1. Introduction

The European legislative proposals on waste, adopted in 2015, set a clear common EU target of recycling 65% of municipal waste by the year 2030 [

1].

Community composting is a sustainable and decentralized way to manage the organic fraction of municipal solid waste (OFMSW) in situ [

2]. This is encouraged by several government policies including those of the European Union [

3,

4].

One of the main factors determining the success of local community composting projects is their reliance on user participation. For community composting to be effective, the level of participation and motivation of the users should be high [

5]. Taking part in community composting programs is voluntary in the great majority of cases. However, in some cases, community composting is the only management system proposed for organic fraction. In these cases, community composting programs are not directed exclusively at citizens who are particularly sensitive to environmental issues with a high level of awareness, which means these initiatives require direct incentives for the participants [

6,

7]. In most cases, the main material motivation for users has been the opportunity to enjoy the compost obtained. In some cases, participants benefitted from a discounted waste tax. However, there is a need to find other more direct and consistent motivation in community composting programs [

4,

7,

8,

9,

10,

11,

12,

13].

In order to encourage local residents to actively participate in composting their household waste, in January 2013, a new community Composter-Henhouse (CH) was established in Noáin, which is a part of Navarre, Spain. The community CH aims to offer families new stimuli such as fresh eggs, the opportunity for urban citizens to interact with animals with relatively few responsibilities and the possibility of being farmers once a month. The egg production and contact with animals could be incentives that help motivate the participants to recycle organic waste and take part in the maintenance of the facility.

The CH includes a small henhouse and a compost bin shared collectively among multiple users. The users deliver their own kitchen waste. Inherently, the hens feed on these organic residues and the action of their beaks and claws contributes to the composting processes. The eggs produced are distributed among the users who receive an effective incentive to keep separating their waste at home.

In recent years, there has been a proliferation in urban chicken farming and shared communal henhouses for both educational and recreational purposes. On the one hand, the number of communal chicken farms and public orchards is growing rapidly, which presents several social benefits [

14,

15]. On the other, the utilization of food waste for feeding animals may be a valid and sustainable way of reusing resources. Since ancient times, farm animals have been fed with food and waste crops. The use of plant residues and by-products of agricultural crops as a source of food for livestock is widely practiced around the world and recommended by the FAO for developing countries [

16,

17,

18]. In addition, the potential of using OFMSW or its vegetal fraction has been explored within a framework of good practice that respects the environment and public health [

19,

20]. Since the first studies, much attention has been focused on the hygiene aspect and the best techniques available for avoiding health risks when feeding animals urban food waste [

21,

22]. There are a few publications on studies of organic waste management by chicken feeding [

23] including the backyard level [

24].

To be sustainable, the CH must meet different technical requirements. On the one hand, the system has to be suitable from a technical point of view as well as adequate for treating a variety of organic waste (kitchen waste, leaves, grass trimmings and pruning residues). There must be a correct development for the composting process including meeting a thermophilic temperature to ensure the production of safe, high quality compost. On the other hand, the system should be very simple, flexible and cheap with minimal labour requirements and a small initial investment. At the same time, it must also provide high incentives as a means of ensuring good user satisfaction and continued motivation. The ultimate aim of this work was to evaluate the different aspects of CH sustainability with a focus on the technical aspects of the composting process. The evaluation was performed in terms of technical adequacy of the composting process, the safety and quality of the final compost, the quantities of OFMSW managed, egg production and animal welfare and social benefits. This evaluation took place over the first three years of the pilot experience.

2. Materials and Methods

2.1. Location and Social Background

The CH in the study is located inside the “Parque de los Sentidos” (the Sensory Park). The municipality of Noáin is in a sprawling urban area near to Pamplona town and holds 195,853 inhabitants. This is the regional capital of Navarre. In the municipality area, there is an important nerve of road and rail transport with many industrial parks and a national airport. Starting as a small village, over the last 50 years, Noáin has undergone rapid urbanization, which increased its population thanks to the location of industrial areas and nearby mining factories. The estimated population of the municipality is 7835 people and currently is very heterogeneous, relatively young and has low unemployment. At the end of the 1990s, Noáin barely had urban woodland or green areas and there was a lack of attention paid to the urban environment. With the creation of the Municipal Office of Climate Change, the municipality has launched “Agenda 21,” which is a program that pursues the implementation of strategies for local sustainability by developing various actions at territorial, social and environmental levels on subjects other than green spaces, waste treatment, sustainable transport, sustainable management of water and energy, which promoted the interest of neighbours to respect nature, the environment and the common collective heritage.

In addition to the adoption of practices of organic gardening in all green areas of the municipality, the “Sensory Park” was created in 2006. This is a 25,000 m2 public park, adjacent to the airport and the main town square, which is home to more than 30 species of trees, 95 bushes and around 70 species of perennials plants. It has won many national and international awards including the prestigious UN recognition for sustainable environmental practices. In this park, a significant program of environmental education has been developed that relies on the work of a non-profit foundation that helps people who are in risk of social exclusion. The park is divided into five distinct areas with each focused on a different sense such as the English garden (sight), French garden (touch), Japanese Garden (hearing), Mediterranean garden (smell) and the vegetable garden (taste). In the area dedicated to taste (800 m2), there is a collective organic orchard as well as the CH.

2.2. Project Overview

The GH project is a partnership between public sector entities, no-profit associations and a private firm. Local authority (Municipality of Noáin, through its Municipal Office of Climate Change and Agenda 21) has worked in all aspects of this project including the initial design of the facility, the search and provision of physical space, holding meetings and maintaining contact with the families involved in the program, making proposal for improvement and monitoring and final evaluation of the project. An external company (Vermican Soluciones de Compostaje, S.L.) has participated in the design and marketing of CH under the brand “Avicompo.” Lastly, the Public University of Navarre with the support of an external consultant (Dr. Ramón Plana) has performed the part of the study and evaluation of the project by participating in training meetings and advising the project in all its phases from pre-design to tracking development. Two non-profit organizations for socio-employment of the disabled and people at risk of exclusion have participated respectively in the construction and in monitoring and maintenance of CH.

The CH became operational in Noáin in January 2013. At the beginning of this program, the official system of urban waste management in the area did not permit the recycling of organic household bio-waste because the managing body had not yet implemented the separate collection of OFMSW.

2.3. Surveys and Characterization of Participants

The CH project started with the participation of 21 volunteer families. Subsequently, the number of families was increased to 26 and later to 30, which corresponds to approximately 90 people. To select the participants, an informative meeting was held with the local residents where a list of interested people was drawn up. The only condition for participation in the CH program was that the volunteers need to be registered in the municipal census and be available to commit to the project.

Social aspects were considered with records kept of the proposals and opinions of the local residents and park users involved in the project as well as their comments on the experience. Two surveys were carried out to characterize the participants and collect their opinion about the CH. The first survey was carried out at the end of the sixth month and it was focused on a sample of 23 families chosen at random among those who participated at that time. The second survey was carried out at the beginning of the second year and it was addressed to a sample of 20 families. In addition, a survey of 25 park visitors was carried out at the end of the third year to record their opinion. All surveys and their results were attached as

Supplementary Materials (in Spanish). The results of surveys showed that most participants had had no prior connection with community composting programs before participating in this initiative and did not have pets at home. The participants were from 5 different nationalities with an average of 3.3 members for each family and children aged from 4 to 10. Based on the results of the second survey, it was possible to observe that, in 60% of cases, women were the ones who took their waste to the park and participated directly in the project tasks. In 20% of the cases, men were responsible and, in 10% of cases, both genders were responsible. In the case that a man brings the waste to the park, the average age of the person surveyed was 36 years, while in the case of a woman, the average age rose to 47 years. In the event that the transfer of the organic waste from the home to the CH is equal, the average age was 42 years.

2.4. Facility and Operation Description

The CH is composed of an indoor section and two outdoor runs of 40 m

2 each (see

Figure 1). The chickens enter the courtyards independently from the coop, which allows their access to be restricted to one run or another. The indoor part comprises a coop that is 18 m

2 and 2.5 m high. The south side is closed by a wire mesh and the other three are closed off with boards. Recycled materials and FSC certified wood were used to construct the CH. Inside are covered feeders, waterers, perches, nesting boxes and three composters. The composting area, located on the north side, consists of three 1.2 m

3 composters sheltered from direct sunlight. Only the first composter is open, which allows organic debris to be introduced and gives the hens access to the OFMSW via wooden ramps (see

Figure 2). Above the first composter are perches (4 × 130 cm) positioned so that the hen droppings fall inside the composter. The second and third composters have closed wooden lids to prevent the hens from accessing the material.

The average number of laying hens over the 3-year study period was 13. However, this varied from 10 to 16 with mainly the autochthonous Basque breed (Euskal oiloa). The 25% of the animals were replaced annually.

Two kinds of organic waste are treated in the CH including household organic waste composed entirely of raw and cooked kitchen residues, provided by the participating families and garden waste used as a bulking agent. A wide variety of materials from the same park and provided by the municipal gardening service were used, which varied their composition in accordance with the time of year or logistical needs. This varied even during the production of the same batch depending on its availability. Approximately four different mixtures of bulking agent can be identified including a mix mainly composed of straw, mixed in variable proportion with leaves and pruned municipal pruning (in batches 1–3), a mix mostly composed of municipal pruning (in batches 3–7), a mix mostly composed of sawmill chips (in batches 7–10) and a mixture of fine pruned municipal and recycled bulking agent obtained after the screening of the compost (in batches 10–13), recycled bulking agent obtained after the screening of the compost (in batches 14–16).

The dosing was fairly constant, with an average ratio of household waste/bulking agent 1:0.18 by fresh weight.

Participants deposit their kitchen waste (in sealed plastic bags) into a red 120 L plastic container at the entrance of the park after having weighed it and noted this on a record sheet. Each user (or family) becomes the “Volunteer of the Day” once a month and is responsible for both the maintenance tasks in the CH and carrying the waste container to composting facility. First, they must spread a layer of bulking agent over the first composting bin. Next, they cover this with the OFMSW. In return, they take home the daily egg production as a reward. If a visit is not made, that day’s eggs are added to those collected the next day by the following volunteer. This happened very punctually, being limited to holiday season (Christmas, Easter) and at most for two consecutive days. The “Volunteer of the Day” provides feed and water and performs cleaning tasks. Every day nests, waterers and tools (buckets, shovels and rakes) were cleaned with a broom, water and sponge. A deep cleaning procedure was performed after each change of composter when starting a new composting batch (cleaning of surfaces and structure, removing dirt from the floor and cleaning of slats). In addition, extraordinary cleanings were performed in the summer (two times in three years) with water under pressure, authorized disinfectant and insecticide for organic farms.

The CH works up on the basis of a compost batch production system. The production time of each batch is determined by the duration of the feeding phase in the first composter bin. The residue is incorporated into the first of the three composters, which is the only one to which the hens have access. No manual pre-mixing is performed. The hens feed on the organic waste and the action of their beaks and claws contribute to mixing and reducing the particle size of the residues. Once the first composter is completely filled (1.2 m

3), the partially composted material is passed to the second module and turned over with a shovel or rake. This turning homogenizes and aerates the organic material in the composting process, avoiding anoxia and facilitating the rise in temperature associated with aerobic decomposition. In this way, further waste added to the newly emptied first composter starts a new batch. Depending on the quantities of waste and the type of bulking agent provided, the first composter will be filled more or less quickly and the phase of storage will be shorter or longer. In the second composter, the composting process passes from the thermophilic to the mesophilic phase. Material is moved from the second to the third composter when the first is full and the material contained in it has to be transferred. In the third bin the compost often appears drier than before and the moisture level is adjusted through watering while turning during a transfer. Occasionally, if necessary, users apply additional pruning and gardening residues as a bulking agent. Additional watering and compost turning are also performed when necessary to guarantee the best conditions for the composting process. Watering of compost was performed when compost humidity was less than 50%, which was determined on the basis of the first test, which is described in

Section 2.5. In this way, the compost reaches full maturity and earthworms can be added. On leaving the third composter, the compost may be considered finalized and ready for sieving.

2.5. Control of Composting Process

The aspects evaluated were the amount OFMSW managed, the evolution of the composting process, the quantity and quality of the compost obtained and egg production.

The OFMSW was weighed and this was recorded in a notebook by participants each time they deposited their waste into the 120 L container located at the entrance to the park.

The evolution of the composting process was measured through several parameters. Weekly visual inspections of the composters were performed and the temperature of the composting material in each composter was measured at four different points using a stem thermometer. The number of thermophilic days (NTD) was calculated as the number of days during which the compost temperature was higher than the thermophilic threshold (45 °C) for each compost batch. Moisture content during composting was monitored qualitatively twice a week using the ‘‘fist test.” This involves squeezing a compost sample in the fist and if water emerges from the fist, then the sample is too wet. The moisture content is suitable (approximately 50–60%) if the pressed sample does not release water but remains compact. If it crumbles apart when released, it is too dry [

25]. Variations in compost volume were estimated by measuring the height of the compost inside the bin. Weight losses were calculated as the percentage of the final compost weight over the cumulative sum of each addition of waste [

26]. The volume-loss ratio was calculated in the same way. Any noise and bad odours were monitored weekly over the first 35 weeks by qualitatively detecting them at distances of 90, 50, 10 and 1 m from the composters. In the first six months, the presence of insects was monitored using adhesive panel traps positioned at four points on the CH roof. These remained in place for two to eight weeks depending on loss of adhesive capacity burdening time after which they were collected and the insects counted and classified taxonomically. The stability and maturity of the compost was measured in the intermediate and final samples of composted organic material. The degree of compost maturity was determined using the Solvita

® kit test (Wood Ends Research Laboratory, Mt Vernon, ME, USA), which estimates the microbial activity by scoring the compost from 1 point (“raw waste”) to 8 points (“mature compost”) against an Index based on CO

2 and NH

3 production [

27]. The stability of the compost was estimated by determining the Rottegrade Index through the Dewar self-heating test. The principle of the method is to record the highest temperature achieved after placement of compost into a Dewar flask for several days. The Rottegrade Index scored the stability of compost from I to V degrees based on division into five levels of 10 °C increments of the compost heating over ambient temperature [

28].

Each time the material was turned during the composting process, it was sampled and subjected to a chemical and physical analysis. Water content of the compost samples was determined by drying a sample at 70 °C until a stable weight was reached [

29]. These analyses were conducted using ground air-dried samples of compost sieved through a 16 mm mesh. The electrical conductivity and pH of the samples from the final compost were determined in a water extract at 1:5 vol. [

29]. The density of the compost was determined following the official German method [

25]. Total N, C and organic C (TOC) were determined by an LECO elemental analyser. Samples of compost were placed into a microwave digester with HNO

3 and H

2O

2 without being further milled and were subsequently analysed by using ICP-OES [

30] to determine the concentrations of nutrients and trace elements (Al, As, P, B, Be, Bi, Ca, Cd, Co, Cu, Fe, Li, Ni, P, Pb, Sb, Se, Ti, Tl, V and Zn).

In terms of human health risks, two indicators were utilized in this work to determine the inactivation of pathogens during composting following the legal requirements in Spain [

31]. These were

Salmonella spp. CFU (Colony Forming Units) in 25 g samples and

Escherichia coli MPN (Most Probable Number) in 1 g samples. Human pathogen levels were determined by analysing compost sampled at the end of the composting process or later in the maturation phase (in composter No. 3) depending on operational reasons.

Salmonella spp. analysis was performed using a technique of pre-enrichment, selective isolation and identification by automated immunoassay analyser VIDAS (adapted from ISO 6579).

E. coli analysis was performed using the horizontal method of MPN (ISO 7251) in bright green broth, isolation on selective media and biochemical confirmation.

The quantity of eggs, their quality and hen feed consumption were considered parameters for evaluating animal production. Animal welfare was evaluated by observing the morphological status of the hens, like feather cover brightness, combs and wattles colour and paws conditions.

2.6. Exploration of Data

The parametric data sub-sets obtained from each final determination of the 16 compost batches were statistically evaluated through a visual summary using the box and whisker plot approach [

32]. A detailed description of this graphic representation is presented in Reference [

33].

3. Results and Discussion

3.1. Waste Diversion: Amount of OFMSW Composted

In three years of operation, the CH was able to process 16,435 kg of OFMSW, equating to an average of 5478 kg/year of which 4630 kg/year was kitchen waste from the participating families.

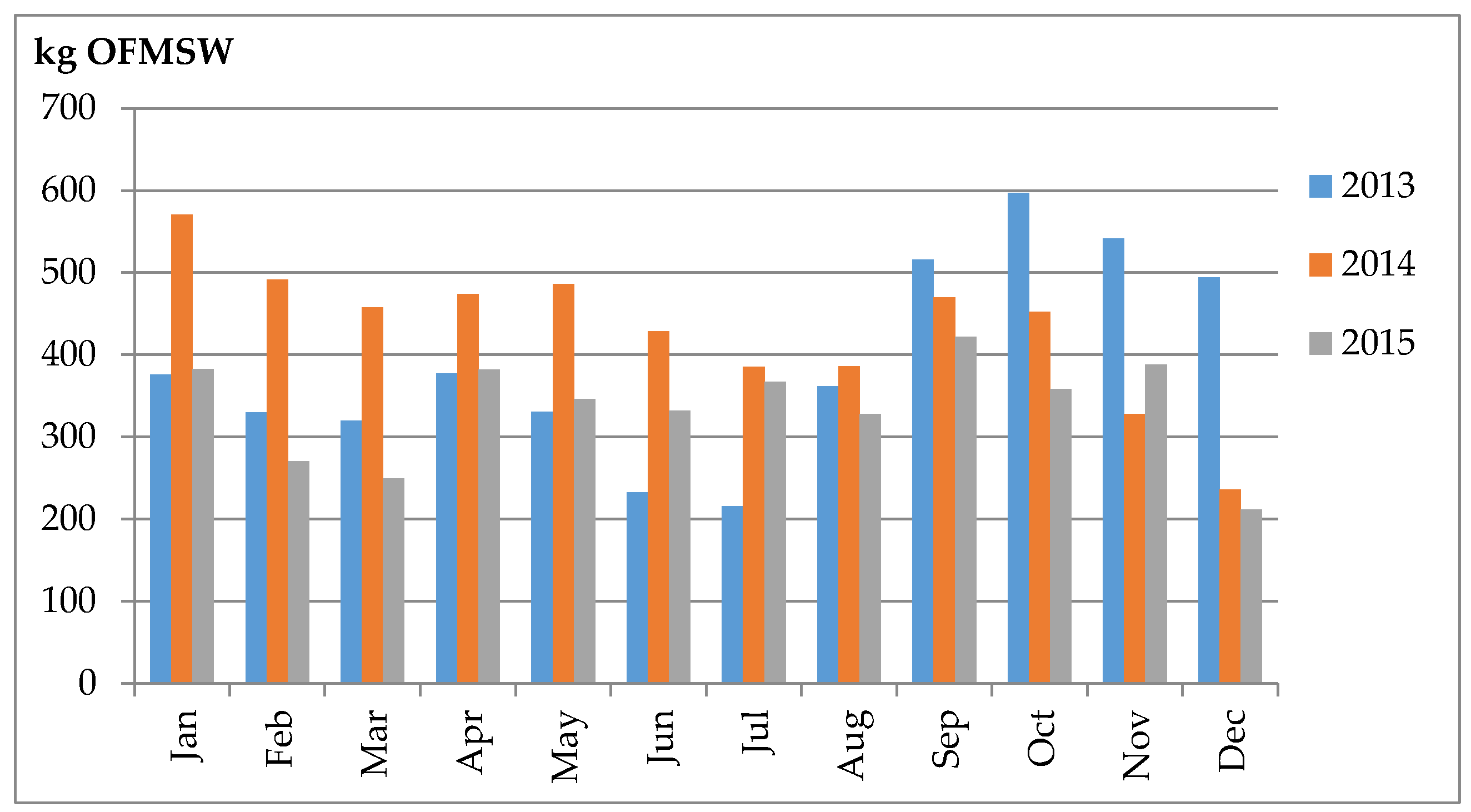

The amount of waste deposited in the composter was not constant over the three years of operation (see

Table 1) with a significant difference recorded between years and months. In addition, the contribution of waste by participants was not uniform with varying quantities provided by the different families. In 2013, the amount of waste managed was lower than the average among the three years possibly because it was the year of implementation. The initial adjustment period was limited to the few first months and the contributions of the second half of 2013 were comparable to those of the other two years. In 2015, which was the third year of the project, the amount of composted waste was the lowest in three years. This may be due to a drop in participant enthusiasm from the initial levels, which decreased the assiduity of waste intake by the CH. Due to the high degree of involvement of the participants, the potential diversion of OFMSW from the official urban waste management system in the area is very important since this result does not include restaurants, refectories, or cafeterias.

Individual contribution by each family over three years varied greatly (between 290 and 978 kg per family) with an average of 546 kg OFMSW per family equivalent to 0.46 kg a day (range 0.32–0.66 kg). The amount of waste provided by each family was influenced by several factors including their different consumption habits and the number of meals made at home. Not all the participant families have the same number of members and larger families generate more organic residue per day.

It is worth stressing that the level of organic waste separation was excellent with the presence of no compostable material like plastic, glass, or metal at less than 0.1%. The monthly trend of OFMSW provided to the CH was markedly seasonal with a drop in quantity recorded in the summer months (see

Figure 3). The amount of waste deposited went down during the holiday periods (summer, Christmas and Easter) due to the absence of the families and the closure of the park. In the spring months, because of the increased consumption of vegetables (leafy vegetables, cabbage, artichokes, cardoons, etc.), a greater amount of kitchen scraps was added to the composter.

Examining the quantities of OFMSW provided on a daily basis, it can be seen that, during the weekend, less waste was deposited (an average of 3.75 kg) compared to other days of the week. Monday (an average of 21.6 kg of OFMSW provided) is a particularly common day for carrying waste to the park due to the increased generation of kitchen waste in households over the weekend. In contrast, in the summer months, most waste is deposited on Saturday due to a greater presence of participants and visitors in the park.

In three years of operation, 16 batches of compost were managed. At the end of the three-year period, the 17th batch was still maturing in the third module of the compost heap, the 18th batch was in the mesophilic phase in the second composter and the 19th batch was started in the first composter.

The amount (volume) of waste composted was fairly constant in all the batches because the capacity of the first module remains the same for all the batches. However, the duration of the feeding phase (see

Table 2) differed. The varying of waste quantities composted in each batch was a result of different composter filling speeds. The duration of the contribution depended more on the amount and type of bulking agent used in each batch than on the seasonal variability of waste generation. The residence time in the first composter also largely depended on the conditions of the composting process and the intensity of organic material decomposition. In fact, the greatest reduction in weight and volume was seen in the first composter, which is where the thermophilic phase of the process began.

Comparing the performance of the CH with full-scale composting facilities, the weight reduction during composting was of the same order of magnitude as that found in industrial composting factories [

34,

35]. The dose and type of bulking agent, the temperature evolution and the evolution of the composting process determined the degree of reduction in weight and performance in the different batches of compost obtained. The type of bulking agent used had more influence than the dose. When the badly chipped pruning residue or sawmill chips was used as a bulking agent, a higher composting throughput and a greater quantity of compost was produced per day of waste intake. Another important influential factor was the duration of the entire composting process and the treatment time per kg of raw waste. As noted above, the composting process time depends on the filling time of the first composter bin (feeding phase), which, in turn, influenced the residence time in each of the other bins. The average weight loss ratio was 59%.

The increases in temperature recorded throughout the composting process indicated a significant intensity of aerobic decomposition and, therefore, a greater weight and volume reduction. As had been described in other studies [

36,

37], it can be hypothesized that a certain relationship between the maximum temperature during composting (and, to a lesser extent, average temperature) and weight reduction exists but the variation in type of bulking agents even during the same composting batch have hidden this effect. The influence of temperature on composting throughput and the amount of compost produced per day of waste intake is not as clear.

3.2. Composting Process Control and Compost Maturity

The composting process developed smoothly with no particular issues in any of the batches. However, the evolution of the composting process was slightly different among the batches as indicated by the differences in the parameters recorded. The variation in the type of bulking agent was an important factor influencing the development of the composting process. For example, some signs of compaction were detected in the first batches where straw was employed as the bulking agent.

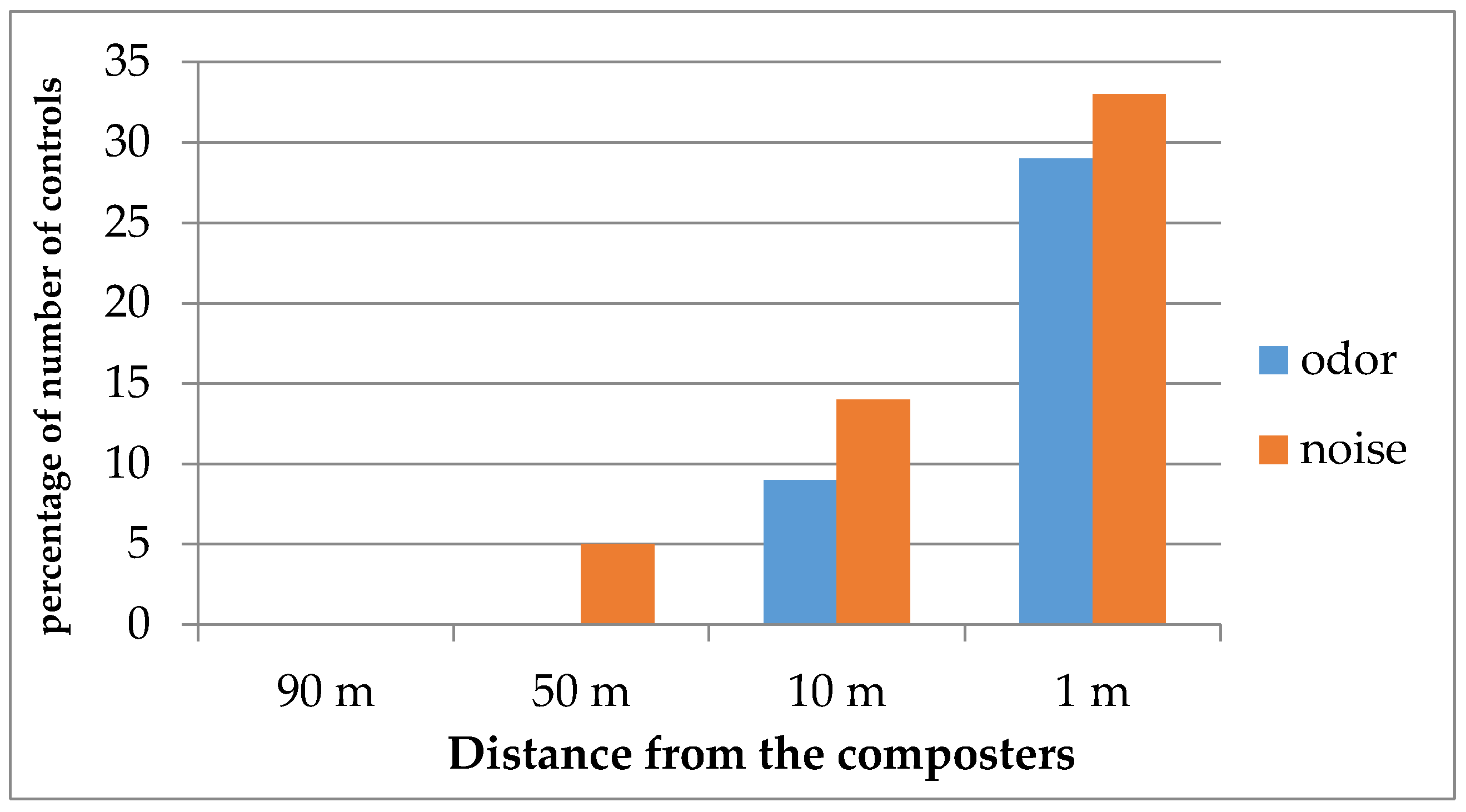

No particular impacts involving odours or an unusually high incidence of insects were recorded. Both were only detected within a 10 m radius of the composters (see

Figure 4). The compilation of the percentage of individuals of each insect species collected in the traps showed a higher incidence of flying insects in early summer (June). This was especially true for fruit flies (

Drosophila melanogaster).

As the composting process progressed, higher values of Solvita and Rottegrade compost maturity Indexes were observed. The Solvita test estimated compost maturity by measuring the production of NH3 and CO2 during composting. The volatile ammonia emissions recorded in the Solvita test were quite constant (Solvita Index range 3–5) while the CO2 emissions presented greater variability between the batches. Batches of different ages presented similar Solvita Index values. The batches where the process evolved more favourably, with higher temperatures recorded, reached maturity more quickly. For this reason, the different composting batches presented different values from the Solvita Index. For example, various batches sampled from weeks 11 to 28 presented a Solvita Index of 4 (“active compost”) and samples of different batches taken from weeks 12 to 34 presented a Solvita Index of 7 (“finished compost”). Rottegrade Index results obtained in the self-heating test showed less variability. Starting at week 22, all the compost gave the maximum Rottegrade Index values (V), which corresponded to mature compost. Based upon Solvita and Rottegrade indices, we conclude that seven months is a suitable compost processing time.

3.3. Temperature and Volume Evolution during Composting

Food residues and bird droppings stimulated the microbial decomposition of the organic matter and promoted the development of high temperatures. Hen activity also influenced the composting process, which helped to reduce particle size and turned the compost. This promoted aerobic conditions for the development of the microbial activity.

The bulking agent played an important role in the development of temperature. The type of bulking agent provided determined the process more than the amount of bulking applied did. Higher initial temperature increases occurred with coarse pruning residues due to greater oxygen availability and, consequently, more aerobic microorganism activity. In contrast, when a finer-ground bulking agent was used, there was compaction and excess moisture in the deeper layers. The weight of the hens walking on the compost contributed to compacting it when the bulking agent employed was structurally weak.

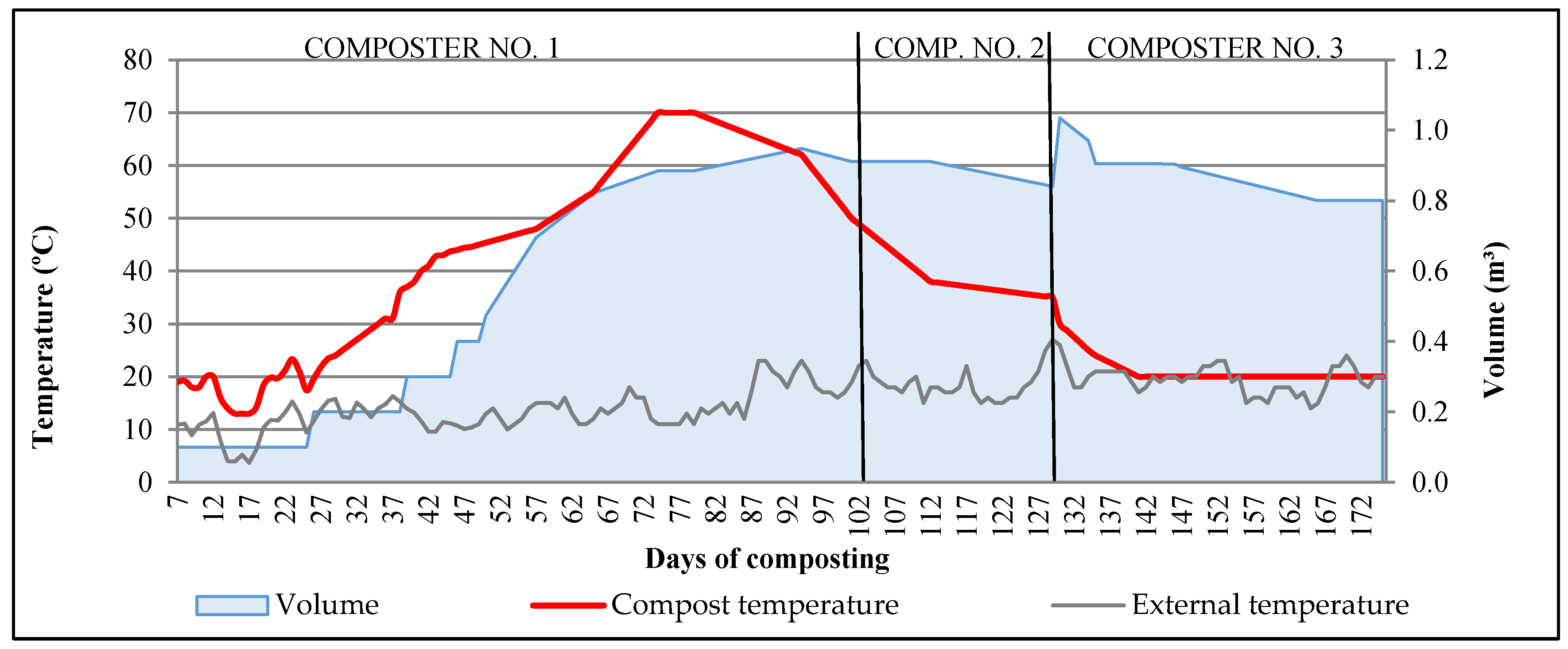

The influence of low environmental temperatures in the winter months hindered the early development of the composting process in the winter batches. In the summer months, due to the higher temperatures, it was necessary to water the compost more often in order to maintain the correct degree of humidity at all times. However, the system was somewhat resilient to changes in outside temperatures. In fact, during composting, higher maximum temperatures were recorded in batches started in the winter and the lowest were seen in batches made in the summer. The evolution of the temperature during the composting process was very variable between the different batches, which influenced the throughput and development of the compost maturity as well as other parameters. However, by observing the different graphs of temperature evolution, it can be seen that various patterns repeat. The temperature evolution during the composting of the eighth batch is shown as example of these typical patterns (see

Figure 5).

The first common pattern is the temperature increase during the period spent in the first composter. Due to the continuous addition of waste, the evolution of the temperature in the first composter bin was not always linear and had a general tendency towards an increased average temperature with an increasing amount of waste in the composter. In the first composter, when the amount of waste contributed was significant, the thermophilic phase began and lasted into the second module. The amount of waste added to the bin and the duration and frequency of the composter feeding phase influenced the temperature development during this first stage. An overview of the average duration of the thermophilic phase and the maximum temperature was recorded during the entire composting process for the 16 composting batches. This was reported in

Table 3. The batches with a longer feeding period and a greater amount of waste were associated with higher average and maximum values of temperature as well as a longer thermophilic phase.

In a few batches, the irregularity of waste addition caused an uneven temperature development that included peaks and inflections. In these batches, it was observed that the temperature increased on weekdays and decreased over the weekend because waste was not added to the composter on Saturday and Sunday, which decreased the process activity. When the compost received new waste on Monday, the process was reactivated and the temperature increased again. It reached a peak midweek. A typical example of this is the temperature evolution in batch 15 (see

Figure 6).

A second common pattern of temperature evolution can be seen after the transfer to the second composter, where, after an initial spike due to turning, the temperature decreases rapidly and started the second part of the composting process called the mesophilic phase. In the second composter the temperature begins to drop because the amount of organic matter decomposition rapidly diminishes and thermophilic bacteria get replaced by mesophilic ones, which are responsible for degrading the most recalcitrant fraction of the organic matter [

38]. A temperature rise with the first turning was recorded in almost all batches and was due to an increase in the presence of oxygen, homogenization of moisture and reduced compaction [

39,

40]. The maximum temperature reached during the entire composting process was recorded in the first module for only six of the 16 monitored batches while the majority occurred after the first transfer and turning.

Irregular temperature development in the second composter was observed in a few batches. This was due to the difficulty of maintaining the correct humidity or the moisture not being homogenously distributed inside the composter. Additional watering and compost turning were performed to guarantee the best conditions for the composting process. During the time of permanence in the same composter, the humidity evolved and its distribution became less homogeneous. In fact, a lack of humidity was often found on the outer-side of the composter as well as on the topmost superficial layer. It has been difficult to control humidity in the summer and in batches made with a coarse bulking agent where water losses were greater because of the higher porosity and higher temperatures reached. However, the lack of moisture and its uniformity seems not to have conditioned the process in any case.

The turning associated with the transfer of material to another composter had a very positive effect on the development of temperature especially in the passage between the first and second composter and, to a lesser extent, between the second and third bins. In fact, a temperature rise as a result of the transfer from the second to third composters was recorded in only three batches. In the third bin, the mesophilic phase of the process was completed and both biological activity and temperature decreased. The maturation phase began where the less easily degradable organic matter was transformed by less exothermic activity. The temperature began to drop because the amount of easily degradable organic matter decreased. At the end of the process, the volume of compost and the temperature stabilized, which only varied according to the ambient temperature. Sometimes, in the driest summer batches, temperature spikes were observed after the compost was watered. The lower temperatures in the third composter allowed worms to be added to the compost. During the first year of operation, an inoculum of 5 kg of California red worms (Eissenia foetida) was added to the third composter. However, instability in the levels of water in the composter was one of the determining factors behind the migration of the worms and vermicomposting difficulties were encountered in this experiment. The worms migrated to less decomposed material, higher humidity and non-thermophilic temperatures. Thanks to their great mobility, some earthworms left the CH structure while others were consumed by the chickens.

The volume evolution during composting was more regular. The volume increased in the first composter because of the addition of waste and bulking agents. In contrast, the volume decreased slowly in the second and third bins due to the decomposition of the organic matter and the loss of gas (water, CO2, nitrogenous gases, VOC, etc.). This volume reduction could also have been due to the caking and compaction of the material in the deeper layers of the compost. When turned, air is introduced into the compost, the material is mixed and its porosity increases while its bulk density decreases. This produces an increased volume at the beginning of the 2nd composter stage. Another reason for volume fluctuations in the second and third composters were due to the watering that took place.

3.4. Characterization and Quality of Compost

The average composition of the final product showed intermediate characteristics between chicken manure compost [

41] and the compost from community composting programs in northern Spain [

42].

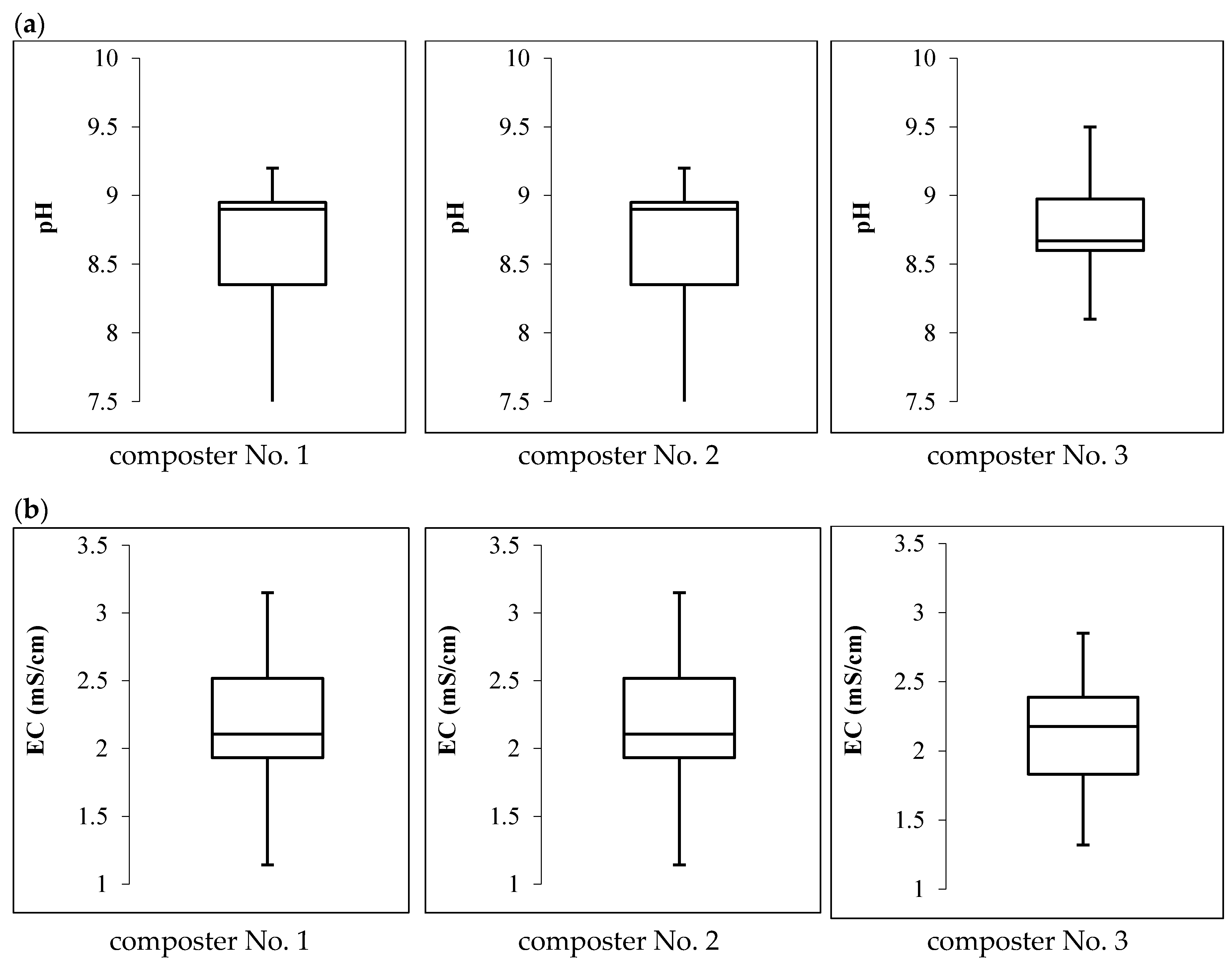

The evolution of pH and electrical conductivity throughout the composting was not the same for all batches and depended on the operational aspects of composter management as well as the variations in waste and bulking agents provided. Overall there was a tendency for the pH to increase weakly as composting progressed but this trend was not seen in all batches. The pH of the compost obtained ranged between 8.1 and 9.5 (see

Figure 7), which was slightly higher than values described in the literature for OFMSW compost from community composting programs in Spain [

42]. This was probably due to a high CaO content after the addition of chicken manure.

The electrical conductivity (EC) increased as composting progressed and salt ions were released during the decomposition of organic matter. However, it was not possible to observe this behaviour in all the batches tested with quite high variability in EC being seen due to varying water content. For this reason, EC is not suitable as a stability indicator [

43]. The average EC obtained in the compost was 2.1 mS/cm (

Figure 7), which is slightly higher than but comparable to OFMSW collective compost [

42,

44] and far lower than composted chicken manure [

41]. These results show that input from chicken manure to the community OFMSW composter did not increase the salinity of the compost to high enough values to impair the quality of the final compost.

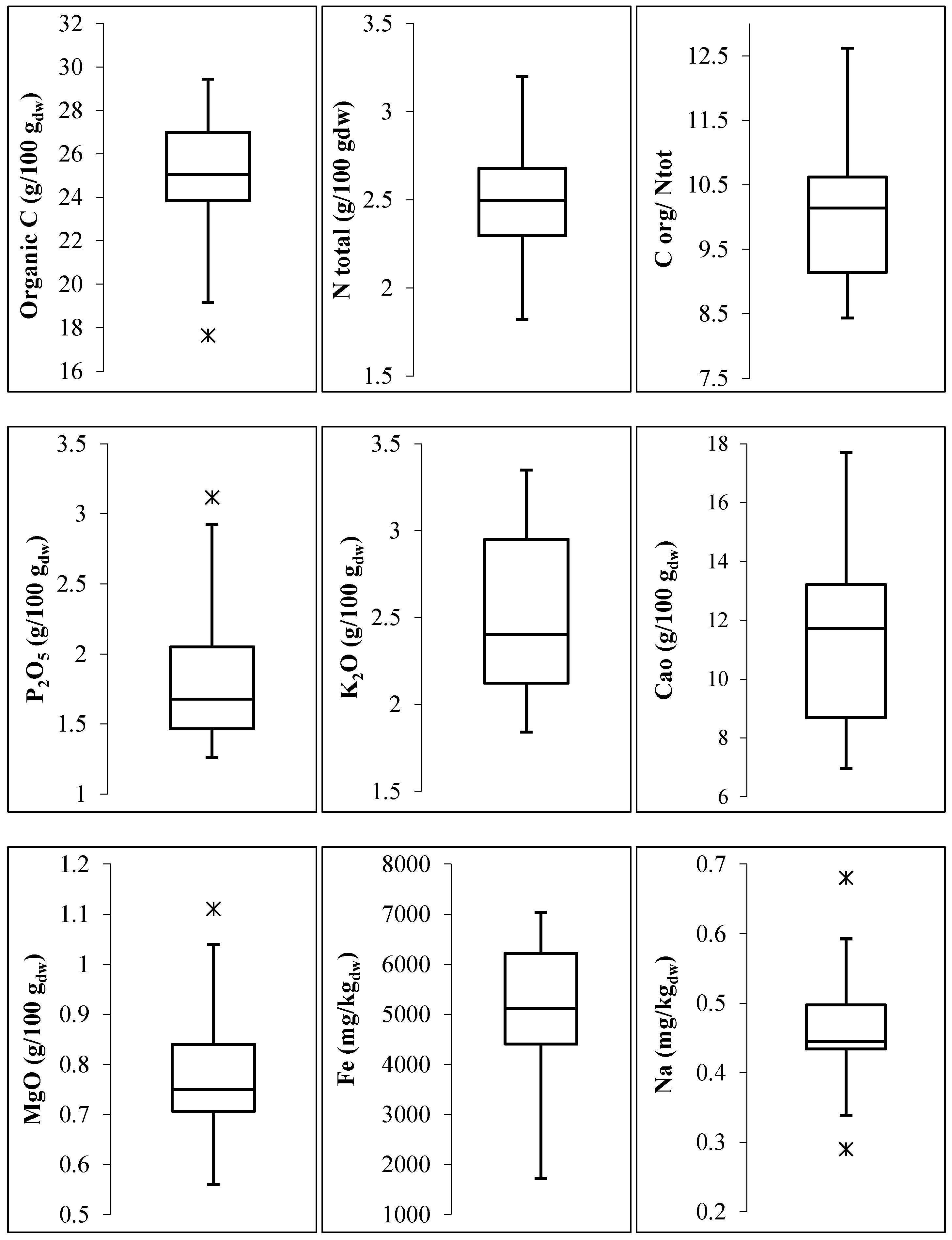

The organic carbon content values of CH compost were higher than composted chicken manure and slightly lower than communal compost. The average total nitrogen content (about 2.5%) was lower than composted chicken manure and similar to OFMSW compost (see

Figure 8). The C/N ratio varied over a range of values slightly below community compost levels, which were similar to composted manure.

The composted manure of laying hens usually presents higher concentrations of P, K and Ca than OFMSW community compost [

41,

42,

44]. In this case, the addition of poultry manure helped increase the calcium and potassium content of compost while no increase in phosphorus was recorded. Iron and sodium concentrations in the CH material were similar to both other composts while the magnesium content was slightly lower.

Generally, the concentrations of most elements were relatively similar for all the batches of compost. However, there was greater variability according to the age of the compost. The variation between batches of the same age was due to seasonal variability in the composition of the initial waste and the distinct intensities of the composting process that generated different temperatures and volume reductions.

The heavy metals content of the CH compost was far below the European limits proposed for compost use in organic agriculture [

45] (see

Table 4). The heavy metals content rose throughout the composting process with the concentrations increasing due to the loss of other compost fractions such as CO

2 and water. Even though there was a consistent reduction in volume during the composting, it was not always possible to observe this increase in concentration in all the batches.

In terms of compost sanitation and the presence of human pathogens, the composting process in the CH ensures quality, safe compost. None of the samples collected after week 21 of the composting process exceeded the limits included in the European Commission technical proposals [

45] or current Spanish legislation on compost [

31]. It is noteworthy that the limits set out in these documents apply only to marketable finished compost while there are no specific regulations for backyard compost or that intended for use in situ. In this context, these limits were used as a guiding reference similar to heavy metals content. In some sampled level of

E. coli exceeding the legal limits was episodically observed (see

Table 5). It has to be underlined that it was in a sample of not completely finished compost that was still in the third composter. The most likely reason is a possible contamination of compost after the thermophilic phase due to accidental intake of faecal material not composted. In the first composting batches, chickens could access the area covered above the second and third composters. When the lids were opened, their droppings could fall to compost. The compost contained in the third composter (and in the later stage of permanence in the second) is not further subjected to the sanitizing action of high temperatures. After this result, to ensure better hygienic conditions, it was decided to close the area above the second and third composters in order to avoid contamination of compost in the mesophilic phase.

Salmonella spp. was not detected in any of the 25 g samples from the composts analysed.

3.5. Egg Production and Animal Welfare

Eggs were a very important aspect of this experience as this encouraged the greater collaboration and participation of families delighted by their quality and freshness. Both visual inspections and user reviews noted the optimal organoleptic characteristics of the eggs with intensely coloured yolks, a medium-large size, firm-textured regular albumen and consistent thick shells. The average weight of the eggs ranged roughly between 55 and 65 g. The microbiological analysis determined the absence of Salmonella spp. inside the eggs.

In the three-year study period of the Noáin CH, 6624 eggs were collected (

Table 6). Although the number of chickens was lower at the beginning, the year of highest production was the first likely because the hens were younger.

Egg production varied over the 36-month period (see

Figure 9).

Figure 7 shows that there was no clear relationship between egg production and the amount of food waste provided but this depended more on the age of the hens and their position along the laying curve. As was expected, the winter months were the least productive likely due to the low number of hours of light and the hens’ increased energy consumption to maintain their body heat.

During the regular visual observations of the birds’ health no mentionable incidents in terms of animal welfare were recorded. From a morphological perspective, the hens had bright, dense plumage and the combs and wattles presented a bright colour at all times. Generally, there were no signs of malnourishment at any time nor were there any conflicts or coexistence problems among the hens. The sporadic presence of hen lice (Dermanyssus gallinae) was recorded in the summer of 2014 but these were easily eliminated by properly cleaning the henhouse. The good condition of the hens and the suitability of the conditions for breeding were confirmed by the birth of four chicks.

Animal feed consumption was very reduced and limited almost exclusively to the initial period of adaptation, weekends and holiday periods. The hens were fed with organic feed (Goimar, S.L.) composed of a mixture of wheat, oats, corn and barley. An average of 102 kilograms of formulated feed supply per year was provided, which was equivalent to 21 g of feed per animal per day. The daily feed intake of laying hens ranged from 100 to 150 g/hen per day in commercial farming [

46,

47]. The feed supplied was an organic feed containing corn, barley, wheat and oats.

3.6. Participatory Behaviour and Social Benefits

During the first three years of CH operation, a total of 59 families from five different nationalities participated, which corresponds to 0.89% of the total Noáin municipality population. The initiative was a success, which means it provided several benefits such as increasing social cohesion and the motivation of local residents to participate directly in recycling their waste.

Thirteen of the 30 current participants have been involved in the CH since the beginning in January 2013. Of all the families who have participated over this three-year period, 29 abandoned the project for different reasons. Most of the withdrawals were voluntary and the main reason was to give other residents the opportunity to participate in the experience. Other reasons for giving up included advanced age, the inability to attend, scheduling incompatibility, or lack of time. In three cases, the participants were not recorded in the municipal census of Noáin or moved to another municipality. Only five participants were discharged because of failure to perform their duties. More than twenty further people still wished to participate in this initiative after the end of the three years and these people have been registered on a waiting list.

From the responses collected in participant surveys, the user satisfaction was rated as outstanding with an average score of 9.1 out of 10. The most highly valued positive aspect was the possibility of direct contact with animals, which were considered pets and were visited an average of twice a week. Other reasons the participants gave for the success of this project were its educational value, especially for children and leisure and recreational functions for retirees and families with children. Although the eggs were one of the most attractive and highly rated factors in the user survey, it is clear that the reward of six eggs once a month was not the determining factor.

The park visitors not participating in the initiative (mostly regular users of the park, young couples with children and the elderly), positively evaluated the CH and showed interest in eventually participating in similar initiatives. Almost all visitors surveyed were aware of the existence of the henhouse but most did not know that it was utilized to treat the bio-waste of local residents. This indicates the low impact of the CH and the high level of public acceptance.

As a result of the success of this project in Noáin, more than 19 further CHs have been installed in the area in which nine are communal plus at least 10 installed in private homes. The trend predicts that this number will continue to grow.

The Noáin CH is currently listed among the composting programs associated with the European SCOW project [

36].

3.7. Economic Considerations

The CH involves simple technology and a low initial cost that could provide substantial economic benefits. However, it is difficult to quantify the initiative monetarily since its benefits are not only economic.

There is an initial investment in the construction of the structure but it is built in situ with recycled or reused materials that can be used over a ten-year period. Among the costs that must be taken into account were the purchase of the hens, supplementary feed and the costs of training volunteers as well as compost monitoring. The labour requirement has been estimated at 15 min a day. Maintenance and handling operation costs were negligible because this was a self-managed initiative involving volunteer labour. The project costs associated with volunteer training, consultancy and promotional campaigns can be considered similar to other community composting programs. In this case, these activities were carried out by the promoters and did not constitute any cost for the project.

The economic benefits include the savings related to the collection and management of OFMSW (over 16 tons in three years), the value of the compost obtained (5.6 tons) and the value of the eggs (more than 6200 in total).

In

Table 7, cost and benefit were summarized.