Assessing the Ability of the Cradle to Cradle Certified™ Products Program to Reliably Determine the Environmental Performance of Products

Abstract

:1. Introduction

2. Background

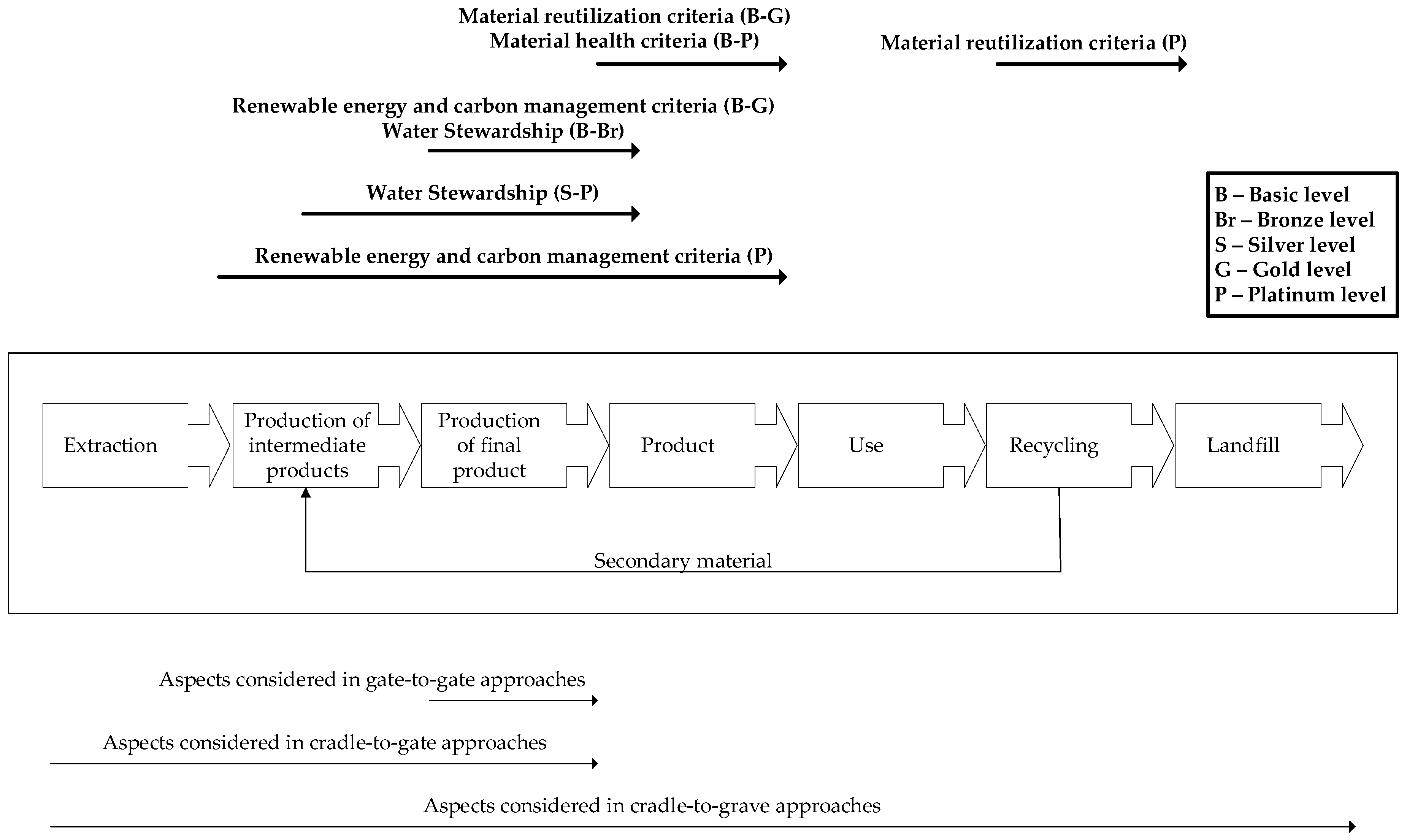

- Waste equals food: All materials and emissions (if not specified otherwise) are seen as beneficial for the environment or the technosphere (i.e., the biological or the technical cycle, respectively). Products shall be designed in a way that they pose no danger to human health and can be recycled continuously. By complying to this principle, no waste is generated, and all outputs are inputs for (an)other system(s). Based on these cycles, closed-looped systems can be defined and established.

- Strengthen renewable energy: Using renewable energy is defined as being of crucial importance to effective design. Their use should be increased as much as possible.

- Celebrate diversity: The key to innovation is to design products that are technically diverse (i.e., avoiding “one-size-fits-all designs”).

- Energy efficiency (referring to using as little energy as possible) is not considered in C2CP, because the long-term goal is to only use renewable energy, which is assumed to have no emissions. However, to reduce environmental impacts, the absolute as well as relative (per product unit) energy consumed has to be considered. Furthermore, even renewable energy cannot be produced without discharging any emissions [18,20,29,31,33].

- C2CP does not consider all relevant substances/emissions over the entire life cycle of the analyzed product [28], e.g., acidifying and eutrophying emissions (impacting the quality of water bodies and soils) as well as particulate matter emissions (impacting human health) are not taken into account. The awarding criteria of C2CP are not product-specific, but generic and equal for all products [25].

3. Methodological Approach

- (1)

- (2)

- Identification of existing assessment schemes for methods addressing environmental impacts: the following assessment schemes exist for evaluating methods determining environmental impacts: Reimann et al. [47]; European Commission-Joint Research Centre [48]; Lehmann et al. [39]; and Forin et al. [49].

- (3)

- Analysis whether existing criteria of the above schemes (Step 2) can contribute to the goal of the herein applied assessment scheme: Not all of the criteria can be used to fit the goal of the assessment scheme (Step 1); e.g., availability of characterization factors in LCA software tools is included in the schemes used by the European Commission-Joint Research Centre [48], Lehmann et al. [39] and Forin et al. [49] but is not relevant to the goal of this assessment. Several criteria can be directly used in the herein developed assessment scheme, e.g., stakeholder acceptance as addressed by Reimann et al. [47], European Commission-Joint Research Centre [48], Lehmann et al. [39] and Forin et al. [49]. For further explanations regarding why certain criteria are relevant, please see information in Section S1 of the Supplementary Materials.

- (4)

- Determination whether certain aspects (for which criteria are needed) are missing to reach the goal of the respective assessment scheme: due to the comprehensiveness of the criteria in the identified publications, there was no need to define additional criteria.

- (5)

- Development of additional criteria for the identified aspects (in Step 4): Not necessary, because missing aspects could not be identified.

- (6)

- Compilation of existing and newly developed criteria into a criteria-based assessment scheme: Criteria identified in (Step 3) are compiled to an overall assessment scheme (see Table 1).

4. Results and Discussion

4.1. Stakeholder Acceptance

4.2. Documentation and Review

4.3. Environmental Relevance

4.4. Scientific Soundness

4.5. Applicability

4.6. Overall Results and Recommendations

- The awarding criteria of C2CP are not product-specific, but generic and equal for all products [25].

- Uncertainties of the method are not addressed sufficiently.

- Biological nutrients are defined as being biodegradable [17].

- It is not considered how many times a material can be recycled.

- A product/material is defined as being recyclable, when it is recycled once [17].

- Quality loses due to recycling are not reflected sufficiently by the awarding criteria.

- For renewable sourced materials, incineration counts as recycling [17].

- Offsetting of GHG emissions is given priority over energy efficiency measures, although the effectiveness of existing offsetting schemes is not proven beneficial.

- Relevant environmental impacts are not considered [28].

- Method has not undergone sufficient scientific review and debate.

- Consider all relevant emissions and therefore also revise the assumption that all nutrients introduced in the environment are beneficial.

- Consider the entire life cycle in the awarding criteria.

- Consider the development of product-specific awarding criteria.

- Consider absolute as well as relative (per product unit) amount of used energy.

- Consider how many times a material and/or a product can be recycled and their possible quality losses.

- Incineration of renewable materials should be excluded from the awarding criteria (or has to be specified for different materials).

- Better specify in the program’s rules the process of stakeholder consultation and the involvement of stakeholders (e.g., notification procedure, etc.) to involve more stakeholders during the update of the Product Standard.

- Transparently communicate the uncertainties of the method and how they can be determined.

- Debate specifics of the C2CP method in a larger circle of stakeholders via, e.g., peer-reviewed journals or other means.

- Provide tool for application.

5. Conclusions

Supplementary Materials

Supplementary File 1Author Contributions

Acknowledgments

Conflicts of Interest

References

- Finkbeiner, M.; Schau, E.M.; Lehmann, A.; Traverso, M. Towards Life Cycle Sustainability Assessment. Sustainability 2010, 2, 3309–3322. [Google Scholar] [CrossRef]

- Finkbeiner, M. Carbon footprinting—Opportunities and threats. Int. J. Life Cycle Assess. 2009, 14, 91–94. [Google Scholar] [CrossRef]

- Berger, M.; Finkbeiner, M. Water Footprinting: How to Address Water Use in Life Cycle Assessment? Sustainability 2010, 2, 919–944. [Google Scholar] [CrossRef]

- ISO 14040 International Standard—Environmental management—Life cycle assessment—Principles and framework 2006. Available online: https://www.iso.org/standard/37456.html (accessed on 10 March 2018).

- European Commission Product Environmental Footprint (PEF) Guide. 2012. Available online: http://ec.europa.eu/environment/eussd/pdf/footprint/PEF%20methodology%20final%20draft.pdf (accessed on 2 May 2018).

- Lehmann, A.; Bach, V.; Finkbeiner, M. EU Product Environmental Footprint—Mid-Term Review of the Pilot Phase. Sustainability 2016, 8, 92. [Google Scholar] [CrossRef]

- Finkbeiner, M. From the 40s to the 70s—The future of LCA in the ISO 14000 family. Int. J. Life Cycle Assess. 2013, 18, 1–4. [Google Scholar] [CrossRef]

- Finkbeiner, M. The International Standards as the Constitution of Life Cycle Assessment: The ISO 14040 Series and its Offspring. In Background and Future Prospects in Life Cycle Assessment. LCA Compendium—The Complete World of Life Cycle Assessment; Springer: Dordrecht, The Netherlands, 2014; pp. 85–106. [Google Scholar]

- European Parliament. Directive 2009/125/EC of the European Parliament and of the Council of 21 October 2009 Establishing a Framework for the Setting of Ecodesign Requirements for Energy-Related Products; European Commission: Brussels, Belgium, 2009. [Google Scholar]

- Carvalho, H.; Govindan, K.; Azevedo, S.G.; Cruz-Machado, V. Modelling green and lean supply chains: An eco-efficiency perspective. Resour. Conserv. Recycl. 2017, 120, 75–87. [Google Scholar] [CrossRef]

- Wang, Z.; Zhao, L.; Mao, G.; Wu, B. Eco-Efficiency Trends and Decoupling Analysis of Environmental Pressures in Tianjin, China. Sustainability 2015, 7, 15407–15422. [Google Scholar] [CrossRef]

- ISO 14020 Environmental labels and declarations—General principles 2000. Available online: https://www.iso.org/obp/ui/#iso:std:iso:14020:ed-2:v1:en (accessed on 10 March 2018).

- ISO Environmental labels and declarations—Type I environmental labelling—Principles and procedures (ISO 14024:1999) 1999. Available online: https://www.iso.org/standard/23145.html (accessed on 10 March 2018).

- ISO Environmental labels and declarations—Type III environmental declarations—Principles and procedures (ISO 14025:2006) 2006. Available online: https://www.iso.org/standard/38131.html (accessed on 10 March 2018).

- Minkov, N.; Lehmann, A.; Winter, L.; Finkbeiner, M. Characterization of environmental labels beyond the criteria of ISO 14020-series. 2017, submitted for publication. 2017; submitted for publication. [Google Scholar]

- Biedermann, H.; Vorbach, S. Innovation und Nachhaltigkeit: Strategisch-operatives Energie- und Ressourcenmanagement; Rainer Hampp Verlag: Augsburg, Germany, 2015; ISBN 9783957101334. [Google Scholar]

- Cradle to Cradle Products Innovation Institute. Cradle to Cradle CertifiedTM Product Standard Version 3.1; Cradle to Cradle Products Innovation Institute: Oakland, CA, USA, 2016. [Google Scholar]

- Bakker, C.A.; Wever, R.; Teoh, C.; de Clercq, S. Designing cradle-to-cradle products: A reality check. Int. J. Sustain. Eng. 2010, 3, 2–8. [Google Scholar] [CrossRef]

- Voorthuis, J.; Gijbels, C. A Fair Accord: Cradle to Cradle as a Design Theory Measured against John Rawls’ Theory of Justice and Immanuel Kant’s Categorical Imperative. Sustainability 2010, 2, 371–382. [Google Scholar] [CrossRef]

- Bjørn, A.; Hauschild, M.Z. Cradle to Cradle and LCA. In Life Cycle Assessment; Hauschild, M.Z., Rosenbaum, R.K., Olsen, S.I., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 605–631. ISBN 978-3-319-56474-6. [Google Scholar]

- Bjørn, A.; Hauschild, M.Z. Cradle to Cradle and LCA—Is there a Conflict? In Glocalized Solutions for Sustainability in Manufacturing; Hesselbach, J., Herrmann, C., Eds.; Springer: Berlin/Heidelberg, Germany, 2011; pp. 599–604. ISBN 978-3-642-19692-8. [Google Scholar]

- ISO 14044 Environmental management - Life cycle assessment - Requirements and guidelines (EN ISO 14044:2006) 2006. Available online: https://www.iso.org/standard/38498.html (accessed on 10 March 2018).

- European Commission Commission Recommendation of 9 April 2013 on the use of common methods to measure and communicate the life cycle environmental performance of products and organisations 2013.

- Rechberger, H.; Brunner, P. Practical Handbook of Material Flow Analysis; Lewis Publisher: Washington, DC, USA, 2003. [Google Scholar]

- Minkov, N.; Bach, V.; Finkbeiner, M. Characterization of the Cradle to Cradle CertifiedTM products program in the context of eco-labels and environmental declarations. Sustainability 2018, 10, 738. [Google Scholar] [CrossRef]

- Kausch, M.F.; Klosterhaus, S. Response to “Are Cradle to Cradle certified products environmentally preferable? Analysis from an LCA approach.” J. Clean. Prod. 2016, 113, 715–716. [Google Scholar] [CrossRef]

- Cradle to Cradle Products Innovation Institute Get Cradle to Cradle Certified. Available online: http://www.c2ccertified.org/get-certified/standards-development (accessed on 1 October 2017).

- Vercoulen, R. Impacts of the Cradle to Cradle Certified Products Program; Technical Report; Cradle to Cradle Centre: Venlo, The Netherlands, 2014. [Google Scholar]

- Llorach-Massana, P.; Farreny, R.; Oliver-Solà, J. Are Cradle to Cradle certified products environmentally preferable? Analysis from an LCA approach. J. Clean. Prod. 2015, 93, 243–250. [Google Scholar] [CrossRef]

- Bor, A.-M.; Hansen, K.; Goedkoop, M.; Riviere, A.; Alvarado, C.; can den Wittendoer, W. Position~Paper:~Usability of Life Cycle Assessment for Cradle to Cradle purposes 2011. Available online: http://www.c2c-centre.com/library-item/usability-life-cycle-assessment-cradle-cradle%C2%AE-purpose (accessed on 2 May 2018).

- Reay, S.D.; McCool, J.P.; Withell, A. Exploring the feasibility of Cradle to Cradle (product) design: Perspective from New Zealand Scientists. J. Sustain. Dev. 2011, 4, 36. [Google Scholar] [CrossRef]

- Reijnders, L. Are emissions or wastes consisting of biological nutrients good or healthy? J. Clean. Prod. 2008, 16, 1138–1141. [Google Scholar] [CrossRef]

- Bjørn, A.; Hauschild, M.Z. Absolute versus Relative Environmental Sustainability. J. Ind. Ecol. 2013, 17, 321–332. [Google Scholar] [CrossRef]

- Finkbeiner, M.; Inaba, A.; Tan, R.; Christiansen, K.; Klüppel, H.-J. The New International Standards for Life Cycle Assessment: ISO 14040 and ISO 14044. Int. J. Life Cycle Assess. 2006, 11, 80–85. [Google Scholar] [CrossRef]

- European Commission. Regulation (EC) No 66/2010 of the European Parliament and of the Council of 25 November 2009 on the EU Ecolabel; European Commission: Brussels, Belgium, 2010. [Google Scholar]

- Germanys’s Federal Environment Agency and RAL gGmbH The Blue Angel. Available online: https://www.blauer-engel.de/en/blue-angel/what-is-behind-it (accessed on 1 October 2017).

- Finkbeiner, M. Product environmental footprint—Breakthrough or breakdown for policy implementation of life cycle assessment? Int. J. Life Cycle Assess. 2014, 19, 266–271. [Google Scholar] [CrossRef]

- European Commission. Product Environmental Footprint Category Rules Guidance - Version 6.2 - June 2017; European Commission: Brussels, Belgium, 2017. [Google Scholar]

- Lehmann, A.; Bach, V.; Finkbeiner, M. Product environmental footprint in policy and market decisions: Applicability and impact assessment. Integr. Environ. Assess. Manag. 2015, 11, 417–424. [Google Scholar] [CrossRef] [PubMed]

- Austrian Standards OENORM S 2096-1:2005-01-01 - Material flow analysis - Part 1: Application in waste management - Concepts; Austrian Standards Institute: Vienna, Austria, 2005.

- Hendriks, C.; Obernosterer, R.; Müller, D.; Kytzia, S.; Baccini, P.; Brunner, P.H. Material Flow Analysis: A tool to support environmental policy decision making. Case-studies on the city of Vienna and the Swiss lowlands. Local Environ. 2000, 5, 311–328. [Google Scholar] [CrossRef]

- Gottschalk, F.; Sonderer, T.; Scholz, R.W.; Nowack, B. Possibilities and limitations of modeling environmental exposure to engineered nanomaterials by probabilistic material flow analysis. Environ. Toxicol. Chem. 2010. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Tanaka, M.; Matsui, Y. Generation amount prediction and material flow analysis of electronic waste: A case study in Beijing, China. Waste Manag. Res. 2006, 24, 434–445. [Google Scholar] [CrossRef] [PubMed]

- Hashimoto, S.; Tanikawa, H.; Moriguchi, Y. Where will large amounts of materials accumulated within the economy go?—A material flow analysis of construction minerals for Japan. Waste Manag. 2007, 27, 1725–1738. [Google Scholar] [CrossRef] [PubMed]

- Davis, J.; Geyer, R.; Ley, J.; He, J.; Clift, R.; Kwan, A.; Sansom, M.; Jackson, T. Time-dependent material flow analysis of iron and steel in the UK. Resour. Conserv. Recycl. 2007, 51, 118–140. [Google Scholar] [CrossRef]

- Bringezu, S.; Moriguchi, Y. Material flow analysis. In A Handbook of Industrial Ecology; Edwar Elgar Publishing: Cheltenham, UK, 2002; pp. 79–90. [Google Scholar]

- Reimann, K.; Finkbeiner, M.; Horvath, A.; Matsuno, Y.; Preto, U.; Pennington, D.; Pant, R. Evaluation of environmental life cycle approaches for policy and decision making support in micro and macro level applications 2010. Available online: http://publications.jrc.ec.europa.eu/repository/bitstream/111111111/15195/1/lbna24562enc.pdf (accessed on 6 July 2017).

- Joint Research Centre International Reference Life Cycle Data System (ILCD) Handbook- Recommendations for Life Cycle Impact Assessment in the European context; European Commission: Luxembourg, 2011.

- Forin, S.; Berger, M.; Finkbeiner, M. Measuring Water-related Environmental Impacts of Organizations: Existing Methods and Research Gaps. Int. J. LCA 2017, submitted. [Google Scholar]

- The Product-Life Institute Cradle to Cradle. Available online: http://www.product-life.org/en/cradle-to-cradle (accessed on 1 October 2017).

- Ellen MacArthur Foundation Schools Of Thought. Available online: https://www.ellenmacarthurfoundation.org/circular-economy/schools-of-thought/cradle2cradle (accessed on 1 October 2017).

- European Commission. Closing the Loop—An EU Action Plan for the Circular Economy; European Commission: Brussels, Belgium, 2015. [Google Scholar]

- BIO. Intelligence Service Assessment of Resource Efficiency Indicators and Targets; Final Report Prepared for the European Commission, DG Environment; Institute for Social Ecology (SEC) and Sustainable Europe Research Institute (SERI): Vienna, Austria, 2012. [Google Scholar]

- Cradle to Cradle Products Innovation Institute US EPA RECOMMENDS CRADLE TO CRADLE CERTIFIED PRODUCT STANDARD. Available online: http://www.c2ccertified.org/news/article/us-epa-recommends-cradle-to-cradle-certified-product-standard (accessed on 1 November 2017).

- UNEP/SETAC Life Cycle Initiative. Towards a Life Cycle Sustainability Assessment - Making Informed Choices on Products; United Nations Environment Programme: Paris, France, 2011. [Google Scholar]

- UNEP. Global Material Flows and Resource Productivity—An Assessment Study of the UNEP International Resource Panel; United Nations Environment Programme: Paris, France, 2016. [Google Scholar]

- Cradle to Cradle Products Innovation Institute. Policy for Revision of the Cradle to Cradle CertifiedTM Product Standard Version 1.0; Cradle to Cradle Products Innovation Institute: Berlin, Germany, 2014. [Google Scholar]

- European Commission Environmental Footprint E-commenting Wiki page. Available online: https://webgate.ec.europa.eu/cas/login?loginRequestId=ECAS_LR-14023568-96ZZJzRUM0tTWT7qbzNWh6BoJXyGHgB5cm1jxk3M4USyeI7ndsheSaeZkQJJEWctAff64fNOdwaa77L45miRHE-PHslUMVSXYCcErG0LecxcC-80RSr1Bw7w2JCpaEGGPWSVSCEEuUE0g9CiIyNSdc0lG (accessed on 1 November 2017).

- Peiró, L.T.; Méndez, G.V.; Ayres, R.U. Material Flow Analysis of Scarce Metals: Sources, Functions, End-Uses and Aspects for Future Supply. Environ. Sci. Technol. 2013, 47, 2939–2947. [Google Scholar] [CrossRef] [PubMed]

- Patrício, J.; Kalmykova, Y.; Rosado, L.; Lisovskaja, V. Uncertainty in Material Flow Analysis Indicators at Different Spatial Levels. J. Ind. Ecol. 2015, 19, 837–852. [Google Scholar] [CrossRef]

- McDonough, W.; Braungart, M.; Clinton, B. The Upcycle: Beyond Sustainabilit—Designing for Abundance, 1st ed.; North Point Press: New York, NY, USA, 2013. [Google Scholar]

- Braungart, M.; McDonough, W. Cradle to Cradle: Remaking the Way We Make Things, 1st ed.; North Point Press: New York, NY, USA, 2012. [Google Scholar]

- Klöpffer, W.; Grahl, B. Ökobilanz (LCA): Ein Leitfaden für Ausbildung und Beruf; Wiley-VCH: Weinheim, Germany, 2009. [Google Scholar]

- Finkbeiner, M. Special Types of Life Ccyle Assessment, 1st ed.; Springer: Dordrecht, The Netherlands, 2016. [Google Scholar]

- Pizzol, M.; Laurent, A.; Sala, S.; Weidema, B.; Verones, F.; Koffler, C. Normalisation and weighting in life cycle assessment: Quo vadis? Int. J. Life Cycle Assess. 2017, 22, 853–866. [Google Scholar] [CrossRef]

- Sonderegger, T.; Dewulf, J.; Fantke, P.; de Souza, D.M.; Pfister, S.; Stoessel, F.; Verones, F.; Vieira, M.; Weidema, B.; Hellweg, S. Towards harmonizing natural resources as an area of protection in life cycle impact assessment. Int. J. Life Cycle Assess. 2017. [Google Scholar] [CrossRef]

- Galatola, M.; Pant, R. Reply to the editorial “Product environmental footprint—Breakthrough or breakdown for policy implementation of life cycle assessment?” written by Prof. Finkbeiner (Int J Life Cycle Assess 19(2):266-271). Int. J. Life Cycle Assess. 2014, 19, 1356–1360. [Google Scholar] [CrossRef]

- Guinée, J.B.; Gorrée, M.; Heijungs, R.; Huppes, G.; Kleijn, R.; de Koning, A.; van Oers, L.; Sleeswijk, A.W.; Suh, S.; de Haes, H.A.U.; et al. Handbook on life Cycle Assessment. Operational Guide to the ISO Standards. I: LCA in Perspective. IIa: Guide. IIb: Operational Annex. III: Scientific Background; Springer: Dordrecht, The Netherlands, 2002. [Google Scholar]

- Hellweg, S.; Mila i Canals, L. Emerging approaches, challenges and opportunities in life cycle assessment. Science 2014, 344, 1109–1113. [Google Scholar] [CrossRef] [PubMed]

- Laner, D.; Rechberger, H.; Astrup, T. Applying Fuzzy and Probabilistic Uncertainty Concepts to the Material Flow Analysis of Palladium in Austria. J. Ind. Ecol. 2015, 19, 1055–1069. [Google Scholar] [CrossRef]

- Manfredi, S.; Allacker, K.; Pelletier, N.; Schau, E.; Chomkhamsri, K.; Pant, R.; Pennington, D. Comparing the European Commission product environmental footprint method with other environmental accounting methods. Int. J. Life Cycle Assess. 2015, 20, 389–404. [Google Scholar] [CrossRef]

- Sandin, G.; Peters, G.M.; Svanström, M. Using the planetary boundaries framework for setting impact-reduction targets in LCA contexts. Int. J. Life Cycle Assess. 2015, 20, 1684–1700. [Google Scholar] [CrossRef]

- Rockström, J.; Steffen, W.; Noone, K.; Persson, A.; Chapin, F.S.; Lambin, E.F.; Lenton, T.M.; Scheffer, M.; Folke, C.; Schellnhuber, H.J.; et al. A safe operating space for humanity. Nature 2009, 461, 472–475. [Google Scholar] [CrossRef] [PubMed]

- Reijnders, L. Phosphorus resources, their depletion and conservation, a review. Resour. Conserv. Recycl. 2014, 93, 32–49. [Google Scholar] [CrossRef]

- Yoshida, S.; Hiraga, K.; Takehana, T.; Taniguchi, I.; Yamaji, H.; Maeda, Y.; Toyohara, K.; Miyamoto, K.; Kimura, Y.; Oda, K. A bacterium that degrades and assimilates poly(ethylene terephthalate). Science 2016, 351, 1196–1199. [Google Scholar] [CrossRef] [PubMed]

- Van Sebille, E.; Wilcox, C.; Lebreton, L.; Maximenko, N.; Hardesty, B.D.; van Franeker, J.A.; Eriksen, M.; Siegel, D.; Galgani, F.; Law, K.L. A global inventory of small floating plastic debris. Environ. Res. Lett. 2015, 10, 124006. [Google Scholar] [CrossRef]

- United Nations Environment Programme. Marine Plastic Debris and Microplastics—Global Lessons and Research to Inspire Action and Guide Policy Change; United Nations Environment Programme: Paris, France, 2016. [Google Scholar]

- Ocean Conservancy Stemming the tide: Land-based strategies for a plastic-free ocean 2015. Available online: https://www.mckinsey.com/business-functions/sustainability-and-resource-productivity/our-insights/stemming-the-tide-land-based-strategies-for-a-plastic-free-ocean (accessed on 6 July 2017).

- Gutzler, C.; Helming, K.; Balla, D.; Dannowski, R.; Deumlich, D.; Glemnitz, M.; Knierim, A.; Mirschel, W.; Nendel, C.; Paul, C.; et al. Agricultural land use changes—A scenario-based sustainability impact assessment for Brandenburg, Germany. Ecol. Indic. 2015, 48, 505–517. [Google Scholar] [CrossRef]

- Garcia, J.C.; De Matos, C.T.; Aurambout, J.-P. Environmental Sustainability Assessment of Bioeconomy Products and Processes—Progress Report 2 2016. Available online: https://ec.europa.eu/jrc/en/publication/brochures-leaflets/environmental-sustainability-assessment-bioeconomy-products-and-processes-progress-report-2 (accessed on 20 March 2018).

- Bach, V.; Berger, M.; Finogenova, N.; Finkbeiner, M. Assessing the Availability of Terrestrial Biotic Materials in Product Systems (BIRD). Sustainability 2017, 9, 137. [Google Scholar] [CrossRef]

- Eerhart, A.J.J.E.; Faaij, A.P.C.; Patel, M.K. Replacing fossil based PET with biobased PEF; process analysis, energy and GHG balance. Energy Environ. Sci. 2012, 5, 6407. [Google Scholar] [CrossRef]

- Chen, L.; Pelton, R.E.O.; Smith, T.M. Comparative life cycle assessment of fossil and bio-based polyethylene terephthalate (PET) bottles. J. Clean. Prod. 2016, 137, 667–676. [Google Scholar] [CrossRef]

- Bach, V.; Berger, M.; Forin, S.; Finkbeiner, M. Comprehensive approach for evaluating different resource types—Case study of abiotic and biotic resource use assessment methodologies. Ecol. Indic. 2017, submitted. [Google Scholar] [CrossRef]

- Schowalter, T.D. Decomposition and Pedogenesis. In Insect Ecology; Elsevier: New York, NY, USA, 2016; pp. 477–510. [Google Scholar]

- Haynes, R. Mineral Nitrogen In The Plant-Soil System (Physiological Ecology), 1st ed.; Academic Press Inc.: Orlando, FL, USA, 1986; ISBN 978-0123349101. [Google Scholar]

- Tsoutsos, T.; Frantzeskaki, N.; Gekas, V. Environmental impacts from the solar energy technologies. Energy Policy 2005, 33, 289–296. [Google Scholar] [CrossRef]

- Gössling, S.; Broderick, J.; Upham, P.; Ceron, J.-P.; Dubois, G.; Peeters, P.; Strasdas, W. Voluntary Carbon Offsetting Schemes for Aviation: Efficiency, Credibility and Sustainable Tourism. J. Sustain. Tour. 2007, 15, 223–248. [Google Scholar] [CrossRef]

- Jindal, R.; Swallow, B.; Kerr, J. Forestry-based carbon sequestration projects in Africa: Potential benefits and challenges. Nat. Resour. Forum 2008, 32, 116–130. [Google Scholar] [CrossRef]

- Bull, J.W.; Suttle, K.B.; Gordon, A.; Singh, N.J.; Milner-Gulland, E.J. Biodiversity offsets in theory and practice. Oryx 2013, 47, 369–380. [Google Scholar] [CrossRef]

- Kjaer, L.L.; Pagoropoulos, A.; Schmidt, J.H.; McAloone, T.C. Challenges when evaluating Product/Service-Systems through Life Cycle Assessment. J. Clean. Prod. 2016, 120, 95–104. [Google Scholar] [CrossRef] [Green Version]

- Berger, M.; Warsen, J.; Krinke, S.; Bach, V.; Finkbeiner, M. Water footprint of European cars: Potential environmental impacts of water consumption along automobile life cycles. Environ. Sci. Technol. 2012. [Google Scholar] [CrossRef] [PubMed]

- Henßler, M.; Bach, V.; Berger, M.; Finkbeiner, M.; Ruhland, K. Resource Efficiency Assessment—Comparing a Plug-In Hybrid with a Conventional Combustion Engine. Resources 2016, 5, 5. [Google Scholar] [CrossRef]

- Pretot, S.; Collet, F.; Garnier, C. Life cycle assessment of a hemp concrete wall: Impact of thickness and coating. Build. Environ. 2014, 72, 223–231. [Google Scholar] [CrossRef] [Green Version]

- Dammer, L.; Carus, M.; Raschka, A.; Scholz, L. Market Developments of and Opportunities for biobased products and chemicals 2013. Available online: https://www.eumonitor.nl/9353000/1/j4nvgs5kjg27kof_j9vvik7m1c3gyxp/vjken6y2ivvo/f=/blg338557.pdf (accessed on 06 July 2017).

- Institut Bauen und Umwelt e.V. Polymatt Sigma Coatings. Available online: https://epd-online.com/EmbeddedEpdList/Download/5728 (accessed on 1 November 2017).

- Al-Salem, S.M.; Lettieri, P.; Baeyens, J. Recycling and recovery routes of plastic solid waste (PSW): A review. Waste Manag. 2009, 29, 2625–2643. [Google Scholar] [CrossRef] [PubMed]

- Welle, F. Twenty years of PET bottle to bottle recycling—An overview. Resour. Conserv. Recycl. 2011, 55, 865–875. [Google Scholar] [CrossRef]

- European Union Directive. 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on waste and repealing certain Directives. Off. J. Eur. Union L 312/3. 2008. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A32008L0098 (accessed on 6 July 2017).

- Braungart, M. The wisdom of the cherry tree. Int. Commer. Rev. 2007, 7, 152–156. [Google Scholar] [CrossRef]

- Braungart, M.; McDonough, W.; Bollinger, A. Cradle-to-cradle design: Creating healthy emissions—A strategy for eco-effective product and system design. J. Clean. Prod. 2007, 15, 1337–1348. [Google Scholar] [CrossRef]

- McManus, M.C.; Taylor, C.M. The changing nature of life cycle assessment. Biomass Bioenergy 2015, 82, 13–26. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gül, S.; Spielmann, M.; Diana, E.; Lehmann, A.; Bach, V.; Finkbeiner, M. Benchmarking and Environmental Performance Classes in Life Cycle Assessment—Development of a Procedure for Non-Leather Shoes in the Context of the Product Environmental Footprint. Int. J. Life Cycle Assess. 2015, 20, 1640–1648. [Google Scholar] [CrossRef]

- Thinkstep GaBi Product Sustainability Software 2016. Available online: http://www.gabi-software.com/switzerland/index/ (accessed on 2 May 2018).

- Ecoinvent. Ecoinvent database 2016. Available online: https://www.ecoinvent.org/database/database.html (accessed on 6 July 2017).

- Ciroth, A. Software for Life Cycle Assessment. In Life Cycle Assessment Handbook; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2012; pp. 143–157. [Google Scholar]

- PRÉ SimaPro LCA software 2017. Available online: https://simapro.com/ (accessed on 6 July 2017).

- TU Wien—Forschungsbereich Abfallwirtschaft und Ressourcenmanagement Stan. Available online: http://www.stan2web.net/ (accessed on 1 December 2017).

| Title and Author(s) | Short Summary |

|---|---|

| Impacts of the Cradle to Cradle certified products program, published by Vercoulen (2014) [28] | Analysis of existing methods addressing impacts relevant to the C2CP and introducing a developed framework as a solution |

| Characterization of the Cradle to Cradle Certified™ Products Program in the Context of Eco-labels and Environmental Declarations, published by Minkov et al. (2018) [25] | Analysis with regard to maturity of C2CP as a tool for external communication |

| Are Cradle to Cradle certified products environmentally preferable? Analysis from an LCA approach, published by Llorach-Massana et al. (2015) [29] | Analysis of C2CP certification with regard to distinguishing environmentally more preferable products as well as informing consumers correctly about the environmental performance |

| Usability of Life Cycle Assessment for Cradle to Cradle purposes—Position paper of Netherlands Ministry of Infrastructure and the Environment, published by Bor et al. (2011) [30] | Exploration of the usability of LCA for C2CP purposes |

| Designing Cradle to Cradle products: a reality check, published by Bakker et al. (2010) [18] | Analysis of the applicability of the C2CP concept in day-to-day product development in a business setting |

| Exploring the Feasibility of Cradle to Cradle (Product) Design: Perspectives from New Zealand Scientists, published by Reay et al. (2011) [31] | Feasibility of using the C2CP for sustainable product design in New Zealand is examined by asking a sample of New Zealand scientists to explore the underlying science and reliability of the C2C framework |

| Are emissions or wastes consisting of biological nutrients good or healthy? —Letter to the editor, published by Reijnders (2008) [32] | Statement that no wastes or emissions derived from biological materials are ecologically irrelevant and intrinsically good or healthy |

| Cradle to Cradle and LCA, published by Bjørn and Hauschild (2018) [20] Absolute versus Relative Environmental Sustainability—What can the Cradle-to-Cradle and Eco-efficiency Concepts Learn from Each Other? published by Bjørn and Hauschild (2013) [33] | Introduction in C2CP framework and certification scheme Comparison of LCA and eco-efficiency with C2CP |

| Criterion | Sub-Criterion |

|---|---|

| (1) Stakeholder acceptance |

|

| (2) Documentation and review |

|

| (3) Environmental relevance |

|

| (4) Scientific soundness |

|

| (5) Applicability |

|

| Methods/Criteria | C2CP | LCA | PEF | MFA | |

|---|---|---|---|---|---|

| Stakeholder acceptance | Used in policies | No | Yes | No 1 | Partly |

| Authoritative body supports method | One | Multiple | One | One | |

| Stakeholder participation | Partly | Yes | Partly | Partly | |

| Documentation and review | Method is documented | Yes | Yes | Yes | Yes |

| Uncertainties are addressed | No | Yes | Partly | Partly | |

| Environmental relevance | Broad coverage of relevant emissions | Partly | Yes | Yes | Partly |

| Relevant environmental impacts are addressed | No | Yes | Partly | No | |

| Entire life cycle is considered | No | Yes | Yes | Yes | |

| Scientific soundness | Method has undergone scientific review | Partly | Yes | Yes | Partly |

| Method is object of scientific work | Partly | Yes | Partly | Yes | |

| Allows for reproducibility | Yes | Yes | Yes | Yes | |

| Applicability | Globally valid | Yes | Partly | Partly | Yes |

| Effort of data collection | High | High | High | High | |

| Tool to support application | No | Yes | Yes | Yes | |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bach, V.; Minkov, N.; Finkbeiner, M. Assessing the Ability of the Cradle to Cradle Certified™ Products Program to Reliably Determine the Environmental Performance of Products. Sustainability 2018, 10, 1562. https://doi.org/10.3390/su10051562

Bach V, Minkov N, Finkbeiner M. Assessing the Ability of the Cradle to Cradle Certified™ Products Program to Reliably Determine the Environmental Performance of Products. Sustainability. 2018; 10(5):1562. https://doi.org/10.3390/su10051562

Chicago/Turabian StyleBach, Vanessa, Nikolay Minkov, and Matthias Finkbeiner. 2018. "Assessing the Ability of the Cradle to Cradle Certified™ Products Program to Reliably Determine the Environmental Performance of Products" Sustainability 10, no. 5: 1562. https://doi.org/10.3390/su10051562