Modelling the Material Resistance of Wood—Part 2: Validation and Optimization of the Meyer-Veltrup Model

Abstract

:1. Introduction

2. Materials and Methods

2.1. The Meyer-Veltrup Model

2.2. Data Acquisition

2.3. Test Methods for Determining the Modifying Factors kinh and kwa

2.4. Evaluation Procedure and Model Fitting

3. Results and Discussion

3.1. Untreated Timber

3.2. Modified Timber

3.3. Preservative-Treated Timber

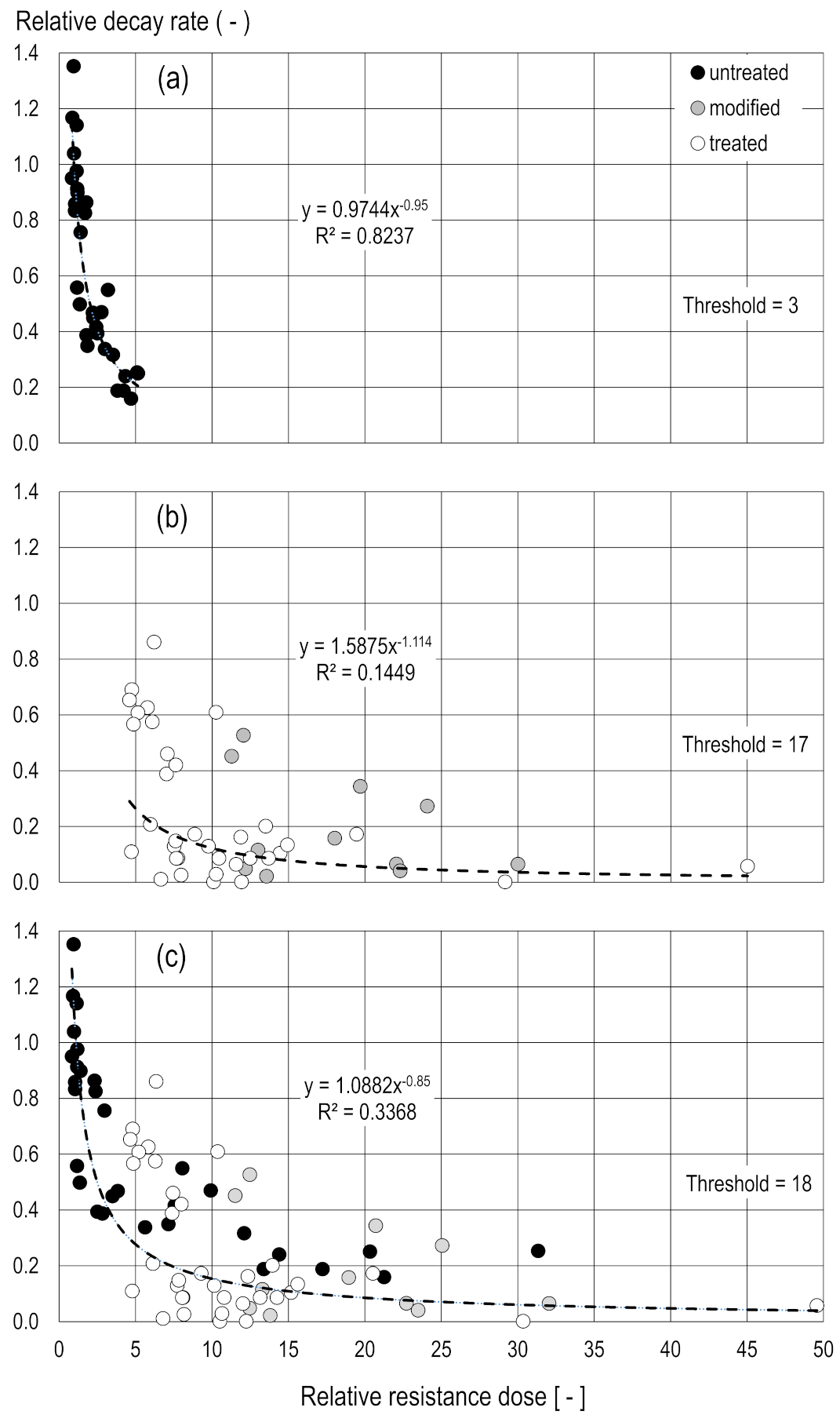

3.4. Model Fitting

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Leicester, R.H.; Wang, C.H.; Nguyen, M.N.; MacKenzie, C.E. Design of Exposed Timber Structures. Austr. J. Struct. Eng. 2009, 9, 241–248. [Google Scholar] [CrossRef]

- Thelandersson, S.; Isaksson, T.; Suttie, E.; Frühwald, E.; Toratti, T.; Grüll, G.; Viitanen, H.; Jermer, J. Service Life of Wood in Outdoor above Ground Applications—Engineering Design Guideline. Background Document; Report TVBK-3061; Div. of Structural Engineering; Lund University: Lund, Sweden, 2011. [Google Scholar]

- Isaksson, T.; Thelandersson, S.; Jermer, J.; Brischke, C. Beständighet för Utomhusträ Ovan Mark. Guide för Utformning och Materialval; Report TVBK-3066; Division of Structural Engineering; Lund University: Lund, Sweden, 2014. [Google Scholar]

- Pousette, A.; Malo, K.A.; Thelandersson, S.; Fortino, S.; Salokangas, L.; Wacker, J. Durable Timber Bridges—Final Report and Guidelines; RISE Research Institutes of Sweden: Skellefteå, Sweden, 2017. [Google Scholar]

- Blanchette, R.A.; Held, B.W.; Jurgens, J.A.; McNew, D.L.; Harrington, T.C.; Duncan, S.M.; Farrell, R.L. Wood-destroying soft rot fungi in the historic expedition huts of Antarctica. Appl. Environ. Microbiol. 2004, 70, 1328–1335. [Google Scholar] [CrossRef] [Green Version]

- Sterflinger, K.; Tesei, D.; Zakharova, K. Fungi in hot and cold deserts with particular reference to microcolonial fungi. Fungal Ecol. 2012, 5, 453–462. [Google Scholar] [CrossRef]

- EN 113-2. Durability of Wood and Wood-Based Products—Test Method against Wood Destroying Basidiomycetes—Part. 2: Assessment of Inherent or Enhanced Durability; European Committee for Standardization: Brussels, Belgium, 2020.

- AWPA E10. Laboratory Method for Evaluating the Decay Resistance of Wood-Based Materials against Pure Basidiomycete Cultures: Soil/Block Test; American Wood Preservers’ Association: Hoover, AL, USA, 2016.

- AWPA E7. Standard Field Test for Evaluation of Wood Preservatives to Be Used in Ground Contact (UC4A, UC4B, UC4C); Stake Test; American Wood Preservers’ Association: Hoover, AL, USA, 2015.

- EN 252. Field Test Method for Determining the Relative Protective Effectiveness of a Wood Preservative in Ground Contact; European Committee for Standardization: Brussels, Belgium, 2015.

- ENV 807. Wood Preservatives—Determination of the Effectiveness against Soft Rotting Micro-Fungi and Other Soil Inhabiting Micro-Organisms; European Committee for Standardization: Brussels, Belgium, 2001.

- CEN/TS 15083-2. Durability of Wood and Wood-Based Products—Determination of the Natural Durability of Solid Wood against Wood-Destroying Fungi, Test Methods—Part. 2: Soft Rotting Micro-Fungi; European Committee for Standardization: Brussels, Belgium, 2015.

- AWPA E14. Laboratory Method for Rapidly Evaluating the Decay Resistance of Wood-Based Materials in Ground Contact: Soil Bed Test; American Wood Preservers’ Association: Hoover, AL, USA, 2016.

- Brischke, C.; Welzbacher, C.R.; Meyer, L.; Bornemann, T.; Larsson-Brelid, P.; Pilgård, A.; Frühwald Hansson, E.; Westin, M.; Rapp, A.O.; Thelandersson, S.; et al. Service Life Prediction of Wooden Components—Part 3: Approaching a Comprehensive Test Methodology. In Proceedings of the IRG Annual Meeting, IRG/WP 11-20464, Queenstown, New Zealand, 8–12 May 2011; p. 25. [Google Scholar]

- Brischke, C.; Meyer, L.; Alfredsen, G.; Humar, M.; Francis, L.; Flæte, P.O.; Larsson-Brelid, P. Natural durability of timber exposed above ground—A survey. Drv. Ind. 2013, 64, 113–129. [Google Scholar] [CrossRef]

- Meyer, L.; Brischke, C.; Preston, A. Testing the durability of timber above ground: A review on methodology. Wood Mater. Sci. Eng. 2016, 11, 283–304. [Google Scholar] [CrossRef]

- EN 350. Durability of Wood and Wood-Based Products—Testing and Classification of the Durability to Biological Agents of Wood and Wood-Based Materials; European Committee for Standardization: Brussels, Belgium, 2016.

- Meyer-Veltrup, L.; Brischke, C.; Alfredsen, G.; Humar, M.; Flæte, P.O.; Isaksson, T.; Larsson Brelid, P.; Westin, M.; Jermer, J. The combined effect of wetting ability and durability on outdoor performance of wood: Development and verification of a new prediction approach. Wood Sci. Technol. 2017, 51, 615–637. [Google Scholar] [CrossRef]

- Humar, M.; Kržišnik, D.; Lesar, B.; Brischke, C. The performance of wood decking after five years of exposure: Verification of the combined effect of wetting ability and durability. Forests 2019, 10, 903. [Google Scholar] [CrossRef] [Green Version]

- Kržišnik, D.; Brischke, C.; Lesar, B.; Thaler, N.; Humar, M. Performance of wood in the Franja partisan hospital. Wood Mater. Sci. Eng. 2019, 14, 24–32. [Google Scholar] [CrossRef]

- Brischke, C.; Hesse, C.; Meyer-Veltrup, L.; Humar, M. Studies on the material resistance and moisture dynamics of Common juniper, yew, black cherry, and rowan. Wood Mater. Sci. Eng. 2018, 13, 222–230. [Google Scholar] [CrossRef]

- De Angelis, M.; Romagnoli, M.; Vek, V.; Poljanšek, I.; Oven, P.; Thaler, N.; Lesar, B.; Kržišnik, D.; Humar, M. Chemical composition and resistance of Italian stone pine (Pinus pinea L.) wood against fungal decay and wetting. Ind. Crops Prod. 2018, 117, 187–196. [Google Scholar] [CrossRef]

- Humar, M.; Balzano, A.; Grbec, S.; Gričar, J.; Kržišnik, D.; Lesar, B.; Vek, V. Investigation of the material resistance and moisture performance of pubescent oak (Quercus pubescens). Holzforschung 2021, 75, 22–36. [Google Scholar] [CrossRef]

- Emmerich, L.; Militz, H.; Brischke, C. Long-term performance of DMDHEU-treated wood installed in different test set-ups in ground, above ground and in the marine environment. Int. Wood Prod. J. 2020, 11, 27–37. [Google Scholar] [CrossRef]

- Meyer-Veltrup, L.; Brischke, C.; Niklewski, J.; Frühwald Hansson, E. Design and performance prediction of timber bridges based on a factorization approach. Wood Mater. Sci. Eng. 2018, 13, 167–173. [Google Scholar] [CrossRef]

- Brischke, C.; Humar, M.; Niklewski, J.; Alfredsen, G. Modelle zur Vorhersage der Gebrauchsdauer von Holzbauteilen auf dem Prüfstand. Holztechnologie 2019, 60, 23–34. [Google Scholar]

- Cook, J.A.; Morris, P.I. Modeling data from stake tests of waterborne wood preservatives. For. Prod. J. 1995, 45, 61. [Google Scholar]

- Isaksson, T.; Brischke, C.; Thelandersson, S. Development of decay performance models for outdoor timber structures. Mater. Struct. 2013, 46, 1209–1225. [Google Scholar] [CrossRef]

- Brischke, C. Untersuchung Abbaubestimmender Faktoren zur Vorhersage der Gebrauchsdauer Feuchtebeanspruchter Holzbauteile. Doctoral’s Thesis, University of Hamburg, Hamburg, Germany, 2007. [Google Scholar]

- Findlay, W.P.K. The natural resistance to decay of some Empire timbers. Emp. For. J. 1938, 17, 249–259. [Google Scholar]

- Van Acker, J.; De Windt, I.; Li, W.; Van den Bulcke, J. Critical parameters on moisture dynamics in relation to time of wetness as factor in service life prediction. In Proceedings of the IRG Annual Meeting, IRG/WP/14-20555, St. George, UT, USA, 11–15 May 2014; p. 22. [Google Scholar]

- Westin, M. Durability of furfurylated wood—Results from laboratory and field tests in the Ecobinders project. In Proceedings of the IRG Annual Meeting, IRG/WP/12-40602, Kuala Lumpur, Malaysia, 6–10 May 2011; p. 7. [Google Scholar]

- Westin, M.; Conti, E.; Creemers, J.; Flæte, P.O.; Gellerich, A.; Irbe, I.; Klamer, M.; Melcher, E.; Moeller, R.; Nunes, L.; et al. 10 year Report on COST E37 Round Robin Tests—Comparison of results from laboratory and field tests. In Proceedings of the IRG Annual Meeting, IRG/WP/17-30718, Ghent, Belgium, 4–8 June 2017; p. 13. [Google Scholar]

- Emmerich, L.; Brischke, C.; Sievert, M.; Schulz, M.S.; Jaeger, A.C.; Beulshausen, A.; Humar, M. Predicting the Outdoor Moisture Performance of Wood Based on Laboratory Indicators. Forests 2020, 11, 1001. [Google Scholar] [CrossRef]

- Wälchli, O. Die Widerstandsfähigkeit verschiedener Holzarten gegen Angriffe durch den echten Hausschwamm (Merulius lacrimans (Wulf.) Fr.). Holz Roh Werkst. 1973, 31, 96–102. [Google Scholar] [CrossRef]

- Wälchli, O. Die Widerstandsfähigkeit verschiedener Holzarten gegen Angriffe durch Coniophora puteana (Schum. ex Fr.) Karst. (Kellerschwamm) und Gloephyllum trabeum (Pers. ex Fr.) Murrill (Balkenblättling). Holz Roh Werkst. 1976, 34, 335–338. [Google Scholar] [CrossRef]

- Clark, J.W. Natural Decay Resistance of Fifteen Exotic Woods Imported for Exterior Use; U.S. Forest Service, Forest Products Laboratory Research Paper, FPL-RP-103; United States Department of Agriculture: Washington, DC, USA, 1969.

- Bultman, J.D.; Southwell, C.R. Natural Resistance of Tropical American Woods to Terrestrial Wood-Destroying Organisms. Biotropica 1976, 8, 71–95. [Google Scholar] [CrossRef]

- Van Acker, J.; Stevens, M.; Carey, J.; Sierra-Alvarez, R.; Militz, H.; Le Bayon, I.; Kleist, G.; Peek, R.D. Biological durability of wood in relation to end-use. Holz Roh Werkst. 2003, 61, 35–45. [Google Scholar] [CrossRef]

- Van Acker, J.; Militz, H.; Stevens, M. The significance of accelerated laboratory testing methods determining the natural durability of wood. Holzforschung 1999, 53, 449–458. [Google Scholar] [CrossRef]

- Edlund, M.-L. Durability of Some Alternatives to Preservative-Treated Wood. In Proceedings of the IRG Annual Meeting, IRG/WP 04-30353, Ljubljana, Slovenia, 6–10 June 2004; p. 13. [Google Scholar]

- Van den Bulcke, J.; De Windt, I.; Defoirdt, N.; Van Acker, J. Non-Destructive Evaluation of Wood Decay. In Proceedings of the IRG Annual Meeting, IRG/WP/11-20479, Queenstown, New Zealand, 8–12 May 2011; p. 11. [Google Scholar]

- Brischke, C.; Meyer, L.; Olberding, S. Durability of wood exposed in ground—Comparative field trials with different soil substrates. Int. Biodeterior. Biodegrad. 2014, 86, 108–114. [Google Scholar] [CrossRef]

- Brischke, C.; Welzbacher, C.R.; Gellerich, A.; Bollmus, S.; Humar, M.; Plaschkies, K.; Scheiding, W.; Alfredsen, G.; Van Acker, J.; De Windt, I. Wood natural durability testing under laboratory conditions: Results from a round-robin test. Eur. J. Wood Wood Prod. 2014, 72, 129–133. [Google Scholar] [CrossRef]

- Brischke, C.; Gellerich, A.; Militz, H.; Starck, M. Performance of coated and uncoated horizontal lap-joint members during 20 years of outdoor exposure. Wood Res. 2017, 62, 883–894. [Google Scholar]

- Meyer, L.; Brischke, C.; Melcher, E.; Brandt, K.; Lenz, M.T.; Soetbeer, A. Durability of English oak (Quercus robur L.)—Comparison of decay progress and resistance under various laboratory and field conditions. Int. Biodeter. Biodegr. 2014, 86, 79–85. [Google Scholar] [CrossRef]

- Thaler, N.; Žlahtič, M.; Humar, M. Performance of recent and old sweet chestnut (Castanea sativa) wood. Int. Biodeterior. Biodegrad. 2014, 94, 141–145. [Google Scholar] [CrossRef]

- Ugovšek, A.; Šubic, B.; Starman, J.; Rep, G.; Humar, M.; Lesar, B.; Thaler, N.; Brischke, C.; Meyer-Veltrup, L.; Jones, D.; et al. Short-term performance of wooden windows and facade elements made of thermally modified and non-modified Norway spruce in different natural environments. Wood Mater. Sci. Eng. 2019, 14, 42–47. [Google Scholar] [CrossRef]

- Scheiding, W.; Jacobs, K.; Bollmus, S.; Brischke, C. Durability Classification of Treated and Modified Wood—Approaching a Guideline for Sampling, Testing, and Statistical Analysis. In Proceedings of the IRG Annual Meeting, IRG/WP 20-20676, Webinar, 10–11 June 2020; p. 8. [Google Scholar]

- Cookson, L.J. Determining the Natural Durability of Eucalypts in Australia. In Durable Eucalypts on Drylands: Protecting and Enhancing Value; Altaner, C.M., Murray, T.J., Morgenroth, J., Eds.; Marlborough Research Centre: Blenheim, New Zealand, 2017; pp. 77–84. [Google Scholar]

- Reinprecht, L.; Vidholdová, Z. Rot resistance of tropical wood species affected by water leaching. BioResources 2019, 14, 8664–8677. [Google Scholar]

- Deklerck, V.; De Ligne, L.; Espinoza, E.; Beeckman, H.; Van den Bulcke, J.; Van Acker, J. Assessing the natural durability of xylarium specimens: Mini-block testing and chemical fingerprinting for small-sized samples. Wood Sci. Technol. 2020, 54, 981–1000. [Google Scholar] [CrossRef]

- Deklerck, V.; De Windt, I.; Defoirdt, N.; Van den Bulcke, J.; Beeckman, H.; Espinoza, E.; Van Acker, J. Assessing the Natural Durability for Different Tropical Timber Species Using the Mini-Block Test. In Proceedings of the IRG Annual Meeting, IRG/WP 17-10886, Ghent, Belgium, 4–8 June 2017; p. 14. [Google Scholar]

- Seehann, G. Zur natürlichen Dauerhaftigkeit von Kempas und Keruing gegenüber holzzerstörenden Pilzen. Holz Roh Werkst. 1973, 31, 269–272. [Google Scholar] [CrossRef]

- Smith, G.A.; Orsler, R.J. The biological natural durability of timber in ground contact. In Proceedings of the IRG Annual Meeting, IRG/WP 94-20051, Nusa Dua, Bali, Indonesia, 29 May–3 June 1994; p. 23. [Google Scholar]

- Welzbacher, C.R.; Rapp, A.O. Determination of the water sorption properties and preliminary results from field tests above ground of thermally modified material from industrial scale processes. In Proceedings of the IRG Annual Meeting, IRG/WP/04-40279, Ljubljana, Slovenia, 6–10 June 2004; p. 14. [Google Scholar]

- Augusta, U. Untersuchung der Natürlichen Dauerhaftigkeit Wirtschaftlich Bedeutender Holzarten bei Verschiedener Beanspruchung im Außenbereich. Doctoral’s Thesis, University of Hamburg, Hamburg, Germany, 2007. [Google Scholar]

- Conti, E. English Oak—Natural Durable Timber—Laboratory Test Results. IRG/WP Durability Database; The International Research Group on Wood Protection, IRG/WP/DDB 14-00014; IRG Secretariat: Stockholm, Sweden, 2014. [Google Scholar]

- Brischke, C.; Meyer-Veltrup, L. Performance of thermally modified wood during 14 years of outdoor exposure. Int. Wood Prod. J. 2016, 7, 89–95. [Google Scholar] [CrossRef]

- Hundhausen, U.; Flæte, P.O.; Mahnert, K.C.; Bysheim, K. Overflatekvalitet på terrassematerialer—Resultater etter to års eksponering. Tretek. Inf. 2016, 1, 23–27. [Google Scholar]

- Westin, M.; Alfredsen, G. Durability of Modified Wood in UC3 and UC4—Results from Lab Tests and 5 Years Testing in 3 Fields. In Proceedings of the IRG Annual Meeting, IRG/WP/11-40562, Queenstown, New Zealand, 8–12 May 2011; p. 9. [Google Scholar]

- Bavendamm, W.; Anuwongse, B. Über die Fäulnisresistenz thailändischer Holzarten. Holz Roh Werkst. 1967, 25, 392–393. [Google Scholar] [CrossRef]

- Francis, L.P.; Norton, J.; Melcher, E.; Wong, A.H.H.; Kok Lai, J.; Klamer, M.; Konkler, M.J.; Morrell, J.J. Performance of Untreated Timbers in above Ground Decking Tests: Preliminary Results from an International Collaborative Trial. In Proceedings of the IRG Annual Meeting, IRG/WP 19-10940, Quebec City, QC, Canada, 12–16 May 2019; p. 21. [Google Scholar]

- Petrenko, I.A. Stoikost’ Zaboloni I Yadra Listvennitsy Sibirskoi K Porazheniyu Razlichnymi Vidami Domovykh Gribov; Sibirskii Tekhnologicheskii Institute: Krasnoyarsk, Russia, 1964; pp. 261–264. (In Russian) [Google Scholar]

- Venäläinen, M.; Heikkonen, S.; Terziev, N.; Torniainen, P. Durability of the Siberian larch heartwood timber of different origin: The results of 11-year ground contact test in Finland. Sib. J. For. Sci. 2019, 3, 14–19, (in English with Russian abstract). [Google Scholar]

- Highley, T.L. Comparative Durability of Untreated Wood in Use Above Ground. Int. Biodeterior. Biodegrad. 1995, 35, 409–419. [Google Scholar] [CrossRef]

- Meyer, L.; Brischke, C.; Pilgård, A. Moisture Performance Based Wood Durability Testing. In Proceedings of the IRG Annual Meeting, IRG/WP 12-20495, Kuala Lumpur, Malaysia, 6–10 May 2012; p. 26. [Google Scholar]

- Metsä Kortelainen, S.; Viitanen, H. Durability of thermally modified sapwood and heartwood of Scots pine and Norway spruce in the modified double layer test. Wood Mater. Sci. Eng. 2017, 12, 129–139. [Google Scholar] [CrossRef]

- Brischke, C.; Melcher, E. Performance of wax-impregnated timber out of ground contact: Results from long-term field testing. Wood Sci. Technol. 2015, 49, 189–204. [Google Scholar] [CrossRef]

- Schulz, G. Vergleichende Untersuchungen mit verschiedenen Stämmen von Lentinus lepideus, gleichzeitig ein Beitrag zum Soil-Block-Verfahren. Holz Roh Werkst. 1958, 16, 435–444. [Google Scholar] [CrossRef]

- Morris, P.I.; Ingram, J.; Larkin, G.; Laks, P. Field tests of naturally durable species. For. Prod. J. 2011, 61, 344–351. [Google Scholar] [CrossRef]

- Palanti, S. Evaluation of Durability Conferred by an Oleothermic Treatment on Chestnut and Douglas fir through Laboratory and in Field Tests. Open J. For. 2013, 3, 66–69. [Google Scholar]

- Stirling, R.; Wong, D. Performance of Naturally Durable Decks after 15 Years of Field Exposure. In Proceedings of the IRG Annual Meeting, IRG/WP 20-10963, Webinar, 10–11 June 2020; p. 9. [Google Scholar]

- Plaschkies, K.; Scheiding, W.; Jacobs, K.; Rangno, N. Virulence of two Laboratory Test Strains and one Natural Isolate of Rhodonia (Oligoporus) placenta against Thermally Modified Pine and Beech Wood. In Proceedings of the IRG Annual Meeting, IRG/WP 13-20524, Stockholm, Sweden, 16–20 June 2013; p. 9. [Google Scholar]

- Viitanen, H.; Metsä-Kortelainen, S. Testing of decay resistance of sapwood and heartwood of thermally modified Scots pine and Norway spruce. In Proceedings of the IRG Annual Meeting, IRG/WP/10-40523, Biarritz, France, 9–13 May 2010; p. 10. [Google Scholar]

- Alfredsen, G.; Brischke, C.; Meyer-Veltrup, L.; Humar, M.; Flæte, P.-O. The effect of different test methods on durability classification on modified wood. ProLigno 2017, 13, 290–297. [Google Scholar]

- Jacobs, K.; Scheiding, W.; Weiß, B. Durability of acetylated Radiata pine: Laboratory tests and performance in practice. In Proceedings of the IRG Annual Meeting, IRG/WP 20-40899, Webinar, 10–11 June 2020; p. 14. [Google Scholar]

- Ziethén, R.; Brynildsen, P.; Lande, S.; Kristoffersen, J.; Westin, M. Kebony—An Alternative to Teak for Boat Decking. In Proceedings of the Fourth European Conference on Wood Modification, Norra Latin City Conference Centre, Stockholm, Sweden, 27–29 April 2009; SP Technical Research Institute of Sweden: Boras, Sweden, 2009. [Google Scholar]

- Alfredsen, G.; Flæte, P.O.; Militz, H. Performance of Novel Wood Protection Systems—Evaluation Based on Five Different Test Setups. In Proceedings of the International Convention of Society of Wood Science and Technology and United Nations Economic Commission for Europe—Timber Committee, Geneva, Switzerland, 11–14 October 2010. [Google Scholar]

- Emmerich, L.; Ehrmann, A.; Brischke, C.; Militz, H. Comparative studies on the durability and moisture performance of wood modified with cyclic N-methylol and N-methyl compounds. Wood Sci. Technol. 2021, submitted. [Google Scholar]

- Humar, M.; Lesar, B.; Thaler, N. Performance of Copper Treated and Naturally Durable Wood in Laboratory and Outdoor Conditions. In Proceedings of the International Conference on Durability of Building Materials and Components, Sao Paulo, Brazil, 2–5 September 2014; pp. 722–727. [Google Scholar]

- Humar, M.; Lesar, B.; Thaler, N.; Kržišnik, D.; Žlatič, M. Influence of the Retention and Penetration of Cu Based Preservatives on the Performance of Softwoods in Ground. In Designing with Bio-Based Building Materials—Challenges and Opportunities, Book of Abstract from Joint Technical Workshop, Madrid, Spain, 24–25 February 2016; De Troya, T., Ed.; National Institute for Agricultural and Food Research and Technology: Madrid, Spain; Eduardo Torroja Institute for Construction Sciences: Madrid, Spain, 2016; pp. 61–62. [Google Scholar]

- Alfredsen, G.; Brischke, C.; Marais, B.N.; Stein, R.F.A.; Zimmer, K.; Humar, M. Modelling the material resistance of wood—Part 1: Utilizing durability test data based on different reference wood species. Forests 2021, 12, 558. [Google Scholar] [CrossRef]

- Bravery, A.F. A Miniaturised Wood-Block Test for the Rapid Evaluation of Preservative Fungicides. In Proceedings of the A Special Seminar Held in Association with the 10th Annual Meeting of the IRG, Peebles, Scotland, 18–22 September 1978; Rep. No. 136; Swedish Wood Preservation Institute: Stockholm, Sweden, 1979. [Google Scholar]

- CEN/TS 16818. Durability of Wood and Wood-Based Products—Moisture Dynamics of Wood and Wood-Based Products; European Committee for Standardization: Brussels, Belgium, 2018.

- CEN/TS 12037. Wood Preservatives—Field Test Method for Determining the Relative Protective Effectiveness of a Wood Preservative Exposed out of Ground Contact—Horizontal Lap-Joint Method; European Committee for Standardization: Brussels, Belgium, 2003.

- EN 330. Wood Preservatives—Determination of the Relative Protective Effectiveness of a Wood Preservative for Use Under a Coating and Exposed out-of-Ground Contact—Field Test: L-Joint Method; European Committee for Standardization: Brussels, Belgium, 2015.

- Stirling, R.; Alfredsen, G.; Brischke, C.; De Windt, I.; Francis, L.P.; Frühwald Hansson, E.; Humar, M.; Jermer, J.; Klamer, M.; Kutnik, M.; et al. Global survey on durability variation—On the effect of the reference species. In Proceedings of the IRG Annual Meeting, IRG/WP 16-20573, Lisbon, Portugal, 15–19 May 2016; p. 26. [Google Scholar]

- Scheffer, T.C.; Morrell, J.J. Natural Durability of Wood: A Worldwide Checklist of Species; Forestry Publications Office; Oregon State University: Corvallis, OR, USA, 1998. [Google Scholar]

- Shida, S.; Saito, Y. Effects of heat treatment on brittleness of Styrax tonkinensis wood. J. Wood Sci. 2007, 53, 181–186. [Google Scholar]

- Brischke, C.; Welzbacher, C.R.; Rapp, A.O. Detection of fungal decay by high-energy multiple impact (HEMI) testing. Holzforschung 2006, 60, 217–222. [Google Scholar] [CrossRef]

- Zelinka, S.L.; Glass, S.V. Water vapor sorption isotherms for southern pine treated with several waterborne preservatives. J. Test. Eval. 2010, 38, 521–525. [Google Scholar]

- Barney, R.; Carroll, J.; Delaet, D. Surfactant studies of quaternary ammonium compounds: Critical surfactant concentration. J. Surfact. Deterg. 2006, 9, 137–140. [Google Scholar] [CrossRef]

- Kamdem, D.P. Copper-based systems for exterior residential applications. Am. Chem. Soc. (ACS) Symp. Ser. 2008, 982, 427–439. [Google Scholar]

- Choi, S.; Ruddick, J.N.; Morris, P. Chemical redistribution in CCA-treated decking. For. Prod. J. 2004, 54, 33–37. [Google Scholar]

- Stirling, R.; Ruddick, J.N.; Xue, W.; Morris, P.I.; Kennepohl, P. Characterization of copper in leachates from ACQ- and MCQ-treated wood and its effect on basidiospore germination. Wood Fib. Sci. 2015, 47, 209–216. [Google Scholar]

- Thaler, N.; Humar, M. Copper leaching from copper-ethanolamine treated wood: Comparison of field test studies and laboratory standard procedures. Bioresources 2014, 9, 3038–3051. [Google Scholar] [CrossRef]

- Brischke, C.; Alfredsen, G.; Humar, M.; Conti, E.; Cookson, L.; Emmerich, E.; Flæte, P.O.; Fortino, S.; Francis, L.; Hundhausen, U.; et al. Modelling the material resistance of wood—Part 3: Relative resistance in above and in ground situations—Results of a global survey. Forests 2021. submitted. [Google Scholar]

| Wood Species | Common Name | Origin | References |

|---|---|---|---|

| Acer platanoides/A. pseudoplatanus | Norway maple/Sycamore | Europe | [18,30,31,32,33,34] |

| Alnus glutinosa | Black alder | Europe | [18,31,34,35,36] |

| Betula pendula/B. pubescens | Silver birch/Downy birch | Europe | [18,31,35,36] |

| Dicorynia guianensis | Basralocus | S. America | [31,34,37,38,39] |

| Fagus sylvatica | European beech | Europe | [15,18,19,31,32,33,34,35,36,39,40,41,42,43,44,45,46,47,48,49] |

| Fraxinus excelsior | European ash | Europe | [18,19,31,35,36] |

| Intsia bijuga | Merbau | Africa | [18,31,50,51] |

| Lophira alata | Bongossi | Africa | [31,34,37,38,39,40,52,53] |

| Peltogyne spp. | Amaranth | C. America | [30,34,38] |

| Populus tremula | Aspen | Europe | [15,18,32,33,35,36] |

| Quercus robur/Q. petraea | European oak | Europe | [15,18,19,30,31,34,35,36,38,39,40,41,43,44,46,49,52,53,54,55,56,57,58,59,60] |

| Robinia pseudoacacia | Black locust | Europe | [18,31,34,36,39,49,52,53,57,61] |

| Salix caprea | Goat willow | Europe | [18] |

| Sorbus aucuparia | Rowan | Europe | [18,21] |

| Tectona grandis | Teak | Asia | [18,31,34,35,36,38,39,62] |

| Tilia cordata | Lime | Europe | [18] |

| Ulmus glabra | Wych elm | Europe | [18,55] |

| Wood Species | Common Name | Origin | References |

|---|---|---|---|

| Abies alba | Silver fir | Europe | [18,57] |

| Juniperus communis | Juniper | Europe | [18,21] |

| Larix decidua | European larch | Europe | [18,19,31,35,36,39,42,45,48,49,55,56,57,63] |

| Larix sibirica | Siberian larch | Europe | [15,18,31,41,42,60,64,65] |

| Picea sitchensis | Sitka spruce | Europe | [18] |

| Pinus spp. | Southern pine sw | N. America | [18,33,61,66] |

| Pinus radiata | Radiata pine sw | New Zealand | [18,31,34] |

| Pinus sylvestris | Scots pine | Europe | [15,18,19,31,39,41,42,43,45,49,55,57,59,60,63,65,67,68] |

| Scots pine sw | [18,19,31,33,34,39,41,42,43,45,48,49,56,57,61,63,68,69] | ||

| Pseudotsuga menziesii | Douglas-fir | N. America, Europe, New Zealand | [15,18,31,34,38,39,40,42,43,45,57,59,63,70,71,72,73] |

| Douglas-fir sw | [18,42,66,72] | ||

| Thuja plicata | Western red-cedar | N. America | [15,18,30,31,39,58,63,71,73] |

| Europe | [18,55] |

| Wood Species | Common Name | Origin | Modification | References |

|---|---|---|---|---|

| Fagus sylvatica | European beech | Europe | HT | [19,48,74] |

| Picea abies | Norway spruce | Europe | HT | [19,32,41,48,59,61,68,75] |

| Pinus sylvestris | Scots pine | Europe | HT | [18,33,34,41,56,59,60,61,68,75,76] |

| Fraxinus excelsior | European ash | Europe | OHT | [18] |

| Picea abies | Norway spruce | Europe | OHT | [18,57] |

| Pinus spp. | Southern pine sw | USA | AC | [18] |

| Pinus sylvestris/P. radiata | Scots pine sw/Radiata pine sw | Europe/New Zealand | AC | [18,34,41,60,61,76,77] |

| Acer platanoides | Norway maple | Europe | FA | [18,32,78] |

| Pinus spp. | Southern pine sw | USA | FA | [18,32] |

| Pinus sylvestris | Scots pine sw | Europe | FA | [18,60,79] |

| Pinus sylvestris | Scots pine sw | Europe | DMDHEU | [18,24,34,76,80] |

| Wood Species | Preservative/Treatment | References |

|---|---|---|

| Pinus sylvestris sw | CCA 2 kg/m3 | [18,61,65] |

| CCA 4 kg/m3 | [18,32,33,41,76,79] | |

| CCA 9 kg/m3 | [32,33,41,61,68,79] | |

| Picea abies | Cu (II) sulphate low: 0.35% aqueous solution | [81] |

| Cu (II) sulphate high: 1.4% aqueous solution | ||

| CuEA low: 0.098% Cu; 0.51% EA | ||

| CuEA high: 0.39% Cu; 2.05% EA | ||

| CuEAOA low: 0.098% Cu; 0.51% EA; 0.07% OA | ||

| CuEAOA high: 0.39% Cu; 2.05% EA; 0.29% OA | ||

| CuEAOAQuat low: 0.098% Cu; 0.51% EA; 0.07% OA; 0.098% Quat | ||

| CuEAOAQuat high: 0.39% Cu; 2.05% EA; 0.29% OA; 0.39% Quat | ||

| BoronEAOAQuat low: 0.098% B; 0.51% EA; 0.07% OA; 0.098% Quat | ||

| BoronEAOAQuat high: 0.39% B; 2.05% EA; 0.29 OA; 0.39% Quat | ||

| Picea abies, Pinus sylvestris sw, Larix decidua | Cu (II) carbonate: 0.25%, dipping 8-h 1 and 24-h | [82] |

| Cu (II) carbonate: 0.25%, vacuum 1 | ||

| Cu (II) carbonate: 0.25%, vacuum + pressure | ||

| Cu (II) carbonate: 0.5%, dipping 8-h1 and 24-h | ||

| Cu (II) carbonate: 0.5%, vacuum | ||

| Cu (II) carbonate: 0.5%, vacuum + pressure | ||

| Pinus sylvestris sw | Metal-free organic | [18,32] |

| Wood Species | kinh | kwa | vrel. | |||||

|---|---|---|---|---|---|---|---|---|

| br | wr | Soil | LWU | VU | WR | CWU | ||

| Acer platanoides/A. pseudoplatanus | 2.54 | 0.94 | 1.02 | 0.80 | 1.14 | 1.07 | 1.02 | 0.90 |

| Alnus glutinosa | 1.09 | 1.04 | 0.72 | 0.87 | 1.14 | 1.16 | 1.06 | 1.35 |

| Betula pendula/B. pubescens | 1.01 | 0.93 | 0.88 | 0.76 | 1.16 | 1.33 | 0.36 | 0.95 |

| Dicorynia guianensis | 15.30 | 16.54 | 5.11 | 1.43 | 1.35 | 1.25 | 1.06 | 0.19 |

| Fagus sylvatica | 1.26 | 0.70 | 0.61 | 0.73 | 1.15 | 1.30 | 1.44 | 1.17 |

| Fraxinus excelsior | 6.62 | 0.75 | 1.30 | 1.01 | 1.17 | 1.07 | 0.74 | 0.39 |

| Intsia bijuga | 16.19 | 9.93 | 16.33 | 1.72 | 1.63 | 0.55 | 4.62 | 0.25 |

| Lophira alata | 13.26 | 14.64 | 10.52 | 1.54 | 1.58 | 1.28 | 1.24 | 0.19 |

| Peltogyne spp. | 16.48 | 18.00 | 5.11 | 2.41 | 1.31 | 2.17 | 1.39 | 0.25 |

| Populus tremula | 1.24 | 0.99 | 0.94 | 0.91 | 1.13 | 1.09 | 0.65 | 1.04 |

| Quercus robur/Q. petraea | 14.62 | 8.04 | 2.77 | 1.70 | 1.34 | 1.70 | 0.88 | 0.47 |

| Robinia pseudoacacia | 12.20 | 12.34 | 2.67 | 2.67 | 2.15 | 1.24 | 1.65 | 0.24 |

| Salix caprea | 1.37 | 1.16 | 1.46 | 1.16 | 1.36 | 0.85 | 0.60 | 0.50 |

| Sorbus aucuparia | 1.27 | 1.25 | 1.46 | 0.94 | 1.00 | 1.07 | 0.44 | 0.56 |

| Tectona grandis | 18.00 | 16.96 | 7.83 | 2.08 | 2.43 | 1.04 | 1.17 | 0.16 |

| Tilia cordata | 0.89 | 1.04 | 1.39 | 0.92 | 1.43 | 0.83 | 0.38 | 0.86 |

| Ulmus glabra | 7.33 | 1.12 | 1.66 | 1.14 | 1.31 | 0.91 | 0.49 | 0.39 |

| Wood Species | kinh | kwa | vrel. | |||||

|---|---|---|---|---|---|---|---|---|

| br | wr | soil | LWU | VU | WR | CWU | ||

| Abies alba | 1.33 | 1.22 | 1.24 | 0.91 | 1.09 | 0.96 | 0.68 | 1.14 |

| Juniperus communis | 13.05 | 13.11 | 7.53 | 1.30 | 1.43 | 0.77 | 1.20 | 0.32 |

| Larix decidua | 4.13 | 6.15 | 2.30 | 1.81 | 1.39 | 0.98 | 1.87 | 0.34 |

| Larix sibirica | 3.32 | 1.55 | 4.86 | 1.01 | 1.30 | 1.05 | 0.46 | 0.45 |

| Picea sitchensis | 1.09 | 1.82 | 1.14 | 1.17 | 1.03 | 1.03 | 3.92 | 0.86 |

| Pinus spp. sw (Southern pine) | 2.38 | 10.88 | 0.87 | 0.89 | 1.01 | 0.69 | 0.58 | 0.76 |

| Pinus radiata sw | 1.95 | 0.89 | 1.16 | 0.63 | 0.92 | 1.29 | 0.85 | 0.98 |

| Pinus sylvestris | 2.98 | 6.85 | 1.86 | 1.06 | 1.21 | 0.89 | 1.37 | 0.47 |

| P. sylvestris sw | 0.97 | 0.91 | 1.14 | 1.00 | 1.08 | 0.88 | 1.03 | 0.83 |

| Pseudotsuga menziesii | 3.46 | 9.30 | 3.34 | 1.61 | 1.25 | 0.93 | 2.84 | 0.55 |

| P. menziesii sw | 1.63 | 4.66 | 1.43 | 1.14 | 1.11 | 0.92 | 1.01 | 0.83 |

| Thuja plicata (N.-America) | 16.73 | 11.67 | 2.63 | 1.13 | 1.61 | 0.59 | 0.27 | 0.42 |

| T. plicata (Europe) | 18.00 | 11.10 | 1.31 | 0.78 | 1.29 | 0.81 | 0.56 | 0.35 |

| Wood Species and Treatment | kinh | kwa | vrel. | |||||

|---|---|---|---|---|---|---|---|---|

| br | wr | Soil | LWU | VU | WR | CWU | ||

| F. sylvatica—TM | 9.60 | 7.60 | 4.68 | 1.79 | 2.86 | 0.43 | 3.24 | 0.02 |

| P. abies—TM | 8.67 | 4.95 | 2.98 | 6.99 | 2.09 | 6.44 | 1.40 | 0.34 |

| P. sylvestris—TM | 8.74 | 9.72 | 5.36 | 1.87 | 1.80 | 1.70 | 1.47 | 0.53 |

| F. excelsior—OHT | 18.00 | 9.71 | 11.79 | 1.99 | 2.91 | 0.60 | 1.60 | 0.07 |

| P. abies—OHT | 18.00 | 18.00 | 9.66 | 1.73 | 2.35 | 0.51 | 0.88 | 0.16 |

| Pinus spp. sw (Southern pine)—AC | 18.00 | 18.00 | 17.78 | 1.32 | 2.86 | 0.31 | 0.76 | 0.04 |

| P. sylvestris P. radiata sw—AC | 18.00 | 18.00 | 16.69 | 1.57 | 3.01 | 1.43 | 1.28 | 0.07 |

| A. platanoides—FA | 14.72 | 10.09 | 3.86 | 1.89 | 2.92 | 0.23 | 1.08 | 0.05 |

| Pinus spp. sw (Southern pine)—FA | 10.88 | 12.67 | 6.54 | 1.73 | 2.23 | 0.40 | 1.45 | 0.12 |

| P. sylvestris sw—FA | 18.00 | 18.00 | 7.53 | 2.79 | 3.30 | 0.23 | 1.54 | 0.27 |

| Wood Species and Treatment | kinh | kwa | vrel. | |||||

|---|---|---|---|---|---|---|---|---|

| br | wr | Soil | LWU | VU | WR | CWU | ||

| P. sylvestris, CCA, 2 kg/m3 | 18.00 | 18.00 | 5.12 | 0.92 | 0.97 | 0.87 | 2.49 | 0.10 |

| P. sylvestris, CCA, 4 kg/m3 | 18.00 | 18.00 | 7.79 | 1.34 | 0.92 | 1.22 | 1.35 | 0.13 |

| P. sylvestris, CCA, 9 kg/m3 | 9.66 | 18.00 | 11.87 | 0.83 | 1.02 | 0.88 | 1.02 | 0.06 |

| P. abies, Cu (II) sulph. low | 6.75 | 10.37 | 1.82 | 0.90 | 0.80 | 0.97 | 1.04 | 0.69 |

| P. abies, Cu (II) sulph. high | 8.77 | 10.54 | 2.66 | 0.89 | 0.77 | 1.31 | 0.81 | 0.63 |

| P. abies, CuEA low | 7.13 | 8.94 | 2.37 | 0.88 | 0.90 | 1.28 | 0.94 | 0.61 |

| P. abies, CuEA high | 8.00 | 7.15 | 2.00 | 0.97 | 0.92 | 0.90 | 1.10 | 0.65 |

| P. abies, CuEAOA low | 6.48 | 8.80 | 1.72 | 1.04 | 0.98 | 1.16 | 0.91 | 0.11 |

| P. abies, CuEAOA high | 7.34 | 6.12 | 1.98 | 0.98 | 0.93 | 1.06 | 1.50 | 0.57 |

| P. abies, CuEAOAQuat low | 13.87 | 9.95 | 1.45 | 0.87 | 1.03 | 0.94 | 0.83 | 0.21 |

| P. abies, CuEAOAQuat high | 16.42 | 7.78 | 1.84 | 0.90 | 1.10 | 0.75 | 1.16 | 0.01 |

| P. abies, BorEAOAQuat low | 12.53 | 9.76 | 0.85 | 0.99 | 0.89 | 0.95 | 1.41 | 0.86 |

| P. abies, BorEAOAQuat high | 13.00 | 8.30 | 0.88 | 1.08 | 0.75 | 1.08 | 4.28 | 0.61 |

| P. abies, Cu 0.25%, dip. 8-h | 11.43 | 16.02 | 1.47 | 1.19 | 0.83 | 0.51 | 0.79 | 0.58 |

| P. abies, Cu 0.25%, dip. 24-h | 13.71 | 18.00 | 1.71 | 1.17 | 0.74 | 0.78 | 0.71 | 0.46 |

| P. abies, Cu 0.25%, vac. | 18.00 | 18.00 | 3.57 | 1.14 | 0.73 | 0.77 | 0.81 | 0.17 |

| P. abies, Cu 0.25%, vac. + press. | 16.01 | 15.30 | 4.50 | 1.20 | 0.83 | 0.45 | 0.75 | 0.03 |

| P. abies, Cu 0.5%, dip. 8-h | 13.76 | 18.00 | 1.54 | 1.21 | 0.81 | 0.36 | 1.01 | 0.39 |

| P. abies, Cu 0.5%, dip. 24-h | 14.48 | 18.00 | 2.94 | 1.16 | 0.83 | 0.33 | 1.02 | 0.42 |

| P. abies, Cu 0.5%, vac. | 15.35 | 15.25 | 3.18 | 1.25 | 0.80 | 0.32 | 0.97 | 0.13 |

| P. abies, Cu 0.5%, vac. + press. | 15.19 | 15.07 | 3.60 | 1.29 | 0.72 | 0.45 | 0.88 | 0.15 |

| P. sylvestris, Cu 0.25%, dip. 8-h | 13.27 | 10.20 | 1.39 | 1.31 | 0.90 | 0.36 | 4.96 | 0.16 |

| P. sylvestris, Cu 0.25%, dip. 24-h | 13.69 | 11.08 | 2.38 | 1.34 | 0.88 | 0.30 | 1.86 | 0.09 |

| P. sylvestris, Cu 0.25%, vac. | 18.00 | 18.00 | 2.01 | 1.28 | 0.80 | 0.53 | 2.64 | 0.09 |

| P. sylvestris, Cu 0.25%, vac. + press. | 18.00 | 17.64 | 3.03 | 1.14 | 0.76 | 0.33 | 1.81 | 0.00 |

| P. sylvestris, Cu 0.5%, dip. 8-h | 13.83 | 14.45 | 2.55 | 1.20 | 0.77 | 0.26 | 2.63 | 0.13 |

| P. sylvestris, Cu 0.5%, dip. 24-h | 16.94 | 15.84 | 2.75 | 1.21 | 0.76 | 0.32 | 2.23 | 0.09 |

| P. sylvestris, Cu 0.5%, vac. | 17.23 | 18.00 | 3.59 | 1.22 | 0.67 | 0.53 | 1.60 | 0.03 |

| P. sylvestris, Cu 0.5%, vac. + press. | 15.49 | 17.34 | 3.28 | 1.22 | 0.65 | 0.37 | 2.73 | 0.00 |

| L. decidua, Cu 0.25%, dip. 24-h | 11.94 | 11.58 | 1.03 | 2.10 | 0.85 | 0.54 | 15.49 | 0.00 |

| L. decidua, Cu 0.25%, vac. + press. | 17.99 | 18.00 | 1.10 | 1.85 | 0.84 | 0.28 | 5.63 | 0.17 |

| L. decidua, Cu 0.5%, dip. 24-h | 13.84 | 14.53 | 1.14 | 2.02 | 0.94 | 0.18 | 4.30 | 0.09 |

| L. decidua, Cu 0.5%, vac. | 17.60 | 18.00 | 0.87 | 2.03 | 0.93 | 0.28 | 17.00 | 0.06 |

| L. decidua, Cu 0.5%, vac. + press. | 14.78 | 14.00 | 1.32 | 1.73 | 0.76 | 0.19 | 4.42 | 0.20 |

| P. sylvestris, metal-free organic | 18.00 | 18.00 | 2.41 | 0.85 | 1.05 | 0.78 | 0.48 | 0.09 |

| kinh | kwa | ||||||

|---|---|---|---|---|---|---|---|

| LWU | VU | WR | CWU | Mean 1 | Min 2 | 1 3 | |

| Soil | 0.133 0.218 (2) | 0.059 0.072 (4) | 0.000 0.202 (1) | 0.291 0.295 (14) | 0.168 0.202 (3) | 0.010 >0.015 (∞) | 0.110 0.166 (3) |

| br:wr,Mean | 0.298 0.299 (26) | 0.255 0.267 (34) | 0.076 0.112 (38) | 0.369 0.375 (36) | 0.341 - | 0.138 0.172 (36) | 0.311 0.313 (26) |

| Min 2 | 0.150 0.241 (2) | 0.073 0.087 (4) | 0.000 >0.002 (∞) | 0.376 0.381 (36) | 0.189 0.217 (3) | 0.018 >0.021 (∞) | 0.133 0.190 (3) |

| Soil:no Soil,Mean | 0.288 0.291 (27) | 0.220 0.241 (35) | 0.045 0.081 (38) | 0.377 0.383 (36) | 0.337 - | 0.109 0.148 (37) | 0.311 0.314 (26) |

| Mean 1 | 0.295 0.297 (26) | 0.238 0.255 (35) | 0.058 0.095 (38) | 0.376 0.381 (36) | 0.342 - | 0.122 0.160 (37) | 0.315 0.317 (26) |

| 1 3 | 0.295 0.297 (34) | 0.000 0.035 (1) | 0.209 0.258 (1) | 0.176 0.177 (16) | 0.094 0.097 (15) | 0.110 0.126 (1) | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brischke, C.; Alfredsen, G.; Humar, M.; Conti, E.; Cookson, L.; Emmerich, L.; Flæte, P.O.; Fortino, S.; Francis, L.; Hundhausen, U.; et al. Modelling the Material Resistance of Wood—Part 2: Validation and Optimization of the Meyer-Veltrup Model. Forests 2021, 12, 576. https://doi.org/10.3390/f12050576

Brischke C, Alfredsen G, Humar M, Conti E, Cookson L, Emmerich L, Flæte PO, Fortino S, Francis L, Hundhausen U, et al. Modelling the Material Resistance of Wood—Part 2: Validation and Optimization of the Meyer-Veltrup Model. Forests. 2021; 12(5):576. https://doi.org/10.3390/f12050576

Chicago/Turabian StyleBrischke, Christian, Gry Alfredsen, Miha Humar, Elena Conti, Laurie Cookson, Lukas Emmerich, Per Otto Flæte, Stefania Fortino, Lesley Francis, Ulrich Hundhausen, and et al. 2021. "Modelling the Material Resistance of Wood—Part 2: Validation and Optimization of the Meyer-Veltrup Model" Forests 12, no. 5: 576. https://doi.org/10.3390/f12050576