A Fuzzy Based Model for Standardized Sustainability Assessment of Photovoltaic Cells

Abstract

:1. Introduction

2. LCA Framework

- Goal and scope: this stage defines the LCA objective and boundaries.

- Inventory analysis: this stage includes the examination of the amount of pollutants and materials involved during the entire life of PV cells.

- Impact assessment: in this stage the amount of required energy, produced pollutants, and involved problems, that will exist during the whole life of PV cell, are emulated.

- Interpretation: this is the stage of the final conclusion regarding the impact of a certain PV cell on the environment, which is required to explore any opportunities to reduce that impact.

- Human toxicity potential.

- Freshwater eutrophication and the addition of unwanted components in drinking water.

- Freshwater ecotoxicity.

- Abiotic depletion potential (the high use of natural sources).

- Child labor.

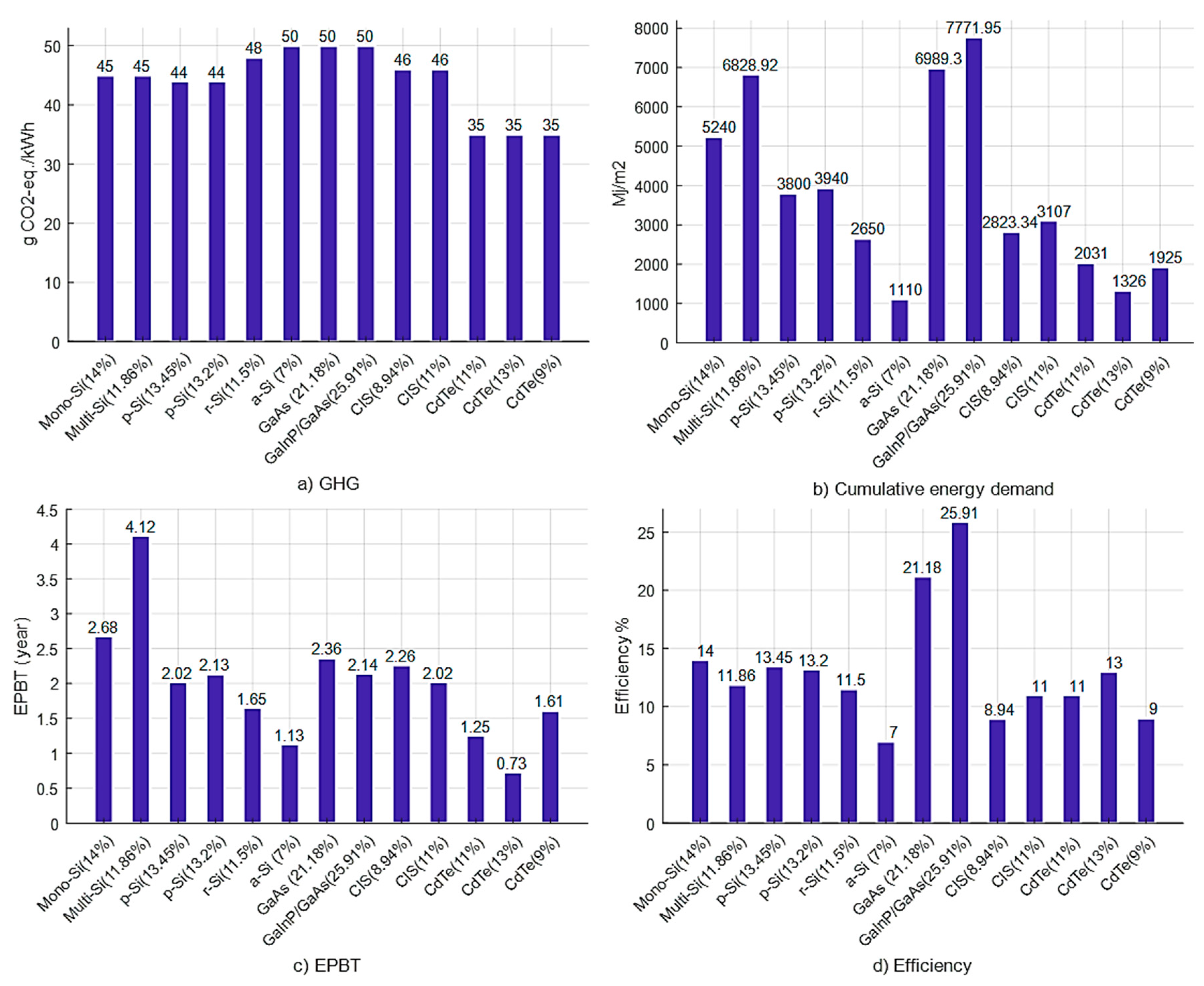

3. Critical Factors Influencing PV Cells’ Environmental Sustainability

3.1. Energy Payback Time (EPBT)

3.2. Greenhouse Gas (GHG)

3.3. Cumulative Energy Demand (CED)

3.4. Risk Factor

- Normal operation risk that has acceptable consequences during normal operation like GHG emissions or chemical waste.

- Routine accidents risk that occur frequently with low impact like small leakage of chemicals and transportation accidents.

- Severe accidents risk that has less occurrence and high impact like nuclear core meltdown or explosion.

- Difficult to evaluate risk like geopolitical and energy security uncertainty.

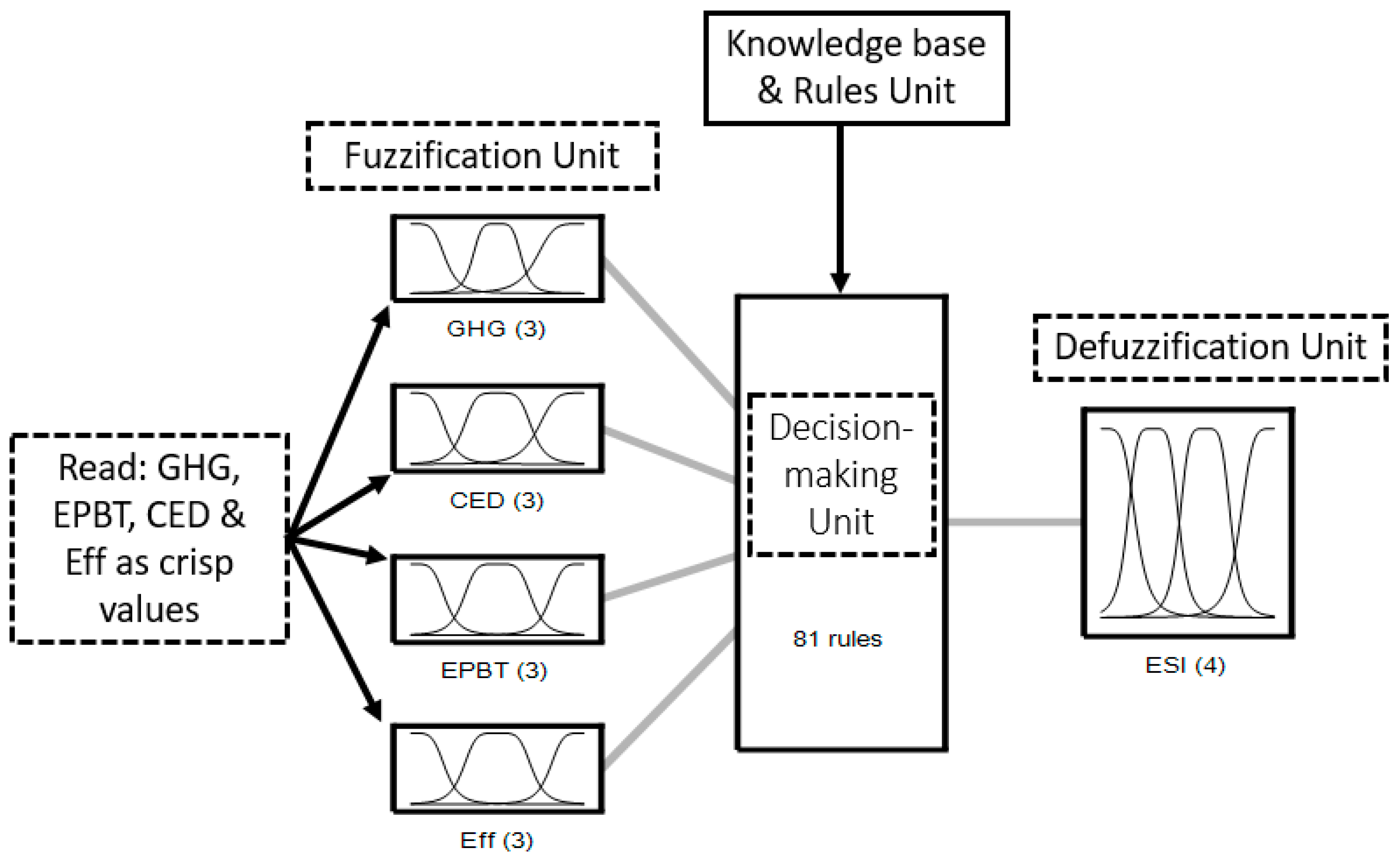

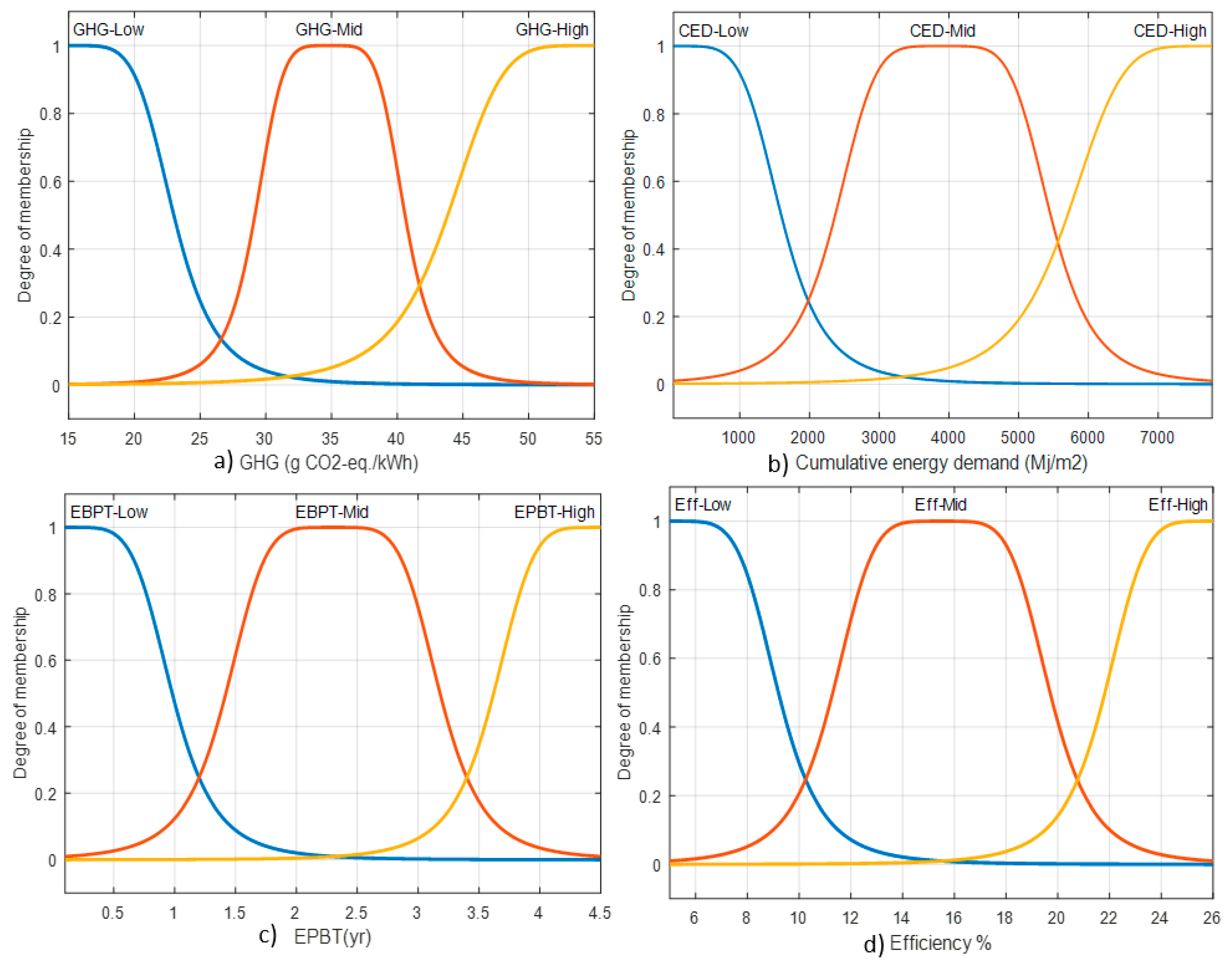

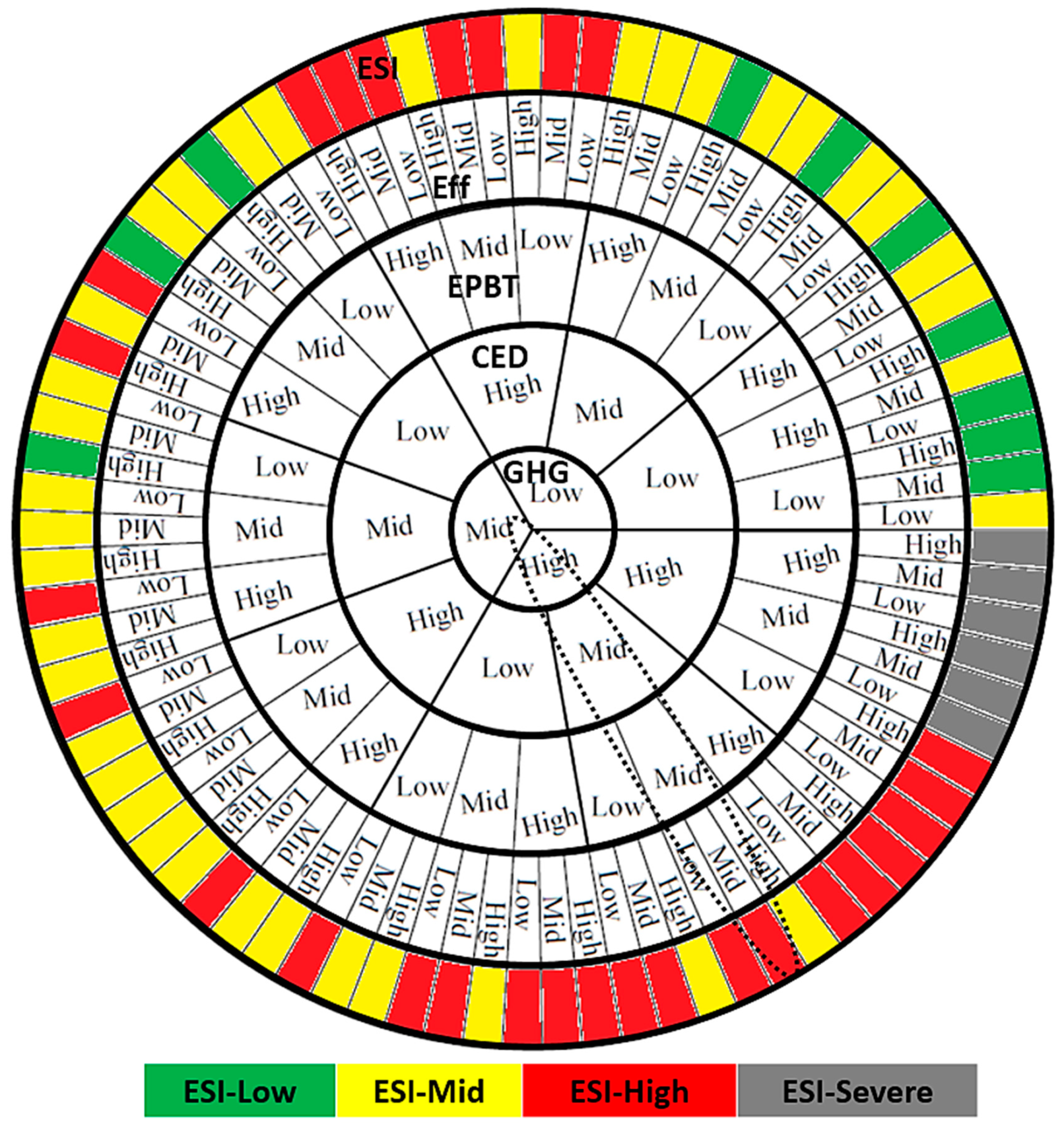

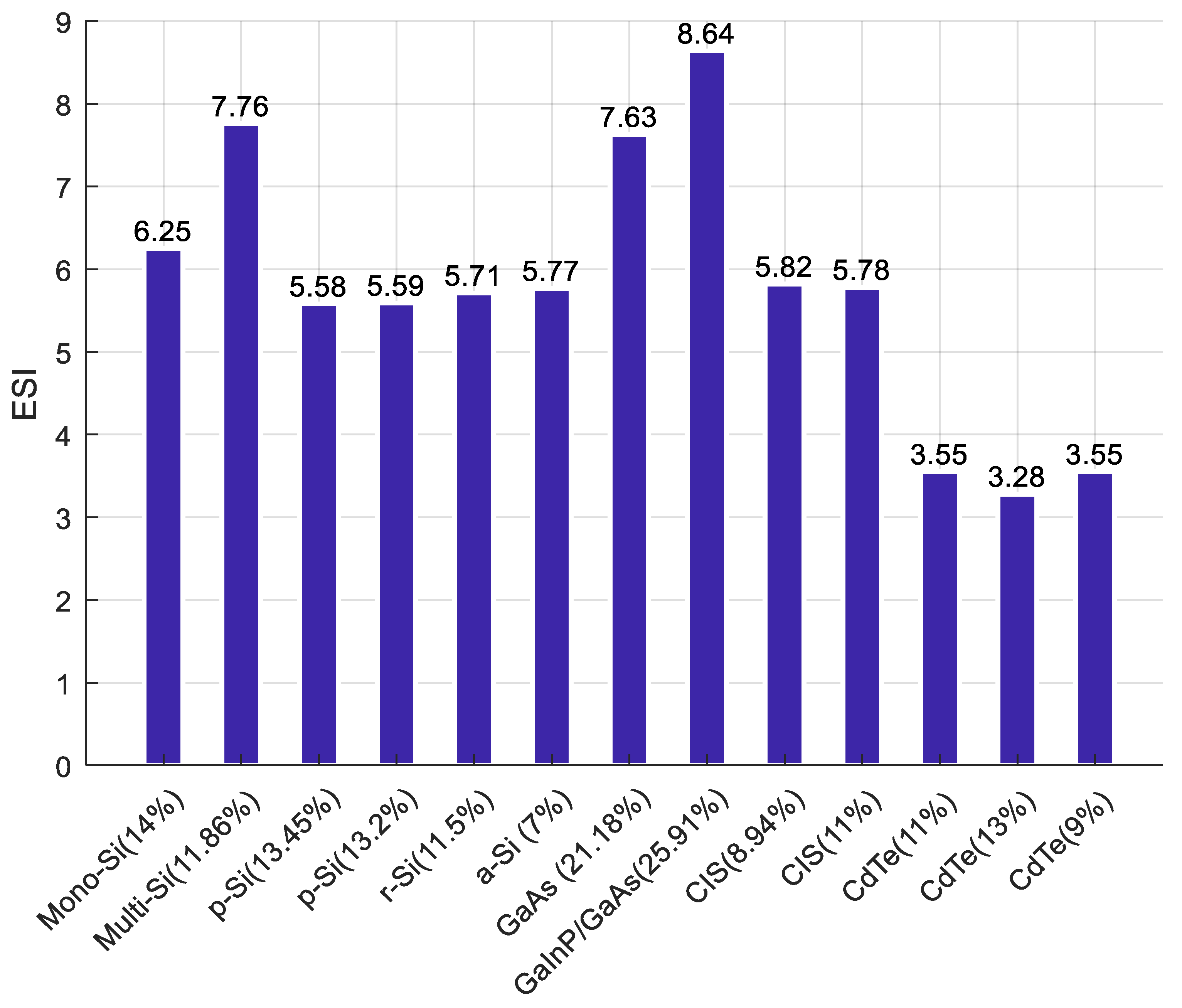

4. Fuzzy Based Environmental Sustainability Indicator

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| LCA | Life cycle analysis |

| PV | Photovoltaic |

| LPG | Liquefied petroleum gas |

| GHG | Greenhouse gas |

| EPBT | Energy payback time |

| CED | Cumulative energy demand |

| OECD | The Organization for Economic Co-operation and Development |

| BNL | Brookhaven National Laboratory |

| NG | Natural gas |

| PSI | Paul Scherrer Institute |

| CdTe | Cadmium Telluride |

| CIS | Copper indium diselenide |

| GaAs | Gallium arsenide |

| GWP | Global warming potential |

| PED | Primary energy demand |

| NOx | Nitrogen oxide |

| SOx | Sulfur oxide |

| mc-Si | Multi-crystalline silicon |

| a-Si | Amorphous silicon |

| c-Si | Crystalline silicon |

| HF | Hydrogen fluoride |

| SiHCl3 | Trichlorosilane |

| HCl | Hydrogen chloride |

| EIF | Environmental Impact Factor |

| FIE | Fuzzy inference engine |

| Wp | Watt peak capacity |

| ISO | International Organization for Standardization |

Appendix A. ESI Calculation Example

| GHG = 45 | CED = 5253 | EPBT = 2.7 | Efficiency = 14 | |

|---|---|---|---|---|

| Low | 0 | 0 | 0 | 0.021 |

| Mid | 0.054 | 0.7 | 0.983 | 0.994 |

| High | 0.634 | 0.271 | 0.0265 | 0.005 |

- Substitute the input membership values inside the rule as shown in Table A2.

- Take the minimum of these values, which is 0.634 for this case.

- Based on this rule, the ESI is high.

| Rule | GHG-High | CED-Mid | EPBT-Mid | Eff-Mid | Min | EIF-High |

|---|---|---|---|---|---|---|

| Value | 0.634 | 0.7 | 0.983 | 0.994 | 0.634 | EIF-High |

References

- International Energy Agency. Available online: https://www.iea.org/ (accessed on 11 May 2018).

- Nugent, D.; Sovacool, B.K. Assessing the lifecycle greenhouse gas emissions from solar PV and wind energy: A critical meta-survey. Energy Policy 2014, 65, 229–244. [Google Scholar] [CrossRef]

- Vellini, M.; Gambini, M.; Prattella, V. Environmental impacts of PV technology throughout the life cycle: Importance of the end-of-life management for Si-panels and CdTe-panels. Energy 2017, 138, 1099–1111. [Google Scholar] [CrossRef]

- Xu, L.; Zhang, S.; Yang, M.; Li, W.; Xu, J. Environmental effects of China’s solar photovoltaic industry during 2011–2016: A life cycle assessment approach. J. Clean. Prod. 2018, 170, 310–329. [Google Scholar] [CrossRef]

- Gerbinet, S.; Belboom, S.; Léonard, A. Life Cycle Analysis (LCA) of photovoltaic panels: A review. Renew. Sustain. Energy Rev. 2014, 38, 747–753. [Google Scholar] [CrossRef]

- Berger, W.; Simon, F.-G.; Weimann, K.; Alsema, E.A. A novel approach for the recycling of thin film photovoltaic modules. Resour. Conserv. Recycl. 2010, 54, 711–718. [Google Scholar] [CrossRef]

- Meijer, A.; Huijbregts, M.A.J.; Schermer, J.J.; Reijnders, L. Life-cycle assessment of photovoltaic modules: Comparison of mc-Si, InGaP and InGaP/mc-Si solar modules. Prog. Photovolt. Res. Appl. 2003, 11, 275–287. [Google Scholar] [CrossRef] [Green Version]

- Drouiche, N.; Cuellar, P.; Kerkar, F.; Medjahed, S.; Boutouchent-Guerfi, N.; Hamou, M.O. Recovery of solar grade silicon from kerf loss slurry waste. Renew. Sustain. Energy Rev. 2014, 32, 936–943. [Google Scholar] [CrossRef]

- Contreras-Lisperguer, R.; Muñoz-Cerón, E.; Aguilera, J.; de la Casa, J. Cradle-to-cradle approach in the life cycle of silicon solar photovoltaic panels. J. Clean. Prod. 2017, 168, 51–59. [Google Scholar] [CrossRef]

- Sumper, A.; Robledo-García, M.; Villafáfila-Robles, R.; Bergas-Jané, J.; Andrés-Peiró, J. Life-cycle assessment of a photovoltaic system in Catalonia (Spain). Renew. Sustain. Energy Rev. 2011, 15, 3888–3896. [Google Scholar] [CrossRef]

- Perez, M.J.R.; Fthenakis, V.; Kim, H.-C.; Pereira, A.O. Façade–integrated photovoltaics: A life cycle and performance assessment case study. Prog. Photovolt. Res. Appl. 2012, 20, 975–990. [Google Scholar] [CrossRef]

- Perpiñan, O.; Lorenzo, E.; Castro, M.A.; Eyras, R. Energy payback time of grid connected PV systems: Comparison between tracking and fixed systems. Prog. Photovolt. Res. Appl. 2009, 17, 137–147. [Google Scholar] [CrossRef] [Green Version]

- Goe, M.; Gaustad, G. Strengthening the case for recycling photovoltaics: An energy payback analysis. Applied Energy 2014, 120, 41–48. [Google Scholar] [CrossRef]

- Pacca, S.; Sivaraman, D.; Keoleian, G.A. Parameters affecting the life cycle performance of PV technologies and systems. Energy Policy 2007, 35, 3316–3326. [Google Scholar] [CrossRef]

- Stoppato, A. Life cycle assessment of photovoltaic electricity generation. Energy 2008, 33, 224–232. [Google Scholar] [CrossRef]

- Zhang, J.; Gao, X.; Deng, Y.; Zha, Y.; Yuan, C. Comparison of life cycle environmental impacts of different perovskite solar cell systems. Sol. Energy Mater. Solar Cells 2017, 166, 9–17. [Google Scholar] [CrossRef]

- Çelik, I.; Song, Z.; Cimaroli, A.J.; Yan, Y.; Heben, M.; Apul, D. Life Cycle Assessment (LCA) of perovskite PV cells projected from lab to fab. Sol. Energy Mater. Solar Cells 2016, 156, 157–169. [Google Scholar] [CrossRef]

- Emmott, C.J.M.; Ekins-Daukes, N.J.; Nelson, J. Dynamic carbon mitigation analysis: The role of thin-film photovoltaics. Energy Environ. Sci. 2014, 7, 1810–1818. [Google Scholar] [CrossRef]

- Raugei, M.; Frankl, P. Life cycle impacts and costs of photovoltaic systems: Current state of the art and future outlooks. Energy 2009, 34, 392–399. [Google Scholar] [CrossRef]

- Emmott, C.J.M.; Urbina, A.; Nelson, J. Environmental and economic assessment of ITO-free electrodes for organic solar cells. Sol. Energy Mater. Sol. Cells 2012, 97, 14–21. [Google Scholar] [CrossRef]

- Asdrubali, F.; Baldinelli, G.; D’Alessandro, F.; Scrucca, F. Life cycle assessment of electricity production from renewable energies: Review and results harmonization. Renew. Sustain. Energy Rev. 2015, 42, 1113–1122. [Google Scholar] [CrossRef]

- Peng, J.; Lu, L.; Yang, H. Review on life cycle assessment of energy payback and greenhouse gas emission of solar photovoltaic systems. Renew. Sustain. Energy Rev. 2013, 19, 255–274. [Google Scholar] [CrossRef]

- Lunardi, M.M.; Moore, S.; Alvarez-Gaitan, J.P.; Yan, C.; Hao, X.; Corkish, R. A comparative life cycle assessment of chalcogenide/Si tandem solar modules. Energy 2018, 145, 700–709. [Google Scholar] [CrossRef]

- Lizin, S.; van Passel, S.; de Schepper, E.; Maes, W.; Lutsen, L.; Manca, J.; Vanderzande, D. Life cycle analyses of organic photovoltaics: A review. Energy Environ. Sci. 2013, 6, 3136–3149. [Google Scholar] [CrossRef]

- García-Valverde, R.; Cherni, J.A.; Urbina, A. Life cycle analysis of organic photovoltaic technologies. Prog. Photovolt. Res. Appl. 2010, 18, 535–558. [Google Scholar] [CrossRef] [Green Version]

- Jungbluth, N.; Bauer, C.; Dones, R.; Frischknecht, R. Life Cycle Assessment for Emerging Technologies: Case Studies for Photovoltaic and Wind Power. Int. J. Life Cycle Assess. 2005, 10, 24–34. [Google Scholar] [CrossRef]

- Desideri, U.; Proietti, S.; Zepparelli, F.; Sdringola, P.; Bini, S. Life Cycle Assessment of a ground-mounted 1778 kWp photovoltaic plant and comparison with traditional energy production systems. Appl. Energy 2012, 97, 930–943. [Google Scholar] [CrossRef]

- Bayod-Rújula, Á.A.; Lorente-Lafuente, A.M.; Cirez-Oto, F. Environmental assessment of grid connected photovoltaic plants with 2-axis tracking versus fixed modules systems. Energy 2011, 36, 3148–3158. [Google Scholar] [CrossRef]

- Menoufi, K.; Chemisana, D.; Rosell, J.I. Life Cycle Assessment of a Building Integrated Concentrated Photovoltaic scheme. Appl. Energy 2013, 111, 505–514. [Google Scholar] [CrossRef]

- Eco-Indicator 99 Manual for Designers. Available online: https://www.pre-sustainability.com/download/EI99_Manual.pdf (accessed on 1 May 2018).

- Eco-Indicator 99: GaBi Software. Available online: http://www.gabi-software.com/support/gabi/gabi-5-lcia-documentation/life-cycle-impact-assessment-lcia-methods/eco-indicator-99/ (accessed on 22 May 2018).

- SimaPro for Business—For Fact-Based Sustainability in Business. SimaPro. Available online: https://simapro.com/business/ (accessed on 22 May 2018).

- Liu, G.; Baniyounes, A.; Rasul, M.G.; Amanullah, M.T.O.; Khan, M.M.K. Fuzzy Logic based Environmental Indicator for Sustainability Assessment of Renewable Energy System using Life Cycle Assessment. Procedia Eng. 2012, 49, 35–41. [Google Scholar] [CrossRef]

- Bitter, J.; Printz, S.; Lahl, K.; Vossen, R.; Jeschke, S. Approach to Sustainability Assessment of Renewable Energy Technologies combining Fuzzy Logic with the Integrative Sustainability Triangle. Int. J. Sustain. Energy Dev. 2016, 5, 252–262. [Google Scholar] [CrossRef]

- Sabaghi, M.; Mascle, C.; Baptiste, P.; Rostamzadeh, R. Sustainability assessment using fuzzy-inference technique (SAFT): A methodology toward green products. Expert Syst. Appl. 2016, 56, 69–79. [Google Scholar] [CrossRef]

- Piluso, C.; Huang, J.; Liu, Z.; Huang, Y. Sustainability Assessment of Industrial Systems under Uncertainty: A Fuzzy Logic Based Approach to Short-Term to Midterm Predictions. Ind. Eng. Chem. Res. 2010, 49, 8633–8643. [Google Scholar] [CrossRef]

- Goe, M.; Gaustad, G. Estimating direct climate impacts of end-of-life solar photovoltaic recovery. Solar Energy Mater. Solar Cells 2016, 156, 27–36. [Google Scholar] [CrossRef]

- Bogacka, M.; Pikoń, K.; Landrat, M. Environmental impact of PV cell waste scenario. Waste Manag. 2017, 70, 198–203. [Google Scholar] [CrossRef] [PubMed]

- Weidema, B.P. The Integration of Economic and Social Aspects in Life Cycle Impact Assessment. Int. J. Life Cycle Assess. 2006, 11, 89–96. [Google Scholar] [CrossRef]

- Leung, C.; Yu, I.; Chen, W. Silicosis, The Lancet. Available online: https://www.sciencedirect.com/science/article/pii/S0140673612602359 (accessed on 14 December 2018).

- Chau, C.K.; Leung, T.M.; Ng, W.Y. A review on Life Cycle Assessment, Life Cycle Energy Assessment and Life Cycle Carbon Emissions Assessment on buildings. Appl. Energy 2015, 143, 395–413. [Google Scholar] [CrossRef]

- Astrup, T.F.; Tonini, D.; Turconi, R.; Boldrin, A. Life cycle assessment of thermal Waste-to-Energy technologies: Review and recommendations. Waste Manag. 2015, 37, 104–115. [Google Scholar] [CrossRef] [Green Version]

- Liang, Y.; Su, J.; Xi, B.; Yu, Y.; Ji, D.; Cui, Y.S.C.; Zhu, J. Life cycle assessment of lithium-ion batteries for greenhouse gas emissions. Resour. Conserv. Recycl. 2017, 117, 285–293. [Google Scholar] [CrossRef]

- Bustamante, M.L.; Hubler, B.; Gaustad, G.; Babbitt, C.W. Life cycle assessment of jointly produced solar energy materials: Challenges and best practices. Sol. Energy Mater. Sol. Cells 2016, 156, 11–26. [Google Scholar] [CrossRef]

- Xie, M.; Ruan, J.; Bai, W.; Qiao, Q.; Bai, L.; Zhang, J.; Li, H.; Lv, F.; Fu, H. Pollutant payback time and environmental impact of Chinese multi-crystalline photovoltaic production based on life cycle assessment. J. Clean. Prod. 2018, 184, 648–659. [Google Scholar] [CrossRef]

- Wu, P.; Ma, X.; Ji, J.; Ma, Y. Review on Life Cycle Assessment of Energy Payback of Solar Photovoltaic Systems and a Case Study. Energy Procedia 2017, 105, 68–74. [Google Scholar] [CrossRef]

- Tripathy, M.; Joshi, H.; Panda, S.K. Energy payback time and life-cycle cost analysis of building integrated photovoltaic thermal system influenced by adverse effect of shadow. Appl. Energy 2017, 208, 376–389. [Google Scholar] [CrossRef]

- Anctil, A.; Babbitt, C.; Landi, B.; Raffaelle, R.P. Life-cycle assessment of organic solar cell technologies. In Proceedings of the 2010 35th IEEE Photovoltaic Specialists Conference, Honolulu, HI, USA, 20–25 June 2010; pp. 000742–000747. [Google Scholar]

- Fthenakis, V.M.; Kim, H.C. Photovoltaics: Life-cycle analyses. Solar Energy 2011, 85, 1609–1628. [Google Scholar] [CrossRef]

- Evans, A.; Strezov, V.; Evans, T.J. Assessment of sustainability indicators for renewable energy technologies. Renew. Sustain. Energy Rev. 2009, 13, 1082–1088. [Google Scholar] [CrossRef]

- Kreiger, M.; Pearce, J.M. Environmental Life Cycle Analysis of Distributed Three-Dimensional Printing and Conventional Manufacturing of Polymer Products. ACS Sustain. Chem. Eng. 2013, 1, 1511–1519. [Google Scholar] [CrossRef]

- Spada, M.; Paraschiv, F.; Burgherr, P. A comparison of risk measures for accidents in the energy sector and their implications on decision-making strategies. Energy 2018, 154, 277–288. [Google Scholar] [CrossRef] [Green Version]

- Burgherr, P.; Hirschberg, S. Comparative risk assessment of severe accidents in the energy sector. Energy Policy 2014, 74, S45–S56. [Google Scholar] [CrossRef]

- Fthenakis, V.M.; Kim, H.C.; Colli, A.; Kirchsteiger, C. Evaluation of Risks in the Life Cycle of Photovoltaics in a Comparative Context. Available online: http://www.clca.columbia.edu/papers/8CO.1.2_Dresden_Risk_06.pdf (accessed on 5 April 2018).

- MATLAB—MathWorks. Available online: https://www.mathworks.com/products/matlab.html (accessed on 22 May 2018).

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bani Salim, M.; Emre Demirocak, D.; Barakat, N. A Fuzzy Based Model for Standardized Sustainability Assessment of Photovoltaic Cells. Sustainability 2018, 10, 4787. https://doi.org/10.3390/su10124787

Bani Salim M, Emre Demirocak D, Barakat N. A Fuzzy Based Model for Standardized Sustainability Assessment of Photovoltaic Cells. Sustainability. 2018; 10(12):4787. https://doi.org/10.3390/su10124787

Chicago/Turabian StyleBani Salim, Muath, Dervis Emre Demirocak, and Nael Barakat. 2018. "A Fuzzy Based Model for Standardized Sustainability Assessment of Photovoltaic Cells" Sustainability 10, no. 12: 4787. https://doi.org/10.3390/su10124787