1. Introduction

Recently, the average annual rate of increase in multi-unit dwellings in South Korea was recorded at 5.6% and despite the decline in the percentage increase resulting from low national growth, their housing market share has steadily been on the rise. Those living in multi-unit dwellings, which are the most common type of housing in South Korea, are likely to be exposed to noise from dwelling as the walls, floors, and ceilings are shared by the vertically and horizontally adjacent housing units. With a growing demand for improved quality of life, there have been frequent cases of civil complaints and disputes in relation to floor impact noises. To be more specific, the number of disputes filed due to floor impact noise more than doubled from 7021 cases in 2012 to 15,485 cases in 2013 [

1,

2,

3]. In an effort to resolve this issue, the government of South Korea has revised the Criteria for the interlayer floor impact sound regulation in multi-family residential housing [

4]. According to the revised standards, the standard floor system is to be excluded, and a floor impact noise performance rating certification institution is to check the performance of the insulation system and introduce a certified floor system to judge the conformity of the system in relation to the noise insulation performance. It should be noted that the noise insulation performance is defined as 43 dB (A) for direct impact noise in day time and 38 dB (A) for night time, and 45 dB (A) for airborne noise in day time and 40 dB (A) for night time at single number quantity (SNQ) with A-weighting. It also prescribes that a slab thickness of at least 160 mm has to be maintained for the frame structure, while in the case of other structures (walls, flat plates, mixed structures, etc.), additional experiments are to be conducted for a performance rating of the insulation against light- and heavyweight floor impact noise [

5].

Researches related to obtaining the best acoustic performance in buildings can be divided into two categories: one is to develop a new material and a floor system to implement higher acoustic insulation in buildings and the other is to exploit testing methods to characterize their acoustic performance. Branco and Godinho [

6] considered various types of lightweight mortars, which are cement mortars containing expanded polystyrene, expanded cork, and expanded clay granulates, to investigate acoustic performance. The acoustic characteristics of lightweight mortars were evaluated through laboratory tests using small-size acoustic chamber. From the results, a sensible impact sound reduction without any floor covering was obtained, especially for higher frequencies. Martins et al. [

7] determined the acoustic behavior of different constructive solutions based on two types of floor, i.e., timber and timber–concrete floor systems. The development of a new floor system is considered an alternative way to improve acoustic performance of a building.

Brancher et al. [

8] evaluated the acoustical performance of the proposed polymer waste based on the mortar. Thickness and replacement percentage of the natural aggregate by EVA (Ethylene Vinyl Acetate) were considered. Results of the impact noise test showed that the performance of 50% EVA replacement product reached an impact sound insulation of 23 dB compared to uncovered slab. They concluded that polymer waste addition decreased the mortar compressive strength, and EVA displayed characteristics of an influential material to intensify other features of the composite.

D’Alessandro et al. [

9] studied a sustainable lightweight concrete containing polymers derived from the recycling of sheets of electric wires. They measured structural properties of the sustainable lightweight concretes, i.e., dynamic stiffness, impact sound pressure reduction, and thermal conductivity. Finally, they concluded that the developed concrete can be successfully used for thermal and acoustic insulating lightweight screeds to be applied above the concrete structural slabs in floors. In addition, Antonio et al. [

10] developed a lightweight cement-based screeds containing cork granule waste. Acoustic performance of the proposed screeds was measured with/without a resilient layer between the heavyweight standard floor and a floating concrete layer. Three different screeds and three thicknesses were considered. It concluded that the impact sound reduction of resilient materials is related to their dynamic stiffness and results of dynamic stiffness are generally found to be related to the values of impact sound reduction when the cement/cork screed is used as floor covering. Kim et al. [

2] stated that the installation of lightweight and low stiffness materials between the concrete slab and the finishing covering can reduce a floor impact noise in buildings. Schiavi et al. [

11] investigated the acoustical performance and mechanical properties, such as dynamic stiffness, compressibility, and compressive creep, of different types of resilient materials in order to reduce transmitted impact noise. They also studied airflow resistivity as a physical parameter characterizing porous and fibrous sound absorbent materials. The evaluation of the dynamic stiffness of the porous and fibrous sound absorbent materials used as underlay in floating floor is needed. Experiments showed that airflow resistivity depends on the density increase, induced by static load, of the porous or fibrous materials [

12].

Maderuelo-Sanz et al. [

13] introduced a new recycled material made from granulated rubber for reducing impact noise and experimentally investigated the acoustical performance. Then the performance was compared to those of commercial products. Caniato et al. [

14] conducted twenty different layers to evaluate the time-depending performance, dynamic stiffness, compressibility, and compressive creep. Experimental results indicated that the presence of coating, different density, and contact shape has been proven to influence the acoustic performance. Baron et al. [

15] investigated that the performance of the floating floor depends on the mechanical properties of the insulation layer, e.g., the dynamic stiffness and mass per unit area. During the experiments, different excitation methods such as the use of a sine sweep, white noise or impact hammer were considered as an excitation signal. From the results, it is advisable to use a sine sweep excitation, as it is better than the other methods. Stewart et al. [

16] proposed a simplified approach allowing the dynamic stiffness of resilient layers. The proposed method gives the stiffness across a frequency range. Reasonable agreements with measurements are obtained. Cho [

17] introduced a method for measuring the creep-induced change of the dynamic stiffness. The proposed method can assess the creep-induced change of the dynamic stiffness and could be helpful to design a vibration isolation system. Monte et al. [

18] studied cork having a low density can be considered as a hydrophobic and viscoelastic materials with good thermal and acoustic insulation properties. A new polymer of inorganic oxides and cork composite with improved thermal and acoustic properties is reported.

Still, many researches have been conducted to solve the floor impact noise by utilizing experimental approaches, installing resilient materials, or considering a systematic analysis of many elements such as impact source, structural properties, etc. A major challenge in this research is that floor impact noise is influenced by a number of factors including slab thickness, spatial arrangement and indoor living space area [

19,

20]. Neves e Sousa and Gibbs proposed an analytical model in order to investigate the effects on impact sound transmission at low frequencies considering the location of the impact, type of floor, structural boundary conditions, floor and room dimensions, position of the receiver and room absorption [

21]. You and Jeon performed both finite element simulations and field measurements in order to investigate the effects of resilient isolators and viscoelastic resilient materials on suppressing floor impact noise. Results showed that the impact vibration acceleration level and floor impact sounds at low frequencies is significantly decreased due to the installation of resilient materials, whereas the impact sound pressure levels at low frequencies were increased as a result of the use of resilient isolators [

3]. Park et al. [

22] studied low-frequency impact sound transmission using a finite element vibration model and an experimental sound field using a rubber ball as an impact source in order to determine the influencing factors. The results indicated that the natural frequency of the floating structures influences low frequency impact sound insulation in that impact energy is attenuated above the natural frequency. In addition, the wave fields of the floating and base plates are coupled below the natural frequency, and dominate the impact sound fields. Recently, Park and Kim [

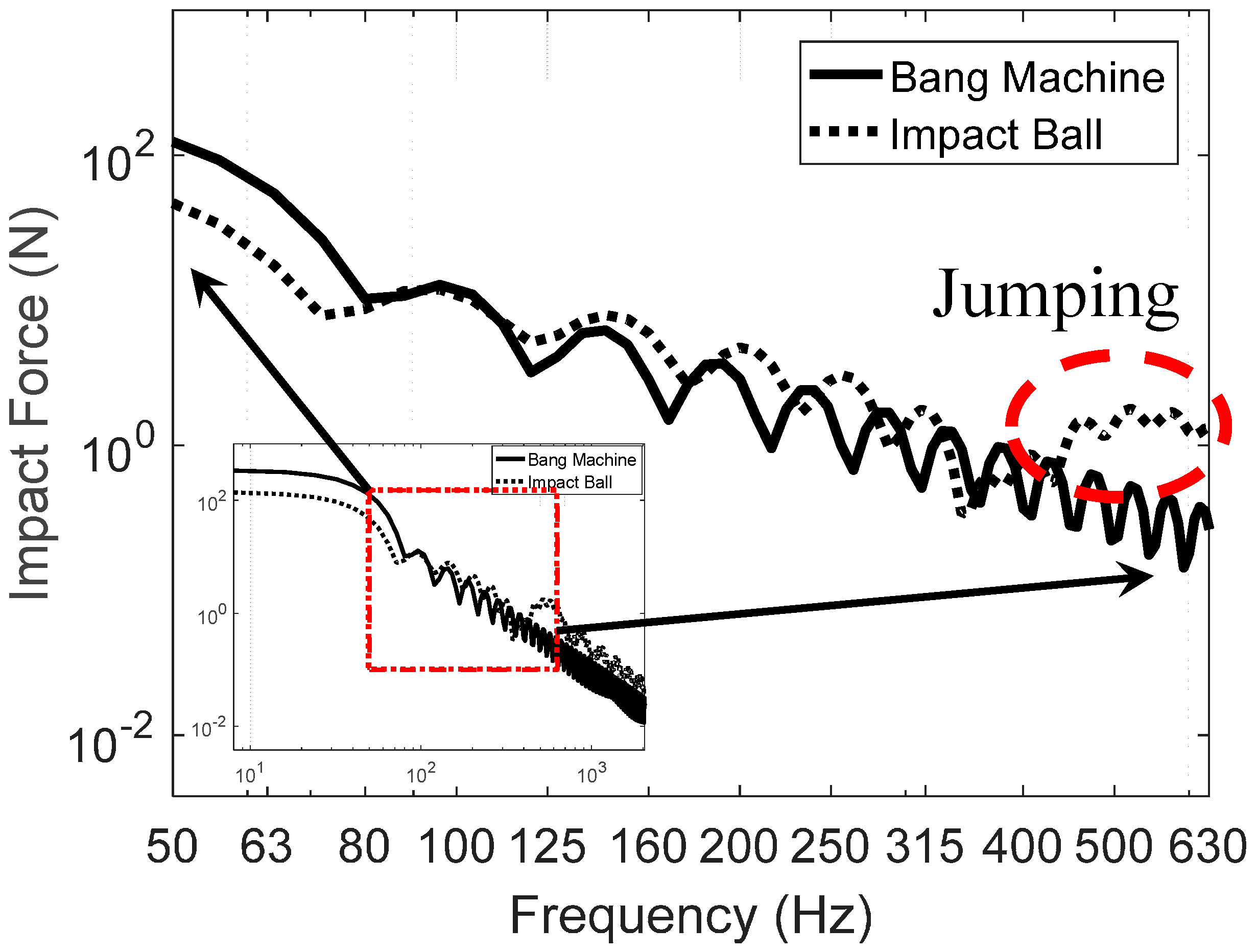

23] proposed an analytical impact force model for both bang machine and impact ball based on the actual measurements. The analytical force model was verified through a comparative review with Korean standards.

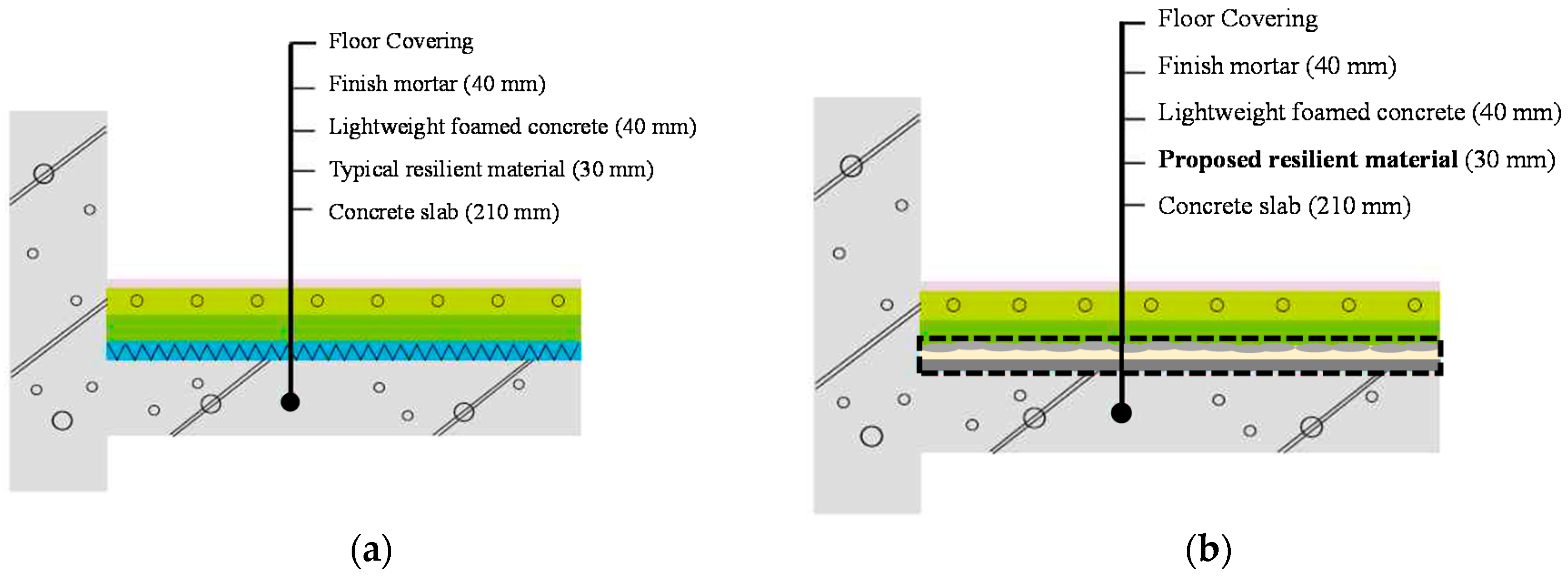

Accordingly, in order to resolve these issues, multiple measures such as use of hollow slabs have been proposed. There are economic and technical limitations in suppressing floor impact noise solely by increasing the thickness of the floor plate [

24,

25,

26]. Under these present circumstances, a resilient material is placed in between a concrete slab and lightweight foamed concrete to eliminate a substantial amount of floor impact noise. Detailed information related to the floor system adopted in this study will be discussed later. However, the currently used resilient materials are made with organic materials with low densities and dynamic stiffness such as EPS (Expanded Polystyrene) and EVA, and when these materials are placed in between the mineral-based concrete slab and foamed concrete, floating floors start to deform due to the use of heterogeneous materials. Moreover, the slab and resilient material do not completely adhere together when such resilient materials are installed on the top of the concrete slab. This can cause problems of resonance and amplification of certain frequencies in the event of impact on the upper part. There have been reports of cracking and settlement in the finish mortar caused by upper load, due to the varying densities of the resilient material and varying shapes of the floor plate (corrugated, embossed, flat, etc.). It has also been reported that the use of a ceramic resilient material such as glass wool or mineral wool effectively reduces floor impact noise, as it enhances strength and creates an integral floor structure, thereby inducing composite behavior [

2]. However, these materials, except mineral wool, are costly and exhibit high thermal conductivity, which limits their use. In order to mitigate the floor noise issues related to the use of resilient materials that are different from the floor structure, there is a need to develop a ceramic, mineral-based resilient material that can prevent resonance, enhance high stiffness, and have low thermal conductivity and high durability by mixing ceramic resins and mineral materials. Therefore, there is a great need to develop new resilient materials that can reduce floor impact noise after being installed to the floor system.

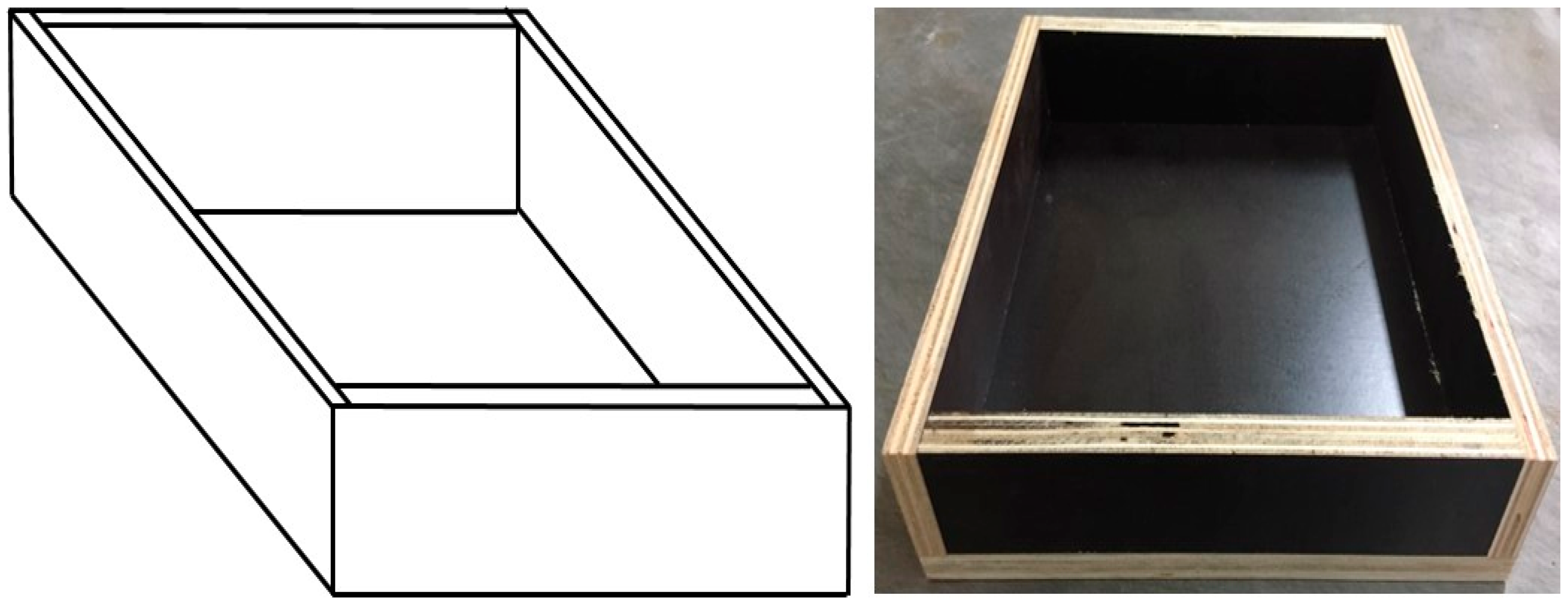

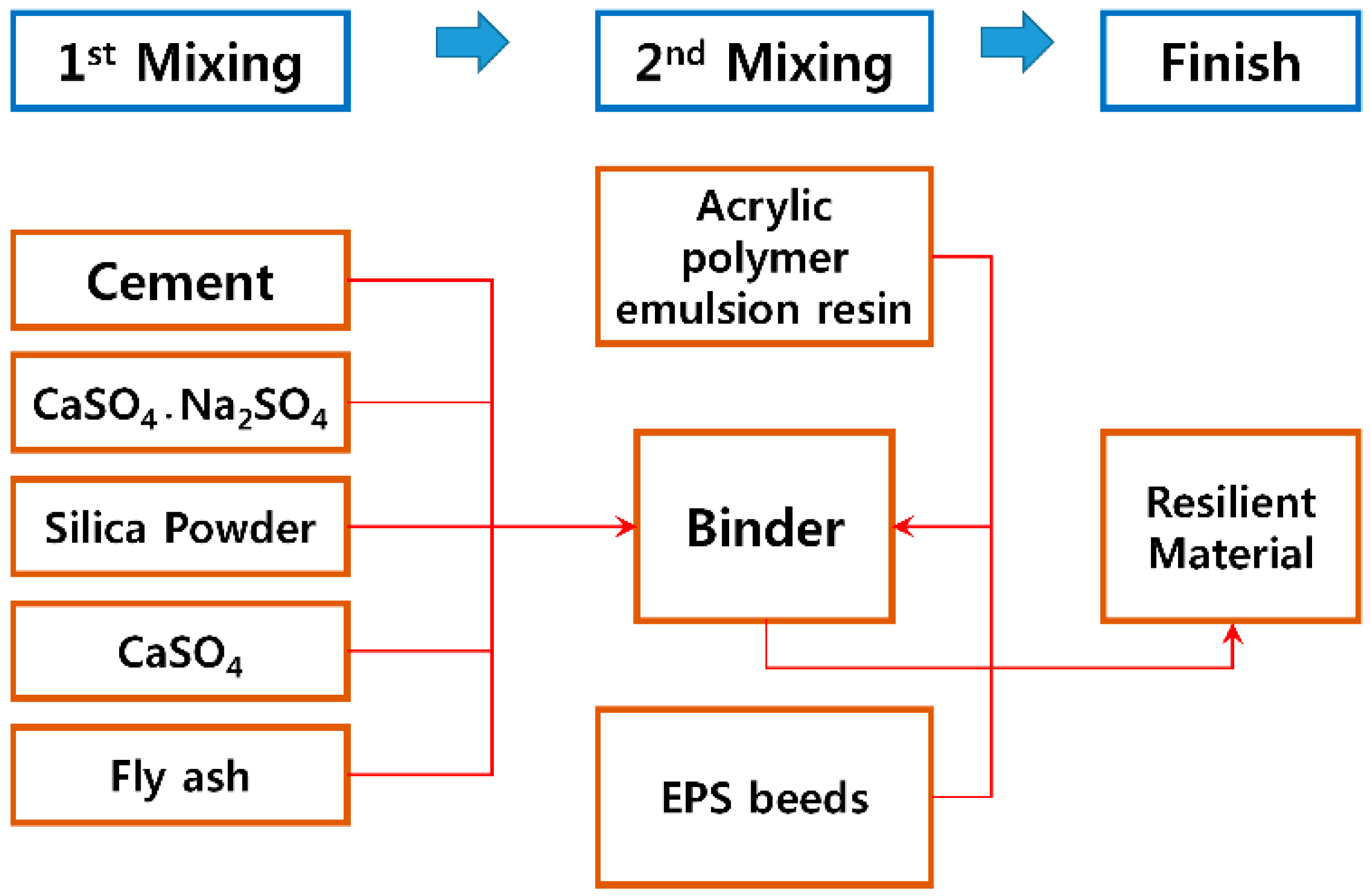

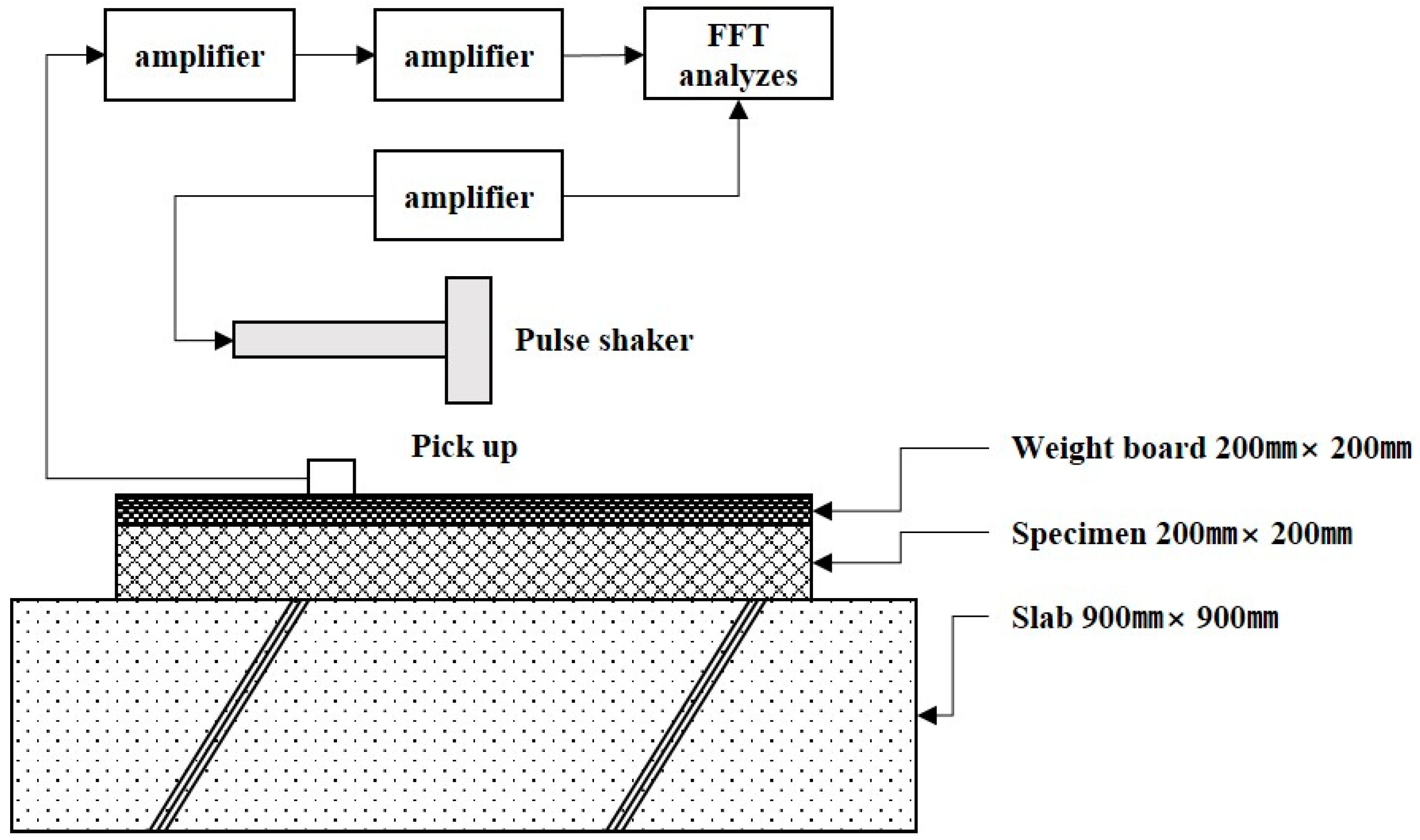

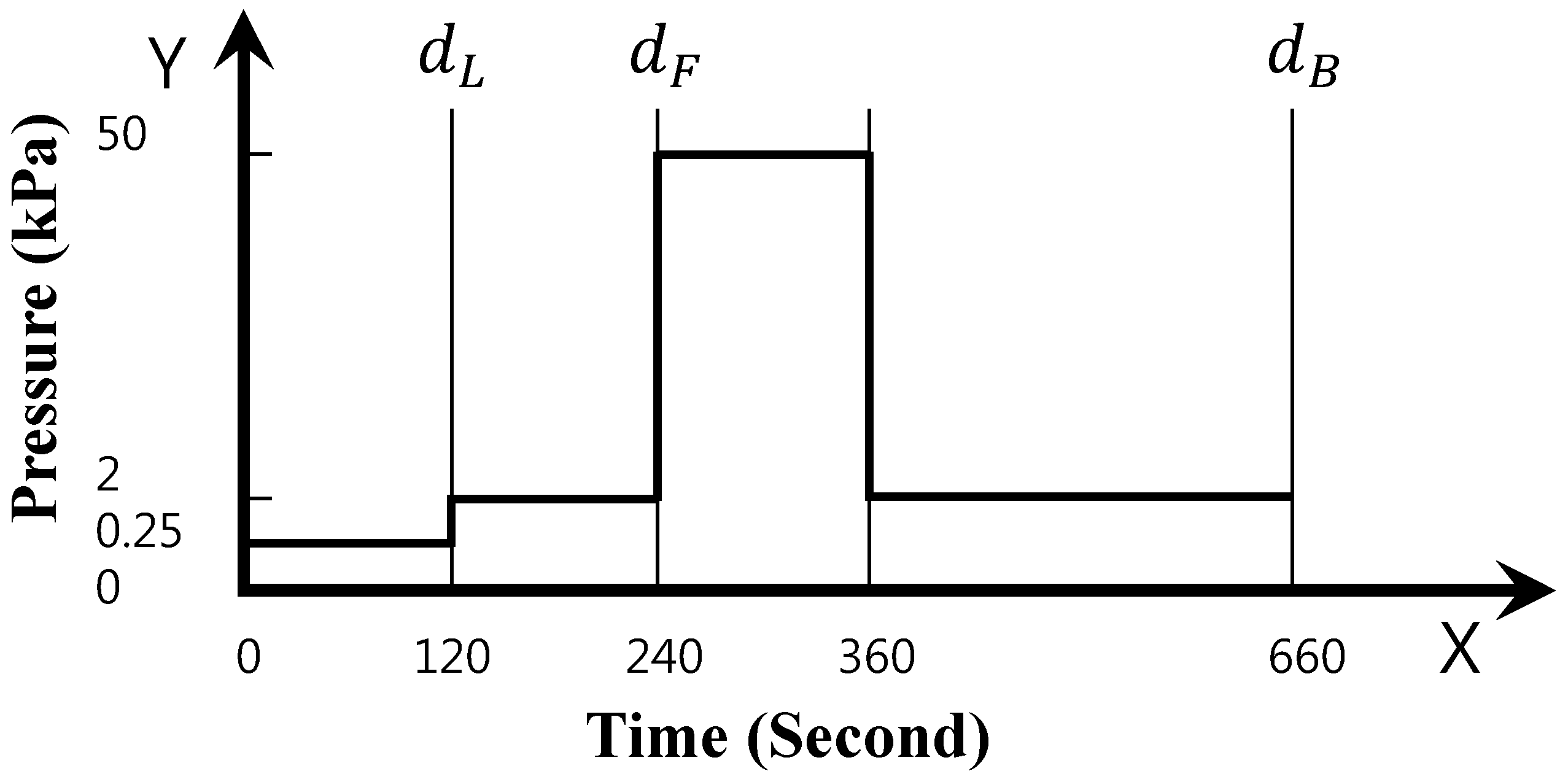

In this study, ceramic resins and mineral binders were selected and mixed together to fabricate a resilient material. Then, its physical characteristics such as density, dynamic stiffness, and remanent strain as well as the heavyweight sound noise properties were investigated. It should be commented that there are two types of dynamic stiffness: one is the dynamic stiffness and its unit is N/m and the other is the dynamic stiffness per area and its unit is MN/m/m2, i.e., MN/m3 or MPa/m. In this study, the dynamic stiffness per area is used. Additionally, the natural frequencies of the proposed materials were evaluated using two-plate system. Two octave bands, i.e., 1/3 Octave bands and 1/1 Octave bands, were used to evaluate the acoustic performance of the material. Finally, its effectiveness of the floor impact noise reduction has been assessed after its application to a floor system.

4. Summary and Conclusions

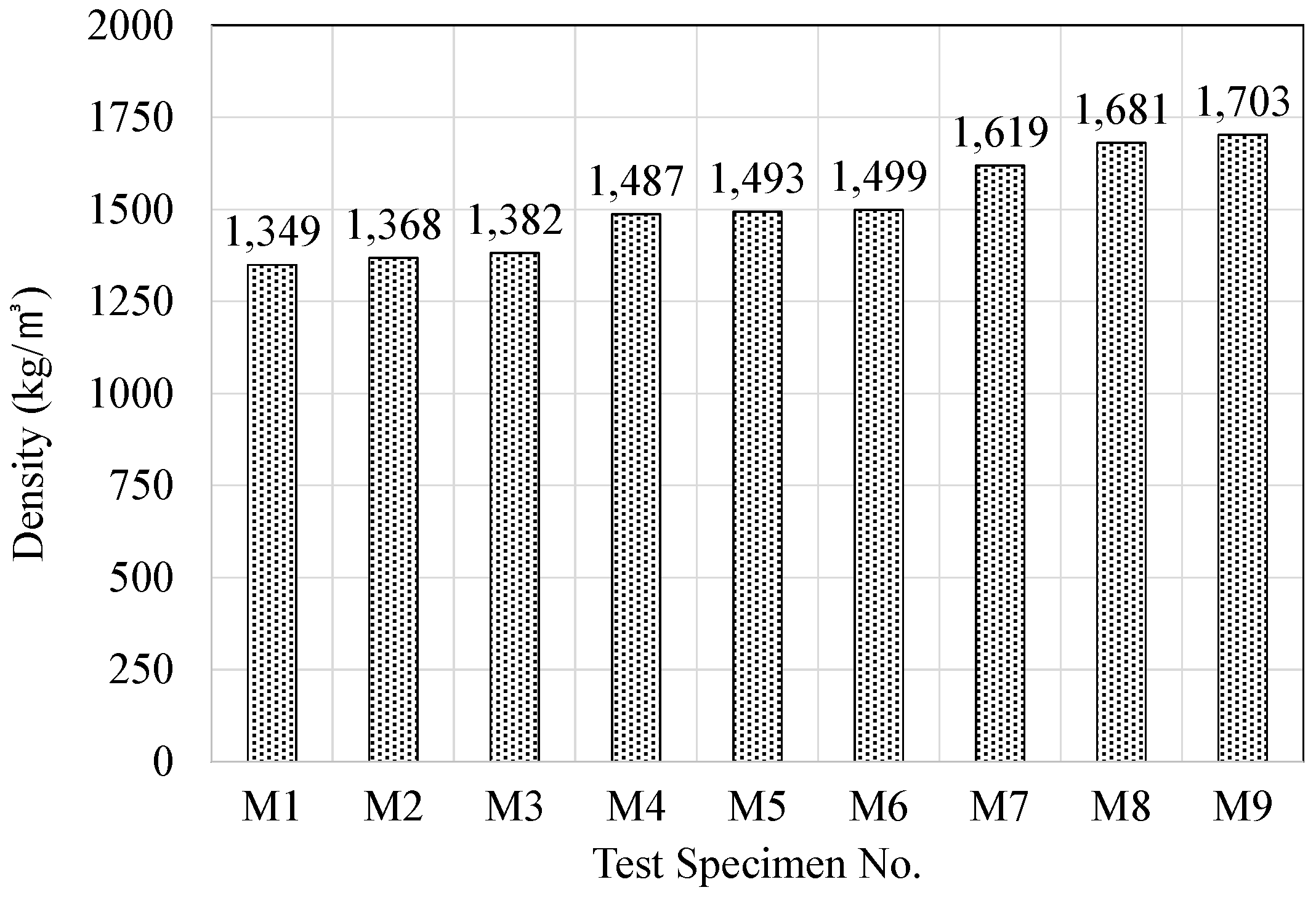

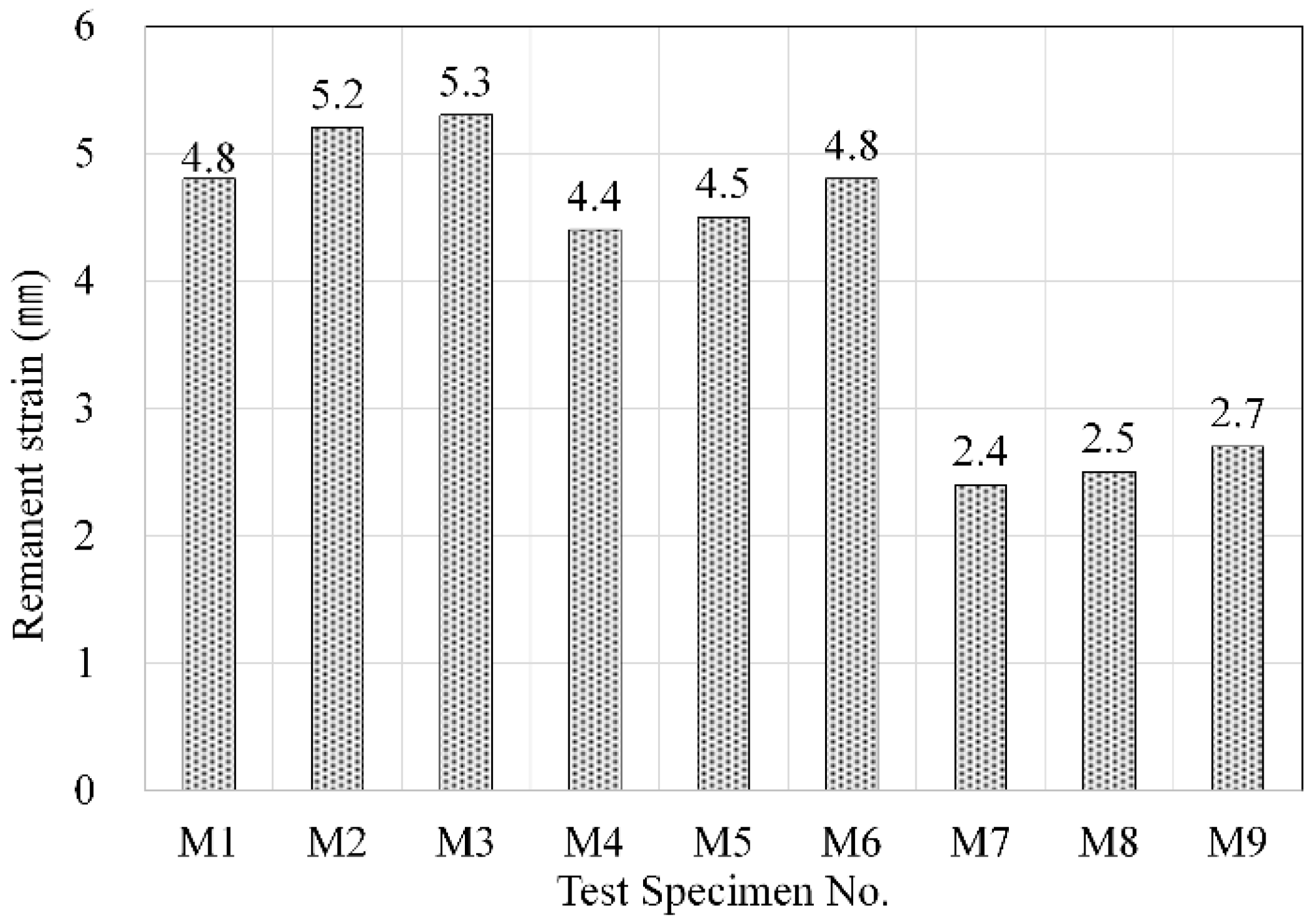

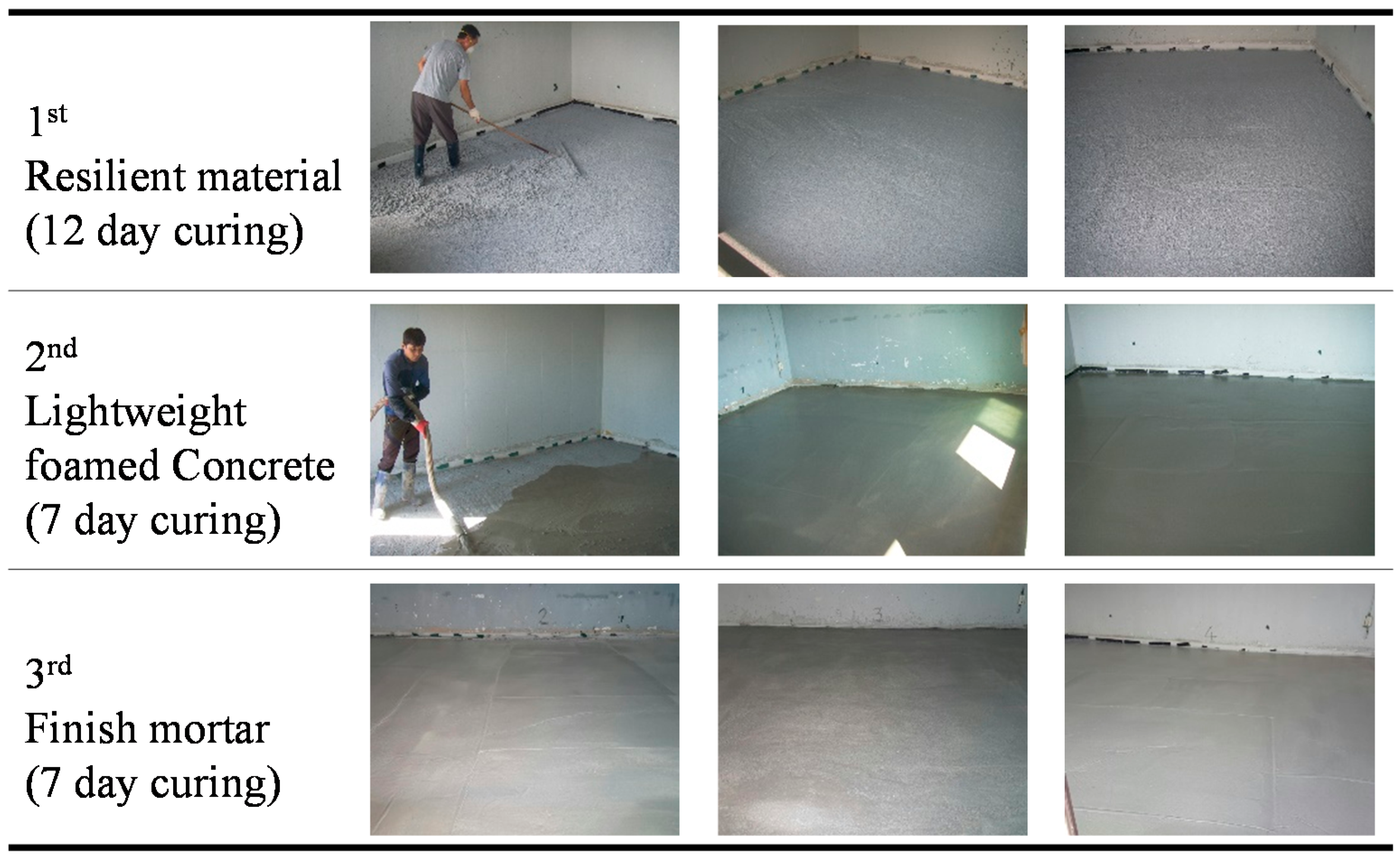

New place-type resilient materials were fabricated using acrylic resin and mineral binders for the purpose of mitigating the floor impact noise issue in multi-unit residential buildings in South Korea. Experiments were conducted for material properties and acoustic performances of the proposed place-type resilient materials.Nine specimens for material properties testing and five specimens, four specimens from the proposed resilient materials and one from conventional EPS resilient material as the specimen base case, for acoustic performance testing are considered during the experiments. Four specimens from nine specimens were chosen for the floor impact experiments based on the testing results of the material properties. Relationship between the mixing ratios of cement and silica powder, and material properties such as density, compressive strength, dynamic stiffness, and remanent strain were investigated.

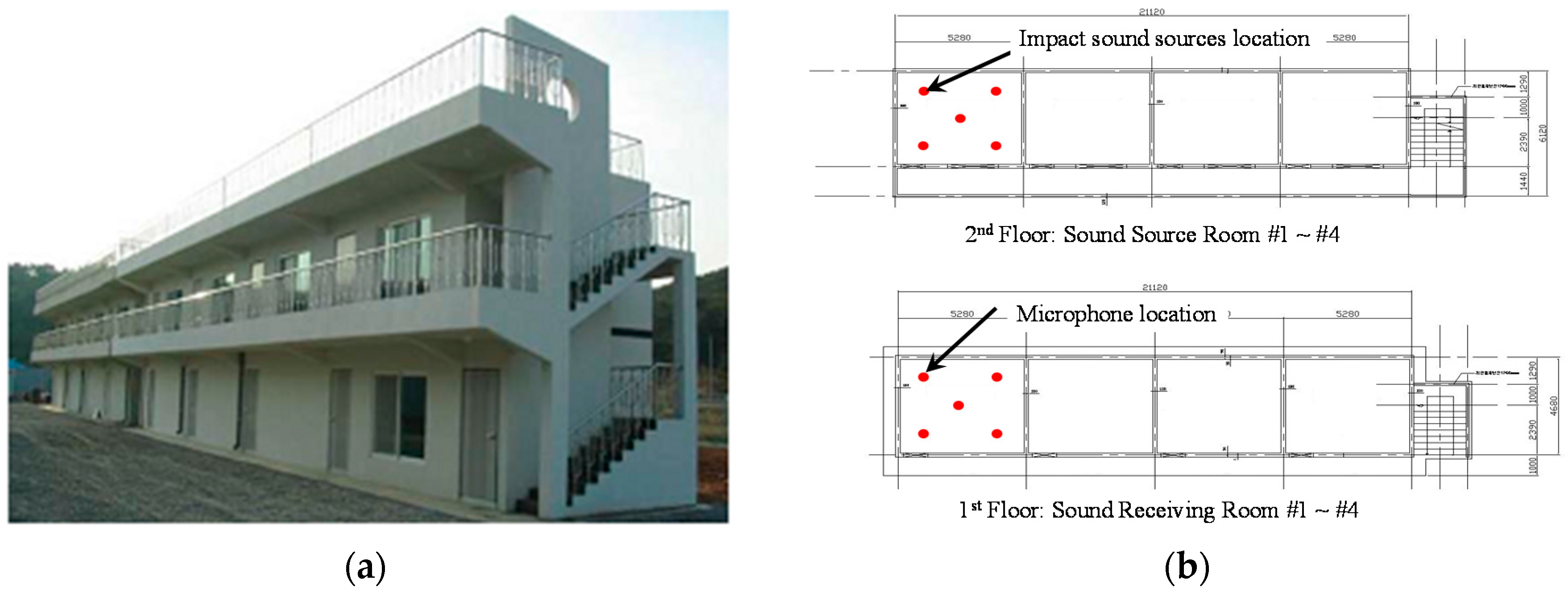

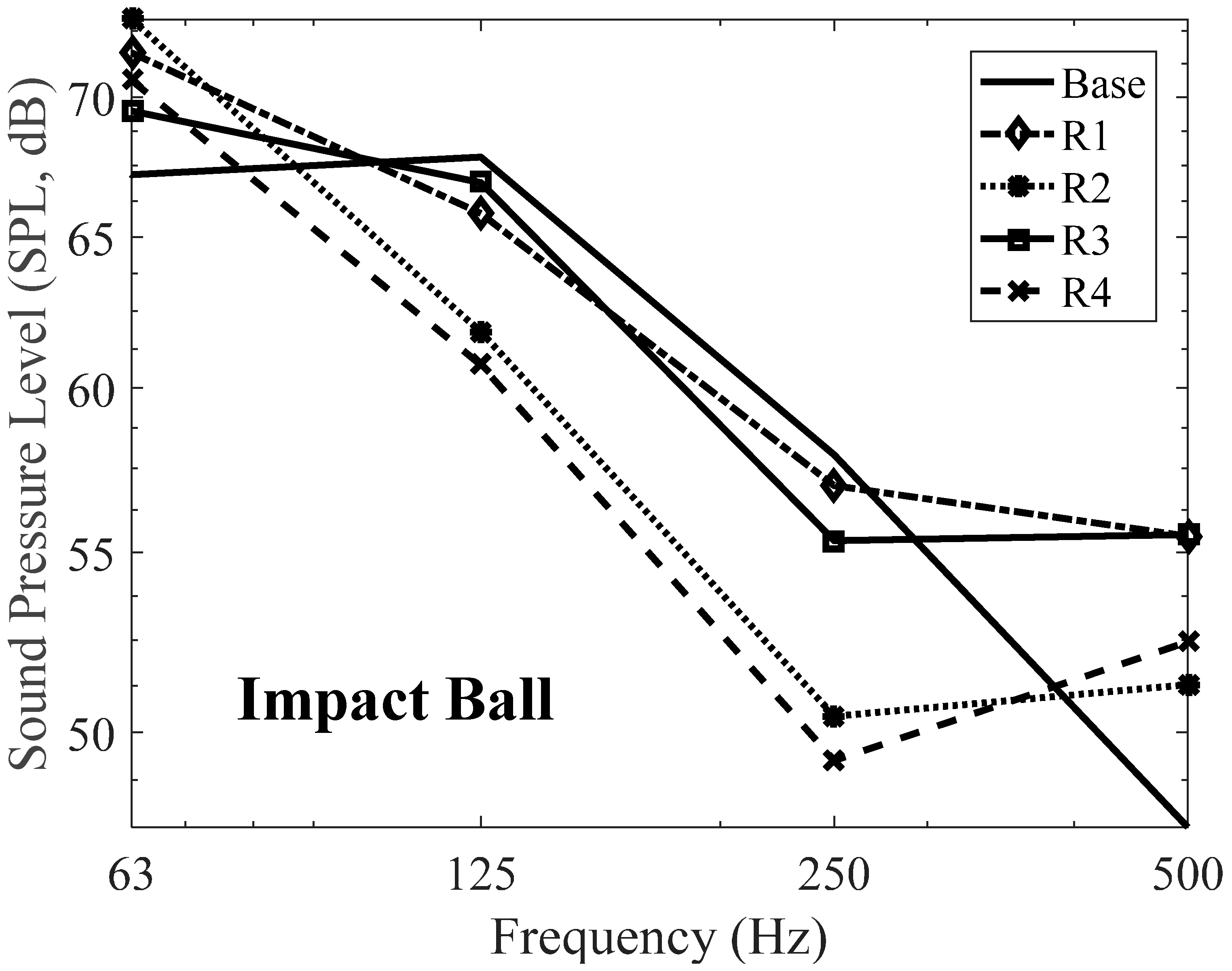

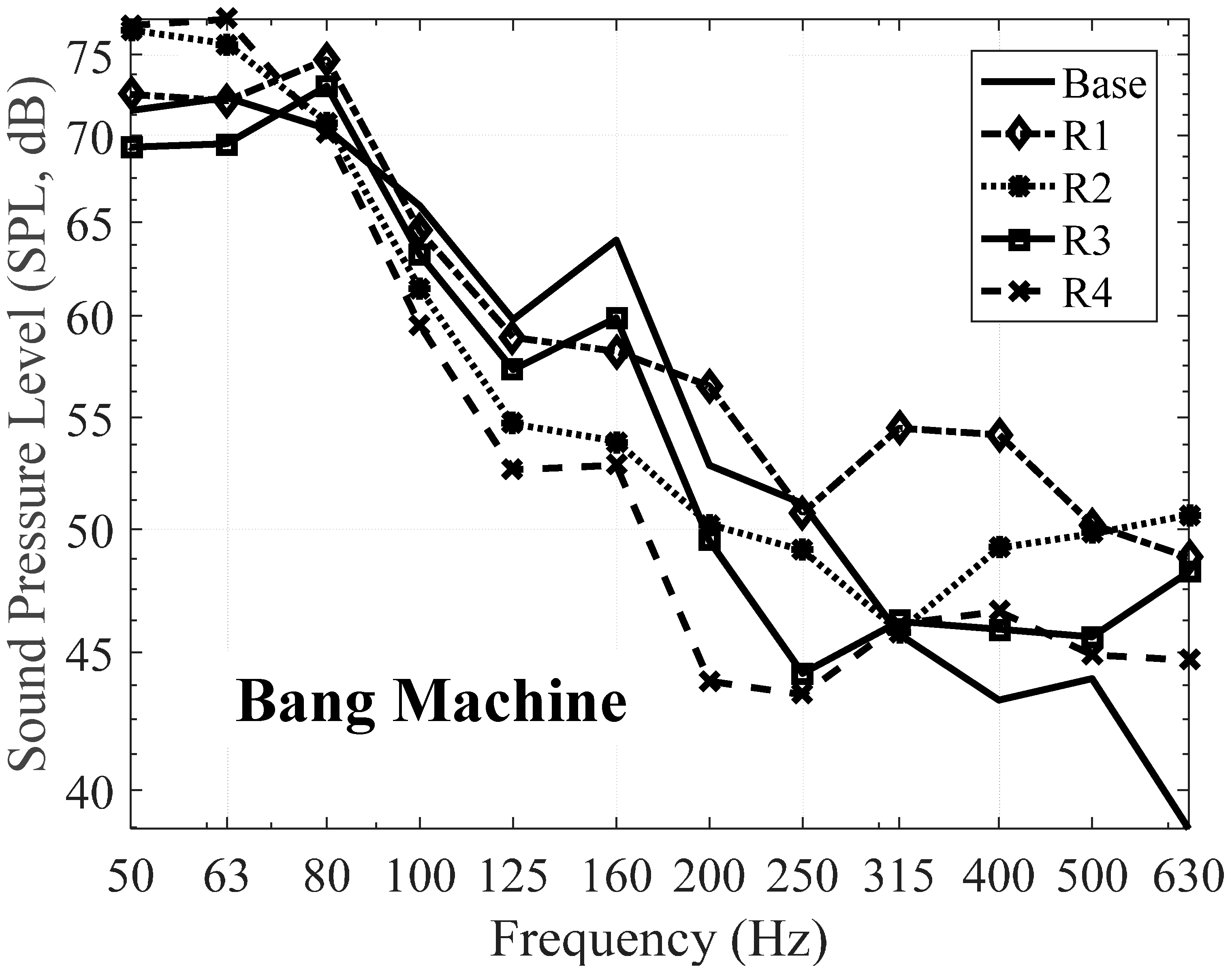

Floor impact noise was measured in a test residential building. Two standard heavyweight floor impact sources, the bang machine and the impact ball, were adopted to simulate the noise. Considering the experimental results, specimen no. R4 is the best product to obtain overall performance for both impact ball and bang machine. It has reduced the SNQ level by 3 dB for the impact ball and 1 dB for the bang machine.

The results of assessing their physical properties and floor impact noise reduction effects are as follows:

- (1)

In the case of resilient materials fabricated with acrylic resin and mineral binders, an increase in the cement and silica powder replacement ratios caused an increase in density due to the high specific gravity of the raw materials, and an increase in density in turn reduced the dynamic stiffness.

- (2)

Resilient materials with high cement and silica powder replacement ratios developed high strength due to the hydration characteristics and promotion effect of the raw materials.

- (3)

Remanent strain was found to be inversely proportional to density and strength. For instance, specimens with high density and strength had low remanent strain.

- (4)

Heavyweight impact noise measurements showed that materials with high density and strength and low remanent strain exhibited high noise reduction rates, and that low dynamic stiffness was also advantageous in reducing the impact noise.

- (5)

The acoustic performance of the materials with low density, low strength, and high remanent strain does not always result in reducing impact nose level due to the resonance around 63 Hz and its effects in the area of adhesion among the resilient material, the concrete slab, foamed concrete, and finish mortar.

In conclusion, the new place-type resilient material proposed in this study demonstrated the possibility of reducing the floor impact noise. The developed resilient materials are able to satisfy the requirements given by the revised standards [

4]. The acoustic performance of the floor system with the developed resilient materials is rated as a fourth level, which is the range between 47 dB and 50 dB, under the heavyweight impact source. From the results, it can be helpful to reduce the floor impact noise by means of using new resilient materials. Additionally, there needs to be further research to determine the ideal type of acrylic resin, mixing ratio, shape and thickness of the place-type resilient material, as well as the lightweight noise reduction effects.