Impact of Insulation Type and Thickness on the Dynamic Thermal Characteristics of an External Wall Structure

Abstract

:1. Introduction

2. Materials and Methods

2.1. External Wall Structure

2.2. External Wall Structure

2.2.1. Thermal Transmittance (U)

2.2.2. Thermal Admittance (Y)

2.2.3. Time LAG (φ)

2.2.4. Time Lead for Thermal Admittance (ω)

2.2.5. Decrement Factor or Amplitude Attenuation (δ)

2.2.6. Surface Factor (F)

2.2.7. Thermal Capacity (η)

3. Results and Discussion

3.1. Impact on Thermal Transmittance (U)

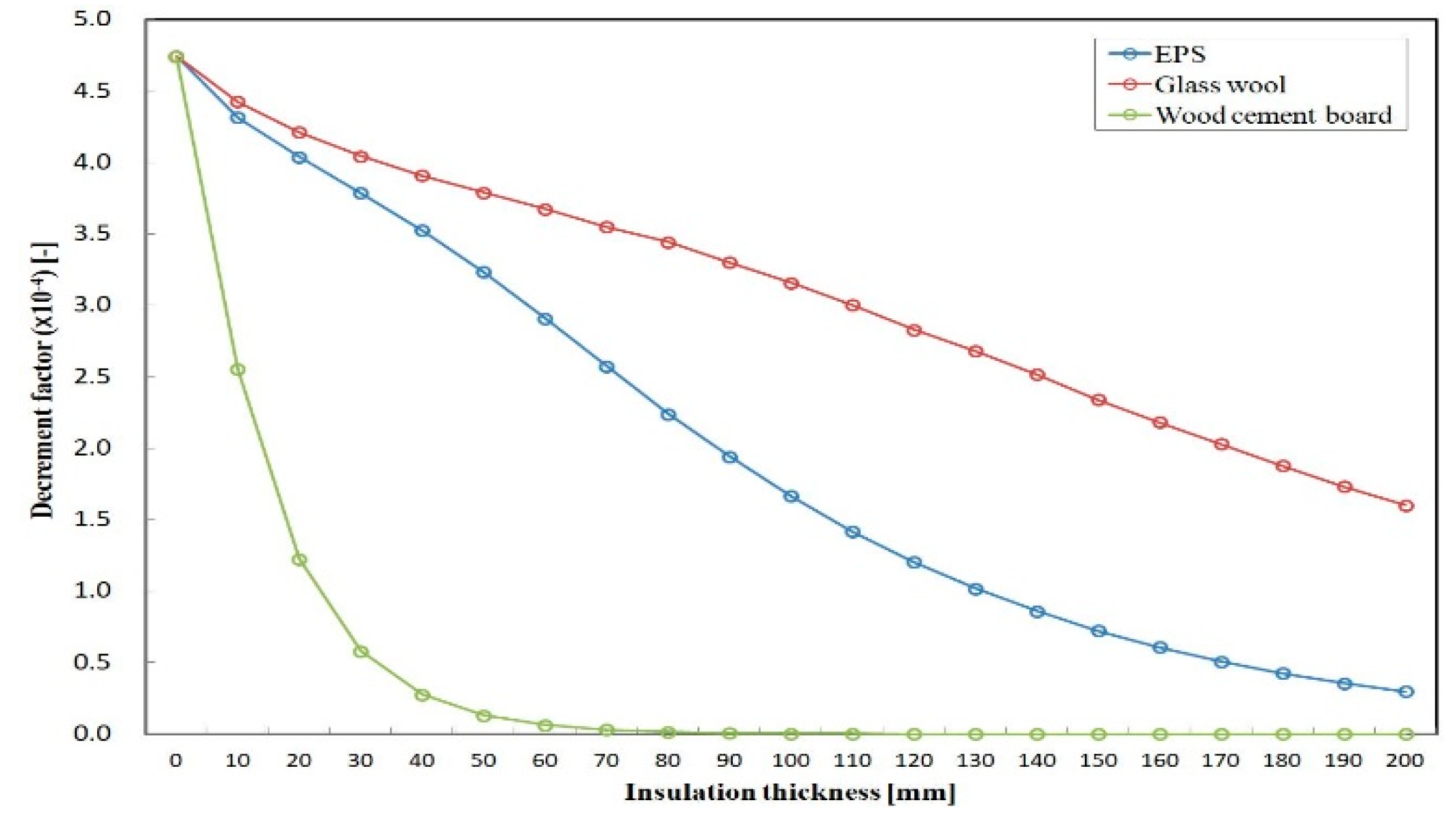

3.2. Impact on Decrement Factor or Amplitude Attenuation (δ)

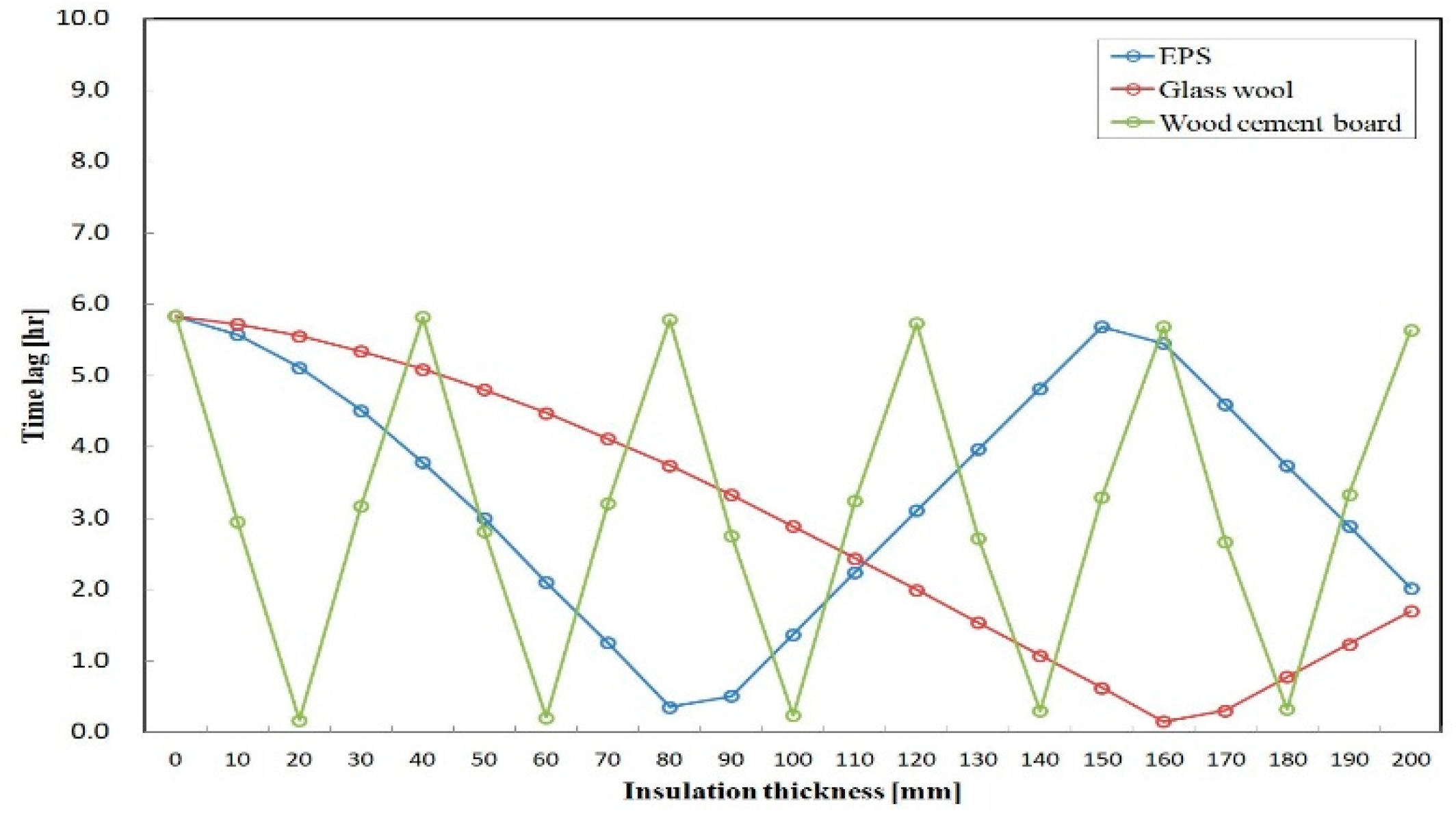

3.3. Impact on Time Lag (φ)

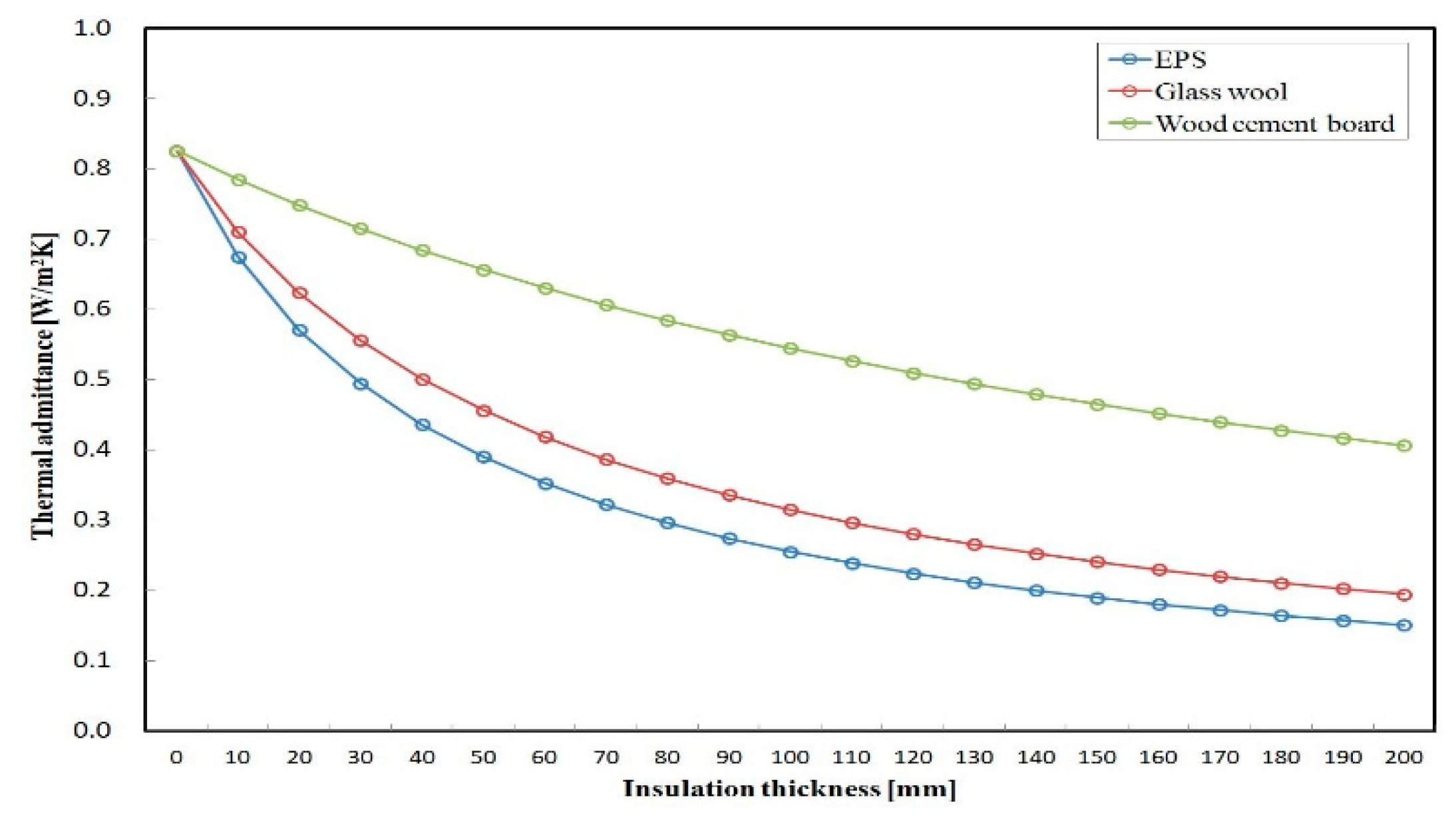

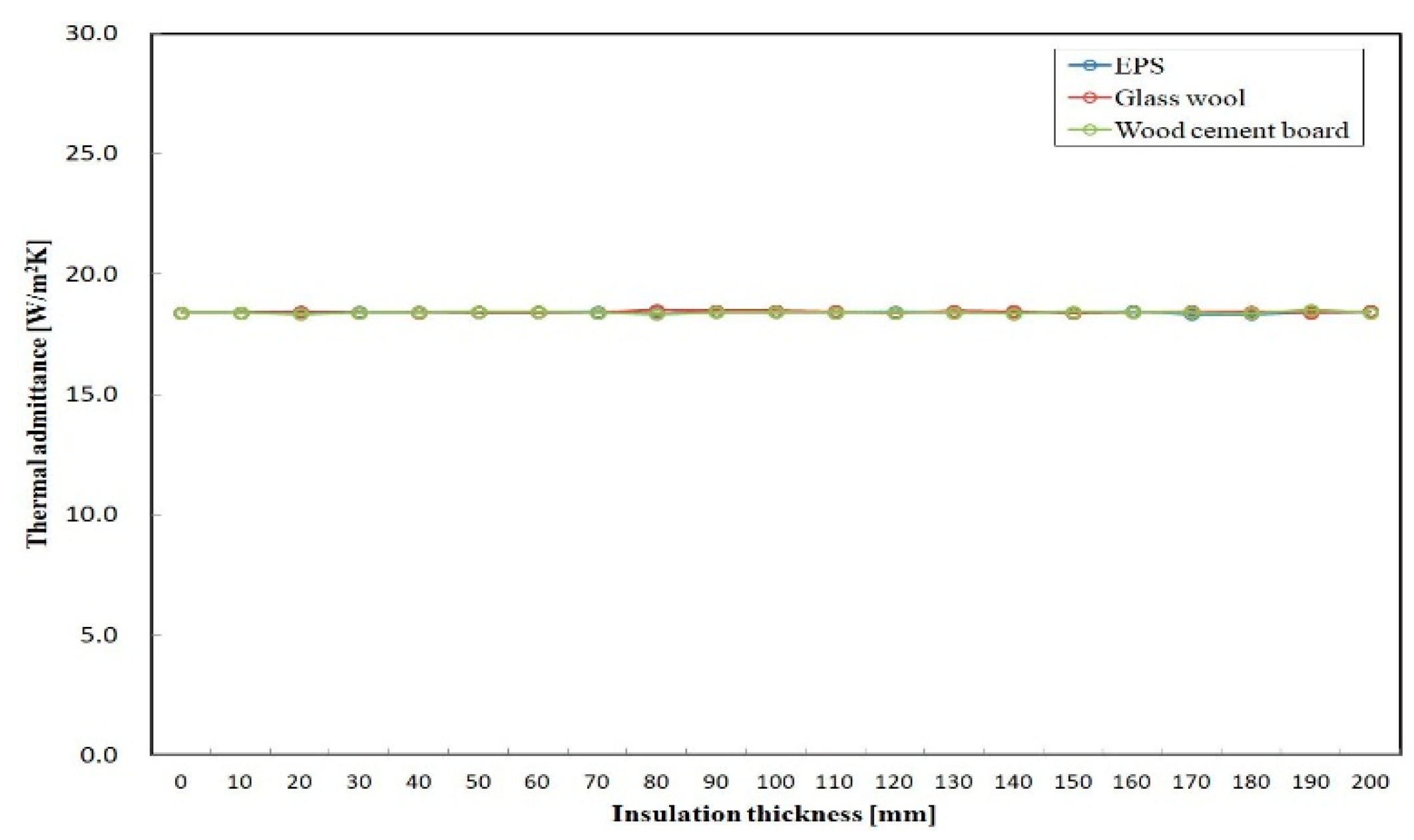

3.4. Impact on Thermal Admittance (Y)

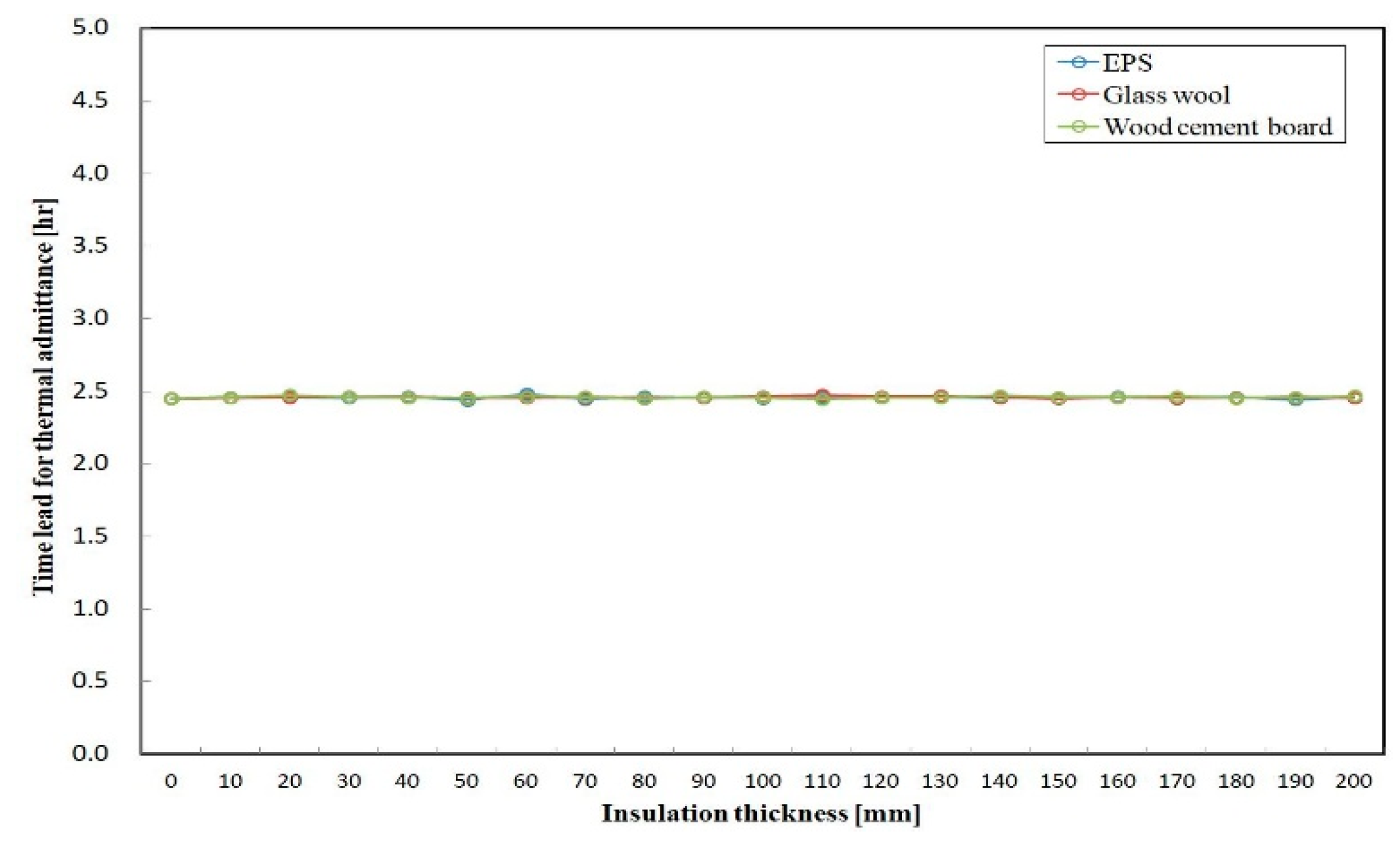

3.5. Impact on Time Lead for Admittance (ω)

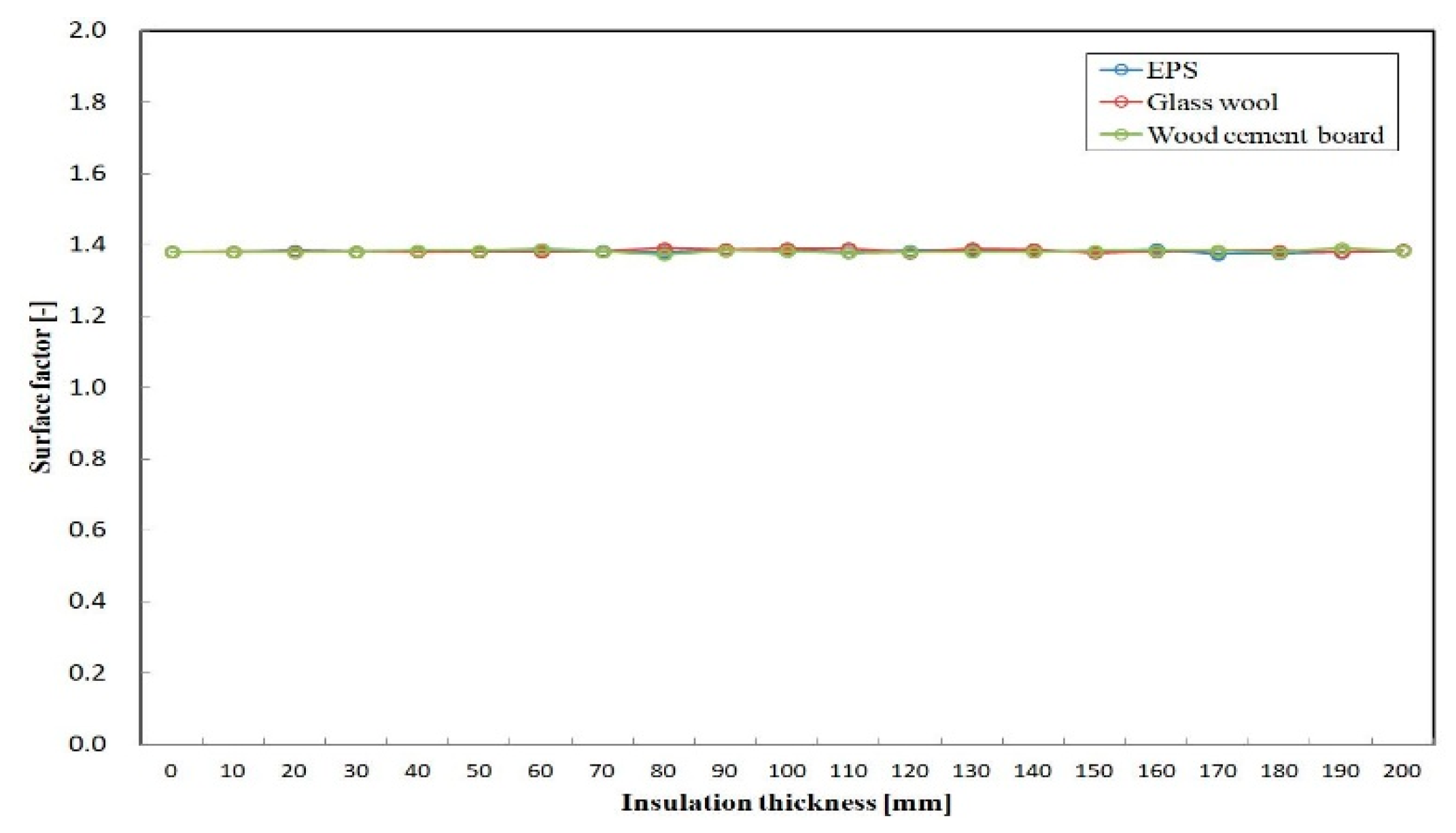

3.6. Impact on Surface Factor (F)

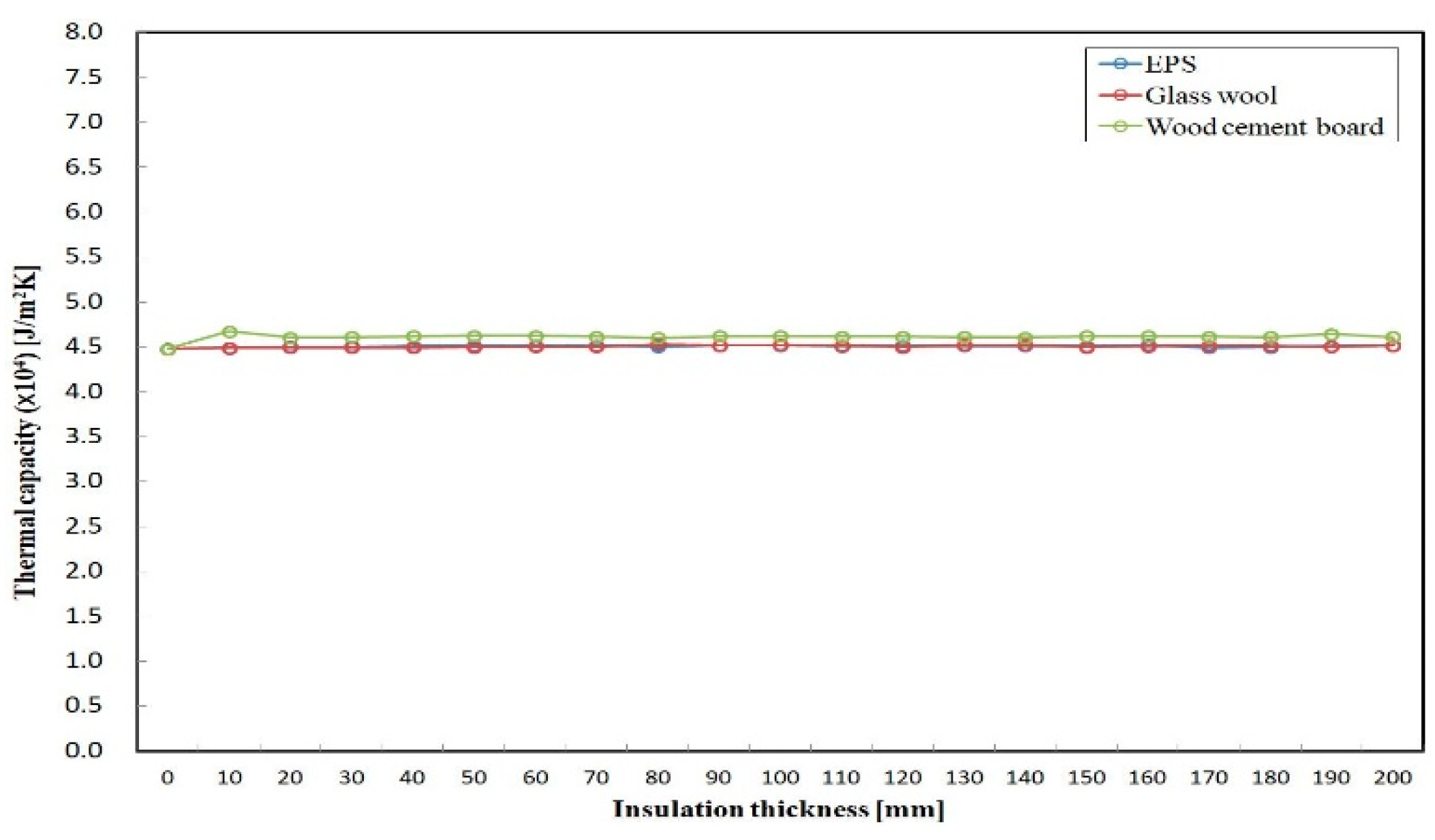

3.7. Impact on Thermal Capacity (η)

4. Conclusions

- The U of the external wall structure varies depending on the different insulation type and thickness of the external wall structure. It was found that there is a critical thickness for the thermal insulation of the external wall structure, and the effect of thermal insulation will not be obvious when the thickness exceeds the critical value.

- The δ of the wall structure could possibly be reduced by increasing the insulation thickness of the wall. The degree of decrease in the decrement factor varies depending on the different type of insulation material.

- There is a change period of φ with the increasing insulation thickness, and it differs for different types of insulation material. The insulation type and thickness in the external wall structure strongly affects the φ of the wall structure.

- The insulation type and thickness will yield no significant change in the Y, ω, F, and η thermal characteristics of the external wall structure.

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| clear; | ||

| P=3600; | % Time periods [s] | |

| pi=3.1415926; | ||

| drt=5.67*10-8; | % Stefan-Boltzmann constant | |

| j=sqrt(-1); | % Imaginary number | |

| Fe=0.9; | % Emissivity factor of wall surface which is equal to K*e [K=1; e=0.9] | |

| Tsi=15+273.15; | % Internal surface absolute temperature [K] | |

| Tso=15+273.15; | % External surface absolute temperature [K] | |

| hi=9.; | % For internal wall surface convective heat transfer coefficient [W/m2K] | |

| ho=23.; | % For external wall surface convective heat transfer coefficient [W/m2K] | |

| Rsint=1/hi; | % Internal surface resistance [m2K/W] | |

| Rsext=1/ho; | % External surface resistance [m2K/W] | |

| % Themophysical properties of building wall enclosure materials (from indoor to outdoor) | ||

| kw=0.179; | % Thermal conductivity of wood [W/mK] | |

| Dw=530; | % Density of wood [kg/m3] | |

| Cw=2300; | % Specific heat of wood [J/kgK] | |

| xw=0.015; | % Thickness of wood [m] | |

| ke=0.16; | % Thermal conductivity of Wood cement board [W/mK] | |

| De=680; | % Density of Wood cement board [kg/m3] | |

| Ce=1675; | % Specific heat of Wood cement board [J/kgK] | |

| xe=0.06; | % Thickness of Wood cement board [m] | |

| ka=0.026; | % Thermal conductivity of air layer [W/mK] | |

| Da=1.2; | % Density of air layer [kg/m3] | |

| Ca=1006; | % Specific heat of air layer [J/kgK] | |

| xa=0.02; | % Thickness of air layer [m] | |

| kc=0.9; | % Thermal conductivity of concrete [W/mK] | |

| Dc=2000; | % Density of concrete [kg/m3] | |

| Cc=879; | % Specific heat of concrete [J/kgK] | |

| xc=0.12; | % Thickness of concrete [m] | |

| kp=0.43; | % Thermal conductivity of plaster [W/mK] | |

| Dp=1250; | % Density of plaster [kg/m3] | |

| Cp=1050; | % Specific heat of plaster [J/kgK] | |

| xp=0.03; | % Thickness of plaster [m] | |

| % The homogeneous wall enclosure transmission matrix coefficients | ||

| % For wood material | ||

| uw=sqrt(pi*Dw*Cw*xw*xw/(kw*P)); | ||

| aw=sqrt(j*2*pi*kw*Dw*Cw/P); | ||

| Awo=cosh(uw)*cos(uw); | ||

| Awt=sinh(uw)*sin(uw); | ||

| Aws=(cosh(uw)*sin(uw)+sinh(uw)*cos(uw))/sqrt(2); | ||

| Awf=(cosh(uw)*sin(uw)-sinh(uw)*cos(uw))/sqrt(2); | ||

| % For Wood cement board material | ||

| ue=sqrt(pi*De*Ce*xe*xe/(ke*P)); | ||

| ae=sqrt(j*2*pi*ke*De*Ce/P); | ||

| Aeo=cosh(ue)*cos(ue); | ||

| Aet=sinh(ue)*sin(ue); | ||

| Aes=(cosh(ue)*sin(ue)+sinh(ue)*cos(ue))/sqrt(2); | ||

| Aef=(cosh(ue)*sin(ue)-sinh(ue)*cos(ue))/sqrt(2); | ||

| % For air layer | ||

| ua=sqrt(pi*Da*Ca*xa*xa/(ka*P)); | ||

| aa=sqrt(j*2*pi*ka*Da*Ca/P); | ||

| Aao=cosh(ua)*cos(ua); | ||

| Aat=sinh(ua)*sin(ua); | ||

| Aas=(cosh(ua)*sin(ua)+sinh(ua)*cos(ua))/sqrt(2); | ||

| Aaf=(cosh(ua)*sin(ua)-sinh(ua)*cos(ua))/sqrt(2); | ||

| % For concrete material | ||

| uc=sqrt(pi*Dc*Cc*xc*xc/(kc*P)); | ||

| ac=sqrt(j*2*pi*kc*Dc*Cc/P); | ||

| Aco=cosh(uc)*cos(uc); | ||

| Act=sinh(uc)*sin(uc); | ||

| Acs=(cosh(uc)*sin(uc)+sinh(uc)*cos(uc))/sqrt(2); | ||

| Acf=(cosh(uc)*sin(uc)-sinh(uc)*cos(uc))/sqrt(2); | ||

| % For plaster material | ||

| up=sqrt(pi*Dp*Cp*xp*xp/(kp*P)); | ||

| ap=sqrt(j*2*pi*kp*Dp*Cp/P); | ||

| Apo=cosh(up)*cos(up); | ||

| Apt=sinh(up)*sin(up); | ||

| Aps=(cosh(up)*sin(up)+sinh(up)*cos(up))/sqrt(2); | ||

| Apf=(cosh(up)*sin(up)-sinh(up)*cos(up))/sqrt(2); | ||

| % Solve matrix X=[E11 E12; E21 E22] | ||

| A=[1 -Rsint; 0 1]; | % For internal layer | |

| B=[Awo+Awt*j (Aws+Awf*j)/aw; (-Awf+Aws*j)*aw Awo+Awt*j]; | % For 1st wood layer | |

| C=[Aeo+Aet*j (Aes+Aef*j)/ae; (-Aef+Aes*j)*ae Aeo+Aet*j]; | % For 2nd Wood cement board layer | |

| D=[Aao+Aat*j (Aas+Aaf*j)/aa; (-Aaf+Aas*j)*aa Aao+Aat*j]; | % For 3th air layer | |

| E=[Aco+Act*j (Acs+Acf*j)/ac; (-Acf+Acs*j)*ac Aco+Act*j]; | % For 4rd concrete layer | |

| F=[Apo+Apt*j (Aps+Apf*j)/ap; (-Apf+Aps*j)*ap Apo+Apt*j]; | % For 5th plaster layer | |

| G=[1 -Rsext; 0 1]; | % For external layer | |

| X=A*B*C*D*E*F*G | ||

| ------ | ||

Appendix B

| clear; | ||

| drt=5.67*10-8; | % Stefan-Boltzmann constant | |

| pi=3.1415926; | ||

| i=sqrt(-1); | ||

| hi=9.; | % For internal wall surface convective heat transfer coefficient [W/m2K] | |

| ho=23.; | % For external wall surface convective heat transfer coefficient [W/m2K] | |

| Rsint=1/hi; | % Internal surface resistance [m2K/W] | |

| Rsext=1/ho; | % External surface resistance [m2K/W] | |

| % Themophysical properties of building wall enclosure materials (from indoor to outdoor) | ||

| kw=0.179; | % Thermal conductivity of wood [W/mK] | |

| Dw=530; | % Density of wood [kg/m3] | |

| Cw=2300; | % Specific heat of wood [J/kgK] | |

| xw=0.015; | % Thickness of wood [m] | |

| ke=0.16; | % Thermal conductivity of Wood cement board [W/mK] | |

| De=680; | % Density of Wood cement board [kg/m3] | |

| Ce=1675; | % Specific heat of Wood cement board [J/kgK] | |

| xe=0.06; | % Thickness of Wood cement board [m] | |

| ka=0.026; | % Thermal conductivity of air layer [W/mK] | |

| Da=1.2; | % Density of air layer [kg/m3] | |

| Ca=1006; | % Specific heat of air layer [J/kgK] | |

| xa=0.02; | % Thickness of air layer [m] | |

| kc=0.9; | % Thermal conductivity of concrete [W/mK] | |

| Dc=2000; | % Density of concrete [kg/m3] | |

| Cc=879; | % Specific heat of concrete [J/kgK] | |

| xc=0.12; | % Thickness of concrete [m] | |

| kp=0.43; | % Thermal conductivity of plaster [W/mK] | |

| Dp=1250; | % Density of plaster [kg/m3] | |

| Cp=1050; | % Specific heat of plaster [J/kgK] | |

| xp=0.03; | % Thickness of plaster [m] | |

| E11= 1.0e+07 *(0.3913 − 0.2623i); | ||

| E12= 1.0e+07 *(-0.0255 − 0.0014i); | ||

| E21= 1.0e+07 *(-2.0146 + 3.2741i); | ||

| E22= 1.0e+07 *(0.1943 − 0.0766i); | ||

| % Thermal transmittance (U) [W/m2K] | ||

| U=1/(Rsext+(xw/kw)+(xe/ke)+(xa/ka)+(xc/kc)+(xp/kp)+Rsint) | ||

| % Decrement factor or attenuation factor or amplitude attenuation (d) [-] | ||

| d=abs(-1/(U*E12)) | ||

| % Decrement delay or time lag or phase shift (tlag) [h] | ||

| tlag=(12/pi)*atan(imag(-1/(U*E12))/real(-1/(U*E12))) | ||

| % Thermal admittance (Y) [W/m2K] | ||

| Y=abs(-E11/E12) | ||

| % Time lead for thermal admittance (w) [h] | ||

| w=(12/pi)*atan(imag(-E11/E12)/real(-E11/E12)) | ||

| % Surface factor (F) [-] | ||

| F=abs(1-Rsint*(-E11/E12)) | ||

| % Associated time delay of surface factor (stlag) [h] | ||

| stlag=(12/pi)*atan(imag(1-Rsint*(-E11/E12))/real(1-Rsint*(-E11/E12))) | ||

| % Thermal heat capcity (Cap) [J/m2K] | ||

| T=3600; | % Times [s] | |

| Cap=(T/2*pi)*abs((E22-1)/E12) | ||

References

- Kesik, T.J. Building Enclosure Design Principles and Strategies. Ph.D. Thesis, University of Toronto, Toronto, ON, Canada, 8 August 2016. [Google Scholar]

- Duffin, R.J.; Knowles, G. A passive wall design to minimize building temperature swings. Sol. Energy 1984, 33, 337–342. [Google Scholar] [CrossRef]

- Knowles, T.R. Proportioning composites for efficient thermal storage walls. Sol. Energy 1983, 31, 319–326. [Google Scholar] [CrossRef]

- Asan, H. Investigation of wall’s optimum insulation position from maximum time lag and minimum decrement factor point of view. Energy Build. 2000, 32, 197–203. [Google Scholar] [CrossRef]

- Asan, H. Effects of Wall’s insulation thickness and position on time lag and decrement factor. Energy Build. 1998, 28, 299–305. [Google Scholar] [CrossRef]

- Evola, G.; Marletta, L. A dynamic parameter to describe the thermal response of buildings to radiant heat gains. Energy Build. 2013, 65, 448–457. [Google Scholar] [CrossRef]

- Kontoleon, K.J.; Eumorfopoulou, E.A. The influence of wall orientation and exterior surface solar absorptivity on time lag and decrement factor in the Greek region. Renew. Energy 2008, 33, 1652–1664. [Google Scholar] [CrossRef]

- Liu, M.; Wittchen, K.B.; Heiselberg, P.K.; Winther, F.V. Development and sensitivity study of a simplified and dynamic method for double glazing facade and verified by a full-scale façade element. Energy Build. 2014, 68, 432–443. [Google Scholar] [CrossRef]

- International Standard ISO 13786. Thermal Performance of Building Components—Dynamic Thermal Characteristics—Calculation Methods, 2nd ed.; International Organization for Standardization: Geneva, Switzerland, 2007. [Google Scholar]

- JIS R 3106 (2017): Test Method for Transmittance, Reflectance, Emissivity and Solar Heat Gain of Flat Glasses. Available online: http://www.jisc.go.jp/app/jis/general/GnrJISSearch.html (accessed on 1 August 2018). (In Japanese)

- JIS R 3107 (2017): Method for Calculating Thermal Resistance of Sheet Glasses and Heat Transmission Coefficient in Construction. Available online: http://www.jisc.go.jp/app/jis/general/GnrJISSearch.html (accessed on 1 August 2018). (In Japanese)

- JIS A 1412-2 (2016): Method for Measuring Thermal Resistance and Thermal Conductivity of Thermal Insulation Material—Part 2: Heat Flow Meter Method (HFM Method). Available online: http://www.jisc.go.jp/app/jis/general/GnrJISSearch.html (accessed on 1 August 2018). (In Japanese)

- Tanaka, J.; Takeda, H.; Adachi, T.; Tsuchiya, T. Latest Building Environmental Engineering (Revision II); Inoue Shoin Co., Ltd.: Tokyo, Japan, 2001; pp. 191–192. (In Japanese) [Google Scholar]

- Davies, T.W. Thermodynamics, Heat & Mass Transfer, and Fluids Engineering, Fourier’s Law. Thermopedia 2011. [Google Scholar] [CrossRef]

- Davies, M.G. Building Heat Transfer; John-Wiley & Sons Ltd.: Chichester, UK, 2004. [Google Scholar]

- Urano, Y.; Watanabe, T. An analysis of multi-layer wall heat transfer by state transition matrix: Part 1 An approximate transfer functions model and its accuracy. Trans. Archit. Inst. Jpn. 1981, 305, 97–111. (In Japanese) [Google Scholar] [CrossRef]

- Urano, Y.; Watanabe, T. An analysis of multi-layer wall heat transfer by state transition matrix: Part 2 A successive calculation method and its accuracy. Trans. Archit. Inst. Jpn. 1982, 311, 57–66. (In Japanese) [Google Scholar] [CrossRef]

- Uezono, M. Present situation of Measuring method for Thermal properties of Building materials. Netsu Bussei 1992, 6, 23–28. (In Japanese) [Google Scholar] [CrossRef]

- Chartered Institution of Building Services Engineers (CIBSE). Environmental Design CIBSE Guide-A, 7th ed.; CIBSE: London, UK, 2006. [Google Scholar]

- Yuan, J.; Emura, K.; Sakai, H. Field measurement of the reflectance of highly reflective roofing sheets installed in school buildings. Soc. Heat. Air-Condi. Sanit. Eng. Jpn. 2012, 180, 23–30. (In Japanese) [Google Scholar]

- Yuan, J.; Farnham, C.; Emura, K.; Alam, M.A. Proposal for optimum combination of reflectivity and insulation thickness of building external walls for annual thermal load in Japan. Build. Environ. 2016, 103, 228–237. [Google Scholar] [CrossRef]

| Building Material | Thermal Conductivity (k) [W/mK] | Density (ρ) [kg/m3] | Specific Heat (Cp) [J/kgK] |

|---|---|---|---|

| Wood | 0.179 | 530 | 2300 |

| Expanded polystyrene | 0.037 | 16 | 1340 |

| Glass wool | 0.051 | 10 | 837 |

| Wood cement board | 0.16 | 680 | 1675 |

| Air layer | 0.026 | 1.2 | 1006 |

| Concrete | 0.9 | 2000 | 879 |

| Plaster | 0.43 | 1250 | 1050 |

© 2018 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, J. Impact of Insulation Type and Thickness on the Dynamic Thermal Characteristics of an External Wall Structure. Sustainability 2018, 10, 2835. https://doi.org/10.3390/su10082835

Yuan J. Impact of Insulation Type and Thickness on the Dynamic Thermal Characteristics of an External Wall Structure. Sustainability. 2018; 10(8):2835. https://doi.org/10.3390/su10082835

Chicago/Turabian StyleYuan, Jihui. 2018. "Impact of Insulation Type and Thickness on the Dynamic Thermal Characteristics of an External Wall Structure" Sustainability 10, no. 8: 2835. https://doi.org/10.3390/su10082835