Advanced Oxidation Processes and Nanofiltration to Reduce the Color and Chemical Oxygen Demand of Waste Soy Sauce

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sampling Procedure

2.2. Characterization

2.3. Size Exclusion Chromatography (SEC)

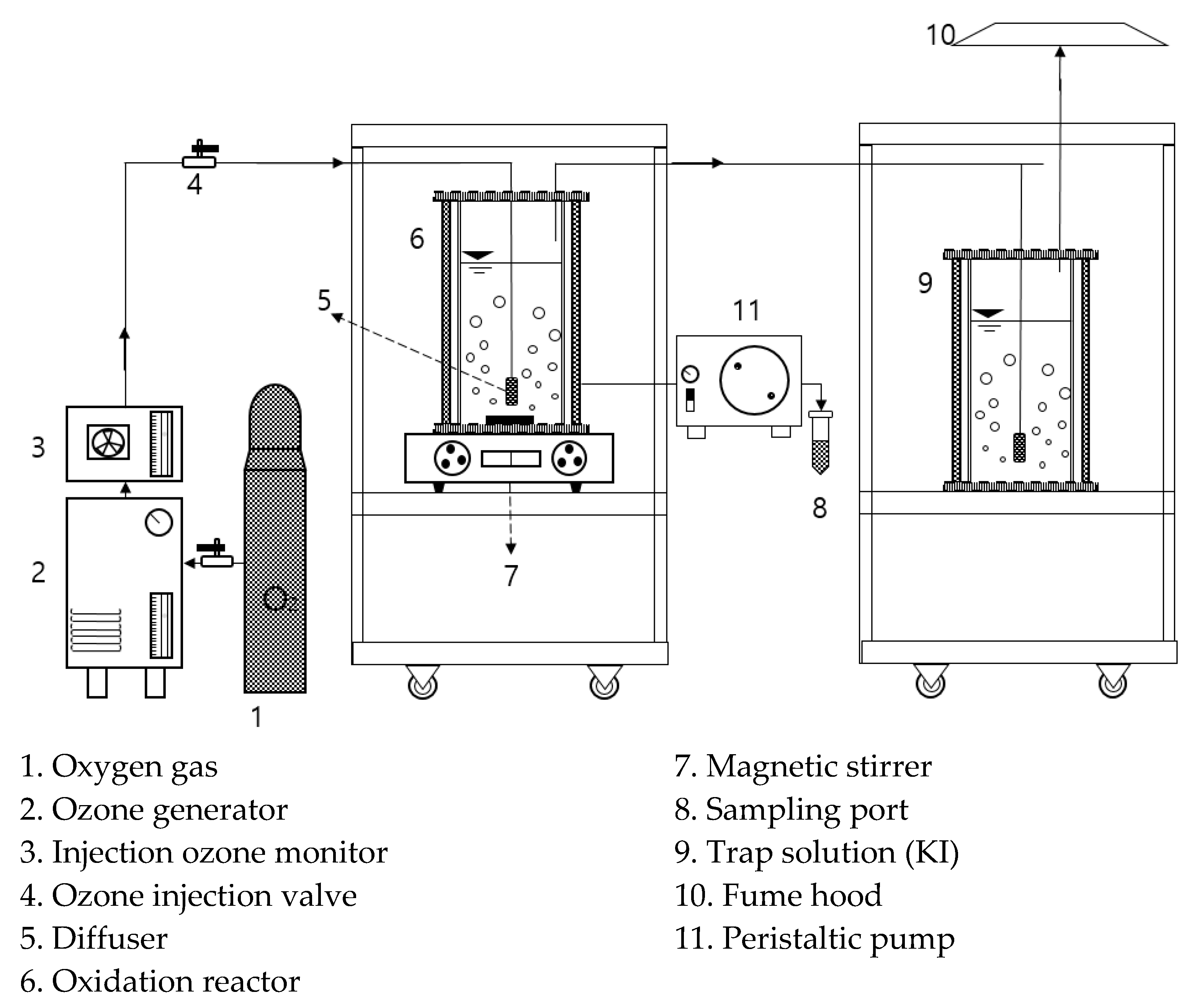

2.4. H2O2/O3 Process

2.5. Nanofiltration (NF) System

3. Results and Discussion

3.1. Characteristics of Waste Soy Sauce

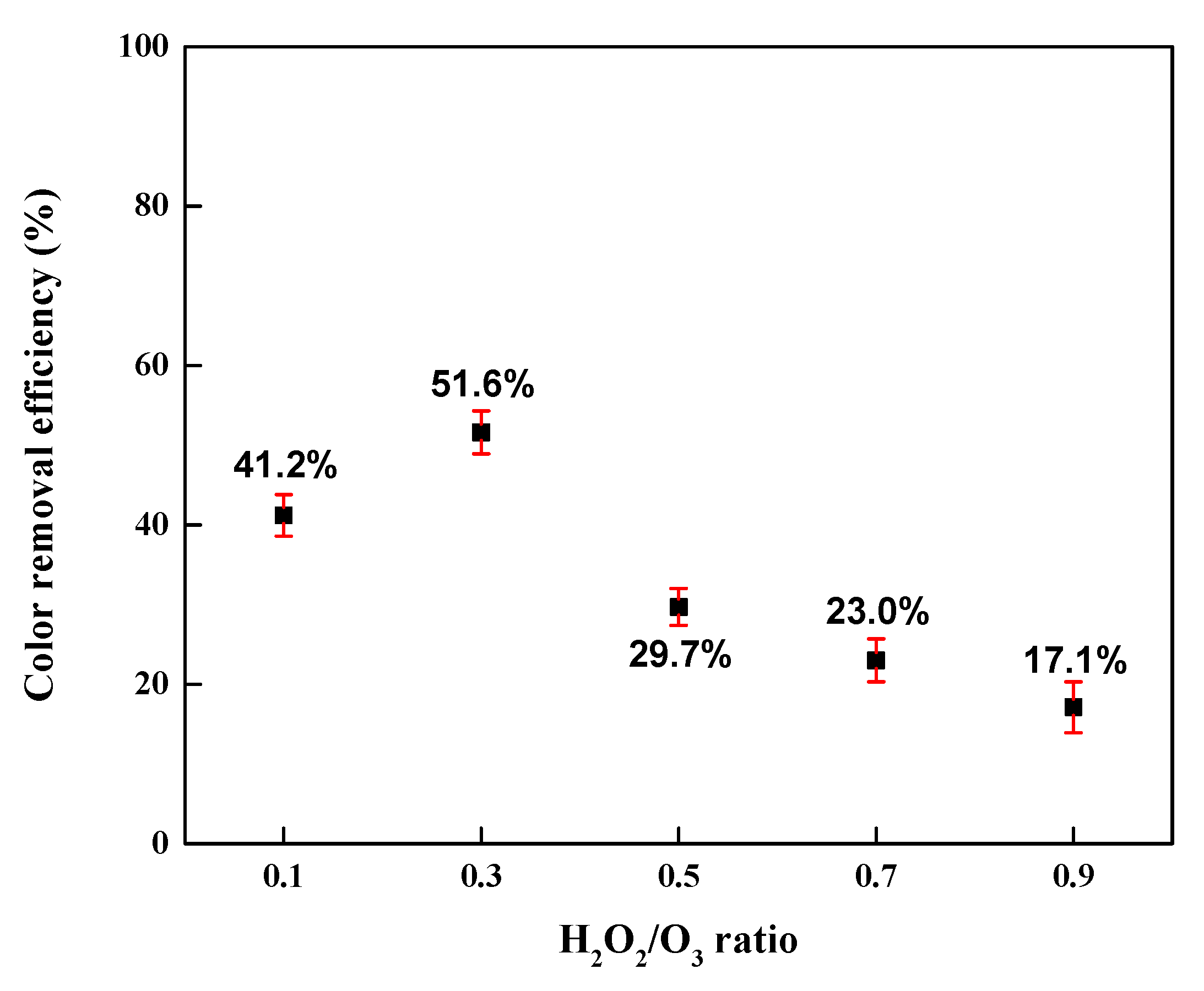

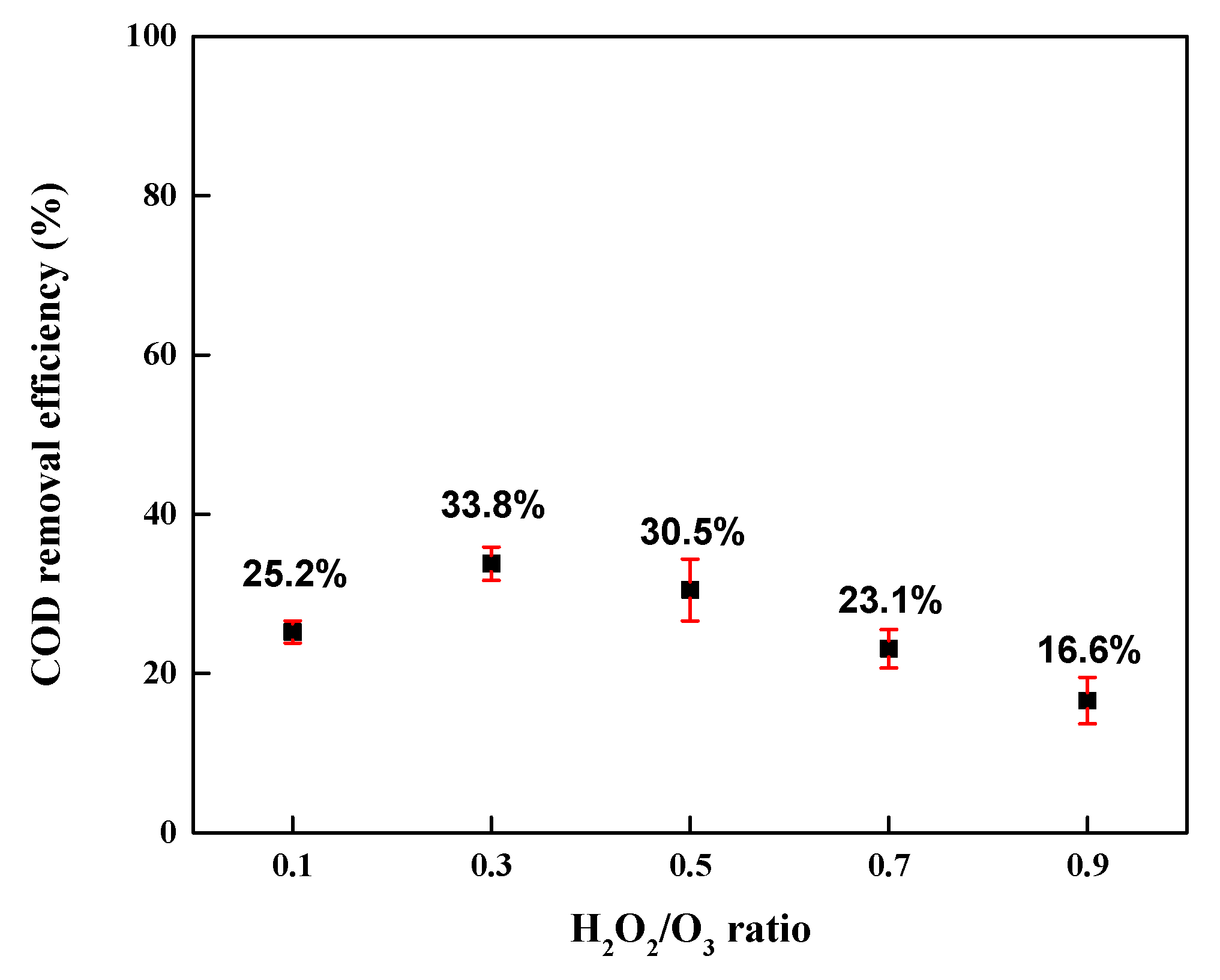

3.2. Optimization of H2O2/O3 Ratio

3.3. Nanofiltration (NF) System

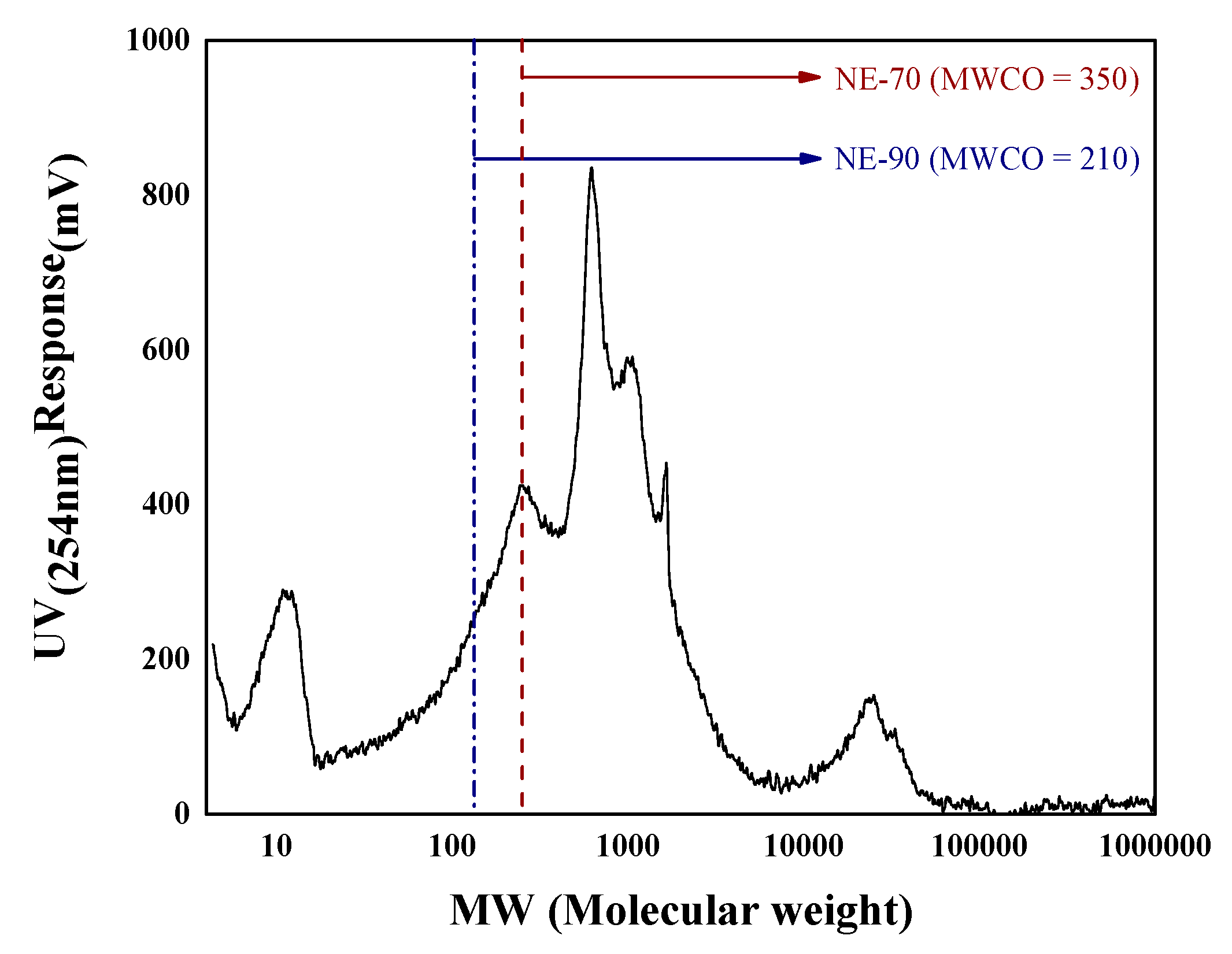

3.3.1. Size Exclusion Chromatography Analysis

3.3.2. Color Removal and COD Reduction by Nanofiltration (NF)

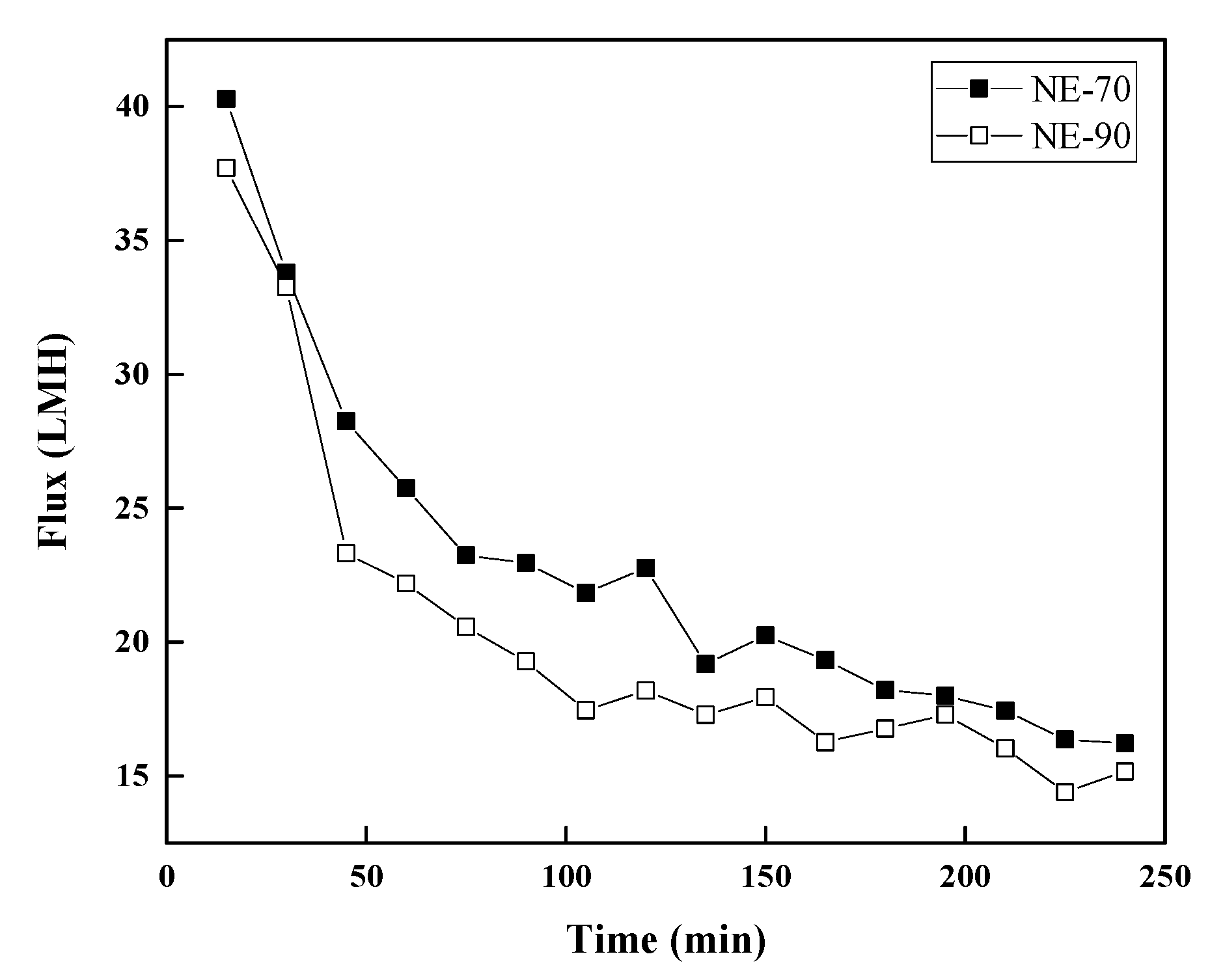

3.3.3. Flux Variation

3.3.4. Comparison of Treatment Methods

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lertsiri, S.; Maungma, R.; Assavanig, A.; Bhumiratana, A. Roles of the Maillard reaction in browning during moromi process of Thai soy sauce. J. Food Process. Preserv. 2001, 25, 149–162. [Google Scholar] [CrossRef]

- Nursten, H.E. The Maillard Reaction: Chemistry, Biochemistry, and Implications; Royal Society of Chemistry: London, UK, 2005. [Google Scholar]

- KOrean Statistical Information Service (KOSIS). Available online: http://kosis.kr/statHtml/statHtml.do?orgId=145&tblId=TX_14503_B016&conn_path=I3 (accessed on 13 April 2018).

- Pooja, R.N. Removal of Organic Matter from Wastewater by Activated Sludge Process—Review. Int. J. Sci. Eng. Technol. Res. 2014, 3, 1260–1263. [Google Scholar]

- Zheng, C.; Zhao, L.; Zhou, X.; Fu, Z.; Li, A. Treatment Technologies for Organic Wastewater; Intech: London, UK, 2013; pp. 249–286. [Google Scholar]

- Pipe-Martin, C. Dissolved organic carbon removal by biological treatment. In Proceedings of the Ninth International Conference on Water Pollution: Modelling, Monitoring, and Management, Alicante, Spain, 9–11 June 2008; pp. 445–452. [Google Scholar]

- Yoon, Y.; Hwang, Y.; Kwon, M.; Jung, Y.; Hwang, T.M.; Kang, J.W. Application of O3 and O3/H2O2 as post-treatment processes for color removal in swine wastewater from a membrane filtration system. J. Ind. Eng. Chem. 2014, 20, 2801–2805. [Google Scholar] [CrossRef]

- Jang, H.H.; Seo, G.T.; Jeong, D.W. Investigation of Oxidation Methods for Waste Soy Sauce Treatment. Int. J. Environ. Res. 2017, 14, 1190. [Google Scholar] [CrossRef] [PubMed]

- Fahmi, M.R.; Abidin, C.Z.A.; Rahmat, N.R. Characteristic of colour and COD removal of azo dye by advanced oxidation process and biological treatment. In Proceedings of the International Conference on Biotechnology and Environment Management, Singapore, 2–4 September 2011; pp. 8–13. [Google Scholar]

- Rollon, A.A.; Dionisio, M.G.G. Treatment of Distillery Wastewater using Combinations of Advanced Oxidation Processes: UV/O3, UV/H2O2 & H2O2/O3. In Proceedings of the 14th International Conference on Environmental Science and Technology, Rhodes, Greece, 3–5 September 2015. [Google Scholar]

- Zheng, Y.; Yu, S.; Shuai, S.; Zhou, Q.; Cheng, Q.; Liu, M.; Gao, C. Color removal and COD reduction of biologically treated textile effluent through submerged filtration using hollow fiber nanofiltration membrane. Desalination 2013, 314, 89–95. [Google Scholar] [CrossRef]

- Abid, M.F.; Zablouk, M.A.; Abid-Alameer, A.M. Experimental study of dye removal from industrial wastewater by membrane technologies of reverse osmosis and nanofiltration. Iranian J. Environ. Health Sci. Eng. 2012, 9, 17. [Google Scholar] [CrossRef] [PubMed]

- Shahata, A.; Omata, T.; Urase, T. Removal of Color from Molasses Wastewater Using Membrane Bioreactor with Acidic Condition. J. Water Environ. Technol. 2013, 11, 539–546. [Google Scholar] [CrossRef] [Green Version]

- Sharma, P.; Joshi, H. MF as Pretreatment of RO for Tertiary Treatment of Biologically Treated Distillery Spentwash. Int. J. Environ. Sci. Technol. 2016, 7, 172. [Google Scholar] [CrossRef]

- Guo, W.D.; Huang, J.P.; Hong, H.S.; Xu, J.; Deng, X. Resolving excitation emission matrix spectroscopy of estuarine CDOM with parallel factor analysis and its application in organic pollution monitoring. J. Environ. Sci. 2010, 31, 1419–1427. [Google Scholar]

- Her, N.; Amy, G.; Foss, D.; Cho, J.; Yoon, Y.; Kosenka, P. Optimization of method for detecting and characterizing NOM by HPLC-size exclusion chromatography with UV and on-line DOC detection. Environ. Sci. Technol. 2002, 36, 1069–1076. [Google Scholar] [CrossRef] [PubMed]

- Kaewsuk, J.; Seo, G.T. A Study on Application of NF Membrane Process for Enhanced Drinking Water Quality. Ph.D. Thesis, Changwon National University, Gyeongsangnam-do, Korea, 2011. [Google Scholar]

- Ministry of Environment. Available online: http://www.me.go.kr/home/web/index/do?menuld=70 (accessed on 10 March 2018).

- Ching, Y.C.; Redzwan, G. Biological Treatment of Fish Processing Saline Wastewater for Reuse as Liquid Fertilizer. Sustainability 2017, 9, 1062. [Google Scholar] [CrossRef]

- Al−Kdasi, A.; Idris, A.; Saed, K.; Guan, C.T. Treatment of textile wastewater by advanced oxidation processes—A review. Glob. Nest J. 2004, 6, 222–230. [Google Scholar]

- Kommineni, S.; Zoeckler, J.; Stocking, A.; Liang, P.S.; Flores, A.; Rodriguez, R.; Brown, T.; Per, R.; Brown, A. 3.0 Advanced Oxidation Processes; Center for Groundwater Restoration and Protection National Water Research Institute: Los Angeles, CA, USA, 2000; pp. 110–208. [Google Scholar]

- Hao, X.; Li, R.; Wang, J.; Yang, X. Numerical simulation of a regenerative thermal oxidizer for volatile organic compounds treatment. Environ. Eng. Res. 2018, 23, 397–405. [Google Scholar] [CrossRef]

- Yuan, R.; Liu, D.; Wang, S.; Zhou, B.; Ma, F. Enhanced photocatalytic oxidation of humic acids using Fe3+-Zn2+ co-doped TiO2: The effects of ions in aqueous solutions. Environ. Eng. Res. 2017, 23, 181–188. [Google Scholar] [CrossRef]

- Cortez, S.; Teixeira, P.; Oliveira, R.; Mota, M. Evaluation of Fenton and ozone-based advanced oxidation processes as mature landfill leachate pre-treatments. J. Environ. Manag. 2011, 92, 749–755. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, G.; He, J.; Wang, D.; Meng, P.; Zeng, M. Optimization and interpretation of O3 and O3/H2O2 oxidation processes to pretreat hydrocortisone pharmaceutical wastewater. Environ. Technol. 2015, 36, 1026–1034. [Google Scholar] [CrossRef] [PubMed]

- Jang, W.J.; Roh, H.S.; Jeong, D. W. An important factor for the water gas shift reaction activity of Cu-loaded cubic Ce0.8Zr0.2O2 catalysts. Environ. Eng. Res. 2018, 23, 339–344. [Google Scholar] [CrossRef]

- Yetilmezsoy, K.; Sakar, S. Improvement of COD and color removal from UASB treated poultry manure wastewater using Fenton’s oxidation. J. Hazard. Mater. 2008, 151, 547–558. [Google Scholar] [CrossRef] [PubMed]

- Yang, D.M.; Yuan, J.M. COD and Color removal from real dyeing wastewater by ozonation. Water Environ. Res. 2016, 88, 403–407. [Google Scholar] [PubMed]

- Kwon, M.; Kye, H.; Jung, Y.; Yoon, Y.; Kang, J.W. Performance characterization and kinetic modeling of ozonation using a new method: ROH, O3 concept. Water Res. 2017, 122, 172–182. [Google Scholar] [CrossRef] [PubMed]

- Kim, K.S.; Kim, S.B.; Kim, J.B.; Jeon, Y.B.; Jang, E.S.; Lee, S.J.; Kim, S.W. Pilot Plant Study for Evaluation of High Concentration Industrial Wastewater by Ozone Oxidation System. Korean Soc. Environ. Eng. 2004, 901–902. [Google Scholar]

- Lee, E.; Lee, H.; Kim, Y.K.; Sohn, K.; Lee, K. Hydrogen peroxide interference in chemical oxygen demand during ozone based advanced oxidation of anaerobically digested livestock wastewater. Int. J. Environ. Sci. Technol. 2011, 8, 381–388. [Google Scholar] [CrossRef] [Green Version]

- Albrektienė, R.; Rimeika, M.; Zalieckienė, E.; Šaulys, V.; Zagorskis, A. Determination of organic matter by UV absorption in the ground water. J. Environ. Eng. Landsc. 2012, 20, 163–167. [Google Scholar] [CrossRef]

- Kaewsuk, J.; Seo, G. T. Verification of NOM removal in MIEX−NF system for advanced water treatment. Sep. Purif. Technol. 2011, 80, 11–19. [Google Scholar] [CrossRef]

- Hassan, A.R.; Rozali, S.; Safari, N.H.M.; Besar, B.H. The roles of polyethersulfone and polyethylene glycol additive on nanofiltration of dyes and membrane morphologies. Environ. Eng. Res. 2018, 23, 316–322. [Google Scholar] [CrossRef]

| Type | Column Packing | Particle Size (µm) | Separation Range (Da) | Column Size (cm) |

|---|---|---|---|---|

| Hydroxylated organic | Protein PAK 125 | 10 | 1000–30,000 | 0.78 × 30 |

| Polyacrylamide | TSK-50S | 30 | <5 × 106 | 2 × 25 |

| Silica | Bio-Gel P-6 | 90–180 | 1000–6000 | 0.5 × 90 |

| Parameter | Value |

|---|---|

| pH | 11 |

| Applied O3 conc. (mg L−1) | 50 |

| H2O2/O3 ratio (wt/wt) | 0.1, 0.3, 0.5, 0.7, and 0.9 |

| Reaction time (min) | 30 |

| Mixing speed (rpm) | 150 |

| Sample volume (mL) | 500 |

| Parameter | 1st Experiment | 2nd Experiment |

|---|---|---|

| Na2S2O3 conc. | 0.1 | |

| Na2S2O3 consumption | 1.4 | 2.9 |

| Vent O3 conc. (mg L−1 min−1) | 1.12 | 2.32 |

| Membrane | Material | MWCO (Da) | Zeta Potential at pH 7 (mV) | Contact Angle (°) | Roughness (nm) |

|---|---|---|---|---|---|

| NE-70 | Sulfonated polyethersulfone | 350 | –47.2 | 22.6 ± 1.9 | 8.69 |

| NE-90 | Meta-phenylene diamine | 210 | –38.7 | 41.5 ± 3.7 | 48 |

| Parameter | Value |

|---|---|

| pH | 4.4 ± 0.2 |

| 1 CODcr (g/L) | 231.5 ± 0.9 |

| 2 BOD5 (g/L) | 129.4 ± 6.6 |

| 3 TN (g/L) | 10.4 ± 0.7 |

| 4 TP (g/L) | 2.8 ± 0.3 |

| 5 TOC (g/L) | 57.6 ± 2.7 |

| Salinity (%) | 16.4 ± 0.2 |

| Color (TCU) | 3810 ± 130 |

| Classification | Type | Amount of Removal (Removal Efficiency) | |

|---|---|---|---|

| Color (TCU) | COD (g/L) | ||

| Treated waste soy sauce (Removal efficiency) | NE-70 | 2908.8 (80.8%) | 173.3 (79.6%) |

| NE-90 | 2926.8 (81.3%) | 175.7 (80.7%) | |

| Parameter | Amount of Removal (Removal Efficiency) | |

|---|---|---|

| Color (TCU) | COD (g/L) | |

| O3 [8] | 1333.8 (34.2%) | 63.3 (27.4%) |

| H2O2/O3 process | 1857.6 (51.6%) | 73.6 (33.8%) |

| NF (NE-70) | 2908.8 (80.8%) | 173.3 (79.6%) |

| NF & O3 | 3344.4 (92.9%) | 206.2 (94.7%) |

| NF & H2O2/O3 process | 3531.6 (98.1%) | 213.8 (98.2%) |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jang, H.-H.; Seo, G.-T.; Jeong, D.-W. Advanced Oxidation Processes and Nanofiltration to Reduce the Color and Chemical Oxygen Demand of Waste Soy Sauce. Sustainability 2018, 10, 2929. https://doi.org/10.3390/su10082929

Jang H-H, Seo G-T, Jeong D-W. Advanced Oxidation Processes and Nanofiltration to Reduce the Color and Chemical Oxygen Demand of Waste Soy Sauce. Sustainability. 2018; 10(8):2929. https://doi.org/10.3390/su10082929

Chicago/Turabian StyleJang, Hyun-Hee, Gyu-Tae Seo, and Dae-Woon Jeong. 2018. "Advanced Oxidation Processes and Nanofiltration to Reduce the Color and Chemical Oxygen Demand of Waste Soy Sauce" Sustainability 10, no. 8: 2929. https://doi.org/10.3390/su10082929