1. Introduction

Companies are at the core of most of the environmental impacts caused by society [

1], contributing to generating impacts across the entire life cycle, from raw material extraction and manufacturing, through to distribution, product use and end-of-use/end-of-life.

Small and medium enterprises (SMEs) play an important role in this context, as they account for the vast majority of existing companies [

2]. SMEs generates more than half of the total value added in Europe [

3] through the manufacturing and delivery of products and services. Furthermore, SMEs still face a number of difficulties for integrating sustainability into their core businesses processes, being still largely reactive to environmental issues [

2].

Currently, a large amount of concepts and tools are available to support the integration of sustainability into companies’ core business. Eco-innovation is seen as one of the key approaches for SMEs [

4,

5], due to its potential to enhance the SMEs green competitiveness’ through the development of innovative products, processes and organizational capabilities [

3,

5,

6].

The main goal of this paper is to present research on the development of a screening tool to identify and evaluate SMEs’ potential for eco-innovation, with a special focus on industrial symbiosis and green business models aspects. The tool has been developed in the context of the Danish “Residue to Resource” project, and carried out in collaboration between the Danish Symbiosis Center, the Technical University of Denmark and six municipalities.

From a theoretical point of view, our aim is to advance the state-of-the-art by proposing a systematic methodology that enables the screening of the eco-innovation potential in SMEs, at a company-level, by using both quantitative and semi-quantitative measures. Furthermore, we aim to advance theory by combining eco-innovation, industrial symbiosis and green business models simultaneously, supported by a readiness assessment. Lastly, by focusing on the municipalities as the main drivers for the evaluation, we aim to provide a deeper understanding of their potential as eco-innovation agents.

The screening tool has been applied across 108 SMEs from a number of sectors, including service industries, distributed in six municipalities in Denmark characterized for the most part by a relatively low level of industrialization. This paper focuses on the approach employed for the development and enhancement of the tool. The results of the application of the tool i.e., the potential of the studied Danish SMES for engaging in eco-innovation are not within the scope of this paper.

The paper is structured as follows. In the next section, the theoretical background for the research is presented, followed by the methodology employed for the development of the screening tool.

Section 4 describes the main characteristics, features and indicators of the tool. In

Section 5, a discussion of the contributions and implications of the research are provided. Finally, the concluding remarks and next steps are presented in

Section 6.

2. Theoretical Background

In this section, the key theoretical background employed for the development of the research is presented, focusing on three main areas: (1) key theoretical concepts underpinning the research; (2) eco-innovation implementation in SMEs, with a focus on industrial symbiosis and green business models; and (3) tools to measure the eco-innovation potential of companies.

2.1. Key Theoretical Concepts

The main underpinning theoretical concepts for the development of this research are four-fold: (1) sustainable development; (2) eco-innovation; (3) industrial symbiosis; and (4) green business models.

Sustainable development is defined by the Brundtland report as a development that “meets the needs of the present without compromising the ability of future generations to meet their own needs” [

7]. Since sustainable development has been proposed as a concept, in 1987, a number of attempts have been developed to make it applicable to different stakeholders, including governmental bodies, non-governmental organizations and companies [

8,

9]. Eco-innovation is seen as one of the most prominent approaches targeted at supporting companies towards sustainable development [

4].

According to the Eco-innovation Action Plan [

10], eco-innovation is defined as “any form of innovation resulting in or aiming at significant and demonstrable progress towards the goal of sustainable development, through reducing impacts on the environment, enhancing resilience to environmental pressures, or achieving a more efficient and responsible use of natural resources”. In the scientific literature, eco-innovation can be defined as “all efforts from relevant actors that introduce, develop, and apply new ideas, behaviors, products and processes and contribute to reducing environmental burdens or ecologically specified sustainability targets” [

9].

Considered a systemic eco-innovation approach [

11,

12], industrial symbiosis is a concept that promotes the engagement of communities of companies in improving their economic and environmental performance through collaborative strategies [

13]. Industrial symbiosis has a high potential to create environmental improvements at the regional and local levels [

14], through resource exchanges (incl. solid materials, energy, water) among collocated companies, where one company’s residues become another (local) company’s resource, hence representing a collective approach towards sustainability [

15,

16]. Ultimately, industrial symbiosis potentially enables an enhancement of resource efficiency, by producing more value from the same resources [

17].

More recently, eco-innovation has been defined by the United Nations Environmental Program (UN Environment) as “the development and application of a business model, shaped by a new business strategy that incorporates sustainability throughout all business operations based on life cycle thinking and in cooperation with partners across the value chain” [

4], which brings an additional important strategic element to the definition, introducing business model innovation as a key concept to it. OECD (Organisation for Economic Co-operation and Development) considers business models as one of the key elements in determining the success of eco-innovation initiatives [

11]. Business models are defined as “the rationale of how an organization creates, delivers and captures economic, social and other forms of values” [

18]. Green business models, in turn, are defined as business models that entail enhanced environmental performance—which can bring radical innovations to reality.

Figure 1 schematically illustrates the links between the aforementioned theoretical concepts. Sustainability is seen as the ultimate goal, which can be achieved by Sustainable Development initiatives. Eco-innovation is one of the possible approaches for Sustainable Development, and can be defined by two main elements: industrial symbiosis (as a systemic eco-innovation model at the operational level) and green business models (as a strategic eco-innovation approach).

It is important to note that the figure focuses on representing the links between the key theoretical concepts employed in this research, and it does not aim to be, by any means, a comprehensive overview of all concepts related to sustainability.

2.2. Implementation of Eco-Innovation in SMEs

The critical determinants for the enhancement of eco-innovation activities within SMEs are related to (i) establishment of supporting policies; (ii) enhanced perception of its strategic importance; (iii) technological advisory support; (iv) methods for product and process eco-innovation; and (v) collaboration within supply networks [

19].

Eco-innovation can be applied in three main levels: (a) business strategy; (b) business model; and (c) operations [

4], and is used within a multitude of research areas [

5], including industrial ecology and industrial symbiosis [

3,

15]; cleaner production [

20,

21]; life cycle assessment [

22]; sustainable manufacturing [

23,

24]; ecodesign [

25,

26]; and circular economy [

27,

28]. Circular economy aims at decoupling value creation from resource consumption, based on the development of solutions that are regenerative by design [

28]. Circular Economy can be seen as an umbrella concept that is built upon by a number of other concepts, such as industrial symbiosis and life cycle thinking [

29].

Despite its potential benefits, the adoption of Industrial Symbiosis approaches are generally limited worldwide; however, they are gaining much attention lately with the rise of the circular economy agenda. When it comes to SMEs, experiences are still very few [

3]. Characterized by relatively small flows, SMEs often present difficulties to handle the costs associated in establishing an industrial symbiosis initiative as well as regularly collecting and exchanging data regarding their input/output resource flows [

30].

Barriers for a larger uptake of industrial symbiosis are related to (1) commitment to sustainable development; (2) access to detailed qualitative/quantitative data on residue streams; (3) cooperation and trust among companies; (4) technical feasibility; (5) regulatory framework; (6) limited community awareness; and (7) lack of a clear business case [

14]. In this context, public administration bodies seem to play a key role in enabling enhanced eco-innovative initiatives [

31].

Even though consolidated to a high degree in the so-called industrial symbiosis parks or eco-industrial parks [

17,

32], the establishment of symbiotic relationships among SMEs not located within industrial parks is still limited—despite their relatively large proximity and high collaboration potential [

33]. Furthermore, recent definitions of industrial symbiosis highlight that the concept is not necessarily geographically related, but rooted in innovation and networks for knowledge sharing, resulting in improved efficiency in the use of materials [

34].

Regional innovation networks are seen as enablers for the SMEs engagement in industrial symbiosis [

35]. The identification of industrial symbiosis across neighboring SMEs within a given region can enable a higher uptake of eco-innovation, leading to a minimization of their environmental negative impacts, and enabling the establishment of the so-called green business models. In order to enable such initiatives, the identification of the SMEs’ potential for engaging in eco-innovation initiatives should be further explored. While eco-innovation can be measured at different levels (e.g., company, sectoral, cluster/park, regional, national and international) [

36], limited efforts could be found dealing with the measurement of the eco-innovation potential at the company level.

2.3. Tools for Measuring the Eco-Innovation Potential

In order to identify the state-of-the-art of existing tools for measuring the eco-innovation potential in companies, a systematic literature review (SLR) was carried out.

The SLR focused on the identification of related eco-innovation tools, using Scopus as the main database, due to its relevance to the topic. The employed search strings encompasses (TITLE-ABS-KEY (“tool” and “eco-innovation”) and (TITLE-ABS-KEY (“tool” and “industrial” and “symbiosis”). The searches, last updated in June 2018 (with no timeframe delimitations), resulted in a total amount of 253 studies, which were subsequently checked in regards to their scope and focus.

In order to further filter the identified studies, the adopted exclusion criteria was “the study should present/propose/analyze a tool that aims to measure the potential in implementing eco-innovation in companies”. The focus was expanded in relation to SMEs to all kinds of companies, in order to enable a broader understanding of the field. The exclusion criteria were applied in successive filters, which focused on the title/abstract; introduction/conclusion and finally the full paper, whenever necessary. Eventually, 76 papers were selected for further analysis—resulting in the identification of a number of eco-innovation tools.

The majority of the identified eco-innovation tools focus at the product level. Some examples of eco-innovation tools at the product level includes: creativity and ideation [

37,

38,

39,

40,

41,

42], Life Cycle Assessment and environmental evaluation [

43,

44], ecodesign [

45,

46,

47,

48], material selection [

49] and biomimetic design [

50]). In total, 13 tools linked with the company level were identified.

Table 1 presents the identified tools, with a description of their main goal and link with the key theoretical concepts of eco-innovation (EI); industrial symbiosis (IS) and green business models (BM).

A more in-depth analysis of

Table 1 enables the identification of interesting highlights about the explored field:

- (i)

Strong predominance of industrial symbiosis tools (10 out of the 13 identified tools contain IS elements), focused on the exchange of material and energy flows. Only one tool is related to business models (through a maturity grid), while five tools are focused on eco-innovation;

- (ii)

Limited number of multidisciplinary tools—only two tools combine industrial symbiosis and eco-innovation elements (at the network and regional levels); and only one tool combines industrial symbiosis and business models (focused on regional industrial collaboration);

- (iii)

Most of the identified industrial symbiosis tools focus on the development of knowledge-based platforms and databases for enabling the identification of potential symbiotic synergies among companies, rather than at understanding the company level potential;

- (iv)

Most of the tools are applied at a network/supply chain level (or product level)—none of the identified tools focus at the company level, which can be seen as an important gap in the current state-of-the-art.

In addition to the tools presented in

Table 1, a number of industrial symbiosis optimization tools were identified [

61,

62,

63], as well as policy-related tools [

64,

65]. Furthermore, many recent publications are directly highlighting the link between industrial symbiosis and circular economy [

59,

66,

67,

68], an emerging concept. These publications focus on developing tools to facilitate resource exchange among companies [

59], a state-of-the-art review linking Circular Economy with industrial symbiosis and related concepts [

67] and exploring non-technical barriers and drivers for Circular Economy implementation by means of industrial symbiosis [

68].

Overall, the literature review highlights the opportunity for developing eco-innovation tools that can support the identification of the implementation potential at the company level, linking industrial symbiosis and business model innovation in an eco-innovation context—which is aligned with the goal of this research presented in

Section 1.

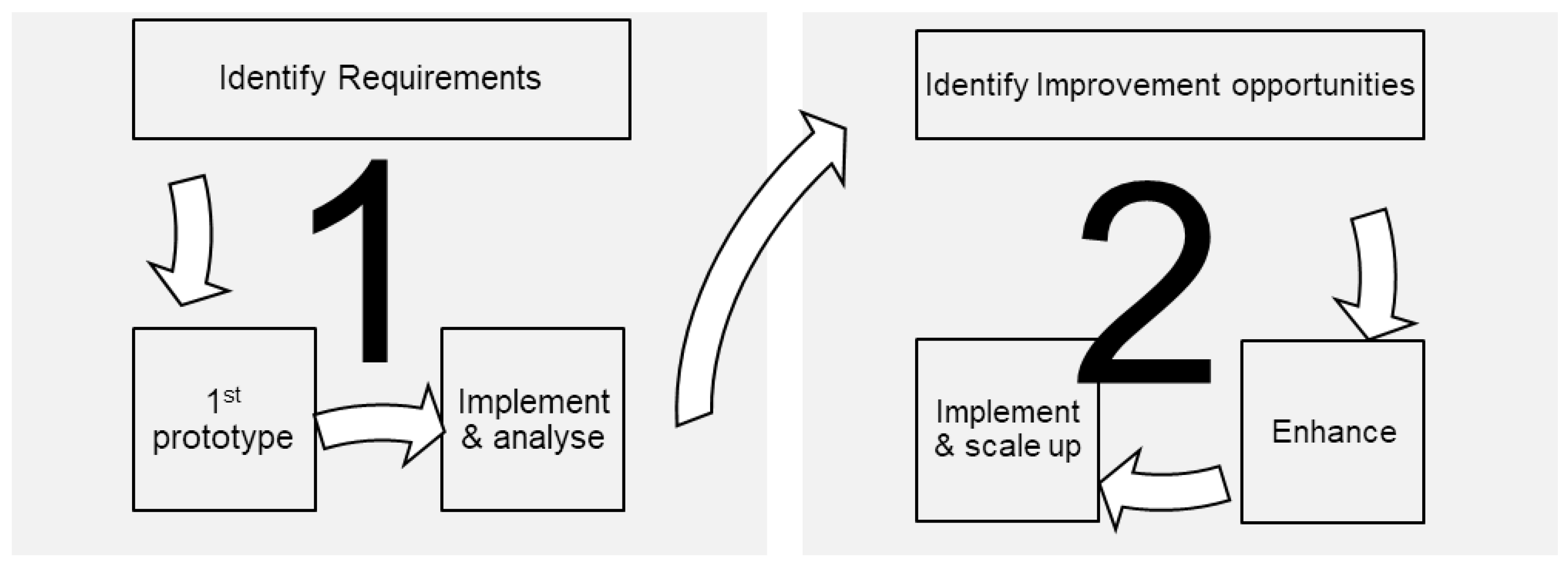

3. Methodology

In order to accomplish the aforementioned goal to develop a screening tool to identify and evaluate the potential of SMEs for eco-innovation, an action research [

69] approach based on two development cycles was employed (

Figure 2).

Action research is a research methodology approach characterized by a problem solving focus, which is applicable to understand, plan and implement changes in organizations [

69]. Action research employs a rigorous scientific approach to study the resolution of key organizational issues together and with the participation of the key involved stakeholders [

69]. One of the main goals of action research is to make more effective action at the same time that scientific and theoretical knowledge is created. According to Reference [

70], action research is widely recognized as an effective way of accomplishing productive and effective outcomes within business and industry, which are scientifically based and practically sound. The two action research cycles carried out in this research project are described in

Section 3.1 and

Section 3.2, from a methodological point of view. The results are presented in

Section 4.

3.1. Cycle 1: Development and Test of the Screening Prototype

The first action research cycle focused on the development of the first prototype version of the screening tool, and was composed of three main steps (

Section 3.1.1,

Section 3.1.2 and

Section 3.1.3).

3.1.1. Step 1.1. Requirements Identification

In order to be able to understand the key features that the screening tool would need to have to enable the screening of SMEs potential for eco-innovation (with focus on industrial symbiosis and green business models), an in-depth identification of requirements was carried out.

The initial requirements list was elaborated based on a literature review of key features to be considered when implementing industrial symbiosis and eco-innovation in SMEs. The identification of requirements was carried out in three main areas: (1) content (i.e., what kind of data would be required for the evaluation of readiness for industrial symbiosis and eco-innovation), (2) procedure (i.e., the steps to be taken for the performance of the assessment) and (3) analysis (i.e., how the collected data would be analyzed to provide an indication of the readiness level of the SMEs).

Subsequently, the list was used as a framework for the requirements consolidation based on a workshop involving key stakeholders in the project, the Danish Symbiosis Center and a number of municipalities. The workshop took ca. 2.5 h, and resulted in a consensus among the stakeholders regarding the key elements that the screening tool would need to consider (presented in

Section 4.1.1).

3.1.2. Step 1.2. Development of the First Prototype

Based on the identified requirements and a literature review of key defining factors for eco-innovation, a first version of the screening tool was developed, bringing together the key elements that would enable the understanding of the potential of SMEs (

Section 4.1.1 and

Section 4.1.2).

Special focus was paid to the development of a quick-assessment tool with information that is usually readily available in the SMEs, and would at the same time provide a good understanding of their potential for innovating. Furthermore, the tool was developed in a way to be easy to use, both for data collection and data analysis.

Internal validations of the prototype were carried out within the project working group, and aimed at providing additional consolidation and refinement of the tool before its pilot implementation. In addition to the content, different forms and means for the delivery of the tool (incl. paper-based, web or desktop-based assessments) were tested out. The key elements of the prototype are presented in

Section 4.1.2.

3.1.3. Step 1.3. Implementation and Analysis of the Results

In order to enable the six engaged municipalities to perform the readiness assessment in the SMEs, a complete training regarding the screening tool and its main features was performed, so to ensure that there would be a good understanding regarding how to engage the SMEs in the assessment. In addition to a face-to-face run-through the tool, a detailed description of the different steps and types of required information were provided. Furthermore, specific knowledge transfer sessions were carried out to enable an enhanced literacy of the municipalities related to both industrial symbiosis and eco-innovation as well as business model development. Moreover, specific guidance was provided in relation to the capture of potential pitfalls with the use of the tool, looking at the feedback for its enhancement in the second action research cycle.

3.2. Cycle 2: Improvement and Scale-Up of the Enhanced Screening Tool

The second action research cycle focused on the enhancement of the screening tool based on the observed improvement opportunities from the first cycle; the development of the enhanced screening tool and its subsequent deployment and scale-up in the project. Three main steps were carried out in the second cycle, as the following section describes.

3.2.1. Step 2.1. Identification and Prioritization of Improvement Opportunities

Improvement opportunities for the further development of the screening tool were identified both from the researchers’ observation of the use of the screening tool by the Danish Symbiosis Center and municipalities (by analyzing its application in practice during a number of evaluations), and also from the feedback received from the municipalities through feedback sessions (after the application in a number of companies has taken place). The feedback sessions were structured around the key elements of the screening tool (e.g., company characterization and readiness areas), based on three main perspectives (content, procedure and analysis)—following a semi-structure questionnaire.

In order to further develop the second version of the screening tool, the identified improvement opportunities in step 1.3 (cycle 1) were prioritized based on two main criteria:

Relevance: The relevance of the identified improvement opportunities was evaluated in light of the initial requirements list and the project context (goals and scope). This was important to ensure that the identified improvement opportunities were not contradictory to the goals, scope and requirements defined in the project.

Feasibility: The feasibility was evaluated in light of their implementation requirements within the timeframe of the project, and considering the available budget. The main goal was to ensure the implementation of the improvement opportunities that were possible within the context of the project, delivering the expected results to the key involved stakeholders.

The prioritized list of improvement opportunities was validated by the key project stakeholders and municipalities to ensure agreement on the changes to be implemented—and alignment on the next steps of the project. The identified and prioritized improvement opportunities are presented in

Section 4.1.3.

3.2.2. Step 2.2. Enhancement of the Screening Tool

In order to be able to enhance the screening tool, a morphological matrix was developed to support the identification of the key alternative solutions that could be implemented to address each one of the prioritized improvement opportunities. Subsequently, alternative concepts were developed (by the combination of the key alternative solutions) and prioritized for implementation, for the development of the enhanced version of the tool. The enhanced version of the screening tool (presented in

Section 4.2.2) was then evaluated by the municipalities and the Danish Symbiosis Center, and small adjustments were made based on their feedbacks before proceeding to the implementation by the other SMEs involved in the project.

3.2.3. Step 2.3. Implementation and Scale-Up

The implementation of the enhanced version of the tool was carried out by the six municipalities, the Danish Symbiosis Center and DTU, involving 108 SMEs in the Zealand region, in Denmark. Based on the screenings, the companies with the highest potential for industrial symbiosis and eco-innovation were selected to engage in the further steps of the project, which included the development of technical plans by associated consultancies (50 companies), the development of eco-innovative business models (30 companies) and the development of symbiotic collaborations (10 companies).

4. Results

The results of the action research employed for the development of the screening tool to measure the SMEs potential for eco-innovation are presented in this section, for each one of the steps presented in the methodology section.

4.1. Cycle 1: Development and Test of the Screening Prototype

4.1.1. Requirements for the Development of the Screening Tool

The requirements for the development of the screening tool were divided into three main areas: (1) screening content; (2) screening procedure; and (3) screening analysis. The consolidated requirements for each one of these areas are presented as following:

- (1)

Screening content—“What should be screened?” (the key factors are described in

Section 4.1.2, with an indication of the supporting literature.)

Characterization questions: Questions used to characterize the SMEs performing the screening should include registration information (e.g., name, address, CVR, size, etc.); financial information (e.g., revenue, costs for waste handling, etc.); certification according to management systems (e.g., ISO 14001 (environmental management systems), ISO 9001 (quality management systems), OHSAS 18001 (focused on occupational health and safety assessment), etc.); key manufacturing processes and services; overview of manufactured products; and previous experience with industrial symbiosis.

Business model questions: In order to be able to support the identification of opportunities for green business models and eco-innovation, the key business areas to be focused on included value proposition, value chain and risks, customers, revenue, channels, key activities, key partners and suppliers, costs, key resources and willingness to take risks.

Readiness questions: In order to be able to measure readiness, a number of areas should be included in the screening tool related to regulatory context, raw material and waste handling practices, technical feasibility (in terms of quality and quantity), capital feasibility (in terms of the required investments), payback period (short, medium and long-terms), potential for virgin resource use avoidance, potential for waste reuse/recycling, willingness to cooperate and share information, willingness to take risks, and practices for sustainable development.

- (2)

Screening procedure—“How should we perform the screening?”

Time for screening: The time required for the screening (including data collection and consolidation) should be between 6 and 8 hours, which corresponds to 1 day of work at each one of the engaged SMEs.

Type of assessment: The assessment should be performed by third parties (i.e., the engaged municipalities), and should not include a self-assessment module for the SMEs. The municipalities are responsible for the quality of the collected data and the consistency of the results.

Organizations carrying out the screening process: The primary responsible organization to perform the screening are the municipalities, but support should be expected from researchers and staff from the other two partners in the project.

Knowledge level of the person carrying out the screening: The screening tool should be developed considering an intermediate knowledge about industrial symbiosis, and limited knowledge about eco-innovation and green business models.

Number of people involved for the screening in the SMEs: 5–10 people from the SMEs are expected to be engaged in the screening process, which brings the possibility of engaging people from different functions and hierarchical levels (incl. managing director and strategy, environment experts/responsible, production manager, finance manager and supply chain/logistics).

Mode of assessment: The screening tool should be developed considering a combination of interviews (or group interviews), questionnaires (to support data collection prior to the screening process), and data collection on site.

Tool for screening: A computer-based tool was selected (e.g., spreadsheet or text document), so to enable an offline assessment and to make sure that all SMEs would have access to the screening tool.

- (3)

Screening analysis—“How to analyze and communicate the results?”

Time required for the analysis of the screening results: the analysis should take 4–6 h per SME, to be performed in collaboration between the key project partners and led by the municipalities.

Communication of the results: Should contain both a single score with the readiness score, and an executive summary of the main conclusions.

In addition to providing the basic requirements for the development of the screening tool, the requirements identification also provides a structured approach for identifying the needs of multiple stakeholders, with a clear structure that can be used for the development of a large range of different tools and approaches, focusing on three basic elements: the tool content, the procedure for carrying out the evaluation, and the analysis of the results.

4.1.2. The First Screening Prototype

The first prototype of the screening tool was developed to address all the aforementioned requirements in relation to the screening content, procedure and analysis, with elements based on a literature review on readiness, industrial symbiosis and eco-innovation.

The screening tool was structured in four complementary blocks: (1) Company characterization; (2) analysis of input & output flows; (3) description of the business model; and (4) readiness areas, preceded by an overall introduction (Block 0). Each block contains a description of the goal, steps for application, stakeholders to be engaged, and data collection types. The screening tool was developed in a spreadsheet, with each block relating to one sheet.

Block 0: Introduction

Block 0 presents an overall introduction to the screening tool, with detailed information about its main elements and characteristics. It includes the following elements: goal of the tool (i.e., to screen the SMEs potential for industrial symbiosis and eco-innovation); the confidentiality issues (i.e., data use and ownership) and the overall tool structure (with the four main blocks).

Furthermore, a detailed description of the process for the screening is provided, with the indication of the key stakeholders to be engaged in the screened SMEs (

Table 2).

In all the different blocks, the defined procedure for the use of the screening tool comprises four main tasks, as described below:

Task 1: The municipality is responsible for initial data collection through databases, and knowledge from previous collaborations/engagements with the SME;

Task 2: The municipality carries out site visit and face-to-face interviews with key stakeholders in the company, aiming to collect information for all the four screening blocks;

Task 3: The company is then responsible for checking the collected data and adding additional information, if necessary.

Task 4: Municipalities, the symbiosis center and the university partners validate the screening assessment and develop a report for the company, regarding their potential for industrial symbiosis and eco-innovation.

Block 1: Company characterization

The main goal of this block is to characterize the company, in relation to registration data, key products/manufacturing processes, and previous experience on eco-innovation and industrial symbiosis related topics. Key collected data includes:

Company information: Includes the company name, address, municipality, registration numbers, sector/branch and number of employees.

Contact information: Collects information from the key stakeholders to be engaged in the company (

Table 1), including name, title/position, telephone number and email.

Financial information: Includes financial information from the company for the past 2 years, related to revenue, income and profit.

Manufacturing sites: Includes information of other manufacturing sites that the company might have (incl. address, number of employees, branch, manufactured products and key manufacturing processes).

Previous experience: Open ended question, which aims to have an initial high level understanding of the company’s experience with sustainability-related topics such as industrial symbiosis, green business models, environmentally friendly design, Life Cycle Assessment, cleaner production, environmental management systems, energy management, green branding, etc.

In addition to supporting the characterization of the companies, this block also enables future comparisons and correlation studies, which can be used to characterize the screened companies.

Block 3: Description of the Business Model

This block is intended to describe the company’s current business model, in order to identify opportunities for the development of green business models. Due to the large dissemination and uptake by industry, the business model canvas was selected as the key framework behind this block and adapted in a slightly simplified form. Furthermore, a number of detailed guiding questions were developed to support the municipalities to obtain data from the SMEs, for each one of the dimensions (

Table 3). The questions were based on the traditional literature of business model innovation, with a strong foundation on the business model canvas and business model generation approach [

18].

Furthermore, additional fields were available for reflections on the current business model by the SMEs and municipalities, with qualitative comments on additional key observations.

Block 4: Readiness Areas

The purpose of this block is to identify the company’s readiness to be involved in eco-innovation and industrial symbiosis development projects, from a varied number of perspectives. In total, 10 readiness areas were evaluated following a 10-point Likert-scale (1–3 = low; 4–7 = medium; 8–10 = high) (

Table 4). The Likert-scale is an ordinal scale, which was selected as a measuring instrument due to the possibility of representing qualitative properties based on a ranking of their relative importance/strength [

71]. Furthermore, the Likert-scale allows the definition of relations within and across variables in terms of equalities, as well as inequalities—which would allow the comparison across categories and within companies.

Table 4 presents a consolidated review of key readiness dimensions in the literature for the implementation of eco-innovation, industrial symbiosis and green business models. In addition to providing a contribution to the state-of-the-art on the field, the readiness dimensions can be employed to further advance the theoretical understanding of the companies’ readiness for eco-innovation, independent from the application of the full screening tool.

In addition to that, there was an additional field for the company/municipality to add additional reflections and comments in order to provide more qualitative data for the scores assigned to each one of the questions. By having the possibility of adding a qualitative assessment of the provided answers, the tool aims at bringing a higher reliability in relation to the obtained results as it allows for further reflections on the proposed answers (both by the SMEs and municipalities), and minimization of the potential bias related to the assessment. Furthermore, because the proposed tool is targeted at screening the potential of SMEs, it is important to ensure the tool’s ability to process qualitative data. A similar approach has been adopted for other similar questions on the tool, both in the pilot version and also in the enhanced version of the screening tool (

Section 4.2), after a positive feedback from its application.

In order to be able to capture the municipalities’ reflections on the screening and the potential of the assessed SME, a number of additional guiding questions were suggested:

Do you see opportunities for internal resource optimization in the company?

Do you see opportunities for green business models innovation?

Do you see opportunities for industrial symbiosis? With which input/output flows and with whom?

Finally, the companies’ experience and interest in joining in network activities was explored.

4.1.3. Implementation of the Tool and Analysis of the Results

During the pilot phase, the screening tool was used by the six municipalities in a total amount of 21 SMEs, from a varied number of sectors (incl. food processing, metal-mechanic, furniture, plastics, etc.). In order to enable the analysis of the results in a systematic and consistent way, so the companies’ potential could be compared in future benchmarking studies, an additional approach was developed for the analysis of the results.

A customized report was developed for each company, containing background information about the project and evaluation methodology, key collected company data, the current business model, overview of input/output flows, and a readiness assessment. The overall potential was then summarized in a unique normalized score, ranging from 0–100.

As previously mentioned, our focus in this paper is on the development of the tool itself—the analysis of the results from the actual screenings are out of the scope of this paper.

4.2. Cycle 2: Improvement and Scale-Up of the Enhanced Screening Tool

4.2.1. Identification and Prioritization of Improvement Opportunities

The implementation of the screening tool by the municipalities and SMEs provided interesting insights related to the tool content, the procedure for carrying out the assessment and the analysis of the results. By following the methodology described in

Section 3.2.1, a number of key learnings and improvement opportunities were consolidated. The main key learnings and improvement opportunities related to the pilot application of the screening tool are presented in

Table 5.

Overall, it was found the need to have more close-ended questions, similar to the readiness questions, in order to be able to have a more objective analysis of the results, to allow for a fair comparison among the screened companies, and their selection in the subsequent steps of the project. Despite being specific for the developed screening tool, these learnings can also be considered for the development of similar tools, which are focused on SMEs and are applied in a similar context to the one used in this research.

Furthermore, it is important to mention the initial resistance of the SMEs to engage with the municipalities in a joint project. Because of the traditional relationship of command-and-control between the municipalities and the SMEs, the companies had a difficult time understanding the role of the municipalities in supporting them to identify opportunities for industrial symbiosis and eco-innovation. Eventually, the barriers were minimized and a good level of collaboration could be experienced.

4.2.2. Enhanced Screening Tool

On the basis of the application of the screening prototype tool and the identification of a number of improvement opportunities, the screening tool was further developed and enhanced. The key implemented enhancements of the screening tool for each block are described in this sub-section.

Block 1: Company Characterization

In order to make the assessment more effective and dynamic, the open-ended question related to experience with sustainability-related topics was eliminated from the new version of the tool. Other than that, no other significant changes were implemented, except for a slight change in the layout. Due to the importance of the financial data for the characterization of the screened SMEs, the project team decided to keep this field in the tool.

Sub-Block 2.1: Preliminary Assessment

The preliminary assessment aims at (1) giving an indication of the company’s general perception of the commercial significance of resource consumption for the company today; (2) understand what business significance resource-saving measures could be expected for the company in the future; as well as (3) to provide an indication of which of the resource streams the company would likely prioritize.

The purpose of the questions in the preliminary assessment are to find out the most significant resource flows (i.e., material, energy or water) for the company. A 5-point Likert scale was employed to support this evaluation: (1) very small importance; (2) small importance; (3) neither small or large importance; (4) large importance; (5) very large importance. The questions are presented in

Table 6.

In addition to the scores, the municipalities/SMEs can also add additional comments to each one of the questions, in order to justify their importance evaluation.

Sub-Block 2.2: Mapping Energy Streams

The mapping of the energy streams is sub-divided into four main areas: (1) energy sources; (2) energy consumption; (3) energy losses; and (4) evaluation of opportunities (

Table 7).

Sub-Block 2.3: Mapping Water Streams

Similarly to sub-block 2.2, the mapping of water streams is sub-divided in a number of main areas: (1) water sources; (2) water consumption; (3) waste water; (4) water discharge; and (5) evaluation of opportunities (

Table 8).

Sub-Block 2.4: Mapping Material Streams

The mapping of material streams is sub-divided into the following main areas: (1) material sources; (2) material consumption; (3) solid waste; (4) evaluation of opportunities for material inputs; and (5) evaluation of opportunities for material outputs (

Table 9).

By enabling the analysis of Input & Output flows through a combination of quantitative measures (related to the flows) and qualitative measures (related to the opportunities for each evaluated area), the assessment enables a richer and more comprehensive evaluation of the potential for industrial symbiosis, which can help to overcome the challenges related to data availability and data quality, which is common in SMEs, and is also present in large organizations.

Furthermore, in order to have a better flow of the collected data, the order of the blocks were changed in the new version of the tool. Block 2 (Analysis of Input & Output flows) and Block 3 (Description of the business model) changed orders, in a way to ensure that the business model data would fit with the overall company characterization.

Block 3: Description of the Business Model

In order to make the characterization of the current business model clearer for both the municipalities and SMEs, examples on how to fill in the business model information were added as a complement to the guiding questions already incorporated in the first prototype version.

Furthermore, in addition to the qualitative description of the current business model, semi-quantitative questions were added to support the identification of the perception of the SMEs in relation to the opportunities to enhance the different business model dimensions. The questions are evaluated by the indication of the agreement level in relation to nine main affirmatives (5-point Likert-scale, from 1 (strongly disagree) to 5 (strongly agree)).

The affirmations (

Table 10) were deployed from the business model’s key factors and references presented in

Table 2, and phrased in a way to be easily understood by the engaged SMEs, considering their knowledge level in relation to the explored concepts.

The word “greener” was employed in order to enable an easier understanding by the companies, and can be understood in this project as “eco-innovation and industrial symbiosis” activities. In addition to the close-ended questions, comment fields for the more qualitative answers were also added in the enhanced version of the tool.

By combining the business model’s elements into guiding affirmations, the proposed approach enables a streamlined approach for capturing the potential for enhanced sustainability performance in SMEs, with a simple and easily understandable language, further advancing the state-of-the-art in the business model innovation literature.

Block 4: Readiness Areas

In order to ensure alignment with the 5-point Likert-scale employed in the other blocks, it has been decided to adapt the same scale for the readiness areas in Block 4. Furthermore, the 10 guiding questions from the prototype were further consolidated into eight guiding affirmations, as presented in

Table 11. The guiding questions related to the “resource minimization”, “reuse/recycle potential” and “waste commercialization” were integrated into the Block 2, as previously presented. “Pay-back willingness” was broadened to more overall managerial support; “knowledge sharing” and “managing trade-offs” were excluded. Furthermore, three additional readiness areas were included: “importance now”, “importance future” and “networks”.

Finally, in order to enable the capture of the municipalities’ reflections on the screening and the potential of the assessed SME, the guiding questions were also transformed into affirmations, and evaluated used the same 5-pont Likert-scale.

4.2.3. Step 2.3. Implementation and Scale-Up

The enhanced version of the screening tool was delivered to the municipalities, which together with the Danish Symbiosis Center performed the screening in all 108 SMEs, from a varied number of sectors. On the basis of the analysis of the results, customized company reports were delivered to the engaged SMEs, with an overview of their readiness for both eco-innovation and industrial symbiosis.

The tool was revised four times, considering a trade-off between easiness of the screening, and the need for detailed data. Some quantitative data proved to be difficult to obtain especially in relation to the input/output flows, particularly for the smaller companies. The tool was accordingly simplified to enable a faster and easier screening process. The semi-qualitative data provided a good indication of the SMEs potential, which was then explored in the subsequent phases of the project.

The feedback from the municipalities and SMEs towards the enhanced version of the tool were mainly positive. The feedback was obtained using the same evaluation criteria for the first action research cycle (i.e., content, screening and analysis, presented in

Section 3.2.1) for each one of the blocks within the readiness tool, covering the evaluation of both the usability and usefulness of the proposed screening tool. The tool, while somewhat comprehensive, seems to be fairly easy to use, easy to understand and accessible for the SMEs. Furthermore, it enables an objective analysis of the results, which is currently being performed directly by the municipalities.

5. Discussion

In this section, the results are discussed in relation to four main areas: (1) contributions of the research to the state-of-the-art; (2) contributions of the research to the eco-innovation practice; (3) potential implications with the application of the proposed screening tool; and (4) other observations.

5.1. Contributions to the State-of-the-Art

The main contributions of the proposed screening tool to the state-of the-art are described in terms of the theoretical background presented in

Section 2, related to the eco-innovation literature. In addition to enabling the evaluation of the eco-innovation potential of SMEs, the proposed RTR screening tool differentiates from existing tools in a number of ways:

- (i)

By enabling the evaluation of eco-innovation potential at the company level, using both qualitative and quantitative data (the existing tools tend to focus either at the product or at the network level, with significant limitations in relation to the evaluation of the potential at the company-level. Furthermore, the tools tend to be strictly quantitative, which makes the application by SMEs more difficult).

- (ii)

By addressing eco-innovation, industrial symbiosis and green business models simultaneously, combined with a readiness assessment for further evaluation of the feasibility in realizing the identified potential (the existing tools tend to focus on one or two of the dimensions, not fully considering the synergy effects with the others-furthermore; readiness was not identified as an element in any of the identified tools).

- (iii)

By enabling the screening of SMEs by municipalities, as key players for enabling eco-innovation among SMEs (the tools are usually applied by network consolidators, with limited involvement of governmental bodies—the involvement of municipalities can provide interesting reflections regarding their roles as eco-innovation agents).

Within this research, efforts were focused on developing a tool that can, ultimately, support researchers to understand the SMEs’ potential for eco-innovation implementation. Furthermore, the tool can support the identification of barriers and success factors for eco-innovation implementation in SMEs, which can lead to the development of a number of eco-innovation tools by academia.

5.2. Contributions to the Eco-Innovation Practice

In the context of the RTR project, the proposed screening tool served a dual purpose. First, it served as a tool to help SMEs to understand their eco-innovation potentials, from the industrial symbiosis and green business models perspectives, with an overview of the viability of the business cases. Furthermore, a number of green business model workshops were held under the guidance of DTU with the Danish Symbiosis Center and participating municipalities. In these workshops, the company screening reports served as a basis for prioritizing the identified interesting eco-innovation potentials and for symbiosis matching. Also, some individual meetings with companies were held with the same purpose. Second, it was serving as a support for the selection of companies to proceed to the next stage of the project, which involved the development of technical eco-innovative solutions based on the identified eco-innovation potential and opportunities. Based on the screening results, ca. 50 companies were selected for further involvement in the project, for the development of ‘Green Technical Plans’ of which 30 companies became engaged in the development of new ‘Green Business Models’ to explore eco-innovation and symbiosis examples. These activities were carried out with the support of consultants paid by the project.

Similar contributions are expected with the application of the proposed tool in a broader context, outside the context of the RTR project. In addition to supporting SMEs to understand their potential for eco-innovation, which can aid to an enhanced perception of its strategic importance, the screening tool can also be applied in a broader sense by municipalities, consultants, sector associations, SMEs associations, or any similar organizations that are interested in understanding the eco-innovation potential of companies in a given context, aimed at subsequent steps in the implementation of the concept.

5.3. Potential Implications

The use of the proposed screening tool in a large range of SMEs, across different geographies and sectors, has the potential to generate data sets that can enable a number of sectorial and regional analysis, which can potentially enhance the scale-up of eco-innovation initiatives.

Some of the potential applications of the datasets obtained through the extensive application of the tool include:

Benchmarking studies: The application of the tool can enable the benchmarking of companies, sectors, regions, etc. regarding the readiness potential for eco-innovation, coupled with green business models and industrial symbiosis opportunities;

Database of inputs & output flows: The data collected regarding material and energy flows can be shared with prior agreement of the participating companies, in regional databases, maximizing the matchmaking opportunities among companies with clear synergies and geographical proximity;

Policy making support: The understanding of the barriers for realizing the identified eco-innovation potential in a given region/country can support the local governments to establish targeted and specific policies aiming at providing incentives for an enhancement of the eco-innovation uptake by SMEs;

Measure progress an evolution over time: The application of the screening tool over time, in the same company, can enable the understanding of the company evolution in implementing eco-innovation, supporting the prioritization of next steps and communication of results.

Other minor potential implications are related to cross-sectorial collaboration (enabled by the networking among the engaged companies), value chain innovation (by the establishment of new partnerships based on eco-innovation potentials); and potential external dissemination of the eco-innovation potential.

5.4. Other Observations

Despite the initial reservation of the SMEs regarding the screening performed by municipalities (up until than largely seen as command & control bodies), the municipalities managed to establish themselves as eco-innovation agents, supporting the SMEs to identify and further implement eco-innovation initiatives. Furthermore, the knowledge of both SMEs and municipalities regarding the potential for eco-innovation in their regions was significantly expanded during the project—starting with the screening tool, and moving towards the subsequent steps of the project (i.e., technical analysis, green business model development and symbiotic networks). It is expected that the created municipal network will be continued after the termination of the project, due to the strong relationships created among the participants and the role of the municipalities in bringing the companies together towards a shared objective.

6. Concluding Remarks and Next Steps

In this paper, the development, test and enhancement of a screening tool to support the measurement of the potential of SMEs for eco-innovation was presented, with a special focus on industrial symbiosis and green business models. The screening tool was developed in the course of two main action research cycles, actively involving the Danish Symbiosis Center and municipalities as key stakeholders, as well as the screened SMEs.

Differently from the identified existing tools, the screening tool proposed in this research aims at supporting companies to understand what their potential for eco-innovation is, combining wider eco-innovation and industrial symbiosis opportunities and green business models, supplemented with a readiness evaluation to explore the existing potential.

In addition to enabling a better understanding about their own internal processes and activities, the evaluation of the potential of 108 SMEs for eco-innovation enabled the selection of companies to be further engaged in the project, and provided them with detailed insights about how to reach the potential benefits with industrial symbiosis and green business models.

Overall, from a theoretical point of view, the state-of-the-art is advanced by the proposition of a systematic methodology that enables the screening of the eco-innovation potential in SMEs, at a company-level, by using both quantitative and semi-quantitative measures. The main theoretical contribution of the screening tool and its constituent elements is related to three main areas, as detailed and described below:

Combined quantitative and qualitative approach for the evaluation of the potential for industrial symbiosis, looking at the material, energy & water flows and at the opportunities for enhanced efficiency, combined with a pre-evaluation of the relative importance of the different flows for the business performance and long-term success;

Streamlined approach for capturing key business models elements (e.g., value proposition and revenue streams) that represent a potential for enhanced sustainability performance, based on state-of-the-art literature for business model innovation and on the use of the guiding affirmations;

Consolidated review and evaluation of key readiness dimensions for the implementation of eco-innovation, industrial symbiosis, and green business models—evaluated by means of a five-point Likert-scale, which enables also a comparison across the different dimensions;

By exploring the potential of municipalities as eco-innovation agents, the approach also highlights the importance of a multi-stakeholder approach for eco-innovation implementation. Last but not least, the use of the proposed screening tool in a large range of SMEs, across different geographies and sectors, has the potential to generate data sets that can enable a number of sectorial and regional analysis, which can potentially enhance the scale-up of eco-innovation initiatives and allow for a better understanding of the uptake and implementation phenomena in SMEs.

The project leadership of the Danish Symbiosis Center secured a coordinated action across their six municipalities. Because of the active involvement of both the Danish Symbiosis Center and the six Danish municipalities as the main players in the screening assessments, we expect to ensure long-lasting relationships and connections with the participating companies beyond the project period.

Currently, the screening tool has been tested only within Danish companies, which poses a limitation to this research. Cultural aspects can have a strong influence in the results of the screening tool, and should be further explored. It is expected that the screening tool can be used by other stakeholders as a way to evaluate the potential of SMEs for eco-innovation, including consultancy companies, universities, other governmental bodies, non-governmental organizations, and the companies themselves (through a self-assessment)—all of these opportunities are yet to be explored, and were not considered in this project.

Furthermore, the expansion of the proposed screening tool towards wider product-oriented Circular Economy solutions should be further explored, as a way to ensure a broader perspective. Also, it is also worth exploring the potential of applying the proposed tool in larger companies, which brings an additional level of complexity in terms of data collection. Finally, the evaluation of the potential for eco-innovation at a company level should be combined with a network evaluation, so to evaluate the feasibility/probability of turning the potentials into reality.

Author Contributions

Conceptualization, M.M.A. and D.C.A.P.; Methodology, D.C.A.P., M.M.A. and A.S.; Software, D.C.A.P. and A.S.; Validation, A.S., D.C.A.P. and M.M.A.; Formal Analysis, N/A; Investigation, A.S., M.M.A. and D.C.A.P.; Resources, N/A; Data Curation, A.S. and M.M.A.; Writing—Original Draft Preparation, D.C.A.P., A.S. and M.M.A.; Writing—Review & Editing, A.S., D.C.A.P. and M.M.A.; Visualization, D.C.A.P. and A.S.; Supervision, M.M.A.; Project Administration, M.M.A.; Funding Acquisition, M.M.A.

Funding

This research project was funded by European Fund for Regional Development. In Danish the project is named ‘Rest til Ressource’. The project has been led by the Symbiosis Center Denmark, with the Technical University of Denmark as the core knowledge partner and developer of the tool and screening approach. The municipalities involved were: Kalundborg, Holbæk, Køge, Slagelse, Guldborgsund and Odsherred.

Acknowledgments

The authors would like to thank the financial support from the European Fund for Regional Development, the Danish Symbiosis Center (project leader) and the six engaged municipalities (Holbæk, Kalundborg, Slagelse, Odsherred, Køge and Guldborgsund). Furthermore, we would like to extend the acknowledgments to Tim C. McAloone, for the valuable inputs for the development and enhancement of the screening tool throughout the duration of the project.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Commission of the European Communities. Integrated Product Policy: Building on Environmental Life-Cycle Thinking: Communication from the Commission to the Council and the European Parliament; Office for Official Publications of the European Communities: Brussels, Belgium, 2003; p. 30. [Google Scholar]

- Ormazabal, M.; Prieto-Sandoval, V.; Puga-Leal, R.; Jaca, C. Circular economy in Spanish SMEs: Challenges and opportunities. J. Clean. Prod. 2018, 185, 157–167. [Google Scholar] [CrossRef]

- Ruiz Puente, M.C.; Arozamena, E.R.; Evans, S. Industrial symbiosis opportunities for small and medium sized enterprises: Preliminary study in the Besaya region (Cantabria, Northern Spain). J. Clean. Prod. 2015, 87, 357–374. [Google Scholar] [CrossRef]

- O’Hare, J.A.; Mcaloone, T.C.; Pigosso, D.C.A.; Howard, T.J. UNEP Eco-i Manual: Eco-Innovation Implementation Process; United Nations Environment Programme: Nairobi, Kenya, 2017. [Google Scholar]

- Klewitz, J.; Hansen, E.G. Sustainability-oriented innovation of SMEs: A systematic review. J. Clean. Prod. 2014, 65, 57–75. [Google Scholar] [CrossRef]

- Triguero, A.; Moreno-Mondéjar, L.; Davia, M.A. Drivers of different types of eco-innovation in European SMEs. Ecol. Econ. 2013, 92, 25–33. [Google Scholar] [CrossRef]

- World Commission on Environment and Development. Report of the World Commission on Environment and Development:Our Common Future; Annex to General Assembly Document A/42/427; Oxford University Press: Oxford, UK, 1987. [Google Scholar]

- Amini, M.; Bienstock, C.C. Corporate sustainability: An integrative definition and framework to evaluate corporate practice and guide academic research. J. Clean. Prod. 2014, 76, 12–19. [Google Scholar] [CrossRef]

- Rennings, K. Redefining innovation—Eco-innovation research and the contribution from ecological economics. Ecol. Econ. 2000, 32, 319–332. [Google Scholar] [CrossRef]

- Commission of the European Communities. Innovation for a Sustainable Future—The Eco-Innovation Action Plan (Eco-AP); Commission of the European Communities: Brussels, Belgium, 2001. [Google Scholar]

- Danish Business Authority. The Future of Eco-Innovation: The Role of Business Models in Green Transformation; OECD/European Commission/Nordic Innovation Joint Workshop: Copenhagen, Denmark, 2012. [Google Scholar]

- Zheng, K.; Jia, S. Promoting the opportunity identification of industrial symbiosis: Agent-based modeling inspired by innovation diffusion theory. Sustainability 2017, 9, 765. [Google Scholar] [CrossRef]

- Taddeo, R.; Simboli, A.; Ioppolo, G.; Morgante, A. Industrial symbiosis, networking and innovation: The potential role of innovation poles. Sustainability 2017, 9, 169. [Google Scholar] [CrossRef]

- Golev, A.; Corder, G.D.; Giurco, D.P. Barriers to industrial symbiosis: Insights from the use of a maturity grid. J. Ind. Ecol. 2015, 19, 141–153. [Google Scholar] [CrossRef]

- Jacobsen, N.B. Industrial symbiosis in Kalundborg, Denmark. J. Ind. Ecol. 2006, 10, 239–255. [Google Scholar] [CrossRef]

- Liu, C.; Côté, R.P.; Zhang, K. Implementing a three-level approach in industrial symbiosis. J. Clean. Prod. 2015, 87, 318–327. [Google Scholar] [CrossRef]

- Herczeg, G.; Akkerman, R.; Hauschild, M.Z. Supply chain collaboration in industrial symbiosis networks. J. Clean. Prod. 2018, 171, 1058–1067. [Google Scholar] [CrossRef]

- Osterwalder, A.; Pigneur, Y. Business Model Generation; John Wiley and Sons: Hoboken, NJ, USA, 2010. [Google Scholar]

- de Jesus Pacheco, D.A.; ten Caten, C.S.; Jung, C.F.; Ribeiro, J.L.D.; Navas, H.V.G.; Cruz-Machado, V.A. Eco-innovation determinants in manufacturing SMEs: Systematic review and research directions. J. Clean. Prod. 2017, 142, 2277–2287. [Google Scholar] [CrossRef]

- Clark, G. Evolution of the global sustainable consumption and production policy and the United Nations Environment Programme’s (UNEP) supporting activities. J. Clean. Prod. 2007, 15, 492–498. [Google Scholar] [CrossRef]

- United Nations Environment Programme (UNEP). Guidelines for the Integration of Cleaner Production and Energy Efficiency; UNEP: Nairobi, Kenya, 2004. [Google Scholar]

- Slattery, K.R.; Guirguis, S. Life cycle assessment—A practical tool for sustainable design. In Proceedings of the 9th International Conference on Durability of Materials and Components, Brisbane, Australia, 17–22 March 2002. [Google Scholar]

- Sanye-Mengual, E.; Perez-Lopez, P.; Gonzalez-Garcia, S.; Garcia Lozano, R.; Feijoo, G.; Teresa Moreira, M.; Gabarrell, X.; Rieradevall, J. Eco-designing the use phase of products in sustainable manufacturing the importance of maintenance and communication-to-user strategies. J. Ind. Ecol. 2014, 18, 545–557. [Google Scholar] [CrossRef]

- Gupta, S.; Dangayach, G.S.; Singh, A.K. Key determinants of sustainable product design and manufacturing. Procedia CIRP 2015, 26, 99–102. [Google Scholar] [CrossRef]

- Pigosso, D.C.A.; McAloone, T.C. Maturity-based approach for the development of environmentally sustainable product/service-systems. CIRP J. Manuf. Sci. Technol. 2016, 15, 33–41. [Google Scholar] [CrossRef] [Green Version]

- Bovea, M.D.; Pérez-Belis, V. A taxonomy of ecodesign tools for integrating environmental requirements into the product design process. J. Clean. Prod. 2012, 20, 61–71. [Google Scholar] [CrossRef]

- Blomsma, F.; Kjaer, L.; Pigosso, D.; McAloone, T.; Lloyd, S. Exploring circular strategy combinations—Towards understanding the role of PSS. Procedia CIRP 2018, 69, 752–757. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation, SUN and McKinsey Center for Business and Environment. Growth Within: A Circular Economy Vision for Competitive Europe; Ellen MacArthur Foundation: Cowes, UK, 2015. [Google Scholar]

- Blomsma, F.; Brennan, G. The emergence of circular economy: A new framing around prolonging resource productivity. J. Ind. Ecol. 2017, 21, 603–614. [Google Scholar] [CrossRef]

- Cecelja, F.; Raafat, T.; Trokanas, N.; Innes, S.; Smith, M.; Yang, A.; Zorgios, Y.; Korkofygas, A.; Kokossis, A. E-symbiosis: Technology-enabled support for industrial symbiosis targeting small and medium enterprises and innovation. J. Clean. Prod. 2015, 98, 336–352. [Google Scholar] [CrossRef] [Green Version]

- Fernández-Viñé, M.B.; Gómez-Navarro, T.; Capuz-Rizo, S.F. Assessment of the public administration tools for the improvement of the eco-efficiency of small and medium sized enterprises. J. Clean. Prod. 2013, 47, 265–273. [Google Scholar] [CrossRef]

- Valentine, S.V. Kalundborg symbiosis: Fostering progressive innovation in environmental networks. J. Clean. Prod. 2016, 118, 65–77. [Google Scholar] [CrossRef]

- Nulkar, G. SMEs and environmental performance—A framework for green business strategies. Procedia Soc. Behav. Sci. 2014, 133, 130–140. [Google Scholar] [CrossRef]

- Lombardi, D.R.; Laybourn, P. Redefining industrial symbiosis: Crossing academic-practitioner boundaries. J. Ind. Ecol. 2012, 16, 28–37. [Google Scholar] [CrossRef]

- Tödtling, F.; Kaufmann, A. The role of the region for innovation activities of SMEs. Eur. Urban Reg. Stud. 2001, 8, 203–215. [Google Scholar] [CrossRef]

- Park, M.S.; Bleischwitz, R.; Han, K.J.; Jang, E.K.; Joo, J.H. Eco-innovation indices as tools for measuring eco-innovation. Sustainability 2017, 9, 2206. [Google Scholar] [CrossRef]

- Pialot, O.; Millet, D. Towards operable criteria of eco-innovation and eco-ideation tools for the early design phases. Procedia CIRP 2018, 69, 692–697. [Google Scholar] [CrossRef]

- Cluzel, F.; Yannou, B.; Millet, D.; Leroy, Y. Eco-ideation and eco-selection of R & D projects portfolio in complex systems industries. J. Clean. Prod. 2016, 112, 4329–4343. [Google Scholar] [CrossRef]

- Russo, D.; Schöfer, M.; Bersano, G. Supporting eco-innovation in SMEs by TRIZ eco-guidelines. Procedia Eng. 2015, 131, 831–839. [Google Scholar] [CrossRef]

- Tyl, B.; Legardeur, J.; Millet, D.; Vallet, F. A comparative study of ideation mechanisms used in eco-innovation tools. J. Eng. Des. 2014, 25, 325–345. [Google Scholar] [CrossRef]

- Dekoninck, E.; Harrison, D.; Stanton, N.A. New tools for the early stages of eco-innovation: An evaluation of simplified TRIZ tools. J. Des. Res. 2007, 6, 122–141. [Google Scholar] [CrossRef]

- Jones, E.; Stanton, N.A.; Harisson, D. Applying structured methods to eco-innovation. An evaluation of the product ideas tree diagram. Des. Stud. 2001, 22, 519–542. [Google Scholar] [CrossRef]

- Rybaczewska-Błażejowska, M.; Sulerz, A. LCA as a tool for assessing product and process oriented eco-innovations undertaken by enterprises. Manag. Prod. Eng. Rev. 2017, 8, 60–69. [Google Scholar] [CrossRef]

- Simboli, A.; Raggi, A.; Rosica, P. Life cycle assessment of process eco-innovations in an sme automotive supply network. Sustainability 2015, 7, 13761–13776. [Google Scholar] [CrossRef]

- Papetti, A.; Germani, M.; Marconi, M.; Favi, C. Lifecycle tools as a support for the eco-design innovation of domestic appliances. In Proceedings of the 22nd Design for Manufacturing and the Life Cycle Conference, Cleveland, OH, USA, 6–9 August 2017. [Google Scholar]

- Bersano, G.; Fayemi, P.-E.; Schoefer, M.; Spreafico, C. An eco-design methodology based on a-LCA and TRIZ. In Proceedings of the International Conference on Sustainable Design and Manufacturing, Bologna, Italy, 26–28 April 2017; pp. 919–928. [Google Scholar]

- Cherifi, A.; Dubois, M.; Gardoni, M.; Tairi, A. Methodology for innovative eco-design based on TRIZ. Int. J. Interact. Des. Manuf. 2015, 9, 167–175. [Google Scholar] [CrossRef]

- Chakroun, M.; Gogu, G.; Pacaud, T.; Thirion, F. Eco-innovative design approach: Integrating quality and environmental aspects in prioritizing and solving engineering problems. Front. Mech. Eng. 2014, 9, 203–217. [Google Scholar] [CrossRef]

- Prendeville, S.; O’Connor, F.; Palmer, L. Material selection for eco-innovation: SPICE model. J. Clean. Prod. 2014, 85, 31–40. [Google Scholar] [CrossRef]

- Chen, W.-C.; Chen, J.L. Eco-innovation by integrating biomimetic design and ARIZ. Procedia CIRP 2014, 15, 401–406. [Google Scholar] [CrossRef]

- Raabe, B.; Low, J.S.C.; Juraschek, M.; Herrmann, C.; Tjandra, T.B.; Ng, Y.T.; Kurle, D.; Cerdas, F.; Lueckenga, J.; Yeo, Z.; et al. Collaboration platform for enabling industrial symbiosis: Application of the by-product exchange network model. Procedia CIRP 2017, 61, 263–268. [Google Scholar] [CrossRef]

- Albu, A.; Stelea, S. Green business development using eco-innovation. Qual. Access Success 2015, 16, 465–472. [Google Scholar]

- Arampatzis, G.; Angelis-Dimakis, A.; Blind, M.; Assimacopoulos, D. A web-based Toolbox to support the systemic eco-efficiency assessment in water use systems. J. Clean. Prod. 2016, 138, 181–194. [Google Scholar] [CrossRef] [Green Version]

- Holgado, M.; Benedetti, M.; Evans, S.; Introna, V. Contextualisation in Industrial Energy Symbiosis: Design Process for a Knowledge Repository. In Proceedings of the Summer School Francesco Turco, Naples, Italy, 13–15 September 2016. [Google Scholar]

- Arbolino, R.; De Simone, L.; Carlucci, F.; Yigitcanlar, T.; Ioppolo, G. Towards a sustainable industrial ecology: Implementation of a novel approach in the performance evaluation of Italian regions. J. Clean. Prod. 2018, 178, 220–236. [Google Scholar] [CrossRef]

- Zhang, C.; Romagnoli, A.; Zhou, L.; Kraft, M. Knowledge management of eco-industrial park for efficient energy utilization through ontology-based approach. Appl. Energy 2017, 204, 1412–1421. [Google Scholar] [CrossRef]

- Benedetti, M.; Holgado, M.; Evans, S. A novel knowledge repository to support industrial symbiosis. In Proceedings of the IFIP International Conference on Advances in Production Management Systems, Hamburg, Germany, 3–7 September 2017; pp. 443–451. [Google Scholar]

- Le Tellier, M.; Berrah, L.; Stutz, B.; Barnabé, S.; Audy, J.-F. From SCM to eco-industrial park management: Modelling eco-industrial park’s symbiosis with the SCOR model. In Proceedings of the IFIP International Conference on Advances in Production Management Systems, Hamburg, Germany, 3–7 September 2017. [Google Scholar]

- Álvarez, R.; Ruiz-Puente, C. Development of the tool symbiosys to support the transition towards a circular economy based on industrial symbiosis strategies. Waste Biomass Valorization 2017, 8, 1521–1530. [Google Scholar] [CrossRef]

- Liwarska-Bizukojc, E.; Bizukojc, M. Overview of european eco-industrial parks: Evaluation of industrial symbiosis potential. Environ. Eng. Manag. J. 2018, 17, 477–490. [Google Scholar]

- Ren, J.; Liang, H.; Dong, L.; Sun, L.; Gao, Z. Design for sustainability of industrial symbiosis based on emergy and multi-objective particle swarm optimization. Sci. Total Environ. 2016, 562, 789–801. [Google Scholar] [CrossRef] [PubMed]

- Cimren, E.; Fiksel, J.; Posner, M.E.; Sikdar, K. Material flow optimization in by-product synergy networks. J. Ind. Ecol. 2011, 15, 315–332. [Google Scholar] [CrossRef]

- Tan, R.R.; Andiappan, V.; Wan, Y.K.; Ng, R.T.L.; Ng, D.K.S. An optimization-based cooperative game approach for systematic allocation of costs and benefits in interplant process integration. Chem. Eng. Res. Des. 2016, 106, 43–58. [Google Scholar] [CrossRef]

- Deutz, P.; Ioppolo, G. From theory to practice: Enhancing the potential policy impact of industrial ecology. Sustainability 2015, 7, 2259–2273. [Google Scholar] [CrossRef]

- Lehtoranta, S.; Nissinen, A.; Mattila, T.; Melanen, M. Industrial symbiosis and the policy instruments of sustainable consumption and production. J. Clean. Prod. 2011. [Google Scholar] [CrossRef]

- Saavedra, Y.M.B.; Iritani, D.R.; Pavan, A.L.R.; Ometto, A.R. Theoretical contribution of industrial ecology to circular economy. J. Clean. Prod. 2018, 170, 1514–1522. [Google Scholar] [CrossRef]

- Merli, R.; Preziosi, M.; Acampora, A. How do scholars approach the circular economy? A systematic literature review. J. Clean. Prod. 2018, 178, 703–722. [Google Scholar] [CrossRef]

- Lombardi, R. Non-technical barriers to (and drivers for) the circular economy through industrial symbiosis: A practical input. Econ. Policy Energy Environ. 2017, 2017, 171–189. [Google Scholar] [CrossRef]

- Coughlan, P.; Coghlan, D. Action research. In Researching Operations Management; Karlsson, C., Ed.; Routledge: Abingdon-on-Thames, UK, 2009; p. 322. [Google Scholar]

- Stringer, E.T. Action Research, 3rd ed.; Sage Publications: Thousand Oaks, CA, USA, 2007. [Google Scholar]

- Blessing, L.T.M.; Chakrabarti, A. DRM, A Design Research Methodology; Springer: Berlin, Germany, 2009; ISBN 9781848825871. [Google Scholar]

- Yu, C.; Davis, C.; Dijkema, G.P.J. Understanding the evolution of industrial symbiosis research—A bibliometric and network analysis. J. Ind. Ecol. 2013, 18, 280–293. [Google Scholar] [CrossRef]

- Organization for Economic Co-operation and Development (OECD). Eco-Innovation in Industry: Enabling Green Growth; OECD: Paris, France, 2010; ISBN 978-92-64-07721-8. [Google Scholar]

- Päivärinne, S.; Lindahl, M. Combining integrated product and service offerings with industrial symbiosis—A study of opportunities and challenges. J. Clean. Prod. 2016, 127, 240–248. [Google Scholar] [CrossRef]

- Martin, M.; Svensson, N.; Eklund, M. Who gets the benefits? An approach for assessing the environmental performance of industrial symbiosis. J. Clean. Prod. 2015, 98, 263–271. [Google Scholar] [CrossRef] [Green Version]

- Päivärinne, S.; Lindahl, M. Exploratory study of combining integrated product and services offerings with industrial symbiosis in order to improve excess heat utilization. Procedia CIRP 2015, 30, 167–172. [Google Scholar] [CrossRef]

- Winans, K.; Kendall, A.; Deng, H. The history and current applications of the circular economy concept. Renew. Sustain. Energy Rev. 2017, 68, 825–833. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).