Performance of a Mobile Star Screen to Improve Woodchip Quality of Forest Residues

Abstract

:1. Introduction

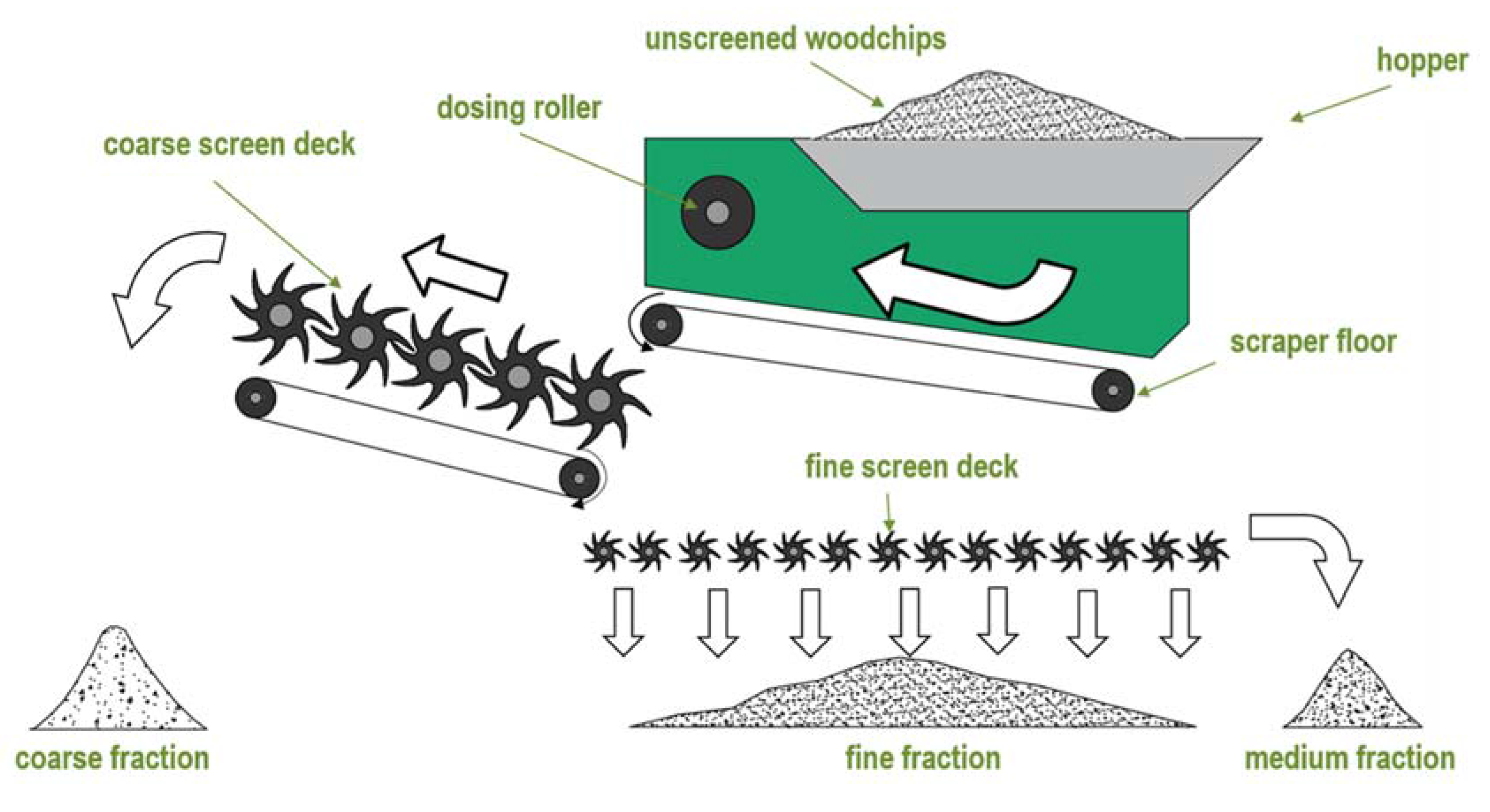

2. Materials and Methods

2.1. Product Analyses

2.2. Production and Cost Analyses

3. Results

3.1. Productivity and Cost

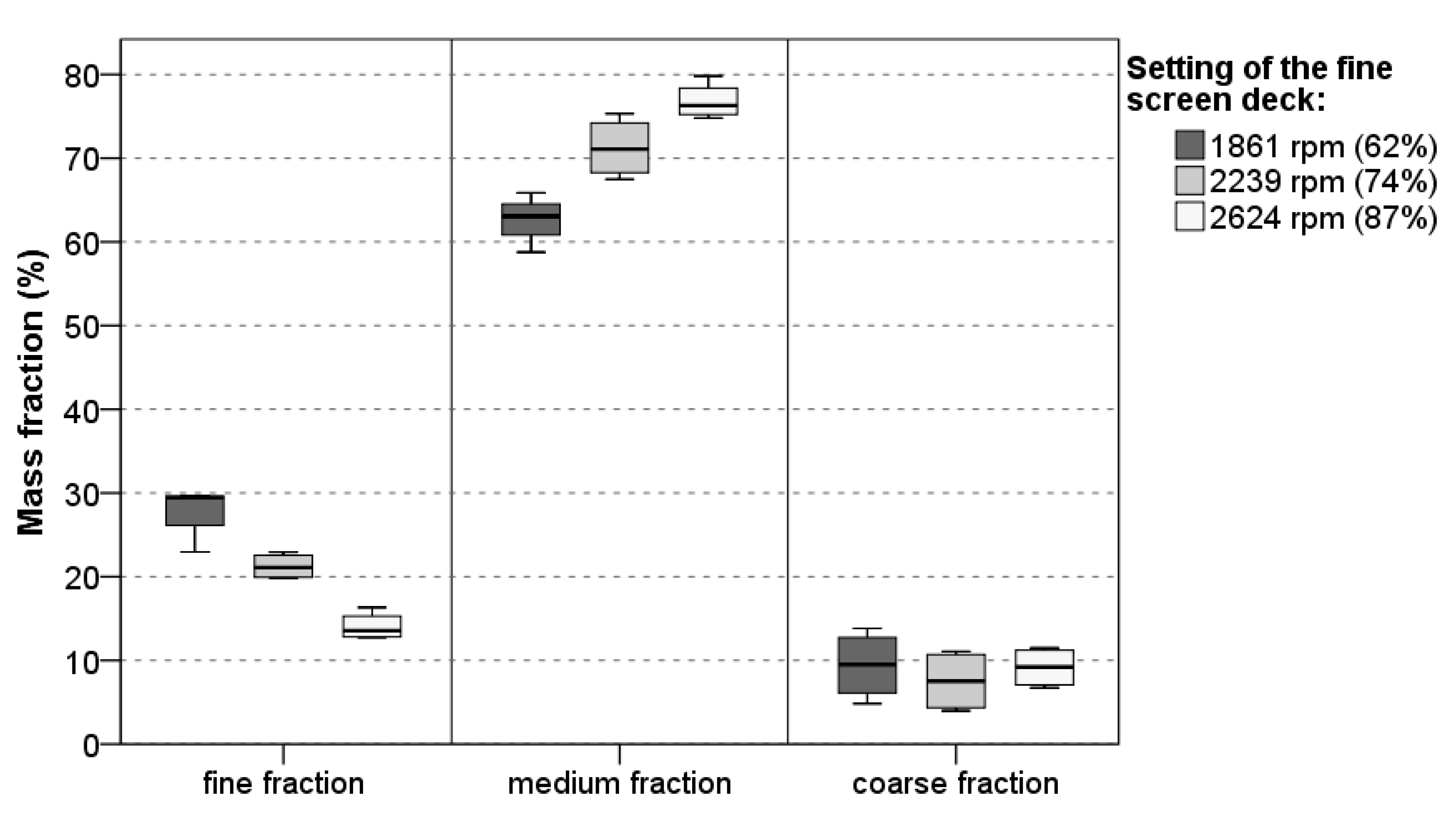

3.2. Product Analyses

3.3. Cost-Benefit Comparison

4. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Food and Agriculture Organization of the United Nations (FAO). The State of the World’s Forest Genetic Resources; Country Report Austria; FAO: Vienna, Austria, 2014. [Google Scholar]

- Hauk, E.; Perzl, F. Freiflächen in Österreichs Wald-Viehweiden und Gefahrenquellen? BFW Praxisinfor. 2013, 32, 24–31. [Google Scholar]

- Visser, R.J.M.; Stampfer, K. Expanding Ground-based Harvesting onto Steep Terrain: A Review. Croat. J. For. Eng. 2015, 36, 321–331. [Google Scholar]

- Heinimann, H.R.; Stampfer, K.; Loschek, J.; Caminada, L. Perspectives on Central European Cable Yarding Systems. Austrian J. For. Sci. 2006, 123, 121–139. [Google Scholar]

- Jacobson, S.; Kukkola, M.; Mälkönen, E.; Tveite, B. Impact of whole-tree harvesting and compensatory fertilization on growth of coniferous thinning stands. For. Ecol. Manag. 2000, 129, 41–51. [Google Scholar] [CrossRef]

- Walmsley, J.D.; Jones, D.L.; Reynolds, B.; Price, M.H.; Healey, J.R. Whole tree harvesting can reduce second rotation forest productivity. For. Ecol. Manag. 2009, 257, 1104–1111. [Google Scholar] [CrossRef]

- Helmisaari, H.-S.; Hanssen, K.H.; Jacobson, S.; Kukkola, M.; Luiro, J.; Saarsalmi, A.; Tamminen, P.; Tveite, B. Logging residue removal after thinning in Nordic boreal forests: Long-term impact on tree growth. For. Ecol. Manag. 2011, 261, 1919–1927. [Google Scholar] [CrossRef]

- Roxby, J.D.; Jones, G.E.; Howard, T.E. Whole-tree harvesting and site productivity: Twenty-nine northern hardwood sites in central New Hampshire and western Maine. For. Ecol. Manag. 2013, 293, 114–121. [Google Scholar] [CrossRef]

- Gotou, J.; Nishimura, T. Pile Movement and Nutrient Distribution in the Soil around Slash Piles Produced during Whole-tree Logging by a Yarder and a Processor. J. For. Res. 2002, 7, 179–184. [Google Scholar] [CrossRef]

- Spinelli, R.; Nati, C.; Sozzi, L.; Magagnotti, N.; Picchi, G. Physical characterization of commercial woodchips on the Italian energy market. Fuel 2011, 90, 2198–2202. [Google Scholar] [CrossRef]

- Kühmaier, M.; Erber, G.; Kanzian, C.; Holzleitner, F.; Stampfer, K. Comparison of costs of different terminal layouts for fuel wood storage. Renew. Energy 2016, 87, 544–551. [Google Scholar] [CrossRef]

- Zamora-Cristales, R.; Sessions, J.; Boston, K.; Murphy, G. Economic Optimization of Forest Biomass Processing and Transport in the Pacific Northwest USA. For. Sci. 2015, 61, 220–234. [Google Scholar] [CrossRef]

- Gamborg, C. Maximising the production of fuelwood in different silvicultural systems. Biomass Bioenergy 1997, 13, 75–81. [Google Scholar] [CrossRef]

- Spinelli, R.; Ivorra, L.; Magagnotti, N.; Picchi, G. Performance of a mobile mechanical screen to improve the commercial quality of wood chips for energy. Bioresour. Technol. 2011, 102, 7366–7370. [Google Scholar] [CrossRef] [PubMed]

- Paulrud, S.; Nilsson, C. The effects of particle characteristics on emissions from burning wood fuel powder. Fuel 2004, 83, 813–821. [Google Scholar] [CrossRef]

- Strehler, A. Technologies of wood combustion. Ecol. Eng. 2000, 16, 25–40. [Google Scholar] [CrossRef]

- Spinelli, R.; Cavallo, E.; Facello, A.; Magagnotti, N.; Nati, C.; Paletto, G. Performance and energy efficiency of alternative comminution principles: Chipping versus grinding. Scand. J. For. Res. 2012, 27, 393–400. [Google Scholar] [CrossRef]

- Spinelli, R.; Glushkov, S.; Markov, I. Managing chipper knife wear to increase chip quality and reduce chipping cost. Biomass Bioenergy 2014, 62, 117–122. [Google Scholar] [CrossRef]

- Eliasson, L.; von Hofsten, H.; Johannesson, T.; Spinelli, R.; Thierfelder, T. Effects of sieve size on chipper productivity, fuel consumption and chip size distribution for open drum chippers. Croat. J. For. Eng. 2015, 36, 11–18. [Google Scholar]

- Laitila, J.; Nuutinen, Y. Efficiency of integrated grinding and screening of stump wood for fuel at roadside landing with a low-speed double-shaft grinder and a star screen. Croat. J. For. Eng. 2015, 36, 19–32. [Google Scholar]

- Nati, C.; Magagnotti, N.; Spinelli, R. The improvement of hog fuel by removing fines, using a trommel screen. Biomass Bioenergy 2015, 75, 155–160. [Google Scholar] [CrossRef]

- Greene, W.D.; Cutshall, J.B.; Dukes, C.C.; Baker, S.A. Improving Woody Biomass Feedstock Logistics by Reducing Ash and Moisture Content. Bioenergy Res. 2014, 7, 816–823. [Google Scholar] [CrossRef]

- Dukes, C.C.; Baker, S.A.; Greene, W.D. In-wood grinding and screening of forest residues for biomass feedstock applications. Biomass Bioenergy 2013, 54, 18–26. [Google Scholar] [CrossRef]

- Huber, C.; Stampfer, K. Evaluation of a modified centrifugal spreader to apply nutrient-rich fine fractions from woodchips as a fertilizer to cutover areas in steep terrain. In Proceedings of the 39th Annual Meeting of the Council of Forest Engineering (COFE), Vancouver, BC, Canada, 19–21 September 2016. [Google Scholar]

- International Organization of Standardization. Solid Biofuels—Determination of Moisture Content—Oven Dry Method—Part 2: Total Moisture—Simplified Method; ISO 18134-2:2017; ISO: Vernier, Switzerland, 2017. [Google Scholar]

- International Organization of Standardization. Solid Biofuels—Determination of Particle Size Distribution for Uncompressed Fuels–Part 1: Oscillating Screen Method Using Sieves with Apertures of 3.15 mm and Above; ISO 17827-1:2016; ISO: Vernier, Switzerland, 2016. [Google Scholar]

- British Standards Institution. Solid Biofuels-Determination of Calorific Value; BS EN 14918:2009; BSI: London, UK, 2010. [Google Scholar]

- International Organization of Standardization. Solid Biofuels—Determination of Ash Content; ISO 18122:2015; ISO: Vernier, Switzerland, 2015. [Google Scholar]

- International Organization of Standardization. Solid Biofuels—Determination of Total Content of Carbon, Hydrogen and Nitrogen; ISO 16948:2015; ISO: Vernier, Switzerland, 2015. [Google Scholar]

- Food and Agriculture Organization of the United Nations (FAO). Cost Control in Forest Harvesting and Road Construction; FAO Forestry Paper; FAO: Rome, Italy, 1992; p. 99. ISBN 92-5-103161-4. [Google Scholar]

- International Organization of Standardization. Solid Biofuels—Fuel Specifications and Classes—Part 1: General Requirements; ISO 17225-1:2014; ISO: Geneva, Switzerland, 2014. [Google Scholar]

- Pöykiö, R.; Rönkkömäki, H.; Nurmesniemi, H.; Perämäki, P.; Popov, K.; Välimäki, I.; Tuomi, T. Chemical and physical properties of cyclone fly ash from the grate-fired boiler incinerating forest residues at a small municipal district heating plant (6 MW). J. Hazard. Mater. 2009, 162, 1059–1064. [Google Scholar] [CrossRef] [PubMed]

- Nurmi, J. The storage of logging residue for fuel. Biomass Bioenergy 1999, 17, 41–47. [Google Scholar] [CrossRef]

- Nurmi, J.; Hillebrand, K. Storage alternatives affect fuelwood properties of Norway spruce logging residues. N. Z. J. For. Sci. 2001, 31, 289–297. [Google Scholar]

- Kanzian, C.; Kühmaier, M.; Erber, G. Effects of moisture content on supply costs and CO2 emissions for an optimized energy wood supply network. Croat. J. For. Eng. 2016, 37, 51–60. [Google Scholar]

- Golser, M.; Pichler, W.; Hader, F. Energieholztrocknung. Endbericht; Kooperationsabkommen Forst-Platte-Papier: Vienna, Austria, 2005. [Google Scholar]

- Stampfer, K.; Kanzian, C. Current state and development possibilities of wood chip supply chains in Austria. Croat. J. For. Eng. 2006, 27, 135–145. [Google Scholar]

- Pettersson, M.; Nordfjell, T. Fuel quality changes during seasonal storage of compacted logging residues and young trees. Biomass Bioenergy 2007, 31, 782–792. [Google Scholar] [CrossRef]

- Spinelli, R.; Visser, R.J.M. Analyzing and estimating delays in wood chipping operations. Biomass Bioenergy 2009, 33, 429–433. [Google Scholar] [CrossRef]

| Manufacturer | Komptech GmbH |

|---|---|

| Model | Multistar L3 |

| Year of manufacture | 2009 |

| Engine type | diesel generator |

| Engine power | 60 kVA |

| Weight (transport position) | ca. 19 t |

| Dimensions in transport position (L × W × H) | 11.3 × 2.6 × 4.0 m |

| Dimensions in working position (L × W × H) | 12.8 × 6.3 × 4.0 m |

| Hopper volume | ca. 7 m3 |

| Coarse screen dimensions (L × W) | 3.2 × 1.3 m |

| Fine screen dimensions (L × W) | 5.8 × 1.3 m |

| Max. throughput capacity | 180 m3/h |

| Setting of the Fine Screen Deck | Harvest Type | Number of Harvesting Sites Sampled |

|---|---|---|

| 1861 rpm (62% of Max. Speed) | Thinning | 4 |

| Clear-cut | 4 | |

| 2239 rpm (74% of Max. Speed) | Thinning | 3 |

| Clear-cut | 4 | |

| 2624 rpm (87% of Max. Speed) | Thinning | 4 |

| Clear-cut | 4 |

| Star Screen (Multistar L3) | Wheel Loader (Volvo L110H) | Unit | |

|---|---|---|---|

| Input Data | |||

| Purchase price | 350,000.00 | 165,000.00 | € |

| Expected useful life | 10,000 | 13,000 | PMH15 |

| Technical obsolescence | 10 | 10 | Years |

| Annual utilization | 1000 | 1000 | PMH15 |

| Utilization barrier | 1000 | 1300 | PMH15 |

| Interest rate | 5.0 | 5.0 | % |

| Repair cost ratio | 0.75 | 0.90 | |

| Material Costs | |||

| Interest | 8.75 | 4.13 | €/PMH15 |

| Insurance | 3.40 | 3.80 | €/PMH15 |

| Depreciation | 35.00 | 16.50 | €/PMH15 |

| Repair costs | 26.25 | 8.79 | €/PMH15 |

| Fuel costs | 10.08 | 27.36 | €/PMH15 |

| Lubricant costs | 2.02 | 5.47 | €/PMH15 |

| Total Material Costs | 85.50 | 66.05 | €/PMH15 |

| Labor Costs | 0.00 | 30.00 | €/PMH15 |

| Total Machine Costs | 85.50 | 96.05 | €/PMH15 |

| Total System Costs | 181.55 | €/PSH15 | |

| Unit | Mean | SD | |

|---|---|---|---|

| Moisture content | % | 44.58 | 1.44 |

| Productivity | t/PSH0 | 20.99 | 2.75 |

| t/PSH15 | 20.62 | 3.27 | |

| m³ (loose)/PSH0 | 143.74 | 18.87 | |

| m³ (loose)/PSH15 | 141.20 | 22.37 | |

| Costs | €/t | 9.02 | 1.47 |

| €/m³(loose) | 1.32 | 0.21 |

| Unscreened Woodchips | Screened Fraction | |||||

|---|---|---|---|---|---|---|

| Fine | Medium | Coarse | ||||

| Setting of the Fine Screen Deck | 1861 rpm (n = 8) | Fibers | 58.23 a | 18.27 b | 69.16 ac | 78.79 c |

| Bark | 13.22 a | 15.29 a | 12.87 a | 7.85 a | ||

| Twigs | 11.75 a | 6.02 a | 9.68 a | 10.94 a | ||

| Needles | 13.32 a | 52.93 b | 5.84 c | 1.43 d | ||

| Others | 3.48 a | 7.48 b | 2.46 a | 0.99 a | ||

| 2239 rpm (n = 7) | Fibers | 58.70 a | 13.17 b | 62.99 ac | 76.47 c | |

| Bark | 15.56 a | 12.44 a | 16.66 a | 12.63 a | ||

| Twigs | 8.19 a | 5.48 a | 11.76 a | 8.10 a | ||

| Needles | 14.07 a | 52.62 b | 6.09 c | 1.92 d | ||

| Others | 3.49 a | 16.29 b | 2.50 ac | 0.88 c | ||

| 2624 rpm (n = 8) | Fibers | 50.16 a | 9.93 b | 48.78 a | 68.62 a | |

| Bark | 14.98 a | 13.33 a | 11.81 a | 9.81 a | ||

| Twigs | 12.17 ab | 4.03 a | 17.57 b | 16.10 ab | ||

| Needles | 17.68 a | 59.64 b | 17.38 a | 3.58 c | ||

| Others | 5.02 a | 13.06 b | 4.47 a | 1.89 a | ||

| Fines, % (<3.15 mm) | Acceptable, % (3.15–63 mm) | Oversize, % (>63 mm) | ||||

|---|---|---|---|---|---|---|

| Setting of the Fine Screen Deck | 1861 rpm (n = 8) | Unscreened Woodchips | 22.86 a | 69.06 a | 8.09 a | |

| Screened | Fine fraction | 71.78 b | 28.22 b | 0.00 a | ||

| Medium fraction | 8.44 c | 84.42 c | 7.15 a | |||

| Coarse fraction | 1.90 c | 49.26 d | 48.85 b | |||

| 2239 rpm (n = 7) | Unscreened Woodchips | 22.24 a | 68.19 ac | 9.58 a | ||

| Screened | Fine fraction | 69.10 b | 30.90 b | 0.00 a | ||

| Medium fraction | 8.97 ac | 80.92 a | 10.11 a | |||

| Coarse fraction | 2.14 c | 54.07 c | 43.79 b | |||

| 2624 rpm (n = 8) | Unscreened Woodchips | 25.93 a | 66.71 a | 7.35 a | ||

| Screened | Fine fraction | 80.56 b | 19.44 b | 0.00 a | ||

| Medium fraction | 23.88 a | 71.16 a | 4.83 a | |||

| Coarse fraction | 5.55 c | 53.15 c | 41.29 b | |||

| Unscreened | Screened Fraction | |||||

|---|---|---|---|---|---|---|

| Fine | Medium | Coarse | ||||

| Setting of the Fine Screen Deck | 1861 rpm (n = 8) | Moisture content (%) | 46.42 ab | 56.97 a | 52.09 a | 41.41 b |

| Ash content (%) | 2.70 a | 7.65 b | 2.36 a | 1.29 a | ||

| Energy content (MJ/kg) | 20.6 a | 20.4 a | 20.7 a | 20.6 a | ||

| Nutrient content: | ||||||

| C (%) | 51.1 a | 47.8 b | 52.4 c | 52.6 c | ||

| N (ppm) | 3727 a | 7139 b | 2963 ac | 2477 c | ||

| P (ppm) | 300 a | 543 b | 241 a | 223 a | ||

| K (ppm) | 1094 a | 1614 b | 948 a | 1082 a | ||

| Ca (ppm) | 3954 a | 6147 b | 3701 a | 3157 a | ||

| Mg (ppm) | 511 a | 781 b | 483 a | 403 a | ||

| 2239 rpm (n = 7) | Moisture content (%) | 45.64 ab | 50.97 a | 48.36 a | 42.87 b | |

| Ash content (%) | 3.56 a | 16.29 b | 2.70 a | 1.41 a | ||

| Energy content (MJ/kg) | 20.4 ab | 19.0 a | 20.5 ab | 20.6 b | ||

| Nutrient content: | ||||||

| C (%) | 51.0 a | 47.9 b | 52.2 c | 52.4 c | ||

| N (ppm) | 3708 a | 7777 b | 3193 ac | 2549 c | ||

| P (ppm) | 295 a | 588 b | 271 a | 231 a | ||

| K (ppm) | 1086 a | 1708 b | 1056 a | 1116 a | ||

| Ca (ppm) | 4111 a | 6223 b | 4248 a | 3687 a | ||

| Mg (ppm) | 512 a | 841 b | 532 a | 433 a | ||

| 2624 rpm (n = 8) | Moisture content (%) | 41.80 a | 55.62 b | 52.92 b | 47.11 a | |

| Ash content (%) | 4.30 a | 10.53 b | 3.34 a | 2.24 a | ||

| Energy content (MJ/kg) | 20.6 ab | 19.6 a | 20.5 ab | 20.7 b | ||

| Nutrient content: | ||||||

| C (%) | 50.8 a | 47.7 b | 52.0 c | 52.3 c | ||

| N (ppm) | 4298 a | 8053 b | 4670 a | 3055 c | ||

| P (ppm) | 350 a | 610 b | 384 a | 279 a | ||

| K (ppm) | 1236 a | 1751 b | 1330 a | 1229 a | ||

| Ca (ppm) | 4473 a | 6436 b | 4459 a | 3737 a | ||

| Mg (ppm) | 576 ac | 856 b | 639 a | 481 c | ||

| Setting of the Fine Screen Deck | |||

|---|---|---|---|

| (1861 rpm) | (2239 rpm) | (2624 rpm) | |

| Screening Costs 1 (€/t) | 14.05 | 12.36 | 11.47 |

| Incidence of Acceptable Particles 1 (%) | 84.42 | 80.92 | 71.16 |

| Av. Energy Content 1 (MJ/kg) | 20.68 | 20.46 | 20.45 |

| Av. Ash Content 1 (%) | 2.36 | 2.70 | 3.34 |

| Av. Nitrogen Content 1 (ppm) | 2963 | 3193 | 4670 |

| Av. Needle Content 1 (%) | 5.84 | 6.09 | 17.38 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huber, C.; Kroisleitner, H.; Stampfer, K. Performance of a Mobile Star Screen to Improve Woodchip Quality of Forest Residues. Forests 2017, 8, 171. https://doi.org/10.3390/f8050171

Huber C, Kroisleitner H, Stampfer K. Performance of a Mobile Star Screen to Improve Woodchip Quality of Forest Residues. Forests. 2017; 8(5):171. https://doi.org/10.3390/f8050171

Chicago/Turabian StyleHuber, Christoph, Huberta Kroisleitner, and Karl Stampfer. 2017. "Performance of a Mobile Star Screen to Improve Woodchip Quality of Forest Residues" Forests 8, no. 5: 171. https://doi.org/10.3390/f8050171

APA StyleHuber, C., Kroisleitner, H., & Stampfer, K. (2017). Performance of a Mobile Star Screen to Improve Woodchip Quality of Forest Residues. Forests, 8(5), 171. https://doi.org/10.3390/f8050171