECD and non-OECD countries. Ann. Oper. Res. 2012, 214, 143–165. [Google Scholar] [CrossRef]

- Felipe, J.; McCombie, J.S.L. Biased technical change, growth accounting, and the conundrum of the East Asian miracle. J. Comp. Econ. 2001, 29, 542–565. [Google Scholar] [CrossRef]

- Färe, R.; Grosskopf, S.; Margaritis, D. Productivity Growth and Convergence in the European Union. J. Product. Anal. 2006, 25, 111–141. [Google Scholar] [CrossRef]

- Zhang, C.; Liu, H.; Bressers, H.T.A.; Buchanan, K.S. Productivity growth and environmental regulations—accounting for undesirable outputs: Analysis of China’s thirty provincial regions using the Malmquist–Luenberger index. Ecol. Econ. 2011, 70, 2369–2379. [Google Scholar] [CrossRef]

- Kaneko, S.; Managi, S. Environmental productivity in China. Econ. Bull. 2004, 17, 1–10. [Google Scholar]

- Zhao, L.; Sun, C.; Liu, F. Interprovincial two-stage water resource utilization efficiency under environmental constraint and spatial spillover effects in China. J. Clean. Prod. 2017, 164, 715–725. [Google Scholar] [CrossRef]

- Fujii, H.; Managi, S. Wastewater Management Efficiency and Determinant Factors in the Chinese Industrial Sector from 2004 to 2014. Water 2017, 9, 586. [Google Scholar] [CrossRef] [Green Version]

- Lin, B.; Xie, C. Energy substitution effect on transport industry of China-based on trans-log production function. Energy 2014, 67, 213–222. [Google Scholar] [CrossRef]

- Liu, P.; Huang, W.-C.; Chen, H. Can the National Green Industrial Policy Improve Production Efficiency of Enterprises?—Evidence from China. Sustainability 2020, 12, 6839. [Google Scholar] [CrossRef]

- Liu, G.; Wang, B.; Zhang, N. A coin has two sides: Which one is driving China’s green TFP growth? Econ. Syst. 2016, 40, 481–498. [Google Scholar] [CrossRef]

- Cao, J. Measuring green productivity growth for China’s manufacturing sectors: 1991–2000. Asian Econ. J. 2007, 21, 425–451. [Google Scholar] [CrossRef]

- Shi, X.; Li, L. Green total factor productivity and its decomposition of Chinese manufacturing based on the MML index: 2003–2015. J. Clean. Prod. 2019, 222, 998–1008. [Google Scholar] [CrossRef]

- Ghosal, V.; Stephan, A.; Weiss, J.F. Decentralized environmental regulations and plant-level productivity. Bus. Strategy Environ. 2019, 28, 998–1011. [Google Scholar] [CrossRef]

- Xie, R.-H.; Yuan, Y.-J.; Huang, J.-J. Different Types of Environmental Regulations and Heterogeneous Influence on “Green” Productivity: Evidence from China. Ecol. Econ. 2017, 132, 104–112. [Google Scholar] [CrossRef]

- Cai, W.-G.; Zhou, X.-L. Dual effect of Chinese environmental regulation on green total factor productivity. Economist 2017, 9, 27–35. [Google Scholar]

- Lei, X.; Wu, S. Improvement of Different Types of Environmental Regulations on Total Factor Productivity: A Threshold Effect Analysis. Discret. Dyn. Nat. Soc. 2019, 2019, 9790545. [Google Scholar] [CrossRef]

- Zhang, C.; Yu, T.-S.; Guo, L. Does environmental regulation influence industrial productivity in China—The Empirical test based on DEA and co-integration analysis. J. Econ. Theory Bus. Manag. 2010, 3, 11–17. [Google Scholar]

- Li, L.; Tao, F. Selection of optimal environmental regulation intensity for Chinese manufacturing industry-based on the green TFP perspective. China Ind. Econ. 2012, 5, 70–82. [Google Scholar]

- Li, B.; Peng, X.; Ouyang, M. Environmental regulation, green total factor productivity and the transformation of China’s industrial development mode: Analysis based on data of China’s 36 industries. China Ind. Econ. 2013, 4, 56–68. [Google Scholar]

- Li, B.; Wu, S. Effects of local and civil environmental regulation on green total factor productivity in China: A spatial Durbin econometric analysis. J. Clean. Prod. 2016, 153, 342–353. [Google Scholar] [CrossRef]

- López-Gamero, M.D.; Molina-Azorín, J.F.; Claver-Cortés, E. The potential of environmental regulation to change managerial perception, environmental management, competitiveness and financial performance. J. Clean. Prod. 2010, 18, 963–974. [Google Scholar] [CrossRef]

- Färe, R.; Grifell-Tatje, E.; Grosskopf, S.; Knox Lovell, C.A. Biased Technical Change and the Malmquist Productivity Index. Scand. J. Econ. 1997, 99, 119–127. [Google Scholar] [CrossRef]

- Sato, R.; Morita, T. Quantity or quality: The impact of labour saving innovation on us and Japanese growth rates, 1960–2004. Jpn. Econ. Rev. 2009, 60, 407–434. [Google Scholar] [CrossRef]

- Yang, Z.; Shao, S.; Li, C.; Yang, L. Alleviating the misallocation of R&D inputs in China’s manufacturing sector: From the perspectives of factor-biased technological innovation and substitution elasticity. Technol. Forecast. Soc. Chang. 2020, 151, 119878. [Google Scholar]

- Barros, C.P.; Managi, S.; Yoshida, Y. Productivity growth and biased technological change in Japanese airports. Transp. Policy 2010, 17, 259–265. [Google Scholar] [CrossRef]

- Briec, W.; Peypoch, N.; Ratsimbanierana, H. Productivity growth and biased technological change in hydroelectric dams. Energy Econ. 2011, 33, 853–858. [Google Scholar] [CrossRef]

- Li, J.; See, K.F.; Chi, J. Water resources and water pollution emissions in China’s industrial sector: A green-biased technological progress analysis. J. Clean. Prod. 2019, 229, 1412–1426. [Google Scholar] [CrossRef]

- Abegaz, B.; Basu, A.K. The Elusive Productivity Effect of Trade Liberalization in the Manufacturing Industries of Emerging Economies. Emerg. Mark. Financ. Trade 2011, 47, 5–27. [Google Scholar] [CrossRef] [Green Version]

- Hsieh, C.T.; Klenow, P.J. Misallocation and Manufacturing TFP in China and India. Q. J. Econ. 2009, 124, 1403–1448. [Google Scholar] [CrossRef] [Green Version]

- Kim, M.; Oh, J.; Shin, Y. Misallocation and Manufacturing TFP in Korea, 1982–2007. Review 2017, 99, 233–244. [Google Scholar] [CrossRef] [Green Version]

- Higon, D.A. The impact of R&D spillovers on UK manufacturing TFP: A dynamic panel approach. Res. Policy 2007, 36, 964–979. [Google Scholar]

- Marchi, V.D. Environmental innovation and R&D cooperation: Empirical evidence from Spanish manufacturing firms. Res. Policy 2012, 41, 614–623. [Google Scholar]

- Brunnermeier, S.B.; Cohen, M.A. Determinants of environmental innovation in US manufacturing industries. J. Environ. Econ. Manag. 2003, 45, 278–293. [Google Scholar] [CrossRef]

- Rubashkina, Y.; Galeotti, M.; Verdolini, E. Environmental regulation and competitiveness: Empirical evidence on the Porter Hypothesis from European manufacturing sectors. Energy Policy 2015, 83, 288–300. [Google Scholar] [CrossRef] [Green Version]

- Cao, Y.; Liu, J.; Yu, Y.; Wei, G. Impact of environmental regulation on green growth in China’s manufacturing industry–based on the Malmquist-Luenberger index and the system GMM model. Environ. Sci. Pollut. Res. 2020, 27, 41928–41945. [Google Scholar] [CrossRef]

- Cheng, M.; Shao, Z.; Yang, C.; Tang, X. Analysis of Coordinated Development of Energy and Environment in China’s Manufacturing Industry under Environmental Regulation: A Comparative Study of Sub-Industries. Sustainability 2019, 11, 6510. [Google Scholar] [CrossRef] [Green Version]

- Gong, M.; You, Z.; Wang, L.; Cheng, J. Environmental Regulation, Trade Comparative Advantage, and the Manufacturing Industry’s Green Transformation and Upgrading. Int. J. Environ. Res. Public Health 2020, 17, 2823. [Google Scholar] [CrossRef] [PubMed]

- Meng, F.; Xu, Y.; Zhao, G. Environmental regulations, green innovation and intelligent upgrading of manufacturing enterprises: Evidence from China. Sci. Rep. 2020, 10, 1–17. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Hu, Y. Measure and Analysis of Skill-biased Technological Progress in China’s Manufacturing Industry. J. Quant. Tech. Econ. 2015, 1, 82–96. [Google Scholar]

- Manasse, P.; Stanca, L. Working on the Train? The Role of Technical Progress and Trade in Explaining Wage Differentials in Italian Firms. Centro Studi Luca d’Agliano Development Studies Working Paper No. 177-2003. 2003. Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=490502 (accessed on 26 January 2021).

- Jaffe, A.B.; Newell, R.G.; Stavins, R.N. Environmental Policy and Technological Change. J. Environ. Resour. Econ. 2002, 22, 41–70. [Google Scholar] [CrossRef]

- Yang, C.H.; Tseng, Y.H.; Chen, C.P. Environmental regulations, induced R&D, and productivity: Evidence from Taiwan’s manufacturing industries. Resour. Energy Econ. 2012, 34, 514–532. [Google Scholar]

- Zhou, X.; Xia, M.; Zhang, T.; Du, J. Energy-and Environment-Biased Technological Progress Induced by Different Types of Environmental Regulations in China. Sustainability 2020, 12, 7486. [Google Scholar] [CrossRef]

- Song, M.; Wang, S. Measuring environment-biased technological progress considering energy saving and emission reduction. Process. Saf. Environ. Prot. 2018, 116, 745–753. [Google Scholar] [CrossRef]

- Song, M.; Wang, S. Can employment structure promote environment-biased technical progress? Technol. Forecast. Soc. Chang. 2016, 112, 285–292. [Google Scholar] [CrossRef]

- Calel, R.; Dechezleprêtre, A. Environmental Policy and Directed Technological Change: Evidence from the European Carbon Market. Rev. Econ. Stat. 2016, 98, 173–191. [Google Scholar] [CrossRef] [Green Version]

- Färe, R.; Grosskopf, S.; Lindgren, B.; Roos, P. Productivity changes in Swedish pharamacies 1980–1989: A non-parametric Malmquist approach. J. Product. Anal. 1992, 3, 85–101. [Google Scholar] [CrossRef]

- Tone, K. Dealing with undesirable outputs in DEA: A slacks-based measure (SBM) approach. In Proceedings of the Presentation at North American Productivity Workshop III, Toronto, ON, Canada, 23–25 June 2004; pp. 44–45. [Google Scholar]

- Weber, W.L.; Domazlicky, B.R. Total factor productivity growth in manufacturing: A regional approach using linear programming. Reg. Sci. Urban Econ. 1999, 29, 105–122. [Google Scholar] [CrossRef]

- Yin, B.Q. Environmental Regulation and China’s Green Total Factor Productivities: Based on the Perspective of Vertical Specialization. J. China Popul. Resour. Environ. 2012, 22, 60–66. [Google Scholar]

- Marrucci, L.; Daddi, T.; Iraldo, F. The integration of circular economy with sustainable consumption and production tools: Systematic review and future research agenda. J. Clean. Prod. 2019, 240, 118268. [Google Scholar] [CrossRef]

- Marrucci, L.; Marchi, M.; Daddi, T. Improving the carbon footprint of food and packaging waste management in a supermarket of the Italian retail sector. Waste Manag. 2020, 105, 594–603. [Google Scholar] [CrossRef]

- Marrucci, L.; Iraldo, F.; Daddi, T. Investigating the management challenges of the EU Ecolabel through multi-stakeholder surveys. Int. J. Life Cycle Assess. 2021. [Google Scholar] [CrossRef]

| Input mix | |||

|---|---|---|---|

| -saving, -using | Neutral | -saving, -using | |

| -saving, -using | Neutral | -saving, -using | |

| -saving, -using | Neutral | -saving, -using | |

| -saving, -using | Neutral | -saving, -using | |

| -saving, -using | Neutral | -saving, -using | |

| -saving, -using | Neutral | -saving, -using | |

| Output mix | |||

| Promote desirable output | Neutral | Increase undesirable output | |

| Increase undesirable output | Neutral | Promote desirable output |

| Variable | Description of Variable | Unit | Min | Max | Average | SD | |

|---|---|---|---|---|---|---|---|

| Inputs and Outputs | L | Labor | Ten thousand-person | 18.610 | 909.260 | 262.219 | 183.058 |

| K | Capital stock | 100 million yuan | 146.400 | 57,316.290 | 4218.415 | 6620.155 | |

| E | Energy consumption | Ten thousand tons | 109.380 | 69,342.000 | 7493.792 | 13,175.540 | |

| MBI | Main business income | 100 million yuan | 510.522 | 77,389.360 | 15,784.550 | 15,952.750 | |

| CO2 | Carbon dioxide emission | Ten thousand tons | 66.537 | 376,910.800 | 22,802.300 | 61,013.560 | |

| Influencing Factors | ER | Environmental regulation | 0.027 | 0.052 | 0.036 | 0.004 | |

| PROP | Proportion of state-owned Assets | 0.008 | 0.993 | 0.282 | 0.253 | ||

| R & D | R&D investment | 0.001 | 0.027 | 0.009 | 0.006 | ||

| EDV | Export delivery value | 21.230 | 46,165.140 | 2824.249 | 6052.567 | ||

| ASE | Average size of enterprises | 0.221 | 70.232 | 3.458 | 8.093 | ||

| SEC | Structure of energy consumption | 0.153 | 0.980 | 0.653 | 0.235 | ||

| Sector | MI | EC | TC | BTC | IBTC | OBTC | MTC | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Value | SD | Value | SD | Value | SD | Value | SD | Value | SD | Value | SD | Value | SD | |

| Processing of Food from Agricultural Products | 1.062 | 0.086 | 1.041 | 0.098 | 1.022 | 0.053 | 1.001 | 0.003 | 1.011 | 0.030 | 0.990 | 0.028 | 1.021 | 0.054 |

| Manufacture of Foods | 1.073 | 0.061 | 1.020 | 0.042 | 1.052 | 0.038 | 1.001 | 0.006 | 1.000 | 0.007 | 1.002 | 0.004 | 1.051 | 0.039 |

| Manufacture of Liquor, Beverages and Refined Tea | 1.099 | 0.058 | 1.025 | 0.040 | 1.072 | 0.043 | 1.001 | 0.007 | 1.001 | 0.007 | 1.001 | 0.005 | 1.070 | 0.039 |

| Manufacture of Tobacco | 1.019 | 0.033 | 1.032 | 0.056 | 0.990 | 0.044 | 0.992 | 0.011 | 1.005 | 0.016 | 0.987 | 0.017 | 0.998 | 0.046 |

| Manufacture of Textile | 1.070 | 0.037 | 1.028 | 0.054 | 1.043 | 0.056 | 1.003 | 0.005 | 1.000 | 0.010 | 1.003 | 0.008 | 1.041 | 0.057 |

| Manufacture of Textile, Wearing Apparel and Accessories | 1.047 | 0.070 | 0.990 | 0.053 | 1.061 | 0.100 | 1.013 | 0.018 | 0.999 | 0.008 | 1.013 | 0.018 | 1.047 | 0.090 |

| Manufacture of Leather, Fur, Feather and Related Products and Footwear | 1.009 | 0.030 | 0.994 | 0.136 | 1.036 | 0.177 | 1.003 | 0.040 | 1.026 | 0.064 | 0.980 | 0.055 | 1.039 | 0.210 |

| Processing of Timber, Manufacture of Wood, Bamboo, Rattan, Palm and Straw Products | 1.045 | 0.070 | 1.012 | 0.048 | 1.034 | 0.067 | 1.011 | 0.015 | 1.003 | 0.013 | 1.008 | 0.012 | 1.024 | 0.077 |

| Manufacture of Furniture | 0.946 | 0.074 | 0.955 | 0.117 | 0.999 | 0.078 | 1.010 | 0.043 | 0.993 | 0.050 | 1.017 | 0.030 | 0.994 | 0.122 |

| Manufacture of Paper and Paper Products | 1.109 | 0.058 | 1.016 | 0.065 | 1.094 | 0.066 | 1.001 | 0.005 | 0.998 | 0.008 | 1.003 | 0.008 | 1.093 | 0.066 |

| Printing and Reproduction of Recording Media | 1.001 | 0.260 | 1.013 | 0.248 | 0.991 | 0.088 | 1.022 | 0.054 | 0.989 | 0.048 | 1.035 | 0.049 | 0.970 | 0.079 |

| Manufacture of Articles for Culture, Education, Arts and Crafts, Sport and Entertainment Activities | 1.000 | 0.070 | 1.002 | 0.057 | 0.998 | 0.030 | 1.006 | 0.007 | 1.000 | 0.027 | 1.007 | 0.028 | 0.992 | 0.025 |

| Processing of Petroleum, Coking and Processing of Nuclear Fuel | 1.017 | 0.013 | 1.001 | 0.013 | 1.016 | 0.006 | 1.001 | 0.003 | 1.001 | 0.001 | 1.000 | 0.003 | 1.015 | 0.007 |

| Manufacture of Raw Chemical Materials and Chemical Products | 1.176 | 0.085 | 1.080 | 0.081 | 1.092 | 0.089 | 0.997 | 0.051 | 0.998 | 0.010 | 0.999 | 0.052 | 1.097 | 0.092 |

| Manufacture of Medicines | 1.084 | 0.078 | 1.022 | 0.065 | 1.062 | 0.048 | 1.002 | 0.006 | 1.002 | 0.006 | 1.000 | 0.005 | 1.060 | 0.046 |

| Manufacture of Chemical Fibers | 1.093 | 0.124 | 0.993 | 0.121 | 1.104 | 0.064 | 1.018 | 0.014 | 1.007 | 0.013 | 1.011 | 0.014 | 1.084 | 0.066 |

| Manufacture of Rubber and Plastics Products | 1.071 | 0.035 | 1.020 | 0.038 | 1.051 | 0.050 | 1.003 | 0.007 | 1.000 | 0.009 | 1.003 | 0.005 | 1.048 | 0.050 |

| Manufacture of Non-metallic Mineral Products | 1.13 | 0.050 | 1.054 | 0.069 | 1.079 | 0.072 | 1.001 | 0.010 | 0.997 | 0.007 | 1.004 | 0.012 | 1.078 | 0.075 |

| Smelting and Pressing of Ferrous Metals | 1.098 | 0.182 | 1.050 | 0.181 | 1.050 | 0.078 | 0.987 | 0.030 | 0.992 | 0.031 | 0.995 | 0.035 | 1.066 | 0.103 |

| Smelting and Pressing of Non-ferrous Metals | 1.121 | 0.184 | 1.088 | 0.172 | 1.030 | 0.044 | 0.998 | 0.008 | 1.010 | 0.030 | 0.989 | 0.027 | 0.998 | 0.008 |

| Manufacture of Metal Products | 1.064 | 0.050 | 1.008 | 0.051 | 1.057 | 0.052 | 1.005 | 0.007 | 1.001 | 0.008 | 1.004 | 0.006 | 1.052 | 0.053 |

| Manufacture of General Purpose Machinery | 1.088 | 0.047 | 1.033 | 0.052 | 1.055 | 0.057 | 1.001 | 0.008 | 0.996 | 0.008 | 1.005 | 0.008 | 1.053 | 0.055 |

| Manufacture of Special Purpose Machinery | 1.084 | 0.028 | 1.028 | 0.057 | 1.057 | 0.051 | 0.998 | 0.007 | 0.997 | 0.005 | 1.001 | 0.006 | 1.058 | 0.048 |

| Manufacture of Transport Equipmem | 1.075 | 0.096 | 1.051 | 0.085 | 1.027 | 0.109 | 0.999 | 0.037 | 1.007 | 0.034 | 0.992 | 0.038 | 1.030 | 0.114 |

| Manufacture of Electrical Machinery and Apparatus | 1.081 | 0.068 | 1.018 | 0.078 | 1.065 | 0.077 | 0.993 | 0.031 | 0.997 | 0.026 | 0.996 | 0.032 | 1.074 | 0.092 |

| Manufacture of Computers, Communication and Other Electronic Equipment | 1.022 | 0.018 | 1.006 | 0.026 | 1.016 | 0.020 | 1.002 | 0.004 | 1.001 | 0.002 | 1.001 | 0.004 | 1.014 | 0.019 |

| Manufacture of Measuring Instruments and Machinery | 1.034 | 0.074 | 1.003 | 0.040 | 1.031 | 0.062 | 1.007 | 0.039 | 1.011 | 0.034 | 0.996 | 0.038 | 1.027 | 0.102 |

| Average | 1.064 | 0.076 | 1.022 | 0.079 | 1.044 | 0.064 | 1.003 | 0.018 | 1.002 | 0.019 | 1.002 | 0.020 | 1.041 | 0.068 |

| Year | IBTC | OBTC | K vs. L | K vs. E | L vs. E | Desirable Output vs. CO2 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| >1 | <1 | >1 | <1 | K-Using | L-Using | K-Using | E-Using | L-Using | E-Using | Desirable Output-Producing | CO2-Producing | |

| 2003 | 13 | 14 | 21 | 6 | 20 | 7 | 10 | 17 | 13 | 14 | 6 | 21 |

| 2004 | 10 | 17 | 21 | 6 | 14 | 13 | 7 | 20 | 9 | 18 | 15 | 12 |

| 2005 | 7 | 20 | 21 | 6 | 18 | 9 | 11 | 16 | 6 | 21 | 7 | 20 |

| 2006 | 9 | 18 | 22 | 5 | 19 | 8 | 12 | 15 | 7 | 20 | 5 | 22 |

| 2007 | 7 | 20 | 18 | 9 | 18 | 9 | 22 | 5 | 16 | 11 | 9 | 18 |

| 2008 | 11 | 16 | 18 | 9 | 16 | 11 | 19 | 8 | 17 | 10 | 9 | 18 |

| 2009 | 17 | 10 | 10 | 17 | 10 | 17 | 10 | 17 | 10 | 17 | 18 | 9 |

| 2010 | 12 | 15 | 12 | 15 | 16 | 11 | 11 | 16 | 11 | 16 | 14 | 13 |

| 2011 | 18 | 9 | 15 | 12 | 8 | 19 | 12 | 15 | 18 | 9 | 12 | 15 |

| 2012 | 12 | 15 | 12 | 15 | 13 | 14 | 15 | 12 | 12 | 15 | 15 | 12 |

| 2013 | 9 | 18 | 20 | 7 | 17 | 10 | 18 | 9 | 22 | 5 | 20 | 7 |

| 2014 | 14 | 13 | 19 | 8 | 14 | 13 | 12 | 15 | 17 | 10 | 10 | 17 |

| 2015 | 19 | 8 | 13 | 14 | 8 | 19 | 6 | 21 | 10 | 17 | 17 | 10 |

| 10thFYP | >1 | >1 | L | K | L | CO2 | ||||||

| 11thFYP | <1 | >1 | K | K | L | CO2 | ||||||

| 12thFYP | >1 | >1 | L | E | L | CO2 | ||||||

| The Threshold Test | LncIBTC | LncOBTC | LncBTC | LncTC | ||||

|---|---|---|---|---|---|---|---|---|

| Single Threshold | Double Threshold | Single Threshold | Double Threshold | Single Threshold | Double Threshold | Single Threshold | Double Threshold | |

| F-Value | 34.310 *** | 22.800 *** | 20.030 *** | 11.87 *** | 25.160 ** | 12.71 * | 20.77 *** | 6.22 |

| p-Value | 0.004 | 0.000 | 0.000 | 0.003 | 0.003 | 0.0867 | 0.000 | 0.53 |

| 1% | 30.213 | 15.839 | 16.046 | 9.89 | 29.47 | 32.7891 | 12.6947 | 15.013 |

| 5% | 27.964 | 13.394 | 14.531 | 8.758 | 23.463 | 15.0074 | 10.3231 | 10.881 |

| 10% | 26.553 | 11.595 | 13.156 | 7.864 | 20.977 | 11.8642 | 8.6902 | 9.594 |

| Variable | lncIBTC | Variable | lncOBTC | Variable | lncBTC | Variable | lncTC | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Coef. | t-Stat. | Coef. | t-Stat. | Coef. | t-Stat. | Coef. | t-Stat. | ||||

| lnER ≤ −3.822 | 0.003 *** | 1.250 | lnER ≤ −3.6218 | −0.02 *** | −4.600 | lnER ≤ −1.8297 | −0.006 ** | −2.22 | lnER ≤ −2.2132 | 0.052 *** | 6.270 |

| −3.822 < lnER ≤ −2.6491 | −0.004 | −1.030 | −3.6218 < lnER ≤ −2.6790 | 0.0002 | 0.030 | −1.8297 < lnER ≤ −1.2931 | −0.043 *** | −3.89 | lnER > −2.2132 | −0.021 | −0.960 |

| lnER > −2.6491 | −0.023 | −0.850 | lnER > −2.6790 | −0.021 *** | −2.470 | lnER > −1.2931 | −0.025 ** | −2.07 | - | - | - |

| lnPROP | −0.032 *** | −6.200 | lnPROP | 0.026 *** | 3.560 | lnPROP | −0.004 | −0.81 | lnPROP | −0.010 | −0.610 |

| lnR&D | 0.020 *** | 3.300 | lnR&D | −0.012 | −1.400 | lnR&D | 0.005 | 0.85 | lnR&D | 0.117 *** | 6.210 |

| lnEDV | 0.002 | 0.680 | lnEDV | −0.018 *** | −4.290 | lnEDV | −0.011 *** | −4.05 | lnEDV | 0.032 *** | 3.320 |

| lnASE | 0.038 *** | 7.910 | lnASE | −0.069 *** | −10.830 | lnASE | −0.03 *** | −7.40 | lnASE | −0.036 *** | −2.430 |

| lnSEC | 0.013 | 1.340 | lnSEC | −0.011 | −0.870 | lnSEC | 0.002 | 0.25 | lnSEC | 0.116 *** | 3.930 |

| Cons. | 0.009 | 0.25 | Cons. | 0.849 * | 1.48 | Cons. | 0.115 *** | 3.1 | Cons. | 0.811 *** | 6.26 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, W.; Du, M.; Bai, Y. Mechanisms of Environmental Regulation’s Impact on Green Technological Progress—Evidence from China’s Manufacturing Sector. Sustainability 2021, 13, 1600. https://doi.org/10.3390/su13041600

Liu W, Du M, Bai Y. Mechanisms of Environmental Regulation’s Impact on Green Technological Progress—Evidence from China’s Manufacturing Sector. Sustainability. 2021; 13(4):1600. https://doi.org/10.3390/su13041600

Chicago/Turabian StyleLiu, Weijiang, Mingze Du, and Yuxin Bai. 2021. "Mechanisms of Environmental Regulation’s Impact on Green Technological Progress—Evidence from China’s Manufacturing Sector" Sustainability 13, no. 4: 1600. https://doi.org/10.3390/su13041600