Water-Energy Nexus: A Pathway of Reaching the Zero Net Carbon in Wastewater Treatment Plants

Abstract

:1. Introduction

2. Materials and Methods

2.1. Wastewater Treatment Plant Selection

2.2. Design and Estimation of Green Energy Production Technologies

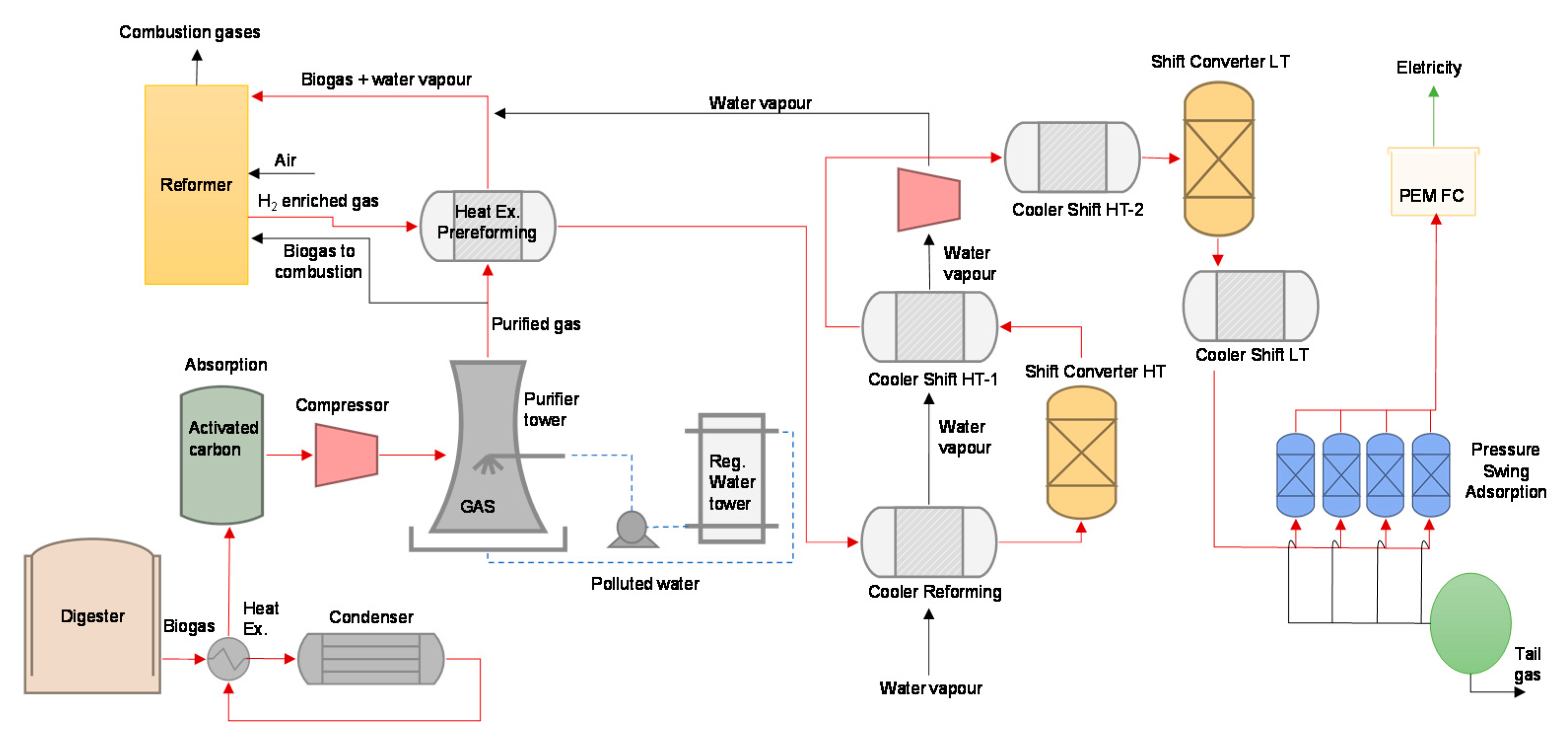

2.2.1. Energy Recovery Technologies Internal to the Plant. Sludge Treatment and Microturbines in Pipes

2.2.2. Energy Production Technologies External to the Plant. Photovoltaic, Wind, and Hydroelectric Energy

2.3. System Analysis

2.4. Energy Storage

3. Results and Discussion

3.1. Internal Renewable Energy Production

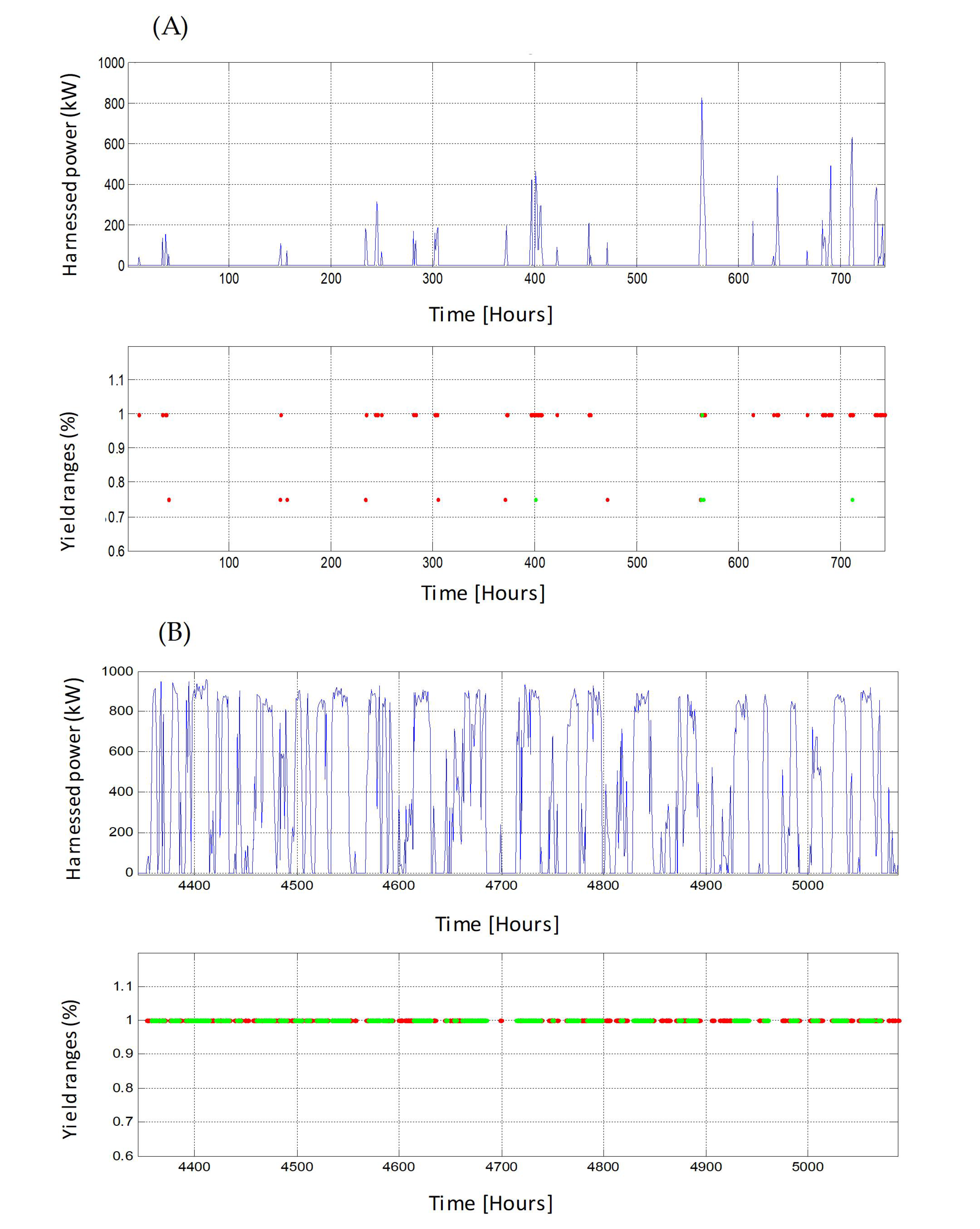

3.2. External Renewable Energy Production

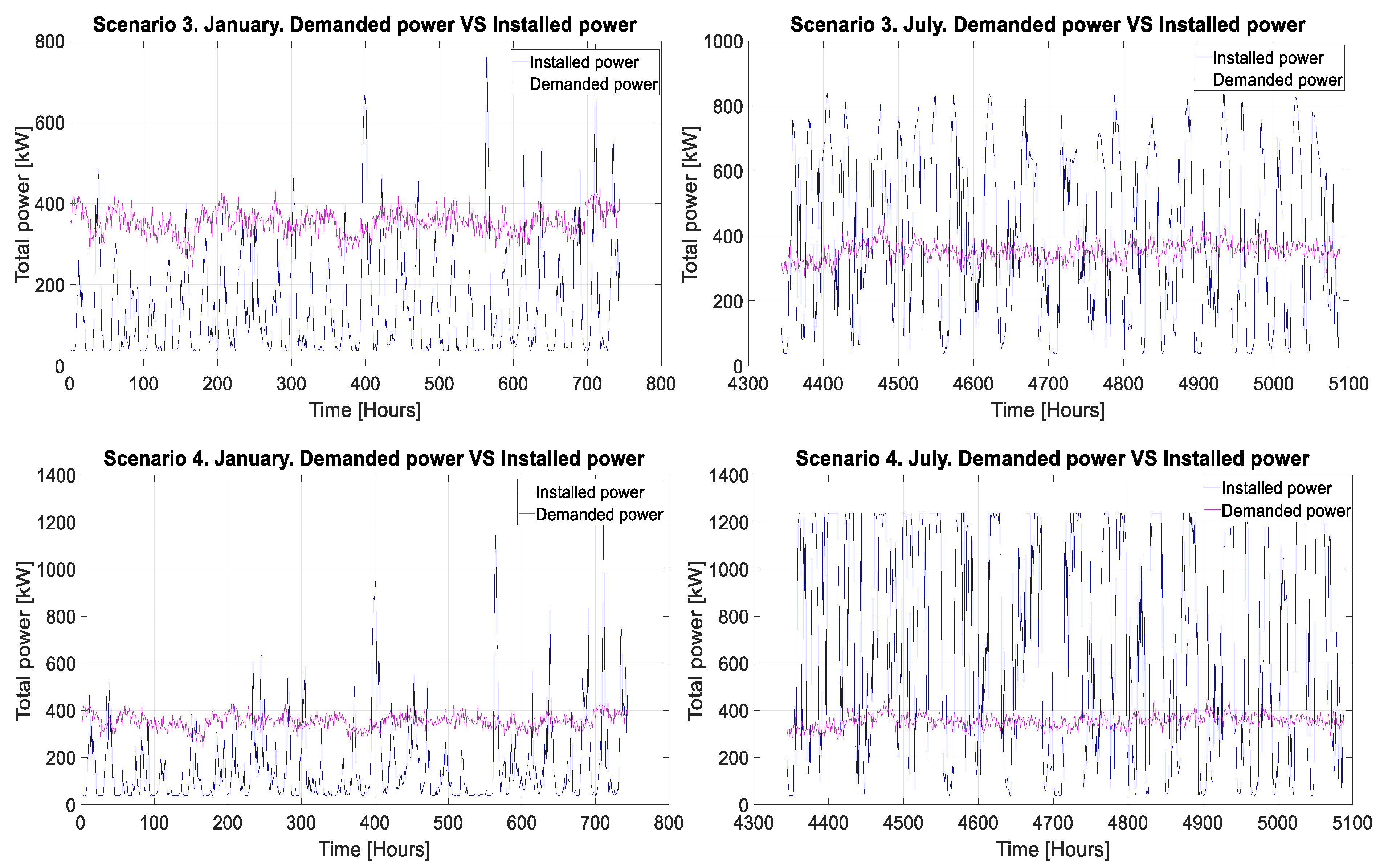

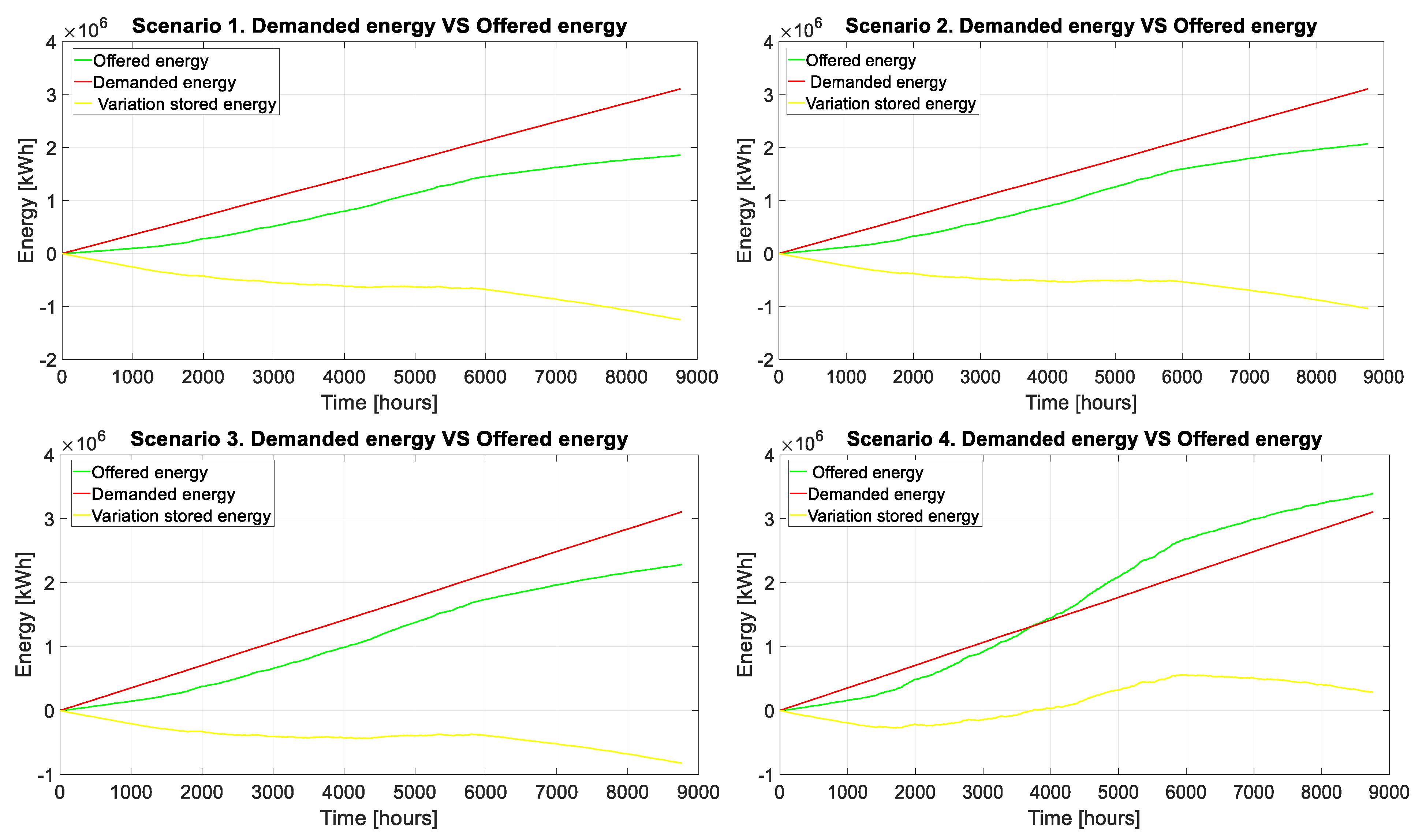

3.3. System Analysis

- Scenario 1 gave a net alternative energy production of 1,859,333 kWh per year, which would avoid the emission of 1,508 tons of CO2 equivalent, reducing the emission value to 889 tons of CO2 per year from a conventional consumption of 1,096,980 kWh/year.

- Scenario 2 gave an annual energy production of 2,072,262 kWh, which would avoid the emission of 1681 tons of CO2 equivalent, with the emission into the atmosphere of a total of 716 tons per year after reducing the conventional energy demand of the plant by 70%.

- Scenario 3 avoided the emission of 1853 tons of greenhouse gases through the production of 2,285,190.6 kWh/year, which is very close to the demand needs of the plant. This scenario reduces the annual emission rate to 544 tons of CO2 being produced by the conventional consumption of 671,123 kWh.

- Scenario 4 confirmed the technical possibility of a 100% power consumption reduction, thereby avoiding the annual emission of 2754 tons of greenhouse gases with a production of 3,396,326.39 kWh/year.

3.4. Management of Energy Surplus

3.4.1. Energy Storage

3.4.2. Network Reinjection

3.5. Economic Feasibility Analysis

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hamiche, A.M.; Stambouli, A.B.; Flazi, S. A review of the water-energy nexus. Renew. Sustain. Energy Rev. 2016, 65, 319–331. [Google Scholar] [CrossRef]

- Hardy, A.L.; Garrido, L.J.S. Análisis y Evaluación de Las Relaciones Entre El Agua y La Energía En España; Fundación Marcelino Botín: Santander, Spain, 2010. [Google Scholar]

- Siddiqi, A.; Anadon, L.D. The water–energy nexus in Middle East and North Africa. Energy Policy 2011, 39, 4529–4540. [Google Scholar] [CrossRef]

- Liu, Y.; Hejazi, M.; Kyle, P.; Kim, S.H.; Davies, E.; Miralles, D.G.; Teuling, A.J.; He, Y.; Niyogi, D. Global and Regional Evaluation of Energy for Water. Environ. Sci. Technol. 2016, 50, 9736–9745. [Google Scholar] [CrossRef] [PubMed]

- World Energy Outlook 2016; Paris. 2016. Available online: https://www.iea.org/reports/world-energy-outlook-2016 (accessed on 23 June 2020).

- World Energy Outlook 2012; Paris. 2012. Available online: https://www.iea.org/reports/world-energy-outlook-2012 (accessed on 25 June 2020).

- Spang, E.S.; Moomaw, W.R.; Gallagher, K.S.; Kirshen, P.H.; Marks, D.H. The water consumption of energy production: An international comparison. Environ. Res. Lett. 2014, 9, 105002. [Google Scholar] [CrossRef]

- Gleick, P.H. Water and Energy. Annu. Rev. Energy Environ. 1994, 19, 267–299. [Google Scholar] [CrossRef]

- Stang, S.; Wang, H.; Gardner, K.H.; Mo, W. Influences of water quality and climate on the water-energy nexus: A spatial comparison of two water systems. J. Environ. Manag. 2018, 218, 613–621. [Google Scholar] [CrossRef]

- Tan, C.; Zhi, Q. The Energy-water Nexus: A literature Review of the Dependence of Energy on Water. Energy Procedia 2016, 88, 277–284. [Google Scholar] [CrossRef] [Green Version]

- Sixt, G.N.; Strambo, C.; Zhang, J.; Chow, N.; Liu, J.; Han, G. Assessing the Level of Inter-Sectoral Policy Integration for Governance in the Water–Energy Nexus: A Comparative Study of Los Angeles and Beijing. Sustainability 2020, 12, 7220. [Google Scholar] [CrossRef]

- Council of the European Union. Paris Agreement on Climate Change. European Council Conclusions on Climate Neutrality. Available online: https://www.consilium.europa.eu/en/policies/climate-change/paris-agreement/ (accessed on 29 October 2020).

- United States Environmental Protection Agency. Reducing Operating Costs and Energy Consumption at Water Utilities Report. Available online: https://www.epa.gov/sustainable-water-infrastructure/reducing-operating-costs-and-energy-consumption-water-utilities (accessed on 29 October 2020).

- Guilera, J.; Andreu, T.; Basset, N.; Boeltken, T.; Timm, F.; Mallol, I.; Morante, J.R. Synthetic natural gas production from biogas in a waste water treatment plant. Renew. Energy 2020, 146, 1301–1308. [Google Scholar] [CrossRef]

- Bhatia, R.K.; Sakhuja, D.; Mundhe, S.; Walia, A. Renewable Energy Products through Bioremediation of Wastewater. Sustainability 2020, 12, 7501. [Google Scholar] [CrossRef]

- Gu, Y.; Li, Y.; Li, X.; Luo, P.; Wang, H.; Robinson, Z.P.; Wang, X.; Wu, J.; Li, F. The feasibility and challenges of energy self-sufficient wastewater treatment plants. Appl. Energy 2017, 204, 1463–1475. [Google Scholar] [CrossRef]

- Wacławek, S.; Grübel, K.; Silvestri, D.; Padil, V.V.T.; Wacławek, M.; Černík, M.; Varma, R.S. Disintegration of Wastewater Activated Sludge (WAS) for Improved Biogas Production. Energies 2018, 12, 21. [Google Scholar] [CrossRef] [Green Version]

- Maktabifard, M.; Zaborowska, E.; Makinia, J. Achieving energy neutrality in wastewater treatment plants through energy savings and enhancing renewable energy production. Rev. Environ. Sci. Biotechnol. 2018, 17, 655–689. [Google Scholar] [CrossRef] [Green Version]

- Gürtekin, E. Experimental and numerical design of renewable-energy-supported advanced biological wastewater treatment plant. Int. J. Environ. Sci. Technol. 2018, 16, 1183–1192. [Google Scholar] [CrossRef]

- Franzen, S.; Madlener, R. Optimal expansion of a hydrogen storage system for wind power (H2-WESS): A real options analysis. Energy Procedia 2017, 105, 3816–3823. [Google Scholar] [CrossRef]

- Kalinci, Y.; Dincer, I.; Hepbasli, A. Energy and exergy analyses of a hybrid hydrogen energy system: A case study for Bozcaada. Int. J. Hydrogen Energy 2017, 42, 2492–2503. [Google Scholar] [CrossRef]

- Gil, A.; Medrano, M.; Martorell, I.; Lázaro, A.; Dolado, P.; Zalba, B.; Cabeza, L.F. State of the art on high temperature thermal energy storage for power generation. Part 1—Concepts, materials and modellization. Renew. Sustain. Energy Rev. 2010, 14, 31–55. [Google Scholar] [CrossRef]

- Gobierno de Canarias. Anuario Energético de Canarias 2017. Available online: http://energiagrancanaria.com/wp-content/uploads/2019/02/A-energetico-canarias-2017.pdf (accessed on 13 July 2020).

- Gikas, P. Towards energy positive wastewater treatment plants. J. Environ. Manag. 2017, 203, 621–629. [Google Scholar] [CrossRef]

- Vo, P.T.; Ngo, H.H.; Guo, W.; Zhou, J.L.; Nguyen, P.D.; Listowski, A.; Wang, X.C. A mini-review on the impacts of climate change on wastewater reclamation and reuse. Sci. Total Environ. 2014, 9–17. [Google Scholar] [CrossRef]

- Torregrossa, D.; Castellet-Viciano, L.; Hernández-Sancho, F. A data analysis approach to evaluate the impact of the capacity utilization on the energy consumption of wastewater treatment plants. Sustain. Cities Soc. 2019, 45, 307–313. [Google Scholar] [CrossRef]

- Awad, H.; Alalm, M.G.; El-Etriby, H.K. Environmental and cost life cycle assessment of different alternatives for improvement of wastewater treatment plants in developing countries. Sci. Total Environ. 2019, 660, 57–68. [Google Scholar] [CrossRef] [PubMed]

- Helal, A.; Ghoneim, W.; Halaby, A. Feasibility Study for Self-Sustained Wastewater Treatment Plants—Using Biogas CHP Fuel Cell, Micro-Turbine, PV and Wind Turbine Systems. Smart Grid Renew. Energy 2013, 4, 227–235. [Google Scholar] [CrossRef] [Green Version]

- Del Rio-Gamero, B. Mitigación del Cambio Climático en el Ciclo Integral del Agua: Aplicación al Proceso de Tratamiento de Aguas Residuals. Ph.D Thesis, Universidad de Las Palmas de Gran Canaria, Las Palmas, Spain, 2018. Available online: https://accedacris.ulpgc.es/handle/10553/55375 (accessed on 30 October 2020).

- Consejo Insular de Aguas de Gran Canaria. Consumo Energético de La Estación Depuradora de Aguas de Jinamar. 2018. Available online: http://www.aguasgrancanaria.com/ (accessed on 2 April 2020).

- Picardo, A.; Soltero, V.M.; Álvarez, M.E.P.; Chacartegui, R. District heating based on biogas from wastewater treatment plant. Energy 2019, 180, 649–664. [Google Scholar] [CrossRef]

- Kollmann, R.; Neugebauer, G.; Kretschmer, F.; Truger, B.; Kindermann, H.; Stoeglehner, G.; Ertl, U.-P.D.D.T.; Narodoslawsky, M. Renewable energy from wastewater - Practical aspects of integrating a wastewater treatment plant into local energy supply concepts. J. Clean. Prod. 2017, 155, 119–129. [Google Scholar] [CrossRef]

- Guven, H.; Ersahin, M.E.; Dereli, R.K.; Ozgun, H.; Isik, I.; Ozturk, I. Energy recovery potential of anaerobic digestion of excess sludge from high-rate activated sludge systems co-treating municipal wastewater and food waste. Energy 2019, 172, 1027–1036. [Google Scholar] [CrossRef]

- Seiple, T.E.; Coleman, A.M.; Skaggs, R.L. Municipal wastewater sludge as a sustainable bioresource in the United States. J. Environ. Manag. 2017, 197, 673–680. [Google Scholar] [CrossRef]

- Tyagi, V.K.; Lo, S.-L. Sludge: A waste or renewable source for energy and resources recovery? Renew. Sustain. Energy Rev. 2013, 25, 708–728. [Google Scholar] [CrossRef]

- Shilpi, S.; Lamb, D.; Bolan, N.; Seshadri, B.; Choppala, G.; Naidu, R. Waste to watt: Anaerobic digestion of wastewater irrigated biomass for energy and fertiliser production. J. Environ. Manag. 2019, 239, 73–83. [Google Scholar] [CrossRef]

- American Public Health Association; American Water Works Association; Water Pollution Control Federation; Water Environment Federation. Standard Methods for the Examination of Water and Wastewater, 2nd ed.; 1915. Available online: https://trove.nla.gov.au/work/16646325 (accessed on 25 April 2020).

- Metcalf and Eddy; Montsoriu, J.D.D.T. Ingeniería Sanitaria: Tratamineto, Evacuación y Reutilización de Aguas Residuales; Labor: Barcelona, Spain, 1985. [Google Scholar]

- Cabanes, J.L. Digestión Anaerobia de Lodos de Depuradora, Etapas Controlantes y Cinética Del Proceso. Ph.D Thesis, Universidad de Alicante, Alicante, Spain, June 1989. [Google Scholar]

- Martínez, M.; Santianes, M.; Crespí, S.; Jimenez, J. Utilización de Biogás En Pilas de Combustible; Madrid. 2008. Available online: http://kimerius.com/app/download/5781446527/Utilizaci%C3%B3n+del+biog%C3%A1s+en+pilas+de+combustible.pdf (accessed on 14 May 2020).

- Ferreira-Aparicio, P.; Benito, M.J.; Sanz, J.L. New Trends in Reforming Technologies: From Hydrogen Industrial Plants to Multifuel Microreformers. Catal. Rev. 2005, 47, 491–588. [Google Scholar] [CrossRef]

- Monteith, H.; Bagley, M.D.; MacLean, M.H.; Kalogo, Y. An Assessment Tool for Managing Cost-Effective Energy Recovery from Anaerobically Digested Wastewater Solids; Alexandria, 2006. Available online: http://assets.matchbin.com/sites/274/assets/IQMT_DigesterGasUse.pdf (accessed on 14 May 2020).

- Santos, J.C.; Cruz, P.; Regala, T.; Magalhães, F.D.; Mendes, A. High-Purity Oxygen Production by Pressure Swing Adsorption. Ind. Eng. Chem. Res. 2007, 46, 591–599. [Google Scholar] [CrossRef]

- Silva, B.; Solomon, I.; Ribeiro, A.M.; Lee, U.-H.; Hwang, Y.K.; Chang, J.-S.; Loureiro, J.M.; Rodrigues, A.E. H2 purification by pressure swing adsorption using CuBTC. Sep. Purif. Technol. 2013, 118, 744–756. [Google Scholar] [CrossRef]

- Forget, A. Manual Para Ayudar La Comprensión Del Diseño de Microaerogeneradores; Lima. 2011. Available online: http://www.astridforget.com/wp-content/uploads/2014/09/Manual-t%C3%A9cnico-AF-eolico-VF-110617.pdf (accessed on 17 May 2020).

- Vargas, F.E.S.; Alarcón, A.F.S.; Fajardo, C.A.G. Pequeñas y microcentrales hidroeléctricas: Alternativa real de generación eléctrica. Informador Técnico 2011, 75, 73–85. [Google Scholar] [CrossRef] [Green Version]

- HOMER. Hybrid Optimization of Multiple Energy Resources. Available online: http://analysis.nrel.gov/homer/ (accessed on 15 June 2018).

- Dierauf, T.; Growitz, A.; Kurtz, S.; Cruz, J.L.B.; Riley, E.; Hansen, C. Weather-Corrected Performance Ratio; National Renewable Energy Laboratory: Golden, CO, USA, 2013; pp. 1–16. [CrossRef] [Green Version]

- Gobierno de Canarias. Visor Grafcan. Sistema de información territorial de Canarias. Available online: https://visor.grafcan.es/visorweb/ (accessed on 22 March 2019).

- Arnés González, C. Estudio del Potencial Eólico Para Generación Eléctrica en el Itsmo de Tehuantepec, Oaxaca, México, Escuela Técnica de Ingenieros Industriales y Telecomunicación. México. 2014. Available online: http://academica-e.unavarra.es/bitstream/handle/2454/11924/Arnes_Gonzalez_Carlos.pdf?sequence=1 (accessed on 24 May 2020).

- Guerrero-Lemus, R.; González-Díaz, B.; Ríos, G.; Dib, R.N. Study of the new Spanish legislation applied to an insular system that has achieved grid parity on PV and wind energy. Renew. Sustain. Energy Rev. 2015, 49, 426–436. [Google Scholar] [CrossRef]

- Consejería de Industria, Comercio y Nuevas Tecnologías. Decreto 32/2006, de 27 de Marzo, Por El Que Se Regula La Instalación y Explotación de Los Parques Eólicos En El Ámbito de La Comunidad Autónoma de Canarias. Available online: http://www.gobiernodecanarias.org/boc/2006/061/002.html (accessed on 1 June 2020).

- Mathworks. Global Optimization Toolbox: User’s Guide (R2018b). 2018. Available online: https://es.mathworks.com/products/global-optimization.html (accessed on 22 May 2020).

- Kim, J.; Choi, H.; Kim, S.; Yu, J. Feasibility analysis of introducing renewable energy systems in environmental basic facilities: A case study in Busan, South Korea. Energy 2018, 150, 702–708. [Google Scholar] [CrossRef]

- Nguyen, H.T.; Safder, U.; Nguyen, X.N.; Yoo, C. Multi-objective decision-making and optimal sizing of a hybrid renewable energy system to meet the dynamic energy demands of a wastewater treatment plant. Energy 2020, 191, 116570. [Google Scholar] [CrossRef]

- Ayodele, T.; Ogunjuyigbe, A. Mitigation of wind power intermittency: Storage technology approach. Renew. Sustain. Energy Rev. 2015, 44, 447–456. [Google Scholar] [CrossRef]

- Khosravi, A.; Koury, R.; Machado, L.; Pabon, J. Energy, exergy and economic analysis of a hybrid renewable energy with hydrogen storage system. Energy 2018, 148, 1087–1102. [Google Scholar] [CrossRef]

- Bhogilla, S.S.; Ito, H.; Segawa, T.; Kato, A.; Nakano, A. Experimental study on laboratory scale Totalized Hydrogen Energy Utilization System using wind power data. Int. J. Hydrogen Energy 2017, 42, 13827–13838. [Google Scholar] [CrossRef]

- Loisel, R.; Baranger, L.; Chemouri, N.; Spinu, S.; Pardo, S. Economic evaluation of hybrid off-shore wind power and hydrogen storage system. Int. J. Hydrogen Energy 2015, 40, 6727–6739. [Google Scholar] [CrossRef]

- de España, G. Factores de Emisión de CO2 y Coeficientes de Paso a Energía Primaria de Diferentes Fuentes de Energía Final Consumidas En El Sector Edificios En España; Madrid. 2014. Available online: https://energia.gob.es/desarrollo/EficienciaEnergetica/RITE/Reconocidos/Reconocidos/Otros%20documentos/Factores_emision_CO2.pdf (accessed on 22 June 2020).

- OMIE. Price Report. 2018. Available online: https://www.omie.es/sites/default/files/publications/omie_informe_precios_2018.pdf (accessed on 20 August 2020).

| Scenarios | Sludge Energy Production | Microturbine Energy Production | Photovoltaic Energy Production | Wind Energy Production | Hydroelectric Energy Production |

|---|---|---|---|---|---|

| 1 |  |  | N.A. |  |  |

| 2 |  |  |  |  |  |

| 3 |  |  |  |  |  |

| 4 |  |  | N.A. |  |  |

| Scenarios | Sludge Energy Production | Microturbine Energy Production | Photovoltaic Energy Production | Wind Energy Production | Hydroelectric Energy Production |

|---|---|---|---|---|---|

| 1 | 31.5 kW | 4 kW | N.A. | 500 kW | 0.97–1.46 kW |

| 2 | 31.5 kW | 4 kW | 100 kW | 500 kW | 0.97–1.46 kW |

| 3 | 31.5 kW | 4 kW | 2 × 100 kW | 500 kW | 0.97–1.46 kW |

| 4 | 31.5 kW | 4 kW | N.A. | 2 × 500 kW | 0.97–1.46 kW |

| Equipment | Total Capital Invested (€) | Operation and Maintenance (€/year) | Replacement (€) | Useful Life (years) |

|---|---|---|---|---|

| Anaerobic digesters | 42,993 | 748 | 26,169 | 30 |

| Reformed steam | 85,160 | 3000 | 51,837 | 10 |

| Fuel cells for sludge | 1459 | 507 | 1142 | 2.5 |

| Fuel cell inverter | 2700 | N/A | 1878 | 25 |

| Hydro-eKIDS microturbines | 5876 | 350 | 4701 | 17 |

| Photovoltaic modules | 172,500 | N/A | 120,000 | 25 |

| Photovoltaic inverters | 7723 | N/A | 5372 | 25 |

| Wind turbine | 509,795 | 7757 | 354,640 | 25 |

| Pico-turbines | 5745 | 700 | 4496 | 30 |

| Specific Cost of the Renewable System (€/kWh) | |||

|---|---|---|---|

| Scenario 1 | Scenario 2 | Scenario 3 | Scenario 4 |

| 0.087 | 0.10 | 0.11 | 0.088 |

| Equipment | Total Capital Invested (€) | Operation and Maintenance (€/year) | Replacement (€) | Useful Life (years) |

|---|---|---|---|---|

| Application 1. Hydrogen storage | ||||

| Electrolyzers | 2,254,000 | 58,800 | 1,470,000 | 7 |

| Hydrogen bottles | 549,516 | N/A | 477,840 | 3 |

| Fuel cells | 1,853,800 | 644,800 | 1,449,188 | 3 |

| Fuel cell inverter | 16,555 | N/A | 11,516 | 25 |

| Application 2. Network reinjection | ||||

| Converter | 189,750 | 2887 | 148,500 | 25 |

| Transformer | 12,420 | 189 | 9720 | 30 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Del Río-Gamero, B.; Ramos-Martín, A.; Melián-Martel, N.; Pérez-Báez, S. Water-Energy Nexus: A Pathway of Reaching the Zero Net Carbon in Wastewater Treatment Plants. Sustainability 2020, 12, 9377. https://doi.org/10.3390/su12229377

Del Río-Gamero B, Ramos-Martín A, Melián-Martel N, Pérez-Báez S. Water-Energy Nexus: A Pathway of Reaching the Zero Net Carbon in Wastewater Treatment Plants. Sustainability. 2020; 12(22):9377. https://doi.org/10.3390/su12229377

Chicago/Turabian StyleDel Río-Gamero, Beatriz, Alejandro Ramos-Martín, Noemi Melián-Martel, and Sebastián Pérez-Báez. 2020. "Water-Energy Nexus: A Pathway of Reaching the Zero Net Carbon in Wastewater Treatment Plants" Sustainability 12, no. 22: 9377. https://doi.org/10.3390/su12229377