Investigating the Drivers of Supply Chain Resilience in the Wake of the COVID-19 Pandemic: Empirical Evidence from an Emerging Economy

Abstract

:1. Introduction

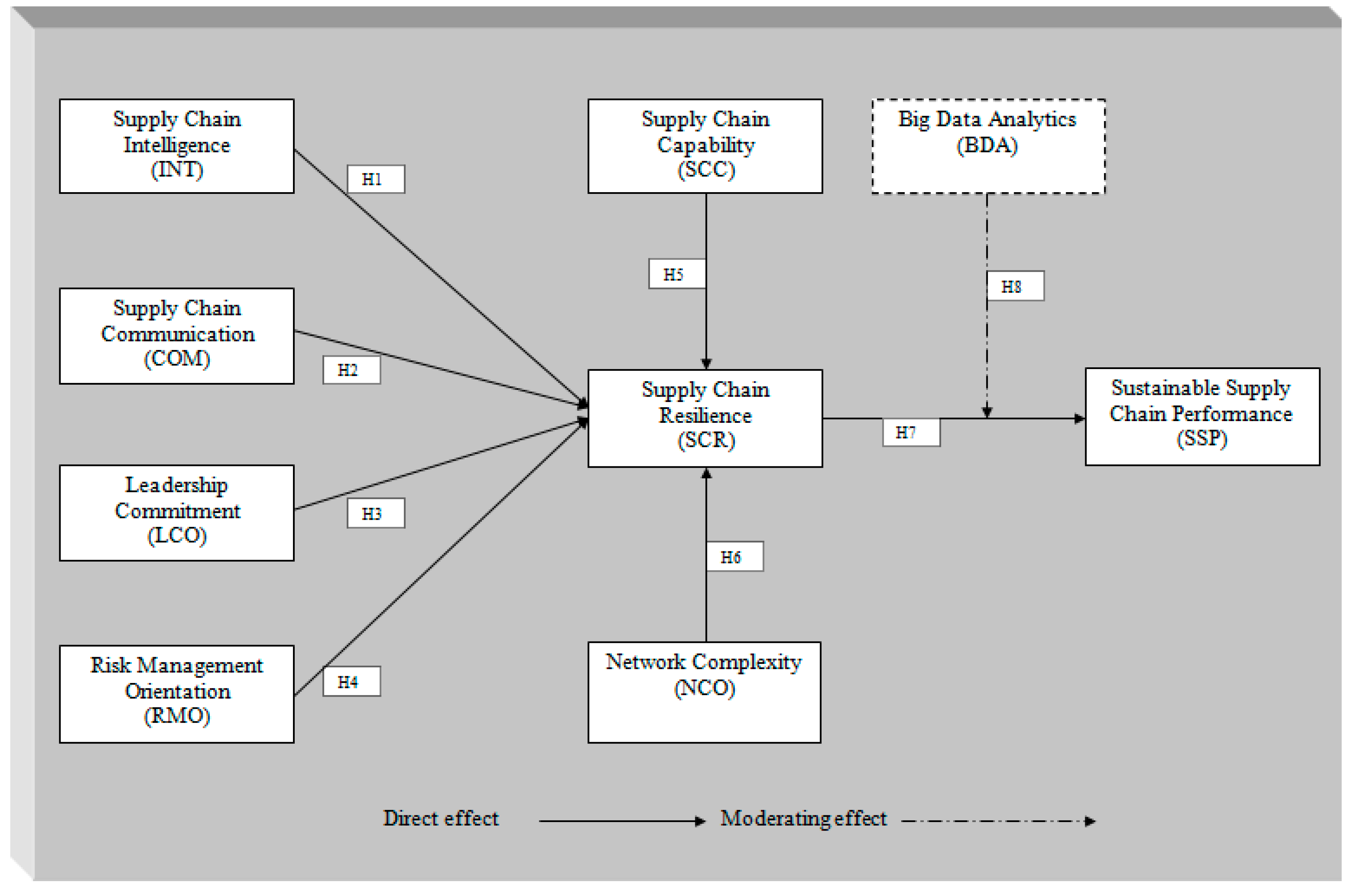

2. Literature Review

2.1. Supply Chain Intelligence and Communication

2.2. The Role of Leadership Commitment and Risk Management Orientation

2.3. Supply Chain Capability and Network Complexity

2.4. Big Data Analytics

3. Research Methods

3.1. Designing Questionnaire and Instrument Development

3.2. Sampling and Data Collection

4. Data Analysis

4.1. Common Method Bias

4.2. Structural Equation Modeling

4.2.1. Assessing Measurement Model

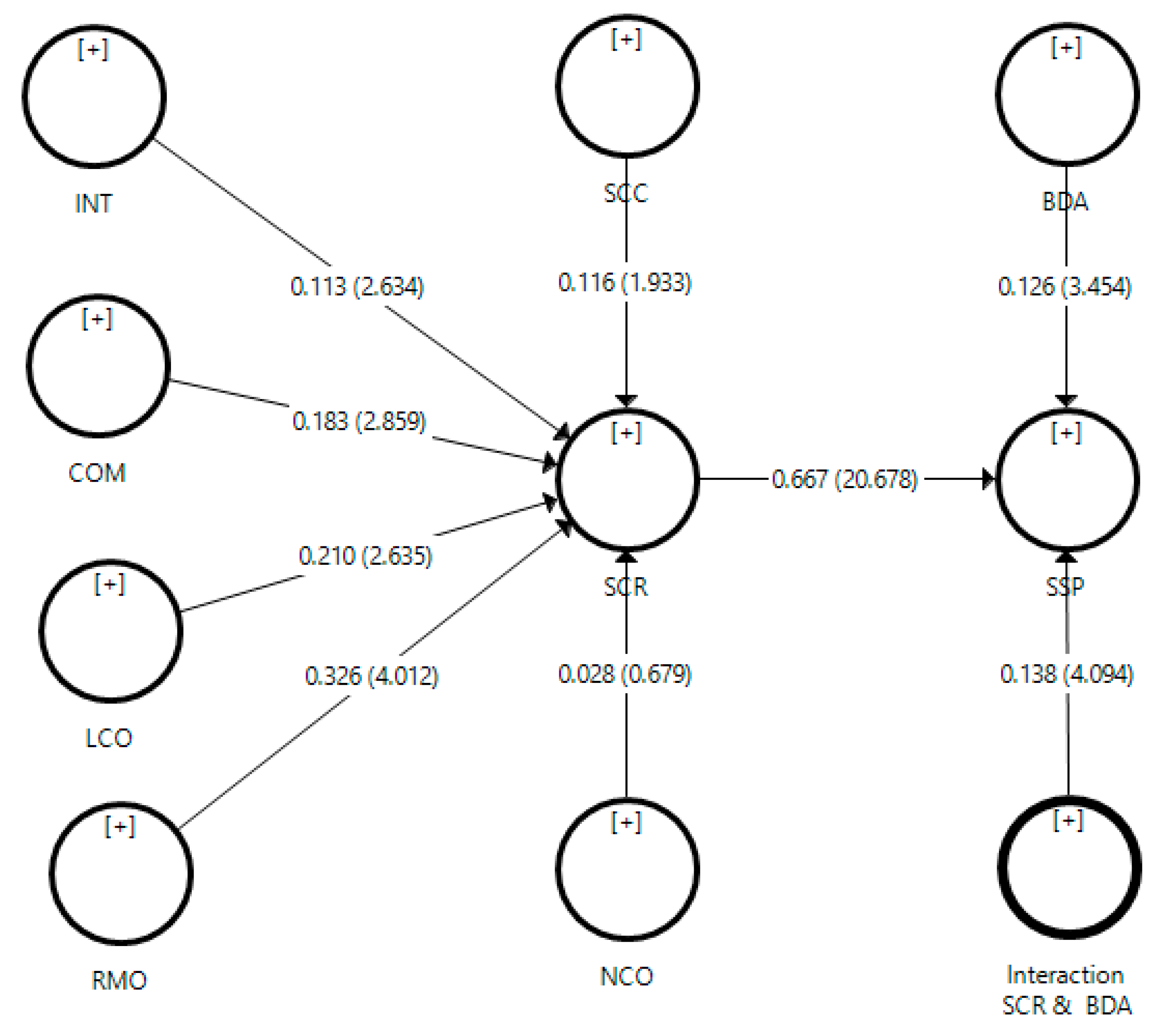

4.2.2. Assessing Structural Model

4.2.3. Assessing Effect Size, Predictive Power and Coefficient of Determination

4.2.4. Importance and Performance Analysis

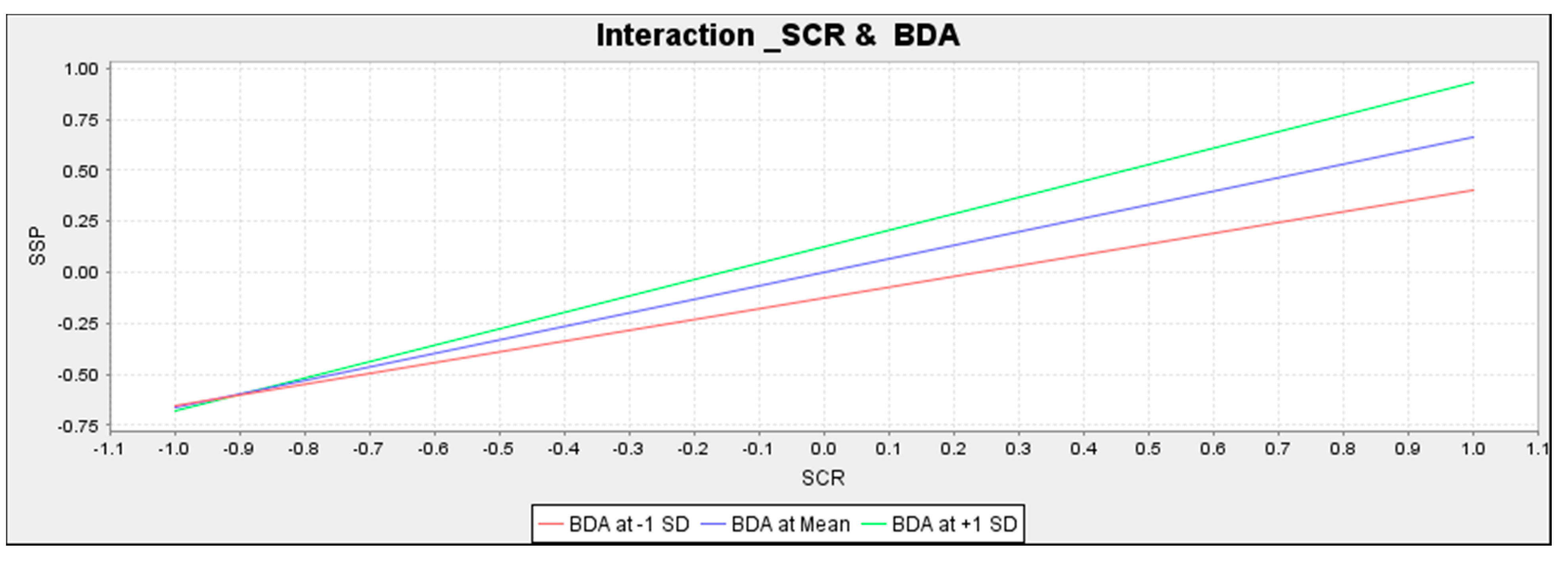

4.3. Moderating Effect of Big Data Analytics

5. Discussion

Research Contribution to Theory and Practice

6. Conclusions

Research Limitations and Future Direction

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Path Coefficient and Significance Level

References

- Brandon-Jones, E.; Squire, B.; Autry, C.W.; Petersen, K. A Contingent Resource-Based Perspective of Supply Chain Resilience and Robustness. J. Supply Chain Manag. 2014, 50, 55–73. [Google Scholar] [CrossRef] [Green Version]

- Bhamra, R.S.; Dani, S.; Burnard, K.J. Resilience: The concept, a literature review and future directions. Int. J. Prod. Res. 2011, 49, 5375–5393. [Google Scholar] [CrossRef]

- Bode, C.; Wagner, S.; Petersen, K.; Ellram, L.M. Understanding Responses to Supply Chain Disruptions: Insights from Information Processing and Resource Dependence Perspectives. Acad. Manag. J. 2011, 54, 833–856. [Google Scholar] [CrossRef]

- Blackhurst, J.; Dunn, K.S.; Craighead, C.W. An Empirically Derived Framework of Global Supply Resiliency. J. Bus. Logist. 2011, 32, 374–391. [Google Scholar] [CrossRef]

- Karmaker, C.L.; Ahmed, T.; Ahmed, S.; Ali, S.M.; Moktadir, M.A.; Kabir, G. Improving supply chain sustainability in the context of COVID-19 pandemic in an emerging economy: Exploring drivers using an integrated model. Sustain. Prod. Consum. 2021, 26, 411–427. [Google Scholar] [CrossRef]

- Belhadi, A.; Kamble, S.; Jabbour, C.J.C.; Gunasekaran, A.; Ndubisi, N.O.; Venkatesh, M. Manufacturing and service supply chain resilience to the COVID-19 outbreak: Lessons learned from the automobile and airline industries. Technol. Forecast. Soc. Chang. 2021, 163, 120447. [Google Scholar] [CrossRef] [PubMed]

- Kaynak, H. The relationship between total quality management practices and their effects on firm performance. J. Oper. Manag. 2003, 21, 405–435. [Google Scholar] [CrossRef]

- Butt, A.S. Strategies to mitigate the impact of COVID-19 on supply chain disruptions: A multiple case analysis of buyers and distributors. Int. J. Logist. Manag. 2021, ahead-of-print. [Google Scholar] [CrossRef]

- Jabbour, A.B.L.D.S.; Jabbour, C.J.C.; Hingley, M.; Vilalta-Perdomo, E.; Ramsden, G.; Twigg, D. Sustainability of supply chains in the wake of the coronavirus (COVID-19/SARS-CoV-2) pandemic: Lessons and trends. Mod. Supply Chain Res. Appl. 2020, 2, 117–122. [Google Scholar] [CrossRef]

- Paul, S.K.; Chowdhury, P.; Moktadir, A.; Lau, K.H. Supply chain recovery challenges in the wake of COVID-19 pandemic. J. Bus. Res. 2021, 136, 316–329. [Google Scholar] [CrossRef]

- Yang, J.; Xie, H.; Yu, G.; Liu, M. Achieving a just–in–time supply chain: The role of supply chain intelligence. Int. J. Prod. Econ. 2020, 231, 107878. [Google Scholar] [CrossRef]

- Barki, H.; Pinsonneault, A. A Model of Organizational Integration, Implementation Effort, and Performance. Organ. Sci. 2005, 16, 165–179. [Google Scholar] [CrossRef]

- Speier, C.; Whipple, J.M.; Closs, D.J.; Voss, M.D. Global supply chain design considerations: Mitigating product safety and security risks. J. Oper. Manag. 2011, 29, 721–736. [Google Scholar] [CrossRef]

- Wieland, A.; Wallenburg, C.M. Dealing with supply chain risks. Int. J. Phys. Distrib. Logist. Manag. 2012, 42, 887–905. [Google Scholar] [CrossRef] [Green Version]

- Durach, C.F.; Wieland, A.; Machuca, J.A. Antecedents and dimensions of supply chain robustness: A systematic literature review. Int. J. Phys. Distrib. Logist. Manag. 2015, 45, 118–137. [Google Scholar] [CrossRef] [Green Version]

- Wu, F.; Yeniyurt, S.; Kim, D.; Cavusgil, S.T. The impact of information technology on supply chain capabilities and firm performance: A resource-based view. Ind. Mark. Manag. 2006, 35, 493–504. [Google Scholar] [CrossRef]

- Dubey, R.; Gunasekaran, A.; Childe, S.J.; Wamba, S.F.; Roubaud, D.; Foropon, C. Empirical investigation of data analytics capability and organizational flexibility as complements to supply chain resilience. Int. J. Prod. Res. 2021, 59, 110–128. [Google Scholar] [CrossRef]

- Schoenherr, T.; Swink, M. The Roles of Supply Chain Intelligence and Adaptability in New Product Launch Success. Decis. Sci. 2015, 46, 901–936. [Google Scholar] [CrossRef]

- Handfield, R. Supply Market Intelligence: A Managerial Handbook for Building Sourcing Strategies, 1st ed.; CRC Press: New York, NY, USA, 2006. [Google Scholar]

- Yamin, M.A.Y.; Mahasneh, M.S. The Impact of Values-based Leadership on Ethical Loyalty in Saudi Arabian Health Organizations. Int. Rev. Manag. Mark. 2018, 8, 6–13. [Google Scholar]

- Zhang, Q.; Cao, M. Exploring antecedents of supply chain collaboration: Effects of culture and interorganizational system appropriation. Int. J. Prod. Econ. 2018, 195, 146–157. [Google Scholar] [CrossRef]

- Asamoah, D.; Agyei-Owusu, B.; Andoh-Baidoo, F.; Ayaburi, E. Inter-organizational systems use and supply chain performance: Mediating role of supply chain management capabilities. Int. J. Inf. Manag. 2021, 58, 102195. [Google Scholar] [CrossRef]

- Benedek, Z.; Fertő, I.; Marreiros, C.G.; de Aguiar, P.M.; Pocol, C.B.; Čechura, L.; Põder, A.; Pääso, P.; Bakucs, Z. Farm diversification as a potential success factor for small-scale farmers constrained by COVID-related lockdown. Contributions from a survey conducted in four European countries during the first wave of COVID-19. PLoS ONE 2021, 16, e0251715. [Google Scholar] [CrossRef]

- Fornell, C.; Larcker, D.F. Structural Equation Models with Unobservable Variables and Measurement Error: Algebra and Statistics. J. Mark. Res. 1981, 18, 382–388. [Google Scholar] [CrossRef]

- Yamin, M.A.Y. Examining the effect of organisational innovation on employee creativity and firm performance: Moderating role of knowledge sharing between employee creativity and employee performance. Int. J. Bus. Innov. Res. 2020, 22, 447–467. [Google Scholar] [CrossRef]

- Grötsch, V.M.; Blome, C.; Schleper, M.C. Antecedents of proactive supply chain risk management—A contingency theory perspective. Int. J. Prod. Res. 2013, 51, 2842–2867. [Google Scholar] [CrossRef]

- Hall, D.J.; Skipper, J.B.; Hazen, B.; Hanna, J.B. Inter-organizational IT use, cooperative attitude, and inter-organizational collaboration as antecedents to contingency planning effectiveness. Int. J. Logist. Manag. 2012, 23, 50–76. [Google Scholar] [CrossRef]

- Jüttner, U.; Maklan, S. Supply chain resilience in the global financial crisis: An empirical study. Supply Chain Manag. Int. J. 2011, 16, 246–259. [Google Scholar] [CrossRef]

- Lin, C.-C.; Wang, T.-H. Build-to-order supply chain network design under supply and demand uncertainties. Transp. Res. Part B Methodol. 2011, 45, 1162–1176. [Google Scholar] [CrossRef]

- Schmitt, A.J. Strategies for customer service level protection under multi-echelon supply chain disruption risk. Transp. Res. Part B Methodol. 2011, 45, 1266–1283. [Google Scholar] [CrossRef]

- Brusset, X.; Teller, C. Supply chain capabilities, risks, and resilience. Int. J. Prod. Econ. 2017, 184, 59–68. [Google Scholar] [CrossRef]

- Faisal, M.N.; Banwet, D.K.; Shankar, R. Information risks management in supply chains: An assessment and mitigation framework. J. Enterp. Inf. Manag. 2007, 20, 677–699. [Google Scholar] [CrossRef]

- Akter, S.; Wamba, S.F.; Gunasekaran, A.; Dubey, R.; Childe, S.J. How to improve firm performance using big data analytics capability and business strategy alignment? Int. J. Prod. Econ. 2016, 182, 113–131. [Google Scholar] [CrossRef] [Green Version]

- Janssen, M.; van der Voort, H.; Wahyudi, A. Factors influencing big data decision-making quality. J. Bus. Res. 2017, 70, 338–345. [Google Scholar] [CrossRef]

- Lai, Y.; Sun, H.; Ren, J. Understanding the determinants of big data analytics (BDA) adoption in logistics and supply chain management. Int. J. Logist. Manag. 2018, 29, 676–703. [Google Scholar] [CrossRef]

- Snapp, S. Is Big Data the Silver Bullet for Supply-Chain Forecasting? In Business Forecasting: The Emerging Role of Artificial Intelligence and Machine Learning; Gilliland, M., Tashman, L., Sglavo, U., Eds.; Wiley: Hoboken, NJ, USA, 2021; pp. 136–141. [Google Scholar]

- Wamba, S.F.; Akter, S.; Edwards, A.; Chopin, G.; Gnanzou, D. How ‘big data’ can make big impact: Findings from a systematic review and a longitudinal case study. Int. J. Prod. Econ. 2015, 165, 234–246. [Google Scholar] [CrossRef]

- Yu, W.; Zhao, G.; Liu, Q.; Song, Y. Role of big data analytics capability in developing integrated hospital supply chains and operational flexibility: An organizational information processing theory perspective. Technol. Forecast. Soc. Chang. 2021, 163, 120417. [Google Scholar] [CrossRef]

- Rowley, J. Designing and using research questionnaires. Manag. Res. Rev. 2014, 37, 308–330. [Google Scholar] [CrossRef]

- Gunasekaran, A.; Papadopoulos, T.; Dubey, R.; Wamba, S.F.; Childe, S.J.; Hazen, B.; Akter, S. Big data and predictive analytics for supply chain and organizational performance. J. Bus. Res. 2017, 70, 308–317. [Google Scholar] [CrossRef]

- Bag, S.; Wood, L.C.; Xu, L.; Dhamija, P.; Kayikci, Y. Big data analytics as an operational excellence approach to enhance sustainable supply chain performance. Resour. Conserv. Recycl. 2020, 153, 104559. [Google Scholar] [CrossRef]

- Hair, J.F., Jr.; Hult, G.T.M.; Ringle, C.; Sarstedt, M. A Primer on Partial Least Squares Structural Equation Modeling (PLS-SEM), 2nd ed.; Sage Publications: Thousand Oaks, CA, USA, 2016. [Google Scholar]

- Yamin, M. Examining the role of transformational leadership and entrepreneurial orientation on employee retention with moderating role of competitive advantage. Manag. Sci. Lett. 2020, 10, 313–326. [Google Scholar] [CrossRef]

- Rahi, S.; Mansour, M.M.O.; Alharafsheh, M.; Alghizzawi, M. The post-adoption behavior of internet banking users through the eyes of self-determination theory and expectation confirmation model. J. Enterp. Inf. Manag. 2021, ahead-of-print. [Google Scholar] [CrossRef]

- Podsakoff, P.M.; Organ, D.W. Self-Reports in Organizational Research: Problems and Prospects. J. Manag. 1986, 12, 531–544. [Google Scholar] [CrossRef]

- Sweiss, M.I.K.; Yamin, M.A.Y. The influence of organisational and individual factors on organisational innovation with moderating role of innovation orientation. Int. J. Bus. Innov. Res. 2020, 23, 103. [Google Scholar] [CrossRef]

- Podsakoff, P.M.; Bommer, W.H.; Podsakoff, N.P.; MacKenzie, S.B. Relationships between leader reward and punishment behavior and subordinate attitudes, perceptions, and behaviors: A meta-analytic review of existing and new research. Organ. Behav. Hum. Decis. Process. 2006, 99, 113–142. [Google Scholar] [CrossRef]

- Podsakoff, P.M.; MacKenzie, S.B.; Lee, J.-Y.; Podsakoff, N.P. Common method biases in behavioral research: A critical review of the literature and recommended remedies. J. Appl. Psychol. 2003, 88, 879–903. [Google Scholar] [CrossRef] [PubMed]

- Rahi, S.; Khan, M.M.; Alghizzawi, M. Extension of technology continuance theory (TCT) with task technology fit (TTF) in the context of Internet banking user continuance intention. Int. J. Qual. Reliab. Manag. 2020, 38, 986–1004. [Google Scholar] [CrossRef]

- Rahi, S.; Mansour, M.M.O.; Alghizzawi, M.; Alnaser, F.M. Integration of UTAUT model in internet banking adoption context. J. Res. Interact. Mark. 2019, 13, 411–435. [Google Scholar] [CrossRef]

- Yamin, M.A.Y. The relationship between right ethical behavior perspective, demographic factors, and best ethical performance. Int. Rev. Manag. Mark. 2020, 10, 27–39. [Google Scholar] [CrossRef]

- Ringle, C.M.; Wende, S.; Becker, J.-M. SmartPLS 3. Boenningstedt: SmartPLS. Available online: https://www.smartpls.com (accessed on 22 May 2021).

- Yamin, M.A.Y.; Sweiss, M.I.K. Investigating employee creative performance with integration of DeLone and McLean information system success model and technology acceptance model: The moderating role of creative self-efficacy. Int. J. Bus. Excel. 2020, 22, 396. [Google Scholar] [CrossRef]

- Yamin, M.A.Y.; Alyoubi, B.A. Adoption of telemedicine applications among Saudi citizens during COVID-19 pandemic: An alternative health delivery system. J. Infect. Public Health 2020, 13, 1845–1855. [Google Scholar] [CrossRef] [PubMed]

- Gold, A.H.; Malhotra, A.; Segars, A.H. Knowledge Management: An Organizational Capabilities Perspective. J. Manag. Inf. Syst. 2001, 18, 185–214. [Google Scholar] [CrossRef]

- Kline, R.B. Principles and Practice of Structural Equation Modeling, 3rd ed.; The Guilford Press: New York, NY, USA, 2011. [Google Scholar]

- Rahi, S.; Ghani, M.A.; Ngah, A.H. Factors propelling the adoption of internet banking: The role of e-customer service, website design, brand image and customer satisfaction. Int. J. Bus. Inf. Syst. 2020, 33, 549. [Google Scholar] [CrossRef]

- Rahi, S.; Ghani, M.A. Integration of DeLone and McLean and self-determination theory in internet banking continuance intention context. Int. J. Account. Inf. Manag. 2019, 27, 512–528. [Google Scholar] [CrossRef]

- Hair, J.F.; Ringle, C.M.; Sarstedt, M. Partial least squares structural equation modeling: Rigorous applications, better results and higher acceptance. SSRN J. 2013, 46, 1–12. [Google Scholar] [CrossRef]

- Ranjan, J.; Foropon, C. Big Data Analytics in Building the Competitive Intelligence of Organizations. Int. J. Inf. Manag. 2021, 56, 102231. [Google Scholar] [CrossRef]

- Rahi, S. Structural Equation Modeling Using SmartPLS, 1st ed.; CreateSpace Independent Publishing Platform: Scotts Valley, CA, USA, 2017. [Google Scholar]

| Total Variance Explained | ||||||

|---|---|---|---|---|---|---|

| Factors | Eigenvalues | Extraction Sums of Squared Loadings | ||||

| Total | % of Variance | Cumulative % | Total | % of Variance | Cumulative % | |

| 1 | 9.422 | 23.737 | 23.737 | 9.422 | 23.737 | 23.737 |

| Indicator | Loadings | (α) | CR | AVE |

|---|---|---|---|---|

| Big Data Analytics (BDA) | ||||

| BDA1: In this firm, advance data analytics tools are used to take decisions. | 0.824 | 0.757 | 0.861 | 0.673 |

| BDA2: In this firm, information is extracted using big data analytics to take decision. | 0.843 | |||

| BDA3: For data visualization, this firm use dashboard display to assist supply chain managers. | 0.793 | |||

| Supply Chain Communication (COM) | ||||

| COM1: This firm has multiple communication channels to facilitate supply chain operations. | 0.826 | 0.854 | 0.902 | 0.696 |

| COM2: This firm uses an integrated organizational system to communicate with stakeholders. | 0.841 | |||

| COM3: This firm uses the latest integrated communication tools for channel communication. | 0.825 | |||

| COM4: The use of frequent communication among supply chain partners enhances firm resilience. | 0.845 | |||

| Supply Chain Intelligence (INT) | ||||

| INT1: This firm is able to search, retrieve and store business information to boost supply chain operation. | 0.717 | 0.700 | 0.834 | 0.628 |

| INT3: This firm is ability to understand sales trends and customer preferences using integrated supply chain tools. | 0.869 | |||

| INT4: This firm uses integrated information retrieved from past events to deal with any kind of unprecedented situation. | 0.784 | |||

| Leadership Commitment (LCO) | ||||

| LCO1: The leadership of this organization is committed to handling all kinds of profit and loss. | 0.752 | 0.785 | 0.860 | 0.606 |

| LCO2: Leaders of this organization take responsibility for all the departments to tackle with unprecedented situation. | 0.798 | |||

| LCO3: Leaders of this organization support long term organizational goals. | 0.752 | |||

| LCO4: Leadership of this organization shows pro-activeness to recover business operations. | 0.809 | |||

| Network Complexity (NCO) | ||||

| NCO2: This organization invests heavily on infrastructure to reduce network complexity. | 0.802 | 0.788 | 0.876 | 0.702 |

| NCO3: In this organization, network complexity occurred due to unexpected changes in supply chain operations. | 0.853 | |||

| NCO4: This organization has a strategic plan to deal with supply chain nodes that reduce network complexity. | 0.858 | |||

| Risk Management Orientation (RMO) | ||||

| RMO2: Risks in this organization are monitored continuously and managed proactively. | 0.748 | 0.736 | 0.849 | 0.652 |

| RMO3: This organization has the ability to identify the source of disruption in a systematic way. | 0.820 | |||

| RMO4: This organization is efficient in assessing own risk, customer risk and supplier risk. | 0.852 | |||

| Supply Chain Capability (SCC) | ||||

| SCC1: In this firm, the information flow is more effective between the firm and supply chain partners. | 0.796 | 0.848 | 0.898 | 0.687 |

| SCC2: This firm has the capacity to handle follow-up activities proactively. | 0.836 | |||

| SCC3: This firm has strong coordination with stake holders for planning and forecasting. | 0.850 | |||

| SCC4: This firm has the competency to respond quickly to changing customer needs and demands. | 0.832 | |||

| Supply Chain Resilience (SCR) | ||||

| SCR1: This firm has the competency to recover supply chain operations quickly. | 0.845 | 0.876 | 0.915 | 0.729 |

| SCR2: In this firm, inventory flow would not take long to restore. | 0.863 | |||

| SCR3: This firm is able to restore operating performance. | 0.867 | |||

| SCR4: This firm has the capacity to deal with all kinds of supply chain disruption without any delay. | 0.840 | |||

| Sustainable Supply Chain Performance (SSP) | ||||

| SSP1: This firm has reduced buffer stock in the supply chain process. | 0.882 | 0.851 | 0.910 | 0.770 |

| SSP2: This firm is following all environmental standards according to customer requirements. | 0.889 | |||

| SSP3: This firm has controlled the supply chain wastage significantly. | 0.862 | |||

| BDA | COM | INT | LCO | NCO | RMO | SCC | SCR | SSP | |

|---|---|---|---|---|---|---|---|---|---|

| BDA | 0.820 | ||||||||

| COM | 0.299 | 0.834 | |||||||

| INT | 0.465 | 0.244 | 0.792 | ||||||

| LCO | 0.400 | 0.323 | 0.386 | 0.778 | |||||

| NCO | 0.595 | 0.277 | 0.513 | 0.396 | 0.838 | ||||

| RMO | 0.390 | 0.315 | 0.384 | 0.897 | 0.352 | 0.808 | |||

| SCC | 0.271 | 0.706 | 0.262 | 0.318 | 0.279 | 0.325 | 0.829 | ||

| SCR | 0.407 | 0.470 | 0.408 | 0.653 | 0.367 | 0.662 | 0.455 | 0.854 | |

| SSP | 0.398 | 0.500 | 0.346 | 0.543 | 0.335 | 0.519 | 0.471 | 0.719 | 0.878 |

| BDA | COM | INT | LCO | NCO | RMO | SCC | SCR | SSP | |

|---|---|---|---|---|---|---|---|---|---|

| BDA1 | 0.824 | 0.232 | 0.388 | 0.360 | 0.564 | 0.371 | 0.257 | 0.365 | 0.352 |

| BDA2 | 0.843 | 0.273 | 0.332 | 0.298 | 0.442 | 0.284 | 0.229 | 0.306 | 0.311 |

| BDA3 | 0.793 | 0.233 | 0.422 | 0.322 | 0.450 | 0.298 | 0.177 | 0.325 | 0.312 |

| COM1 | 0.212 | 0.826 | 0.200 | 0.320 | 0.218 | 0.288 | 0.562 | 0.391 | 0.432 |

| COM2 | 0.242 | 0.841 | 0.186 | 0.264 | 0.195 | 0.266 | 0.533 | 0.415 | 0.409 |

| COM3 | 0.295 | 0.825 | 0.221 | 0.293 | 0.254 | 0.298 | 0.619 | 0.377 | 0.427 |

| COM4 | 0.252 | 0.845 | 0.210 | 0.202 | 0.259 | 0.199 | 0.646 | 0.384 | 0.400 |

| INT1 | 0.342 | 0.187 | 0.717 | 0.268 | 0.327 | 0.263 | 0.233 | 0.287 | 0.270 |

| INT3 | 0.409 | 0.190 | 0.869 | 0.328 | 0.433 | 0.332 | 0.187 | 0.352 | 0.282 |

| INT4 | 0.351 | 0.205 | 0.784 | 0.317 | 0.451 | 0.313 | 0.210 | 0.327 | 0.274 |

| LCO1 | 0.309 | 0.258 | 0.296 | 0.752 | 0.361 | 0.540 | 0.245 | 0.433 | 0.385 |

| LCO2 | 0.345 | 0.262 | 0.329 | 0.798 | 0.340 | 0.700 | 0.233 | 0.464 | 0.415 |

| LCO3 | 0.256 | 0.208 | 0.239 | 0.752 | 0.219 | 0.725 | 0.186 | 0.497 | 0.415 |

| LCO4 | 0.335 | 0.276 | 0.333 | 0.809 | 0.323 | 0.793 | 0.312 | 0.608 | 0.464 |

| NCO2 | 0.391 | 0.228 | 0.439 | 0.292 | 0.802 | 0.287 | 0.245 | 0.288 | 0.299 |

| NCO3 | 0.491 | 0.195 | 0.445 | 0.316 | 0.853 | 0.274 | 0.214 | 0.290 | 0.244 |

| NCO4 | 0.599 | 0.267 | 0.410 | 0.381 | 0.858 | 0.321 | 0.242 | 0.340 | 0.297 |

| RMO2 | 0.310 | 0.257 | 0.324 | 0.711 | 0.291 | 0.748 | 0.237 | 0.429 | 0.388 |

| RMO3 | 0.304 | 0.233 | 0.278 | 0.721 | 0.240 | 0.820 | 0.241 | 0.531 | 0.408 |

| RMO4 | 0.333 | 0.275 | 0.334 | 0.748 | 0.323 | 0.852 | 0.302 | 0.621 | 0.456 |

| SCC1 | 0.245 | 0.570 | 0.233 | 0.275 | 0.211 | 0.271 | 0.796 | 0.380 | 0.384 |

| SCC2 | 0.219 | 0.619 | 0.154 | 0.221 | 0.216 | 0.241 | 0.836 | 0.351 | 0.382 |

| SCC3 | 0.208 | 0.582 | 0.246 | 0.255 | 0.229 | 0.285 | 0.850 | 0.369 | 0.369 |

| SCC4 | 0.225 | 0.569 | 0.230 | 0.295 | 0.263 | 0.277 | 0.832 | 0.403 | 0.423 |

| SCR1 | 0.346 | 0.360 | 0.301 | 0.610 | 0.294 | 0.633 | 0.383 | 0.845 | 0.554 |

| SCR2 | 0.331 | 0.331 | 0.342 | 0.532 | 0.283 | 0.559 | 0.369 | 0.863 | 0.535 |

| SCR3 | 0.355 | 0.435 | 0.324 | 0.498 | 0.352 | 0.502 | 0.404 | 0.867 | 0.616 |

| SCR4 | 0.354 | 0.465 | 0.416 | 0.582 | 0.320 | 0.566 | 0.393 | 0.840 | 0.726 |

| SSP1 | 0.335 | 0.445 | 0.280 | 0.466 | 0.318 | 0.457 | 0.420 | 0.633 | 0.882 |

| SSP2 | 0.362 | 0.455 | 0.382 | 0.527 | 0.306 | 0.476 | 0.423 | 0.676 | 0.889 |

| SSP3 | 0.351 | 0.414 | 0.240 | 0.430 | 0.254 | 0.431 | 0.396 | 0.578 | 0.862 |

| BDA | COM | INT | LCO | NCO | RMO | SCC | SCR | SSP | |

|---|---|---|---|---|---|---|---|---|---|

| BDA | |||||||||

| COM | 0.374 | ||||||||

| INT | 0.637 | 0.318 | |||||||

| LCO | 0.516 | 0.394 | 0.518 | ||||||

| NCO | 0.757 | 0.336 | 0.690 | 0.503 | |||||

| RMO | 0.519 | 0.398 | 0.536 | 0.170 | 0.460 | ||||

| SCC | 0.335 | 0.832 | 0.343 | 0.381 | 0.339 | 0.406 | |||

| SCR | 0.496 | 0.537 | 0.516 | 0.771 | 0.437 | 0.810 | 0.525 | ||

| SSP | 0.494 | 0.585 | 0.446 | 0.656 | 0.406 | 0.651 | 0.553 | 0.821 |

| Hypothesis | Relationship | Path Coefficient | STDEV | T-Statistics | Significance | Decision |

|---|---|---|---|---|---|---|

| H1 | INT → SCR | 0.113 | 0.043 | 20.634 | 0.005 | Accepted |

| H2 | COM → SCR | 0.183 | 0.064 | 20.859 | 0.003 | Accepted |

| H3 | LCO → SCR | 0.210 | 0.080 | 20.635 | 0.005 | Accepted |

| H4 | RMO → SCR | 0.326 | 0.081 | 40.012 | 0.000 | Accepted |

| H5 | SCC → SCR | 0.116 | 0.060 | 10.933 | 0.028 | Accepted |

| H6 | NCO → SCR | 0.028 | 0.042 | 0.679 | 0.249 | Not Accepted |

| H7 | SCR → SSP | 0.667 | 0.032 | 20.678 | 0.000 | Accepted |

| Supply Chain Resilience | ||||

|---|---|---|---|---|

| Constructs | Findings | |||

| Supply Chain Resilience | 54.8% | 37.4% | ||

| Supply chain communication | 0.036 | Small | ||

| Supply chain intelligence | 0.019 | Small | ||

| Leadership commitment | 0.018 | Small | ||

| Network complexity | 0.001 | Small | ||

| Risk management orientation | 0.045 | Small | ||

| Supply chain capability | 0.014 | Small | ||

| Sustainable Supply Chain Performance | ||||

| Constructs | Findings | |||

| Sustainable Supply Chain Performance | 55.0% | 40.0% | ||

| Big data analytics | 0.030 | Small | ||

| Supply chain resilience | 0.826 | Substantial | ||

| Constructs | Total Effects of Constructs | Total Performance of the Constructs |

|---|---|---|

| Big data analytics | 0.157 | 7.890 |

| Supply chain communication | 0.128 | 73.379 |

| Supply chain intelligence | 0.095 | 69.381 |

| Leadership commitment | 0.167 | 67.870 |

| Network complexity | 0.023 | 72.166 |

| Risk management orientation | 0.261 | 68.990 |

| Supply chain capability | 0.086 | 71.953 |

| Supply chain resilience | 0.690 | 66.904 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yamin, M.A. Investigating the Drivers of Supply Chain Resilience in the Wake of the COVID-19 Pandemic: Empirical Evidence from an Emerging Economy. Sustainability 2021, 13, 11939. https://doi.org/10.3390/su132111939

Yamin MA. Investigating the Drivers of Supply Chain Resilience in the Wake of the COVID-19 Pandemic: Empirical Evidence from an Emerging Economy. Sustainability. 2021; 13(21):11939. https://doi.org/10.3390/su132111939

Chicago/Turabian StyleYamin, Mohammad Ali. 2021. "Investigating the Drivers of Supply Chain Resilience in the Wake of the COVID-19 Pandemic: Empirical Evidence from an Emerging Economy" Sustainability 13, no. 21: 11939. https://doi.org/10.3390/su132111939