Biased Technical Change, Factor Substitution, and Carbon Emissions Efficiency in China

Abstract

:1. Introduction

2. Literature Review

3. Methodology

3.1. Evaluation of Total Factor Carbon Emissions Efficiency Based on Two-Stage Super-Efficiency DEA Model

3.2. Estimation of Biased Technical Change Based on Time-Varying Elasticity Production Function

3.3. Panel Analysis on the Effect of Biased Technical Change on Carbon Emissions Efficiency

4. Data

4.1. Variables

- (1)

- Labor (L). Here, labor is one of the inputs in the production, so unemployment is not included in labor. Labor is measured as each province’s employment. Its unit is millions of workers. The data are from China Labor Statistical Yearbook.

- (2)

- Capital stock (K). Capital stock (constant 2001 price) in China’s 30 provinces is estimated by applying the perpetual inventory method [45]. 2001 is set as the base year. Gross fixed capital formation is converted into constant 2001 price by each province’s fixed assets investment price index. Then, capital stocks from 2001 to 2014 are calculated by the specific depreciation rates and base-year stocks in different provinces. The depreciation rates are obtained by using the method of [46]. The calculation of capital stock is expressed aswhere and are capital stock and gross fixed capital formation in constant 2001 price. is the depreciation rate.

- (3)

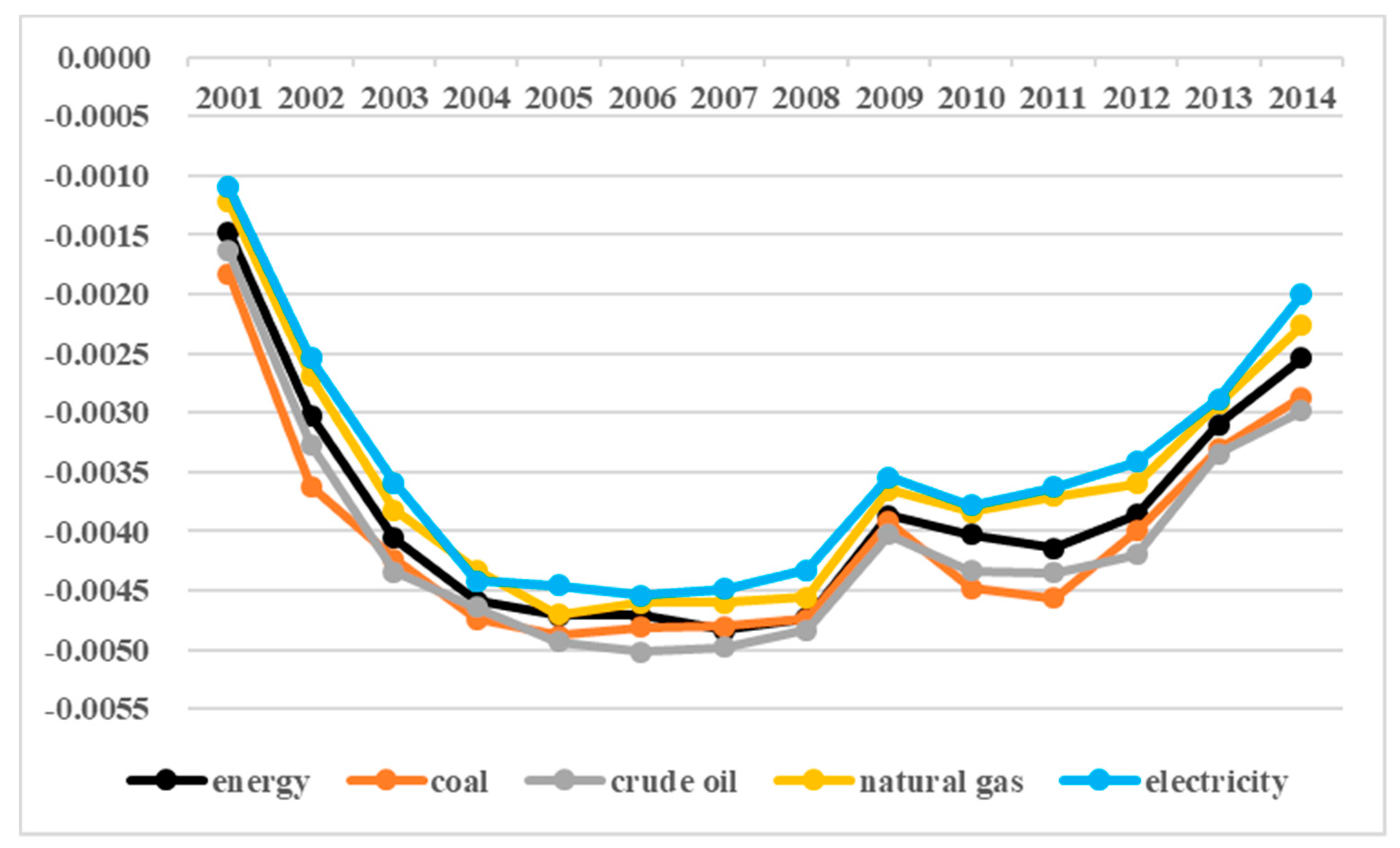

- Energy consumption (E). Energy consumption is a comprehensive indicator to show the total consumption of various kinds of energy. It includes coal, crude oil, natural gas, and electricity. Its unit is million tons of coal equivalent. The data are collected from the China Energy Statistical Yearbook.

- (4)

- Real gross domestic product (GDP). It is measured by RMB billion in constant 2001 price. In this paper, billion refers to one thousand million.

- (5)

- Carbon dioxide emissions (CE). For lack of official statistical data of China’s carbon dioxide emissions, it is calculated by applying the method introduced by Intergovernmental Panel on Climate Change (IPCC) in 2006 [47] aswhere FCEi is carbon dioxide emissions from fossil fuel i. CC is carbon dioxide emissions from cement production. ECi is consumption of fossil fuel i, and Ei is carbon dioxide emissions coefficient of fossil fuel i. Q is the cement production, and F is carbon dioxide emissions coefficient of cement production. The data are collected from the China Energy Statistical Yearbook. Carbon dioxide emissions coefficients are shown in Table 1.

- (1)

- R&D stock (rd). R&D stock is measured by the perpetual inventory method aswhere rdit denotes R&D stock, and Zit denotes R&D expenditure. is the depreciation rate. The calculation is as follows. Firstly, according to [48], Chinese R&D expenditure price index = 0.55 consumer price index + 0.45fixed assets investment price index. Then, R&D expenditure price index is used to deflate R&D expenditure into constant 2001 price. Finally, R&D stock is estimated by specific depreciation rate and base-year R&D stock. According to the existing studies [49], the depreciation rate is set to 15%. The base-year R&D stock is calculated aswhere g is the average growth rate of R&D expenditure before the observation period. Here, g is set to 5%, according to [50]. The data on R&D expenditure are from China Science and Technology Statistical Yearbook.

- (2)

- FDI stock (fdi). The calculation method of FDI stock is the same to R&D stock. FDI is converted into constant 2001 price by fixed assets investment price index. The average growth rate of FDI is set as 15%, and the depreciation rate of FDI stock is set to 5% here.

- (3)

- Industrial structure transformation (ois). The structural transformation in manufacturing sector is calculated by [51] aswhere represents the share of the jth industry’s output for province i in year t (j = 1,2,3). 2001 is the initial year, i.e., t = 0.

- (4)

- Value added of industry (ivalue). The statistical scope of industrial value-added includes all the industrial enterprises above designated size. It is calculated by the National Bureau of Statistics in the production approach.

4.2. Descriptive Statistics

5. Results

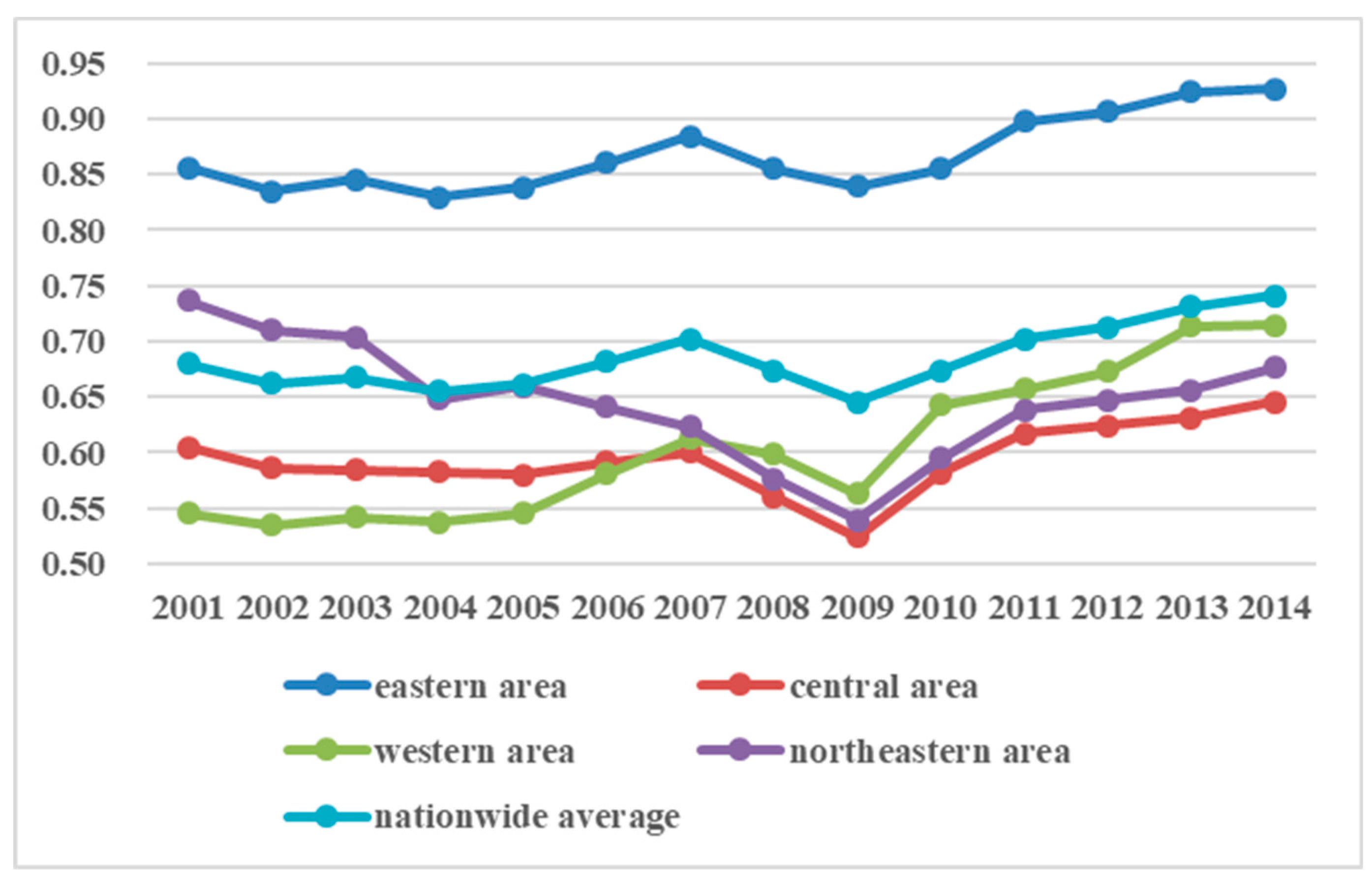

5.1. China’s Regional Carbon Emissions Efficiency

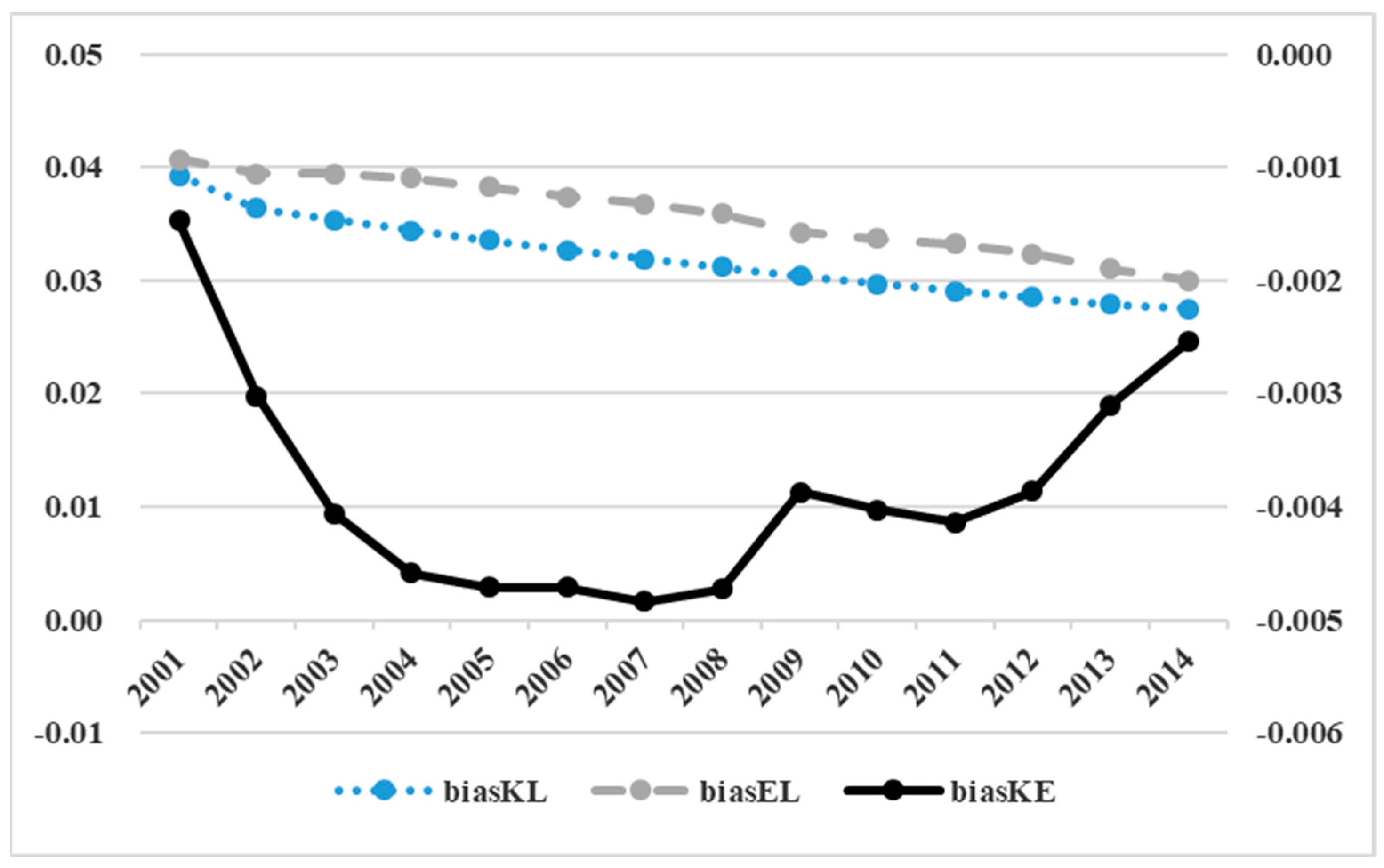

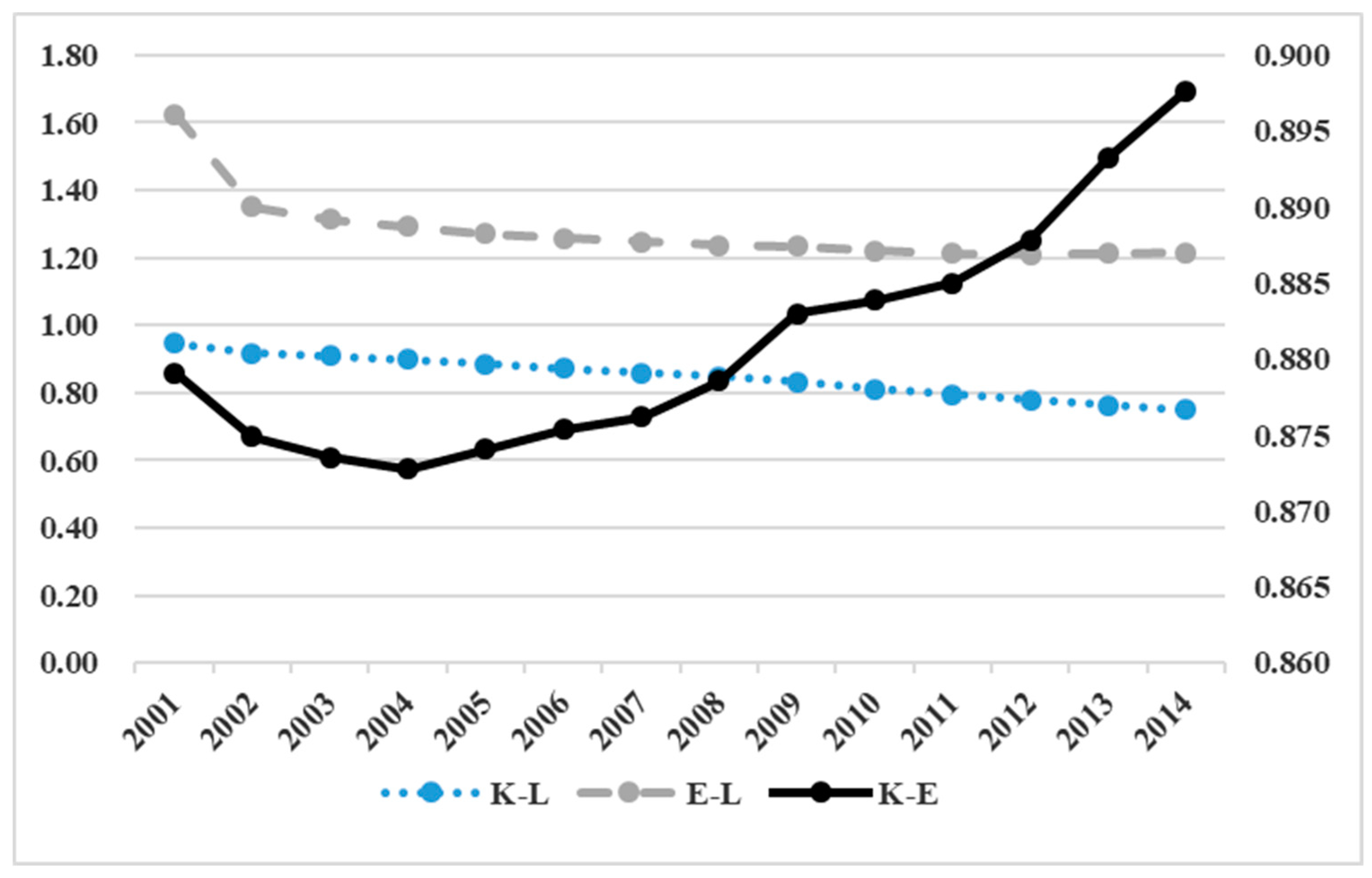

5.2. China’s Biased Technical Change

5.3. The Effects of Biased Technical Change on Carbon Emissions Efficiency

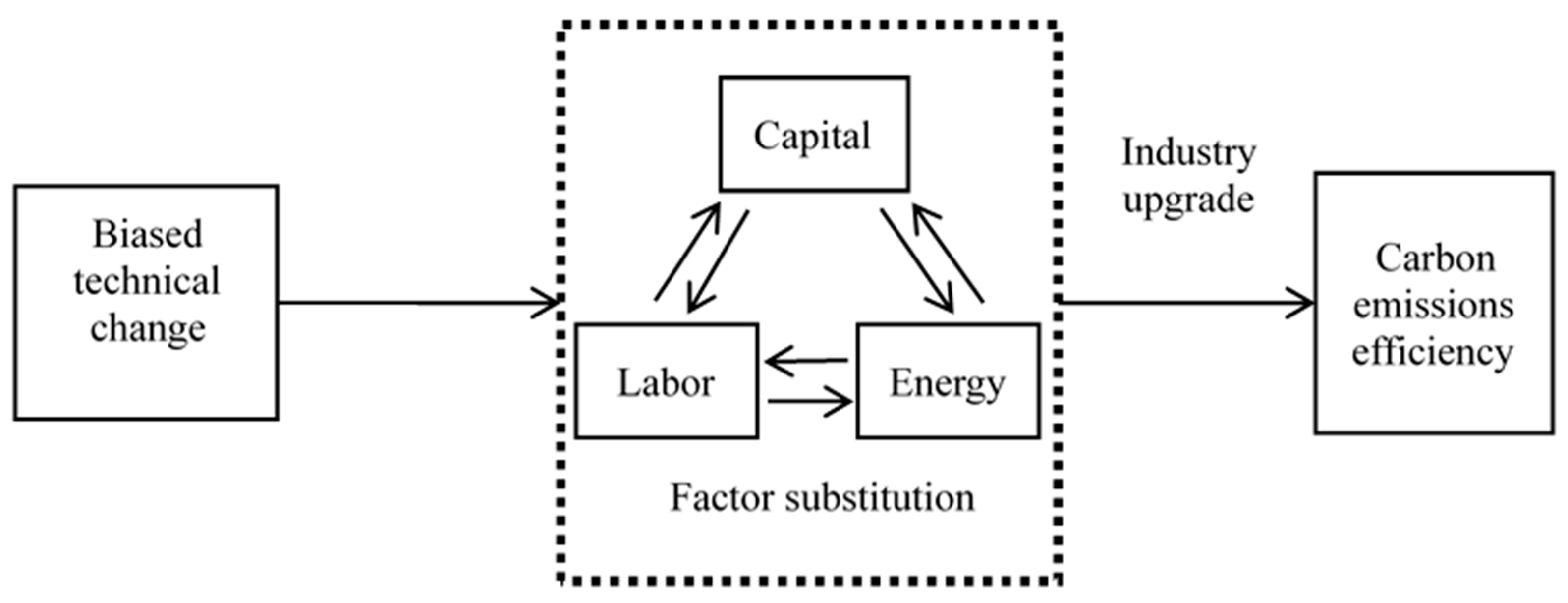

5.4. Mechanism

5.5. Robustness of Biased Technical Change’s Measurement

6. Conclusions and Policy Implications

Acknowledgments

Conflicts of Interest

References

- Lin, B.; Li, J. The rebound effect for heavy industry: Empirical evidence from China. Energy Policy 2014, 74, 589–599. [Google Scholar] [CrossRef]

- Tol, R.S. Estimates of the damage costs of climate change. Part 1: Benchmark estimates. Environ. Resour. Econ. 2002, 21, 47–73. [Google Scholar] [CrossRef]

- Wang, B.; Qi, S. Biased technology progress, factor substitution and China's industrial energy intensity. Econ. Res. J. 2014, 2, 115–127. (In Chinese) [Google Scholar]

- Acemoglu, D. Directed Technical Change. Rev. Econ. Stud. 2002, 69, 781–809. [Google Scholar] [CrossRef] [Green Version]

- Popp, D. Induced Innovation and Energy Prices. Am. Econ. Rev. 2001, 92, 160–180. [Google Scholar] [CrossRef]

- Hassler, J.; Krusell, P.; Olovsson, C. Energy-Saving Technical Change; Social Science Electronic Publishing: Rochester, NY, USA, 2012. [Google Scholar]

- Wing, I.S. Representing induced technological change in models for climate policy analysis. Energy Econ. 2006, 28, 539–562. [Google Scholar] [CrossRef]

- Donadelli, M.; Grüning, P.; Jüppner, M.; Kizys, R. Global temperature, R&D, Expenditure and Growth. SAFE Working Paper n. 188. 2017. Available online: https://www.econstor.eu/bitstream/10419/171922/1/1006417478.pdf (accessed on 26 January 2019).

- Park, J. Will We Adapt? Temperature Shocks, Labor Productivity, and Adaptation to Climate Change in the United States (1986–2012); Harvard Project on Climate Agreements Discussion Paper Series 81; Harvard University: Cambridge, MA, USA, 2016. [Google Scholar]

- Donadelli, M.; Jüppner, M.; Riedel, M.; Schlag, C. Temperature shocks and welfare costs. J. Econ. Dyn. Control 2017, 82, 331–355. [Google Scholar] [CrossRef] [Green Version]

- Deschênes, O.; Greenstone, M. Climate change, mortality, and adaptation: Evidence from annual fluctuations in weather in the US. Am. Econ. J. Appl. Econ. 2011, 3, 152–185. [Google Scholar] [CrossRef]

- Burke, M.; Emerick, K. Adaptation to climate change: Evidence from US agriculture. Am. Econ. J. Econ. Policy 2016, 8, 106–140. [Google Scholar] [CrossRef]

- Ang, B.W. Is the energy intensity a less useful indicator than the carbon factor in the study of climate change? Energy Policy 1999, 27, 943–946. [Google Scholar] [CrossRef]

- Ramanathan, R. Combining indicators of energy consumption and CO2 emissions: A cross-country comparison. Int. J. Glob. Energy Issues 2002, 17, 214–227. [Google Scholar] [CrossRef]

- Zaim, O.; Taskin, F. Environmental efficiency in carbon dioxide emissions in the OECD: A non-parametric approach. J. Environ. Manag. 2000, 58, 95–107. [Google Scholar] [CrossRef] [Green Version]

- Chung, Y.H.; Färe, R.; Grosskopf, S. Productivity and Undesirable Outputs: A Directional Distance Function Approach. J. Environ. Manag. 1997, 51, 229–240. [Google Scholar] [CrossRef]

- Tone, K. Dealing with Undesirable Outputs in DEA: A Slacks-based Measure (SBM) Approach. 2003. Available online: https://ci.nii.ac.jp/naid/120005571101/ (accessed on 26 January 2019).

- Zhou, P.; Ang, B.W.; Poh, K.L. Slacks-based efficiency measures for modeling environmental performance. Ecol. Econ. 2006, 60, 111–118. [Google Scholar] [CrossRef]

- Zhang, B.; Bi, J.; Fan, Z.; Yuan, Z.; Ge, J. Eco-efficiency analysis of industrial system in China: A data envelopment analysis approach. Ecol. Econ. 2008, 68, 306–316. [Google Scholar] [CrossRef]

- Wang, K.; Wei, Y.M.; Zhang, X. A comparative analysis of China’s regional energy and emission performance: Which is the better way to deal with undesirable outputs? Energy Policy 2012, 46, 574–584. [Google Scholar] [CrossRef]

- Zhou, P.; Ang, B.W.; Wang, H. Energy and CO2 emission performance in electricity generation: A non-radial directional distance function approach. Eur. J. Oper. Res. 2012, 221, 625–635. [Google Scholar] [CrossRef]

- Lin, B.; Du, K. Energy and CO2 emissions performance in China’s regional economies: Do market-oriented reforms matter? Energy Policy 2015, 78, 113–124. [Google Scholar] [CrossRef]

- Yin, K.; Wang, R.; An, Q.; Yao, L.; Liang, J. Using eco-efficiency as an indicator for sustainable urban development: A case study of Chinese provincial capital cities. Ecol. Indic. 2014, 36, 665–671. [Google Scholar] [CrossRef] [Green Version]

- Li, K.; Lin, B. Economic growth model, structural transformation, and green productivity in China. Appl. Energy 2017, 187, 489–500. [Google Scholar] [CrossRef]

- Kemfert, C.; Welsch, H. Energy-Capital-Labor Substitution and the Economic Effects of CO2 Abatement: Evidence for Germany. J. Policy Model. 2000, 22, 641–660. [Google Scholar] [CrossRef]

- Popp, D. The effect of new technology on energy consumption. Resour. Energy Econ. 2001, 23, 215–239. [Google Scholar] [CrossRef] [Green Version]

- Welsch, H.; Ochsen, C. The determinants of aggregate energy use in West Germany: Factor substitution, technological change, and trade. Energy Econ. 2005, 27, 93–111. [Google Scholar] [CrossRef]

- Fisher-Vanden, K.; Jefferson, G.H. Technology diversity and development: Evidence from China's industrial enterprises. J. Comp. Econ. 2008, 36, 658–672. [Google Scholar] [CrossRef] [Green Version]

- Chen, X.; Xu, S.; Lian, Y. Factor substitution elasticity and biased technology’s effects on industrial energy intensity. J. Quant. Tech. Econ. 2015, 3, 58–76. (In Chinese) [Google Scholar]

- Färe, R.; Grosskopf, S.; Pasurka, C.A., Jr. Environmental production functions and environmental directional distance functions. SSRN Electron. J. 2007, 32, 1055–1066. [Google Scholar] [CrossRef]

- Lozano, S.; Gutiérrez, E. Non-parametric frontier approach to modelling the relationships among population, GDP, energy consumption and CO2 emissions. Ecol. Econ. 2008, 66, 687–699. [Google Scholar] [CrossRef]

- Wang, Q.; Zhou, P.; Zhou, D. Efficiency measurement with carbon dioxide emissions: The case of China. Appl. Energy 2012, 90, 161–166. [Google Scholar] [CrossRef]

- Werf, E.V.D. Production functions for climate policy modeling: An empirical analysis. Energy Econ. 2008, 30, 2964–2979. [Google Scholar] [CrossRef] [Green Version]

- Diamond, P.A. Disembodied technical change in a two-sector model. Rev. Econ. Stud. 1965, 32, 161–168. [Google Scholar] [CrossRef]

- Hao, F. Formula correction and estimation methods comparison on elasticity of substitution within translog function. J. Quant. Tech. Econ. 2015, 4, 88–105. [Google Scholar]

- Zhou, X.; Zhang, J.; Li, J. Industrial structural transformation and carbon dioxide emissions in China. Energy Policy 2013, 57, 43–51. [Google Scholar] [CrossRef]

- Lin, B.; Ouyang, X. A revisit of fossil-fuel subsidies in china: Challenges and opportunities for energy price reform. Energy Convers. Manag. 2014, 82, 124–134. [Google Scholar] [CrossRef]

- Gireesh, N.; Leif, G.; Krushna, M. Factors influencing energy efficiency investments in existing Swedish residential buildings. Energy Policy 2010, 38, 2956–2963. [Google Scholar]

- Poortinga, W.; Steg, L.; Vlek, C.; Wiersma, G. Household preferences for energy-saving measures: A conjoint analysis. J. Econ. Psychol. 2003, 24, 49–64. [Google Scholar] [CrossRef]

- Lee, K.H.; Min, B. Green R&D for eco-innovation and its impact on carbon emissions and firm performance. J. Clean. Prod. 2015, 108, 534–542. [Google Scholar] [Green Version]

- Lee, J.W. The contribution of foreign direct investment to clean energy use, carbon emissions and economic growth. Energy Policy 2013, 55, 483–489. [Google Scholar] [CrossRef]

- Diakoulaki, D.; Mandaraka, M. Decomposition analysis for assessing the progress in decoupling industrial growth from CO2 emissions in the EU manufacturing sector. Energy Econ. 2007, 29, 636–664. [Google Scholar] [CrossRef]

- Song, M.; Wang, S.; Cen, L. Comprehensive efficiency evaluation of coal enterprises from production and pollution treatment process. J. Clean. Prod. 2015, 104, 374–379. [Google Scholar] [CrossRef]

- Liu, H.; Lin, B. Ecological indicators for green building construction. Ecol. Indic. 2016, 67, 68–77. [Google Scholar] [CrossRef]

- Shan, H. Re-estimating the capital stock of China: 1952–2006. J. Quant. Tech. Econ. 2008, 10, 17–31. (In Chinese) [Google Scholar]

- Wu, Y. Productivity, Efficiency and Economic Growth in China; Palgrave Macmillan: Basingstoke, UK, 2008. [Google Scholar]

- Intergovernmental Panel on Climate Change (IPCC). IPCC Guidelines for National Greenhouse Gas Inventories; Intergovernmental Panel on Climate Change: London, UK, 2006. [Google Scholar]

- Bai, J.; Jiang, K.; Li, J. On the efficiency and total factor productivity growth of China’s R&D innovation. J. Quant. Tech. Econ. 2009, 3, 139–151. (In Chinese) [Google Scholar]

- Wu, Y. Indigenous R&D, technology imports and productivity: Evidence from industries across regions of China. Econ. Res. J. 2008, 8, 51–64. (In Chinese) [Google Scholar]

- Hall, B.H.; Mairesse, J. Exploring the relationship between R&D and productivity in French manufacturing firms. J. Econom. 1995, 65, 263–293. [Google Scholar]

- Moore, J.H. A measure of structural change in output. Rev. Income Wealth 1978, 24, 105–118. [Google Scholar] [CrossRef]

| Sources | Coal | Coke | Gasoline | Kerosene | Crude oil | Fuel oil | Gas | Cement |

| coefficients | 1.647 | 2.848 | 3.045 | 3.174 | 3.150 | 3.064 | 21.670 | 0.527 |

| Variables | Units | Mean | Std. Dev. | Min | Max |

|---|---|---|---|---|---|

| Labor (L) | Million workers | 24.42 | 16.38 | 2.78 | 66.15 |

| Capital stock (K) | RMB billion (Constant 2001 price) | 790.27 | 754.07 | 19.58 | 4431.17 |

| Energy consumption (E) | Million tons of coal equivalent | 105.94 | 74.66 | 5.20 | 388.99 |

| Real gross domestic product (GDP) | RMB billion (Constant 2001 price) | 933.96 | 895.13 | 30.01 | 5089.54 |

| CO2 emissions (CE) | Million tons | 299.82 | 220.45 | 18.88 | 1099.69 |

| Industrial structural transformation (ois) | \ | 0.1198 | 0.0876 | 0 | 0.3566 |

| Energy price (price) | base = 100 | 174.41 | 52.90 | 97.1 | 301.64 |

| Popularization of higher education (edu) | % | 0.33 | 0.19 | 0.04 | 0.87 |

| R&D stock (rd) | RMB billion (Constant 2001 price) | 53.78 | 76.38 | 0.44 | 434.82 |

| FDI stock (fdi) | RMB billion (Constant 2001 price) | 117.53 | 159.53 | 0.73 | 780.25 |

| Value added of industry (ivalue) | RMB billion (Constant 2001 price) | 234.7 | 296.6 | 6.53 | 1671.9 |

| TFCE | (1) FGLS | (2) FGLS | (3) FGLS | (4) FGLS | (5) Diff-GMM |

|---|---|---|---|---|---|

| biasKE | 6.3817 *** (1.6728) | 4.5690 *** (0.4982) | 3.9246 *** (0.9901) | 4.1922 *** (0.9380) | 2.8219 *** (0.7258) |

| ois | 0.4788 *** (0.1519) | 0.3521 *** (0.1210) | 0.3274 *** (0.1141) | 0.3057 *** (0.0626) | |

| price | −0.0040 *** (0.0005) | −0.0007 *** (0.0002) | −0.0002 (0.0003) | −0.0003 (0.0008) | |

| edu | 0.2629 *** (0.0714) | 0.2975 *** (0.0656) | 0.2391 ** (0.0525) | 0.2869 *** (0.0502) | |

| rd | 0.0012 *** (0.0004) | 0.0009 *** (0.0003) | 0.0008 *** (0.0002) | 0.0009 *** (0.0003) | |

| fdi | 0.0006 *** (0.0002) | 0.0004 ** (0.0002) | 0.0004 ** (0.0002) | 0.0003 ** (0.0001) | |

| ivalue | −0.0005 ** (0.0002) | −0.0004 ** (0.0002) | −0.0004 ** (0.0002) | −0.0003 * (0.0002) | |

| province fixed effect | No | No | Yes | Yes | |

| year fixed effect | No | No | No | Yes | |

| Lag.TFCE | 0.5833 ** (0.2663) | ||||

| Constant | 0.4625 *** (0.0280) | 0.2553 *** (0.0511) | 0.3020 *** (0.0592) | 0.3029 *** (0.0616) | |

| R2 | 0.0494 | 0.5312 | 0.8911 | 0.8961 | |

| AR (1) test | 0.1626 [0.0021] | ||||

| AR (2) test | 0.0480 [0.3371] | ||||

| Sargan test | 25.1189 [0.2420] | ||||

| Sample | 420 | 420 | 420 | 420 | 360 |

| TFCE | (1) FGLS | (2) FGLS | (3) FGLS | (4) FGLS | (5) Diff-GMM |

|---|---|---|---|---|---|

| biasKE | 5.0261 *** (1.8573) | 4.1249 *** (0.9555) | 3.6657 *** (0.9928) | 3.8263 *** (0.9528) | 2.7293 *** (0.7046) |

| ois | 0.3163 *** (0.1162) | 0.4032 ** (0.2006) | 0.3556 ** (0.1489) | 0.3760 ** (0.1634) | 0.3090 ** (0.1232) |

| biasKE × ois | 1.8792 *** (0.2411) | 1.2243 *** (0.3801) | 1.5282 *** (0.5305) | 1.5136 *** (0.5121) | 1.4729 *** (0.4646) |

| other control variables | No | Yes | Yes | Yes | Yes |

| province fixed effect | No | No | Yes | Yes | |

| year fixed effect | No | No | No | Yes | |

| Lag.TFCE | 0.4906 ** (0.2106) | ||||

| Sample | 420 | 420 | 420 | 420 | 360 |

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhong, J. Biased Technical Change, Factor Substitution, and Carbon Emissions Efficiency in China. Sustainability 2019, 11, 955. https://doi.org/10.3390/su11040955

Zhong J. Biased Technical Change, Factor Substitution, and Carbon Emissions Efficiency in China. Sustainability. 2019; 11(4):955. https://doi.org/10.3390/su11040955

Chicago/Turabian StyleZhong, Jingdong. 2019. "Biased Technical Change, Factor Substitution, and Carbon Emissions Efficiency in China" Sustainability 11, no. 4: 955. https://doi.org/10.3390/su11040955