Optimizing Nitrogen and Residue Management to Reduce GHG Emissions while Maintaining Crop Yield: A Case Study in a Mono-Cropping System of Northeast China

Abstract

:1. Introduction

2. Materials and Methods

2.1. LCA Assessment of GHG Emissions

2.1.1. Life-Cycle Inventory Analysis

2.1.2. Calculation of Greenhouse Gas Emission

2.2. APSIM Model and Simulations

2.2.1. Field Site and Experimental Data

2.2.2. Meteorological Data

2.2.3. Model Calibration and Validation

2.3. Scenarios to Assess the Effect of Alternative Management

3. Results

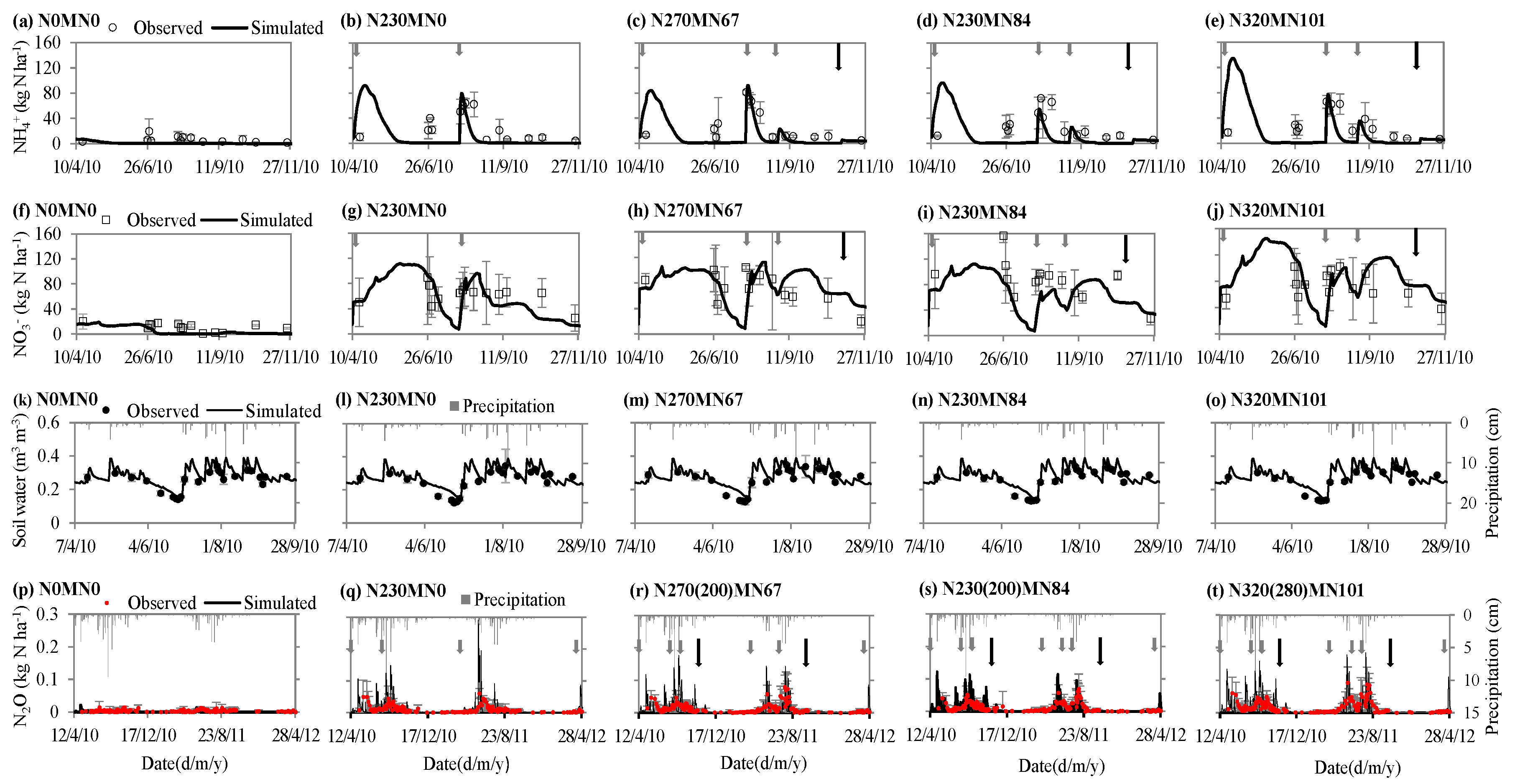

3.1. Model Performance

3.2. Scenario Analysis

3.2.1. Optimized N Rate

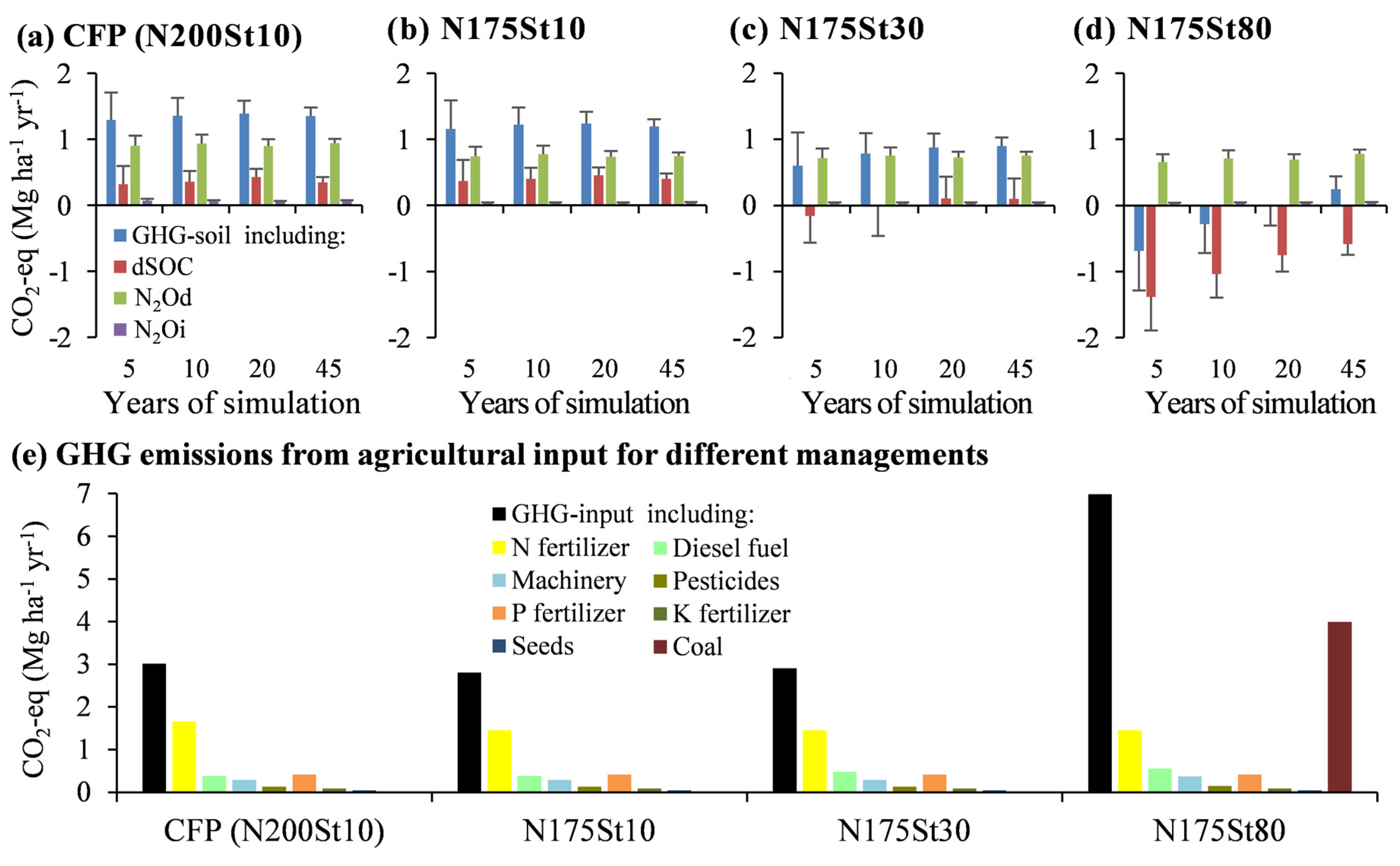

3.2.2. GHG Emissions and GHG Intensity

4. Discussion

4.1. Nearly Optimal for Crop Production in Terms of N and Residue Management

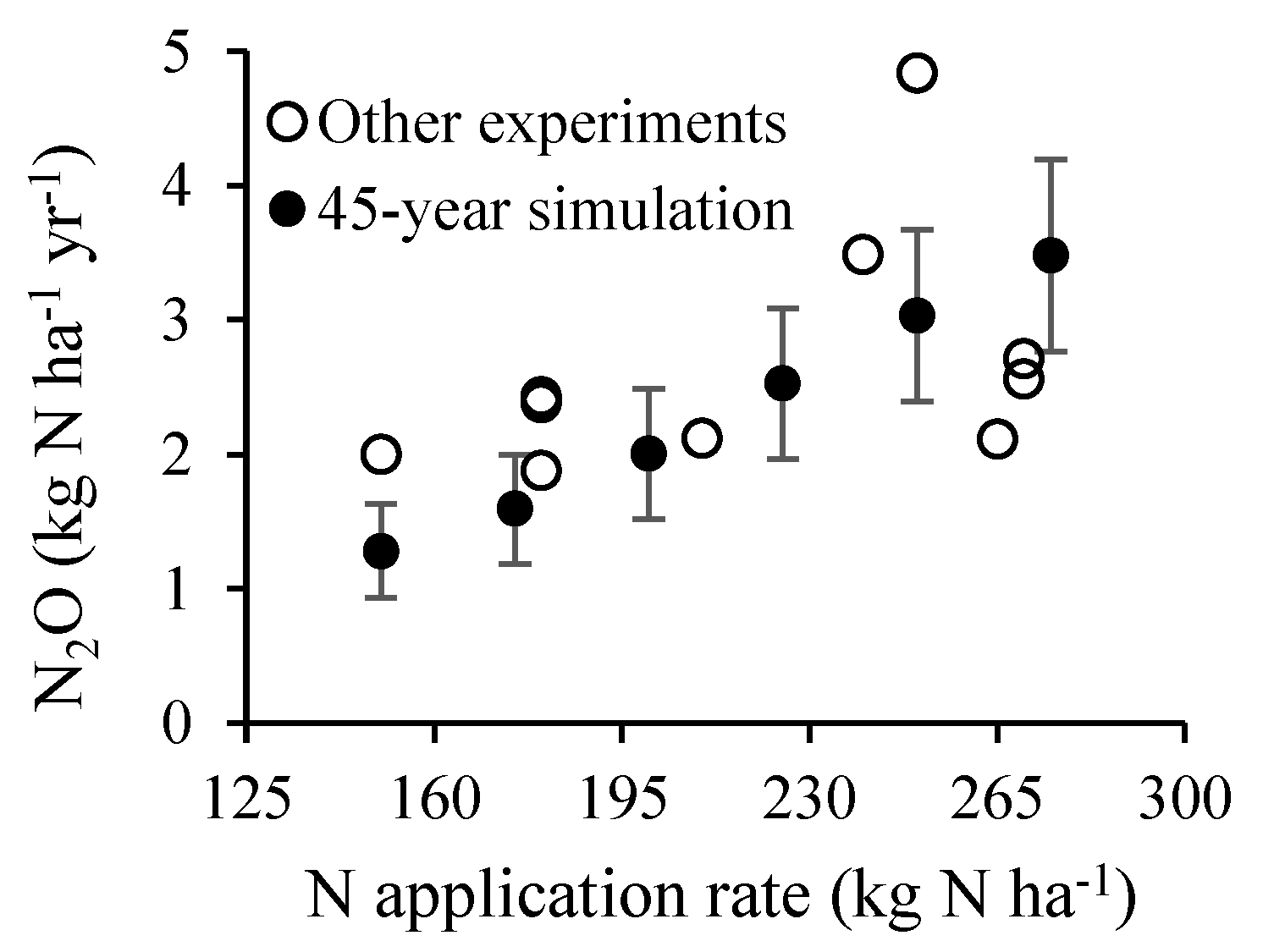

4.2. Model Performance for Simulating N2O Emissions and SOC Change

4.3. GHG Emissions and Emission Factor of Agricultural Inputs

4.4. Limitations and Suggestions

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Winiwarter, W.; Höglund-Isaksson, L.; Klimont, Z.; Schöpp, W.; Amann, M. Technical opportunities to reduce global anthropogenic emissions of nitrous oxide. Environ. Res. Lett. 2018, 13, 014011. [Google Scholar] [CrossRef]

- Gerber, J.S.; Carlson, K.M.; Makowski, D.; Mueller, N.D.; de Cortazar-Atauri, I.G.; Havlik, P.; Herrero, M.; Launay, M.; O’Connell, C.S.; Smith, P.; et al. Spatially explicit estimates of N2O emissions from croplands suggest climate mitigation opportunities from improved fertilizer management. Glob. Chang. Biol. 2016, 22, 3383–3394. [Google Scholar] [CrossRef] [PubMed]

- Searchinger, T.; Heimlich, R.; Houghton, R.A.; Dong, F.; Elobeid, A.; Fabiosa, J.; Tokgoz, S.; Hayes, D.; Yu, T.H. Use of U.S. croplands for biofuels increases greenhouse gases through emissions from land-use change. Science 2008, 319, 1238–1240. [Google Scholar] [CrossRef] [PubMed]

- Lal, R. Sequestering carbon in soils of agro-ecosystems. Food Policy 2011, 36, S33–S39. [Google Scholar] [CrossRef]

- Adviento-Borbe, M.A.A.; Haddix, M.L.; Binder, D.L.; Walters, D.T.; Dobermann, A. Soil greenhouse gas fluxes and global warming potential in four high-yielding maize systems. Glob. Chang. Biol. 2007, 13, 1972–1988. [Google Scholar] [CrossRef]

- Huang, J.; Chen, Y.; Liu, W.; Zheng, H.; Sui, P.; LI, Y.; Shi, X.; Nei, S.; Gao, W. Effect on net greenhouse gases emission under different conservation tillages in Jilin Province. Sci. Agric. Sin. 2011, 44, 2935–2942. [Google Scholar]

- Minasny, B.; Malone, B.P.; McBratney, A.B.; Angers, D.A.; Arrouays, D.; Chambers, A.; Chaplot, V.; Chen, Z.-S.; Cheng, K.; Das, B.S.; et al. Soil carbon 4 per mille. Geoderma 2017, 292, 59–86. [Google Scholar] [CrossRef]

- Grassini, P.; Cassman, K.G. High-yield maize with large net energy yield and small global warming intensity. Proc. Natl. Acad. Sci. USA 2012, 109, 1074–1079. [Google Scholar] [CrossRef] [Green Version]

- Chen, X.; Cui, Z.; Fan, M.; Vitousek, P.; Zhao, M.; Ma, W.; Wang, Z.; Zhang, W.; Yan, X.; Yang, J.; et al. Producing more grain with lower environmental costs. Nature 2014, 514, 486–489. [Google Scholar] [CrossRef]

- Chu, Y.; Xie, L.; Yuan, Z. Composition and spatiotemporal distribution of the agro-ecosystem carbon footprint: A case study in Hebei Province, north China. J. Clean. Prod. 2018, 190, 838–846. [Google Scholar] [CrossRef]

- Hoffman, E.; Cavigelli, M.A.; Camargo, G.; Ryan, M.; Ackroyd, V.J.; Richard, T.L.; Mirsky, S. Energy use and greenhouse gas emissions in organic and conventional grain crop production: Accounting for nutrient inflows. Agric. Syst. 2018, 162, 89–96. [Google Scholar] [CrossRef]

- Qi, J.-Y.; Yang, S.-T.; Xue, J.-F.; Liu, C.-X.; Du, T.-Q.; Hao, J.-P.; Cui, F.-Z. Response of carbon footprint of spring maize production to cultivation patterns in the Loess Plateau, China. J. Clean. Prod. 2018, 187, 525–536. [Google Scholar] [CrossRef]

- Goglio, P.; Smith, W.N.; Grant, B.B.; Desjardins, R.L.; Gao, X.; Hanis, K.; Tenuta, M.; Campbell, C.A.; McConkey, B.G.; Nemecek, T.; et al. A comparison of methods to quantify greenhouse gas emissions of cropping systems in LCA. J. Clean. Prod. 2018, 172, 4010–4017. [Google Scholar] [CrossRef] [Green Version]

- Gao, B.; Huang, T.; Ju, X.; Gu, B.; Huang, W.; Xu, L.; Rees, R.M.; Powlson, D.S.; Smith, P.; Cui, S. Chinese cropping systems are a net source of greenhouse gases despite soil carbon sequestration. Glob. Chang. Biol. 2018, 24, 5590–5606. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cui, Z.; Zhang, H.; Chen, X.; Zhang, C.; Ma, W.; Huang, C.; Zhang, W.; Mi, G.; Miao, Y.; Li, X.; et al. Pursuing sustainable productivity with millions of smallholder farmers. Nature 2018, 555, 363–366. [Google Scholar] [CrossRef] [PubMed]

- Zhang, G.; Wang, X.; Zhao, H.; Sun, B.; Lu, F.; Hu, L. Extension of residue retention increases net greenhouse gas mitigation in China’s croplands. J. Clean. Prod. 2017, 165, 1–12. [Google Scholar] [CrossRef]

- Zhang, D.; Shen, J.; Zhang, F.; Li, Y.; Zhang, W. Carbon footprint of grain production in China. Sci. Rep. 2017, 7, 4126. [Google Scholar] [CrossRef]

- Cui, Z.; Yue, S.; Wang, G.; Meng, Q.; Wu, L.; Yang, Z.; Zhang, Q.; Li, S.; Zhang, F.; Chen, X. Closing the yield gap could reduce projected greenhouse gas emissions: A case study of maize production in China. Glob. Chang. Biol. 2013, 19, 2467–2477. [Google Scholar] [CrossRef]

- He, L.; Zhang, A.; Wang, X.; Li, J.; Hussain, Q. Effects of different tillage practices on the carbon footprint of wheat and maize production in the Loess Plateau of China. J. Clean. Prod. 2019, 234, 297–305. [Google Scholar] [CrossRef]

- Li, J. Production, Breeding and Process of Maize in China; Springer: Berlin/Heidelberg, Germany, 2009; pp. 563–576. [Google Scholar]

- MOAC. The Action Plan for Zero Growth in Fertilizer Use by 2020 (in Chinese). Available online: http://www.moa.gov.cn/zwllm/tzgg/tz/201503/t20150318_4444765.htm (accessed on 18 March 2015).

- Holzworth, D.P.; Huth, N.I.; deVoil, P.G.; Zurcher, E.J.; Herrmann, N.I.; McLean, G.; Chenu, K.; van Oosterom, E.J.; Snow, V.; Murphy, C.; et al. APSIM—Evolution towards a new generation of agricultural systems simulation. Environ. Model. Softw. 2014, 62, 327–350. [Google Scholar] [CrossRef]

- Liu, Z.; Hubbard, K.G.; Lin, X.; Yang, X. Negative effects of climate warming on maize yield are reversed by the changing of sowing date and cultivar selection in Northeast China. Glob. Chan. Biol. 2013, 19, 3481–3492. [Google Scholar] [CrossRef] [PubMed]

- Wang, G.; Wang, E.; Huang, Y.; Xu, J. Soil Carbon Sequestration Potential as Affected by Management Practices in Northern China: A Simulation Study. Pedosphere 2014, 24, 529–543. [Google Scholar] [CrossRef]

- Zhao, J.; Yang, X. Distribution of high-yield and high-yield-stability zones for maize yield potential in the main growing regions in China. Agric. For. Meteorol. 2018, 248, 511–517. [Google Scholar] [CrossRef]

- Liu, Z.; Xie, J.; Zhang, K.; Wang, X.; Hou, Y.; Yin, C.; Li, S. Maize growth and nutrient uptake as influenced by nitrogen management in Jilin province. Plant Nutr. Fert. Sci. 2011, 17, 38–47. [Google Scholar]

- Gao, Q.; Feng, G.; Wang, Z. Present Situation of Fertilizer Application on Spring Maize in Northeast China. Chin. Agric. Sci. Bull. 2010, 26, 229–231. [Google Scholar]

- TAMB. Historical Breakthrough Happened in Tieling City for 1.91 Million Mu of Mechanical Harvesting of Maize (in Chinese). Available online: http://www.moa.gov.cn/fwllm/qgxxlb/ln/201311/t20131104_3665518.htm (accessed on 4 November 2013).

- MAPRC (Ministry of Agriculture of the People’s Republic of China). Harvest Level with Machine for Maize Increased by More Than 6% Consecutively Over 5 Years (in Chinese). Available online: http://www.gov.cn/gzdt/2013-12/04/content_2541831.htm (accessed on 4 December 2013).

- Yu, B. Study on Countermeasures of Straw Energy-oriented Utilization in Liaoning Province; Graduate School of Chinese Academy of Agricultural Sciences: Beijing, China, 2013. [Google Scholar]

- Na, W.; Zhao, X.; Huang, X. Evaluation on the utilizable resource of corn stalks in Jilin province. Chin. J. Agric. Res. Reg. Plan 2010, 6, 32–36. [Google Scholar]

- Hou, P.; Gao, Q.; Xie, R.; Li, S.; Meng, Q.; Kirkby, E.A.; Römheld, V.; Müller, T.; Zhang, F.; Cui, Z.; et al. Grain yields in relation to N requirement: Optimizing nitrogen management for spring maize grown in China. Field Crops Res. 2012, 129, 1–6. [Google Scholar] [CrossRef]

- IPCC(Intergovernmental Panel on Climate Change). 2006 IPCC Guidelines for National Greenhouse Gas Inventories, Prepared by the National Greenhouse Gas Inventories Programme; Eggelston, S., Buendia, L., Miwa, K., Ngara, T., Tanabe, K., Eds.; IGES: Hayama, Japan, 2006. [Google Scholar]

- IPCC(Intergovernmental Panel on Climate Change). Climate Change 2013: The Physical Science Basis. Contribution of Working Group I to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Stocker, T.F., Dahe, Q., Gian-Kasper, P., Melinda, T., Simon, A.K., Judith, B., Alexander, N., Yu, X., Vincent, B., Pauline, M.M., Eds.; Cambridge University Press: Cambridge, UK, 2013. [Google Scholar]

- Probert, M.; Dimes, J.; Keating, B.; Dalal, R.; Strong, W. APSIM’s water and nitrogen modules and simulation of the dynamics of water and nitrogen in fallow systems. Agric. Syst. 1998, 56, 1–28. [Google Scholar] [CrossRef]

- Luo, Z.; Wang, E.; Sun, O.J.; Smith, C.J.; Probert, M.E. Modeling long-term soil carbon dynamics and sequestration potential in semi-arid agro-ecosystems. Agric. For. Meteorol. 2011, 151, 1529–1544. [Google Scholar] [CrossRef]

- Luo, Z.; Wang, E.; Zheng, H.; Baldock, J.A.; Sun, O.J.; Shao, Q. Convergent modelling of past soil organic carbon stocks but divergent projections. Biogeosciences 2015, 12, 4373–4383. [Google Scholar] [CrossRef] [Green Version]

- Del Grosso, S.J.; Ojima, D.S.; Parton, W.J.; Stehfest, E.; Heistemann, M.; DeAngelo, B.; Rose, S. Global scale DAYCENT model analysis of greenhouse gas emissions and mitigation strategies for cropped soils. Glob. Planet. Chang. 2009, 67, 44–50. [Google Scholar] [CrossRef]

- Thorburn, P.J.; Biggs, J.S.; Collins, K.; Probert, M.E. Using the APSIM model to estimate nitrous oxide emissions from diverse Australian sugarcane production systems. Agric. Ecosyst. Environ. 2010, 136, 343–350. [Google Scholar] [CrossRef]

- Parton, W.J.; Holland, E.A.; Del Grosso, S.J.; Hartman, M.D.; Martin, R.E.; Mosier, A.R.; Ojima, D.S.; Schimel, D.S. Generalized model for NOx and N2O emissions from soils (1984–2012). J. Geophys. Res. Atmos. 2001, 106, 17403–17419. [Google Scholar] [CrossRef]

- Li, Y.; White, R.; Chen, D.; Zhang, J.; Li, B.; Zhang, Y.; Huang, Y.; Edis, R. A spatially referenced water and nitrogen management model (WNMM) for (irrigated) intensive cropping systems in the North China Plain. Ecol. Model. 2007, 203, 395–423. [Google Scholar] [CrossRef]

- Li, J.; Wang, E.; Wang, Y.; Xing, H.; Wang, D.; Wang, L.; Gao, C. Reducing greenhouse gas emissions from a wheat-maize rotation system while still maintaining productivity. Agric. Syst. 2016, 145, 90–98. [Google Scholar] [CrossRef]

- Guo, Y.; Luo, L.; Chen, G.; Kou, Y.; Xu, H. Mitigating nitrous oxide emissions from a maize-cropping black soil in northeast China by a combination of reducing chemical N fertilizer application and applying manure in autumn. Soil Sci. Plant Nutr. 2013, 59, 392–402. [Google Scholar] [CrossRef] [Green Version]

- Black, J.N.; Bonython, C.W.; Prescott, J.A. Solar radiation and the duration of sunshine. Quart. J. R. Met. Soc. 1954, 80, 231–235. [Google Scholar] [CrossRef]

- Jones, H.G. Plant and Microclimate. A Quantitative Approach to Environ. Plant Physiology, 2nd ed.; Camberidge University Press: Cambridge, UK, 1992. [Google Scholar]

- Liu, Z.; Yang, X.; Hubbard, K.G.; Lin, X. Maize potential yields and yield gaps in the changing climate of northeast China. Glob. Chang. Biol. 2012, 18, 3441–3454. [Google Scholar] [CrossRef]

- Chen, C.; Wang, E.; Yu, Q. Modeling Wheat and Maize Productivity as Affected by Climate Variation and Irrigation Supply in North China Plain. Agron. J. 2010, 102, 1037. [Google Scholar] [CrossRef]

- Ning, Y.; Li, Y.; Ding, T.; Tonooka, Y. A Survey on Energy Consumption in Rural Households in North-East China. Sustain. Energy 2012, 2, 76–81. [Google Scholar]

- Yue, J.; Zhang, J.; Xu, G.; Yang, S.; Zhang, B. The measurement and analysis of main elements and calorific value of maize straw. J. Henan Agric. Sci. 2006, 9, 30–32. [Google Scholar]

- DCCNDRC. National Greenhouse Gas Inventory of China (2005); China Environmental Science Press: Beijing, China, 2014. [Google Scholar]

- Shcherbak, I.; Millar, N.; Robertson, G.P. Global metaanalysis of the nonlinear response of soil nitrous oxide (N2O) emissions to fertilizer nitrogen. Proc. Natl. Acad. Sci. USA 2014, 111, 9199–9204. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Xiao, C.; Wu, D.; Xia, T.; Chen, Q.; Chen, F.; Yuan, L.; Mi, G. Effects of nitrogen application rate on grain yield and grain nitrogen concentration in two maize hybrids with contrasting nitrogen remobilization efficiency. Eur. J. Agron. 2015, 62, 79–89. [Google Scholar] [CrossRef]

- Xu, X.; He, P.; Qiu, S.; Pampolino, M.F.; Zhao, S.; Johnston, A.M.; Zhou, W. Estimating a new approach of fertilizer recommendation across small-holder farms in China. Field Crops Res. 2014, 163, 10–17. [Google Scholar] [CrossRef]

- Cui, Z.; Zhang, F.; Chen, X.; Miao, Y.; Li, J.; Shi, L.; Xu, J.; Ye, Y.; Liu, C.; Yang, Z.; et al. On-farm evaluation of an in-season nitrogen management strategy based on soil Nmin test. Field Crops Res. 2008, 105, 48–55. [Google Scholar] [CrossRef]

- Hu, S.; Wu, L.; Chen, X.; Cui, Z.; Zhang, W.; Zhang, F. Establishing a Regional Nitrogen Management Approach to Mitigate Greenhouse Gas Emission Intensity from Intensive Smallholder Maize Production. PLoS ONE 2014, 9, e98481. [Google Scholar]

- Li, H.; Qiu, J.; Wang, L.; Xu, M.; Liu, Z.; Wang, W. Estimates of N2O Emissions and Mitigation Potential from a Spring Maize Field Based on DNDC Model. J. Integr. Agric. 2012, 11, 2067–2078. [Google Scholar] [CrossRef]

- Ni, K.; Ding, W.; Zaman, M.; Cai, Z.; Wang, Y.; Zhang, X.; Zhou, B. Nitrous oxide emissions from a rainfed-cultivated black soil in Northeast China: Effect of fertilization and maize crop. Biol. Fertil. Soils 2012, 48, 973–979. [Google Scholar] [CrossRef]

- Song, C.; Zhang, J. Effects of soil moisture, temperature, and nitrogen fertilization on soil respiration and nitrous oxide emission during maize growth period in northeast China. Acta Agric. Scand. Sect. B Soil Plant Sci. 2009, 59, 97–106. [Google Scholar] [CrossRef]

- Yang, L.; Wang, L.; Li, H.; Qiu, J.; Liu, H. Impacts of Fertilization Alternatives and Crop Straw Incorporation on N2O Emissions from a Spring Maize Field in Northeastern China. J. Integr. Agric. 2014, 13, 881–892. [Google Scholar] [CrossRef]

- Zheng, Y. Effect of Nitrogen Application Methods on N2O, CO2 Emissions and Nitrogen Balance in Typical Black Soil Farmland; Hainan University: Hainan, China, 2014. [Google Scholar]

- Yang, X.; Zhang, X.; Fang, H.; Liang, A. Changes in Organic Matter and Total Nitrogen of Black Soils in Jilin Province over the Past Two Decades. Sci. Geogr. Sin. 2004, 24, 710–714. [Google Scholar]

- Xu, Y. The Economic Explanation for the Change of Soil Organic Carbon Storage in Northern Agro-Ecological Zones of China; China Agricultural University: Beijing, China, 2005. [Google Scholar]

- Zhang, G.; Wang, X.; Zhang, L.; Xiong, K.; Zheng, C.; Lu, F.; Zhao, H.; Zheng, H.; Ouyang, Z. Carbon and water footprints of major cereal crops production in China. J. Clean. Prod. 2018, 194, 613–623. [Google Scholar] [CrossRef]

- West, T.O.; Marland, G. A synthesis of carbon sequestration, carbon emissions, and net carbon flux in agriculture: Comparing tillage practices in the United States. Agric. Ecosyst. Environ. 2002, 91, 217–232. [Google Scholar] [CrossRef]

- Zheng, G.; Bu, W. Review of Heating Methods for Rural Houses in China. Energies 2018, 11, 3402. [Google Scholar] [CrossRef]

- Zhang, W.; Dou, Z.; He, P.; Ju, X.; Powlson, D.; Chadwick, D.; Norse, D.; Lu, Y.; Zhang, Y.; Wu, L.; et al. New technologies reduce greenhouse gas emissions from nitrogenous fertilizer in China. Proc. Natl. Acad. Sci. USA 2013, 110, 8375–8380. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Maize seed | N | P2O5 | K2O | Herbicides | Insecticides | Fungicides | |

|---|---|---|---|---|---|---|---|

| Application rate (kg ha-1) | 25 (9) | 199 (30) | 83 (15) | 80 (11) | 4 (1) | 0 | 0 |

| Rotary tillage | Sowing and fertilization | Soil compaction | Spraying herbicides | Harvest | Grain transportation to home | ||

| Diesel fuel consumption (kg ha−1) | 27 (6) | 8 (2) | 4 (2) | 2 (1) | 34 (5) | 8 (3) | |

| Mechanical power (kW) | 56 (14) | 18 (0.3) | 18 (0.3) | 1 (0.3) | 100 (19) | / | |

| Operating area (ha yr-1) | 60 (28) | 33 (12) | 31 (10) | 58 (20) | 61 a | / | |

| Depth (m) | BD (g cm−3) | LL (mm mm−1) | DUL (mm mm−1) | SAT (mm mm−1) | SOC (%) | pH | Ini NO3-N (kg ha−1) | Ini NH4+-N (kg ha−1) |

|---|---|---|---|---|---|---|---|---|

| 0–0.1 | 1.31 | 0.1 | 0.3 | 0.44 | 1.52 | 6.2 | 12.56 | 5.88 |

| 0.1–0.2 | 1.31 | 0.1 | 0.3 | 0.44 | 1.52 | 6.2 | 12.56 | 5.88 |

| 0.2–0.3 | 1.42 | 0.11 | 0.29 | 0.42 | 0.96 | 6.6 | 10.14 | 4.43 |

| 0.3–0.4 | 1.42 | 0.11 | 0.29 | 0.42 | 0.96 | 6.6 | 10.14 | 4.43 |

| 0.4–0.6 | 1.44 | 0.11 | 0.28 | 0.41 | 0.49 | 6.8 | 11.4 | 6.51 |

| 0.6–0.8 | 1.5 | 0.11 | 0.27 | 0.38 | 0.37 | 7.1 | 7.44 | 6.51 |

| 0.8–1.0 | 1.59 | 0.11 | 0.26 | 0.36 | 0.36 | 7.2 | 6.9 | 6.65 |

| Date of Fertilization (Day Month Year) | Fertilizer Type | Amount of Fertilizer Application (kg N ha−1) | ||||

|---|---|---|---|---|---|---|

| N0MN0 | N230MN0 | N270MN67 | N230MN84 | N320MN101 | ||

| 29 October 2009 | Manure | 0 | 0 | 67 | 84 | 101 |

| 12 April 2010 | Urea | 0 | 95 | 78 | 90 | 130 |

| 31 July 2010 | Urea | 0 | 135 | 153 | 95 | 130 |

| 31 August 2010 | Urea | 0 | 0 | 39 | 45 | 60 |

| 29 October 2010 | Manure | 0 | 0 | 67 | 84 | 101 |

| N0MN0 | N230MN0 | N200MN67 | N200MN84 | N280MN101 | ||

| 11 April 2011 | Urea | 0 | 230 | 85 | 72 | 100 |

| 24 June 2011 | Urea | 0 | 0 | 0 | 45 | 60 |

| 25 July 2011 | Urea | 0 | 0 | 115 | 83 | 120 |

| 29 October 2011 | Manure | 0 | 0 | 67 | 84 | 101 |

| 16 April 2012 | Urea | 0 | 230 | 85 | 72 | 100 |

| Parameters | Values |

|---|---|

| tt_emerg_to_endjuv (thermal time required from emergence to end of juvenile (°Cd)) | 235 |

| Photoperiod_slope (change in thermal time required to floral initiation per hour photoperiod increase) (°C/hour) | 19 |

| tt_flower_to_maturity (thermal time required from flower to maturity (°Cd)) | 750 |

| Head_grain_no_max (maximum grain numbers per head) | 720 |

| Grain_gth_rate (grain-filling rate (mg/grain/day)) | 8.0 |

| Radiation use efficiency | 2.0 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Luo, Z.; Wang, Y.; Li, H.; Xing, H.; Wang, L.; Wang, E.; Xu, H.; Gao, C.; Ren, T. Optimizing Nitrogen and Residue Management to Reduce GHG Emissions while Maintaining Crop Yield: A Case Study in a Mono-Cropping System of Northeast China. Sustainability 2019, 11, 5015. https://doi.org/10.3390/su11185015

Li J, Luo Z, Wang Y, Li H, Xing H, Wang L, Wang E, Xu H, Gao C, Ren T. Optimizing Nitrogen and Residue Management to Reduce GHG Emissions while Maintaining Crop Yield: A Case Study in a Mono-Cropping System of Northeast China. Sustainability. 2019; 11(18):5015. https://doi.org/10.3390/su11185015

Chicago/Turabian StyleLi, Jianzheng, Zhongkui Luo, Yingchun Wang, Hu Li, Hongtao Xing, Ligang Wang, Enli Wang, Hui Xu, Chunyu Gao, and Tianzhi Ren. 2019. "Optimizing Nitrogen and Residue Management to Reduce GHG Emissions while Maintaining Crop Yield: A Case Study in a Mono-Cropping System of Northeast China" Sustainability 11, no. 18: 5015. https://doi.org/10.3390/su11185015