The Seismic Coat: A Sustainable and Integrated Approach to the Retrofit of Existing Buildings

Abstract

:1. Introduction

2. Materials and Methods

2.1. A Structural “Skin”

2.2. Natural Stone

2.3. Environmental Impact

- -

- Use local materials, which do not require long-distance and expensive transportation;

- -

- Choose materials based on their lifespan;

- -

- Prefer recycled or recyclable materials;

- -

- Design with the possibility of de-construction at the end of the building’s life cycle in mind by reusing as much demolition materials as possible.

- -

- Local Stone 0.4;

- -

- Mortar 1.3;

- -

- Reinforced Concrete 2.6;

- -

- Plasterboard 2.7;

- -

- Bricks 3;

- -

- Cellulose Insulation 3.3;

- -

- Concrete Blocks 3.5;

- -

- Rock Wool Insulation 16.8;

- -

- Wood Fiber Insulation 20;

- -

- Glass Wool Insulation 28;

- -

- PVC 77.2;

- -

- EPS 88.6.

2.4. Reinforced Masonry

2.5. Building Envelope and Energy Consumption

2.6. The Case Study

3. Results

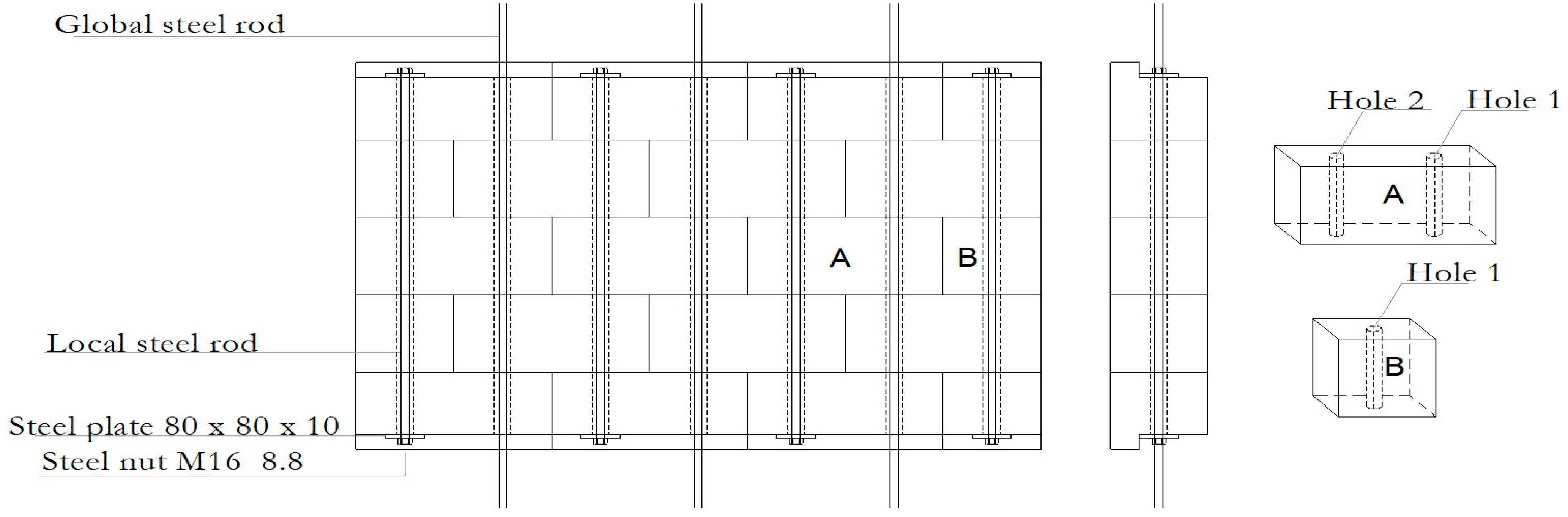

- ✓ The construction features of the new seismic stone coat;

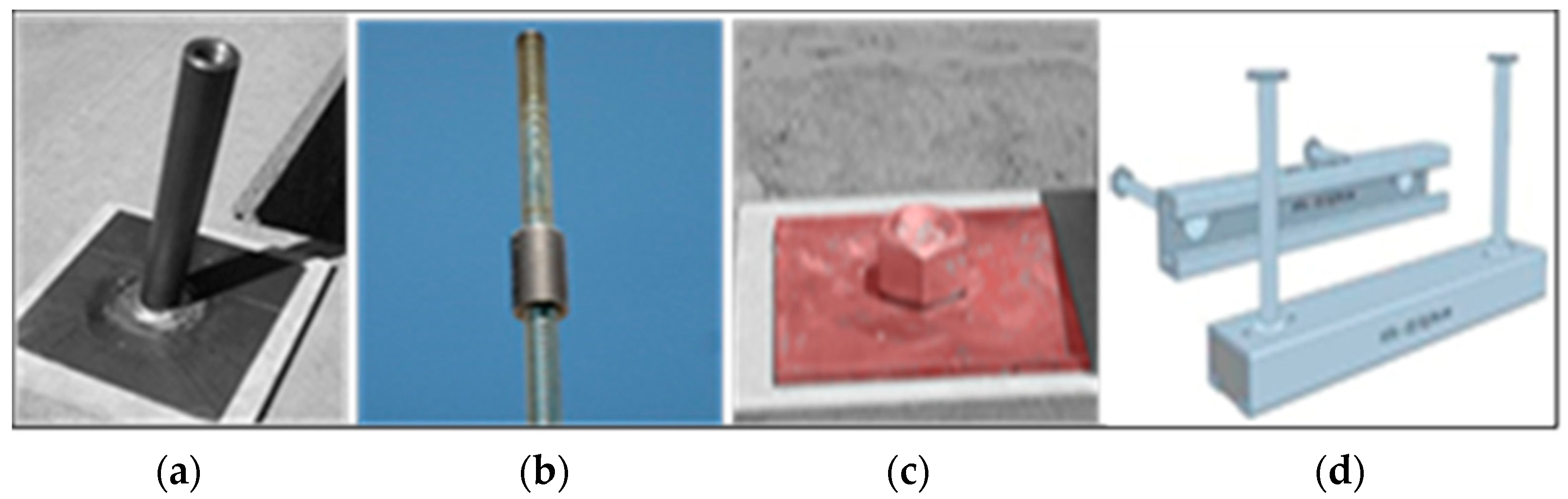

- ✓ The construction of a single prefabricated panel with industrialized systems;

- ✓ The methods of simplified installation on site of the panels;

- ✓ All types of panel connections: panel-panel, panel-existing structure, and panel-foundation.

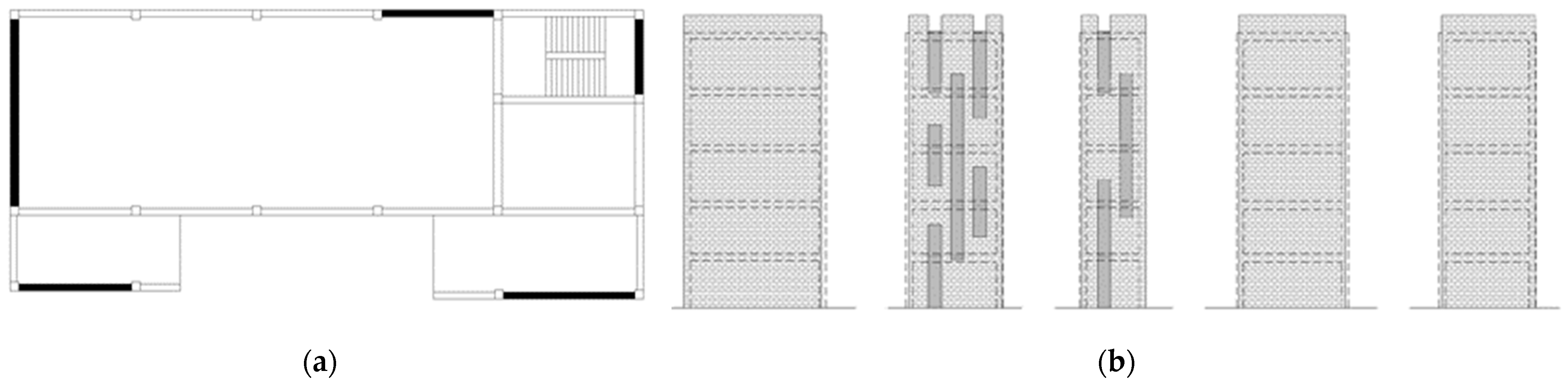

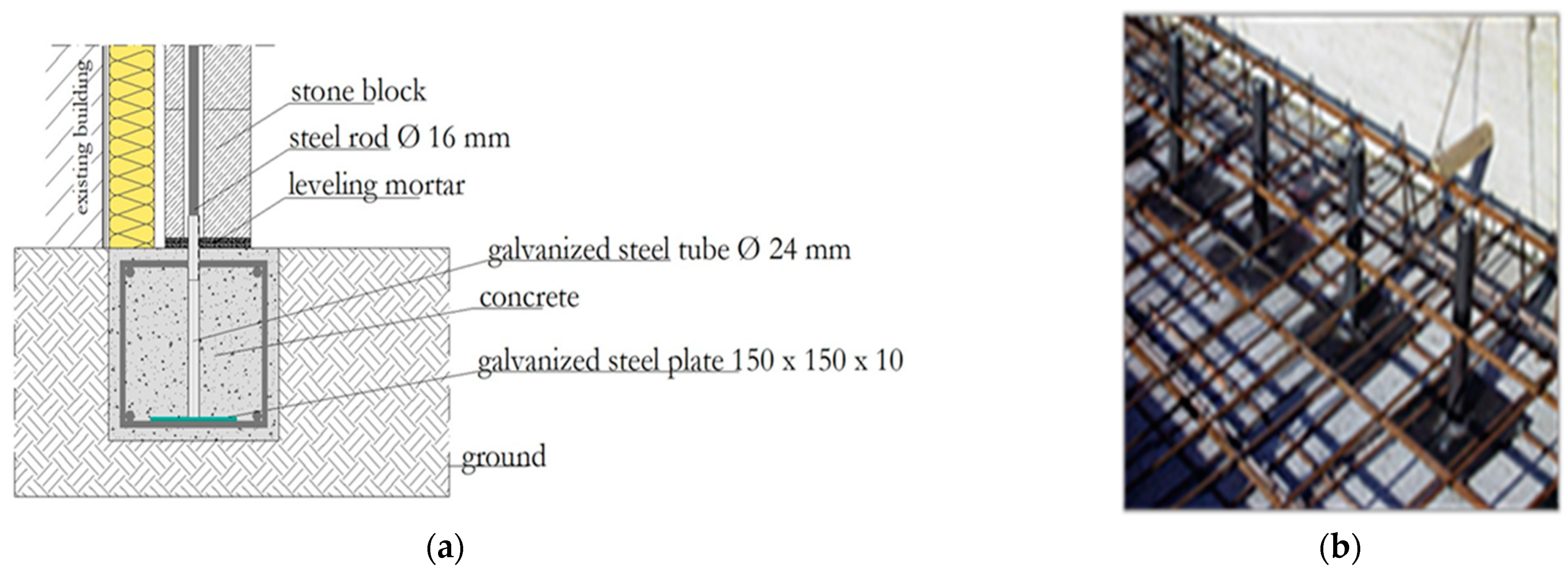

3.1. The New Stone Seismic Coat

3.2. Application to the Case Study

3.3. The Installation of the Panel and the Connections on Site

4. Discussion

5. Conclusions

- ✓ Industrial prefabrication of individual panels prestressed in the factory;

- ✓ Easy maintenance because the panel can be easily removed;

- ✓ Complete recovery of the material to be recycled;

- ✓ Far higher durability without requiring any maintenance;

- ✓ Low environmental impact;

- ✓ Flexibility to adopt it as the only envelope or as a second skin;

- ✓ Operation of installation on site extremely simplified;

- ✓ Very fast execution times;

- ✓ Use of unskilled labor;

- ✓ Aesthetic quality of the stone facade;

- ✓ Genius loci with the use of a material of local tradition.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bradley, P.E.; Kohler, N. Methodology for the survival analysis of urban building stocks. Build. Res. Inf. 2007, 35, 529–542. [Google Scholar] [CrossRef]

- Thomsen, A.; Van der Flier, K. Obsolescence and the end of life phase of buildings. In Management and Innovation for a Sustainable Built Environment MISBE 2011, Proceedings of the CIB International Conference, Amsterdam, The Netherlands, 20–23 June 2011; TU Delft: Delft, The Netherlands, 2011. [Google Scholar]

- Boeri, A.; Gabrielli, L.; Longo, D. Evaluation and feasibility study of retrofitting interventions on social housing in Italy. Procedia Eng. 2011, 21, 1161–1168. [Google Scholar] [CrossRef]

- Turchini, G. New Research for the Restoration; Arketipo: Calenziano, Italy, 2011. [Google Scholar]

- Lombardo, G. La Modernità del Basalto dell’Etna Innovazione e Sperimentazione; Il Lunario: Enna, Italy, 2004; ISBN 88-8181-059-X. [Google Scholar]

- Lombardo, G. Built architecture with natural stone. Int. J. Hous. Sci. Appl. 2011, 35, 103–114. [Google Scholar]

- Pertile, V.; Stella, A.; De Stefani, L.; Scotta, R. Miglioramento Sismico ed Energetico di Edifici in Muratura Mediante Cappotto Sismico: Seconda Campagna di Prove Sperimentali. Ingenio. 2020. Available online: https://www.ingenio-web.it/25301-miglioramento-sismico-ed-energetico-di-edifici-mediante-geniale-cappotto-sismico-i-test-su-edifici-in-muratura (accessed on 9 December 2020).

- Scotta, R.; De Stefani, L.; Stella, A.; Pertile, V. Miglioramento Sismico ed Energetico degli Edifici Esistenti Mediante “Cappotto Sismico”: Prove Sperimentali ed Interpretazione dei Risultati. Ingenio. 2020. Available online: https://www.ingenio-web.it/20416-miglioramento-sismico-ed-energetico-degli-edifici-esistenti-mediante-cappotto-sismico (accessed on 9 December 2020).

- Scotta, R.; Lucchetta, S. Adeguamento Sismico ed Efficientamento Energetico di una Scuola Mediante Cappotto Sismico: La Progettazione. Ingenio. 2020. Available online: https://www.ingenio-web.it/26274-adeguamento-sismico-ed-efficientamento-energetico-di-una-scuola-mediante-cappotto-sismico-la-progettazione (accessed on 9 December 2020).

- Trovato, M.R.; Nocera, F.; Giuffrida, S. Life-cycle assessment and monetary measurements for the carbon footprint reduction of public buildings. Sustainability 2020, 12, 3460. [Google Scholar] [CrossRef] [Green Version]

- Nocera, F.; Faro, A.L.; Costanzo, V.; Raciti, C. Daylight performance of classrooms in a mediterranean school heritage building. Sustainability 2018, 10, 3705. [Google Scholar] [CrossRef] [Green Version]

- Molinari, C. Manutenzione in Edilizia; Franco Angeli: Milan, Italy, 1989; ISBN 8820430975. [Google Scholar]

- Cicero, C.; Lombardo, G. Buildings envelopes and energy. J. Civ. Eng. Archit. 2011, 5, 986–995. [Google Scholar]

- Hammond, G.; Jones, G. Inventory of Carbon & Energy (ICE); Version 2.0; Department of Mechanical Engineering, University of Bath: Bath, UK, 2011. [Google Scholar]

- Paolini, R. Sistemi di Isolamento Termico a Cappotto; Arketipo: Calenziano, Italy, 2008; Volume 24, pp. 130–131. [Google Scholar]

- Campioli, A.; Ferrari, S.; Lavagna, M. Il Comportamento Energetico-Ambientale di Involucri in Laterizio. Costr. Laterizio 2007, 120, 58–65. [Google Scholar]

- Lavagna, M. Life Cycle Assessmente in Edilizia; Hoepli: Milan, Italy, 2008. [Google Scholar]

- Lombardo, G. Architectural Vanguard Stone. Front. Archit. Res. 2012, 1, 244–252. [Google Scholar] [CrossRef] [Green Version]

- Salehi, A.; Fayaz, R.; Bozorgi, M.; Asadi, S.; Costanzo, V.; Imani, N.; Nocera, F. Investigation of thermal comfort efficacy of solar chimneys under different climates and operation time periods. Energy Build. 2019, 205, 109528. [Google Scholar] [CrossRef]

- Fernandez-Antolin, M.; del Río, J.M.; Costanzo, V.; Nocera, F.; Gonzalez-Lezcano, R. Passive design strategies for residential buildings in different Spanish climate zones. Sustainability 2019, 11, 4816. [Google Scholar] [CrossRef] [Green Version]

- Gajda, J.; Van Geem, M. Energy Use in Residential Housing: A Comparison of Insulating Concrete Form and Wood Frame Walls; Portland Cement Association: Skokie, IL, USA, 2000. [Google Scholar]

- Gajda, J. Energy Use of Single-Family Houses with Various Exterior Walls; Portland Cement Association: Skokie, IL, USA, 2001. [Google Scholar]

| Material | fb,k | f1b,k | Mi | E | G | dutt. | γ | fk | fvko | fk,tab | fvko,tab |

|---|---|---|---|---|---|---|---|---|---|---|---|

| MPa | MPa | MPa | MPa | MPa | MPa | MPa | MPa | MPa | |||

| Basalt | 150 | 130 | 1 | 60,000 | 24,000 | 9.9 | 270 | 60 | 1 | 14 | 0 |

| Height h [m] | ƛs = h/s | Seism. Force Fs [kN] | Ord. Mas. P = 0 kN | Reinf. Mas. p = 0 kN | Reinf. Mas. p = 1000 kN | Reinf. Mas. p = 2000 kN | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Collap. Force FxR [kN] | Saf. Fac. TxR/Fs | Collap. Force FxR [kN] | Saf. Fac. TxR/Fs | Collap. Force FxR [kN] | Saf. Fac. TxR/Fs | Collap. Force FxR [kN] | Saf. Fac. TxR/Fs | |||

| 3.50 | 14.58 | 4.253 | 4.633 | 1.09 | 24.382 | 5.73 | 132.313 | 31.11 | 172.855 | 40.65 |

| 9.00 | 37.50 | 10.935 | 3.735 | 0.34 | 11.239 | 1.03 | 52.346 | 4.79 | 67.322 | 6.16 |

| 20.00 | 83.33 | 24.300 | 3.376 | 0.14 | 6.639 | 0.27 | 24.358 | 1.00 | 30.386 | 1.25 |

| 22.00 | 91.67 | 26.730 | 3.344 | 0.13 | 6.297 | 0.24 | 22.276 | 0.83 | 27.615 | 1.03 |

| Heat Capacity | EnRyear | Insulation 0.04 m2 KW | PCM | Basalt | Concrete | Brick | Wood |

|---|---|---|---|---|---|---|---|

| KJm2 K | KWhm2 | (cm) | (cm) | (cm) | (cm) | (cm) | (cm) |

| 175 | 41.2 | 8 |  3 |  5 |  9 |  12 |  19 |

| 350 | 40.2 | 8 |  5 |  10 |  18 |  23 |  38 |

| 1050 | 37.9 | 8 |  15 |  30 |  54 |  70 |  115 |

| 1750 | 35.3 | 4 |  25 |  50 |  91 |  116 |  192 |

| 3500 | 29.7 | 4 |  50 |  100 |  180 |  230 |  350 |

| Opaque Vertical Closure Actual Situation | S (m) | C (W/mK) | D (Kg/m3) |

|---|---|---|---|

| Internal Finish | 0.02 | 0.7 | 1400 |

| Concrete Full Bricks | 0.20 | 1.1 | 180 |

| Air Chamber | 0.08 | 1.3 | 1.23 |

| Concrete Full Bricks | 0.30 | 1.1 | 180 |

| Total Thickness | 0.60 m | ||

| Opaque Vertical Closure Project | S (m) | C (W/mK) | D (Kg/m3) |

|---|---|---|---|

| Internal Finish | 0.02 | 0.7 | 1400 |

| Plasterboard Panel | 0.013 | 0.43 | 1250 |

| Thermal Insulation | 0.08 | 0.04 | 60 |

| Air Chamber | 0.025 | 1.3 | 1.23 |

| Stone Panel | 0.10 | 2.1 | 2800 |

| Total Thickness | 0.238 m |

| Opaque Vertical Closure | Limit of Law | Actual Situation | After Intervention |

|---|---|---|---|

| Transmittance “U” (W/m2 K) | 0.41 | 1.344 | 0.322 |

| Phase Shift “S” (hours) | >12 | 4.35 | 9.82 |

| Attenuation “Fd” | <0.15 | 0.767 | 0.251 |

| Envelope summer performance | Class III | Class V | Class III |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lombardo, G. The Seismic Coat: A Sustainable and Integrated Approach to the Retrofit of Existing Buildings. Sustainability 2021, 13, 6466. https://doi.org/10.3390/su13116466

Lombardo G. The Seismic Coat: A Sustainable and Integrated Approach to the Retrofit of Existing Buildings. Sustainability. 2021; 13(11):6466. https://doi.org/10.3390/su13116466

Chicago/Turabian StyleLombardo, Grazia. 2021. "The Seismic Coat: A Sustainable and Integrated Approach to the Retrofit of Existing Buildings" Sustainability 13, no. 11: 6466. https://doi.org/10.3390/su13116466