Indoor Air Quality Enhancement Performance of Liquid Desiccant and Evaporative Cooling-Assisted Air Conditioning Systems

Abstract

:1. Introduction

2. System Overview

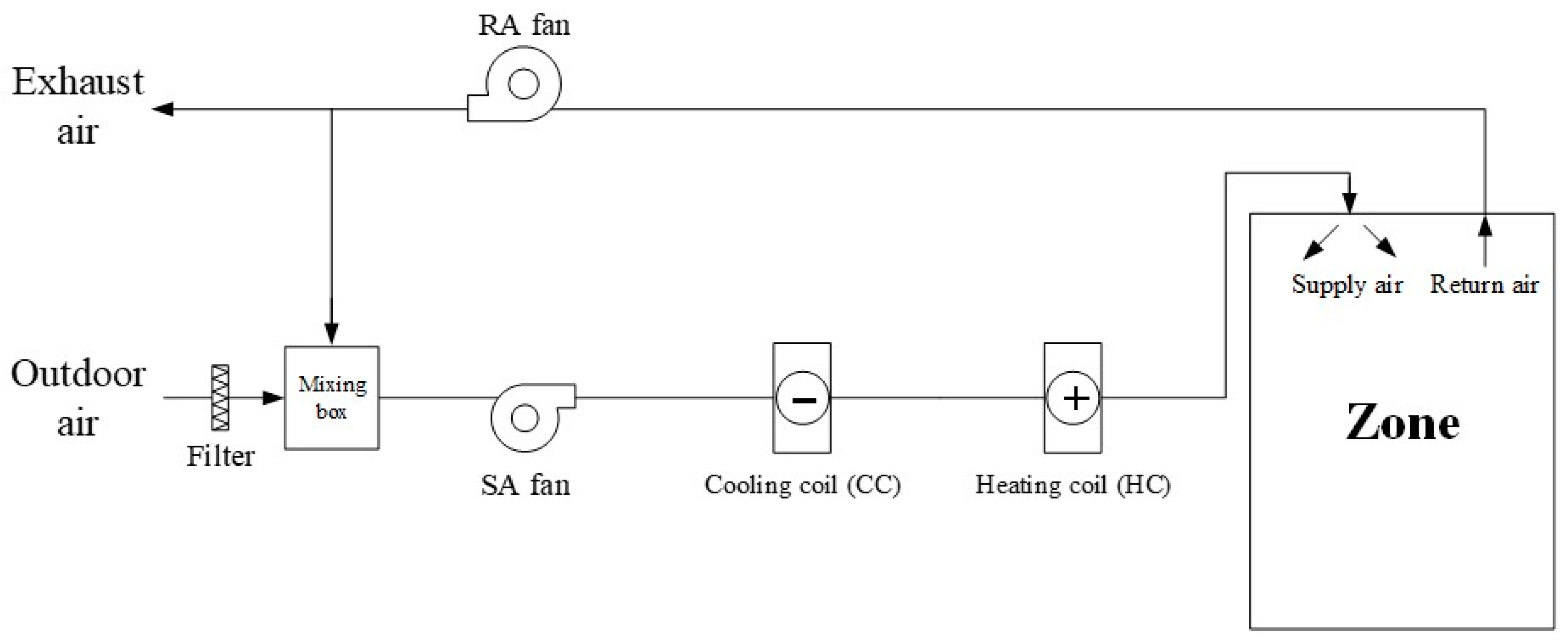

2.1. Variable Air Volume System

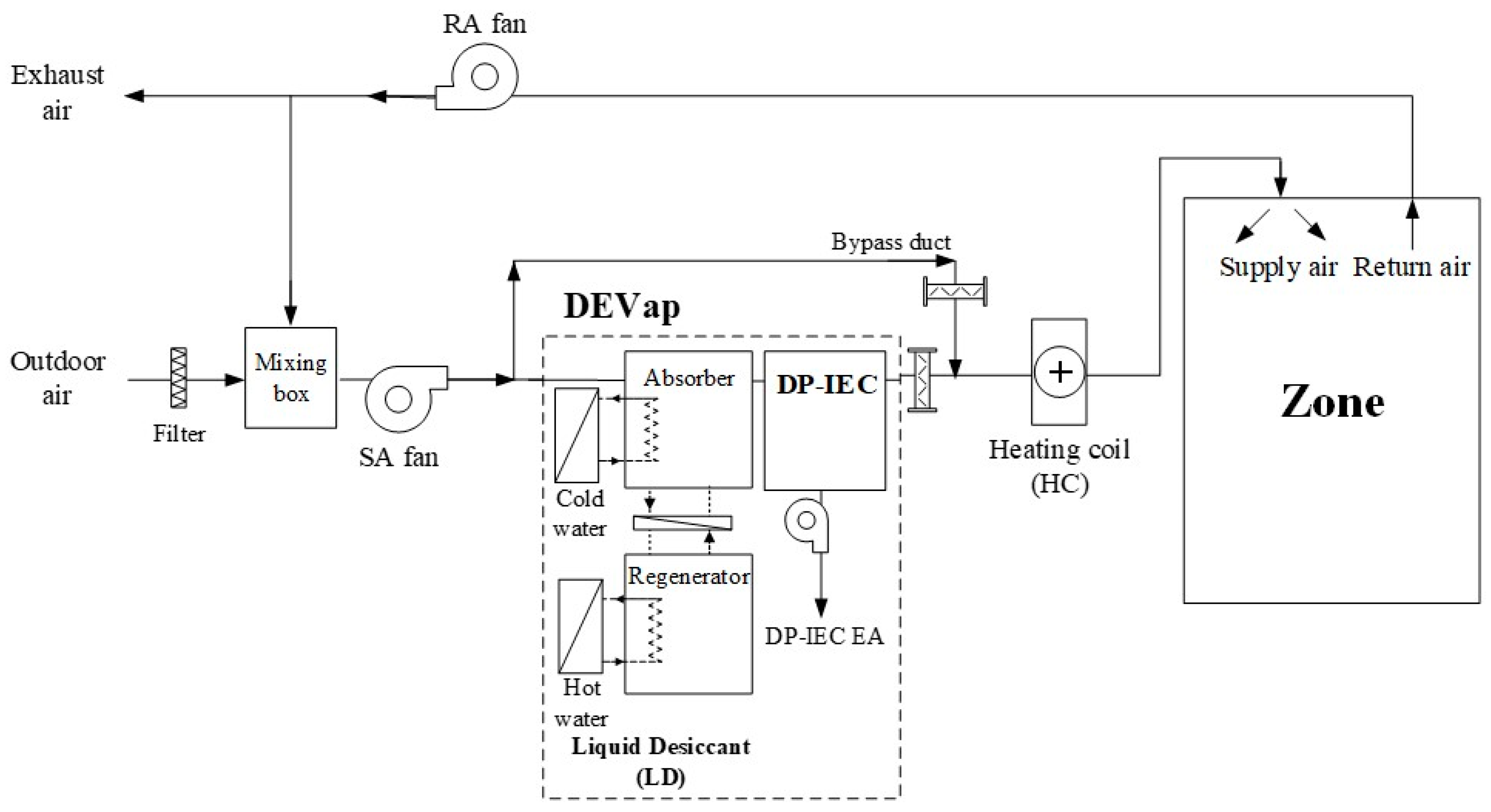

2.2. Desiccant-enhanced Evaporative Cooling System

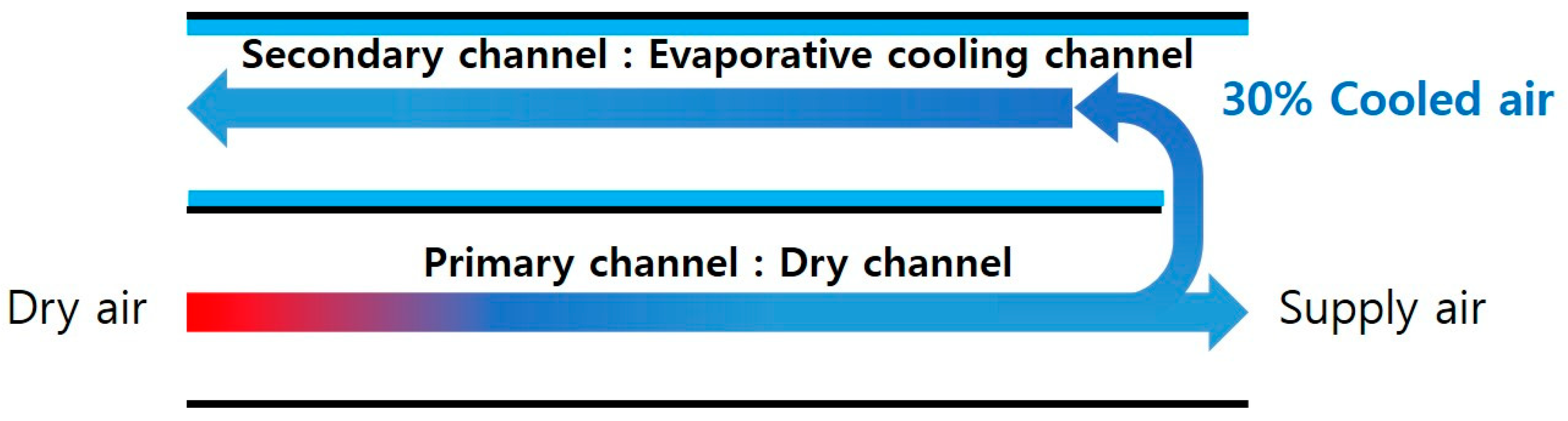

2.2.1. DEVap System Overview

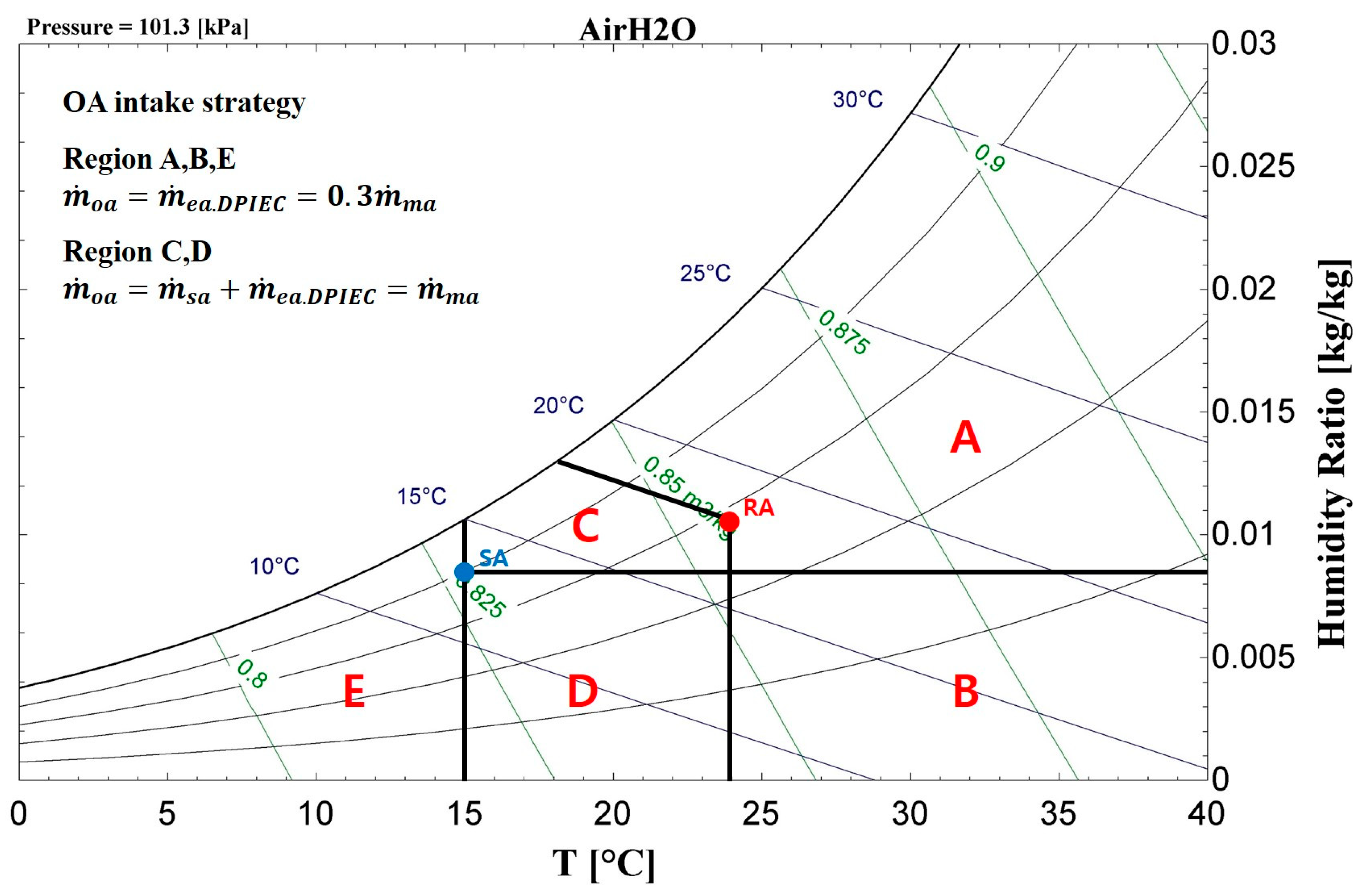

2.2.2. Annual Operation

2.3. Liquid Desiccant and Evaporative Cooling-Assisted 100% Outdoor Air System

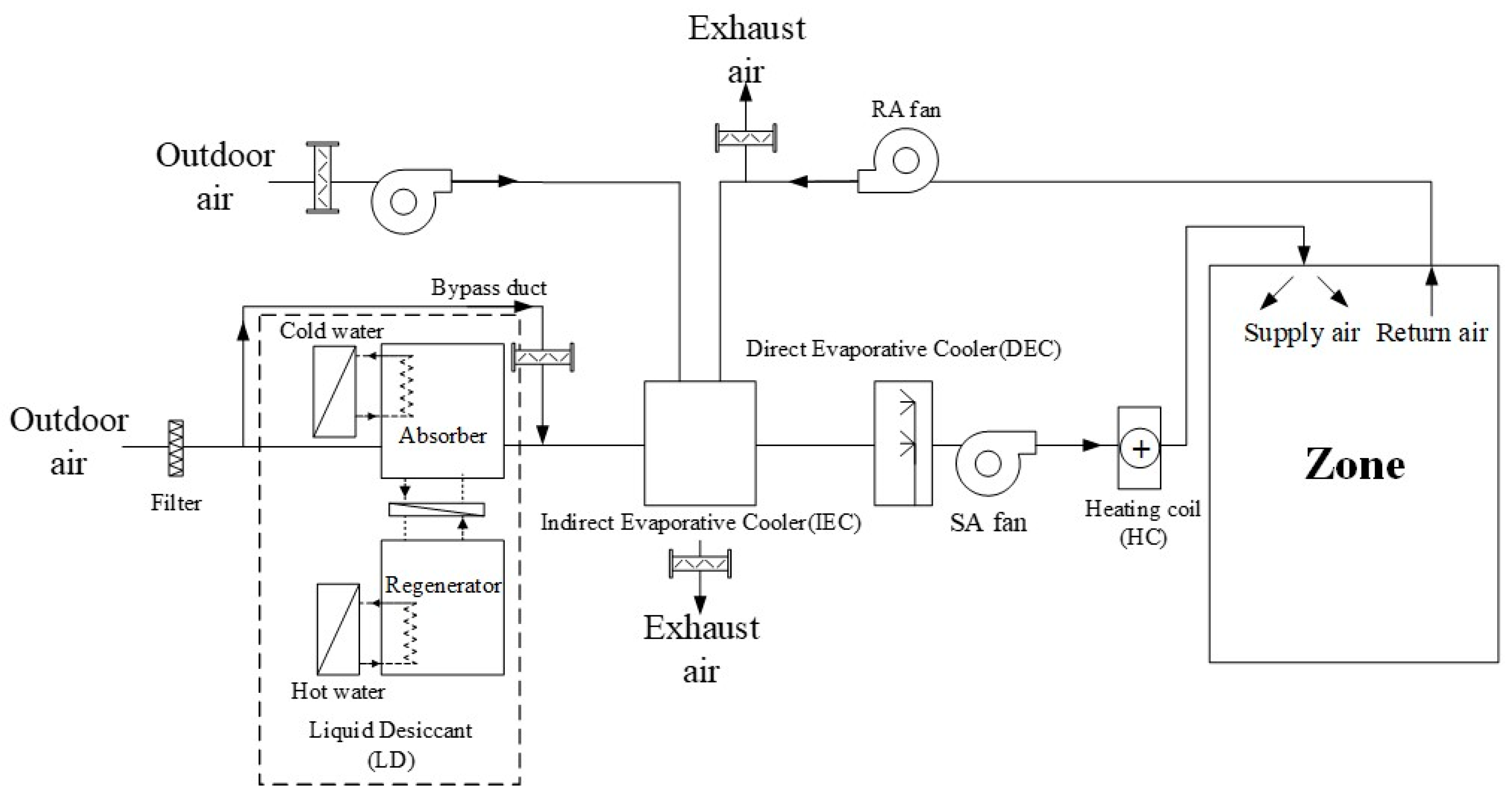

2.3.1. LD-IDECOAS Overview

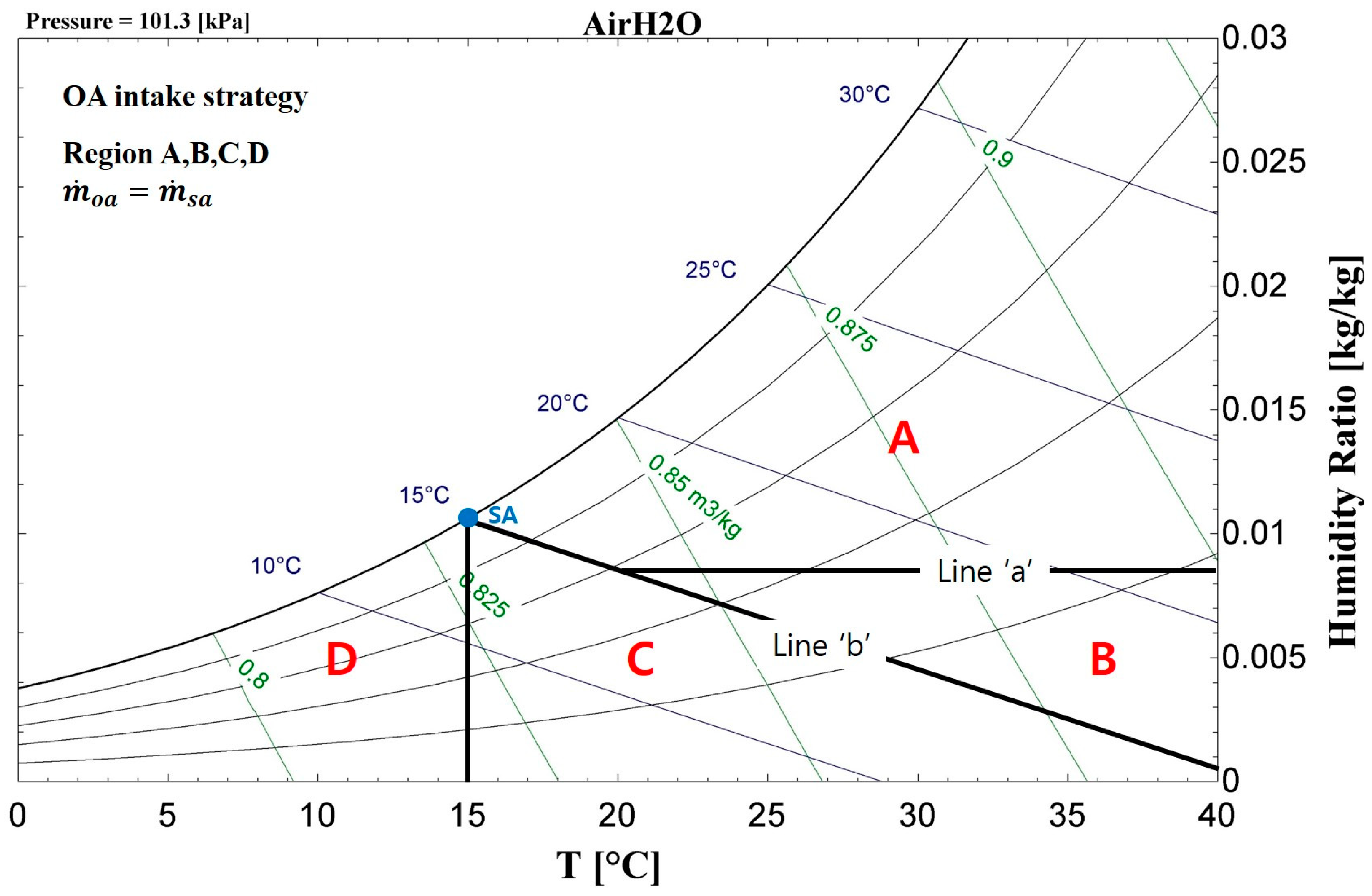

2.3.2. Annual Operation

3. Indoor Air Quality Simulation

3.1. Simulation Overview

3.2. Model Space

3.3. Simulation Method

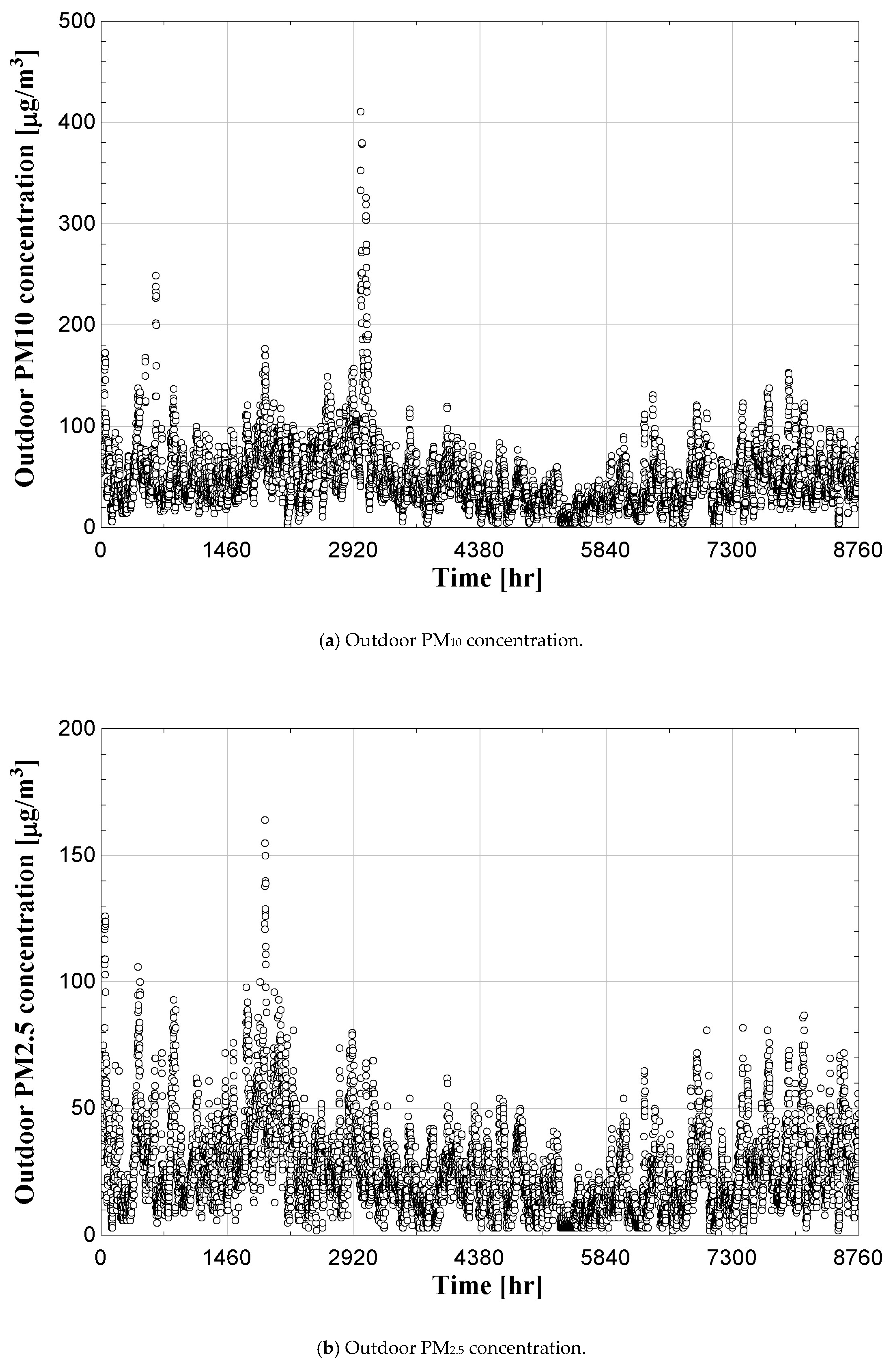

3.4. Particle Removal Rates

4. Simulation Results

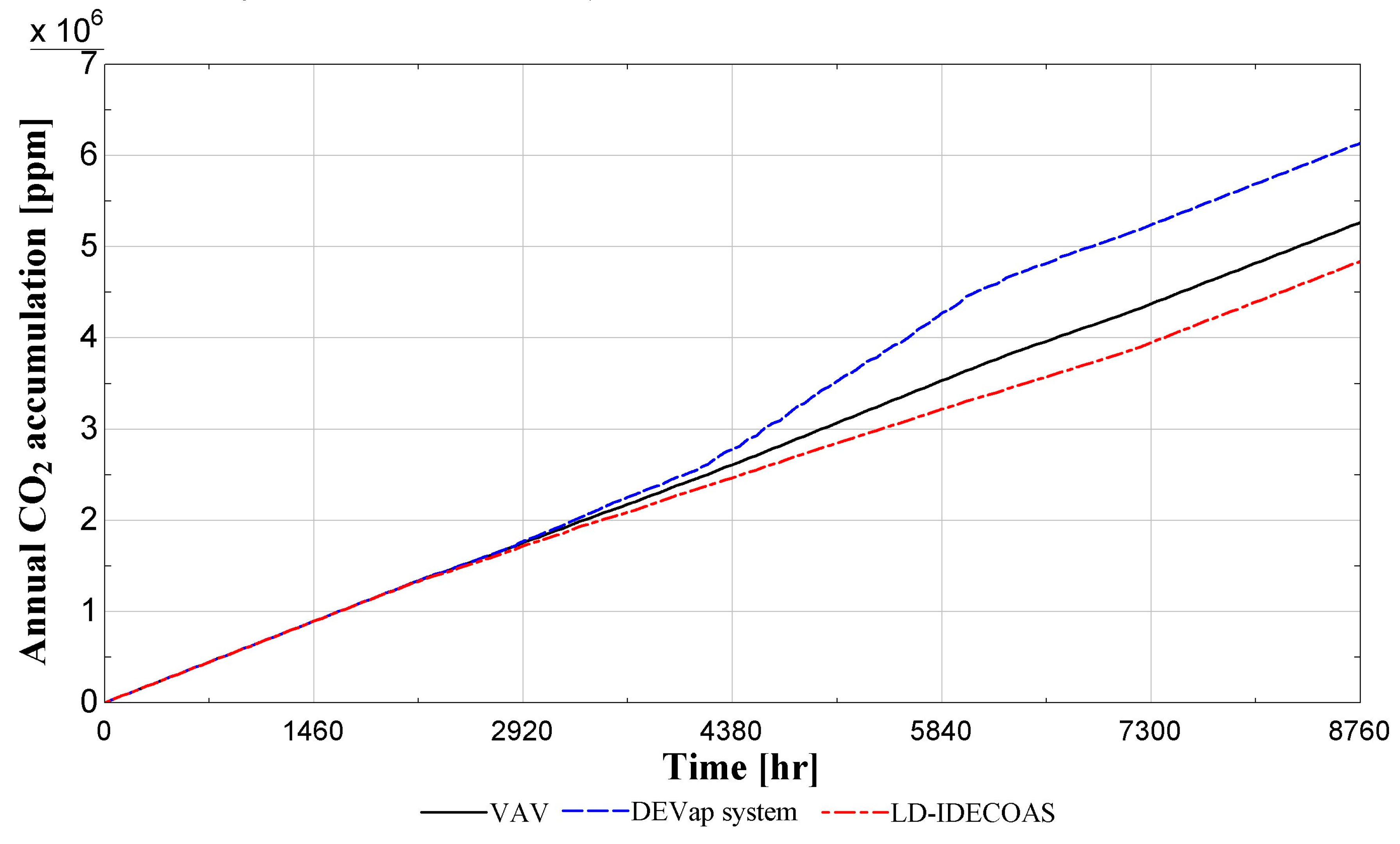

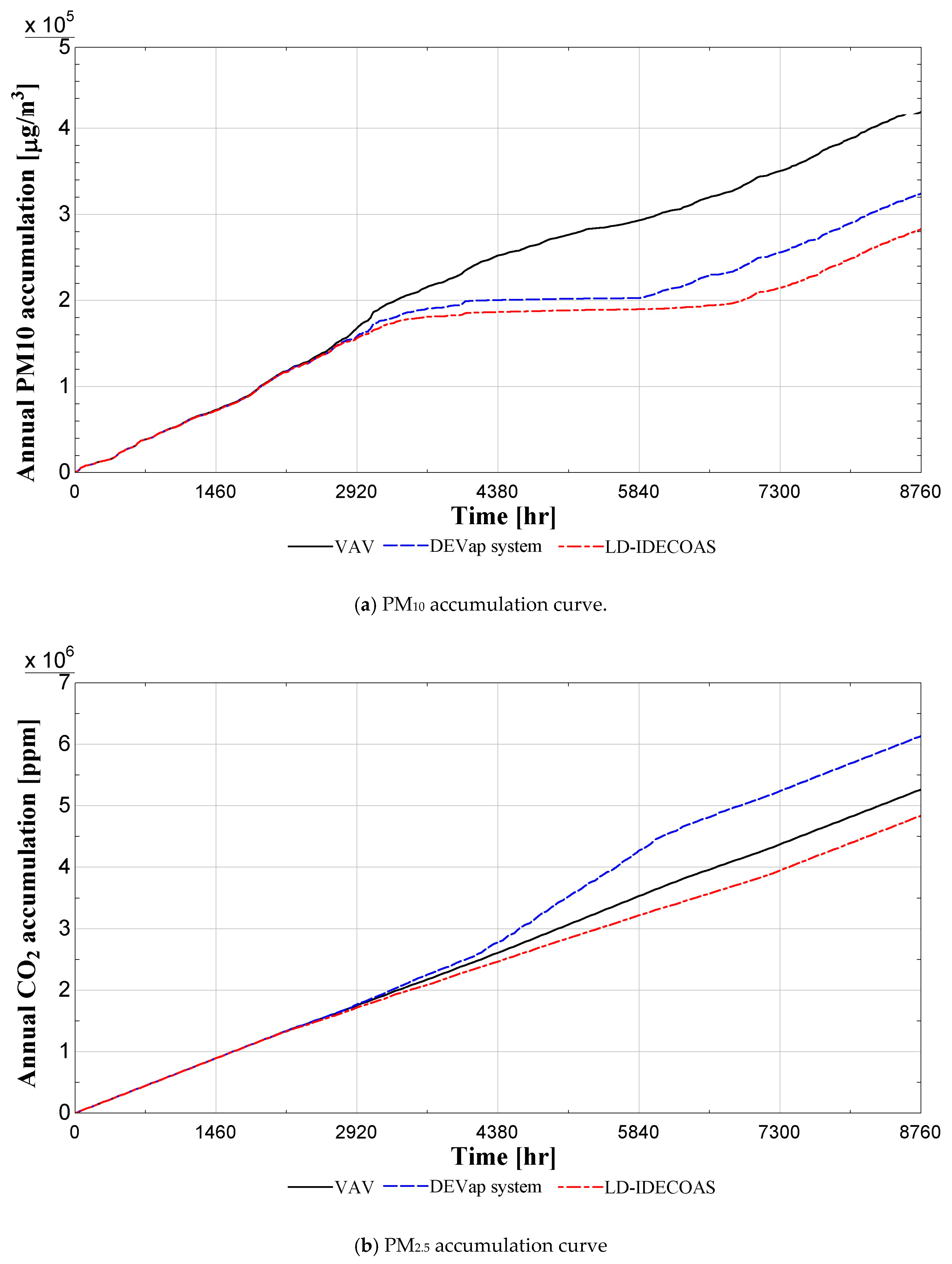

4.1. Indoor CO2 Concentration

4.2. Indoor PM2.5 and PM10 Concentrations

5. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Goetzler, W.; Zogg, R.; Young, J.; Johnson, C. Energy Savings Potential and RD&D Opportunities for Non-Vapor-Compression HVAC Technologies; US Department of Energy: Washington, DC, USA, 2014.

- Dieckmann, J.; Roth, K.; Brodrick, J. Liquid Desiccant Air Conditioners. ASHRAE J. 2008, 50, 90–95. [Google Scholar]

- Kozubal, E.; Woods, J.; Burch, J.; Boranian, A.; Merrigan, T. Desiccant Enhanced Evaporative Air-Conditioning (DEVap): Evaluation of a New Concept in Ultra Efficient Air Conditioning. Available online: https://www.nrel.gov/docs/fy11osti/49722.pdf (accessed on 16 February 2019).

- Lee, S.J.; Kim, H.J.; Dong, H.W.; Jeong, J.W. Energy saving assessment of a desiccant-enhanced evaporative cooling system in variable air volume applications. Appl. Therm. Eng. 2017, 117, 94–108. [Google Scholar] [CrossRef]

- Dong, H.W.; Lee, S.J.; Yoon, D.S.; Park, J.Y.; Jeong, J.W. Impact of district heat source on primary energy savings of a desiccant-enhanced evaporative cooling system. Energy 2017, 123, 432–444. [Google Scholar] [CrossRef]

- Kim, M.H.; Kim, J.H.; Kwon, O.H.; Choi, A.S.; Jeong, J.W. Energy conservation potential of an indirect and direct evaporative cooling assisted 100% outdoor air system. Build. Serv. Eng. Res. Technol. 2011, 32, 345–360. [Google Scholar] [CrossRef]

- Kim, M.H.; Park, J.Y.; Sung, M.K.; Choi, A.S.; Jeong, J.W. Annual operating energy savings of liquid desiccant and evaporative-cooling-assisted 100% outdoor air system. Energy Build. 2014, 76, 538–550. [Google Scholar] [CrossRef]

- Park, J.Y.; Yoon, D.S.; Li, S.; Park, J.; Bang, J.I.; Sung, M.; Jeong, J.W. Empirical analysis of indoor air quality enhancement potential in a liquid-desiccant assisted air conditioning system. Build. Environ. 2017, 121, 11–25. [Google Scholar] [CrossRef]

- Kim, M.H.; Dong, H.W.; Park, J.Y.; Jeong, J.W. Primary energy savings in desiccant and evaporative cooling-assisted 100% outdoor air system combined with a fuel cell. Appl. Energy 2016, 180, 446–456. [Google Scholar] [CrossRef]

- Shin, J.H.; Park, J.Y.; Jo, M.S.; Jeong, J.W. Impact of Heat Pump-Driven Liquid Desiccant Dehumidification on the Energy Performance of an Evaporative Cooling-Assisted Air Conditioning System. Energies 2018, 11, 345. [Google Scholar] [CrossRef]

- Park, J.Y.; Jeong, J.W. Operating energy savings of a liquid desiccant and evaporative cooling-assisted air-handling system in marine applications. Energies 2017, 10, 487. [Google Scholar] [CrossRef]

- Paschold, H.; Li, W.W.; Morales, H.; Walton, J. Laboratory study of the impact of evaporative coolers on indoor PM concentrations. Atmos. Environ. 2003, 37, 1075–1086. [Google Scholar] [CrossRef]

- Liu, X.; Guan, B.; Liu, X. Experimental Study on the Filtration Efficiency of Structured Packing Air Handling Processors. Procedia Eng. 2015, 121, 2037–2043. [Google Scholar] [CrossRef] [Green Version]

- Li, W.W.; Paschold, H.; Morales, H.; Chianelli, J. Correlations between short-term indoor and outdoor PM concentrations at residences with evaporative coolers. Atmos. Environ. 2003, 37, 2691–2703. [Google Scholar] [CrossRef]

- ASHRAE. ANSI/ASHRAE/IES Standard 62.1-2016 Ventilation for Acceptable Indoor Air Quality; American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc.: Atlanta, Georgia, 2016. [Google Scholar]

- Woods, J.; Kozubal, E. A desiccant-enhanced evaporative air conditioner: Numerical model and experiments. Energy Convers. Manag. 2013, 65, 208–220. [Google Scholar] [CrossRef]

- Meckler, M. Improving Indoor Air Quality Through Design, Operation and Maintenance; Fairmont Press: Lilburn, Georgia, 1996. [Google Scholar]

- Ward, M.; Siegel, J.A.; Corsi, R.L. The effectiveness of stand alone air cleaners for shelter-in-place. Indoor Air 2005, 15, 127–134. [Google Scholar] [CrossRef] [PubMed]

- NOAA Earth System Research Laboratory, Global Monitoring Division, Trends in Atmospheric Carbon Dioxide. 2018. Available online: https://www.esrl.noaa.gov/gmd/ccgg/trends/global (accessed on 17 August 2018).

- Airkorea, Airkorea download final Confirmation Data. 2018. Available online: https://www.airkorea.or.kr/last_amb_hour_data (accessed on 6 April 2018).

- Marsik, T.; Johnson, R. HVAC air-quality model and its use to test a PM2.5 control strategy. Build. Environ. 2008, 43, 1850–1857. [Google Scholar] [CrossRef]

- Abt, E.; Suh, H.H.; Catalano, P.; Koutrakis, P. Relative contribution of outdoor and indoor particle sources to indoor concentrations. Environ. Sci. Technol. 2000, 34, 3579–3587. [Google Scholar] [CrossRef]

- Jamriska, M.; Morawska, L.; Clark, B.A. Effect of ventilation and filtration on submicrometer particles in an indoor environment. Indoor Air 2000, 10, 19–26. [Google Scholar] [CrossRef] [PubMed]

- Macintosh, D.L.; Myatt, T.A.; Ludwig, J.F.; Baker, B.J.; Suh, H.H.; Spengler, J.D. Whole house particle removal and clean air delivery rates for in-duct and portable ventilation systems. J. Air Waste Manag. Assoc. 2008, 58, 1474–1482. [Google Scholar] [CrossRef] [PubMed]

- Jamriska, M. Relation between indoor and outdoor exposure to fine particles near a busy Arterial Road. Indoor Air 1999, 9, 75–84. [Google Scholar] [CrossRef] [PubMed]

| Site | Seoul, South Korea | ||

|---|---|---|---|

| Weather data | Seoul weather data | ||

| Building type | Open-plan office (20 m × 20 m × 3 m) | ||

| U-values [W/m2K] | Roof | 0.149 | |

| Wall | 0.252 | ||

| Floor | 0.297 | ||

| Windows (0.33 window/wall ratio) | 1.4 | ||

| Internal heat gain | Equipment | Light six W per floor area | |

| Occupants | Load | 115 W per person | |

| Room set point | Summer | Temperature Relative humidity | 26 °C 50% |

| Intermediate | Temperature Relative humidity | 24 °C 50% | |

| Winter | Temperature Relative humidity | 20 °C 30% | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, B.-J.; Park, J.; Jeong, J.-W. Indoor Air Quality Enhancement Performance of Liquid Desiccant and Evaporative Cooling-Assisted Air Conditioning Systems. Sustainability 2019, 11, 1036. https://doi.org/10.3390/su11041036

Kim B-J, Park J, Jeong J-W. Indoor Air Quality Enhancement Performance of Liquid Desiccant and Evaporative Cooling-Assisted Air Conditioning Systems. Sustainability. 2019; 11(4):1036. https://doi.org/10.3390/su11041036

Chicago/Turabian StyleKim, Beom-Jun, Junseok Park, and Jae-Weon Jeong. 2019. "Indoor Air Quality Enhancement Performance of Liquid Desiccant and Evaporative Cooling-Assisted Air Conditioning Systems" Sustainability 11, no. 4: 1036. https://doi.org/10.3390/su11041036