The Effects of Gliricidia-Derived Biochar on Sequential Maize and Bean Farming

Abstract

:1. Introduction

2. Methods

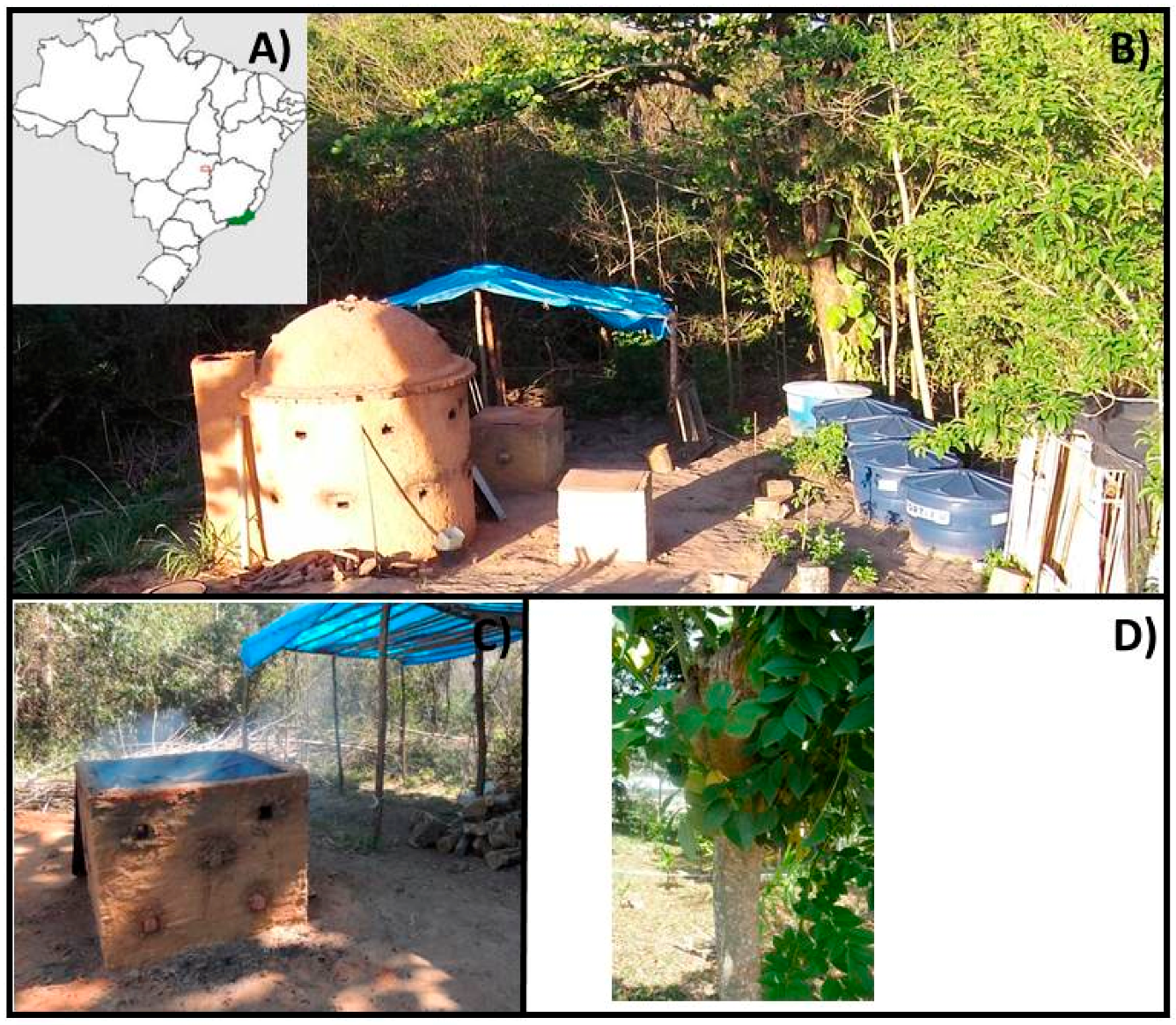

2.1. Study Area

2.2. Experimental Design

2.3. Biochar

2.4. Vegetative Cycles

2.5. Soil and Plant Analyses

2.6. Statistics

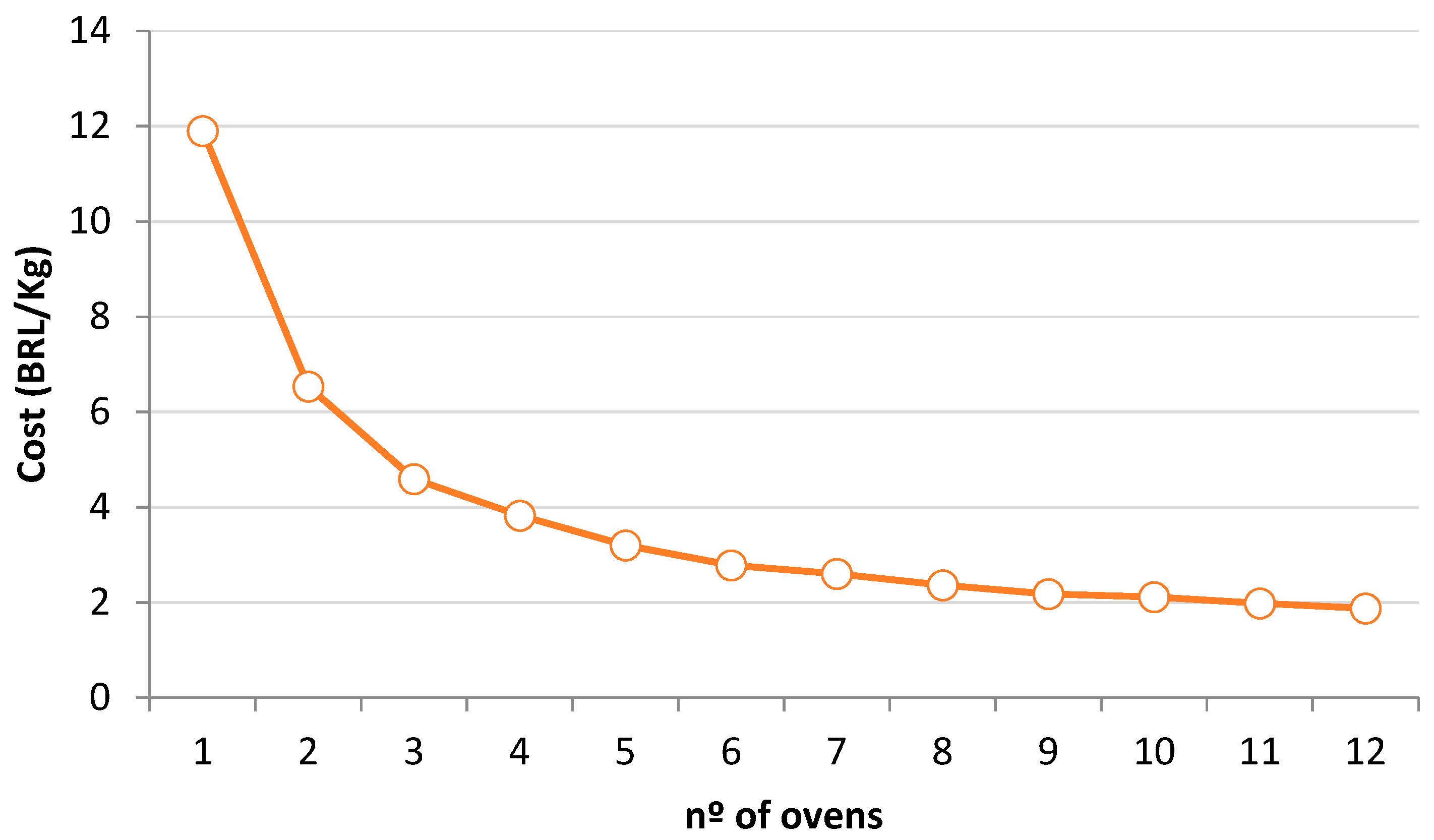

2.7. Biochar Production Costs

3. Results and Discussion

3.1. Biomass Yields for Maize (Zea mays) VAR. Caatingueiro

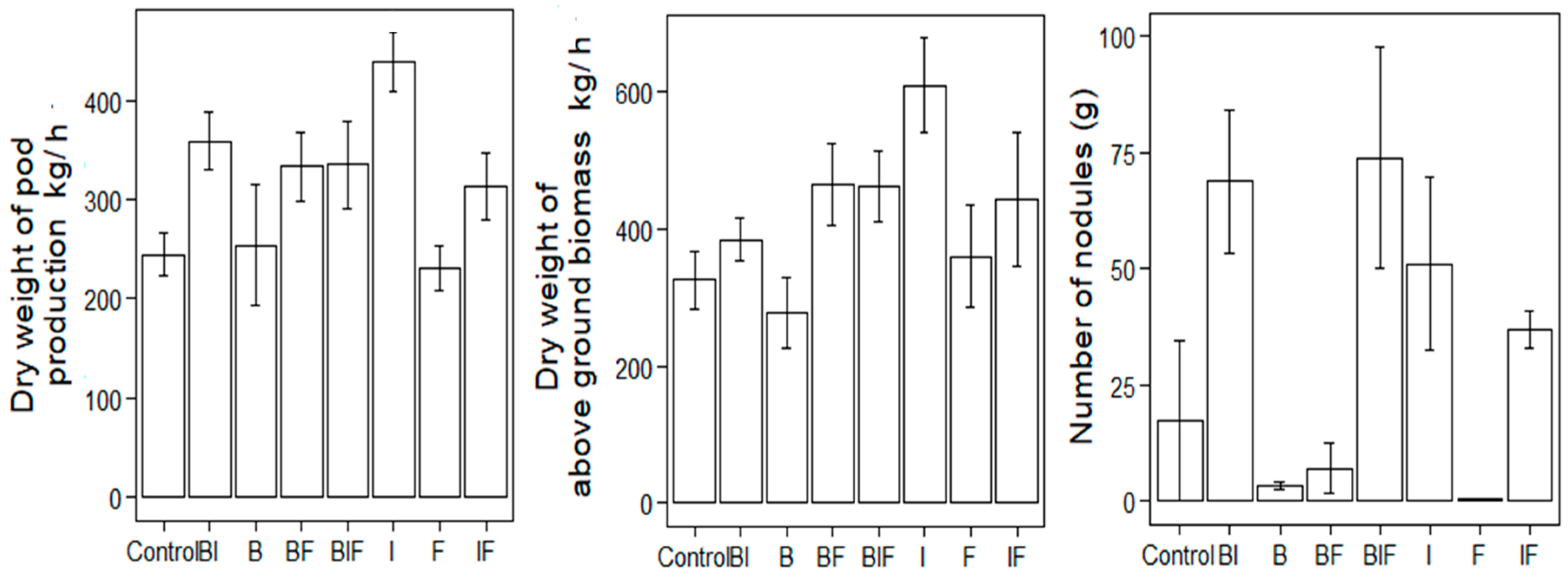

3.2. Biomass Yields for Snap Bean (Phaseolus Vulgaris) cv. Alessa

3.3. Change of Soil Properties over the Two Cropping Seasons

3.4. Biochar-production Costs

4. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Strassburg, B.B.N.; Latawiec, A.E.; Barioni, L.G.; Nobre, C.A.; Da Silva, V.P.; Valentim,, J.F.; Vianna, M.; Assad, E.D. When enough should be enough: Improved use of current agricultural lands could meet demands and spare nature in Brazil. Glob. Environ. Chang. 2014, 28, 84–97. [Google Scholar] [CrossRef] [Green Version]

- Strassburg, B.B.N.; Latawiec, A.E.; Creed, A.; Nguyen, N.; Sunnenberg, G.; Miles, L.; Lovett, A.; Joppa, L.; Ashton, R.; Scharlemann, J.P.W.; et al. Biophysical suitability, economic pressure and land-cover change: A global probabilistic approach and insights for REDD+. Sustain. Sci. 2014, 9, 129–141. [Google Scholar] [CrossRef] [Green Version]

- FAO. Family Farmers. Feeding the World, Caring for the Earth. 2014. Available online: http://www.fao.org/assets/infographics/FAO-Infographic-IYFF14-FamilyFarms-en.pdf (accessed on 3 March 2017).

- França, C.G.; Del Grossi, M.E.; Marques, V.P.M.A. O Censo Agropecuário 2006 e a Agricultura Familiar No Brasil; Ministério do Desenvolvimento Agrário (MDA): Brasília, Brazil, 2009; p. 96. Available online: http://www.bb.com.br/docs/pub/siteEsp/agro/dwn/CensoAgropecuario.pdf (accessed on 3 March 2017).

- Guanziroli, C.E.; Buainain, A.M.; Di Sabbato, A. Dez Anos de Evolução da Agricultura Familiar no Brasil: (1996 e 2006). Rev. Econ. Sociol. Rural 2012, 50, 351–370. [Google Scholar] [CrossRef]

- Scholz, S.M.; Sembres, T.; Roberts, K.; Whitman, T.; Wilson, K.; Lehmann, J. Biochar Systems for Smallholders in Developing Countries: Leveraging Current Knowledge and Exploring Future; A World Bank Studies: Washington, DC, USA, 2014; p. 208. [Google Scholar]

- Sohi, S.P.; Krull, E.; Lopez-Capel, E.; Bol, R. A review of biochar and its use and function in soil. Adv. Agron. 2010, 105, 47–82. [Google Scholar]

- Steiner, C.; Teixeira, W.G.; Lehmann, J.; Nehls, T.; de Macedo, J.L.V.; Blum, W.E.H.; Zech, W. Long term effects of manure, charcoal and mineral fertilization on crop production and fertility on a highly weathered Central Amazonian upland soil. Plant Soil 2007, 291, 275–290. [Google Scholar] [CrossRef]

- Major, J.; Rondon, M.; Molina, D.; Riha, S.J.; Lehmann, J. Maize yield and nutrition during 4 years after biochar application to a Colombian savanna oxisol. Plant Soil 2010, 333, 117–128. [Google Scholar] [CrossRef]

- Petter, F.A.; Madari, B.E.; Silva, M.A.S.; Carneiro, M.A.C.; Carvalho, T.M.C.; Junior, B.H.M.; Pacheco, L.P. Fertilidade do solo e produtividade do arroz de terras altas no Cerrado após aplicação de “biochar”. Pesqui. Agropecu. Bras. 2012, 47, 699–706. [Google Scholar] [CrossRef]

- Cornelissen, G.; Martinsen, V.; Shitumbanuma, V.; Alling, V.; Breedveld, G.D.; Rutherford, D.W.; Sparrevik, M.; Hale, S.H.; Obia, A.; Mulder, J. Biochar Effect on Maize Yield and Soil Characteristics in Five Conservation Farming Sites in Zambia. Agronomy 2013, 3, 256–274. [Google Scholar] [CrossRef] [Green Version]

- Martinsen, V.; Mulder, J.; Shitumbanuma, V.; Sparrevik, M.; Borresen, T.; Cornelissen, G. Farmer-led maize biochar trials: Effect on crop yield and soil nutrients under conservation farming. J. Plant Nutr. Soil Sci. 2014, 177, 681–695. [Google Scholar] [CrossRef]

- Lehmann, J.; Joseph, S. Biochar for Environmental Management: An Introduction. In Biochar for Environmental Management Science and Technology; Lehmann, J., Joseph, S., Eds.; Earthscan: New York, NY, USA, 2009; Available online: http://www.biochar-international.org/projects/book (accessed on 2 February 2017).

- Verheijen, F.; Jeffery, S.; Bastos, A.C.; van der Velde, M.; Diafas, I. Biochar Application to Soils: A Critical Scientific Review of Effects on Soil Properties, Processes and Functions; JRC Scientific and International Reports; Office for the Official Publication of the European Communities: Luxembourg, Luxembourg, 2010; p. 166. [Google Scholar]

- Basso, A.S.; Miguez, F.E.; Laird, D.A.; Horton, R.; Westgate, M. Assessing potential of biochar for increasing water-holding capacity of sandy soils. GCB Bioenergy 2013, 5, 132–143. [Google Scholar] [CrossRef]

- Obia, A.; Mulder, J.; Martinsen, V.; Cornelisse, G.; Borresen, T. In situ effects of biochar on aggregation, water retention and porosity in light-textured tropical soils. Soil Tillage Res. 2016, 155, 35–44. [Google Scholar] [CrossRef]

- Barrnes, R.T.; Gallagher, M.E.; Masiello, C.A.; Liu, Z.; Dugan, B. Biochar-Induced Changes in Soil Hydraulic Conductivity and Dissolved Nutrient Fluxes Constrained by Laboratory Experiments. PLoS ONE 2014, 9, e108340. [Google Scholar] [CrossRef] [PubMed]

- Cernansky, R. Agriculture: Stet-of-the-art soil. Nature 2015, 517, 258–260. [Google Scholar] [CrossRef] [PubMed]

- Deal, C.; Brewer, C.E.; Brown, R.C.; Okure, M.A.E.; Amoding, A. Comparison of kiln-derived and gasifier-derived biochars as soil amendment in the wet tropics. Biomass Bioenergy 2012, 37, 161–168. [Google Scholar] [CrossRef]

- Cheng, C.-H.; Lehmann, J.; Thies, J.E.; Burton, S.D.; Engelhard, M. Oxidation of black carbon by biotic and abiotic processes. Org. Geochem. 2006, 37, 1477–1488. [Google Scholar] [CrossRef]

- Novotny, E.H.; Azevedo, E.R.; Bonagamba, T.J.; Cunha, T.J.F.; Madari, B.E.; Benites, V.M.; Hayes, M.H.B. Studies of the compositions of humic acids from Amazonian Dark Earth soils. Environ. Sci. Technol. 2007, 41, 400–405. [Google Scholar] [CrossRef] [PubMed]

- Beesley, L.; Moreno-Jiménez, E.; Gomez-Eyles, J.L.; Harris, E.; Robinson, B.; Sizmur, T. A review of biochars’ potential role in the remediation, revegetation and restoration of contaminated soils. Environ. Pollut. 2011, 159, 3269–3282. [Google Scholar] [CrossRef] [PubMed]

- Mohan, D.; Sarswat, A.; Ok, Y.S.; Pittman, C.U., Jr. Organic and inorganic contaminants removal from water with biochar, a renewable, low cost and sustainable adsorbent—A critical review. Bioresour. Technol. 2014, 160, 191–202. [Google Scholar] [CrossRef] [PubMed]

- Jeffery, S.; Abalos, D.; Prodana, M.; Bastos, A.C.; van Groenigen, J.W.; Hungate, B.A.; Verheijen, F. Biochar boosts tropical but not temperate crop yields. Environ. Res. Lett. 2017, 12, 053001. [Google Scholar] [CrossRef]

- Novotny, E.H.; Maia, C.M.B.F.; Carvalho, M.T.M.; Madar, B.E. Biochar: Pyrogenic carbon for agricultural use—A critical review. Revista Brasileira de Ciência do Solo 2015, 39, 321–344. [Google Scholar] [CrossRef] [Green Version]

- Schmidt, H.-P.; Pandit, B.H.; Martinsen, V.; Cornelissen, G.; Conte, P.; Kammann, C.I. Fourfold Increase in Pumpkin Yield in Response to Low-Dosage Root Zone Application of Urine-Enhanced Biochar to a Fertile Tropical Soil. Agriculture 2015, 5, 723–741. [Google Scholar] [CrossRef] [Green Version]

- Lehmann, J.; Rillig, M.; Thies, J.; Masiello, C.A.; Hockaday, W.C.; Crowley, D. Biochar effects on soil biota: A review. Soil Biol. Biochem. 2011, 43, 1812–1836. [Google Scholar] [CrossRef]

- Jeffery, S.; Verheijen, F.G.A.; van der Velde, M.; Bastos, A.C. A quantitative review of the effects of biochar application to soils on crop productivity using meta-analysis. Agric. Ecosyst. Environ. 2011, 144, 175–187. [Google Scholar] [CrossRef]

- Biederman, L.A.; Harpole, W.S. Biochar and its effects on plant productivity and nutrient cycling: A meta-analysis. GCB Bioenergy 2013, 5, 202–214. [Google Scholar] [CrossRef]

- Gray, M.; Johnson, M.G.; Dragila, M.I.; Kleber, M. Water uptake in biochars: The roles of porosity and hydrophobicity. Biomass Bioenergy 2014, 61, 196–205. [Google Scholar] [CrossRef]

- Oliveira, D.M. Biocarvão de Bambu e Fontes de Fósforo Afetando a Disponibilidade de p e o Crescimento de Feijão Caupi e Milho em Latossolo Amarelo Distrófico da Amazônia. Ph.D. Thesis, Instituto Nacional de Pesquisas da Amazônia (INPA), Manaus, Brazil, 2012. [Google Scholar]

- OCDE-FAO. Perspectivas Agrícolas No Brasil: Desafios da Agricultura Brasileira 2015–2024. 2015, p. 54. Available online: http://www.fao.org.br/download/PA20142015CB.pdf (accessed on 2 February 2017).

- MAPA. Projeções do Agronegócio Brasil 2016/2017–2026/2027. Projeções de Longo Prazo. 2017. Available online: http://www.agricultura.gov.br/assuntos/politica-agricola/todas-publicacoes-de-politica-agricola/projecoes-do-agronegocio/projecoes-do-agronegocio-2017-a-2027-versao-preliminar-25-07-17.pdf/view (accessed on 5 September 2017).

- Conab. Evolução dos Custos de Produção de Feijão no Brasil e Sua Rentabilidade—Safra 2010/2011 a 2015/2016. 2016. Available online: https://www.conab.gov.br/OlalaCMS/uploads/arquivos/17_01_24_14_49_18_compendio_de_estudos_conab_-_volume_5_2017.pdf (accessed on 10 September 2017).

- Campanhola, C.; Valarini, P.J. A agricultura orgânica e seu potencial para o pequeno agricultor. Cad. Cienc. Tecnol. 2001, 18, 69–101. [Google Scholar]

- Crowder, D.W.; Reganold, J.P. Financial competitiveness of organic agriculture on a global scale. Proc. Natl. Acad. Sci. USA 2015, 112, 7611–7616. [Google Scholar] [CrossRef] [PubMed]

- Carvalho, J.F. Avaliação de Cultivares de Feijão-Caupi e Feijão Vagem Arbustivo em Sistema Orgânico de Produção. Master’s Thesis, Universidade Estadual do Norte Fluminense, Campos dos Goytacazes, Brazil, 2012; pp. 36–62. [Google Scholar]

- Latawiec, A.E.; Strassburg, B.B.N.; Rodriguez, A.M.; Matt, E.; Nijbroek, R.; Silos, M. Suriname: Reconciling agricultural development and conservation of unique natural wealth. Land Use Policy 2014, 38, 627–636. [Google Scholar] [CrossRef] [Green Version]

- Neves, M.C.P.; Guerra, J.G.M.; Carvalho, S.R.; Ribeiro, R.L.D.; Almeida, D.L. Sistema Integrado de Produção Agroecológica ou Fazendinha Agroecológica do km 47. In Agroecologia: Princípios e Técnica Para Uma Agricultura Orgânica Sustentável; Embrapa Informação Tecnológica: Brasília, Brazil, 2005; pp. 147–172. [Google Scholar]

- Carvalho, D.F.; Faria, R.A.; Sousa, S.A.V.; Borges, H.Q. Espacialização do período de veranico para diferentes níveis de perda de produção na cultura do milho, na bacia do Rio Verde Grande, MG. Rev. Bras. Eng. Agric. Ambient. 2000, 4, 172–176. [Google Scholar] [CrossRef]

- FAO. World Reference Base for Soil Resources; Food and Agriculture Organization of the United Nations: Rome, Italy, 1998. [Google Scholar]

- Oliveira, N.G.; De-Polli, H.; Almeida, D.L.; Guerra, J.G.M. Feijão-vagem semeado sobre cobertura viva perene de gramínea e leguminosa e em solo mobilizado, com adubação orgânica. Pesqui. Agropecu. Bras. 2006, 41, 1361–1367. [Google Scholar] [CrossRef]

- Guedes, R.E.; Guerra, J.; Ribeiro, R.; Coelho, R.; de Paula, P.D.; Moreira, V. Avaliação de Cultivares de Feijão-De-Vagem de Crescimento Determinado Sob Manejo Orgânico, nas Condições da Baixada Fluminense-Seropédica/RJ; Comunicado Técnico 102; Embrapa: Brasília, Brazil, 2007; pp. 1–4. Available online: https://ainfo.cnptia.embrapa.br/digital/bitstream/CNPAB-2010/34502/1/cot102.pdf (accessed on 2 February 2017).

- Higa, T. Effective microorganisms: A biotechnology for mankind. In Proceedings of the First International Conference on Kyusei Nature Farming, Khon Kaen, Thailand, 17–21 October 1989; Parr, J.F., Hornick, S.B., Whitman, C.E., Eds.; U.S. Department of Agriculture: Washington, DC, USA, 1991; pp. 8–14. [Google Scholar]

- Asia Pacific Natural Agriculture Network (APNAN). Application Manual for APNAN Countries Asia-Pacific Natural Agriculture Network, 1st ed.; APNAN: Bankok, Thailand, 1995. [Google Scholar]

- Freire, L.R.; Balieiro, F.C.; Zonta, E.; Anjos, L.H.C.; Pereira, M.G.; Lima, L.; Guerra, J.G.M.; Ferreira, M.B.C.; Leal, M.A.A.; Campos, D.V.B.; et al. Manual de Calagem e Adubação do Estado do Rio de Janeiro; Embrapa: Brasília, Brazil; EDUR: Seropédica, Brazil, 2013; p. 430. [Google Scholar]

- Filho, O.M.C.; Drumond, M.A.; Languidey, P.H. Gliricidia Sepium—Leguminosa Promissora Para Regiões Semi-Áridas. Embrapa–Circular Técnica 35. 1997. Available online: https://www.infoteca.cnptia.embrapa.br/infoteca/bitstream/doc/131682/1/CTE35.pdf (accessed on 2 February 2017).

- Elevitch, C.R.; Francis, J.K. Gliricidia sepium (gliricidia). In Species Profiles for Pacific Island Agroforestry; Elevitch, C.R., Ed.; Permanent Agriculture Resources (PAR): Honolulu, HI, USA, 2006; Available online: https://raskisimani.files.wordpress.com/2013/01/gliricidia-gliricidia.pdf (accessed on 2 February 2017).

- Wandelli, E.V.; Costa, J.R.; Souza, S.G.A.; Perin, R. Cerca-Viva de Gliricidia Sepium. Embrapa—Comunicado Técnico 37; 2006, pp. 1–6. Available online: https://www.infoteca.cnptia.embrapa.br/handle/doc/681499 (accessed on 5 March 2017).

- Marin, A.M.P.; Menezes, R.S.C.; Silva, E.D.; Sampaio, E.V.S.B. Efeito da Gliricidia sepium sobre nutrients do solo, microclima e produtividade do milho em Sistema agroflorestal no Agreste Paraibano. Rev. Bras. Cienc. Solo 2006, 30, 555–564. [Google Scholar] [CrossRef]

- Paula, P.D.; Campello, E.F.C.; Guerra, J.G.M.; Santos, G.A.; Resende, A.S. Decomposição das podas das leguminosas arbóreas Gliricia sepium e Acacia angustissima em um sistema groflorestal. Cienc. Florest. 2015, 25, 791–800. [Google Scholar] [CrossRef]

- Sparrevik, M.; Adam, C.; Martinsen, V.; Cornelissen, G. Emissions of gases and particles from charcoal/biochar production in rural areas using medium-sized traditional and improved “retort” kilns. Biomass Bioenergy 2015, 72, 65–73. [Google Scholar] [CrossRef]

- Lehmann, J.; Gaunt, J.; Rondon, M. Bio-char sequestration in terrestrial ecosystems—A review. Mitig. Adapt. Strateg. Glob. Chang. 2006, 11, 403–427. [Google Scholar] [CrossRef]

- Asai, H.; Samson, B.K.; Haefele, S.M.; Songyikhangs, K.; Homma, K.; Kiyono, Y.; Inoue, Y.; Shiraiwa, T.; Horie, T. Biochar amendment techniques for upland rice production in Northern Laos. 1. Soil physical properties, leaf SPAD and grain yield. Field Crops Res. 2009, 111, 81–84. [Google Scholar] [CrossRef]

- Hungria, M.; Campo, R.J.; Mendes, I.C. Benefits of inoculation of the common bean (Phaseolus vulgaris) crop with efficient and competitive Rhizobium tropici strains. Biol. Fertil. Soils 2003, 39, 88–93. [Google Scholar] [CrossRef]

- Embrapa. Uso do Extrato Aquoso de Folhas de NIM Para o Controle de Spodoptera Frugiperda na Cultura do Milho—Circular Técnica 88. 2006, pp. 1–5. Available online: https://www.embrapa.br/documents/1344498/2767891/uso-do-extrato-aquoso-de-folhas-de-nim-para-o-controle-de-spodoptera-frugiperda-na-cultura-do-milho.pdf/f1d204a5-fa0d-4818-b859-59d30d039605 (accessed on 10 April 2017).

- Leite, L.F.C.; Araújo, A.S.F.; Costa, C.N.; Ribeiro, A.M.B. Nodulação e produtividade de grãos do feijão-caupi em resposta ao molibdênio. Rev. Cienc. Agron. 2009, 40, 492–497. [Google Scholar]

- Carmo, H.F.; Silva, M.A.; Madari, B.E. Utilização do biochar como adicionador de carbono no solo e seus efeitos químicos nas propriedades do solo, sob feijoeiro comum no Cerrado brasileiro. In Proceedings of the Anais do II Workshop Internacional Sobre Clima e Recursos Naturais nos Países de Língua Portuguesa, Bragança, Portugal, 15–19 November 2010; pp. 159–165. [Google Scholar]

- Ferreira, E.P.B.; Martins, L.M.V.; Xavier, G.R.; Rumanjek, N.G. Nodulação e produção de grãos em feijão-caupi (Vigna unguiculata L. Walp.) Inoculado com isolados de rizóbio. Rev. Caatinga 2011, 24, 27–35. [Google Scholar]

- Gualter, R.M.R.; Boodey, R.M.; Rumjanek, N.G.; Freitas, A.C.R.; Xavier, G.R. Eficiência agronômica de estirpes de rizóbio em feijão-caupi cultivado na região da Pré-Amazônia maranhense. Pesqui. Agropecu. Bras. 2011, 46, 303–308. [Google Scholar] [CrossRef]

- Mankiw, N.G. Principles of Economics, 6th ed.; Library of Congress Control Number: 2010941869; South-Western: London, UK, 2011; ISBN 13 978-0-538-45305-9. [Google Scholar]

- Yamato, M.; Okimori, Y.; Wibowo, I.F.; Anshori, S.; Ogawa, M. Effects of the application of charred bark of Acacia mangium on the yield of maize, cowpea and peanut, and soil chemical properties in South Sumatra, Indonesia. Soil Sci. Plant Nutr. 2006, 52, 489–495. [Google Scholar] [CrossRef]

- Bergamaschi, C. Ocorrência de Bactérias Diazotróficas Associadas às Raízes e Colmos de Cultivares de Sorgo. Master’s Thesis, Universidade Federal do Rio Grande do Sul, Porto Alegre, Brazil, 2006; p. 83. [Google Scholar]

- Latawiec, A.E.; Peake, L.; Baxter, H.; Cornelissen, G.; Grotkiewicz, K.; Hale, S.; Królczyk, J.B.; Kubon, M.; Łopatka, A.; Medynska-Juraszek, A.; et al. A reconnaissance-scale GIS-based multicriteria decision analysis to support sustainable biochar use: Poland as a case study. J. Env. Eng. Land. Manag. 2017, 25, 208–222. [Google Scholar] [CrossRef]

- Glaser, B.; Wiedner, K.; Seelig, S.; Schmidt, H.-P.; Gerber, H. Biochar organic fertilizers from natural resources as substitute for mineral fertilizers. Agron. Sustain. Dev. 2015, 35, 667–678. [Google Scholar] [CrossRef]

- Kammann, C.I.; Schmidt, H.P.; Messerschmidt, N.; Linsel, S.; Steffens, D.; Müller, C.; Koyro, H.-W.; Conte, P.; Joseph, S. Plant growth improvement mediated by nitrate capture in co-composted biochar. Sci. Rep. 2015, 5, 11080. [Google Scholar] [CrossRef] [PubMed]

- Conte, P.; Marsala, V.; de Pasquale, C.; Bubici, S.; Valagussa, M.; Pozzi, A.; Alonzo, G. Nature of water-biochar interface interactions. GCB Bioenergy 2013, 5, 116–121. [Google Scholar] [CrossRef] [Green Version]

- Chan, K.Y.; Van Zwieten, L.; Meszaros, I.; Downie, A.; Joseph, S. Agronomic values of greenwaste biochar as a soil amendment. Aust. J. Soil Res. 2007, 45, 629–634. [Google Scholar] [CrossRef]

- Coelho, F.C.; Vieira, C.; Mosquim, P.R.; Cassini, S.T.A. Nitrogênio e molibdênio nas culturas do milho e do feijão em monocultivos e em consórcios: Efeitos sobre o feijão. Revista Ceres 1998, 45, 393–407. [Google Scholar]

- Dobereiner, J. A importância da fixação biológica de nitrogênio para a agricultura sustentável. Biotecnol. Cienc. 1997, 1, 2–3. [Google Scholar]

- Bashan, Y.; Bashan, L.E. Chapter two-how the plant growth-promoting bacterium Azospirillum promotes plant growth-a critical assessment. Adv. Agron. 2010, 108, 77–136. [Google Scholar]

- Souza, J.E.B. Co-Inoculação de Rhizobium Tropici e Azospirillum Brasilense No Feijoeiro-Comum Visando Aumento de Produtividade e Reduçao de Custo de Produção. Master’s Thesis, Universidade Federal de Goiás, Goiânia, Brazil, 2015; p. 83. [Google Scholar]

- Bruun, E.W.; Ambus, P.; Egsgaard, H.; Hauggaard-Nielsen, H. Effects of slow and fast pyrolysis biochar on soil C and N turnover dynamics. Soil Biol. Biochem. 2012, 46, 73–79. [Google Scholar] [CrossRef]

- Guereña, D.; Lehmann, J.; Hanley, K.; Enders, A.; Hyland, C.; Riha, S. Nitrogen dynamics following field application of biochar in a temperate North American maize-based production system. Plant Soil 2013, 365, 239–254. [Google Scholar] [CrossRef]

- Graber, E.R.; Harel, Y.M.; Kolton, M.; Cytryn, E.; Silber, A.; David, D.R.; Tsechansky, L.; Borenshtein, M.; Elad, Y. Biochar impact on development and productivity of pepper and tomato grown in fertigated soilless media. Plant Soil 2010, 337, 481–496. [Google Scholar] [CrossRef]

- Rondon, M.A.; Lehmann, J.; Ramírez, J.; Hurtado, N. Biological nitrogen fixation by common beans (Phaseolus vulgaris L.) increases with bio-char additions. Biol. Fertil. Soils 2007, 43, 699–708. [Google Scholar] [CrossRef]

- Chintala, R.; Mollinedo, J.; Schumacher, T.E.; Malo, D.D.; Julson, J.L. Effect of biochar on chemical properties of acidic soil. Arch. Agron. Soil Sci. 2014, 60, 393–404. [Google Scholar] [CrossRef]

- Gao, S.; DeLuca, T.H. Influence of Biochar on Soil Nutrient Transformations, Nutrient Leaching, and Crop Yield. Adv. Plants Agric. Res. 2016, 4, 1–16. [Google Scholar]

- Monterumici, C.M. Processed vs. Non-Processed Biowastes for Agriculture: Effects of Post-Harvest Tomato Plants and Biochar on Radish Growth, Chlorophyll Content and Protein Production. Int. J. Mol. Sci. 2015, 16, 8826–8843. [Google Scholar] [CrossRef] [PubMed]

- Novak, J.M.; Buscher, W.J.; Laird, D.L.; Ahmedna, M.; Watts, D.W.; Niandou, M.A.S. Impact of biochar amendment on fertility of a southeastern coastal plain soil. Soil Sci. 2009, 174, 105–112. [Google Scholar] [CrossRef]

- Glaser, B.; Lehmann, J.; Zech, W. Ameliorating physical and chemical properties of highly weathered soils in the tropics with charcoal—A review. Biol. Fertil. Soils 2002, 35, 219–230. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Castro, A.; Da Silva Batista, N.; Latawiec, A.E.; Rodrigues, A.; Strassburg, B.; Silva, D.; Araujo, E.; De Moraes, L.F.D.; Guerra, J.G.; Galvão, G.; et al. The Effects of Gliricidia-Derived Biochar on Sequential Maize and Bean Farming. Sustainability 2018, 10, 578. https://doi.org/10.3390/su10030578

Castro A, Da Silva Batista N, Latawiec AE, Rodrigues A, Strassburg B, Silva D, Araujo E, De Moraes LFD, Guerra JG, Galvão G, et al. The Effects of Gliricidia-Derived Biochar on Sequential Maize and Bean Farming. Sustainability. 2018; 10(3):578. https://doi.org/10.3390/su10030578

Chicago/Turabian StyleCastro, Ana, Nilcileny Da Silva Batista, Agnieszka E. Latawiec, Aline Rodrigues, Bernardo Strassburg, Daniel Silva, Ednaldo Araujo, Luiz Fernando D. De Moraes, Jose Guilherme Guerra, Gabriel Galvão, and et al. 2018. "The Effects of Gliricidia-Derived Biochar on Sequential Maize and Bean Farming" Sustainability 10, no. 3: 578. https://doi.org/10.3390/su10030578

APA StyleCastro, A., Da Silva Batista, N., Latawiec, A. E., Rodrigues, A., Strassburg, B., Silva, D., Araujo, E., De Moraes, L. F. D., Guerra, J. G., Galvão, G., Alves-Pinto, H., Mendes, M., Dos Santos, J. S., Rangel, M. C., Figueredo, M., Cornelissen, G., & Hale, S. (2018). The Effects of Gliricidia-Derived Biochar on Sequential Maize and Bean Farming. Sustainability, 10(3), 578. https://doi.org/10.3390/su10030578