Design of Green Cold Chain Networks for Imported Fresh Agri-Products in Belt and Road Development

Abstract

:1. Introduction

2. Literature Review

3. Problem Description and Formulation

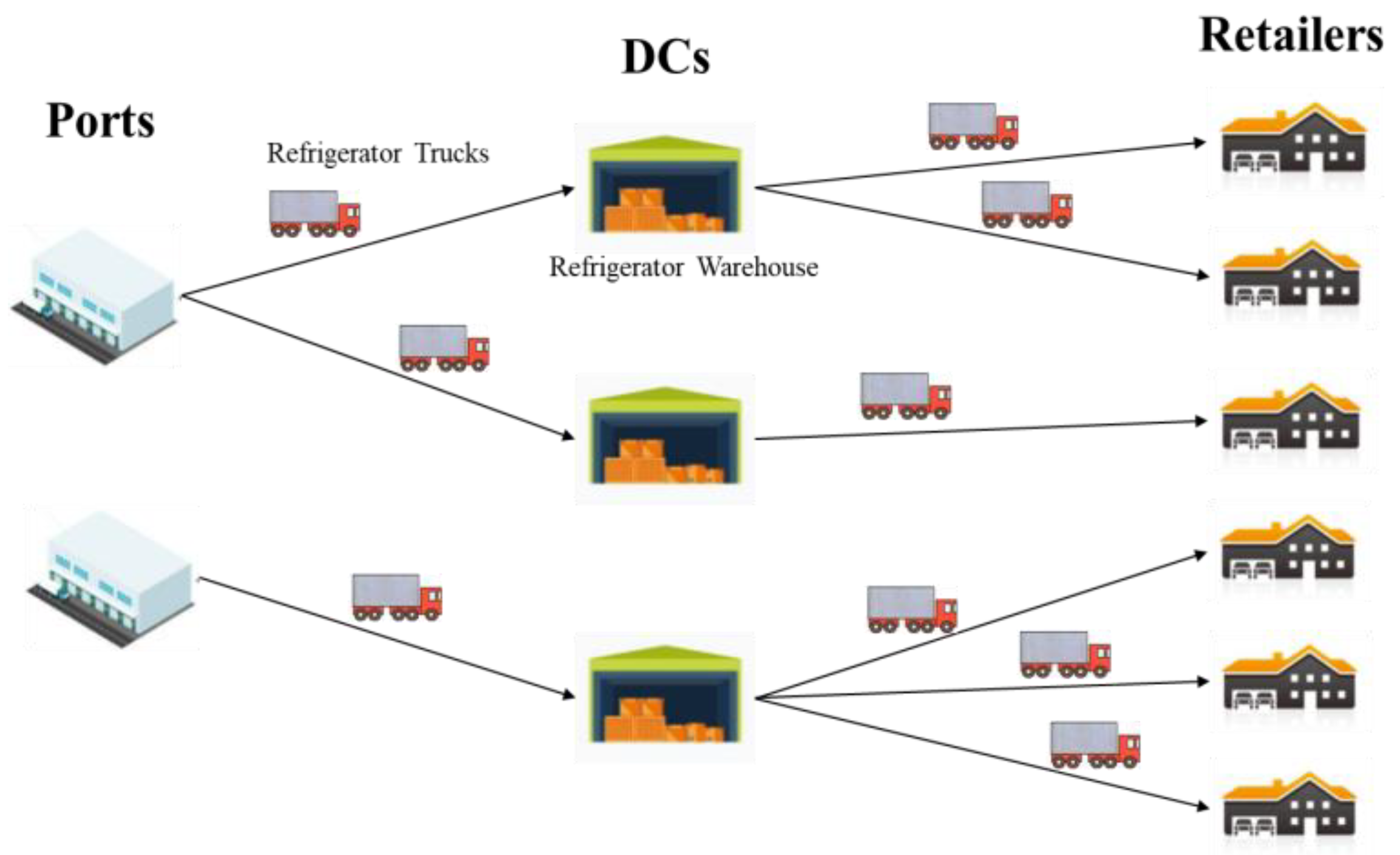

3.1. Problem Descriptions

3.2. Model Development

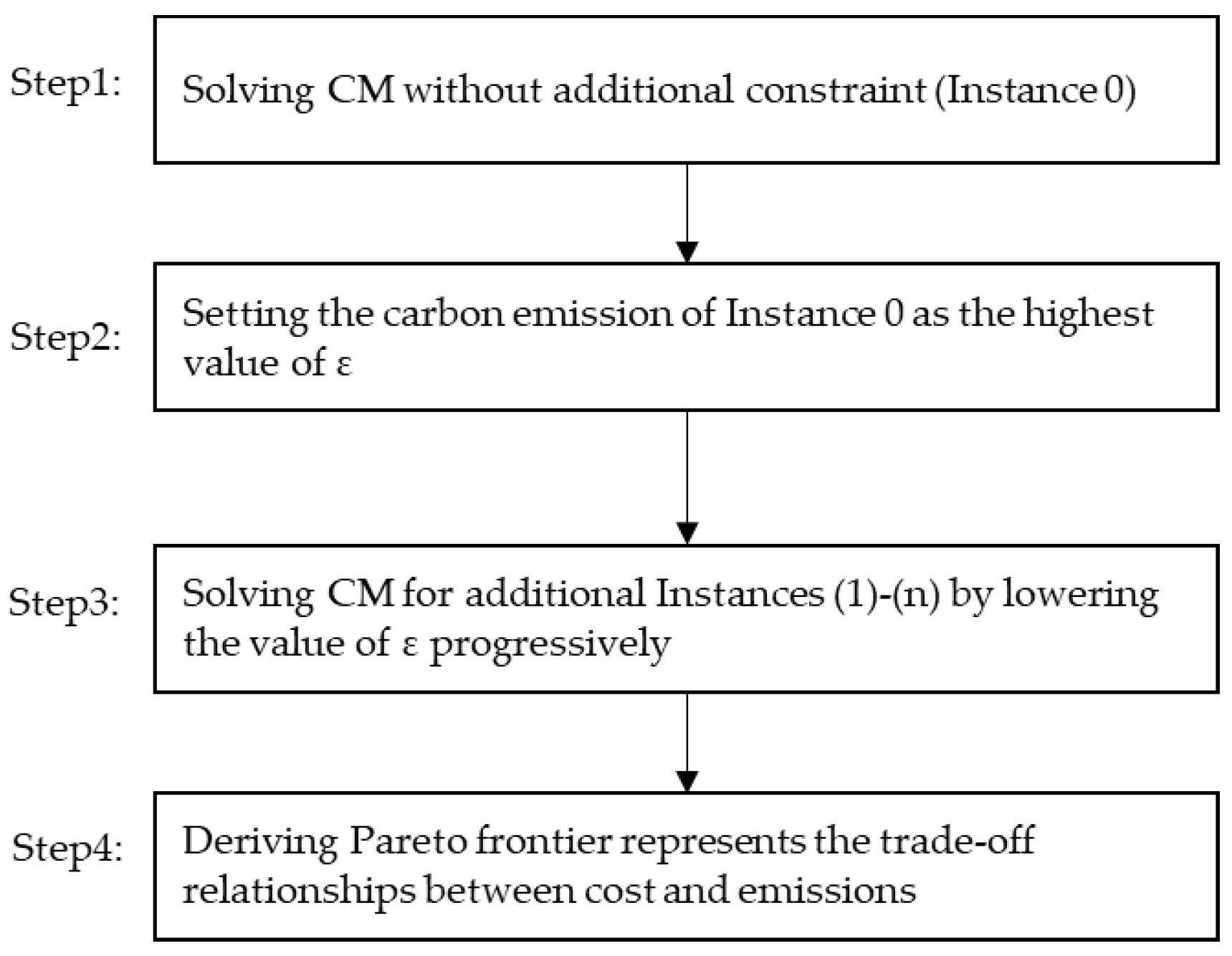

3.3. Model Solution

- CM: min OF1 (1)

- s.t.: Constraints (3)–(11);

4. Numerical Experiments

4.1. Data Collection

4.2. Analysis and Discussion

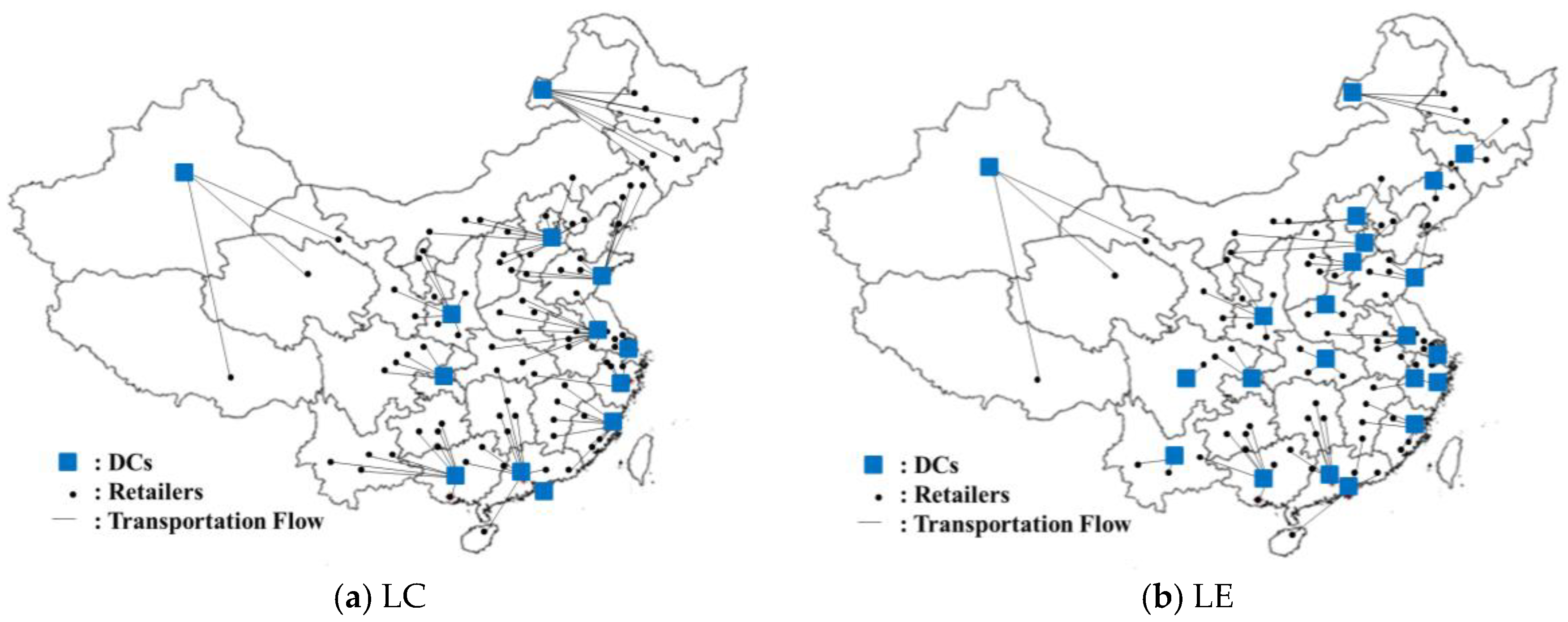

4.2.1. Solutions of the Two Base Scenarios with a Single Objective

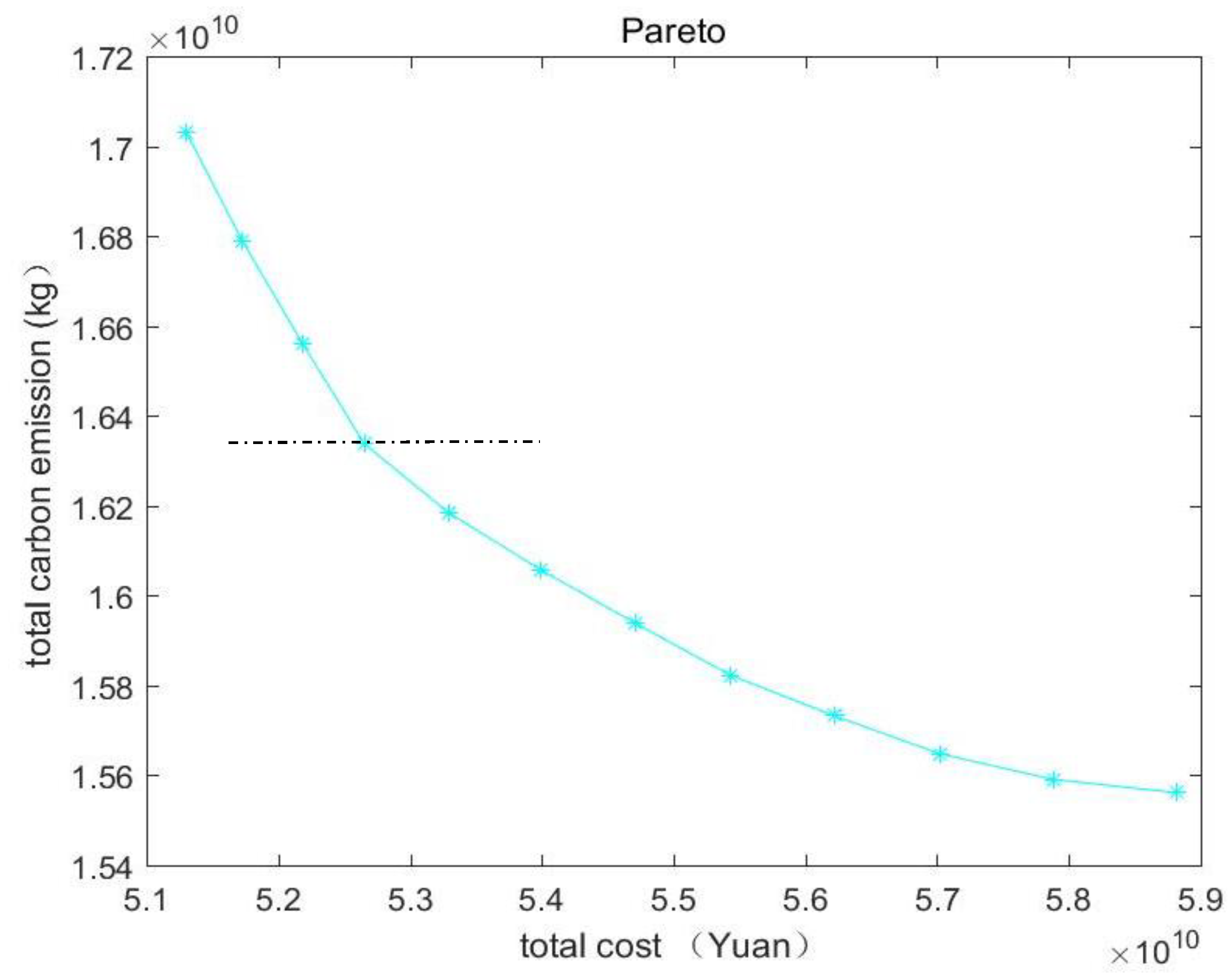

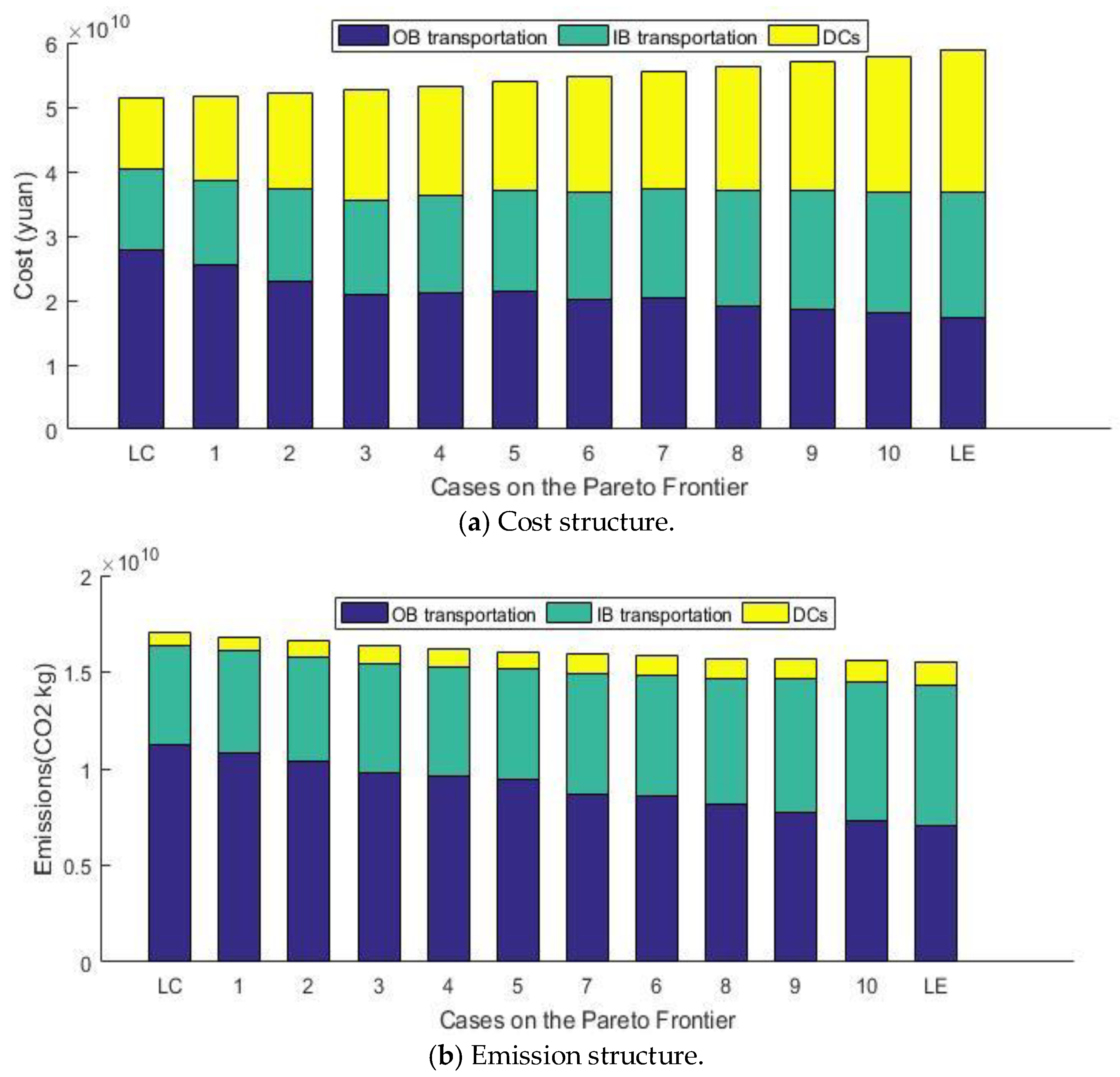

4.2.2. The Trade-Offs between the Two Objectives

- (1)

- The main reason for emission reduction on the cold chain is because of the increase of DC numbers. When more DCs are selected, the distance of outbound transportation will sharply drop. Then, the emission items related to outbound transportation will decrease, which can compensate for the emission increase related to inbound transportation and DC maintenance.

- (2)

- By carefully comparing the average temperature of each DC as shown in Table 4, we can see that when the number of DCs is increased, the average temperatures of DCs increase accordingly. Meanwhile, when the number of DCs stays equal—for example, in Scenarios 3, 4, and 5—the average temperature declines, which can, in turn, reduce the overall carbon emissions. This explains the decline on the Pareto frontier at the Scenario 3 point. The number of DCs increases at a rate of 2 for Scenarios 1, 2, 3, and the LC scenario. Meanwhile, the number stays stable for Scenario 4. This means that the emission reductions of outbound transportation cannot cover the emission increase caused by opening a DC. Consequently, an emission reduction can be obtained by moving DCs to lower-temperature places, which consequently increases the transportation cost.

- (3)

- The cost and emissions for inbound transportation and DC maintenance are positively related to the number of DCs, while the effect on outbound transportation is exactly the same in the opposite way. Moreover, the carbon emissions caused by transportation account for the largest share of the total emissions. This provides an important direction for the control of carbon emissions in cold supply chains.

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Ports | Manzhouli | Urumqi | Qingdao | Tianjin | Ningbo | Shanghai | Fuzhou |

| AAT (°C) | −1.2 | 8.4 | 12.3 | 13.8 | 16.6 | 17.6 | 21 |

| Supply of Fruit (ton) | 8000 | 10,000 | 32,000 | 26,000 | 52,000 | 47,000 | 23,000 |

| Supply of Frozen Product (ton) | 18,000 | 15,000 | 29,000 | 20,000 | 49,000 | 45,000 | 24,000 |

| Ports | Guangzhou | Nanning | Shenzhen | ||||

| AAT (°C) | 21.9 | 22.3 | 22.5 | ||||

| Supply of Fruit (ton) | 36,000 | 18,000 | 33,000 | ||||

| Supply of Frozen Product (ton) | 32,000 | 12,000 | 35,000 |

| Potential DCs | Manzhouli | Changchun | Urumqi | Shenyang | Qingdao | Beijing | Tianjin |

| AAT (°C) | −1.2 | 6.6 | 8.4 | 8.8 | 12.3 | 13.8 | 13.8 |

| Potential DCs | Shijiazhuang | Kunming | Nanjing | Xi'an | Zhengzhou | Ningbo | Chengdu |

| AAT (°C) | 14.6 | 15.0 | 15.1 | 15.8 | 16.4 | 16.6 | 16.8 |

| Potential DCs | Hefei | Wuhan | Shanghai | Hangzhou | Chongqing | Fuzhou | Guangzhou |

| AAT (°C) | 17.0 | 17.3 | 17.6 | 18.2 | 19.5 | 21.0 | 21.9 |

| Potential DCs | Nanning | Shenzhen | |||||

| AAT (°C) | 22.3 | 22.5 |

| Retailers | Manzhouli | Jiamusi | Qiqihar | Chifeng | Harbin | Jilin | Daqing |

|---|---|---|---|---|---|---|---|

| AAT (°C) | −1.2 | 3.0 | 3.2 | 3.5 | 3.5 | 3.9 | 4.2 |

| Demand of Fruit (ton) | 2511 | 2524 | 1009 | 2042 | 1578 | 1025 | 2196 |

| Demand of Frozen Product (ton) | 1674 | 1803 | 1442 | 1856 | 3155 | 1025 | 1464 |

| Retailers | Hohhot | Siping | Datong | Changchun | Fushun | Jiuquan | Zhangzhou |

| AAT (°C) | 4.3 | 5.9 | 6.4 | 6.6 | 6.6 | 6.6 | 6.7 |

| Demand of Fruit (ton) | 1033 | 2363 | 2369 | 3483 | 1312 | 2015 | 1505 |

| Demand of Frozen Product (ton) | 1475 | 1969 | 1974 | 3166 | 1312 | 1832 | 1505 |

| Retailers | Baotou | Lhasa | Urumqi | Yinchuan | Anshan | Shizuishan | Shenyang |

| AAT (°C) | 7.2 | 7.4 | 8.4 | 8.5 | 8.5 | 8.6 | 8.8 |

| Demand of Fruit (ton) | 2240 | 1766 | 1896 | 2449 | 1062 | 1354 | 2215 |

| Demand of Frozen Product (ton) | 1493 | 1766 | 1264 | 3061 | 1327 | 1504 | 3691 |

| Retailers | Pingliang | Yan'an | Taiyuan | Wuhai | Qinhuangdao | Yangquan | Lanzhou |

| AAT (°C) | 9.0 | 9.1 | 9.5 | 9.6 | 10.0 | 10.0 | 10.3 |

| Demand of Fruit (ton) | 1959 | 1122 | 4036 | 989 | 1422 | 2209 | 3830 |

| Demand of Frozen Product (ton) | 1306 | 1603 | 3363 | 1977 | 1580 | 1699 | 3482 |

| Retailers | Dalian | Tongchuan | Tianshui | Xianyang | Qingdao | Tangshan | Kaifeng |

| AAT (°C) | 10.5 | 10.6 | 11.0 | 11.1 | 12.3 | 12.5 | 12.5 |

| Demand of Fruit (ton) | 3020 | 2513 | 864 | 1952 | 4763 | 923 | 1216 |

| Demand of Frozen Product (ton) | 3020 | 1933 | 1440 | 1627 | 3664 | 1846 | 1216 |

| Retailers | Dongying | Zibo | Liupanshui | Beijing | Tianjin | Jinan | Handan |

| AAT (°C) | 12.8 | 13.3 | 13.5 | 13.8 | 13.8 | 13.8 | 14.0 |

| Demand of Fruit (ton) | 1579 | 1686 | 1683 | 4490 | 3636 | 4190 | 2356 |

| Demand of Frozen Product (ton) | 1435 | 1297 | 1870 | 7484 | 7271 | 3809 | 1812 |

| Retailers | Anshun | Zaozhuang | Qujing | Luoyang | Shijiazhuang | Huzhou | Luohe |

| AAT (°C) | 14.0 | 14.5 | 14.5 | 14.5 | 14.6 | 14.7 | 14.7 |

| Demand of Fruit (ton) | 1123 | 1817 | 1543 | 1554 | 1841 | 3951 | 2258 |

| Demand of Frozen Product (ton) | 1871 | 1817 | 1102 | 1036 | 3069 | 3592 | 1882 |

| Retailers | Kunming | Nanjing | Bengbu | Zunyi | Guiyang | Changzhou | Wuhu |

| AAT (°C) | 15.0 | 15.1 | 15.1 | 15.1 | 15.3 | 15.5 | 15.5 |

| Demand of Fruit (ton) | 2971 | 2494 | 2064 | 1216 | 3934 | 3991 | 2297 |

| Demand of Frozen Product (ton) | 3301 | 3563 | 1474 | 1216 | 3278 | 3070 | 1641 |

| Retailers | Baoshan | Zhenjiang | Suzhou | Xi'an | Jiaxing | Mianyang | Deyang |

| AAT (°C) | 15.5 | 15.6 | 15.7 | 15.8 | 15.9 | 16.0 | 16.0 |

| Demand of Fruit (ton) | 727 | 4371 | 3548 | 5298 | 2694 | 822 | 1735 |

| Demand of Frozen Product (ton) | 1212 | 3362 | 3225 | 3784 | 3367 | 1643 | 1446 |

| Retailers | Fuyang | Guangyuan | Xiangtan | Wuxi | Zhengzhou | Huainan | Jiujiang |

| AAT (°C) | 16.0 | 16.1 | 16.1 | 16.2 | 16.4 | 16.5 | 16.5 |

| Demand of Fruit (ton) | 1262 | 1681 | 1980 | 4801 | 2484 | 2016 | 1229 |

| Demand of Frozen Product (ton) | 1578 | 1681 | 1320 | 3693 | 3105 | 1440 | 1229 |

| Retailers | Ningbo | Chengdu | Yichang | Hefei | Zhuzhou | Huang Shi | Changsha |

| AAT (°C) | 16.6 | 16.8 | 16.9 | 17.0 | 17.0 | 17.0 | 17.2 |

| Demand of Fruit (ton) | 10910 | 10445 | 1250 | 1824 | 1678 | 1798 | 11,634 |

| Demand of Frozen Product (ton) | 7793 | 7461 | 1389 | 3648 | 1291 | 1798 | 7756 |

| Retailers | Wuhan | Nanchang | Shanghai | Hengyang | Hangzhou | Sanming | Ji'an |

| AAT (°C) | 17.3 | 17.4 | 17.6 | 18.0 | 18.2 | 18.2 | 18.5 |

| Demand of Fruit (ton) | 6421 | 4719 | 4225 | 1128 | 7858 | 2209 | 1732 |

| Demand of Frozen Product (ton) | 7134 | 3146 | 7041 | 1611 | 7858 | 1699 | 1924 |

| Retailers | Liuzhou | Ganzhou | Guilin | Chongqing | Yuxi | Shantou | Quanzhou |

| AAT (°C) | 18.8 | 18.8 | 19.3 | 19.5 | 19.8 | 20.0 | 20.2 |

| Demand of Fruit (ton) | 974 | 1495 | 4565 | 5977 | 1882 | 5179 | 1547 |

| Demand of Frozen Product (ton) | 1218 | 1359 | 3804 | 7471 | 1568 | 3984 | 1547 |

| Retailers | Fuzhou | Xiamen | Zhangzhou | Guangzhou | Huizhou | Nanning | Shenzhen |

| AAT (°C) | 21.0 | 21.0 | 21.4 | 21.9 | 22.0 | 22.3 | 22.5 |

| Demand of Fruit (ton) | 3108 | 4938 | 520 | 10,641 | 2256 | 2775 | 4490 |

| Demand of Frozen Product (ton) | 3453 | 3292 | 1039 | 7601 | 1880 | 3469 | 7483 |

| Retailers | North Sea | Haikou | |||||

| AAT (°C) | 22.9 | 24.2 | |||||

| Demand of Fruit (ton) | 2100 | 1443 | |||||

| Demand of Frozen Product (ton) | 1750 | 1443 |

| Parameters | Values/Estimations | Sources |

|---|---|---|

| Fuel conversion factor | 2.63 kg CO2/L | https://www.gov.uk/government/uploads/system/uploads/attachment_data/file/69568/pb13792-emission-factor-methodologypaper-120706.pdf [52] |

| Fuel consumption rate for inbound transportation | 0.01427 L/kg·km | Kellner and Igl (2015) [5] |

| Fuel consumption rate for outbound transportation | 0.01958 L/kg·km | Kellner and Igl (2015) [5] |

| Base value of fuel consumption of refrigerators | 3.6 × 10–6 L/kg·km | Wu et al. (2013) [7] |

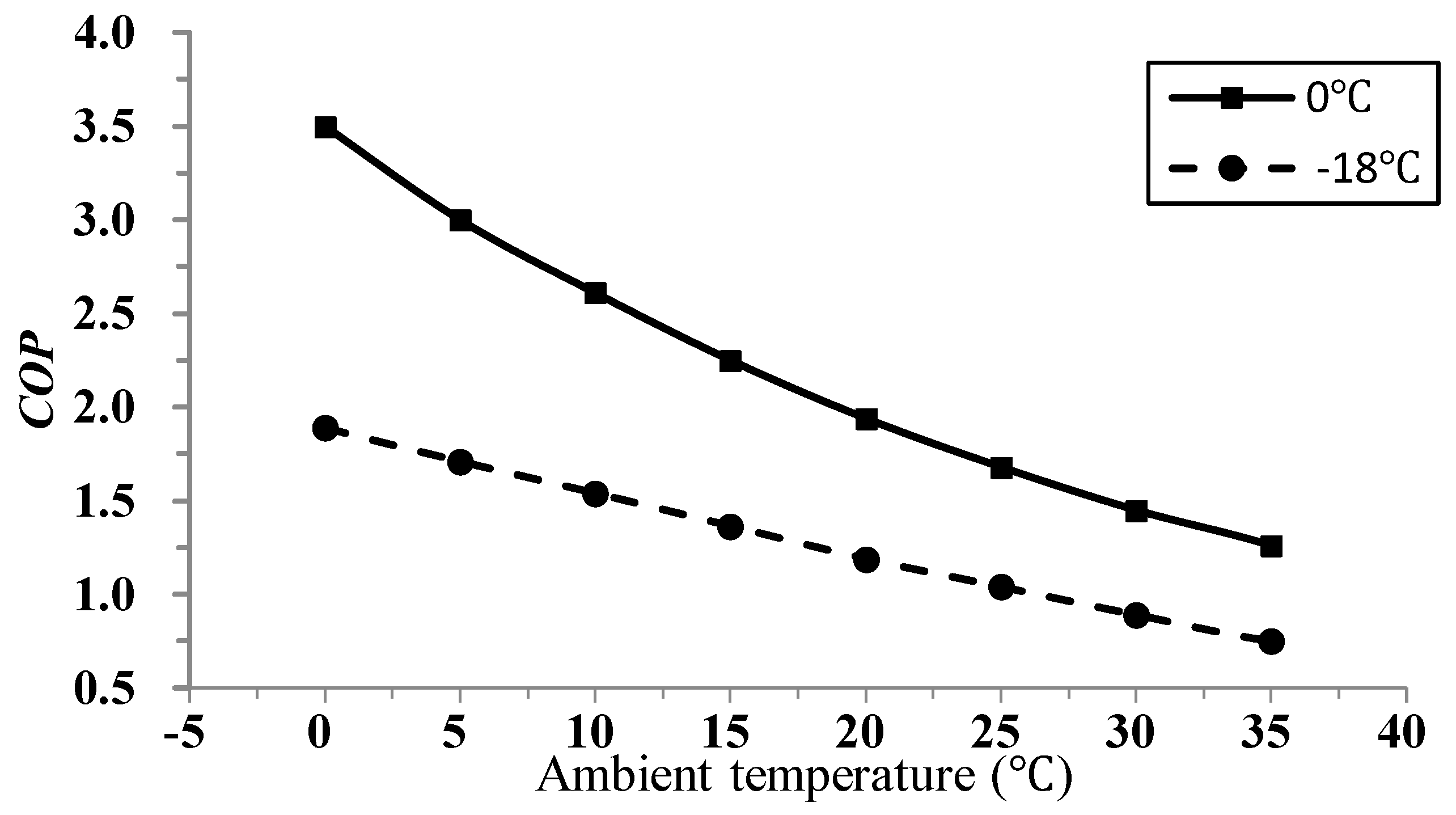

| Coefficient of performance of refrigerators | Data according to Figure 4 | Wu et al. (2013) [7] |

| Fuel price | 6.2 yuan/L [54] | http://youjia.chemcp.com [54] |

| Emission factor of electricity | 0.766 kg CO2/kWh | http://www.iea.org/publications/freepublications/publication/name,32870,en.html [55] |

| Fixed cost for maintaining DCs | 1,000,000,000 yuan | Assumption |

| Electricity price | 1.2 yuan/kWh | http://www.nea.gov.cn/ [56] |

References

- United Nations Development Programme in China (UNDP). Belt and Road Initiative. Available online: http://www.cn.undp.org/content/china/en/home/belt-and-road.html (accessed on 5 December 2017).

- Reports on Chinese Dinner Consumption Trend in 2018. Available online: http://www.cbndata.com/report/551/detail?isReading=report&page=1 (accessed on 20 January 2018).

- Coulomb, D. Refrigeration and cold chain serving the global food industry and creating a better future: Two key IIR challenges for improved health and environment. Trends Food Sci. Technol. 2008, 19, 413–417. [Google Scholar] [CrossRef]

- James, S.J.; James, C.; Evans, J.A. Modelling of food transportation systems—A review. Int. J. Refrigeration 2006, 29, 947–957. [Google Scholar] [CrossRef]

- Kellner, F.; Igl, J. Greenhouse gas reduction in transport: Analyzing the carbon dioxide performance of different freight forwarder networks. J. Clean. Prod. 2015, 99, 177–191. [Google Scholar] [CrossRef]

- Meneghetti, A.; Monti, L. Greening the food supply chain: An optimisation model for sustainable design of refrigerated automated warehouses. Int. J. Prod. Res. 2015, 53, 6567–6587. [Google Scholar] [CrossRef]

- Wu, X.; Hu, S.; Mo, S. Carbon footprint model for evaluating the global warming impact of food transport refrigeration systems. J. Clean. Prod. 2013, 54, 115–124. [Google Scholar] [CrossRef]

- Soysal, M.; Bloemhof-Ruwaard, J.M.; van der Vorst, J.G.A.J. Modelling food logistics networks with emission considerations: The case of an international beef supply chain. Int. J. Prod. Econ. 2014, 152, 57–70. [Google Scholar] [CrossRef]

- Eskandarpour, M.; Dejax, P.; Miemczyk, J.; Pétona, O. Sustainable supply chain network design: An optimization-oriented review. Omega 2015, 54, 11–32. [Google Scholar] [CrossRef] [Green Version]

- Arıkan, E.; Fichtinger, J.; Ries, J.M. Impact of transportation lead-time variability on the economic and environmental performance of inventory systems. Int. J. Prod. Econ. 2014, 157, 279–288. [Google Scholar] [CrossRef]

- Lee, K.H.; Cheong, I.M. Measuring a carbon footprint and environmental practice: The case of Hyundai Motors Co.(HMC). Ind. Manag. Data Syst. 2011, 111, 961–978. [Google Scholar] [CrossRef]

- Elhedhli, S.; Merrick, R. Green supply chain network design to reduce carbon emissions. Transp. Res. Part D Transp. Environ. 2012, 17, 370–379. [Google Scholar] [CrossRef]

- Benjaafar, S.; Li, Y.; Daskin, M. Carbon footprint and the management of supply chains: Insights from simple models. IEEE Trans. Autom. Sci. Eng. 2013, 10, 99–116. [Google Scholar] [CrossRef]

- Gallo, A.; Accorsi, R.; Baruffaldi, G.; Manzini, R. Designing Sustainable Cold Chains for Long-Range Food Distribution: Energy-Effective Corridors on the Silk Road Belt. Sustainability 2017, 9, 2044. [Google Scholar] [CrossRef]

- Lee, D.H.; Dong, M.; Bian, W. The design of sustainable logistics network under uncertainty. Int. J. Prod. Econ. 2010, 128, 159–166. [Google Scholar] [CrossRef]

- Pishvaee, M.S.; Razmi, J. Environmental supply chain network design using multi-objective fuzzy mathematical programming. Appl. Math. Model. 2012, 36, 3433–3446. [Google Scholar] [CrossRef]

- Tozzi, M.; Corazza, M.V.; Musso, A. Urban goods movements in a sensitive context: The case of Parma. Res. Transp. Bus. Manag. 2014, 11, 134–141. [Google Scholar] [CrossRef]

- Borodin, V.; Bourtembourg, J.; Hnaien, F.; Labadiec, N. Handling uncertainty in agricultural supply chain management: A state of the art. Eur. J. Oper. Res. 2016, 254, 348–359. [Google Scholar] [CrossRef]

- Tzamalis, P.G.; Panagiotakos, D.B.; Drosinos, E.H. A ‘best practice score’ for the assessment of food quality and safety management systems in fresh-cut produce sector. Food Control 2016, 63, 179–186. [Google Scholar] [CrossRef]

- Validi, S.; Bhattacharya, A.; Byrne, P.J. A case analysis of a sustainable food supply chain distribution system—A multi-objective approach. Int. J. Prod. Econ. 2014, 152, 71–87. [Google Scholar] [CrossRef]

- Brandenburg, M.; Govindan, K.; Sarkis, J.; Seuringa, S. Quantitative models for sustainable supply chain management: Developments and directions. Eur. J. Oper. Res. 2014, 233, 299–312. [Google Scholar] [CrossRef]

- Panozzo, G.; Cortella, G. Standards for transport of perishable goods are still adequate? Connections between standards and technologies in perishable foodstuffs transport. Food Sci. Technol. 2008, 19, 432–440. [Google Scholar] [CrossRef]

- Yang, S.; Xiao, Y.; Zheng, Y.; Liu, Y. The Green Supply Chain Design and Marketing Strategy for Perishable Food Based on Temperature Control. Sustainability 2017, 9, 1511. [Google Scholar] [CrossRef]

- Pipatprapa, A.; Huang, H.H.; Huang, C.H. A novel environmental performance evaluation of Thailand’s food industry using structural equation modeling and fuzzy analytic hierarchy techniques. Sustainability 2016, 8, 246. [Google Scholar] [CrossRef]

- Gwanpua, S.G.; Verboven, P.; Leducq, D.; Brownc, T.; Verlindend, B.E.; Bekelea, E.; Aregawia, W.; Evansc, J.; Fosterc, A.; Duretb, S.; et al. The FRISBEE tool, a software for optimising the trade-off between food quality, energy use, and glob al warming impact of cold chains. J. Food Eng. 2015, 148, 2–12. [Google Scholar] [CrossRef]

- Strotmann, C.; Göbel, C.; Friedrich, S.; Kreyenschmidt, J.; Ritter, G.; Teitscheid, P. A participatory approach to minimizing food waste in the food industry—A manual for managers. Sustainability 2017, 9, 66. [Google Scholar] [CrossRef]

- Bosona, T.G.; Gebresenbet, G. Cluster building and logistics network integration of local food supply chain. Biosyst. Eng. 2011, 108, 293–302. [Google Scholar] [CrossRef]

- Amorim, P.; Almada-Lobo, B. The impact of food perishability issues in the vehicle routing problem. Comput. Ind. Eng. 2014, 67, 223–233. [Google Scholar] [CrossRef]

- Wang, S.; Tao, F.; Shi, Y.; Wen, H. Optimization of vehicle routing problem with time windows for cold chain logistics based on carbon tax. Sustainability 2017, 9, 694. [Google Scholar] [CrossRef]

- Jindal, A.; Sangwan, K.S. Closed loop supply chain network design and optimisation using fuzzy mixed integer linear programming model. Int. J. Prod. Res. 2014, 52, 4156–4173. [Google Scholar] [CrossRef]

- Hasani, A.; Khosrojerdi, A. Robust global supply chain network design under disruption and uncertainty considering resilience strategies: A parallel memetic algorithm for a real-life case study. Transp. Res. Part E Logist. Transp. Rev. 2016, 87, 20–52. [Google Scholar] [CrossRef]

- Rezaee, A.; Dehghanian, F.; Fahimnia, B.; Beamon, B. Green supply chain network design with stochastic demand and carbon price. Ann. Oper. Res. 2017, 250, 463–485. [Google Scholar] [CrossRef]

- Farahani, R.Z.; Rezapour, S.; Drezner, T.; Fallahd, S. Competitive supply chain network design: An overview of classifications, models, solution techniques and applications. Omega 2014, 45, 92–118. [Google Scholar] [CrossRef]

- Govindan, K.; Fattahi, M.; Keyvanshokooh, E. Supply chain network design under uncertainty: A comprehensive review and future research directions. Eur. J. Oper. Res. 2017, 263, 108–141. [Google Scholar] [CrossRef]

- Srivastava, S.K. Network design for reverse logistics. Omega 2008, 36, 535–548. [Google Scholar] [CrossRef]

- Chaabane, A.; Ramudhin, A.; Paquet, M. Design of sustainable supply chains under the emission trading scheme. Int. J. Prod. Econ. 2012, 135, 37–49. [Google Scholar] [CrossRef]

- Akgul, O.; Shah, N.; Papageorgiou, L.G. An optimisation framework for a hybrid first/second generation bioethanol supply chain. Comput. Chem. Eng. 2012, 42, 101–114. [Google Scholar] [CrossRef]

- Bortolini, M.; Faccio, M.; Ferrari, E.; Gamberib, M.; Pilatib, F. Fresh food sustainable distribution: Cost, delivery time and carbon footprint three-objective optimization. J. Food Eng. 2016, 174, 56–67. [Google Scholar] [CrossRef]

- Osvald, A.; Stirn, L.Z. A vehicle routing algorithm for the distribution of fresh vegetables and similar perishable food. J. Food Eng. 2008, 85, 285–295. [Google Scholar] [CrossRef]

- Coskun, S.; Ozgur, L.; Polat, O.; Gungor, A. A model proposal for green supply chain network design based on consumer segmentation. J. Clean. Prod. 2016, 110, 149–157. [Google Scholar] [CrossRef]

- Analysis on the Development Prospect of China’s Cold Chain Logistics Industry in 2017. Available online: http://www.chyxx.com/industry/201709/560686.html (accessed on 19 January 2018).

- Olsthoorn, X.; Tyteca, D.; Wehrmeyer, W.; Wagnerc, M. Environmental indicators for business: A review of the literature and standardisation methods. J. Clean. Prod. 2001, 9, 453–463. [Google Scholar] [CrossRef]

- Andersson, J. A Survey of Multi-objective Optimization in Engineering Design; Department of Mechanical Engineering, Linktjping University: Linköping, Sweden, 2000. [Google Scholar]

- Eating on Chinese New Year—Report on Consumption Trends of E-Commerce for Fresh Produce. Available online: http://www.sohu.com/a/126521289_476012 (accessed on 28 October 2017).

- Insights of E-Commerce for China’s Fresh Produce in 2018. Available online: http://report.iresearch.cn/report/201801/3123.shtml (accessed on 10 February 2018).

- Weather of China. Available online: http://www.weather.com.cn (accessed on 11 December 2017).

- Baidu Map. Available online: https://map.baidu.com/ (accessed on 12 December 2017).

- National Bureau of Statistics of China. Available online: http://www.stats.gov.cn/tjsj/ (accessed on 1 February 2018).

- Chinaports. Available online: http://www.chinaports.com/thruput (accessed on 2 February 2018).

- McKinnon, A.C.; Piecyk, M.I. Measurement of CO2 emissions from road freight transport: A review of UK experience. Energy Policy 2009, 37, 3733–3742. [Google Scholar] [CrossRef]

- DEFRA (Department for Environment, Food and Rural Affairs). Greenhouse Gas Conversion Factors for Company Reporting. 2012. Available online: https://www.gov.uk/government/uploads/system/uploads/attachment_data/file/69555/pb13773-ghg-conversionfactors2012.xls (accessed on 27 January 2018).

- DEFRA (Department for Environment, Food and Rural Affairs). Guidelines to Defra/DECC’s GHG Conversion Factors for Company Reporting, Methodology Paper for Emission Factors. 2012. Available online: https://www.gov.uk/government/uploads/system/uploads/attachment_data/file/69568/pb13792-emission-factor-methodologypaper-120706.pdf (accessed on 27 January 2018).

- Tsao, Y.C.; Lu, J.C. A supply chain network design considering transportation cost discounts. Transp. Res. Part E Logist. Transp. Rev. 2012, 48, 401–414. [Google Scholar] [CrossRef]

- Oil Price in China. Available online: http://youjia.chemcp.com (accessed on 1 March 2018).

- International Energy Agency (IEA). CO2 Emissions from Fuel Combustion—Highlights. 2012. Available online: http://www.iea.org/publications/freepublications/publication/name,32870,en.html (accessed on 27 January 2018).

- National Energy Administration. Available online: http://www.nea.gov.cn/ (accessed on 8 March 2018).

| Indices | |

| i = 1,…,I | Set of ports |

| j = 1,…,J | Set of potential DCs |

| k = 1,…,K | Set of retailers |

| u = 1,…,U | Set of products |

| Parameters | |

| Average annual temperatures of ports | |

| Average annual temperature of DCs | |

| Average annual temperature of cities of retailers | |

| Unit carbon emission rate of transporting product u from port i to DC j (kg CO2/kg·km ) | |

| Unit carbon emission rate of transporting product u from DC j to retailer k (kg CO2/kg·km) | |

| Unit cost of transporting product u from port i to DC j (yuan/ kg·km) | |

| Unit cost of transporting product u from DC j to retailer k (yuan/ kg·km) | |

| Distance from port i to DC j | |

| Distance from DC j to retailer k | |

| Supply of product u of port i | |

| Demand of product u of retailer j | |

| Cost of DC j | |

| Emission of DC j | |

| Minimum number of DCs required by the decision-maker | |

| Maximum number of DCs required by the decision-maker | |

| A large number for modeling | |

| Decision Variables | |

| =1, if DC j is selected (binary decision variable) | |

| Amount of products u transported from port i to DC j | |

| Amount of products u transported from DC j to retailer k | |

| Vehicle Type | Fuel Consumption: Totally Loaded | Max. Payload |

|---|---|---|

| HGV-40 | 37.1 L/100 km | 26 tons |

| HGV-24 | 23.5 L/100 km | 12 tons |

| LC (Lowest Cost ) | LE (Lowest Emission) | |

|---|---|---|

| Transportation Cost (Yuan) | ||

| Inbound Transportation | 1.25 × 1010 | 1.94 × 1010 |

| Outbound Transportation | 2.78 × 1010 | 1.74 × 1010 |

| Cost of DCs | 1.10 × 1010 | 2.20 × 1010 |

| Total | 5.13 × 1010 | 5.88 × 1010 |

| Carbon emission (kg CO2) | ||

| Inbound Transportation | 5.19 × 109 | 7.30 × 109 |

| Outbound Transportation | 1.12 × 1010 | 7.01 × 109 |

| Emission of DCs | 6.37 × 108 | 1.20 × 109 |

| Total | 1.70 × 1010 | 1.55 × 1010 |

| General | ||

| Number of DCs | 11 | 22 |

| Scenarios | LC | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | LE |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of DCs | 11 | 13 | 15 | 17 | 17 | 17 | 18 | 18 | 19 | 20 | 21 | 22 |

| Average °C of DCs | 7.20 | 9.03 | 10.03 | 11.34 | 11.01 | 10.67 | 12.00 | 11.58 | 12.38 | 13.09 | 13.88 | 14.48 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fang, Y.; Jiang, Y.; Sun, L.; Han, X. Design of Green Cold Chain Networks for Imported Fresh Agri-Products in Belt and Road Development. Sustainability 2018, 10, 1572. https://doi.org/10.3390/su10051572

Fang Y, Jiang Y, Sun L, Han X. Design of Green Cold Chain Networks for Imported Fresh Agri-Products in Belt and Road Development. Sustainability. 2018; 10(5):1572. https://doi.org/10.3390/su10051572

Chicago/Turabian StyleFang, Yan, Yiping Jiang, Lijun Sun, and Xingxing Han. 2018. "Design of Green Cold Chain Networks for Imported Fresh Agri-Products in Belt and Road Development" Sustainability 10, no. 5: 1572. https://doi.org/10.3390/su10051572