Multi-Objective Optimization for Healthcare Waste Management Network Design with Sustainability Perspective

Abstract

:1. Introduction

2. Literature Review

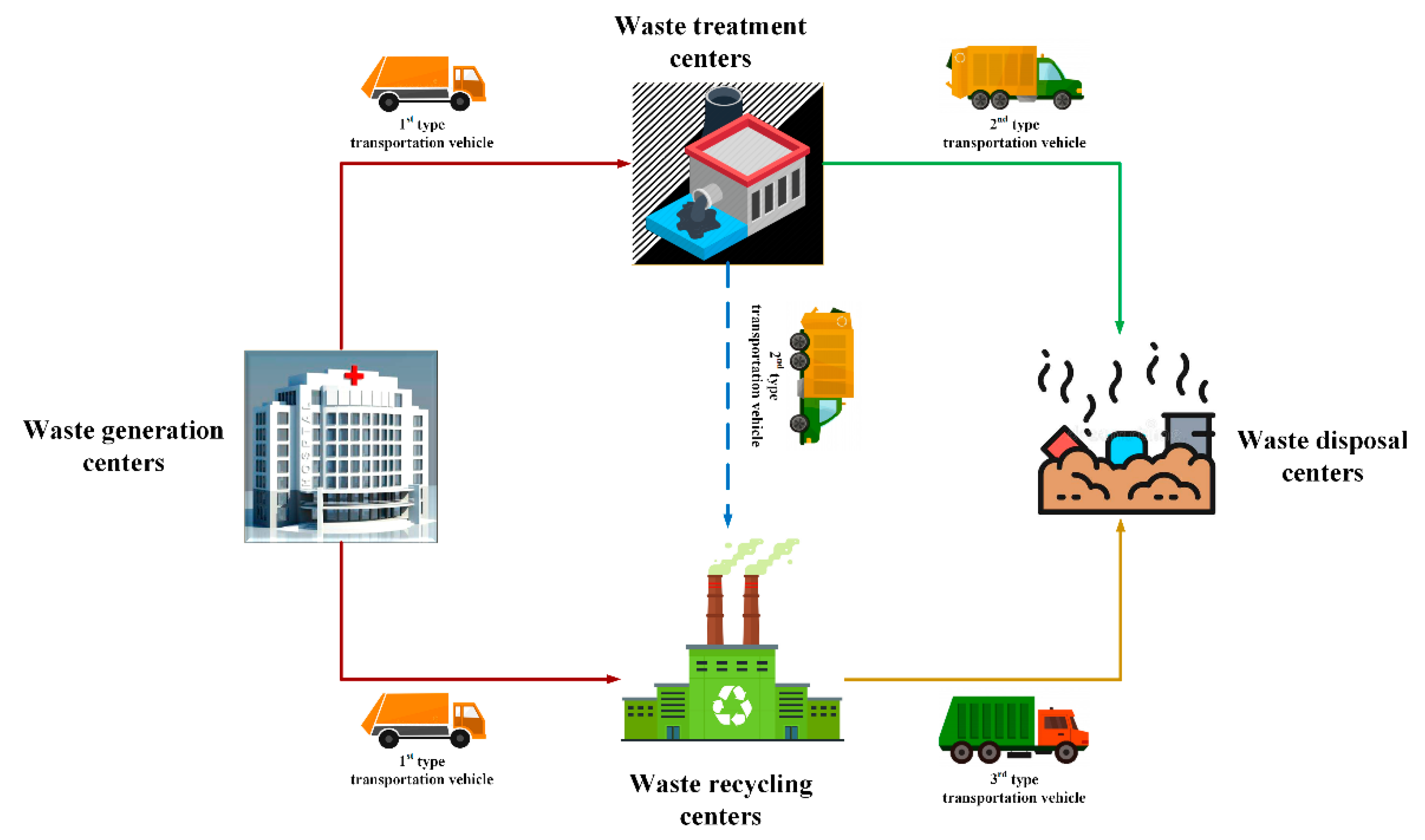

3. Problem Definition

- (1)

- Locational decisions are made on the levels of treatment, recycling, and disposal centers;

- (2)

- Three types of vehicles are defined to be used between different levels, where the first type of transportation vehicles are used between waste generation centers and waste treatment centers/waste recycling centers, the second type of transportation vehicles are used between the waste treatment centers and the waste recycling centers/waste disposal centers, and the third type of transportation vehicles are used between the waste recycling centers and waste disposal centers;

- (3)

- A planning horizon is considered;

- (4)

- There are multiple types of HW;

- (5)

- All the parameters are deterministic;

- (6)

- Waste generation points include hospitals and infirmaries;

- (7)

- The given flow rates of waste are regarded between different centers;

- (8)

- The capacity of different centers is limited as well as the capacity of the vehicles.

Mathematical Model

- 1.

- Objective Functions

- 2.

- Constraints

4. Improved Multi-Choice Goal Programming (IMCGP)

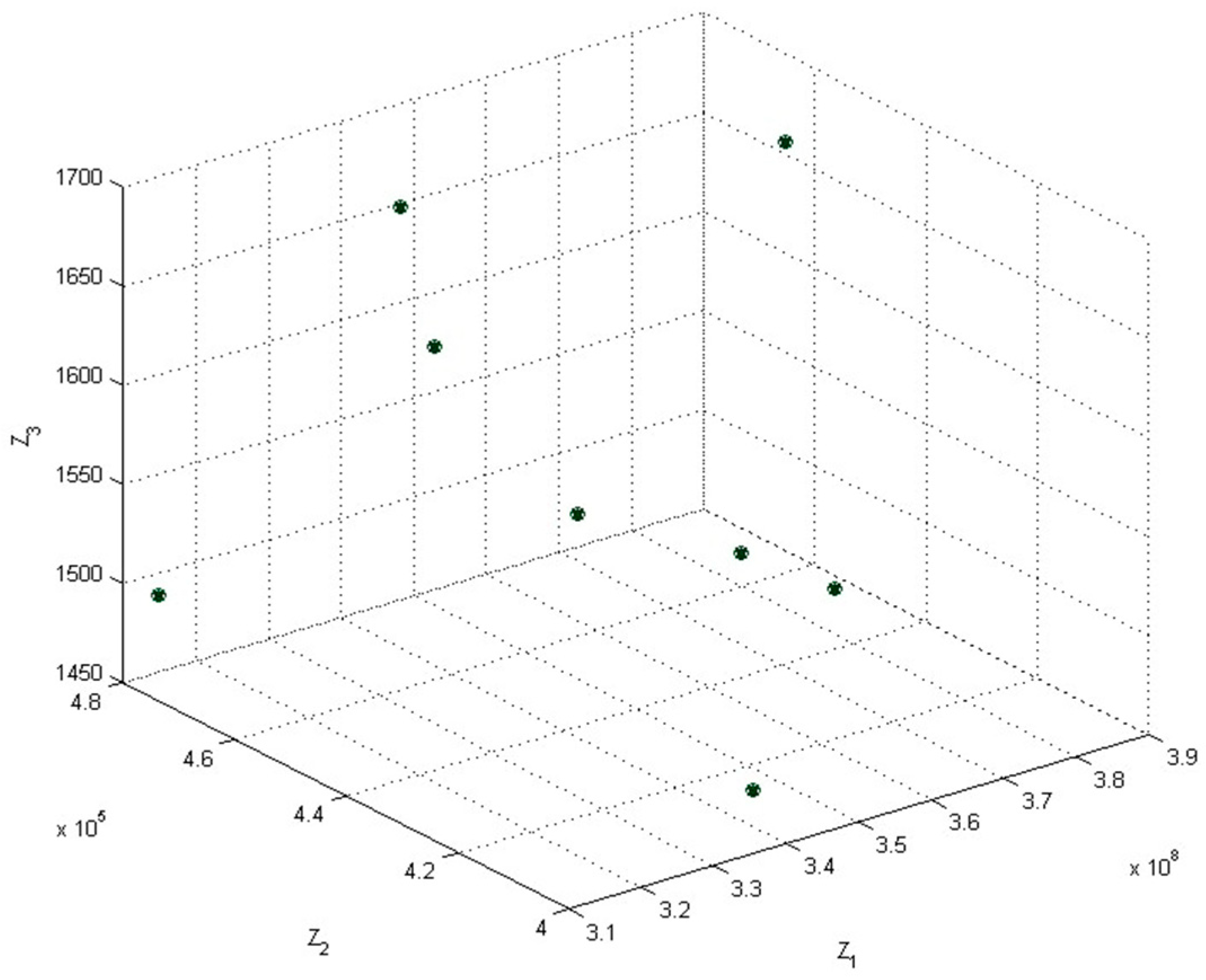

5. Illustrative Example

5.1. IMCGP vs. GAM

5.2. Sensitivity Analysis

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Sets and indices | |

| Set of waste generation centers (hospitals and infirmaries) (), | |

| Set of waste treatment centers (), | |

| Set of waste recycling centers (), | |

| Set of waste disposal centers (), | |

| Set of time periods (), | |

| Set of waste types (), | |

| Set of vehicles (), including , and as the sets of 1st, 2nd and 3rd type vehicles, respectively. | |

| Parameters | |

| Amount of waste type generated at waste generation center in period . | |

| Flow rate of generated waste type w which is transferred from waste generation center to waste treatment centers in period . | |

| Flow rate of generated waste type which is transferred from waste generation center to waste recycling centers in period . | |

| Flow rate of generated waste type which is transferred from waste treatment center to waste recycling centers in period . | |

| Flow rate of generated waste type which is transferred from waste treatment center to waste disposal centers in period . | |

| Flow rate of generated waste type which is transferred from waste recycling center to waste disposal centers in period . | |

| Capacity of waste treatment center to process waste type in each period. | |

| Capacity of waste recycling center to process waste type in each period. | |

| Capacity of waste disposal center to process waste type in each period. | |

| Capacity of 1st type transportation vehicles. | |

| Capacity of 2nd type transportation vehicles. | |

| Capacity of 3rd type transportation vehicles. | |

| Distance between waste generation center and waste treatment center . | |

| Distance between waste generation center and waste recycling center . | |

| Distance between waste treatment center and waste recycling center . | |

| Distance between waste treatment center and waste disposal center . | |

| Distance between waste recycling center and waste disposal center . | |

| Cost of transporting waste type from waste generation center to waste treatment center with 1st type transportation vehicle in period . | |

| Cost of transporting waste type from waste generation center to waste recycling center with 1st type transportation vehicle in period . | |

| Cost of transporting waste type from waste treatment center to waste recycling center with 2nd type transportation vehicle in period . | |

| Cost of transporting waste type from waste treatment center to waste disposal center with 2nd type transportation vehicle in period . | |

| Cost of transporting waste type from waste recycling center to waste disposal center with 3rd type transportation vehicle in period . | |

| Processing cost of waste type at waste treatment center in period . | |

| Processing cost of waste type at waste recycling center in period . | |

| Processing cost of waste type at waste disposal center in period . | |

| Fixed cost of establishing waste treatment center in period . | |

| Fixed cost of establishing waste recycling center in period . | |

| Fixed cost of establishing waste disposal center in period . | |

| Fixed cost of using a 1st type transportation vehicle in period . | |

| Fixed cost of using a 2nd type transportation vehicle in period . | |

| Fixed cost of using a 3rd type transportation vehicle in period | |

| Population risk for transporting waste type between waste generation center and waste treatment center . | |

| Population risk for transporting waste type between waste generation center and waste recycling center . | |

| Population risk for transporting waste type between waste treatment center and waste recycling center . | |

| Population risk for transporting waste type between waste treatment center and waste disposal center . | |

| Population risk for transporting waste type between waste recycling center and waste disposal center . | |

| Number of potential job opportunities obtained when waste treatment center is established. | |

| Number of potential job opportunities obtained when waste recycling center is established. | |

| Number of potential job opportunities obtained when waste disposal center is established. | |

| Variables | |

| Quantity of waste type transferred from waste generation center to waste treatment center by 1st type transportation vehicle in period . | |

| Quantity of waste type transferred from waste generation center to waste recycling center by 1st type transportation vehicle in period . | |

| Quantity of waste type transferred from waste treatment center to waste recycling center by 2nd type transportation vehicle in period . | |

| Quantity of waste type transferred from waste treatment center to waste disposal center by 2nd type transportation vehicle in period . | |

| Quantity of waste type transferred from waste recycling center to waste disposal center by 3rd type transportation vehicle in period . | |

References

- Vandchali, H.R.; Cahoon, S.; Chen, S.L. Creating a sustainable supply chain network by adopting relationship management strategies. J. Bus. Bus. Mark. 2020, 27, 125–149. [Google Scholar] [CrossRef]

- Vandchali, H.R.; Cahoon, S.; Chen, S.-L. The impact of supply chain network structure on relationship management strategies: An empirical investigation of sustainability practices in retailers. Sustain. Prod. Consum. 2021, 28, 281–299. [Google Scholar] [CrossRef]

- Vandchali, H.R.; Cahoon, S.; Chen, S.L. The impact of power on the depth of sustainability collaboration in the supply chain network for Australian food retailers. Int. J. Procure. Manag. 2021, 14, 165. [Google Scholar] [CrossRef]

- Zaman, A.U.; Lehmann, S. Urban growth and waste management optimization towards ‘zero waste city’. City Cult. Soc. 2011, 2, 177–187. [Google Scholar] [CrossRef]

- Tirkolaee, E.B.; Mahdavi, I.; Esfahani, M.M.S.; Weber, G.-W. A hybrid augmented ant colony optimization for the multitrip capacitated arc routing problem under fuzzy demands for urban solid waste management. Waste Manag. Res. 2019, 38, 156–172. [Google Scholar] [CrossRef] [PubMed]

- Mantzaras, G.; Voudrias, E.A. An optimization model for collection, haul, transfer, treatment and disposal of infectious medical waste: Application to a Greek region. Waste Manag. 2017, 69, 518–534. [Google Scholar] [CrossRef] [PubMed]

- Tirkolaee, E.B.; Aydın, N.S. A sustainable medical waste collection and transportation model for pandemics. Waste Manag. Res. 2021. [Google Scholar] [CrossRef]

- Minoglou, M.; Gerassimidou, S.; Komilis, D. Healthcare waste generation worldwide and its dependence on socioeconomic and environmental factors. Sustainability 2017, 9, 220. [Google Scholar] [CrossRef] [Green Version]

- Ferreira, V.; Teixeira, M.R. Healthcare waste management practices and risk perceptions: Findings from hospitals in the Algarve region, Portugal. Waste Manag. 2010, 30, 2657–2663. [Google Scholar] [CrossRef]

- Yu, H.; Sun, X.; Solvang, W.D.; Zhao, X. Reverse Logistics Network Design for Effective Management of Medical Waste in Epidemic Outbreaks: Insights from the Coronavirus Disease 2019 (COVID-19) Outbreak in Wuhan (China). Int. J. Environ. Res. Public Health 2020, 17, 1770. [Google Scholar] [CrossRef] [Green Version]

- Kargar, S.; Pourmehdi, M.; Paydar, M.M. Reverse logistics network design for medical waste management in the epidemic outbreak of the novel coronavirus (COVID-19). Sci. Total. Environ. 2020, 746, 141183. [Google Scholar] [CrossRef]

- Olapiriyakul, S.; Pannakkong, W.; Kachapanya, W.; Starita, S. Multiobjective Optimization Model for Sustainable Waste Management Network Design. J. Adv. Transp. 2019, 2019, 1–15. [Google Scholar] [CrossRef]

- Mamashli, Z.; Javadian, N. Sustainable design modifications municipal solid waste management network and better optimization for risk reduction analyses. J. Clean. Prod. 2021, 279, 123824. [Google Scholar] [CrossRef]

- Torkayesh, A.E.; Malmir, B.; Asadabadi, M.R. Sustainable waste disposal technology selection: The stratified best-worst multi-criteria decision-making method. Waste Manag. 2021, 122, 100–112. [Google Scholar] [CrossRef] [PubMed]

- Torkayesh, A.E.; Zolfani, S.H.; Kahvand, M.; Khazaelpour, P. Landfill location selection for healthcare waste of urban areas using hybrid BWM-grey MARCOS model based on GIS. Sustain. Cities Soc. 2021, 67, 102712. [Google Scholar] [CrossRef]

- Kannangara, M.; Dua, R.; Ahmadi, L.; Bensebaa, F. Modeling and prediction of regional municipal solid waste generation and diversion in Canada using machine learning approaches. Waste Manag. 2018, 74, 3–15. [Google Scholar] [CrossRef]

- Beltrami, E.J.; Bodin, L.D. Networks and vehicle routing for municipal waste collection. Networks 1974, 4, 65–94. [Google Scholar] [CrossRef]

- Kim, B.-I.; Kim, S.; Sahoo, S. Waste collection vehicle routing problem with time windows. Comput. Oper. Res. 2006, 33, 3624–3642. [Google Scholar] [CrossRef]

- Buhrkal, K.; Larsen, A.; Ropke, S. The waste collection vehicle routing problem with time windows in a city logistics con-text. Procedia Soc. Behav. Sci. 2012, 39, 241–254. [Google Scholar] [CrossRef] [Green Version]

- Huang, S.H.; Lin, P.C. Vehicle routing–scheduling for municipal waste collection system under the “Keep Trash off the Ground” policy. Omega 2015, 55, 24–37. [Google Scholar] [CrossRef]

- Son, L.H.; Louati, A. Modeling municipal solid waste collection: A generalized vehicle routing model with multiple transfer stations, gather sites and inhomogeneous vehicles in time windows. Waste Manag. 2016, 52, 34–49. [Google Scholar] [CrossRef]

- Asefi, H.; Shahparvari, S.; Chhetri, P.; Lim, S. Variable fleet size and mix VRP with fleet heterogeneity in Integrated Solid Waste Management. J. Clean. Prod. 2019, 230, 1376–1395. [Google Scholar] [CrossRef]

- Wu, H.; Tao, F.; Qiao, Q.; Zhang, M. A chance-constrained vehicle routing problem for wet waste collection and transportation considering carbon emissions. Int. J. Environ. Res. Public Health 2020, 17, 458. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ghannadpour, S.F.; Zandieh, F.; Esmaeili, F. Optimizing triple bottom-line objectives for sustainable health-care waste collection and routing by a self-adaptive evolutionary algorithm: A case study from tehran province in Iran. J. Clean. Prod. 2021, 287, 125010. [Google Scholar] [CrossRef]

- Zografros, K.G.; Samara, S. Combined location-routing model for hazardous waste transportation and disposal. Trans-Portation Res. Rec. 1989, 1245. Available online: http://worldcat.org/isbn/0309049679 (accessed on 26 May 2021).

- Alumur, S.; Kara, B.Y. A new model for the hazardous waste location-routing problem. Comput. Oper. Res. 2007, 34, 1406–1423. [Google Scholar] [CrossRef] [Green Version]

- Shi, L.; Fan, H.; Gao, P.; Zhang, H. Network model and optimization of medical waste reverse logistics by improved genetic algorithm. In International Symposium on Intelligence Computation and Applications; Springer: Berlin/Heidelberg, Germany, 2009; pp. 40–52. [Google Scholar]

- Das, A.; Mazumder, T.N.; Gupta, A.K. Pareto frontier analyses based decision making tool for transportation of hazardous waste. J. Hazard. Mater. 2012, 227, 341–352. [Google Scholar] [CrossRef]

- Mohsenizadeh, M.; Tural, M.K.; Kentel, E. Municipal solid waste management with cost minimization and emission control objectives: A case study of Ankara. Sustain. Cities Soc. 2020, 52, 101807. [Google Scholar] [CrossRef]

- Darmian, S.M.; Moazzeni, S.; Hvattum, L.M. Multi-objective sustainable location-districting for the collection of munici-pal solid waste: Two case studies. Comput. Ind. Eng. 2020, 150, 106965. [Google Scholar] [CrossRef]

- Tirkolaee, E.B.; Abbasian, P.; Weber, G.W. Sustainable fuzzy multi-trip location-routing problem for medical waste management during the COVID-19 outbreak. Sci. Total. Environ. 2021, 756, 143607. [Google Scholar] [CrossRef]

- Zaeimi, M.B.; Rassafi, A.A. Designing an integrated municipal solid waste management system using a fuzzy chanceconstrained programming model considering economic and environmental aspects under uncertainty. Waste Manag. 2021, 125, 268–279. [Google Scholar] [CrossRef] [PubMed]

- Ghiani, G.; Manni, A.; Manni, E.; Toraldo, M. The impact of an efficient collection sites location on the zoning phase in municipal solid waste management. Waste Manag. 2014, 34, 1949–1956. [Google Scholar] [CrossRef]

- Inghels, D.; Dullaert, W.; Vigo, D. A service network design model for multimodal municipal solid waste transport. Eur. J. Oper. Res. 2016, 254, 68–79. [Google Scholar] [CrossRef]

- López-Sánchez, A.; Hernández-Díaz, A.; Gortázar, F.; Hinojosa, M. A multiobjective GRASP–VND algorithm to solve the waste collection problem. Int. Trans. Oper. Res. 2016, 25, 545–567. [Google Scholar] [CrossRef]

- Yadav, V.; Karmakar, S.; Dikshit, A.K.; Bhurjee, A. Interval-valued facility location model: An appraisal of municipal solid waste management system. J. Clean. Prod. 2018, 171, 250–263. [Google Scholar] [CrossRef]

- Habib, M.S.; Sarkar, B.; Tayyab, M.; Saleem, M.W.; Hussain, A.; Ullah, M.; Omair, M.; Iqbal, M.W. Large-scale disaster waste management under uncertain environment. J. Clean. Prod. 2019, 212, 200–222. [Google Scholar] [CrossRef]

- Tirkolaee, E.B.; Mahdavi, I.; Esfahani, M.M.S.; Weber, G.-W. A robust green location-allocation-inventory problem to design an urban waste management system under uncertainty. Waste Manag. 2020, 102, 340–350. [Google Scholar] [CrossRef] [PubMed]

- Yu, H.; Sun, X.; Solvang, W.D.; Laporte, G.; Lee, C.K.M. A stochastic network design problem for hazardous waste management. J. Clean. Prod. 2020, 277, 123566. [Google Scholar] [CrossRef] [PubMed]

- Rathore, P.; Sarmah, S. Economic, environmental and social optimization of solid waste management in the context of circular economy. Comput. Ind. Eng. 2020, 145, 106510. [Google Scholar] [CrossRef]

- Abdallah, M.; Hamdan, S.; Shabib, A. A multi-objective optimization model for strategic waste management master plans. J. Clean. Prod. 2021, 284, 124714. [Google Scholar] [CrossRef]

- Asefi, H.; Lim, S.; Maghrebi, M.; Shahparvari, S. Mathematical modelling and heuristic approaches to the location-routing problem of a cost-effective integrated solid waste management. Ann. Oper. Res. 2019, 273, 75–110. [Google Scholar] [CrossRef]

- Valizadeh, J.; Hafezalkotob, A.; Alizadeh, S.M.S.; Mozafari, P. Hazardous infectious waste collection and government aid distribution during COVID-19: A robust mathematical leader-follower model approach. Sustain. Cities Soc. 2021, 69, 102814. [Google Scholar] [CrossRef] [PubMed]

- Jadidi, O.; Cavalieri, S.; Zolfaghari, S. An improved multi-choice goal programming approach for supplier selection prob-lems. Appl. Math. Model. 2015, 39, 4213–4222. [Google Scholar] [CrossRef]

- Rezaei, E.; Paydar, M.M.; Safaei, A.S. Customer relationship management and new product development in designing a robust supply chain. RAIRO-Oper. Res. 2020, 54, 369–391. [Google Scholar] [CrossRef]

- Motevalli-Taher, F.; Paydar, M.M. Supply chain design to tackle coronavirus pandemic crisis by tourism management. Appl. Soft Comput. 2021, 104, 107217. [Google Scholar] [CrossRef]

- Gembicki, F. Vector Optimization for Control with Performance and Parameter Sensitivity Indices. Ph.D. Thesis, Case Western Reserve University, Cleveland, OH, USA, 1974. [Google Scholar]

| Reference | Problem Characteristics | Problem Type | Objective Function | Methodology | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Location | Allocation | Inventory | Transportation | Deterministic | Uncertain | Economic | Environmental | Social | ||

| Huang and Lin [20] | ✓ | ✓ | ✓ | Ant colony optimization algorithm for linear programming. | ||||||

| Mohsenizadeh et al. [29] | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | Bi-objective MILP | |||

| Ghiani et al. [33] | ✓ | ✓ | ✓ | ✓ | Mathematical modeling and heuristic algorithms. | |||||

| Ingheles et al. [34] | ✓ | ✓ | ✓ | ✓ | ✓ | Integrated linear programming and simulation modeling. | ||||

| López-Sánchez et al. [35] | ✓ | ✓ | ✓ | ✓ | Variable neighborhood search algorithm for a multi-objective optimization model. | |||||

| Yadav et al., [36] | ✓ | ✓ | ✓ | Interval-valued facility location model. | ||||||

| Habib et al. [37] | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | The multi-objective mathematical model under fuzzy environment. | |||

| Tirkolaee et al. [38] | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | Robust optimization model. | ||

| Yu et al. [39] | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | Multi-objective mathematical model under stochastic environment. | |||

| Tirkolaee and Aydin [7] | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | Bi-objective mixed-integer linear programming. | |||

| Rathore and Sarmah [40] | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | Multi-objective MILP and particle swarm optimization algorithm | ||

| Abdullah et al. [41] | ✓ | ✓ | ✓ | ✓ | ✓ | AHP and Multi-objective optimization model | ||||

| Asefi et al. [42] | ✓ | ✓ | ✓ | ✓ | ✓ | MILP model with variable neighborhood search | ||||

| Valizadeh et al. [43] | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | Stochastic programming and Benders decomposition | ||

| Our study | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | Multi-objective MILP model, Improved Multi-Choice Goal Programing, and Goal Attainment Method | ||

| Scale | |G| | |T| | |R| | |D| | |H| | |W| | |K| | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Value | 20 | 6 | 6 | 6 | 7 | 3 | 7 | 7 | 7 | 7 | 7 |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| uniform (1000,5000) | uniform (0.4,0.6) | ||

| uniform (0.4,0.6) | uniform (0.1,0.3) | ||

| uniform (180,000,220,000) | uniform (180,000,220,000) | ||

| uniform (180,000,220,000) | 15,000 | ||

| 10,000 | 8000 | ||

| uniform (10,100) | uniform (10,100) | ||

| uniform (10,100) | uniform (10,100) | ||

| uniform (10,100) | uniform (1,3) | ||

| uniform (1,3) | uniform (1,3) | ||

| uniform (1,3) | uniform (1,3) | ||

| uniform (2,5) | uniform (2,5) | ||

| uniform (2,5) | uniform (100,000,300,000) | ||

| uniform (100,000,300,000) | uniform (100,000,300,000) | ||

| uniform (1000,3000) | uniform (1000,3000) | ||

| uniform (1000,3000) | uniform (0.1,0.3) | ||

| uniform (0.1,0.3) | uniform (0.1,0.3) | ||

| uniform (0.1,0.3) | uniform (0.1,0.3) | ||

| uniformint (100,200) | uniformint (100,200) | ||

| uniformint (100,200) | 108 | ||

| (0.5, 0.3, 0.2) | (0.5, 0.3, 0.2) | ||

| (4.685512 × 108, 523,663.149, 354) | (6.941714 × 107, 282,966.137, 1715) | ||

| (6.941714 × 107, 282,966.137, 1715) | (4.685512 × 108, 523,663.149, 354) |

| Variable | Runtime (s) | ||||

|---|---|---|---|---|---|

| Value | 0.755 | 3.360903 × 108 | 464,277.679 | 1684 | 5.27 |

| Variable | Solution Method | |

|---|---|---|

| IMCGP | GAM | |

| 3.360903 × 108 | 8.130581 × 107 | |

| 464,277.679 | 465,944.123 | |

| 1684 | 1666 | |

| Runtime (s) | 5.27 | 129.94 |

| Variables | |||||

|---|---|---|---|---|---|

| −20% | −10% | 0% | +10% | +20% | |

| 0.565 | 0.661 | 0.755 | 0.739 | - | |

| 2.806736 × 108 | 3.129266 × 108 | 3.360903 × 108 | 3.147639 × 108 | - | |

| 3.72241 × 105 | 4.16891 × 105 | 4.64277 × 105 | 4.77076 × 105 | - | |

| 1642 | 1642 | 1684 | 1646 | - | |

| Variables | |||||

| −20% | −10% | 0% | +10% | +20% | |

| - | 0.673 | 0.755 | 0.736 | - | |

| - | 3.080476 × 108 | 3.360903 × 108 | 3.351169 × 108 | - | |

| - | 4.31786 × 105 | 4.64277 × 105 | 4.67695 × 105 | - | |

| - | 1639 | 1684 | 1532 | - | |

| Variables | |||||

| −20% | −10% | 0% | +10% | +20% | |

| 0.693 | 0.650 | 0.755 | 0.713 | 0.747 | |

| 3.179353 × 108 | 3.024876 × 108 | 3.360903 × 108 | 3.180348 × 108 | 3.285489 × 108 | |

| 4.44649 × 105 | 4.32470 × 105 | 4.64277 × 105 | 4.59516 × 105 | 4.71544 × 105 | |

| 1583 | 1519 | 1684 | 1592 | 1629 | |

| Variables | |||||

| −20% | −10% | 0% | +10% | +20% | |

| 0.744 | 0.715 | 0.755 | 0.697 | 0.710 | |

| 3.511672 × 108 | 3.239917 × 108 | 3.360903 × 108 | 3.320888 × 108 | 3.354814 × 108 | |

| 4.47964 × 105 | 4.55373 × 105 | 4.64277 × 105 | 4.41305 × 105 | 4.45765 × 105 | |

| 1618 | 1589 | 1684 | 1514 | 1534 | |

| (0.5, 0.3, 0.2) | 0.755 | 3.360903 × 108 | 464,277.679 | 1684 |

| (0.5, 0.2, 0.3) | 0.734 | 3.400649 × 108 | 437,537.653 | 1563 |

| (0.5, 0.4, 0.1) | 0.710 | 3.121720 × 108 | 476,392.155 | 1497 |

| (0.6, 0.2, 0.2) | 0.809 | 3.825484 × 108 | 456,083.940 | 1677 |

| (0.6, 0.3, 0.1) | 0.704 | 3.334987 × 108 | 454,209.999 | 1631 |

| (0.6, 0.1, 0.3) | 0.699 | 3.364545 × 108 | 400,897.908 | 1480 |

| (0.7, 0.2, 0.1) | 0.717 | 3.584374 × 108 | 431,522.267 | 1532 |

| (0.7, 0.1, 0.2) | 0.738 | 3.595847 × 108 | 417,509.831 | 1532 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Torkayesh, A.E.; Vandchali, H.R.; Tirkolaee, E.B. Multi-Objective Optimization for Healthcare Waste Management Network Design with Sustainability Perspective. Sustainability 2021, 13, 8279. https://doi.org/10.3390/su13158279

Torkayesh AE, Vandchali HR, Tirkolaee EB. Multi-Objective Optimization for Healthcare Waste Management Network Design with Sustainability Perspective. Sustainability. 2021; 13(15):8279. https://doi.org/10.3390/su13158279

Chicago/Turabian StyleTorkayesh, Ali Ebadi, Hadi Rezaei Vandchali, and Erfan Babaee Tirkolaee. 2021. "Multi-Objective Optimization for Healthcare Waste Management Network Design with Sustainability Perspective" Sustainability 13, no. 15: 8279. https://doi.org/10.3390/su13158279