Exploring the Regional Potential of Lignocellulosic Biomass for an Emerging Bio-Based Economy: A Case Study from Southwest Germany

Abstract

1. Introduction

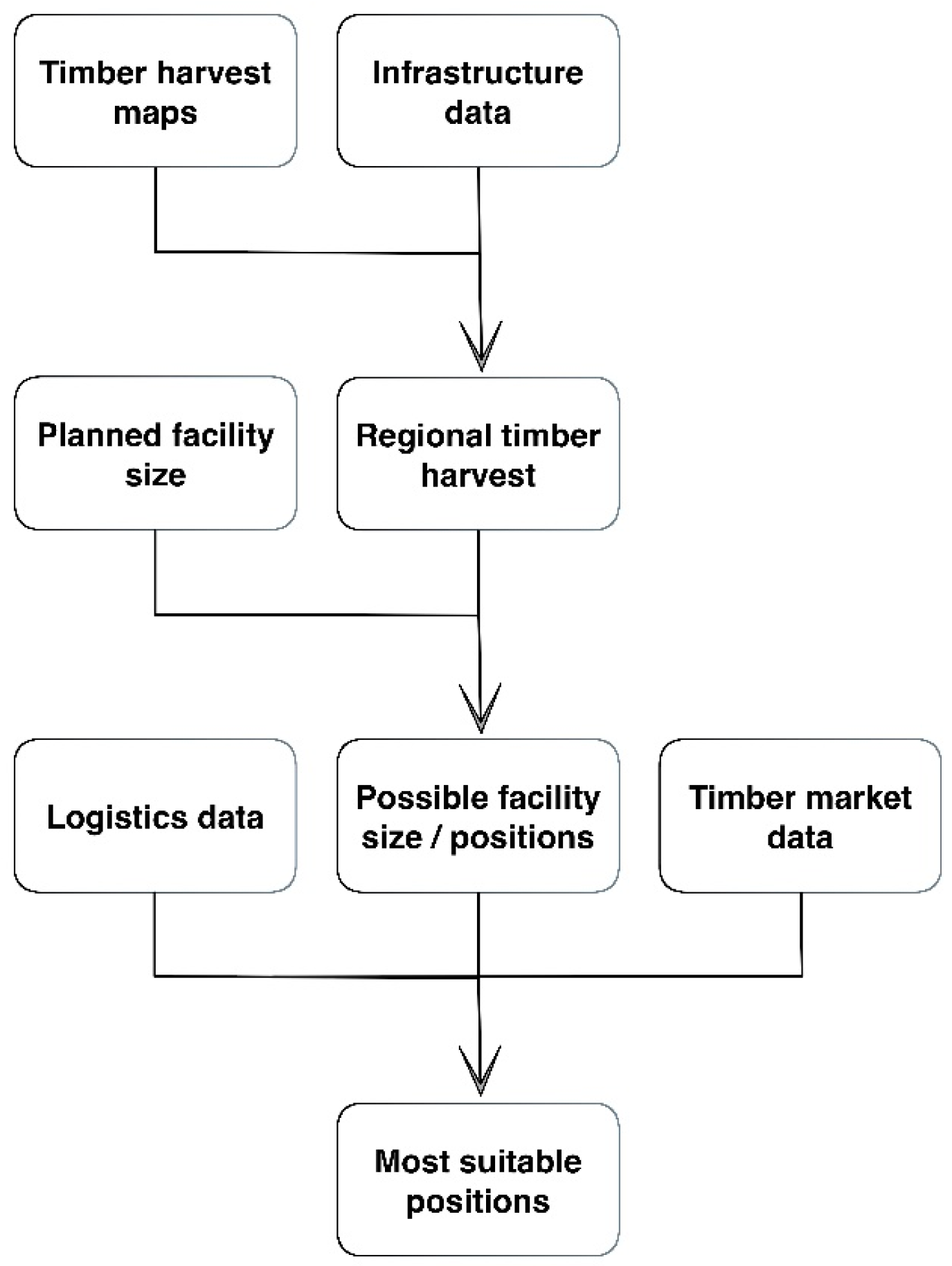

2. Materials and Methods

2.1. Study Site

2.2. Biomass Maps

2.3. Calculating Regional Harvest

2.4. Transportation Cost of Woody Biomass

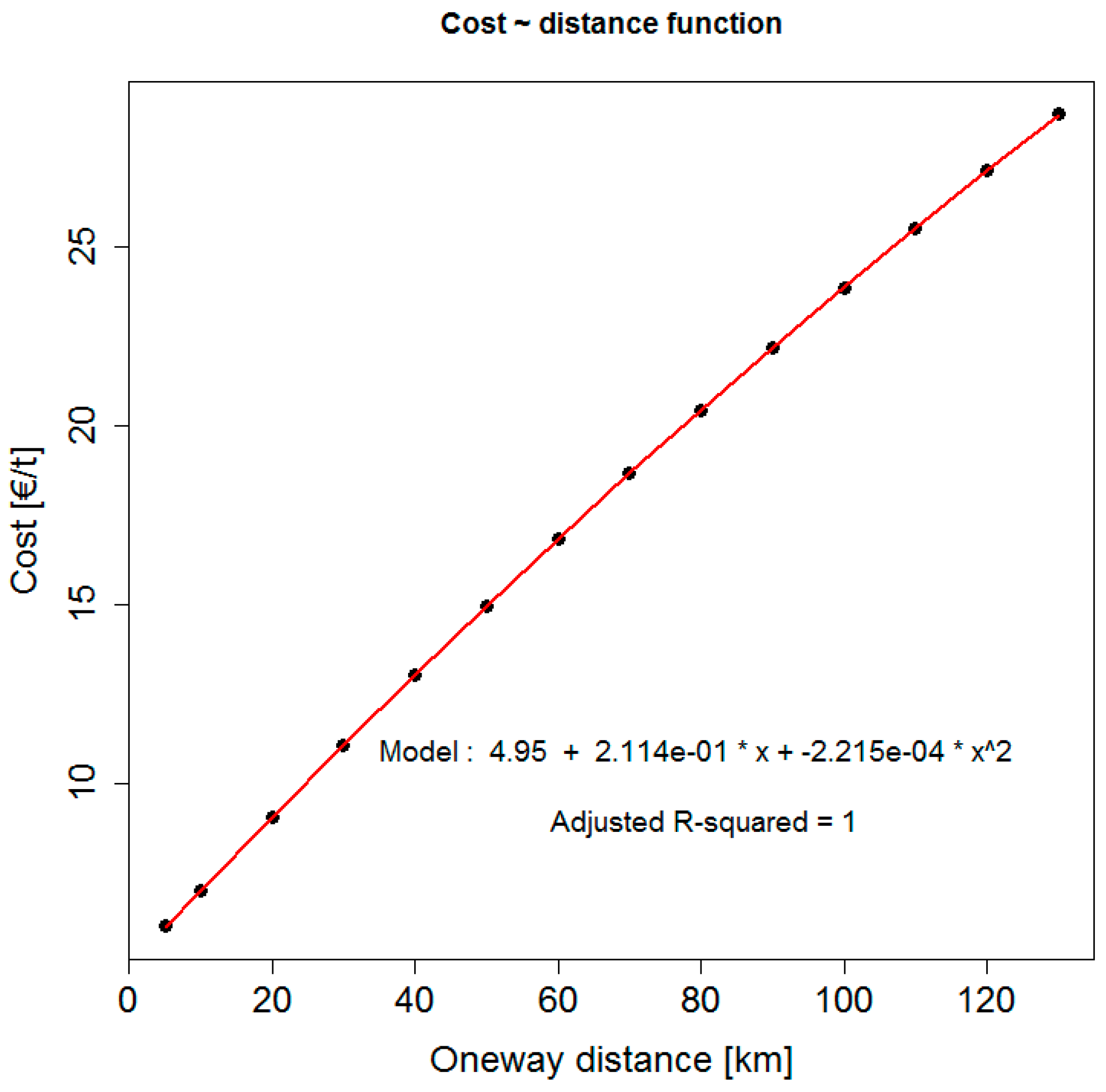

2.5. Transportation Tariff

2.6. Timber Assortments and Pricing

3. Results

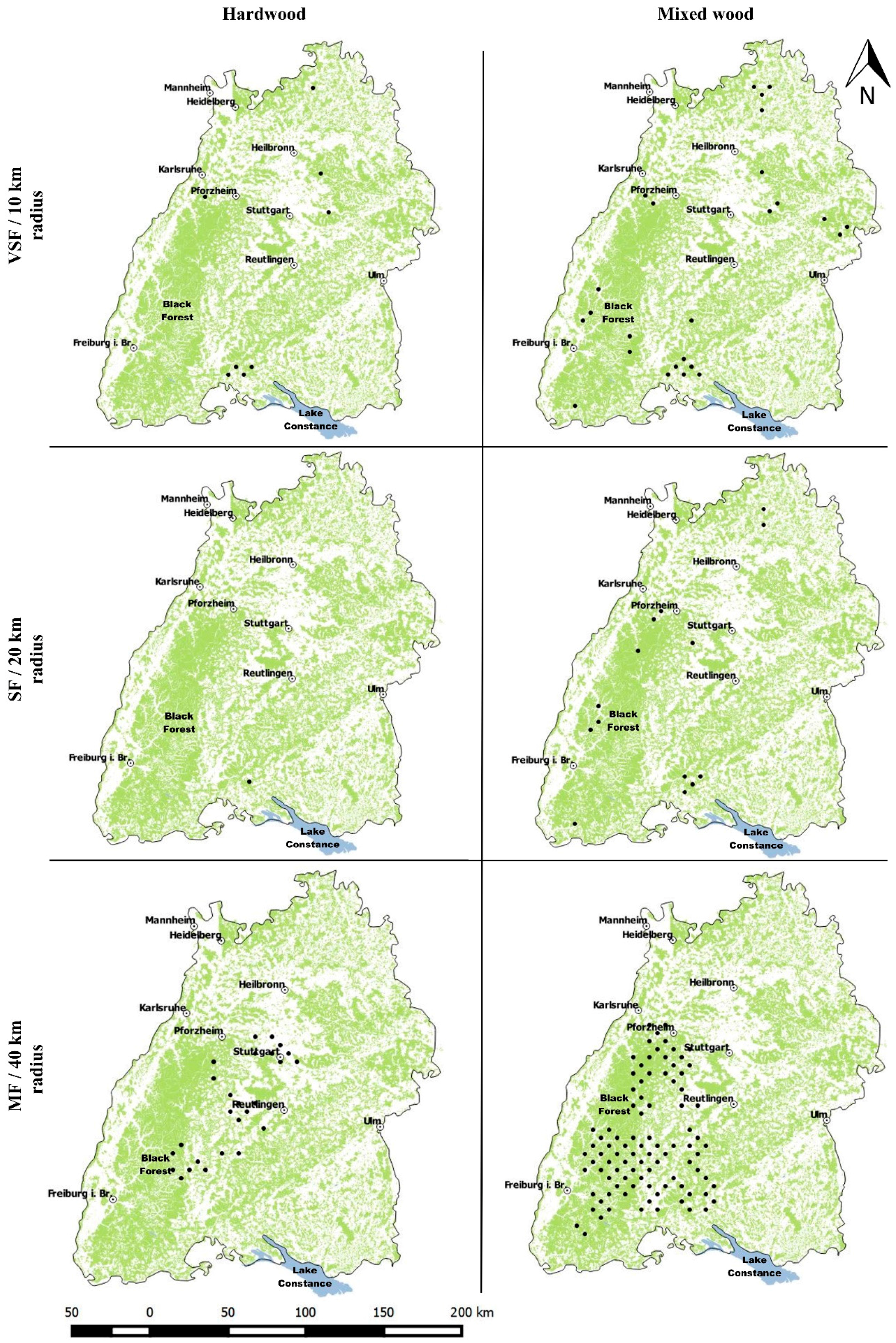

3.1. Scenarios

- Very small facility (VSF) processing 20,000 Mg year−1 of woody biomass.

- Small-size facility (SF) processing 80,000 Mg year−1 of woody biomass.

- Medium-size facility (MF) processing 250,000 Mg year−1 of woody biomass.

3.2. Suitable Positions

3.3. Final Costs

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Federal Ministry of Education and Research (BMBF). Bioeconomy in Germany: Opportunities for a Bio-Based and Sustainable Future; Federal Ministry of Education and Research (BMBF): Berlin, Germany, 2015. [Google Scholar]

- European Association for Bioindustries (EuropaBio). Building a Bio-Based Economy for Europe in 2020; European Association for Bioindustries (EuropaBio): Brussels, Belgium, 2011. [Google Scholar]

- European Commission (EC). Innovating for Sustainable Growth: A Bioeconomy for Europe; European Commission (EC): Brussels, Belgium, 2012. [Google Scholar]

- Organisation for Economic Cooperation and Development (OECD). The Bioeconomy to 2030: Designing a Policy Agenda, Main Findings; Organisation for Economic Cooperation and Development (OECD): Paris, France, 2009. [Google Scholar]

- Federal Ministry of Education and Research (BMBF). Nationale Forschungsstrategie BioÖkonomie 2030—Unser Weg zu Einer Bio-Basierten Wirtschaft; Federal Ministry of Education and Research (BMBF): Berlin, Germany, 2010. [Google Scholar]

- German Presidency. En Route to the Knowledge-Based Bio-Economy; German Presidency: Cologne, Germany, 2007. [Google Scholar]

- Langeveld, J.W.; Sanders, J.P.M. The Biobased Economy: Biofuels, Materials and Chemicals in the Post-Oil Era; Langeveld, H., Sanders, J., Meeusen, M., Eds.; Earthscan: London, UK, 2012. [Google Scholar]

- Rudel, T.K.; Coomes, O.T.; Moran, E.; Achard, F.; Angelsen, A.; Xu, J.; Lambin, E. Forest transitions: Towards a global understanding of land use change. Glob. Environ. Chang. 2005, 15, 23–31. [Google Scholar] [CrossRef]

- Treuhaft, R.N.; Asner, G.P.; Law, B.E. Structure-based forest biomass from fusion of radar and hyperspectral observations. Geophys. Res. Lett. 2003, 30. [Google Scholar] [CrossRef]

- Alam, M.B.; Shahi, C.; Pulkki, R. Wood biomass supply model for bioenergy production in Northwestern Ontario. In Proceedings of the 1st International Conference on the Developments in Renewable Energy Technology (ICDRET), Dhaka, Bangladesh, 17–19 December 2009; pp. 1–3. [Google Scholar]

- Chinese, D.; Meneghetti, A. Optimisation models for decision support in the development of biomass-based industrial district-heating networks in Italy. Appl. Energy 2005, 82, 228–254. [Google Scholar] [CrossRef]

- Han, S.K.; Murphy, G.E. Solving a woody biomass truck scheduling problem for a transport company in Western Oregon, USA. Biomass Bioenergy 2012, 44, 47–55. [Google Scholar] [CrossRef]

- Kanzian, C.; Holzleitner, F.; Stampfer, K.; Ashton, S. Regional energy wood logistics-optimizing local fuel supply. Silva Fenn. 2009, 43, 113–128. [Google Scholar] [CrossRef]

- Freppaz, D.; Minciardi, R.; Robba, M.; Rovatti, M.; Sacile, R.; Taramasso, A. Optimizing forest biomass exploitation for energy supply at a regional level. Biomass Bioenergy 2004, 26, 15–25. [Google Scholar] [CrossRef]

- Frombo, F.; Minciardi, R.; Robba, M.; Rosso, F.; Sacile, R. Planning woody biomass logistics for energy production: A strategic decision model. Biomass Bioenergy 2009, 33, 372–383. [Google Scholar] [CrossRef]

- Keirstead, J.; Samsatli, N.; Pantaleo, A.M.; Shah, N. Evaluating biomass energy strategies for a UK eco-town with an MILP optimization model. Biomass Bioenergy 2012, 39, 306–316. [Google Scholar] [CrossRef]

- Rauch, P.; Gronalt, M. The effects of rising energy costs and transportation mode mix on forest fuel procurement costs. Biomass Bioenergy 2011, 35, 690–699. [Google Scholar] [CrossRef]

- Ragauskas, A.J.; Williams, C.K.; Davison, B.H.; Britovsek, G.; Cairney, J.; Eckert, C.A.; Frederick, W.J.; Hallett, J.P.; Leak, D.J.; Liotta, C.L.; et al. The path forward for biofuels and biomaterials. Science 2006, 311, 484–489. [Google Scholar] [CrossRef] [PubMed]

- Richardson, B. From a fossil-fuel to a biobased economy: The politics of industrial biotechnology. Environ. Plan. C Gov. Policy 2012, 30, 282–296. [Google Scholar] [CrossRef]

- Maack, J.; Lingenfelder, M.; Weinacker, H.; Koch, B. Modelling the standing timber volume of Baden-Württemberg—A large-scale approach using a fusion of Landsat, airborne LiDAR and National Forest Inventory data. Int. J. Appl. Earth Obs. Geoinform. 2016, 49, 107–116. [Google Scholar] [CrossRef]

- Maack, J.; Lingenfelder, M.; Eilers, C.; Smaltschinski, T.; Weinacker, H.; Jaeger, D.; Koch, B. Estimating the spatial distribution, extent and potential lignocellulosic biomass supply of Trees Outside Forests in Baden-Wuerttemberg using airborne LiDAR and OpenStreetMap data. Int. J. Appl. Earth Obs. Geoinform. 2017, 58, 118–125. [Google Scholar] [CrossRef]

- Kändler, G.; Cullmann, D. Der Wald in Baden-Württemberg. In Ausgewählte Ergebnisse der Dritten Bundeswaldinventur; Forstliche Versuchs- und Forschungsanstalt Baden-Württemberg: Freiburg, Germany, 2014. [Google Scholar]

- Wood, S.N. Generalized Additive Models: An Introduction with R; Chapman and Hall/CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar]

- Chambers, J.M.; Hastie, T.J. Statistical models. In Scientific Modeling and Simulation SMNS; Springer: Dordrecht, The Netherlands, 1992. [Google Scholar]

- European Environment Agency (EEA). Corine Land Cover (CLC) 2012. Available online: http://land.copernicus.eu/pan-european/corine-land-cover/clc-2012/view (accessed on 15 November 2017).

- Reich, T.; Bernhard, J.; Geimer, M. Fahrzeugsystemtechnik. Karlsruher Institut für Technologie. In Optimierung des Holztransports in Baden-Württemberg; Arbeitsgemeinschaft Rohholzverbraucher: Berlin, Germany, 2015. [Google Scholar]

- Deutsche Bank. Personal Communication; Deutsche Bank: Frankfurt, Germany, 2017. [Google Scholar]

- Klenk, A. Analyse Konkreter Rundholztransporte. Bachelor’s Thesis, Hochschule für Forstwirtschaft Rottenburg, Neckar, Germany, 2015. [Google Scholar]

- Wagenfuehr, R. Holzatlas; Fachbuchverlag Leipzig, Hanser: Munich, Germany, 2000; ISBN 3-446-21390-2. [Google Scholar]

- Forest Research Institute Baden-Württemberg (FVA). Personal Communication; Forest Research Institute Baden-Württemberg (FVA): Breisgau, Germany, 2017. [Google Scholar]

- Le Toan, T.; Quegan, S.; Davidson, M.W.J.; Balzter, H.; Paillou, P.; Papathanassiou, K.; Plummer, S.; Rocca, F.; Saatchi, S.; Shugart, H.; et al. The BIOMASS mission: Mapping global forest biomass to better understand the terrestrial carbon cycle. Remote Sens. Environ. 2011, 115, 2850–2860. [Google Scholar] [CrossRef]

- Sörgel, C.; Mantau, U.; Weimar, H. Standorte der Holzwirtschaft—Aufkommen von Sägenebenprodukten und Hobelspänen; Arbeitsbereich Ökonomie der Holz- und Forstwirtschaft, Universität Hamburg Zentrum Holzwirtschaft: Hamburg, Germany, 2006. [Google Scholar]

| Item | Value | |

|---|---|---|

| Tractor unit, crane, trailer | 172,400 | € |

| Annual mileage | 96,718 | km |

| Annual operating days | 248 | days |

| Fuel price per liter | 1.25 | € |

| Fuel consumption per 100 km | 47 | l |

| Tire cost per km | 0.058 | € |

| Lubricant costs per km | 0.022 | € |

| Road toll per km | 0.130 | € |

| Maintenance and repair per km | 0.101 | € |

| Personnel costs (including social contributions) per month for the driver | 3600 | € |

| Cost Type | Cost Item | Value (€ year−1) |

|---|---|---|

| Variable costs | Fuel | 56,870 |

| Tires | 5562 | |

| Lubricant | 2100 | |

| Maintenance and repair | 9751 | |

| Sum variable costs | 74,283 | |

| Fixed costs | Annual credit rate (4%) | 31,607 |

| Vehicle tax | 1500 | |

| Vehicle insurance | 3500 | |

| Road toll | 4523 | |

| Other test costs | 400 | |

| Mobile phone and internet | 600 | |

| Sum fix costs | 42,130 | |

| Personnel costs | Salary plus social security contributions | 43,200 |

| Impute costs | Administrative costs | 3000 |

| Company risk | 12,000 | |

| Sum impute costs | 15,000 | |

| All costs | Sum of all costs | 174,613 |

| Distance (km) | |||||||

|---|---|---|---|---|---|---|---|

| One-Way | Forest Road | Speed Limit 60 km h−1 | Speed Limit 80 km h−1 | Mean Speed (km h−1) | Trips Per Day (n) | Costs Per m3 (€) | Costs Per Mg (Dry) (€) |

| 5 | 2.7 | 2.3 | 0.0 | 35.0 | 8.1 | 3.23 | 6.03 |

| 10 | 2.7 | 7.3 | 0.0 | 42.6 | 6.9 | 3.76 | 7.02 |

| 20 | 2.7 | 16.8 | 0.6 | 47.2 | 5.4 | 4.86 | 9.07 |

| 30 | 2.7 | 25.7 | 1.7 | 49.1 | 4.4 | 5.94 | 11.09 |

| 40 | 2.7 | 34.0 | 3.3 | 50.5 | 3.7 | 7.00 | 13.06 |

| 50 | 2.7 | 41.8 | 5.5 | 51.6 | 3.2 | 8.03 | 14.98 |

| 60 | 2.7 | 49.1 | 8.3 | 52.5 | 2.9 | 9.03 | 16.85 |

| 70 | 2.7 | 55.8 | 11.6 | 53.4 | 2.6 | 10.00 | 18.67 |

| 80 | 2.7 | 61.9 | 15.4 | 54.2 | 2.4 | 10.96 | 20.44 |

| 90 | 2.7 | 67.5 | 19.8 | 55.0 | 2.2 | 11.88 | 22.18 |

| 100 | 2.7 | 72.6 | 24.8 | 55.8 | 2.0 | 12.79 | 23.87 |

| 110 | 2.7 | 77.1 | 30.3 | 56.6 | 1.9 | 13.67 | 25.52 |

| 120 | 2.7 | 81.0 | 36.3 | 57.3 | 1.8 | 14.54 | 27.13 |

| 130 | 2.7 | 84.4 | 42.9 | 58.1 | 1.7 | 15.38 | 28.70 |

| Radius Service Area (km) | Mean Distance One Way (km) | Fitted Costs Per Mg (Dry) (€) |

|---|---|---|

| 10 | 6.67 | 6.35 |

| 20 | 13.33 | 7.73 |

| 30 | 20.00 | 9.09 |

| 40 | 26.67 | 10.43 |

| 50 | 33.33 | 11.75 |

| Type | Class | Relative Share of Annual Harvest (%) | Relative Share of Annual Harvest by Wood Class (%) | Sales Price (€ m−3) | Sales Price (€ Mg−1 (Dry)) |

|---|---|---|---|---|---|

| Hardwood | Fuelwood | 15.2 | 50.7 | 49.2 | 91.8 |

| Pulpwood | 7.8 | 26 | 46.4 | 86.6 | |

| Roundwood | 7.0 | 23.3 | 82.6 | 154.1 | |

| Softwood | Fuelwood | 0.7 | 1.0 | 26.2 | 48.9 |

| Pulpwood | 6.3 | 9.0 | 46.3 | 86.4 | |

| Roundwood | 62.9 | 90.0 | 80.7 | 150.6 |

| Radius Service Area (km) | Softwood (Mg year−1) | Hardwood (Mg year−1) | Mixed Wood (Mg year−1) | Transport Cost (€ Mg−1) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| All | Fuel | Pulp | All | Fuel | Pulp | All | Fuel | Pulp | ||

| 10 | 114,852 | 2793 | 10,316 | 55,730 | 29,729 | 13,838 | 149,487 | 31,754 | 20,701 | 6.35 |

| 20 | 375,399 | 8018 | 33,620 | 214,059 | 114,088 | 53,046 | 522,973 | 119,675 | 73,218 | 7.73 |

| 30 | 833,686 | 16,157 | 74,534 | 415,518 | 225,925 | 100,600 | 1,182,900 | 239,236 | 162,680 | 9.09 |

| 40 | 1,435,263 | 27,939 | 128,152 | 681,646 | 371,476 | 164,580 | 2,087,763 | 395,820 | 288,956 | 10.43 |

| 50 | 2,013,982 | 41,078 | 179,428 | 1,092,278 | 584,652 | 269,352 | 3,074,860 | 623,060 | 446,095 | 11.75 |

| Min. Service Area Radius (km) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 100% Resources Usage | 50% Resources Usage | 5% Resources Usage | |||||||

| Soft-Wood | Hard-Wood | Mixed Wood | Soft-Wood | Hard-Wood | Mixed Wood | Soft-Wood | Hard-Wood | Mixed Wood | |

| VSF | 20 | 10 | 10 | 20 | 10 | 10 | - | 40 | 40 |

| SF | 30 | 20 | 20 | 50 | 20 | 20 | - | - | - |

| MF | - | 30 | 30 | - | 40 | 40 | - | - | - |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maack, J.; Lingenfelder, M.; Smaltschinski, T.; Jaeger, D.; Koch, B. Exploring the Regional Potential of Lignocellulosic Biomass for an Emerging Bio-Based Economy: A Case Study from Southwest Germany. Forests 2017, 8, 449. https://doi.org/10.3390/f8110449

Maack J, Lingenfelder M, Smaltschinski T, Jaeger D, Koch B. Exploring the Regional Potential of Lignocellulosic Biomass for an Emerging Bio-Based Economy: A Case Study from Southwest Germany. Forests. 2017; 8(11):449. https://doi.org/10.3390/f8110449

Chicago/Turabian StyleMaack, Joachim, Marcus Lingenfelder, Thomas Smaltschinski, Dirk Jaeger, and Barbara Koch. 2017. "Exploring the Regional Potential of Lignocellulosic Biomass for an Emerging Bio-Based Economy: A Case Study from Southwest Germany" Forests 8, no. 11: 449. https://doi.org/10.3390/f8110449

APA StyleMaack, J., Lingenfelder, M., Smaltschinski, T., Jaeger, D., & Koch, B. (2017). Exploring the Regional Potential of Lignocellulosic Biomass for an Emerging Bio-Based Economy: A Case Study from Southwest Germany. Forests, 8(11), 449. https://doi.org/10.3390/f8110449