Life Cycle Assessment and Indoor Environmental Quality of Wooden Family Houses

Abstract

:1. Introduction

2. Materials and Methods

2.1. Objects

2.2. Methods

2.2.1. Life Cycle Assessment

2.2.2. Indoor Environmental Quality

3. Results and Discussion

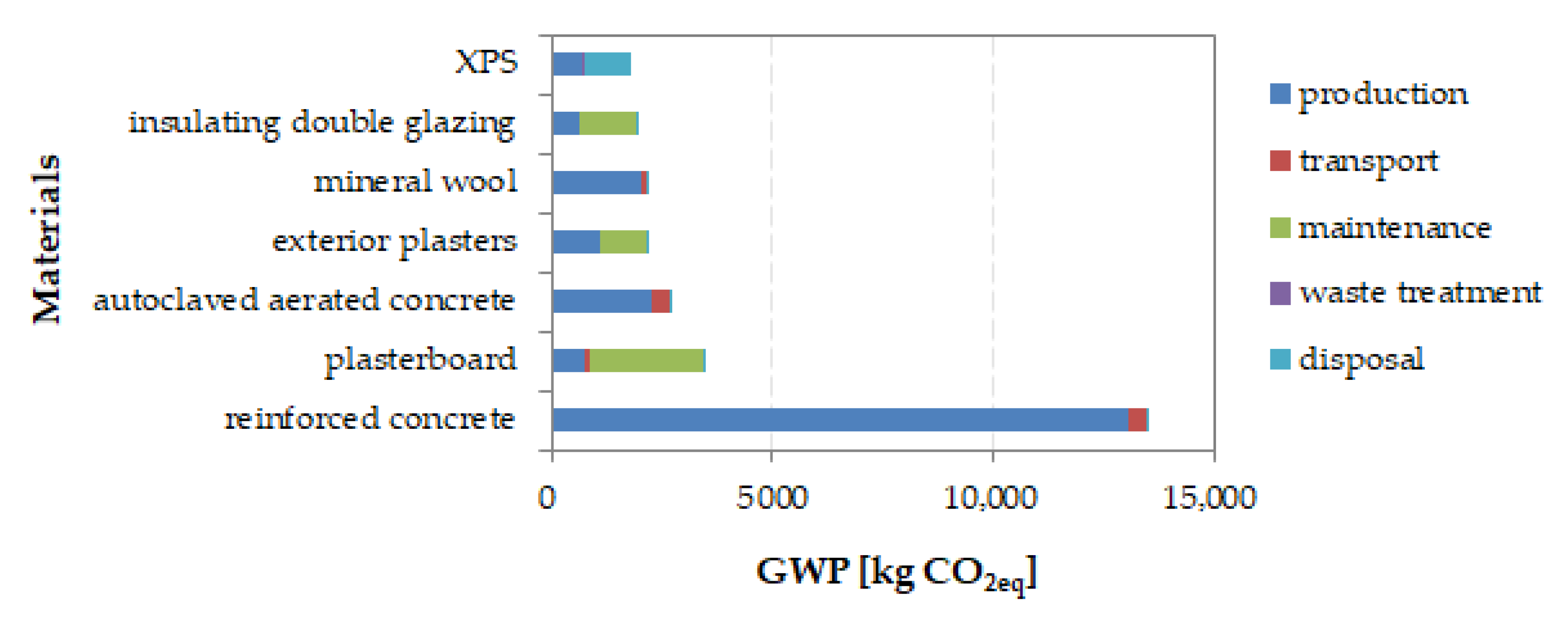

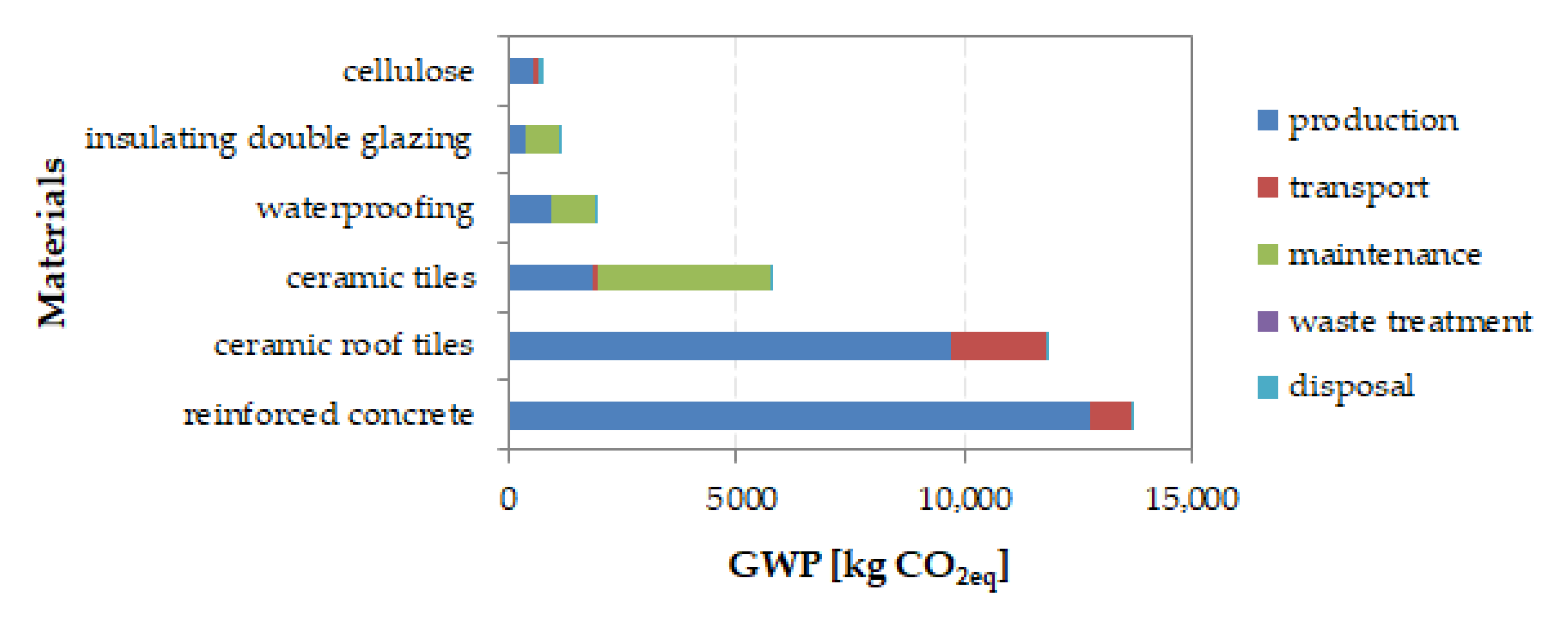

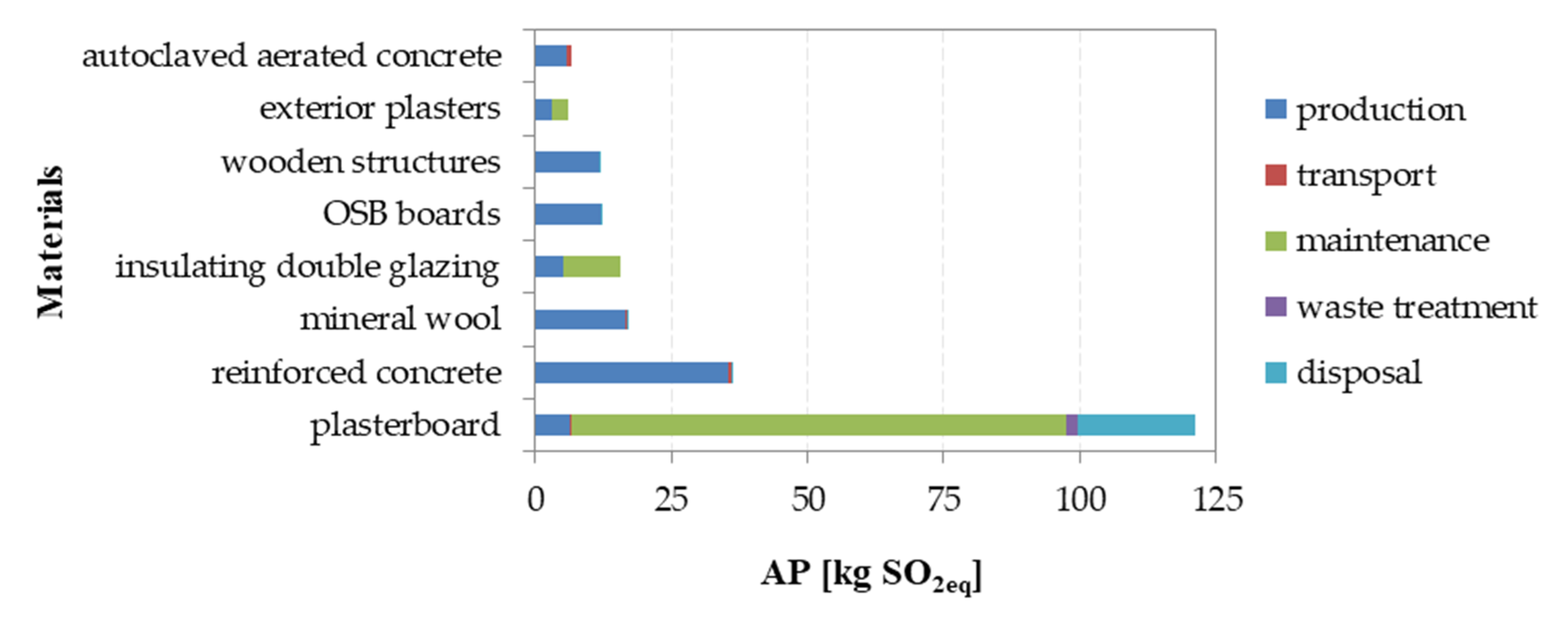

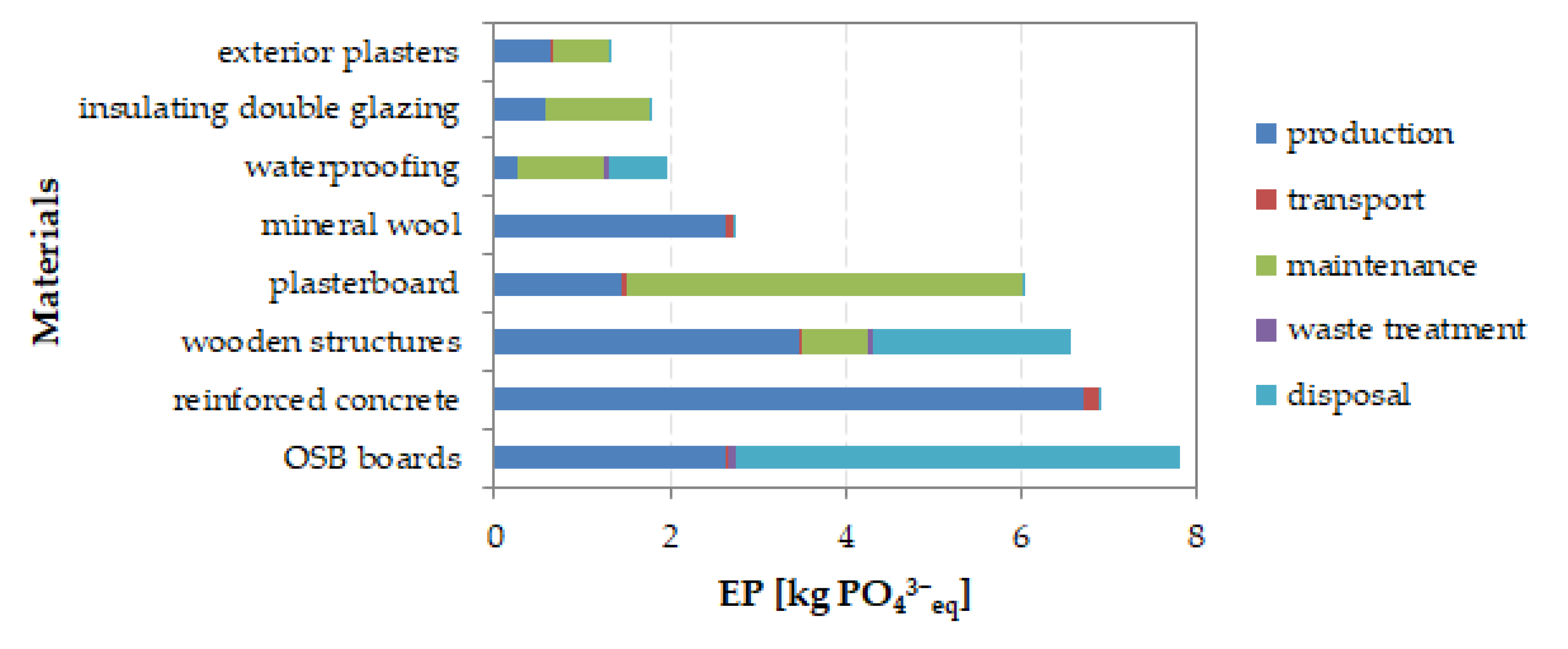

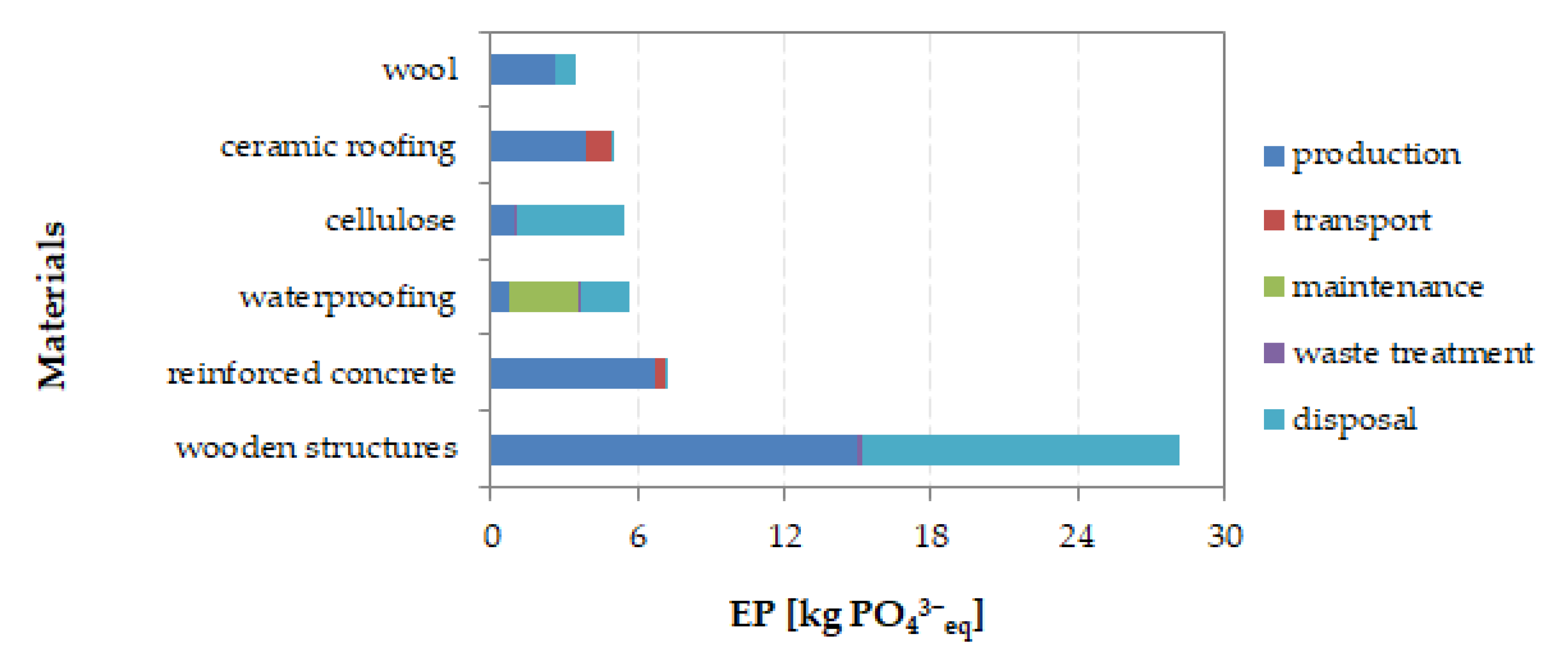

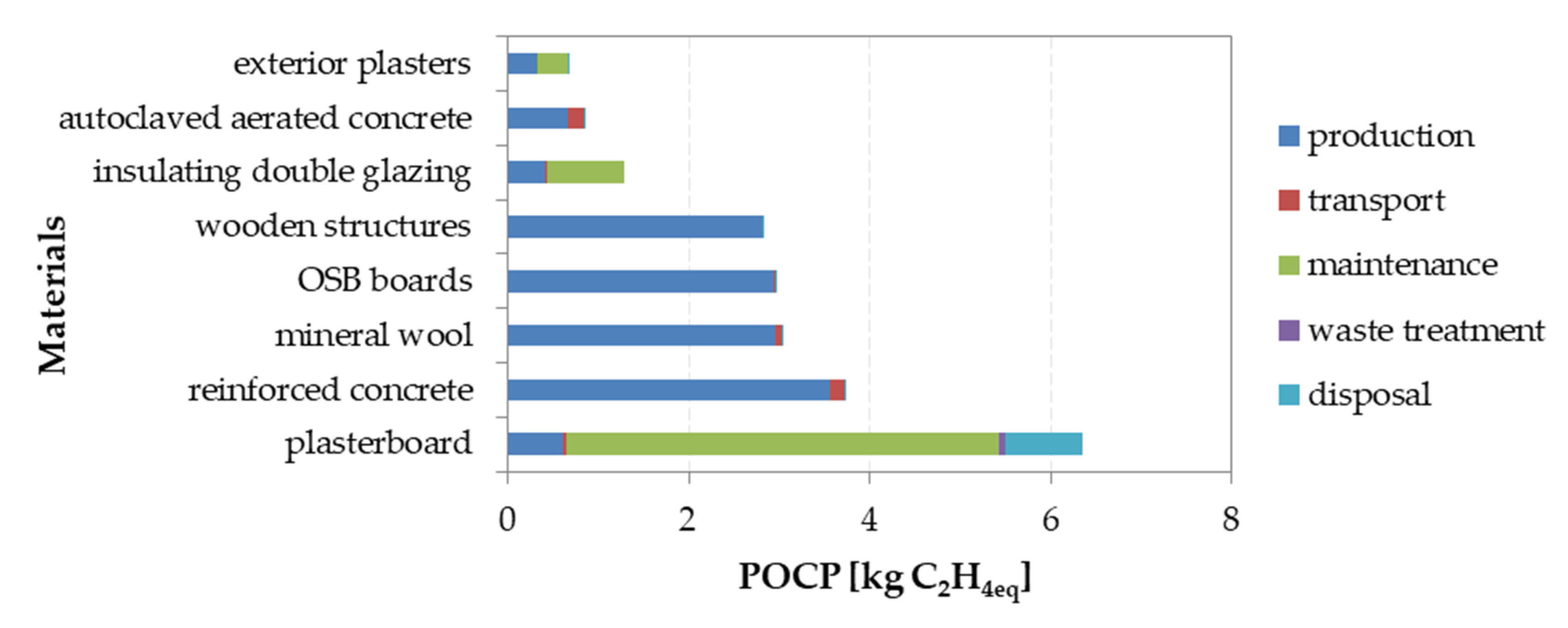

3.1. Results of Life Cycle Assessment

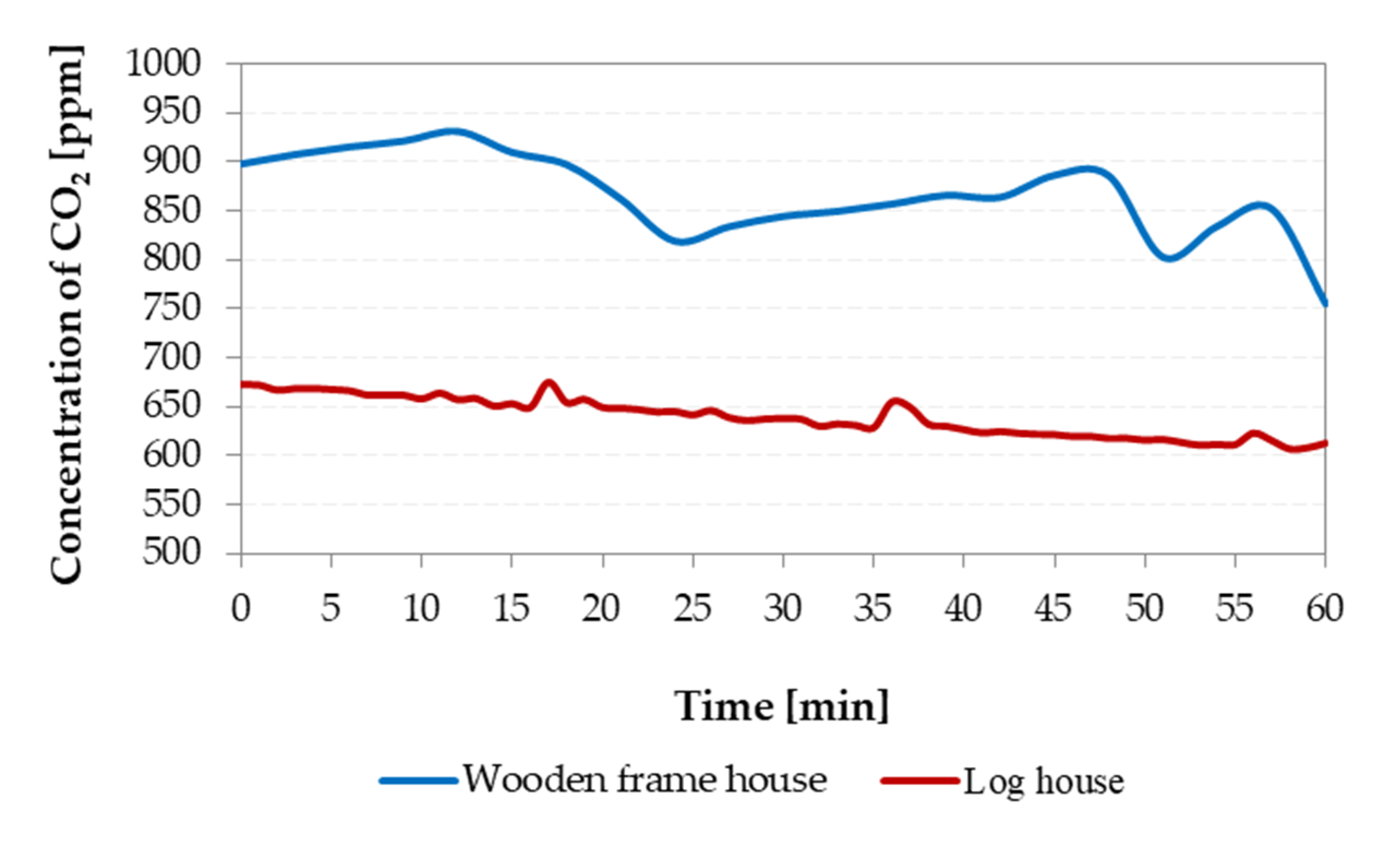

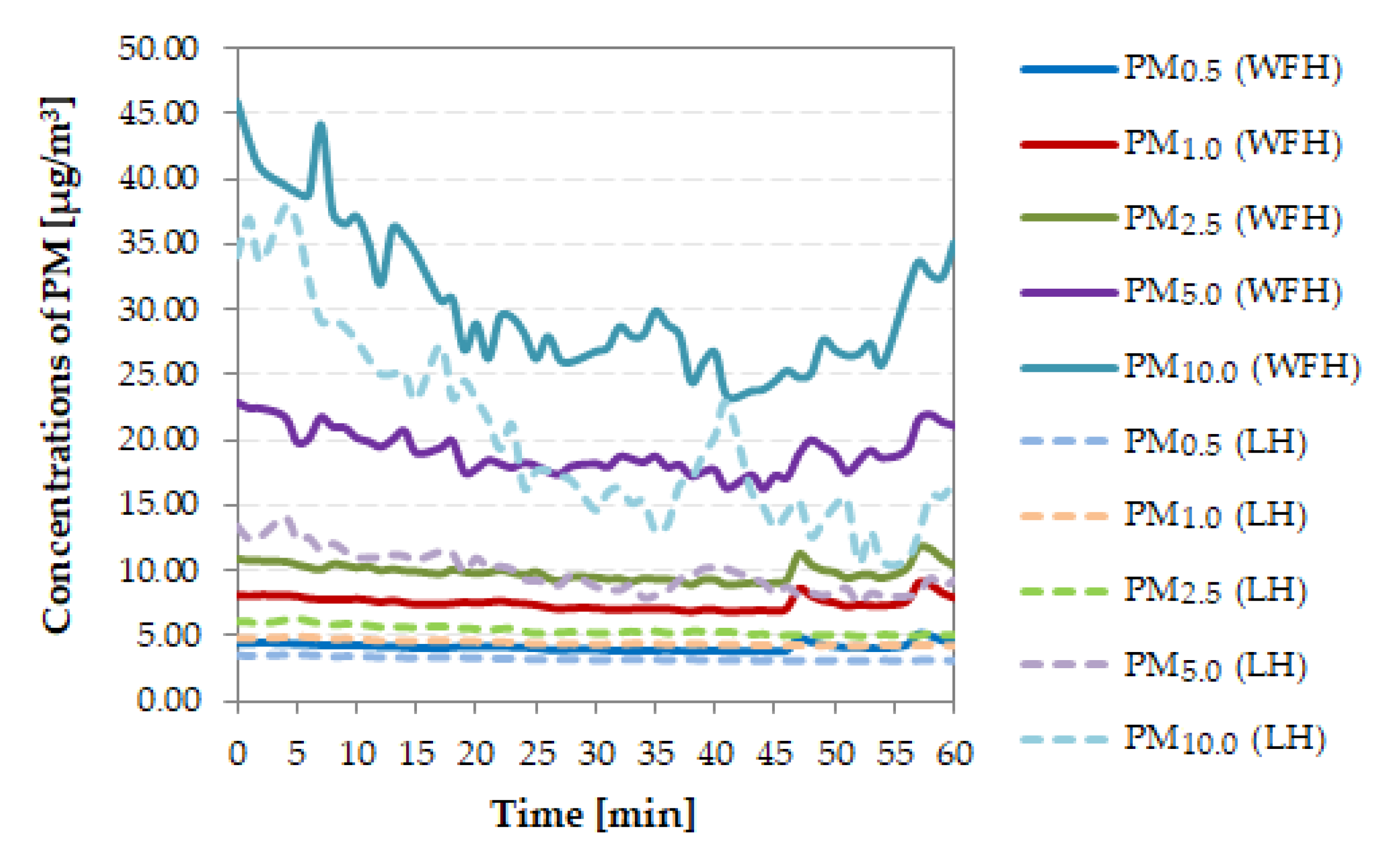

3.2. Results of Indoor Air Quality Measurements

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sandanayake, M.; Lokuge, W.; Zhang, G.; Setunge, S.; Thushar, Q. Greenhouse gas emissions during timber and concrete building construction—A scenario based comparative case study. Sustain. Cities Soc. 2018, 38, 91–97. [Google Scholar] [CrossRef] [Green Version]

- Zubizarreta, M.; Cuadrado, J.; Orbe, A.; García, H. Modeling the environmental sustainability of timber structures: A case study. Environ. Impact Assess. Rev. 2019, 78, 106286. [Google Scholar] [CrossRef]

- Asdrubali, F.; Ferracuti, B.; Lombardi, L.; Guattari, C.; Evangelisti, L.; Grazieschi, G. A review of structural, thermo-physical, acoustical, and environmental properties of wooden materials for building applications. Build. Environ. 2017, 114, 307–332. [Google Scholar] [CrossRef]

- Liang, S.; Gu, H.; Bergman, R.; Kelley, S.S. Comparative life-cycle assessment of a mass timber building and concrete alternative. Wood Fiber Sci. 2020, 52, 217–229. [Google Scholar] [CrossRef]

- Petrovic, B.; Myhren, J.A.; Zhang, X.; Wallhagen, M.; Eriksson, O. Life cycle assessment of a wooden single-family house in Sweden. Appl. Energy 2019, 251, 113253. [Google Scholar] [CrossRef]

- Hafner, A.; Schäfer, S. Comparative LCA study of different timber and mineral buildings and calculation method for substitution factors on building level. J. Clean. Prod. 2017, 167, 630–642. [Google Scholar] [CrossRef]

- Hanandeh, A. Environmental assessment of popular single-family house construction alternatives in Jordan. Build. Environ. 2015, 92, 192–199. [Google Scholar] [CrossRef] [Green Version]

- Li, P.; Froese, T.M. Life-cycle assessment of high performance, low cost homes. Procedia Eng. 2016, 145, 1322–1329. [Google Scholar] [CrossRef] [Green Version]

- Gerilla, G.P.; Teknomo, K.; Hokao, K. An environmental assessment of wood and steel reinforced concrete housing construction. Build. Environ. 2007, 42, 2778–2784. [Google Scholar] [CrossRef]

- Eštoková, A.; Porhinčák, M. Reduction of primary energy and CO2 emissions through selection and environmental evaluation of building materials. Theor. Found. Chem. Eng. 2012, 46, 704–712. [Google Scholar] [CrossRef]

- Häfliger, I.F.; John, V.; Passer, A.; Lasvaux, S.; Hoxha, E.; Saade, M.R.M.; Habert, G. Buildings environmental impacts’ sensitivity related to LCA modelling choices of construction materials. J. Clean. Prod. 2017, 156, 805–816. [Google Scholar] [CrossRef] [Green Version]

- Guggemos, A.A.; Horvath, A. Comparison of environmental effects of steel-and concrete-framed buildings. J. Infrastruct. Syst. 2005, 11, 93–101. [Google Scholar] [CrossRef]

- Kylili, A.; Ilic, M.; Fokaides, P.A. Whole-building Life Cycle Assessment (LCA) of a passive house of the sub-tropical climatic zone. Resour. Conserv. Recycl. 2017, 116, 169–177. [Google Scholar] [CrossRef]

- Mitterpach, J.; Štefko, J. An environmental impact of a wooden and brick house by the LCA Method. Key Eng. Mater. 2016, 688, 204–209. [Google Scholar] [CrossRef]

- Pajchrowski, G.; Noskowiak, A.; Lewandowska, A.; Strykowski, W. Wood as a building material in the light of environmental assessment of full life cycle of four buildings. Constr. Build. Mater. 2014, 52, 428–436. [Google Scholar] [CrossRef]

- Jašek, M.; Česelský, J.; Vlček, P.; Černíková, M.; Berankova, E.W. Application of BIM process by the evaluation of building energy sustainability. Adv. Mater. Res. 2014, 899, 7–10. [Google Scholar] [CrossRef]

- Vilčeková, S.; Selecká, I.; Burdová, E.K.; Mečiarová, Ľ. Interlinked sustainability aspects of low-rise residential family house development in Slovakia. Sustainability 2018, 10, 3966. [Google Scholar] [CrossRef] [Green Version]

- Sviták, M.; Krontorád, K.; Kropáček, J.; Hlásková, L.; Solař, A. Parameters of indoor air quality (IAQ) in wooden houses. BioResources 2018, 13, 8222–8238. [Google Scholar] [CrossRef]

- Fürhapper, C.; Habla, E.; Stratev, D.; Weigl, M.; Dobianer, K. Living Conditions in Timber Houses: Emission Trends and Indoor Air Quality. Front. Built Environ. 2019, 5, 151. [Google Scholar] [CrossRef] [Green Version]

- Langer, S.; Bekö, G.; Bloom, E.; Widheden, A.; Ekberg, L. Indoor air quality in passive and conventional new houses in Sweden. Build. Environ. 2015, 93, 92–100. [Google Scholar] [CrossRef]

- Čech, P.; Tesařová, D.; Hadačová, J.; Jeřábková, E. The quality of indoor air in wooden based buildings and the factors with impact of them. Wood Res. 2016, 61, 583–598. [Google Scholar]

- Hermon, P. eTool. Life Cycle Assessment. Office Presentation Example, Isetta Square, eToolLCD. 2017. Available online: https://etoollcd.com (accessed on 1 January 2018).

- Bertoldi, P. (Ed.) Guidebook “How to Develop a Sustainable Energy and Climate Action Plan (SECAP)”—Part 2—Baseline Emission Inventory (BEI) and Risk and Vulnerability Assessment (RVA); European Union: Brussels, Belgium, 2018. [Google Scholar]

- CoM Default Emission Factors for the Member States of the European Union—Version 2017. Available online: https://jeodpp.jrc.ec.europa.eu/ftp/jrc-opendata/COM-EF/dataset/comw/JRC-CoM-EF-CoMW-EF-2017.pdf (accessed on 30 December 2017).

- Moňoková, A.; Vilčeková, S. Sustainable Construction—Environmental Impacts Assessment of Architectural Elements and Building Services. Int. J. Eng. Res. Afr. 2020, 47, 77–83. [Google Scholar] [CrossRef]

- Kaoula, D.; Bouchair, A. Identification of the best material-energy-climate compatibility for five ecological houses and the contribution of their impact sources to the overall balance. Sustain. Cities Soc. 2020, 52, 101781. [Google Scholar] [CrossRef]

- Sathre, R.; González-García, S. Life cycle assessment (LCA) of wood-based building materials. In Eco-Efficient Construction and Building Materials; Woodhead Publishing: Cambridge, UK, 2014; pp. 311–337. [Google Scholar]

- Ministry of Health, Slovak Republic. Detailed Requirements for the Internal Environment of Buildings and on Minimum Requirements for Apartments of Lower Standard and Accommodation Facilities; Governmental Regulation Number 259/2008 Coll; Government of the Slovak Republic: Bratislava, Slovakia, 2008.

- Ministry of Health, Slovak Republic. Detailed Requirements for Indoor Environment of Buildings and Minimum Requirements for Low-Standard Flats and Accommodation Facilities; Governmental Regulation Number 259/2008 Coll; Government of the Slovak Republic: Bratislava, Slovakia, 2006.

- Derbez, M.; Berthineau, B.; Cochet, V.; Pignon, C.; Ribéron, J.; Wyart, G.; Kirchner, S. A 3-year follow-up of indoor air quality and comfort in two energy-efficient houses. Build. Environ. 2014, 82, 288–299. [Google Scholar] [CrossRef]

- Pettenkofer, M.V. Über den Luftwechsel in Wohngebäuden; Literarischartistische Anstalt der Cotta’schen Buchhandlungen: München, Germany, 1858. [Google Scholar]

- Plaisance, H.; Vignau-Laulhere, J.; Mocho, P.; Sauvat, N.; Raulin, K.; Desauziers, V. Volatile organic compounds concentrations during the construction process in newly-built timber-frame houses: Source identification and emission kinetics. Environ. Sci. Process. Impacts 2017, 19, 696–710. [Google Scholar] [CrossRef] [PubMed]

- Derbez, M.; Berthineau, B.; Cochet, V.; Lethrosne, M.; Pignon, C.; Riberon, J.; Kirchner, S. Indoor air quality and comfort in seven newly built, energy-efficient houses in France. Build. Environ. 2014, 72, 173–187. [Google Scholar] [CrossRef]

| Wooden Frame House | Log House | |

|---|---|---|

| Built-up area | 80 m2 | 120 m2 |

| Useful area | 117 m2 | 170 m2 |

| Enclosed volume | 400 m3 | 500 m3 |

| Total floor area | 145 m2 | 198 m2 |

| Number of floors | 2 | 1 + loft |

| Number of housing units | 1 | 1 |

| Number of occupants | 4 | 3 |

| Heat demand for DHW heating | 3800 kWh/year | 3200 kWh/year |

| Heat demand at central heating | 16,081 kWh/year | 9900 kWh/year |

| Impact | Materials and Construction | Use Stage | End of Life Stage | Total | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| A1–A3 | A4 | A5 | B1 | B2 | B5 | B6 | B7 | C4 | ||

| GWP (kg CO2eq) | 62.00 | 15.00 | 8.10 | 0 | 0.076 | 54.00 | 1080 | 26.00 | 8.50 | 1254 |

| ODP (kgCFC11eq) | 7.2 × 10−6 | 9.9 × 10−7 | 4.9 × 10−7 | 0 | 3.9 × 10−9 | 6.8 × 10−6 | 2.5 × 10−6 | 1.4 × 10−6 | 3.8 × 10−9 | 1.94 × 10−5 |

| AP (kg SO2eq) | 1.6 | 0.13 | 0.048 | 0 | 4.6 × 10−4 | 0.62 | 0.42 | 0.13 | 6.7 × 10−4 | 2.95 |

| EP (kg (PO4)3−eq) | 0.26 | 0.077 | 0.014 | 0 | 8.1 × 10−5 | 0.082 | 0.11 | 0.031 | 0.061 | 0.64 |

| POCP (kg C2H4eq) | 0.11 | 6.6 × 10−3 | 0.1 | 0 | 2.0 × 10−5 | 0.058 | 0.053 | 7.77 × 10−3 | 6.1 × 10−3 | 0.34 |

| ADPE (kg Sbeq) | 1.7 × 10−3 | 8.6 × 10−8 | 1.6 × 10−7 | 0 | 7.6 × 10−9 | 8.0 × 10−4 | 4.9 × 10−6 | 6.2 × 10−6 | 2.2 × 10−8 | 2.51 × 10−3 |

| ADPF (MJ) | 3800 | 470 | 110 | 0 | 1.2 | 840 | 770 | 410 | 0.13 | 6401 |

| PERE (MJ) | 1700 | 0.31 | 0.53 | 0 | 0.023 | 130 | 15 | 18 | 0.053 | 1864 |

| PERM (MJ) | 1.80 × 10−2 | 2.1 × 10−6 | 3.5 × 10−6 | 0 | 7.7 × 10−7 | 2.4 × 10−3 | 1.2 × 10−4 | 5.5 × 10−5 | 6.5 × 10−7 | 0.0206 |

| PENRE (MJ) | 3900 | 210 | 110 | 0 | 1.5 | 900 | 930 | 500 | 0.32 | 6552 |

| FW (m3) | 19 | 0.024 | 0.045 | 0 | 2.0 × 10−4 | 0.89 | 0.7 | 37 | 2.2 × 10−4 | 57.66 |

| HWD (kg) | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| NHWD (kg) | 1.3 | 0 | 6.9 | 0 | 0 | 24 | 0 | 0 | 230 | 262.2 |

| RWD (kg) | 5.8 × 10−3 | 1.3 × 10−3 | 6.7 × 10−4 | 0 | 7.1 × 10−6 | 3.2 × 10−3 | 5.0 × 10−3 | 2.4 × 10−3 | 3.4 × 10−6 | 0.0184 |

| CRU (kg) | 0 | 0 | 1.3 | 0 | 0 | 1.6 | 0 | 0 | 13 | 15.9 |

| MFR (kg) | 0 | 0 | 60 | 0 | 0 | 120 | 0 | 0 | 1684 | 1702 |

| MER (kg) | 0.15 | 0 | 0.15 | 0 | 0 | 0.37 | 0 | 0 | 5.8 | 6.47 |

| Impact | Materials and Construction | Use Stage | End of Life Stage | Total | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| A1–A3 | A4 | A5 | B1 | B2 | B5 | B6 | B7 | C4 | ||

| GWP (kg CO2eq) | −160 | 28 | 5.8 | −1.4 | 0.057 | 51 | 27.5 | 19 | 2.2 | −27.84 |

| ODP (kgCFC11eq) | 8.6 × 10−6 | 1.8 × 10−6 | 3.6 × 10−7 | 0 | 2.9 × 10−9 | 5.0 × 10−6 | 9.0 × 10−7 | 9.9 × 10−7 | 4.1 × 10−8 | 1.8 × 10−5 |

| AP (kg SO2eq) | 0.89 | 0.065 | 0.049 | 0 | 2.7 × 10−4 | 0.67 | 0.22 | 0.097 | 0.11 | 2.1 |

| EP (kg (PO4)3−eq) | 0.19 | 0.014 | 0.011 | 0 | 6.1 × 10−5 | 0.075 | 0.075 | 0.023 | 0.11 | 0.49 |

| POCP (kg C2H4eq) | 0.16 | 0.012 | 7.7 × 10−3 | 0 | 1.5 × 10−5 | 0.066 | 0.14 | 5.6 × 10−3 | 4.7 × 10−3 | 0.396 |

| ADPE (kg Sbeq) | 1.3 × 10−3 | 1.6 × 10−7 | 1.2 × 10−7 | 0 | 5.7 × 10−9 | 3.2 × 10−4 | 9.0 × 10−7 | 4.6 × 10−6 | 2.1 × 10−8 | 1.63 × 10−3 |

| ADPF (MJ) | 2200 | 400 | 84 | 0 | 0.9 | 890 | 230 | 300 | 0.14 | 4105 |

| PERE (MJ) | 4700 | 0.6 | 0.4 | 0 | 0.017 | 120 | 13,000 | 13 | 0.064 | 17,834 |

| PERM (MJ) | 2.0 × 10−3 | 3.9 × 10−6 | 2.6 × 10−6 | 0 | 1.3 × 10−7 | 3.1 × 10−3 | 1.1 × 10−5 | 4.0 × 10−5 | 5.6 × 10−7 | 5.2 × 10−3 |

| PENRE (MJ) | 2300 | 380 | 84 | 0 | 1.1 | 950 | 240 | 360 | 0.37 | 4316 |

| FW (m3) | 2 | 0.045 | 0.034 | 0 | 1.4 × 10−3 | 0.84 | 0.14 | 61 | 2.4 × 10−4 | 64.06 |

| HWD (kg) | 3.6 × 10−3 | 0 | 0 | 0 | 0 | 5.8 × 10−3 | 0 | 0 | 2.0 × 10−3 | 0.011 |

| NHWD (kg) | 0.018 | 7.2 × 10−4 | 13 | 0 | 0 | 18 | 0 | 0 | 230 | 261 |

| RWD (kg) | 9.7 × 10−3 | 2.3 × 10−3 | 4.9 × 10−4 | 0 | 5.4 × 10−6 | 2.5 × 10−3 | 1.3 × 10−3 | 1.7 × 10−3 | 4.1 × 10−6 | 0.018 |

| CRU (kg) | 0 | 0 | 3.3 | 0 | 0 | 1.2 | 0 | 0 | 28 | 32.5 |

| MFR (kg) | 0 | 0 | 80 | 0 | 0 | 100 | 0 | 0 | 1100 | 1280 |

| MER (kg) | 0 | 8.0 × 10−5 | 0.28 | 0 | 0 | 0.27 | 0 | 0 | 14 | 14.55 |

| Air Temperature (°C) | Relative Humidity (%) | Air Velocity (m/s) | CO2 (ppm) | PM2.5 (µg/m3) | PM10 (µg/m3) | ||

|---|---|---|---|---|---|---|---|

| Wooden frame house | Mean | 24.6 | 32.5 | 0.04 | 866 | 9.92 | 30.57 |

| Min | 23.3 | 26.0 | 0.00 | 755 | 8.94 | 23.34 | |

| Max | 25 | 34.5 | 0.22 | 931 | 11.77 | 45.91 | |

| SD 1 | 0.4 | 1.59 | 0.04 | 43.44 | 0.66 | 5.63 | |

| Log house | Mean | 23.7 | 27.5 | 0.01 | 639 | 5.44 | 20.24 |

| Min | 23.5 | 27.2 | 0.00 | 607 | 4.99 | 10.64 | |

| Max | 23.8 | 28.3 | 0.07 | 675 | 6.36 | 37.87 | |

| SD 1 | 0.08 | 0.19 | 0.01 | 19.85 | 0.36 | 7.25 |

| Wooden Frame House | Log House | |

|---|---|---|

| Toluene (µg/m3) | <LOD 2 | <LOD 2 |

| Xylenes (m-, p-,o-) (µg/m3) | 8.62 | 123.25 |

| Styrene (µg/m3) | <LOD 2 | <LOD 2 |

| Tetrachloroethene (µg/m3) | 141.43 | 1593.86 |

| n-Butylacetate (µg/m3) | 11.53 | <LOD 2 |

| Isobutanol (µg/m3) | 8.23 | 32.78 |

| Limonene (µg/m3) | 300.57 | <LOD 2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vilčeková, S.; Harčárová, K.; Moňoková, A.; Burdová, E.K. Life Cycle Assessment and Indoor Environmental Quality of Wooden Family Houses. Sustainability 2020, 12, 10557. https://doi.org/10.3390/su122410557

Vilčeková S, Harčárová K, Moňoková A, Burdová EK. Life Cycle Assessment and Indoor Environmental Quality of Wooden Family Houses. Sustainability. 2020; 12(24):10557. https://doi.org/10.3390/su122410557

Chicago/Turabian StyleVilčeková, Silvia, Katarína Harčárová, Andrea Moňoková, and Eva Krídlová Burdová. 2020. "Life Cycle Assessment and Indoor Environmental Quality of Wooden Family Houses" Sustainability 12, no. 24: 10557. https://doi.org/10.3390/su122410557