Study of the Cutting Mechanism of Oil Tree Peony Stem

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation of Stem

2.2. Stem Cutting Experiment

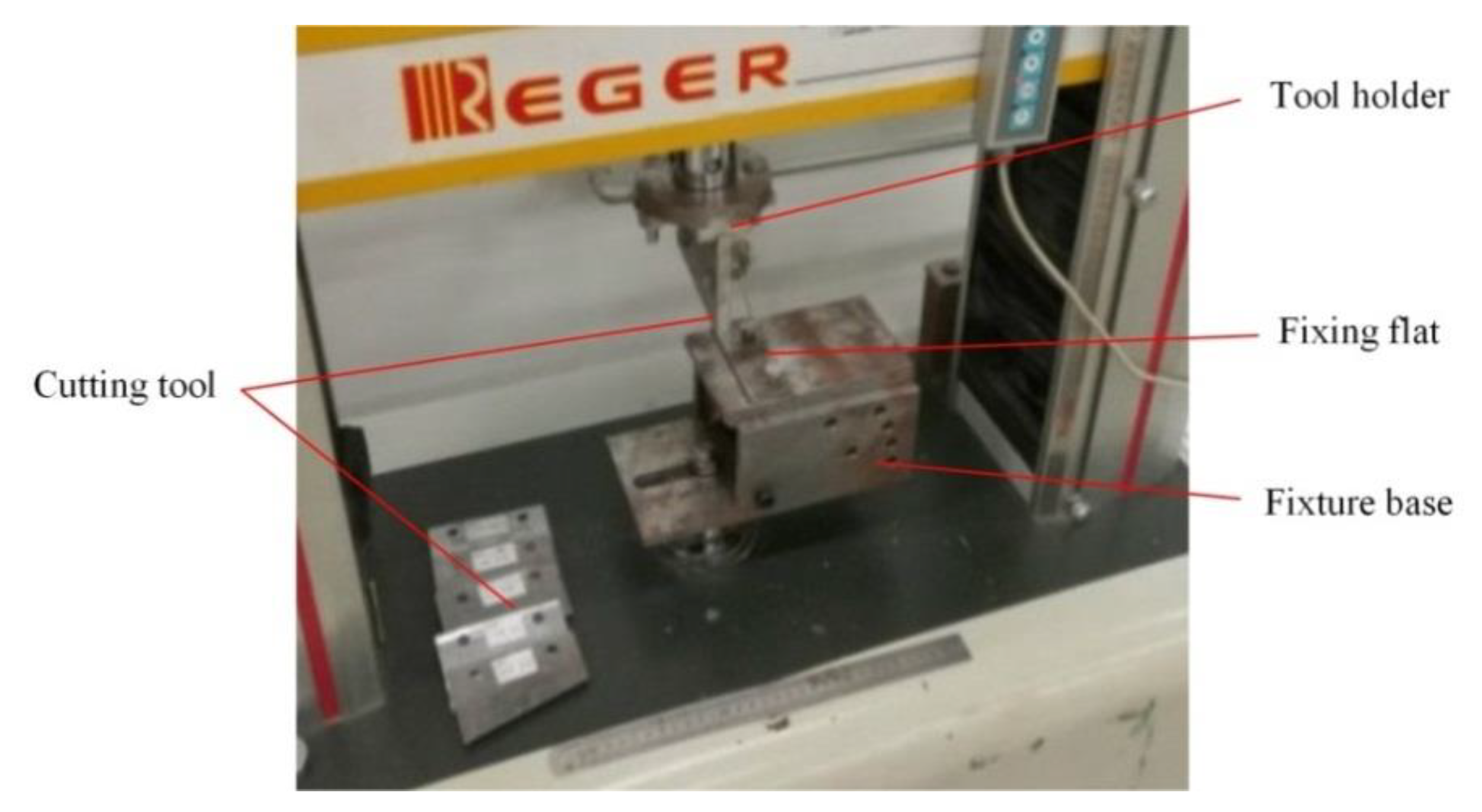

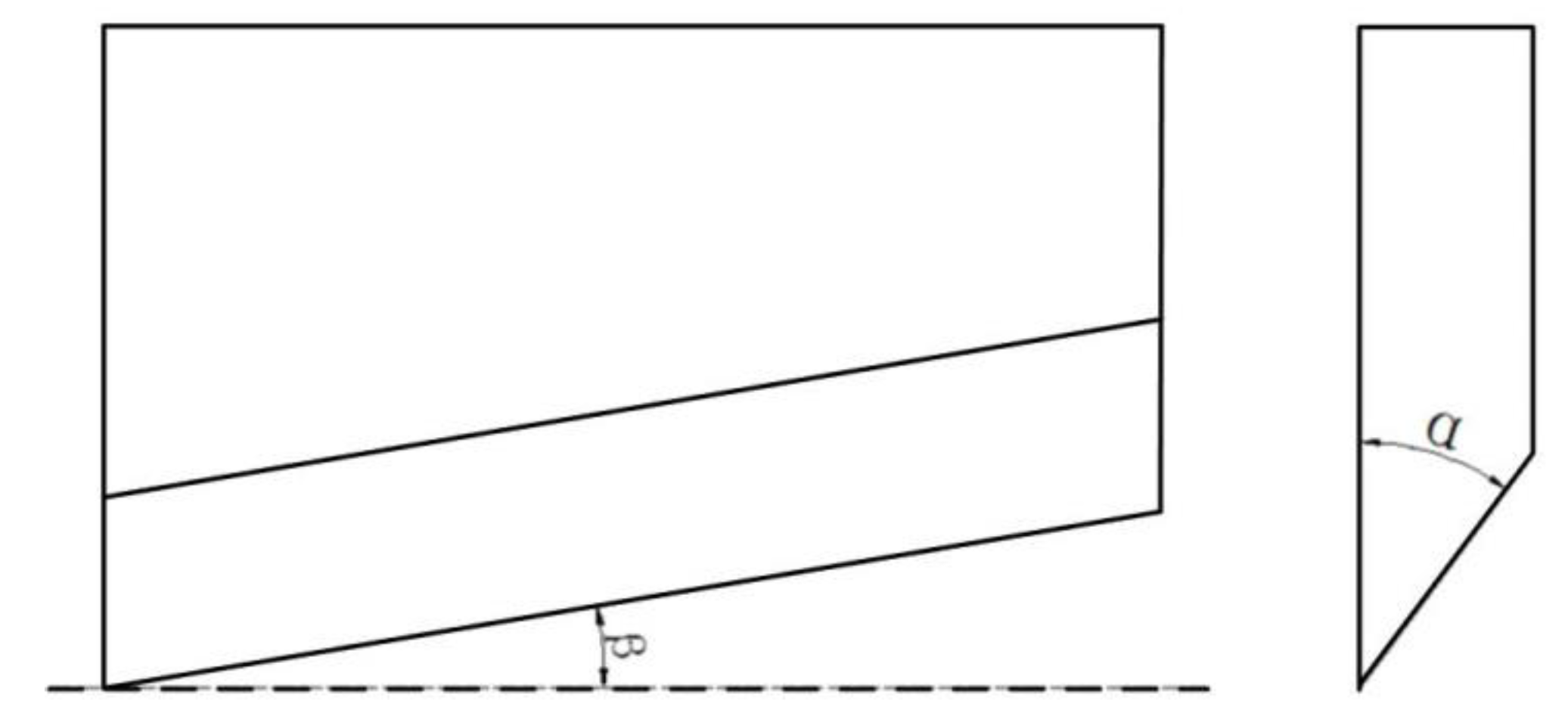

2.2.1. Cutting Device and Cutting Tools

2.2.2. Cutting Speed

2.2.3. Experiment Process

3. Results

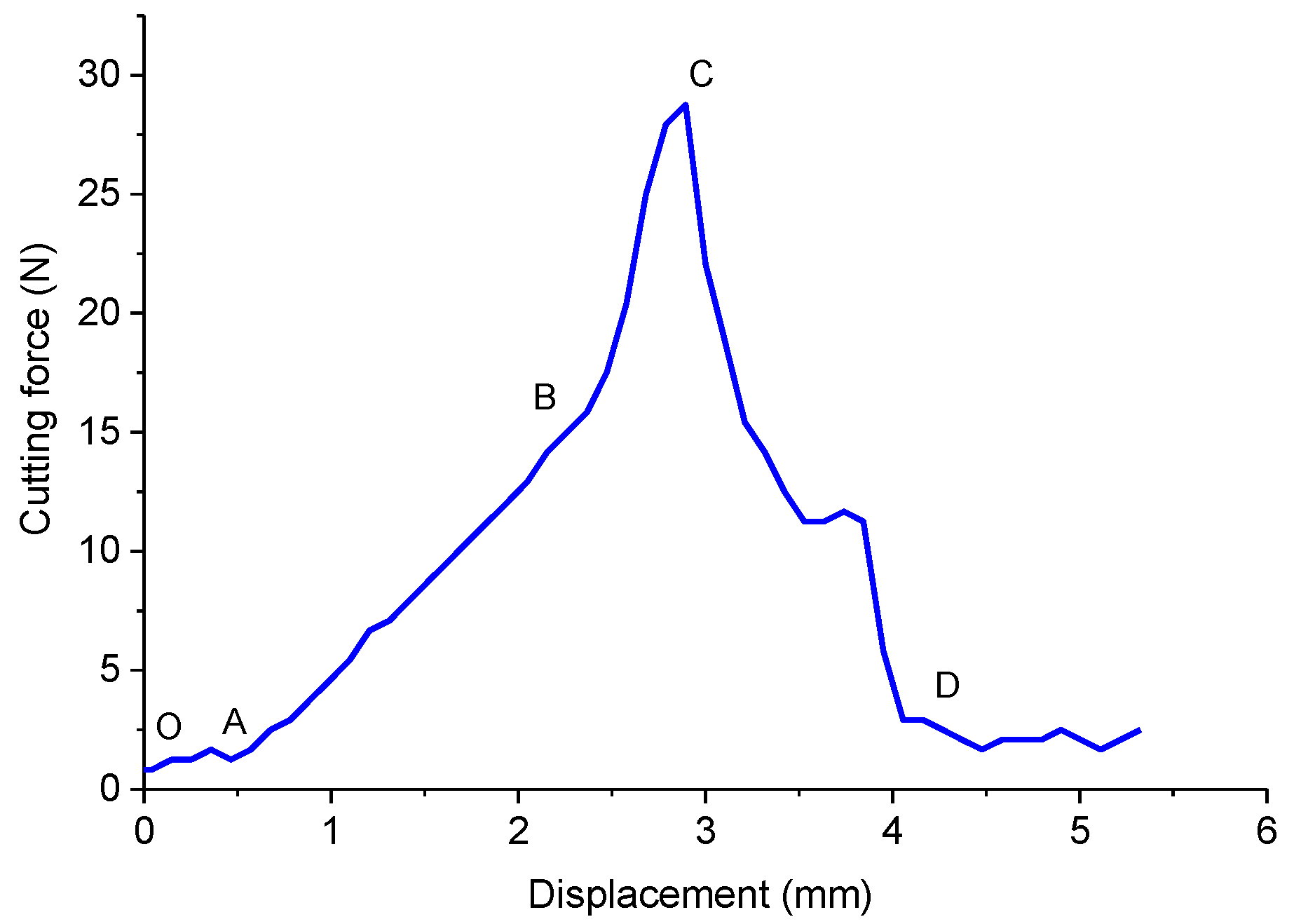

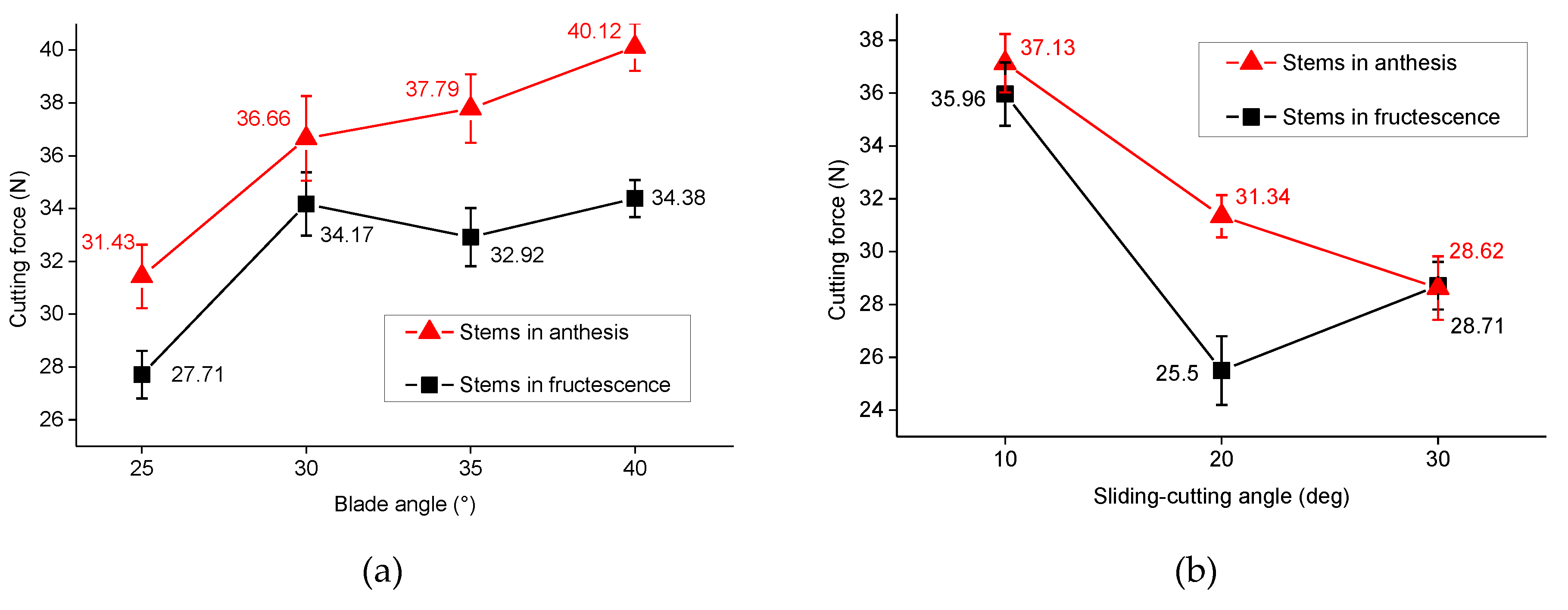

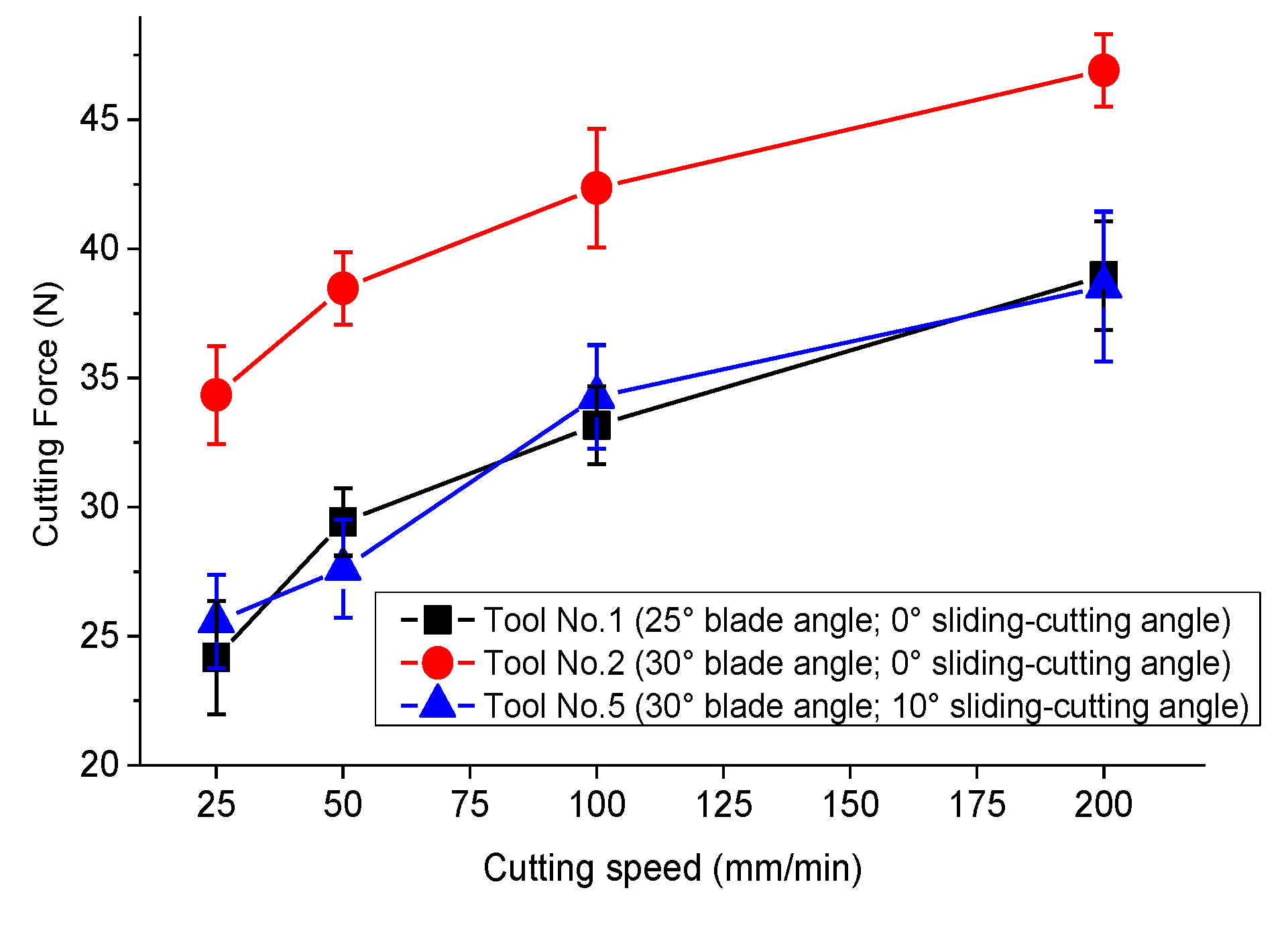

3.1. Cutting Force

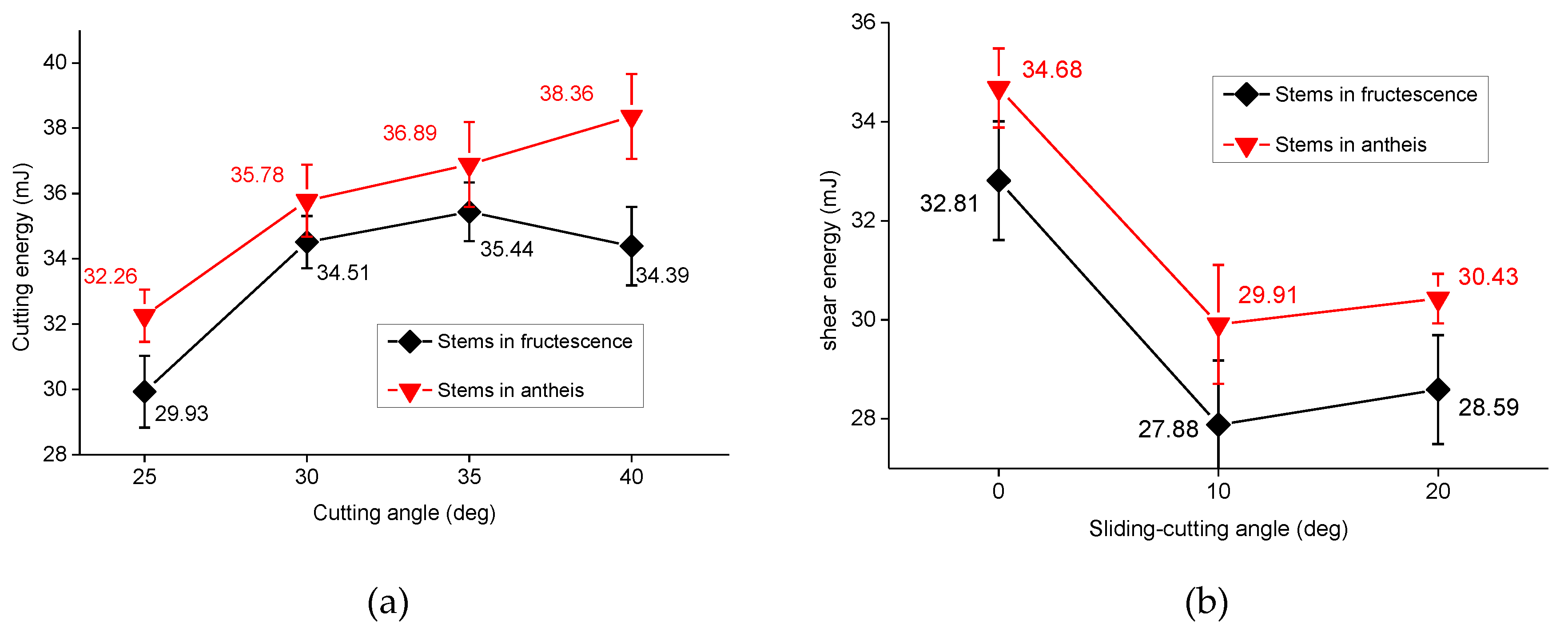

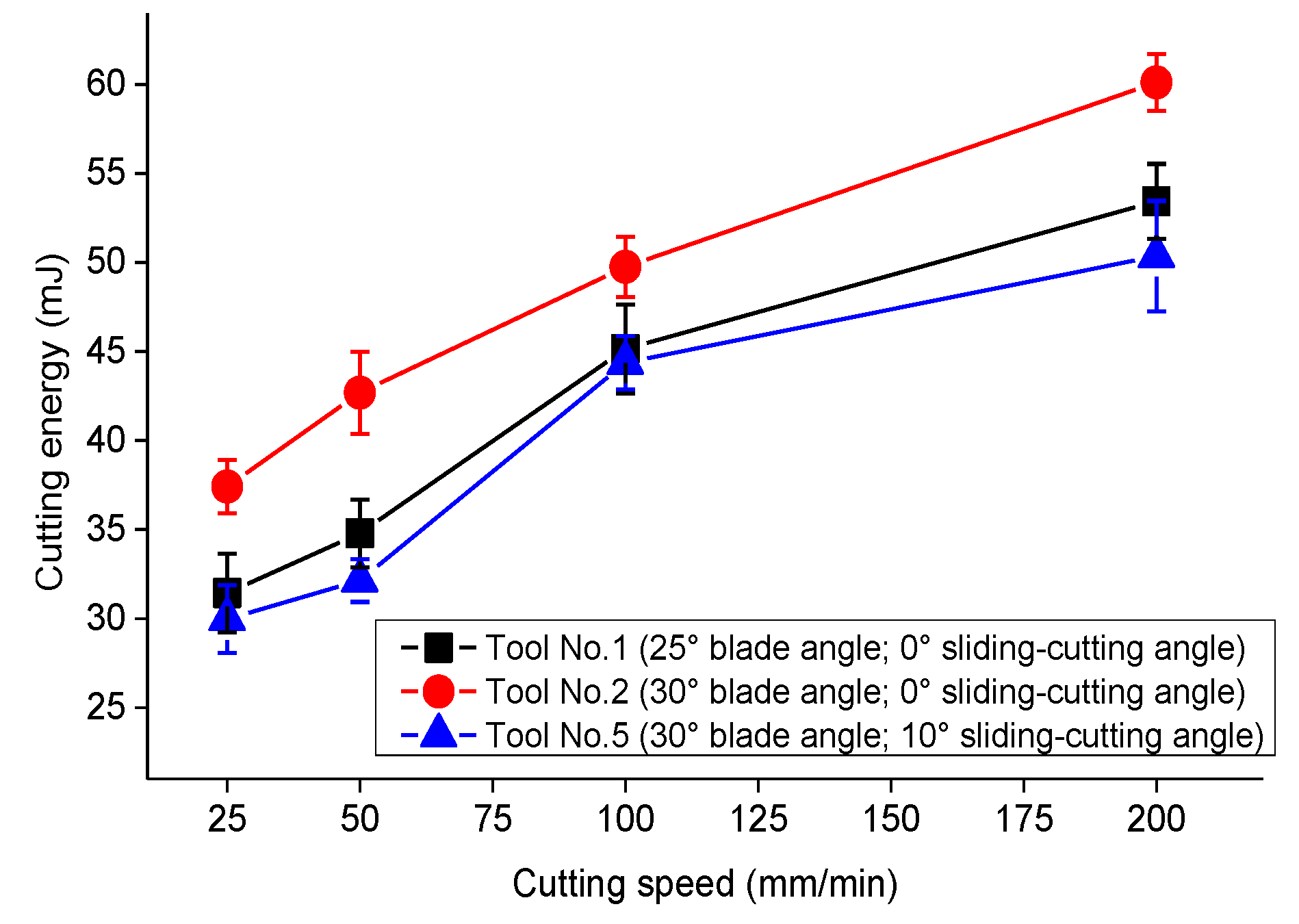

3.2. Cutting Energy

4. Discussion

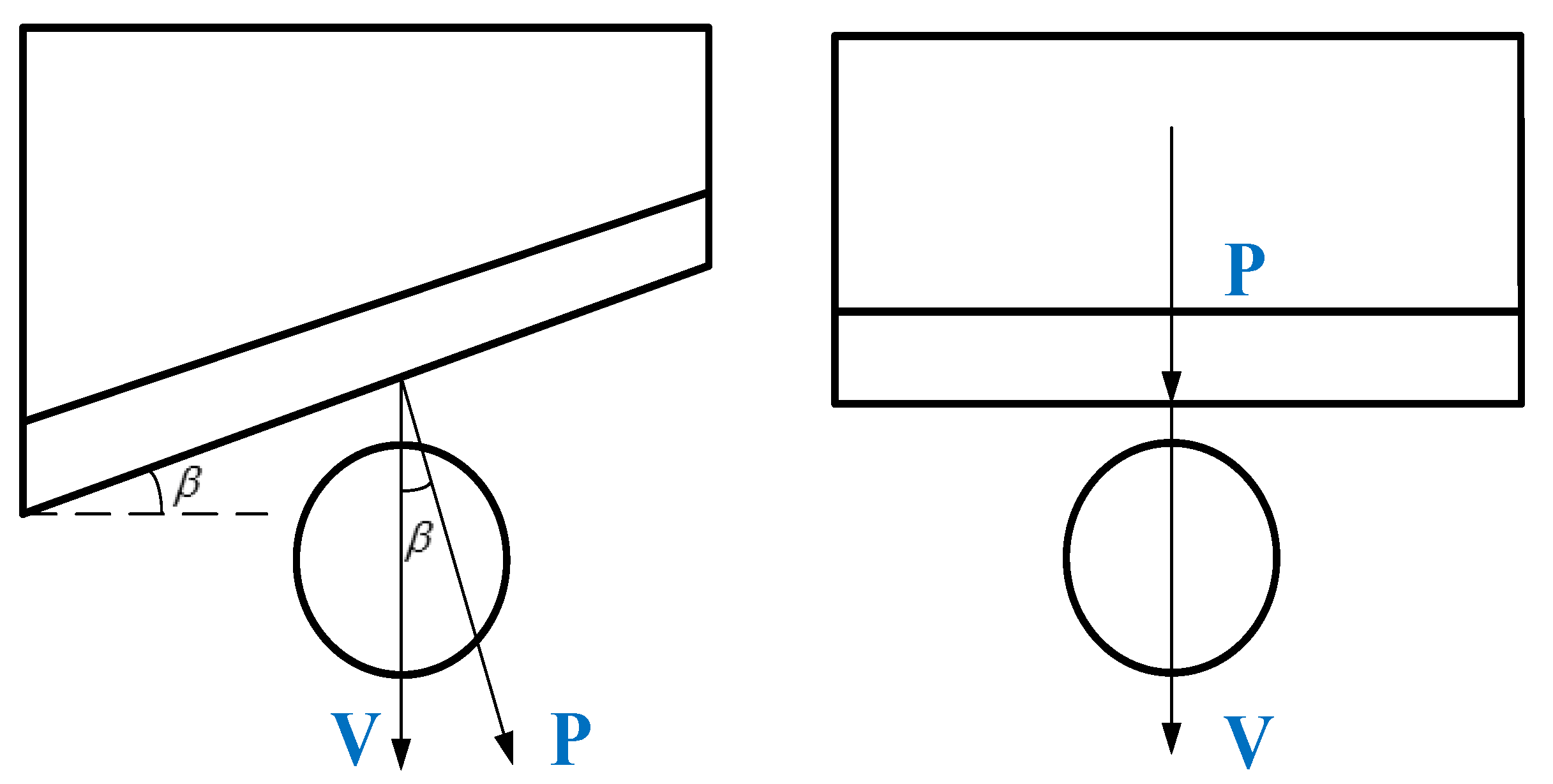

4.1. Theoretical Analysis of Cutting Tool Geometric Parameters

4.2. Cutting Tool Geometric Parameters in Shrub Cutting

4.3. About Cutting Speed

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Sun, X.; Li, W.; Li, J.; Zu, Y.; Hse, C.; Xie, J. Process optimisation of microwave-assisted extraction of peony (Paeonia suffruticosa Andr.) seed oil using hexane-ethanol mixture and its characterisation. Int. J. Food Sci. Technol. 2016, 51, 2663–2673. [Google Scholar] [CrossRef]

- Su, J.; Ma, C.; Liu, C.; Gao, C.; Nie, R.; Wang, H. Hypolipidemic activity of peony seed oil rich in α-linolenic, is mediated through inhibition of lipogenesis and upregulation of fatty acid β-oxidation. J. Food Sci. 2016, 81, H1001–H1009. [Google Scholar] [CrossRef] [PubMed]

- Mao, Y.; Han, J.; Tian, F.; Tang, X.; Hu, Y.; Guan, Y. Chemical composition analysis, sensory, and feasibility study of tree peony seed. J. Food Sci. 2017, 82, 553–561. [Google Scholar] [CrossRef]

- Zhao, D.; Zhang, X.; Fang, Z.; Wu, Y.; Tao, J. Physiological and transcriptomic analysis of tree peony (Paeonia Section Moutan DC.) in response to drought stress. Forests 2019, 10, 135. [Google Scholar] [CrossRef]

- Zhang, D. Design and Implementation of Oil Peony Fruit Picking Device; Beijing Forestry University: Beijing, China, 2016. [Google Scholar]

- Zhang, Y. Design and Implementation of Self-Propelled Oil Peony Fruit Picking Machine; Beijing Forestry University: Beijing, China, 2017. [Google Scholar]

- Derikvand, M.; Kotlarewski, N.; Lee, M.; Jiao, H.; Nolan, G. Characterisation of physical and mechanical properties of unthinned and unpruned plantation-grown Eucalyptus nitens H.Deane & maiden lumber. Forests 2019, 10, 1949. [Google Scholar] [CrossRef]

- Felker, P.; McLauchlan, R.A.; Conkey, A.; Brown, S. Case study: Development of a swath harvester for small diameter (. Biomass Bioenergy 1999, 17, 1–17. [Google Scholar] [CrossRef]

- Fen, C.; Gao, Z.; Yu, G.; Liu, Y. Effect of cutting machine parameters on salix branch’s peak cutting force. J. For. Environ. 2019, 39, 107–112. [Google Scholar]

- Facello, A.; Cavallo, E.; Magagnotti, N.; Paletto, G.; Spinelli, R. The effect of chipper cut length on wood fuel processing performance. Fuel Process. Technol. 2013, 116, 228–233. [Google Scholar] [CrossRef]

- Abdallah, R.; Sébastien, A.; Pierre, J. Experimental study about the effects of disc chipper settings on the distribution of wood chip size. Biomass Bioenergy 2011, 35, 843–852. [Google Scholar] [CrossRef]

- Bello, S.R.; Onilude, M.A. Force relations and dynamics of cutting knife in a vertical disc mobile wood chipper. Leonardo Electron. J. Pract. Technol. 2011, 10, 17–34. [Google Scholar]

- Phillip, C.; Clairmont, L.; Sunil, K.; Tony, E.; Alan, C. Cutting energy characteristics of miscanthus x giganteus stems with varying oblique angle and cutting speed. Biosyst. Eng. 2012, 112, 42–48. [Google Scholar] [CrossRef]

- Sunil, K.; Tony, E.; Alan, C. Effect of blade oblique angle and cutting speed on cutting energy for energycane stems. Biosyst. Eng. 2015, 133, 64–70. [Google Scholar] [CrossRef]

- Persson, S. Mechanics of Cutting Plant Material; Asae Monograph No 7 (Book 7); American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 1987. [Google Scholar]

- Srivastava, A.; Goering, C.; Rohrbach, R.; Buckmaster, D. Hay and forage harvesting. In Engineering Principles of Agricultural Machines, 2nd ed.; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2007; pp. 325–402. [Google Scholar]

- Prasad, J.; Gupta, C. Mechanical properties of maize stalk as related to harvesting. J. Agric. Eng. Res. 1975, 21, 79–87. [Google Scholar] [CrossRef]

- McRandal, D.; McNulty, P. Impact cutting behaviour of forage crops. J. Agric. Eng. Res. 1978, 23, 313–328. [Google Scholar] [CrossRef]

- Yiljep, Y.; Mohammed, U. Effect of knife velocity on cutting energy and efficiency during impact cutting of sorghum stalk. Agric. Eng. Int. CIGR J. 2005, 8, 493–512. [Google Scholar]

- O’Doghekty, M.; Gale, G. Laboratory studies of the effect of blade parameters and stem configuration on the dynamics of cutting grass. J. Agric. Eng. Res. 1991, 49, 99–111. [Google Scholar] [CrossRef]

- Dauda, S.; Ahmad, D.; Khalina, A.; Jamarei, O. Effect of cutting speed on cutting torque and cutting power of varying kenaf-stem diameters at different moisture contents. Trop. Agric. Sci. 2015, 38, 549–561. [Google Scholar]

- Taghijarah, H.; Ahmadi, H.; Ghahderijani, M.; Tavakoli, M. Cutting forces and energy during an impact cut of sugarcane stalks. Aust. J. Crop Sci. 2011, 5, 630–634. [Google Scholar] [CrossRef]

- Clementson, C.; Hansen, A. Pilot study of manual sugarcane harvesting using biomechanical analysis. Trans. ASABE 2008, 14, 309–320. [Google Scholar] [CrossRef]

- Igathinathane, C.; Womac, A.; Sokhansanj, S. Corn stem orientation effect on mechanical cutting. Biosyst. Eng. 2010, 107, 97–106. [Google Scholar] [CrossRef]

- Zhang, Y.; Gui, Q.; Guo, Y. Experiment and analysis of cutting mechanical properties of millet stem. Trans. Chin. Soc. Agric. Mach. 2019, 50, 146–155,162. [Google Scholar] [CrossRef]

- Al-Salloum, Y.; Almusallam, T.; Ibrahim, S.; Abbas, H.; Alsayed, S. Rate dependent behavior and modeling of concrete based on shpb experiments. Cem. Concr. Compos. 2015, 55, 34–44. [Google Scholar] [CrossRef]

- Oudjene, M.; Khelifa, M. Elasto-plastic constitutive law for wood behaviour under compressive loadings. Constr. Build. Mater. 2013, 11, 3359–3366. [Google Scholar] [CrossRef]

- Pan, S. On the theory of sliding cutting and the choice of its angle. J. Huazhong Agric. Coll. 1982, 6, 64–69. [Google Scholar] [CrossRef]

- Xun, H. Research of the theory of sliding cutting. Trans. Chin. Soc. Agric. Mach. 1979, 10, 107–111. [Google Scholar]

- Zhong, W.; Den, Z.; Huang, X. Investigation on Anisotropic Behavior of Spruce Mechanical Properties Under Medium Strain Rate Loading Conditions. Eng. Mech. 2016, 33, 25–32. [Google Scholar] [CrossRef]

| Collecting Date | Numbers of Stems | Growth Stage |

|---|---|---|

| 20 April 2018 | 10 | Anthesis |

| 19 August 2018 | 10 | Fructescence |

| Tool Number | Blade Angle (deg) | Sliding-Cutting Angle (deg) |

|---|---|---|

| 1 | 25 | 0 |

| 2 | 30 | 0 |

| 3 | 35 | 0 |

| 4 | 40 | 0 |

| 5 | 30 | 10 |

| 6 | 30 | 20 |

| Cutting Speed (mm/min) | Cutting Tool |

|---|---|

| 25 | Tool No.1 (25° blade angle, 0° sliding-cutting angle) |

| 50 | |

| 100 | |

| 200 | |

| 25 | Tool No.2 (30° blade angle, 0°sliding-cutting angle) |

| 50 | |

| 100 | |

| 200 | |

| 25 | Tool No.5 (30° blade angle, 10°sliding-cutting angle) |

| 50 | |

| 100 | |

| 200 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Zhao, D.; Zhao, J. Study of the Cutting Mechanism of Oil Tree Peony Stem. Forests 2020, 11, 760. https://doi.org/10.3390/f11070760

Liu J, Zhao D, Zhao J. Study of the Cutting Mechanism of Oil Tree Peony Stem. Forests. 2020; 11(7):760. https://doi.org/10.3390/f11070760

Chicago/Turabian StyleLiu, Jiaming, Dong Zhao, and Jian Zhao. 2020. "Study of the Cutting Mechanism of Oil Tree Peony Stem" Forests 11, no. 7: 760. https://doi.org/10.3390/f11070760

APA StyleLiu, J., Zhao, D., & Zhao, J. (2020). Study of the Cutting Mechanism of Oil Tree Peony Stem. Forests, 11(7), 760. https://doi.org/10.3390/f11070760