2.2. Model Formulation

In this section, we introduce two harvest scheduling models. Firstly, the deterministic model (DET) of harvesting will be specified and the robust model (ROB) and its development from the first model (DET) will be described. The DET model represents a deterministic description of the harvest scheduling situation where no uncertainty is assumed. The ROB model describes the analogous situation but with aspects of uncertainty also included. Both models are described further in detail.

The DET maximizes the volume of the harvest units over a certain number of harvest periods while the harvest balance across the planning horizon as well as the spatial restrictions between the cutting units are preserved. This model generally falls into the category of Unit restriction models of spatial harvest scheduling (URM), which specifically proposes harvesting not only in the time but also in the space. The DET model is a discrete programming model and consists of a set of decision 0–1 variables , four sets of constraints and one objective function. The model is generally applied to cutting units over periods, and the indices of decision variables are and .

The optimization goal is given as the maximization of the harvested volume

under the constraints that harvesting fluency, unit adjacency, and other logical conditions are satisfied. For modelling purposes, we assumed 5% growth from period to period. Let us denote the DET model as:

subject to

The objective function (1) maximizes the harvested volume of each unit in every period over the set of all units and the set of all periods . where expresses the stand volume. The first set of constraints (2) ensures that each unit is harvested at most once during the planning horizon, the second set of constraints (3) ensures the fluent harvest flow with the maximum deviation such that and the third set of constraints (4) describes the spatial restrictions of the problem while the set includes all units adjacent to the unit . The last set of constraints (5) merely shows what values the decision variable can attain. The value of means the unit is not harvested in period , while shows the opposite. Let us denote the feasibility subset (2, 4, and 5) of DET as (defined later).

The solution of the DET model is based on the assumption that all exact parameter values of its components are known. Specifically, it is considered that the estimated volume of all harvest units is not going to change in any way over the planning horizon of periods. In practice, this is hardly a certainty with respect to all thinkable influences of environmental changes or human-caused actions.

It is possible to overcome these unexpected deviations by building a robust optimization model. A robust alternative to the standard deterministic optimization model is called a

robust counterpart (ROB). In the following section, the modified approach of Palma and Nelson [

5] (originally based on [

26]) that accounts also for the robustness of left-hand side coefficients will be briefly summarized.

Let us have a general constraint of an optimization model given as

. Let us assume that the coefficients

belong to a symmetric interval

, where

is the expected symmetric deviation from the original deterministic value of the coefficient

. To acquire the ROB model, one must perform several steps to transform the original model into its robust counterpart. The deviations shown in this paragraph refer to the changes in the left-hand side coefficients in an arbitrary constraint of an optimization problem given as:

The robust counterpart of (6, 7) model is then defined as:

There are several new variables and parameters in (8, 9) that need to be explained. Auxiliary variables

and

are products of the ROB model inference from the DET and have no significantly important real interpretation for our purposes.

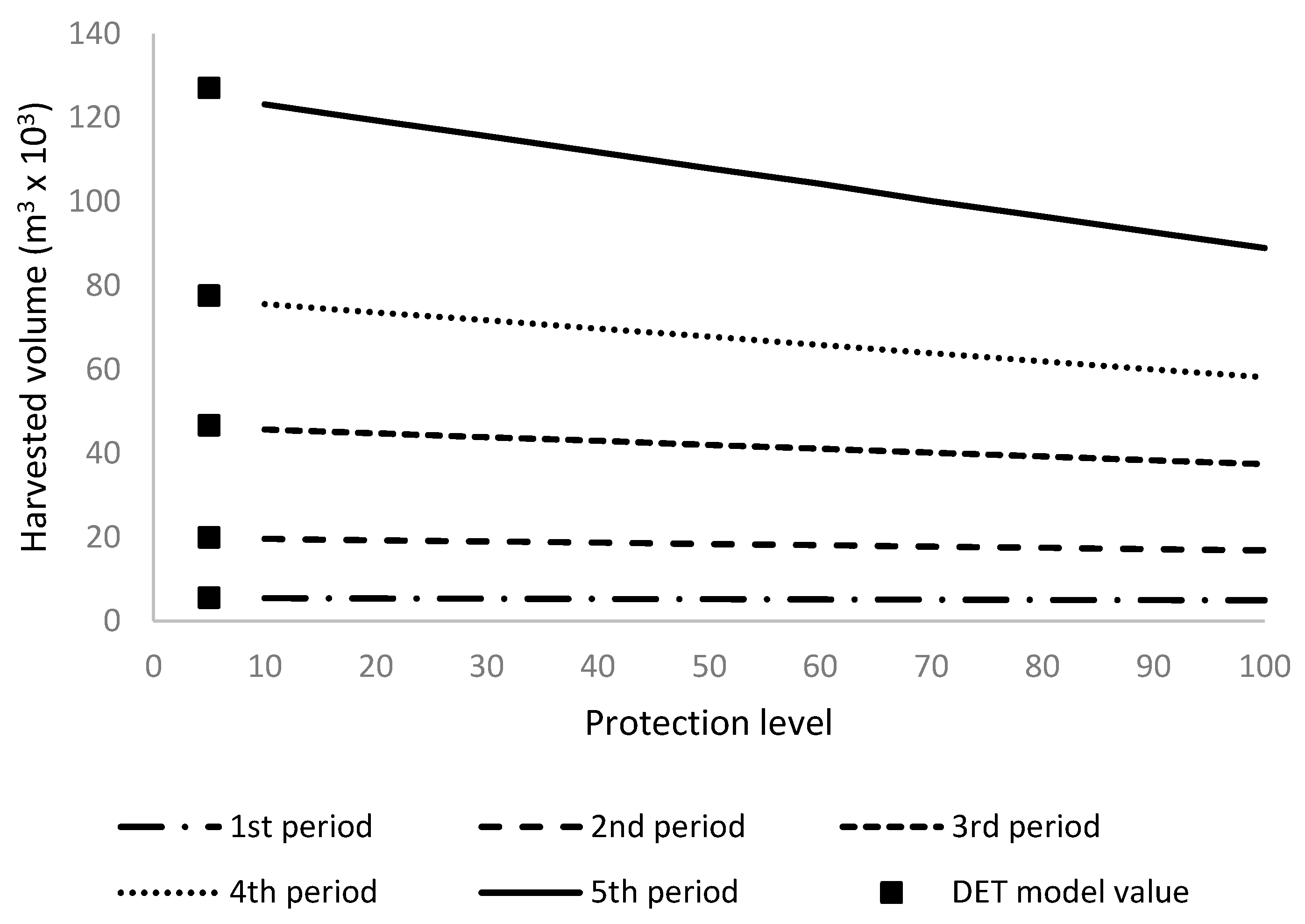

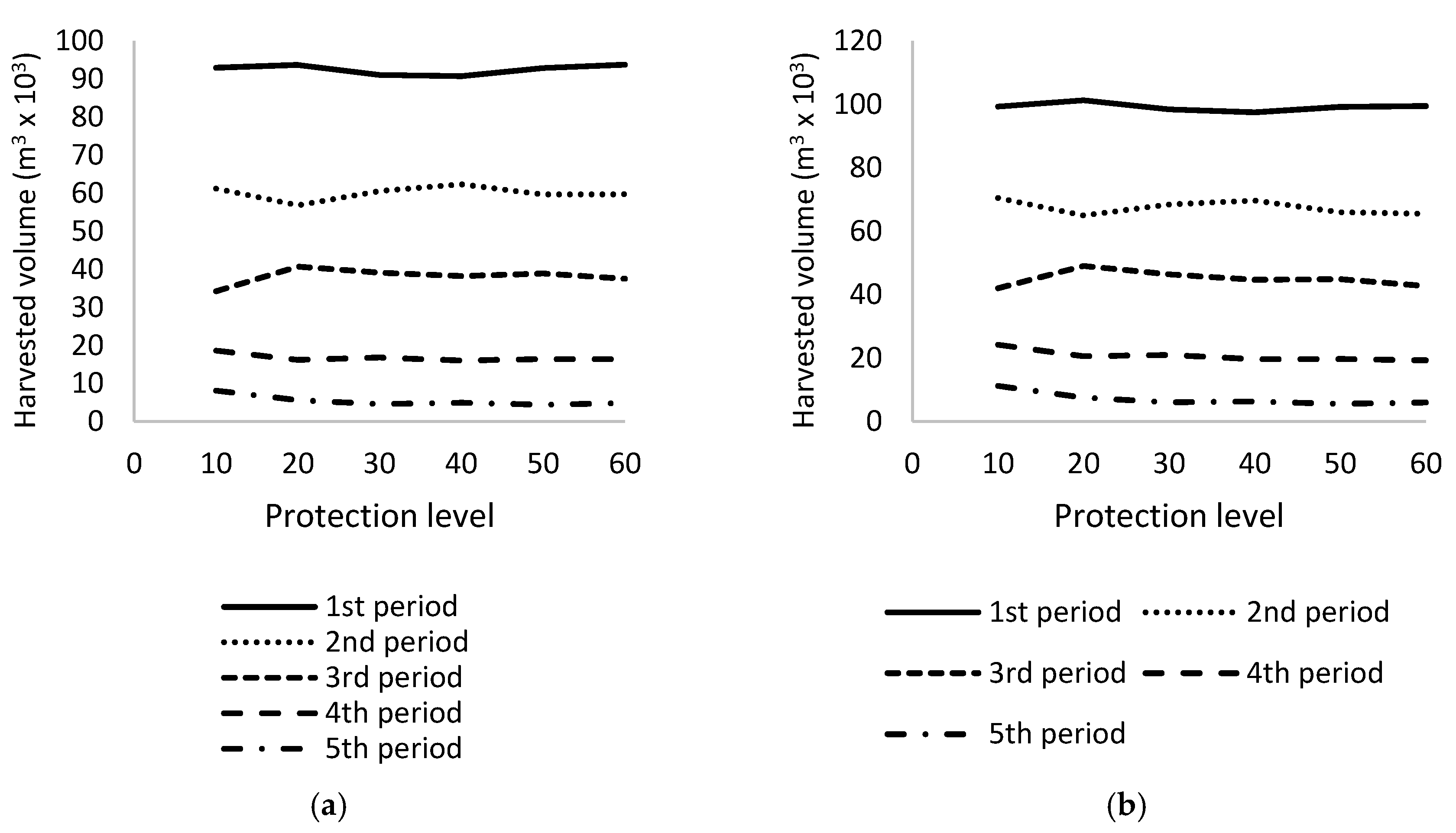

is an important parameter that controls the uncertainty for each constraint. The value of

(protection level) represents how many left-hand side coefficients of that constraint we assume have deviations from their original values

by

. The set of indices

is the set of uncertain coefficients that are considered for each constraint. We refer the reader to Bertsimas and Sim [

26] for the detailed proof of creating (8, 9) from (6, 7).

Going back to our DET model, one can realize that imposing the uncertainty on any left-hand side coefficients in constraints (2–5) would be sensible only in the case of constraints (3). In the remaining constraints (2, 4, and 5), no such coefficients are explicitly included. In the case of (3), it could be assumed to impose the uncertainty on parameter or parameter(s) The parameter alone is given by the harvest-flow standards where no deviations can be logically assumed. The group of parameters is more of our interest since the volume of individual stands is a quantity that can be hardly measured with absolute precision. Thus, we will concentrate on assuming deflections in the parameters.

The

s in the DET model are found in constraints (3) that express the ratio between the total volumes harvested in two consequent periods. One must notice that the very same parameters also appear in the objective function of the DET model. We can assume that the uncertainty of

s must be then considered in both constraints (3) and objective function (1). We will apply the transformation from DET model (6, 7) to ROB model (8, 9) as described above. However, the given form of ROB (8, 9) assumes uncertainties only in the left-hand sided coefficients of the model constraints. In our case, the uncertainty is needed in the constraints and in the objective function. One can overcome this issue by transforming the objective function into a constraint in the following way:

Is equivalent to (11) with (12)

subject to

with

as an auxiliary function. Now in (12) the objective function coefficients are on the left-hand side and hence, it is possible to treat them in terms of building a robust counterpart.

However, the number of expected deviations

controlled by

parameter is known. To solve it, let us assume that some of the

s will deviate in the objective function (or now in constraint (12)) by at most

. By setting

to a specific value we state that this is the maximum possible number of coefficients

that will possibly deviate from their expected values. However, the coefficients are not specified. Practically, it means that the number of the coefficients, which will change in every period

, is unknown. This is a problem in relation to the set of constraints (3) wherein the same

s are also included. To deal with this situation we have to split the objective function into a sum of

functions with each representing one period. That leads to the following equivalent re-definition of (11) and (12) into:

subject to

This allows us to treat the uncertainty in the individual periods separately. It is now possible to design the final ROB model:

subject to

This was an expected obstacle since the problem is NP-hard (non-deterministic polynomial-time hard) on its own (due to the presence of integral variables). The time limit for solving had to be set to 1200 s. The instances of the described models were computed on a personal computer with Intel

® Core ™ processor (Intel, Santa Clara, CA, USA) with 3.40 GHz and 16.0 GB random-access memory, which represents common computer equipment available today. The Gurobi

® 6. 5 (Gurobi, Houston, TX, USA) [

27] optimization solver was used. The branching solving algorithm allows for lower and upper bounds to be found on the optimal solution. The optimal solution might not be found in a reasonable time but the lower and upper bounds might be. This approach can sometimes provide a sufficiently tight estimate of the result. Once the lower and upper bounds on the optimal solution are available the software is able to calculate the feasible solution

whose objective is within

% of the optimum value

. The difference between

and

is called a gap.