Standard Data-Based Predictive Modeling for Power Consumption in Turning Machining

Abstract

:1. Introduction

1.1. Background of Study

1.2. Proposed Approach

2. Materials and Methods

2.1. Identification and Categorization of Process Feature Data

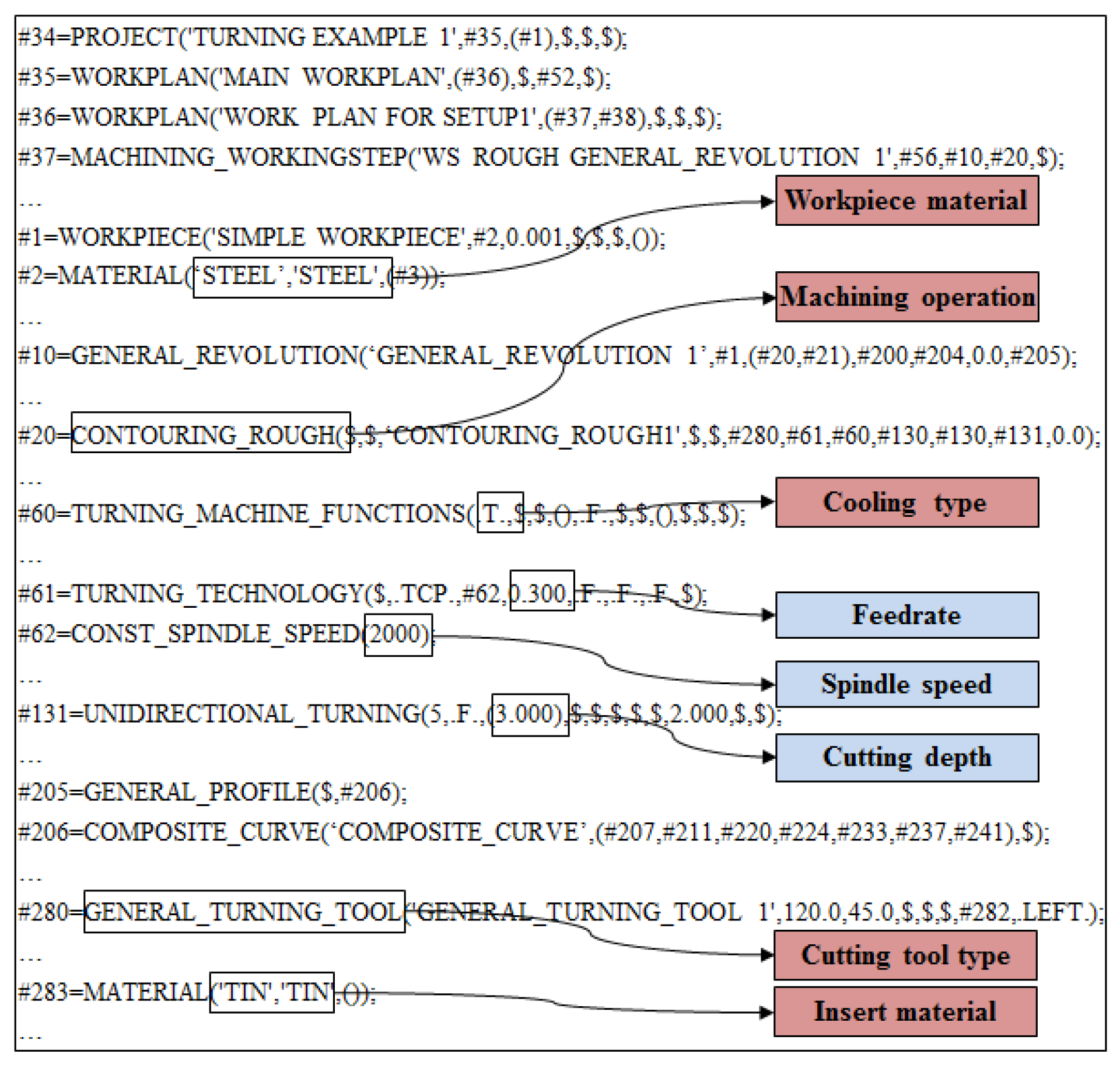

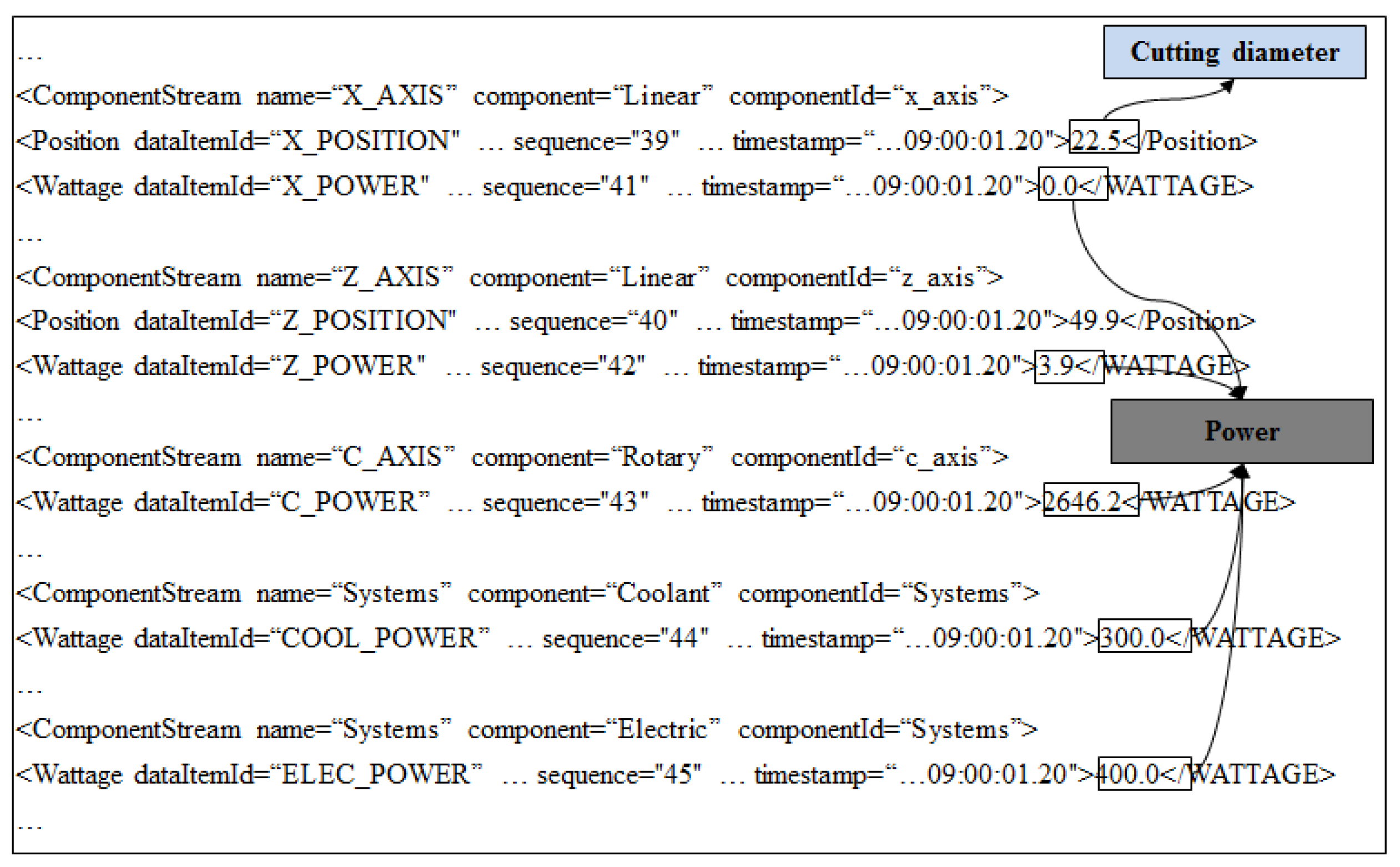

2.1.1. Identification of Process Feature Data

2.1.2. Categorization of Process Feature Data

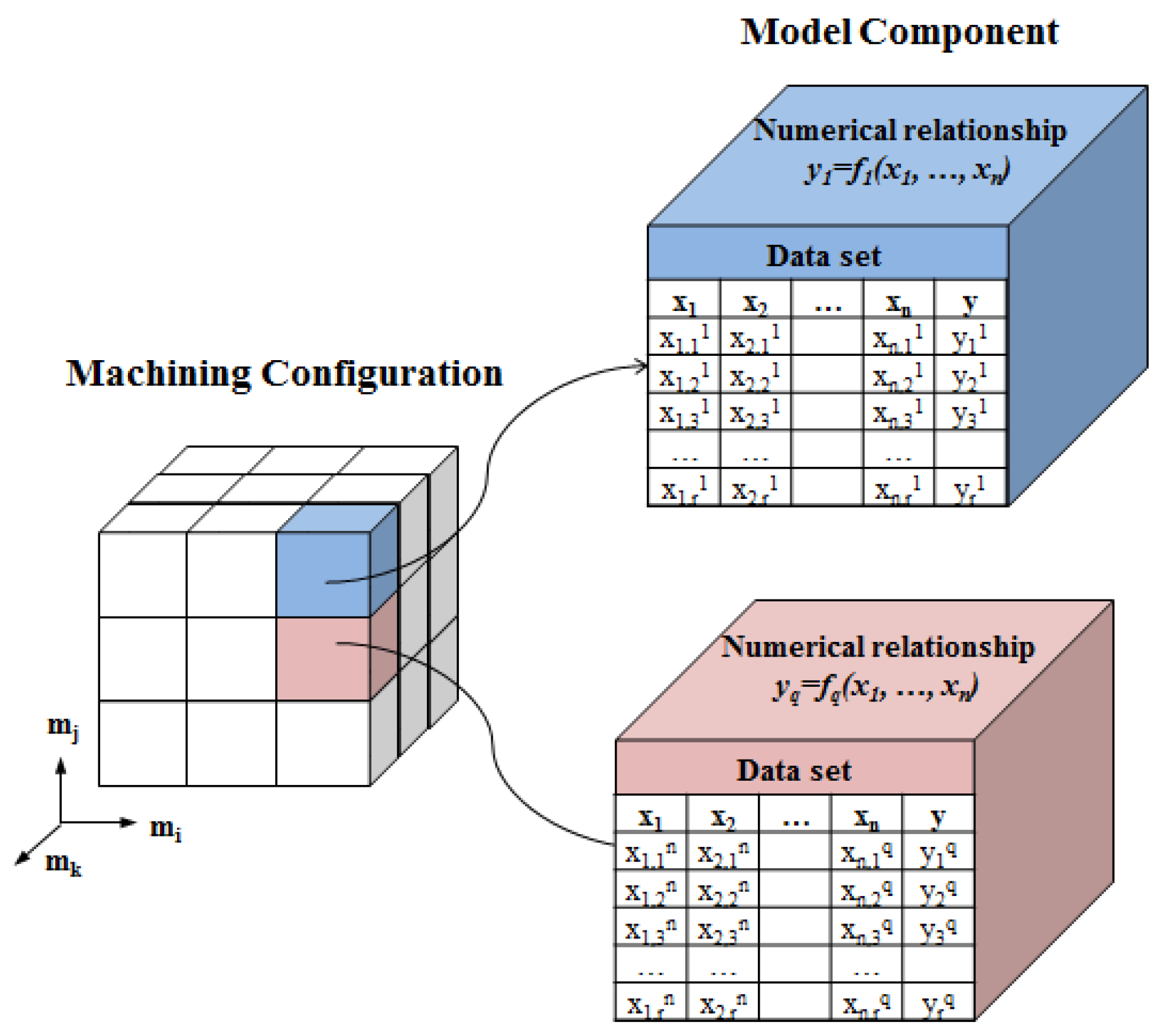

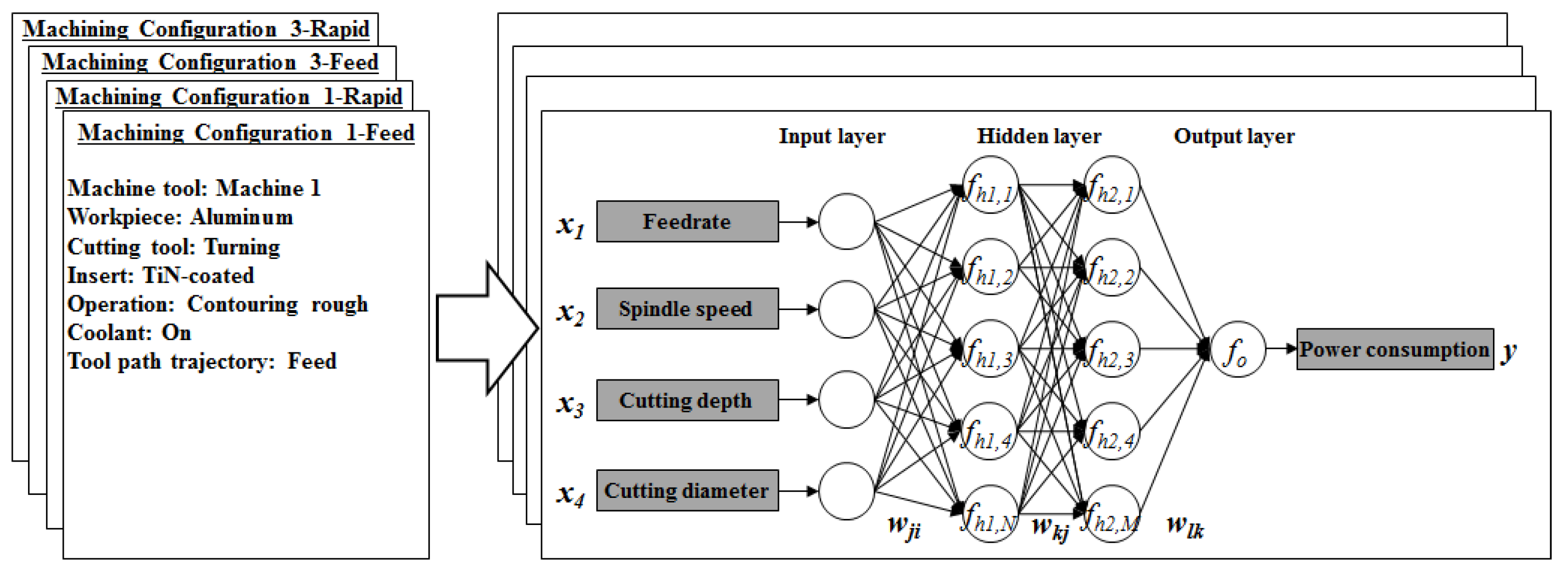

2.2. Predictive Modeling Process

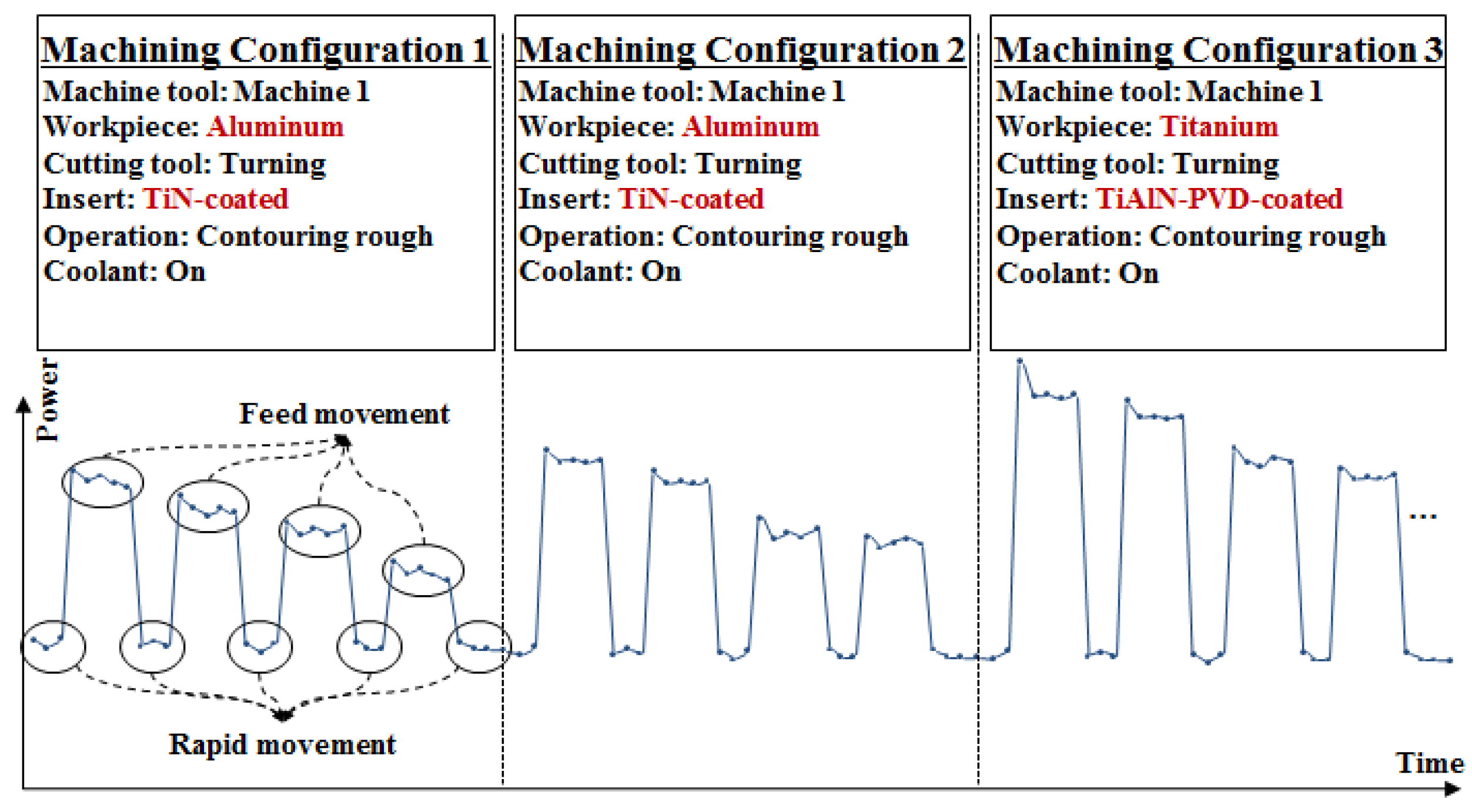

2.2.1. Extraction of Process Feature Data Instances

2.2.2. Preparation of Training Datasets

2.2.3. Computation of Numerical Functions

2.2.4. Performance Measurement of Numerical Functions

3. Analysis and Results

3.1. Case Scenario

3.2. Creation of Predictive Models

3.3. Performance Analysis of Predictive Models

- (1)

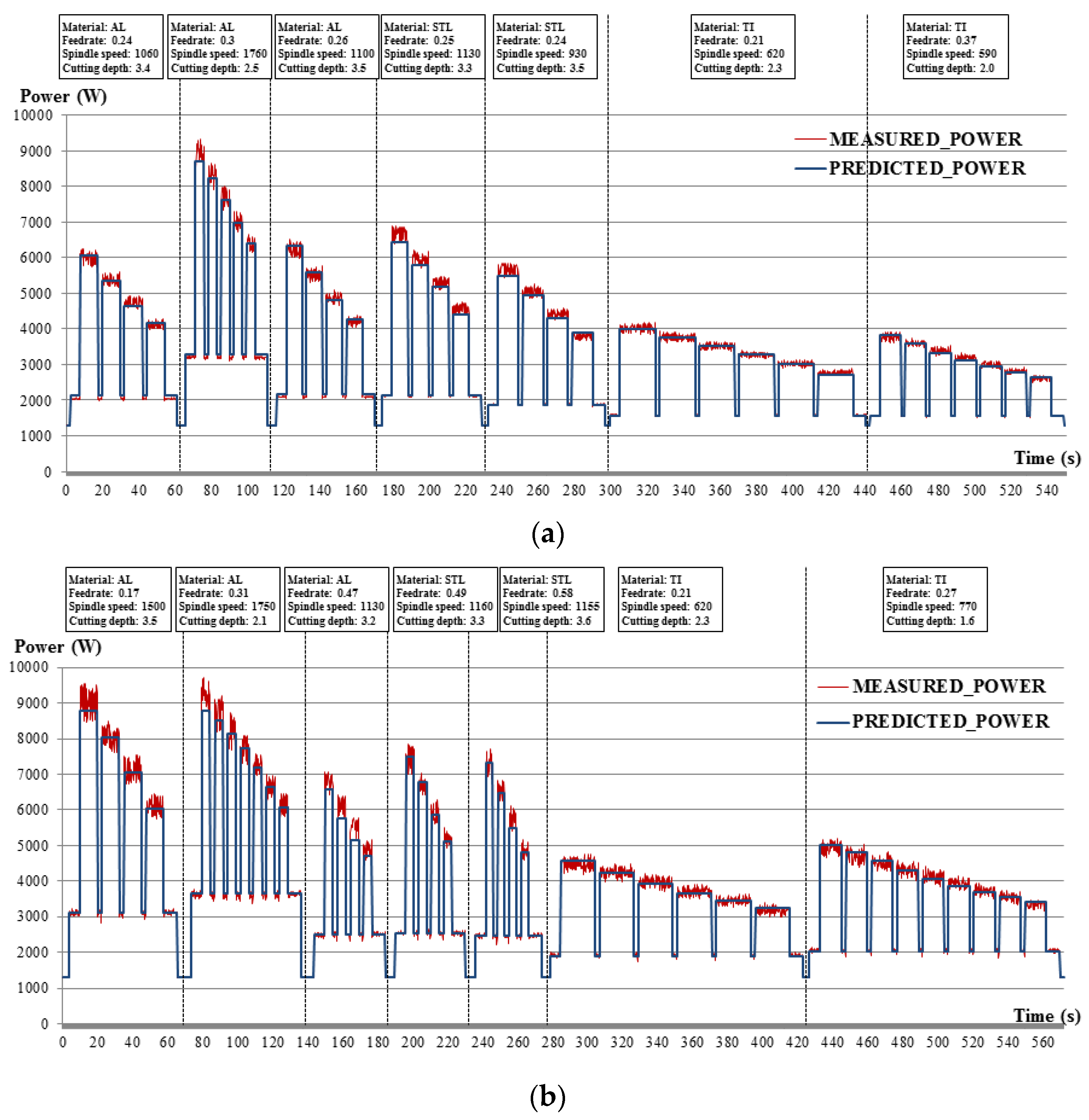

- Comparison between the measured power and the predicted power: Using the validation datasets, we can make a time-series of measured and predicted power profiles for the two machine tools’ operations. Figure 7 presents some captures of the power profiles to compare the predicted power that the predictive models generate with the measured power that the machining simulator generates. Figure 7a,b show the power profiles of Machine 1 and Machine 2, respectively, which produce seven parts with three workpiece materials and different process parameter sets. The predicted power coincides well with the measured power. The cutting power and the machine power have separate patterns on the measured power. The cutting power varies in terms of the values of feed rate, spindle speed, and cutting depth. Also, it gradually decreases as cutting diameter decreases. The machine power keeps steady state during spindle rotation. Our predictive models can capture these phenomena.

- (2)

- Statistical analysis of predictive models: we perform statistical analysis for the twelve predictive models computed by neural networks using statistical metrics including the coefficient of determination (R2) and the RMSE. Table 5 shows the result. The values of the statistical metrics indicate our predictive models can make good performances with minimum 84.1% R2 and maximum 0.066 RMSE. It is noted that the RMSE is measured on a 0-to-1 scale for min-max normalization of power values.

- (3)

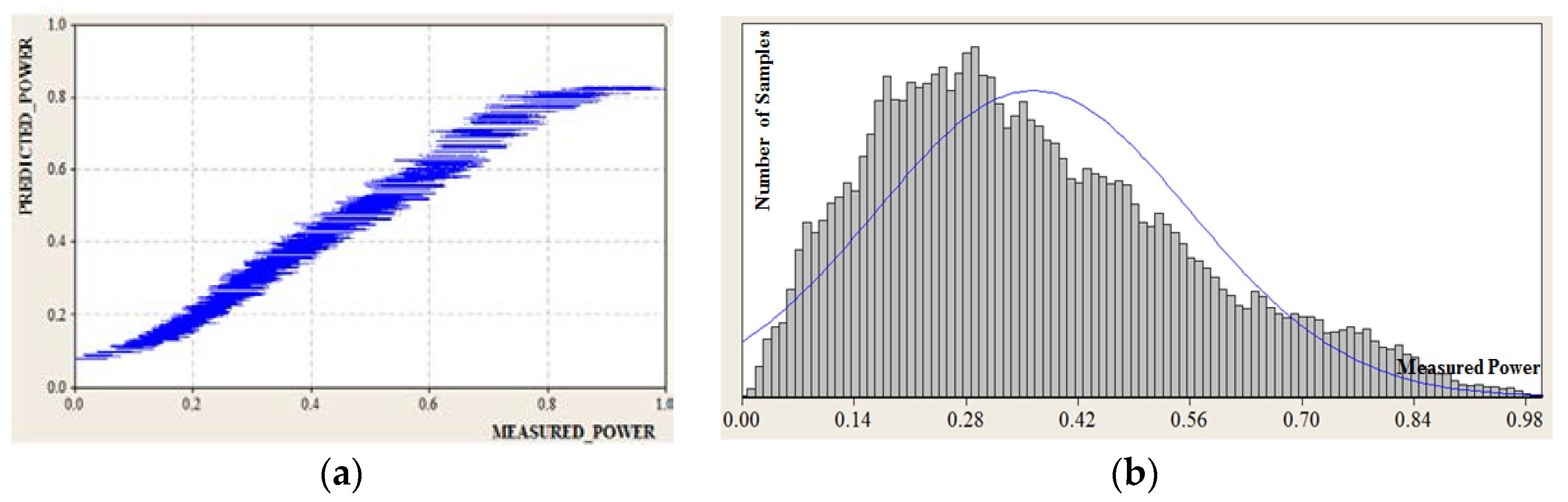

- Power distributions in predictive models: We analyze the power distribution of each predictive model to check its accuracy to predict the desired results correctly within the range of minimum and maximum power. Figure 8a presents, for example, the scatter plot that maps the normalized predicted power with the normalized measured power for the case of “Machine 1”,“TI”, and “feed”. Here, the normalized power means a 0-to-1 scaled power converted from an original power value. The accuracy of the predictive model coincides with the middle of the power distribution. However, it falls off at both edges of the power distribution. In particular, these models slightly lose their predictive power at the top area of power distribution. The predicted power is distributed from 0.079 to 0.828; whereas, the measured power is distributed from 0 to 1. The RMSEs, respectively, score 0.022 in the validation samples less than the first quartile number, 0.021 in the samples between the first quartile and the third quartile numbers. However, the RMSE indicates 0.035 in the samples higher than the third quartile number. This fall-off occurs in all the predictive models. We conjecture that the distribution of the training dataset is left-skewed, as shown in Figure 8b; and thus the number of training data samples for predicting higher power values is very small compared to the numbers for lower and middle power values to learn these data samples.

4. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Shin, S.J.; Suh, S.H.; Stroud, I. A green productivity based process planning system for a machining process. Int. J. Prod. Res. 2014, 53, 5085–5105. [Google Scholar] [CrossRef]

- Vijayaraghavan, A.; Dornfeld, D. Automated energy monitoring of machine tools. CIRP Ann. Manuf. Technol. 2010, 59, 21–24. [Google Scholar] [CrossRef]

- Gutowski, T.; Dahmus, J.; Thiriez, A. Electrical energy requirements for manufacturing processes. In Proceedings of the 13th CIRP International Conference on Life Cycle Engineering, Leuven, Belgium, 31 May–2 June 2006; pp. 623–628. [Google Scholar]

- Kara, S.; Li, W. Unit process energy consumption models for material removal processes. CIRP Ann. Manuf. Technol. 2011, 60, 37–40. [Google Scholar] [CrossRef]

- Newman, S.T.; Nssehi, A.; Imani-Asrai, R.; Dhokia, V. Energy efficient process planning for CNC machining. CIRP J. Manuf. Sci. Technol. 2012, 5, 127–136. [Google Scholar] [CrossRef] [Green Version]

- Altintas, Y. Manufacturing Automation: Metal Cutting Mechanics, Machine Tool Vibrations, and CNC Design; Cambridge University Press: New York, NY, USA, 2011. [Google Scholar]

- Bayoumi, A.E.; Yucesan, G.; Hutton, D.V. On the closed form mechanistic modeling of milling: Specific cutting energy, torque, and power. Mater. Eng. Perform. 1994, 3, 151–158. [Google Scholar] [CrossRef]

- Munoz, A.A.; Sheng, P. An analytical approach for determining the environmental impact of machining processes. Mater. Process. Technol. 1995, 53, 736–758. [Google Scholar] [CrossRef]

- Kishawy, H.A.; Kannan, S.; Balazinski, M. An energy based analytical force model for orthogonal cutting of metal matrix composites. CIRP Ann. Manuf. Technol. 2004, 53, 91–94. [Google Scholar] [CrossRef]

- Palanisamy, P.; Rajendran, I.; Shanmugasundaram, S.; Saravanan, R. Prediction of cutting force and temperature rise in the end-milling operation. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2006, 220, 1577–1587. [Google Scholar] [CrossRef]

- Astakhov, V.P.; Xiao, X. The principle of minimum strain energy to fracture of the workpiece material and its application in modern cutting technologies. In Metal Cutting Technology; Davim, J.P., Ed.; Walter de Gruyter GmbH & Co.: Berlin, Germany, 2016. [Google Scholar]

- Dietmair, A.; Verl, A. Energy consumption forecasting and optimization for tool machines. Mod. Mach. Sci. J. 2009, 62–67. [Google Scholar] [CrossRef]

- Weinert, N.; Chiotellis, S.; Seliger, G. Methodology for planning and operating energy-efficient production systems. CIRP Ann. Manuf. Technol. 2011, 60, 41–44. [Google Scholar] [CrossRef]

- Draganescu, F.; Gheorghe, M.; Doicin, C.V. Models of machine tool efficiency and specific consumed energy. Mater. Process. Technol. 2003, 141, 9–15. [Google Scholar] [CrossRef]

- Diaz, N.; Ninomiya, K.; Noble, J.; Dornfeld, D. Environmental impact characterization of milling and implications for potential energy savings in industry. Procedia CIRP 2012, 1, 518–523. [Google Scholar] [CrossRef]

- Astakhov, V.P.; Xiao, X. A methodology for practical cutting force evaluation based on the energy spent in the cutting system. Mach. Sci. Technol. 2008, 12, 325–347. [Google Scholar] [CrossRef]

- Helu, M.; Rühl, J.; Dornfeld, D.; Werner, P.; Lanza, G. Evaluating trade-offs between sustainability, performance, and cost of green machining technologies. In Proceedings of the 18th CIRP International Conference on Life Cycle Engineering, Braunschweig, Germany, 2–4 May 2011; pp. 195–200. [Google Scholar]

- Iqbal, A.; Zhang, H.C.; Kong, L.L.; Hussain, G. A rule-based system for trade-off among energy consumption, tool life, and productivity in machining process. J. Intell. Manuf. 2015, 26, 1217–1232. [Google Scholar] [CrossRef]

- Peng, T.; Xu, X. A holistic approach to achieving energy efficiency for interoperable machining systems. Int. J. Sustain. Eng. 2013, 7, 111–129. [Google Scholar] [CrossRef]

- Jia, S.; Tang, R.; Lv, J. Therblig-based energy demand modeling methodology of machining process to support intelligent manufacturing. J. Intell. Manuf. 2014, 25, 913–931. [Google Scholar] [CrossRef]

- Bhinge, R.; Biswas, N.; Dornfeld, D.; Park, J.K.; Law, K.; Helu, M.; Rachuri, S. An intelligent machine monitoring system for energy prediction using a Gaussian process regression. In Proceedings of the 2014 IEEE International Conference on Big Data, Washington, DC, USA, 27–30 October 2014; pp. 978–986. [Google Scholar]

- Behrendt, T.; Zein, A.; Min, S.K. Development of an energy consumption monitoring procedure for machine tools. CIRP Ann. Manuf. Technol. 2012, 61, 43–46. [Google Scholar] [CrossRef]

- Campatelli, G.; Lorenzini, L.; Scippa, A. Optimization of process parameters using a response surface method for minimizing power consumption in the milling of carbon steel. J. Clean. Prod. 2014, 66, 309–316. [Google Scholar] [CrossRef]

- International Standards Organization (ISO). ISO14649. Industrial Automation Systems and Integration—Physical Device Control—Data Model for Computerized Numerical Controllers—Part 1: Overview and Fundamental Principles; International Standards Organization: Geneva, Switzerland, 2003. [Google Scholar]

- MTConnect. MTConnect Standard Part 1—Overview and Protocol; MTConnect Institute: McLean, VA, USA, 2011. [Google Scholar]

- Mori, M.; Fujishima, M.; Inamasu, Y.; Oda, Y. A study on energy efficiency improvement for machine tools. CIRP Ann. Manuf. Technol. 2011, 60, 145–148. [Google Scholar] [CrossRef]

- Aramcharoen, A.; Mativenga, P.T. Critical factors in energy demand modelling for CNC milling and impact of toolpath strategy. J. Clean. Prod. 2014, 78, 63–74. [Google Scholar] [CrossRef]

- Abushawashi, Y.; Xiao, X.; Astakhov, V. A novel approach for determining material constitutive parameters for a wide range of triaxiality under plane strain loading conditions. Int. J. Mech. Sci. 2013, 74, 133–142. [Google Scholar] [CrossRef]

- Astakhov, V.P.; Shvets, S. The assessment of plastic deformation in metal cutting. J. Mater. Process. Technol. 2004, 146, 193–202. [Google Scholar] [CrossRef]

- Li, J.; Lu, Y.; Zhao, H.; Li, P.; Yao, X. Optimization of cutting parameters for energy saving. Int. J. Adv. Manuf. Technol. 2014, 70, 117–124. [Google Scholar] [CrossRef]

- Zhang, Y.; Zou, P.; Li, B.; Liang, S. Study on optimized principles of process parameters for environmentally friendly machining austenitic stainless steel with high efficiency and little energy consumption. Int. J. Adv. Manuf. Technol. 2015, 79, 89–99. [Google Scholar] [CrossRef]

- Shokrani, A.; Dhokia, A.; Newman, S.T. Environmentally conscious machining of difficult-to-machine materials with regard to cutting fluids. Int. J. Mach. Tools Manuf. 2012, 57, 83–101. [Google Scholar] [CrossRef] [Green Version]

- Velchev, S.; Kolev, I.; Ivanov, K.; Gechevski, S. Empirical models for specific energy consumption and optimization of cutting parameters for minimizing energy consumption during turning. J. Clean. Prod. 2014, 80, 139–149. [Google Scholar] [CrossRef]

- Amstead, B.H.; Ostwald, P.F.; Begeman, M. Manufacturing Processes; John Wiley & Sons Inc.: New York, NY, USA, 1987. [Google Scholar]

- Bhushan, R.K. Optimization of cutting parameters for minimizing power consumption and maximizing tool life during machining of Al alloy SiC particle composites. J. Clean. Prod. 2013, 39, 242–254. [Google Scholar] [CrossRef]

- International Standards Organization (ISO). ISO/TS14649. Industrial Automation Systems and Integration—Physical Device Control—Data Model for Computerized Numerical Controllers—Part 201: Machine Tool Data for Cutting Processes; International Standards Organization: Geneva, Switzerland, 2011. [Google Scholar]

- International Standards Organization (ISO). ISO14649. Industrial Automation Systems and Integration—Physical Device Control—Data Model for Computerized Numerical Controllers—Part 12: Process Data for Turning; International Standards Organization: Geneva, Switzerland, 2005. [Google Scholar]

- International Standards Organization (ISO). ISO14649. Industrial Automation Systems and Integration—Physical Device Control—Data Model for Computerized Numerical Controllers—Part 121: Tools for Turning Machines; International Standards Organization: Geneva, Switzerland, 2005. [Google Scholar]

- International Standards Organization (ISO). ISO 6983. Automation Systems and Integration—Numerical Control of Machines—Program Format and Definitions of Address Words—Part 1: Data Format for Positioning, Line Motion and Contouring Control Systems; International Standards Organization: Geneva, Switzerland, 2009. [Google Scholar]

- MTConnect. MTConnect Standard Part 2—Components and Data Items; MTConnect Institute: McLean, VA, USA, 2012. [Google Scholar]

- Chandrasekaran, M.; Muralidhar, M.; Krishna, C.M.; Dixit, U.S. Application of soft computing techniques in machining performance prediction and optimization: A literature review. Int. J. Adv. Manuf. Technol. 2010, 46, 445–464. [Google Scholar] [CrossRef]

- Lippmann, R.P. An introduction to computing with neural nets. IEEE ASSP Mag. 1987, 4, 4–22. [Google Scholar] [CrossRef]

- Szecsi, T. Cutting force modeling using artificial neural networks. J. Mater. Process. Technol. 1999, 92, 344–349. [Google Scholar] [CrossRef]

- Nannapaneni, S.; Mahadevan, S. Uncertainty quantification in performance evaluation of manufacturing processes. In Proceedings of the 2014 IEEE International Conference on Big Data, Washington, DC, USA, 27–30 October 2014; pp. 996–1005. [Google Scholar]

- Shin, S.J.; Woo, J.W.; Kim, D.B.; Kumaraguru, S.; Rachuri, S. Developing a virtual machining model to generate MTConnect machine-monitoring data from STEP-NC. Int. J. Prod. Res. 2015, 54, 4487–4505. [Google Scholar] [CrossRef]

- KNIME Analytics Platform. Available online: http://www.knime.org/ (accessed on 29 July 2014).

- Markopoulos, A.P.; Manolakos, D.E.; Vaxevanidis, N.M. Artificial neural network models for the prediction of surface roughness in electrical discharge machining. J. Intell. Manuf. 2008, 19, 283–292. [Google Scholar] [CrossRef]

| Category | PFD Item | Influencing Variable | Data Type | Examples |

|---|---|---|---|---|

| Machining configuration | Machine tool model | Pmachine | Nominal | Machine tool 1, Machine tool 2 |

| Cutting tool type | k | Nominal | Turning, Grooving, End mill | |

| Insert material | k | Nominal | Titanium coated, High speed steel | |

| Workpiece material | k | Nominal | Aluminum, Steel, Titanium | |

| Machining operation | k | Nominal | Contouring, Facing, Rough or Finish | |

| Cooling type | k | Nominal | Emulsion, Mineral Oil, Dry | |

| Path trajectory | k | Enumeration | Rapid/Feed | |

| Input variable | Cutting depth | Q | Numeric | |

| Feed rate | Q | Numeric | ||

| Spindle speed | Q | Numeric | ||

| Cutting diameter | Q | Numeric | ||

| Output variable | Power consumption | P | Numeric |

| Machining Configuration Number | Sample No. | Input Variables | Output Variable | |||

|---|---|---|---|---|---|---|

| Cutting Depth | Feed Rate | Spindle Speed | Cutting Diameter | Power Consumption | ||

| 1 | 1 | 1.6 | 0.27 | 1000 | 23.4 | 4598.3 |

| 2 | 1.6 | 0.27 | 1000 | 23.4 | 4561.1 | |

| 3 | 1.6 | 0.27 | 1000 | 21.8 | 4343.1 | |

| ... | ||||||

| 2 | 4 | 2.8 | 0.46 | 1137 | 22.2 | 6294.3 |

| 5 | 2.8 | 0.46 | 1137 | 19.4 | 5554.5 | |

| … | ||||||

| Process Parameter | Unit | Workpiece Material | ||

|---|---|---|---|---|

| AL | STL | TI | ||

| Feed rate | mm/rev | 0.1–0.5 | 0.2–0.6 | 0.2–0.4 |

| Spindle speed | RPM | 900–2000 | 900–1200 | 500–1000 |

| Cutting depth | mm | 1–4 | 2–6 | 1–3 |

| Hidden Layer 1 | Hidden Layer 2 | Output Layer | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Neuron | N1,0 | N1,1 | N1,2 | N1,3 | N1,4 | Neuron | N2,0 | N2,1 | N2,2 | N2,3 | N2,4 | Neuron | N3,0 | |||

| Input | Input | Input | ||||||||||||||

| f | −0.014 | 0.051 | 0.092 | −0.330 | −0.377 | N1,0 | 1.380 | 0.787 | 0.191 | 0.522 | −1.074 | N2,0 | −0.948 | |||

| N | −0.905 | 3.751 | 1.635 | 1.016 | −2.855 | N1,1 | 0.029 | −2.017 | −0.787 | 0.664 | 0.401 | N2,1 | −1.117 | |||

| t | −0.919 | 0.189 | 1.767 | 3.213 | 0.734 | N1,2 | −0.493 | −0.738 | −0.703 | 1.313 | 0.829 | N2,2 | −1.386 | |||

| D | −0.138 | −0.358 | 2.511 | 3.326 | 0.325 | N1,3 | −2.266 | −0.967 | −2.134 | 2.800 | 1.283 | N2,3 | 0.504 | |||

| Bias | 0.035 | −1.650 | −1.839 | −4.475 | 0.017 | N1,4 | −0.277 | 2.651 | 1.689 | 1.802 | −1.348 | N2,4 | 1.804 | |||

| Bias | −0.145 | 1.296 | 1.253 | −0.200 | 0.216 | Bias | −0.639 | |||||||||

| Machine | Workpiece | Path Trajectory | Training Samples | Validation Samples | R2 (%) | RMSE |

|---|---|---|---|---|---|---|

| Machine 1 | AL | Feed | 77,241 | 74,683 | 96.7 | 0.031 |

| Rapid | 35,449 | 35,509 | 97.9 | 0.040 | ||

| STL | Feed | 16,679 | 16,217 | 95.9 | 0.044 | |

| Rapid | 12,944 | 12,879 | 97.1 | 0.042 | ||

| TI | Feed | 121,657 | 123,379 | 98.3 | 0.025 | |

| Rapid | 33,050 | 33,022 | 98.4 | 0.033 | ||

| Machine 2 | AL | Feed | 36,758 | 36,670 | 95.5 | 0.037 |

| Rapid | 20,657 | 20,615 | 98.2 | 0.033 | ||

| STL | Feed | 16,564 | 15,967 | 95.3 | 0.042 | |

| Rapid | 15,165 | 14,988 | 84.1 | 0.064 | ||

| TI | Feed | 25,684 | 22,329 | 96.8 | 0.035 | |

| Rapid | 8018 | 7740 | 88.1 | 0.066 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shin, S.-J.; Woo, J.; Rachuri, S.; Meilanitasari, P. Standard Data-Based Predictive Modeling for Power Consumption in Turning Machining. Sustainability 2018, 10, 598. https://doi.org/10.3390/su10030598

Shin S-J, Woo J, Rachuri S, Meilanitasari P. Standard Data-Based Predictive Modeling for Power Consumption in Turning Machining. Sustainability. 2018; 10(3):598. https://doi.org/10.3390/su10030598

Chicago/Turabian StyleShin, Seung-Jun, Jungyub Woo, Sudarsan Rachuri, and Prita Meilanitasari. 2018. "Standard Data-Based Predictive Modeling for Power Consumption in Turning Machining" Sustainability 10, no. 3: 598. https://doi.org/10.3390/su10030598