Improved Agricultural Products Drying Through a Novel Double Collector Solar Device

Abstract

:1. Introduction

2. Materials and Methods

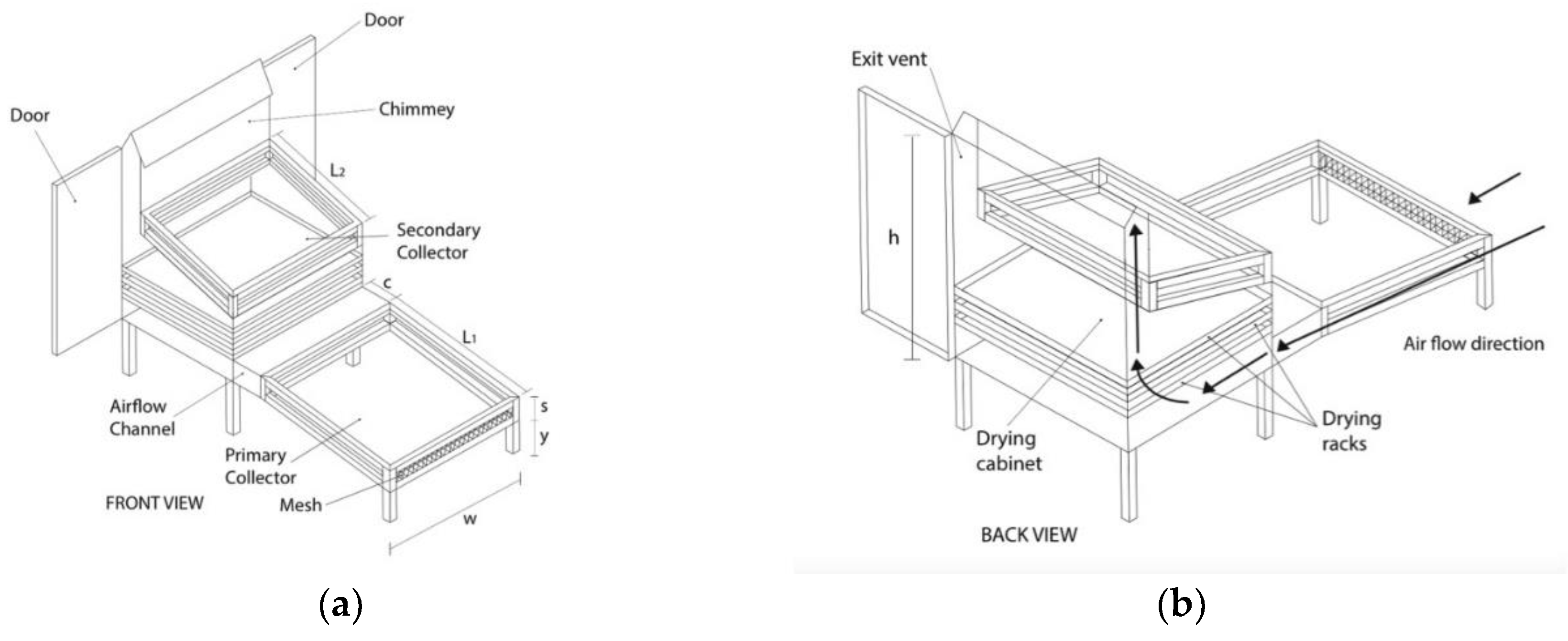

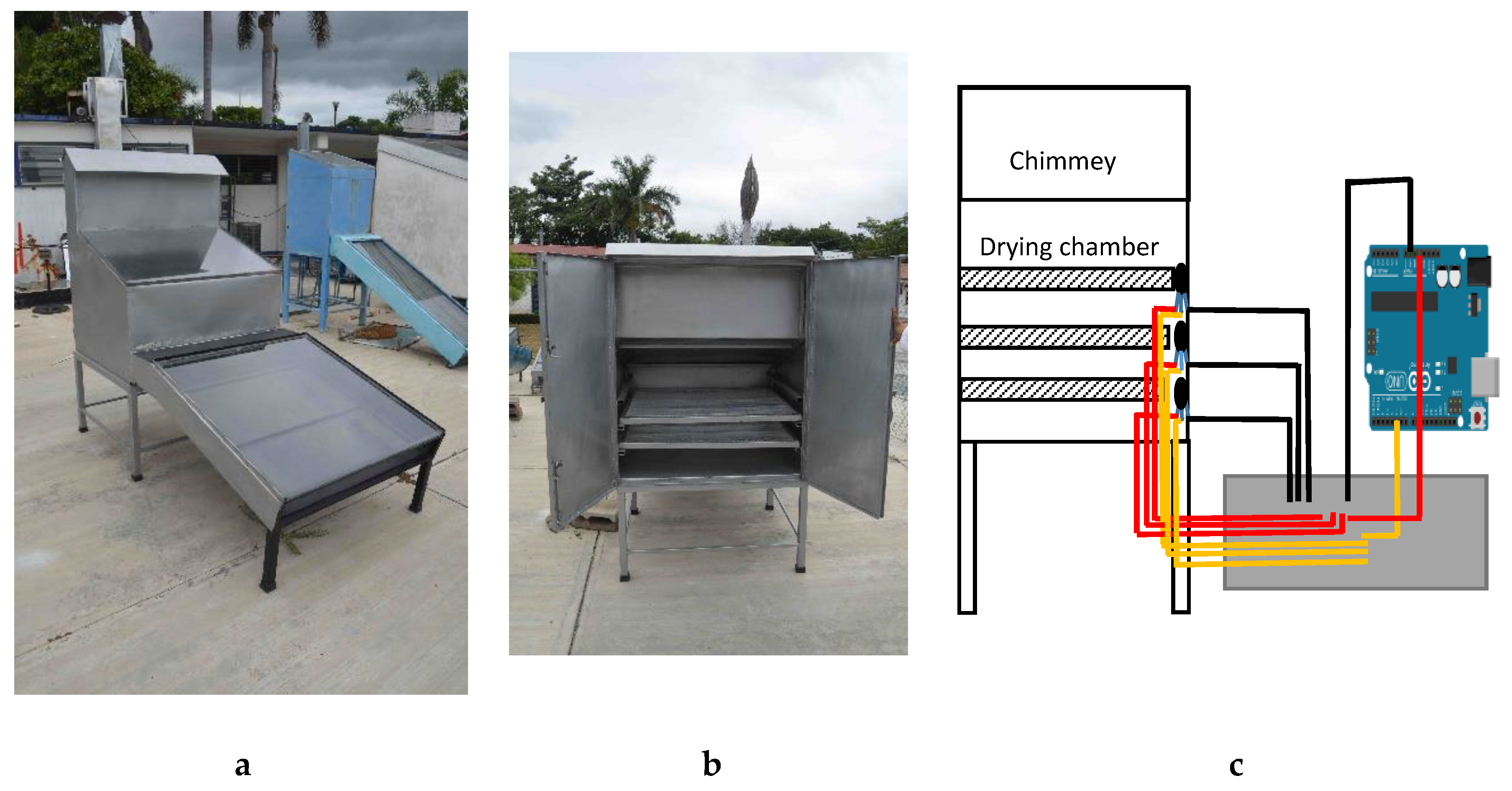

2.1. Description fo the Double Collector Solar Dryer

2.2. Crop Characteristics

2.3. Drying Curves

2.4. Drying Efficiency

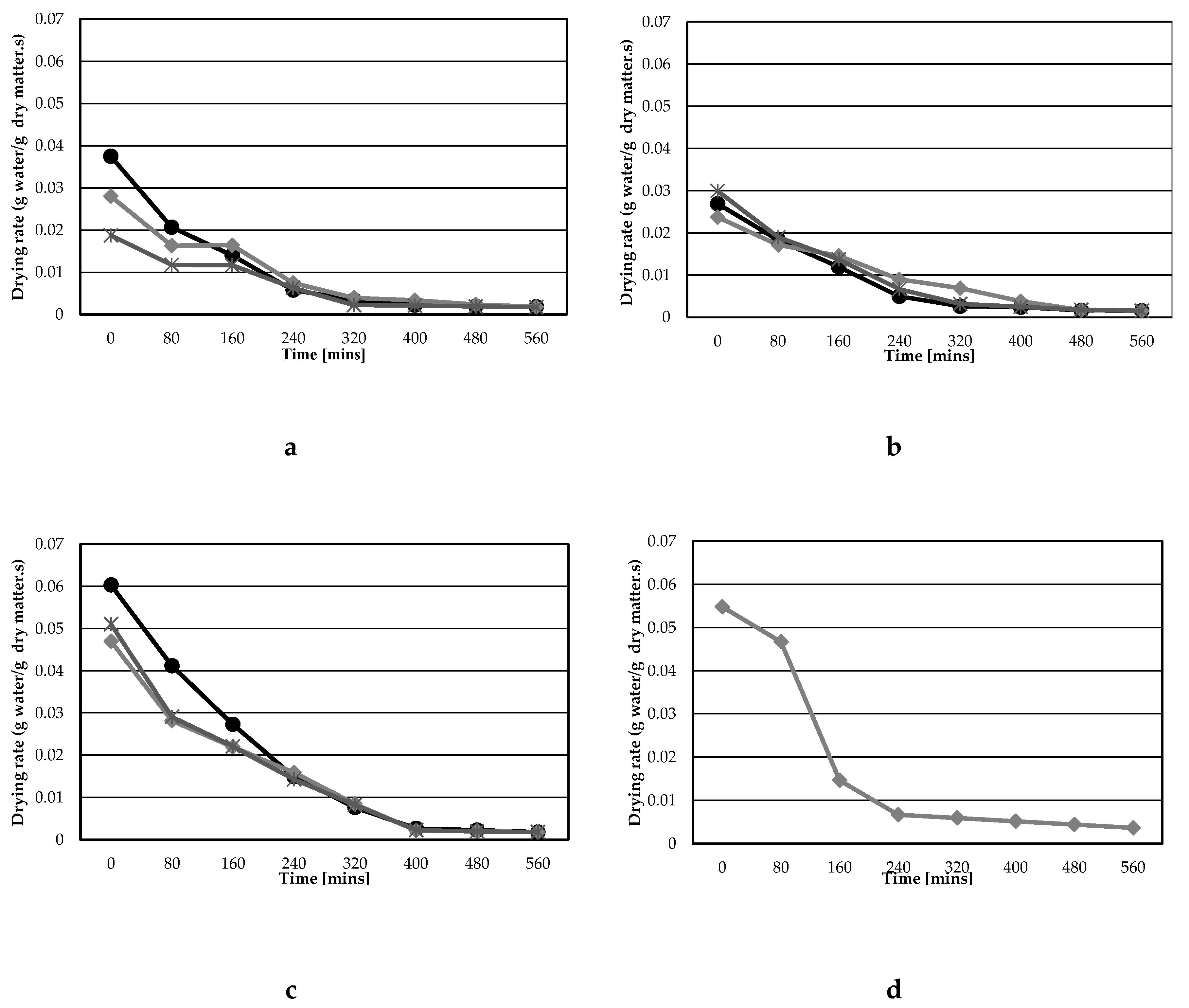

2.5. Drying Rate

3. Results and Discussion

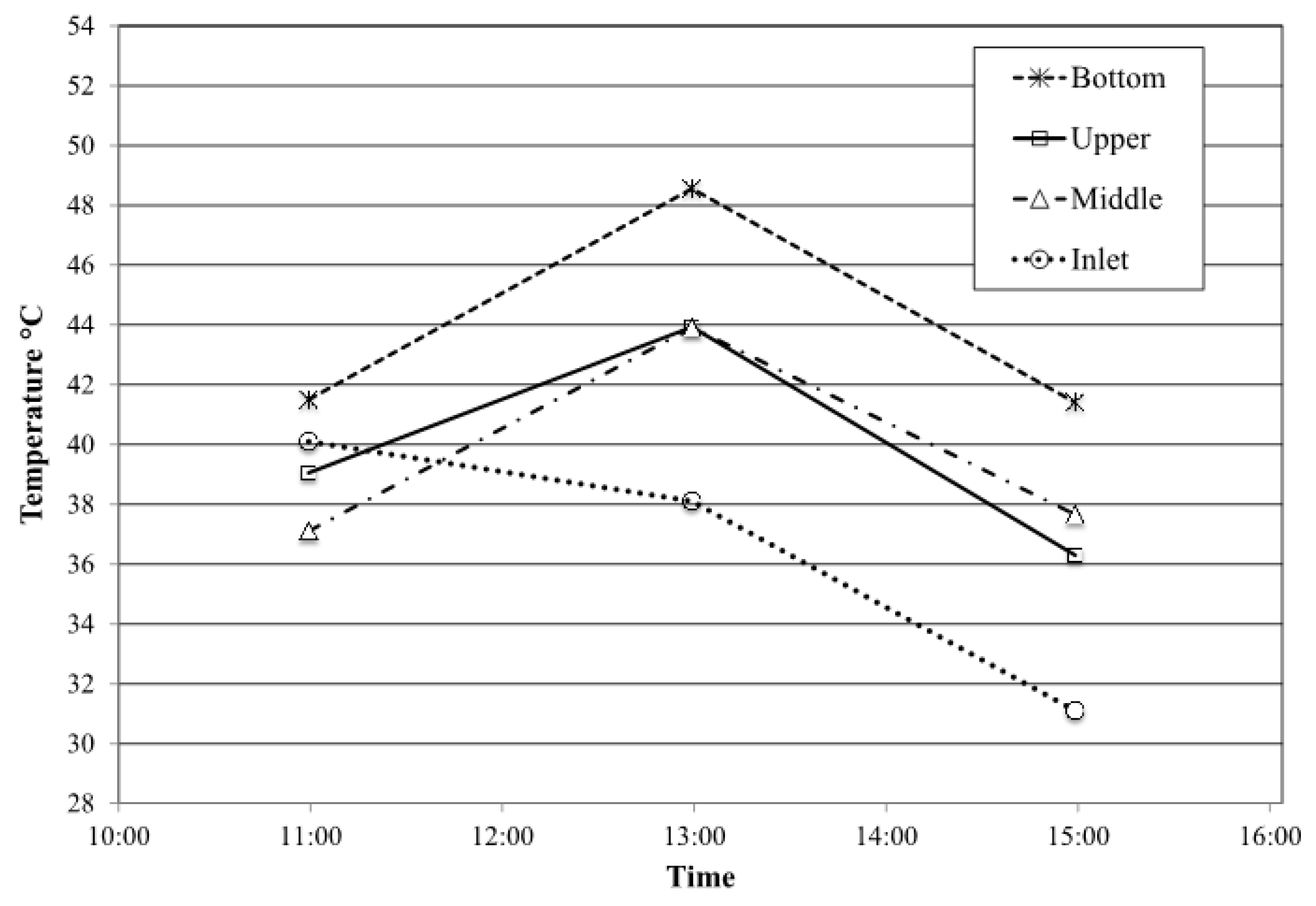

3.1. Drying Conditions

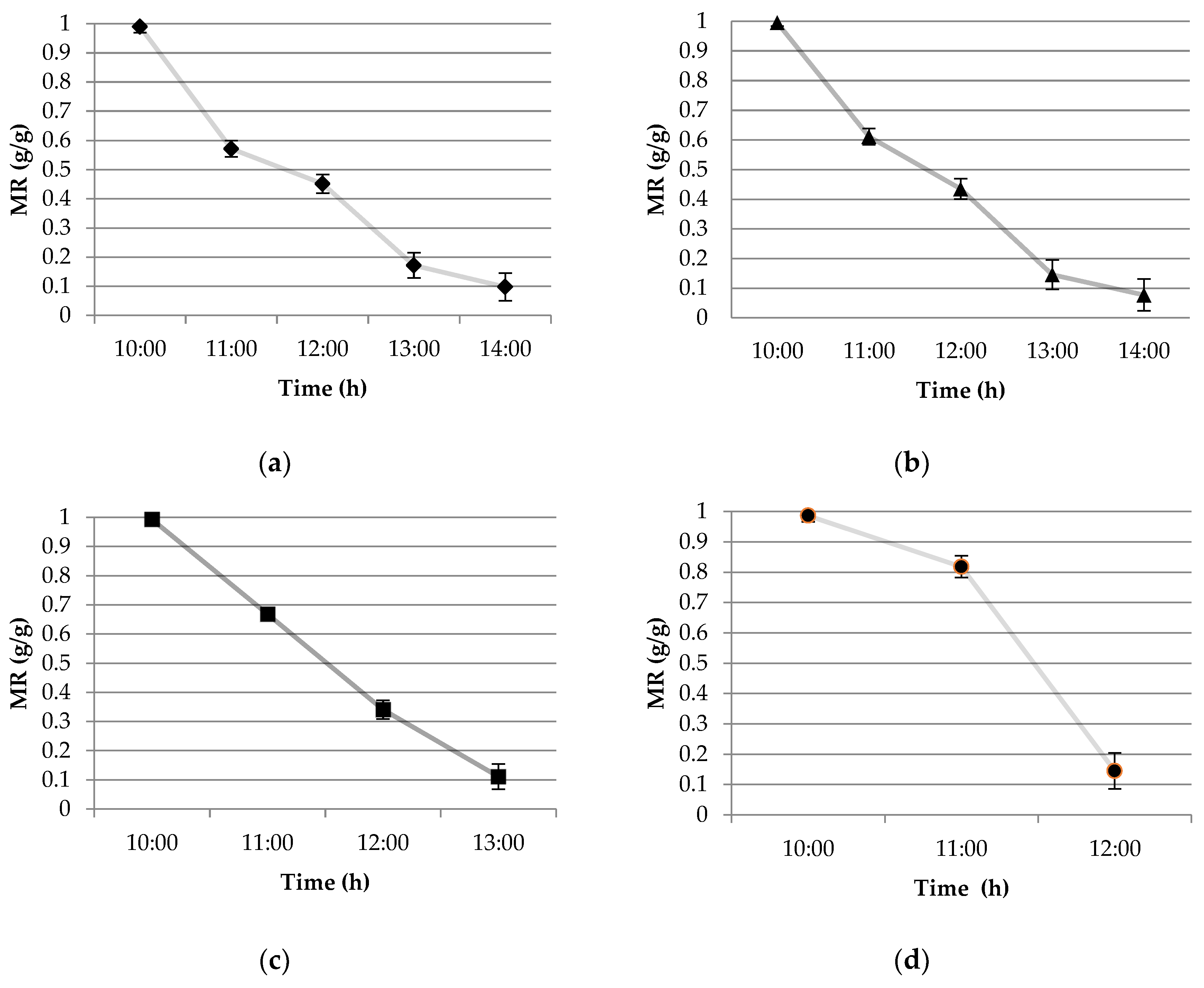

3.2. Drying Curves

3.3. Drying Efficiency

3.4. Dried Products

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Eriksson, H.; Adhuri, D.S.; Adrianto, L.; Andrew, N.L.; Apriliani, T.; Daw, T.; Evans, L.; Garces, L.; Kamanyi, E.; Mwaipopo, R.; et al. An ecosystem approach to small-scale fisheries through participatory diagnosis in four tropical countries. Glob. Environ. Chang. 2016, 36, 56–66. [Google Scholar] [CrossRef]

- FAO. The Future of Food and Agriculture–Trends and Challenges; Food and Agriculture Organization: Rome, Italy, 2017; ISBN 9789251095515. [Google Scholar]

- Graeub, B.E.; Chappell, M.J.; Wittman, H.; Ledermann, S.; Kerr, R.B.; Gemmill-Herren, B. The State of Family Farms in the World. World Dev. 2016, 87, 1–15. [Google Scholar] [CrossRef] [Green Version]

- Pennington, J.T.; Mahoney, K.L.; Kuwahara, V.S.; Kolber, D.D.; Calienes, R.; Chavez, F.P. Primary production in the eastern tropical Pacific: A review. Prog. Oceanogr. 2006, 69, 285–317. [Google Scholar] [CrossRef]

- Renwick, A.R.; Vickery, J.A.; Potts, S.G.; Bolwig, S.; Nalwanga, D.; Pomeroy, D.E.; Mushabe, D.; Atkinson, P.W. Achieving production and conservation simultaneously in tropical agricultural landscapes. Agric. Ecosyst. Environ. 2014, 192, 130–134. [Google Scholar] [CrossRef]

- United Nations United Nations Millennium Development Goals. Available online: http://www.un.org/millenniumgoals/ (accessed on 19 May 2019).

- FAO. Global Agriculture Towards 2050. In Proceedings of the High Level Expert Forum-How to Feed World 2050, Rome, Italy, 12–13 October 2009; pp. 1–4. [Google Scholar]

- Albores Pérez, B.; Álvarez Gutiérrez, P.E. Chain value analysis of production of mushroom species (Pleurotus spp.) In four populations of Chiapas. Acta Univ. 2015, 25, 51–58. [Google Scholar] [CrossRef]

- Arias-Reyes, L.M. El Huerto Familiar o Solar Maya-Yucateco Actual; Secretaría de Recursos Naturales y Protección Ambiental del Estado de Tabasco: Villahermosa, México, 2012; p. 544. ISBN 9786077637684. [Google Scholar]

- Chávez-García, E.; Rist, S.; Galmiche-Tejeda, Á. Lógica de manejo del huerto familiar en el contexto del impacto modernizador en Tabasco, México. Cuadernos Desarrollo Rural 2012, 9, 177–200. [Google Scholar]

- Kirschenmann, F. Alternative agriculture in an energy- and resource-depleting future. Renew. Agric. Food Syst. 2010, 25, 85–89. [Google Scholar] [CrossRef] [Green Version]

- Martínez-Rodríguez, J.C.; García-Chong, N.R.; Trujillo-Olivera, L.E.; Noriero-Escalante, L. Inseguridad alimentaria y vulnerabilidad social en Chiapas: El rostro de la pobreza. Nutr. Hosp. 2015, 31, 475–481. [Google Scholar]

- Bvenura, C.; Afolayan, A.J. The role of wild vegetables in household food security in South Africa: A review. Food Res. Int. 2015, 76, 1001–1011. [Google Scholar] [CrossRef]

- Damon, A.; Soriano, M.P.; Rivera del Lourdes, M.; Rivera, M.D. Substrates and fertilization for the rustic cultivation of in vitro propagated native orchids in Soconusco, Chiapas. Renew. Agric. Food Syst. 2005, 20, 214–222. [Google Scholar] [CrossRef]

- Goland, C.; Bauer, S. When the apple falls close to the tree: Local food systems and the preservation of diversity. Renew. Agric. Food Syst. 2004, 19, 228–236. [Google Scholar] [CrossRef]

- Pretty, J.N.; Morison, J.I.L.; Hine, R.E. Reducing food poverty by increasing agricultural sustainability in developing countries. Agric. Ecosyst. Environ. 2003, 95, 217–234. [Google Scholar] [CrossRef]

- FAO. Pérdidas y Desperdicios de Alimentos en América Latina y el Caribe; Food and Agriculture Organization: Rome, Italy, 2015; pp. 1–44. [Google Scholar]

- Castillo-Téllez, M.; Pilatowsky-Figueroa, I.; López-Vidal, E.C.; Sarracino-Martínez, O.; Hernández-Galvez, G. Dehydration of the red chilli (Capsicum annuum L., costeño) using an indirect-type forced convection solar dryer. Appl. Therm. Eng. 2017, 114, 1137–1144. [Google Scholar] [CrossRef]

- Gatea, A.A. Performance evaluation of a mixed-mode solar dryer for evaporating moisture in beans. J. Agric. Biotechnol. Sustain. Dev. 2011, 3, 65–71. [Google Scholar]

- Hegde, V.N.; Hosur, V.S.; Rathod, S.K.; Harsoor, P.A.; Narayana, K.B. Design, fabrication and performance evaluation of solar dryer for banana. Energy. Sustain. Soc. 2015, 5, 23. [Google Scholar] [CrossRef]

- Mghazli, S.; Ouhammou, M.; Hidar, N.; Lahnine, L.; Idlimam, A.; Mahrouz, M. Drying characteristics and kinetics solar drying of Moroccan rosemary leaves. Renew. Energy 2017, 108, 303–310. [Google Scholar] [CrossRef]

- Mustayen, A.G.M.B.; Rahman, M.M.; Mekhilef, S.; Saidur, R. Performance evaluation of a solar powered air dryer for white oyster mushroom drying. Int. J. Green Energy 2015, 12, 1113–1121. [Google Scholar] [CrossRef]

- Yahya, M.; Fudholi, A.; Hafizh, H.; Sopian, K. Comparison of solar dryer and solar-assisted heat pump dryer for cassava. Sol. Energy 2016, 136, 606–613. [Google Scholar] [CrossRef]

- Baniasadi, E.; Ranjbar, S.; Boostanipour, O. Experimental investigation of the performance of a mixed-mode solar dryer with thermal energy storage. Renew. Energy 2017, 112, 143–150. [Google Scholar] [CrossRef]

- Qiu, Y.; Li, M.; Hassanien, R.; Wang, Y.; Luo, X.; Yu, Q. Performance and operation mode analysis of a heat recovery and thermal storage solar-assisted heat pump drying system. Sol. Energy 2016, 137, 225–235. [Google Scholar] [CrossRef]

- Madhlopa, A.; Ngwalo, G. Solar dryer with thermal storage and biomass-backup heater. Sol. Energy 2007, 81, 449–462. [Google Scholar] [CrossRef] [Green Version]

- Prasad, J.; Vijay, V.K. Experimental studies on drying of Zingiber officinale, Curcuma longa l. and Tinospora cordifolia in solar-biomass hybrid drier. Renew. Energy 2005, 30, 2097–2109. [Google Scholar] [CrossRef]

- Reyes, A.; Mahn, A.; Cubillos, F.; Huenulaf, P. Mushroom dehydration in a hybrid-solar dryer. Energy Convers. Manag. 2013, 70, 31–39. [Google Scholar] [CrossRef]

- Azaizia, Z.; Kooli, S.; Elkhadraoui, A.; Hamdi, I.; Guizani, A.A. Investigation of a new solar greenhouse drying system for peppers. Int. J. Hydrogen Energy 2017, 42, 8818–8826. [Google Scholar] [CrossRef]

- Fadhel, A.; Kooli, S.; Farhat, A.; Bellghith, A. Study of the solar drying of grapes by three different processes. Desalination 2005, 185, 535–541. [Google Scholar] [CrossRef]

- Lingayat, A.; Chandramohan, V.P.; Raju, V.R.K. Design, Development and Performance of Indirect Type Solar Dryer for Banana Drying. Energy Procedia 2017, 109, 409–416. [Google Scholar] [CrossRef]

- Sallam, Y.I.; Aly, M.H.; Nassar, A.F.; Mohamed, E.A. Solar drying of whole mint plant under natural and forced convection. J. Adv. Res. 2015, 6, 171–178. [Google Scholar] [CrossRef]

- Hossain, M.A.; Woods, J.L.; Bala, B.K. Optimisation of solar tunnel drier for drying of chilli without color loss. Renew. Energy 2005, 30, 729–742. [Google Scholar] [CrossRef]

- Huang, Y.; Lu, R.; Chen, K. Prediction of firmness parameters of tomatoes by portable visible and near-infrared spectroscopy. J. Food Eng. 2018, 222, 185–198. [Google Scholar] [CrossRef]

- Nummer, B.A. National Centre for Home Food Preservation. Available online: https://nchfp.uga.edu/publications/nchfp/factsheets/chayote.html (accessed on 9 May 2019).

- Alasalvar, C.; Grigor, J.M.; Zhang, D.; Quantick, P.C.; Shahidi, F. Comparison of volatiles, phenolics, sugars, antioxidant vitamins, and sensory quality of different colored carrot varieties. J. Agric. Food Chem. 2001, 41, 1410–1416. [Google Scholar] [CrossRef]

- Girmay, Z.; Gorems, W.; Birhanu, G.; Zewdie, S. Growth and yield performance of Pleurotus ostreatus (Jacq. Fr.) Kumm (oyster mushroom) on different substrates. AMB Express 2016, 6, 87. [Google Scholar] [CrossRef] [Green Version]

- FAO. Codex Alimentaius: Code of Hygienic Practice for Dehydrated Fruits and Vegetables including Edible Fungi (CAC/RCP5-1971). Available online: http://www.fao.org/fao-who-codexalimentarius/codex-texts/codes-of-practice/en/ (accessed on 9 May 2019).

- Normas Mexicanas. NMX-F-428-1982. Determination of Moisture (Thermobalance Rapid Method); DGN: Naucalpan, Mexico, 1982. [Google Scholar]

- FAO. Codex Alimentaius: Code of Hygienic Practice for Low-Moisture Foods. (CAC/RCP 75-2015). Available online: http://www.fao.org/fao-who-codexalimentarius/codex-texts/codes-of-practice/en/ (accessed on 9 May 2019).

- FAO. Codex Alimentaius: Codex Standard for Dried Edible Fungi Codex Stan 1939–1981. Available online: http://www.fao.org/fao-who-codexalimentarius/sh-proxy/es/?lnk=1&url=https%253A%252F%252Fworkspace.fao.org%252Fsites%252Fcodex%252FStandards%252FCODEX%2BSTAN%2B39-1981%252FCXS_039s.pdf (accessed on 9 May 2019).

- Ibrahim, M.; Sopian, K.; Daud, W.R.W. Study of the drying kinetics of Lemon grass. Am. J. Appl. Sci. 2009, 6, 1070. [Google Scholar] [CrossRef]

- Fudholi, A.; Othman, M.Y.; Ruslan, M.H.; Yahya, M.; Zaharim, A.; Sopian, K. Design and Testing of Solar Dryer for Drying Kinetics of Seaweed in Malaysia; University Kebangs Malaysia: Bangi New Town, Selangor, Malaysia, 2011; pp. 119–124. [Google Scholar]

- Mitchell, P.H. Calculating the Equilibrium Moisture Content for Wood Based on Humidity Measurements. Bioresources 2018, 13, 171–175. [Google Scholar] [CrossRef]

- Shiga, T.M.; Peroni-Okita, F.H.G.; Carpita, N.C.; Lajolo, F.M.; Cordenunsi, B.R. Polysaccharide composition of raw and cooked chayote (Sechium edule Sw.) fruits and tuberous roots. Carbohydr. Polym. 2015, 130, 155–165. [Google Scholar] [CrossRef]

- Apati, G.P.; Furlan, S.A.; Laurindo, J.B. Drying and rehydration of Oyster mushroom. Braz. Arch. Biol. Technol. 2010, 53, 945–952. [Google Scholar] [CrossRef]

- Brooks, M.S.; Abou El-Hana, N.H.; Ghaly, A.E. Effects of tomato geometries and air temperature on the drying behavior of plum tomato. Am. J. Appl. Sci. 2008, 5, 1369–1375. [Google Scholar] [CrossRef]

- Ruiz-López, I.I.; Huerta-Mora, I.R.; Vivar-Vera, M.A.; Martínez-Sánchez, C.E.; Herman-Lara, E. Effect of Osmotic Dehydration on Air-Drying Characteristics of Chayote. Dry. Technol. 2010, 28, 1201–1212. [Google Scholar] [CrossRef]

- Imsic, M.; Winkler, S.; Tomkins, B.; Jones, R. Effect of storage and cooking on beta-carotene isomers in carrots (Daucus carota L. cv. ’Stefano’). J. Agric. Food Chem. 2010, 58, 5109–5113. [Google Scholar] [CrossRef]

| Parameter | Carrot | Chayote Squash | Tomato | Oyster Mushroom |

|---|---|---|---|---|

| Mean ambient temperature (°C) | 26 | 29.8 | 30.25 | 33.48 |

| Ambient relative humidity (%) | 79.75 | 74.9 | 68.5 | 74.82 |

| Average insolation (W/m2) | 565.0 | 641.1 | 723.48 | 600.14 |

| Drying time (h) | 5.33 | 8 | 6.66 | 5.33 |

| Average product temperature (°C) | 32 | 37.35 | 41.43 | 34.62 |

| Initial moisture content (%) | 81 | 93 | 93 | 89 |

| Final moisture content (%) | 12.26 | 12.30 | 12.04 | 9.58 |

| Average drying kinetics (kg w/kg dry s) | 0.0109 | 0.0097 | 0.0197 | 0.0177 |

| Drying efficiency (ηd) (%) | 37.9 | 22.8 | 36.3 |

| Product | Tmin (°C) | Tmax (°C) | Tavg (°C) |

|---|---|---|---|

| Carrot | 29 | 41.5 | 32 |

| Chayote squash | 29.7 | 45.8 | 37 |

| Tomato | 34 | 45 | 41 |

| Oyster mushroom | 24.1 | 48.1 | 33.9 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Camas-Nafate, M.P.; Alvarez-Gutiérrez, P.; Valenzuela-Mondaca, E.; Castillo-Palomera, R.; Perez-Luna, Y.d.C. Improved Agricultural Products Drying Through a Novel Double Collector Solar Device. Sustainability 2019, 11, 2920. https://doi.org/10.3390/su11102920

Camas-Nafate MP, Alvarez-Gutiérrez P, Valenzuela-Mondaca E, Castillo-Palomera R, Perez-Luna YdC. Improved Agricultural Products Drying Through a Novel Double Collector Solar Device. Sustainability. 2019; 11(10):2920. https://doi.org/10.3390/su11102920

Chicago/Turabian StyleCamas-Nafate, Monica Patricia, Peggy Alvarez-Gutiérrez, Edgar Valenzuela-Mondaca, Roger Castillo-Palomera, and Yolanda del Carmen Perez-Luna. 2019. "Improved Agricultural Products Drying Through a Novel Double Collector Solar Device" Sustainability 11, no. 10: 2920. https://doi.org/10.3390/su11102920