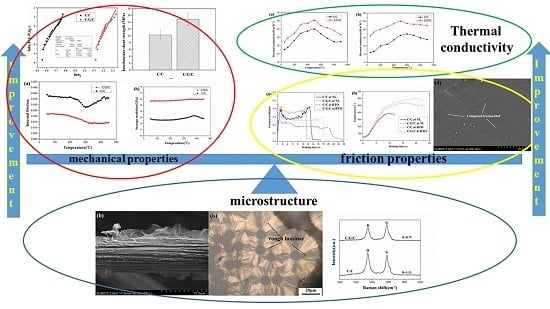

Effect of Interface Modified by Graphene on the Mechanical and Frictional Properties of Carbon/Graphene/Carbon Composites

Abstract

:1. Introduction

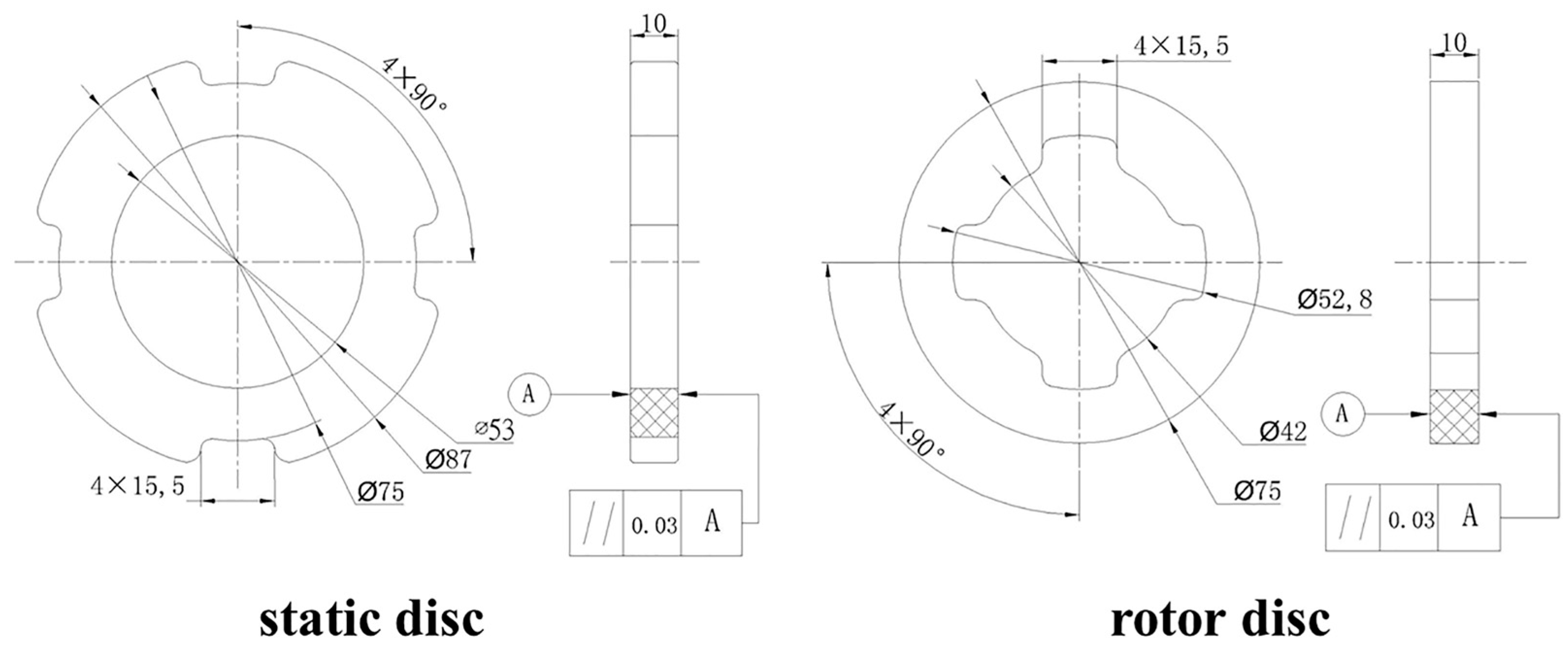

2. Material and Methods

2.1. Materials

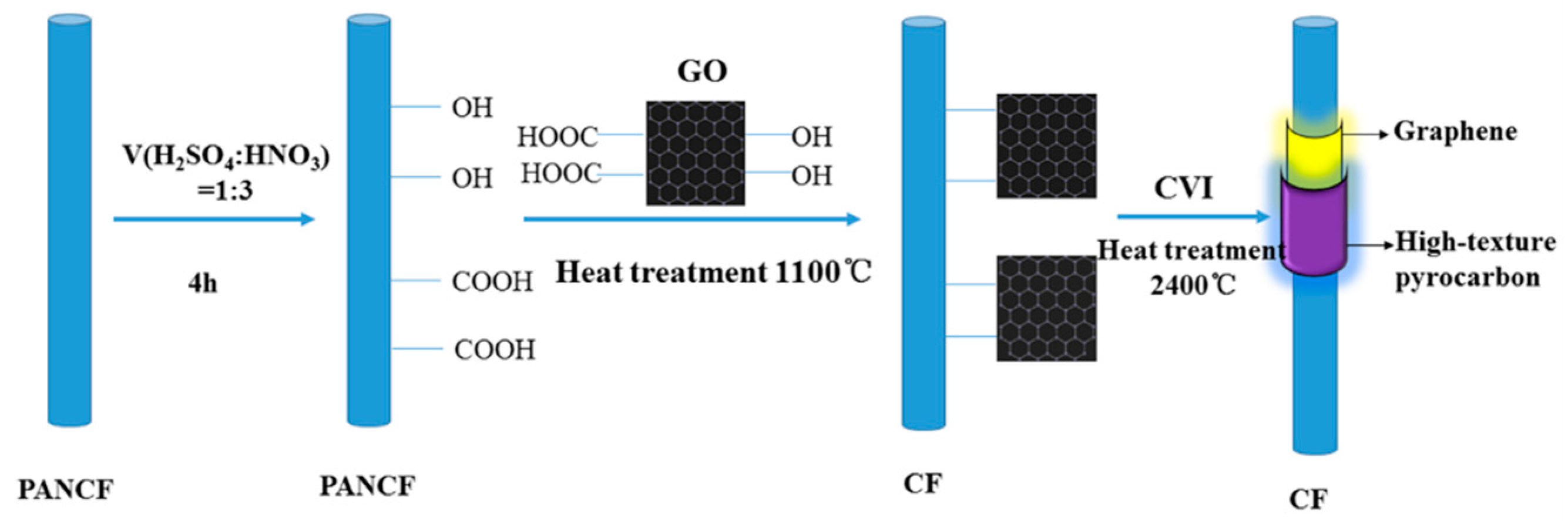

2.2. Preparation of Samples

2.2.1. Preparation of Graphene Oxide

2.2.2. Preparation of C/G/C Composites

2.3. Characterization

3. Results and Discussion

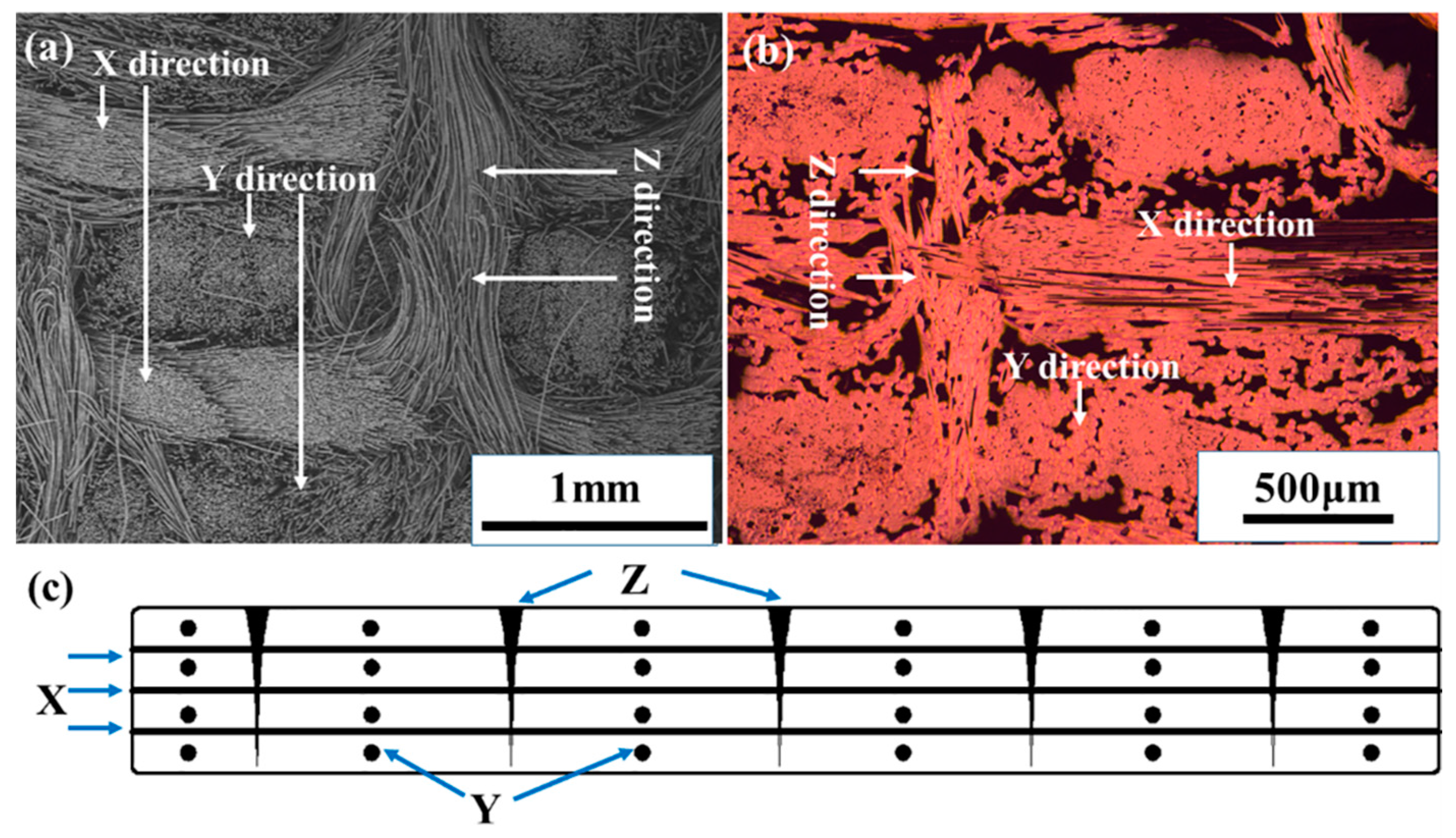

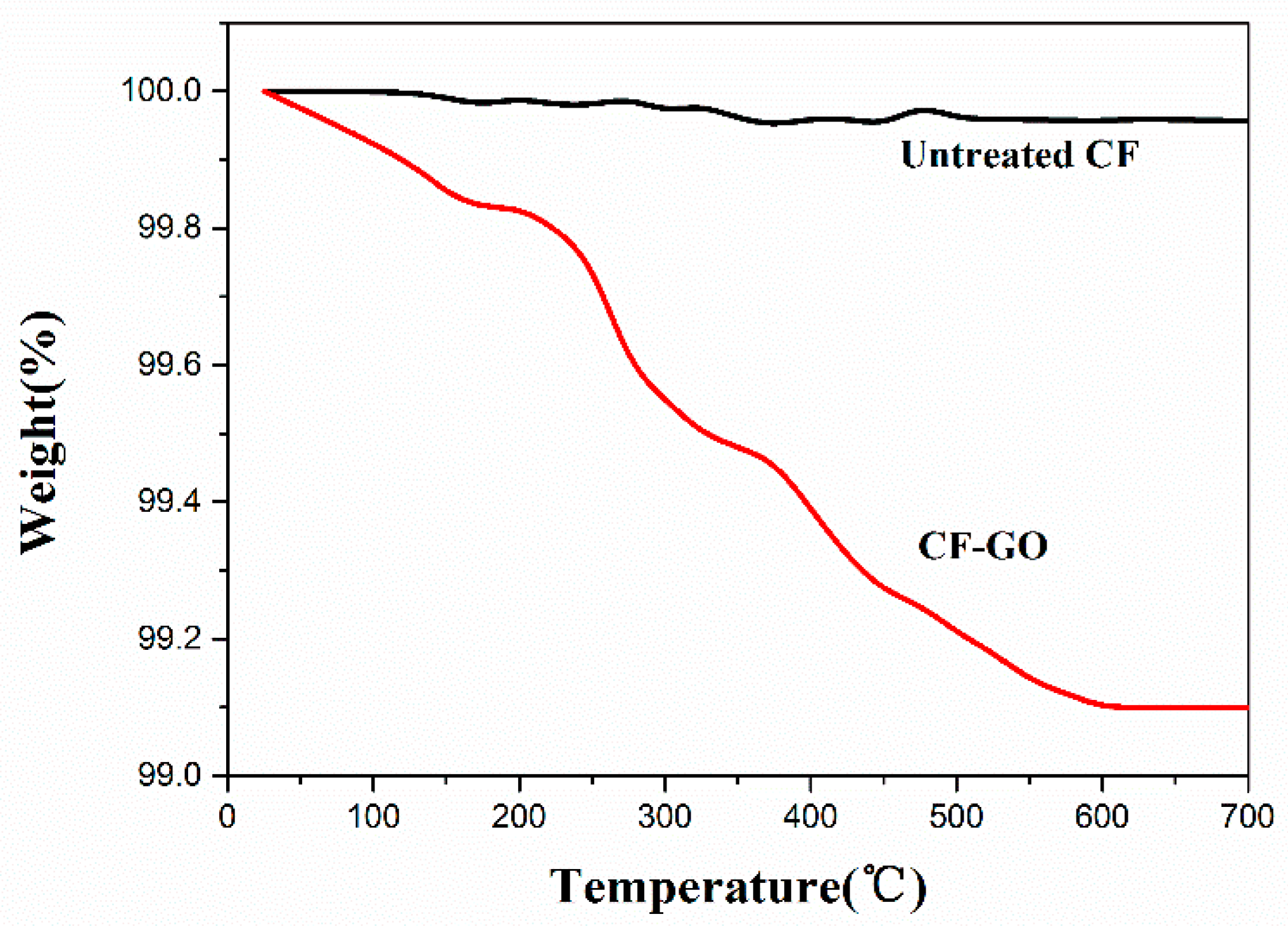

3.1. Morphology and Microstructure

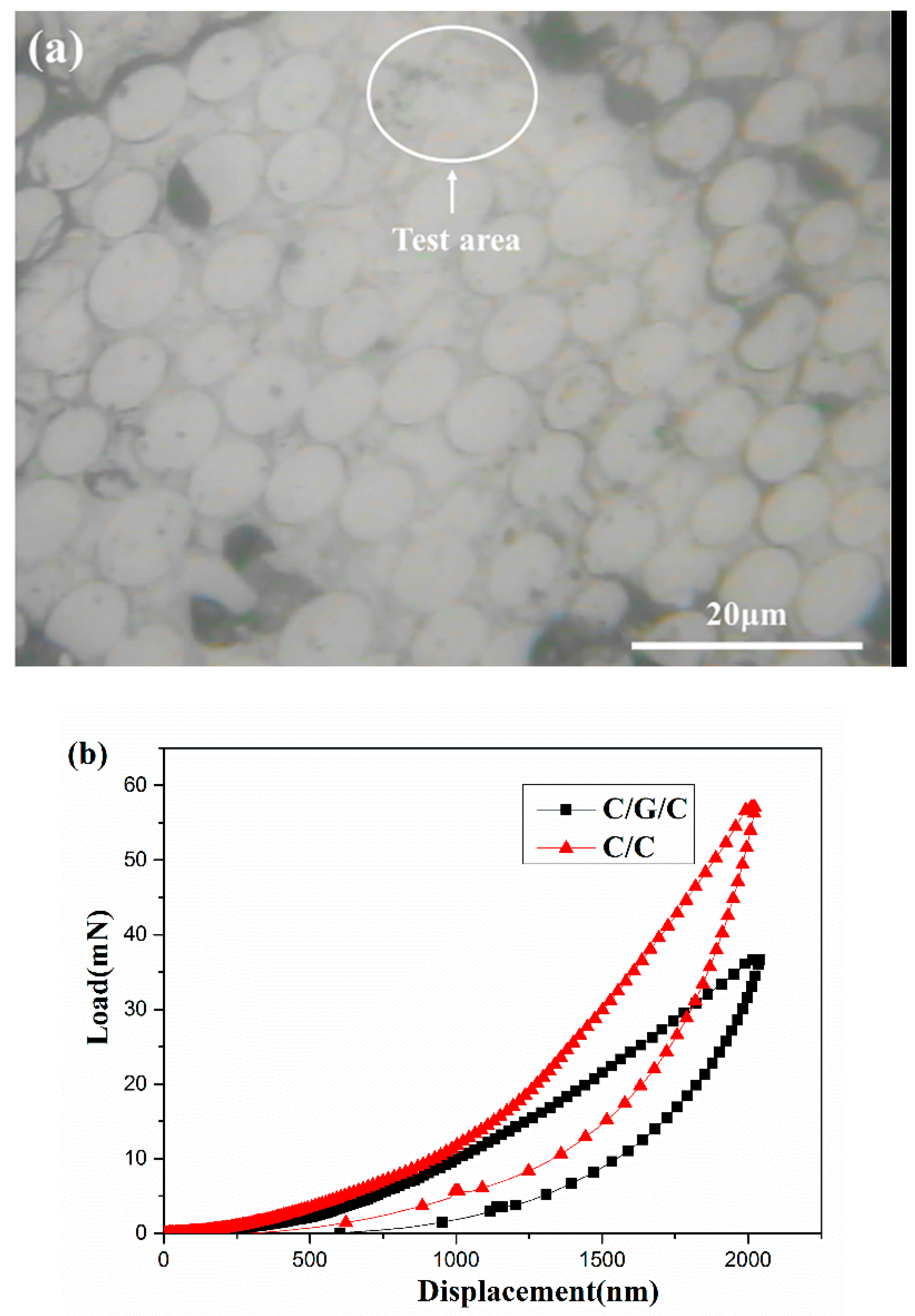

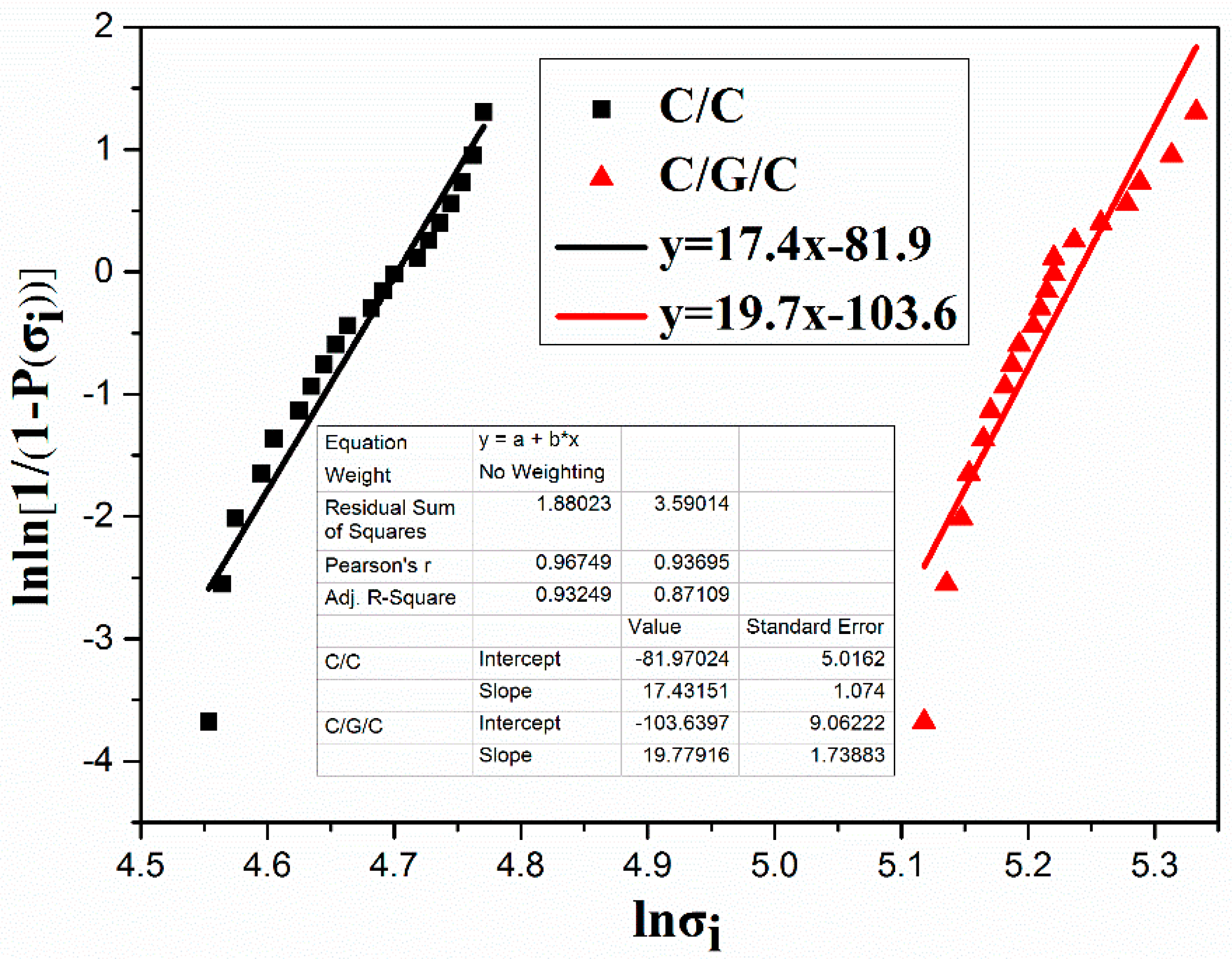

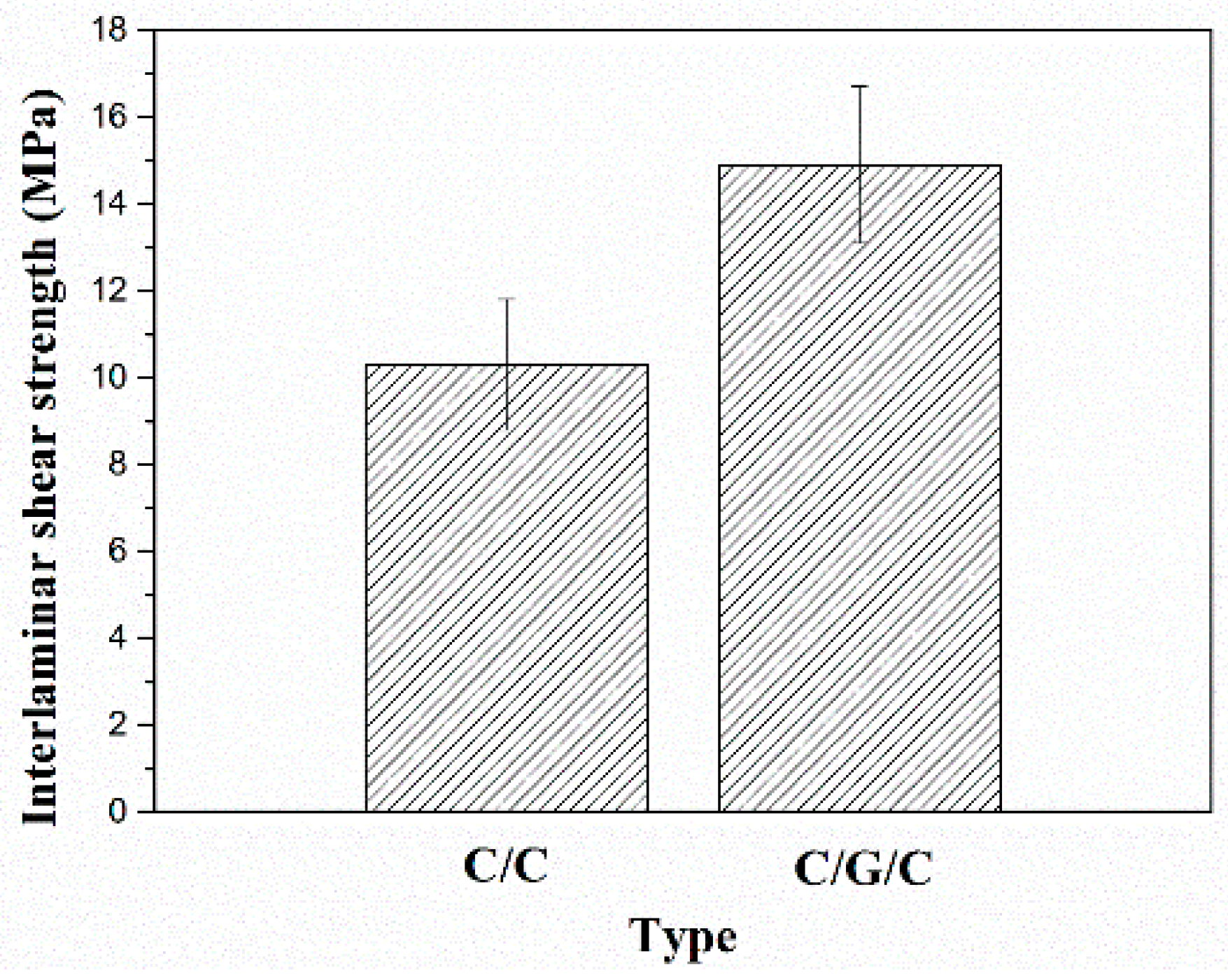

3.2. Static Mechanical Performance

3.3. Dynamic Mechanical Properties

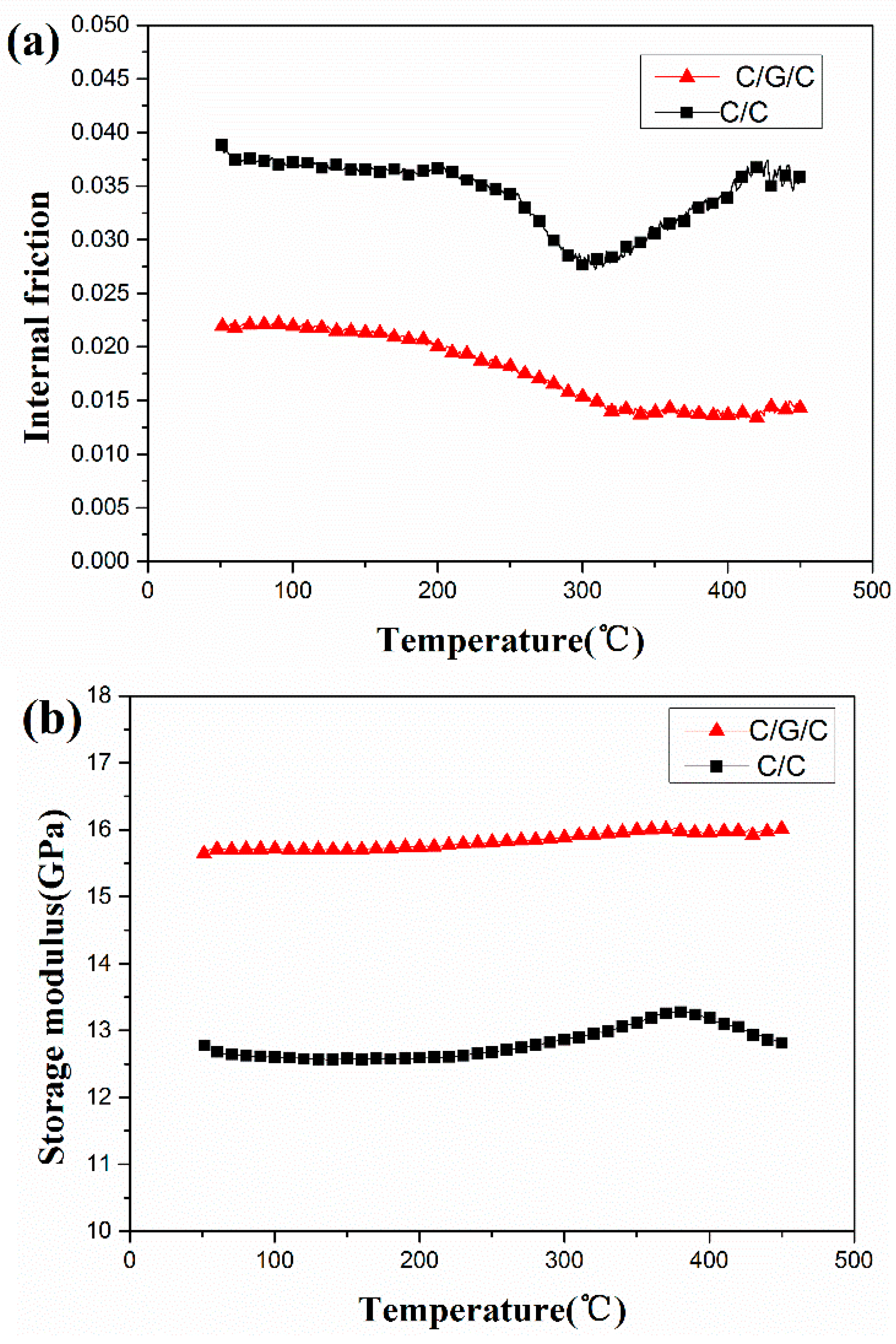

3.4. Thermal Conductivity

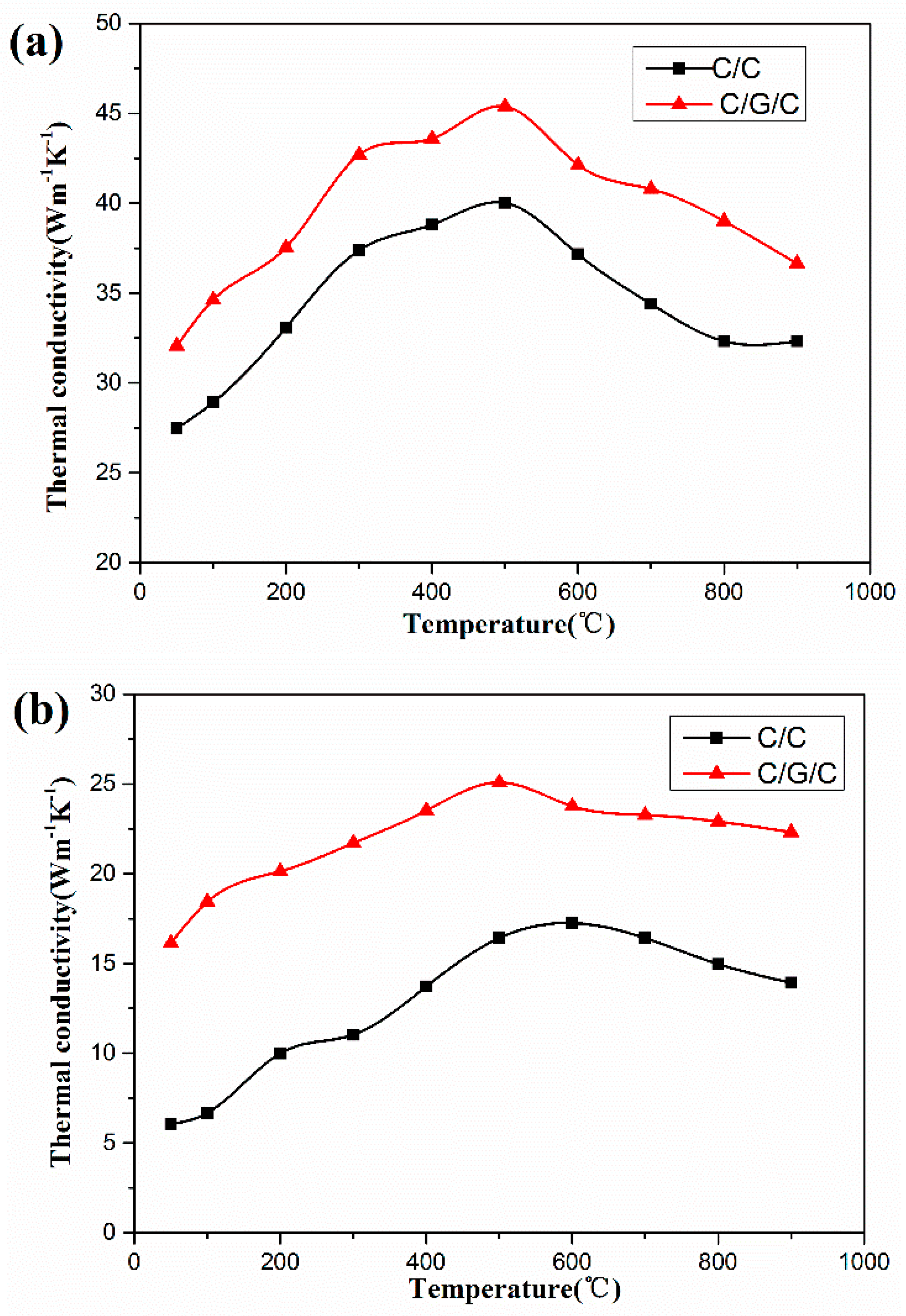

3.5. Frictional Properties

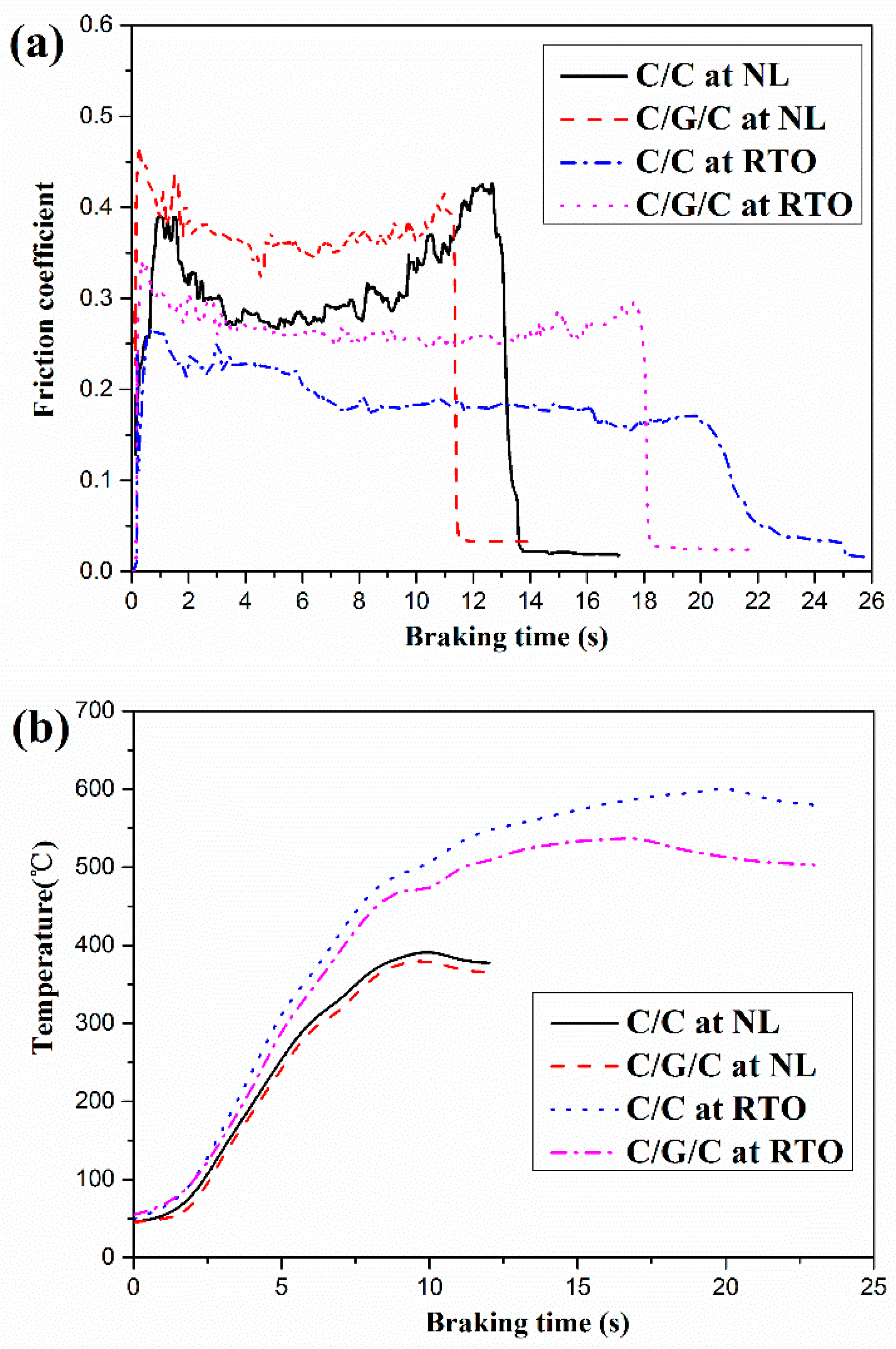

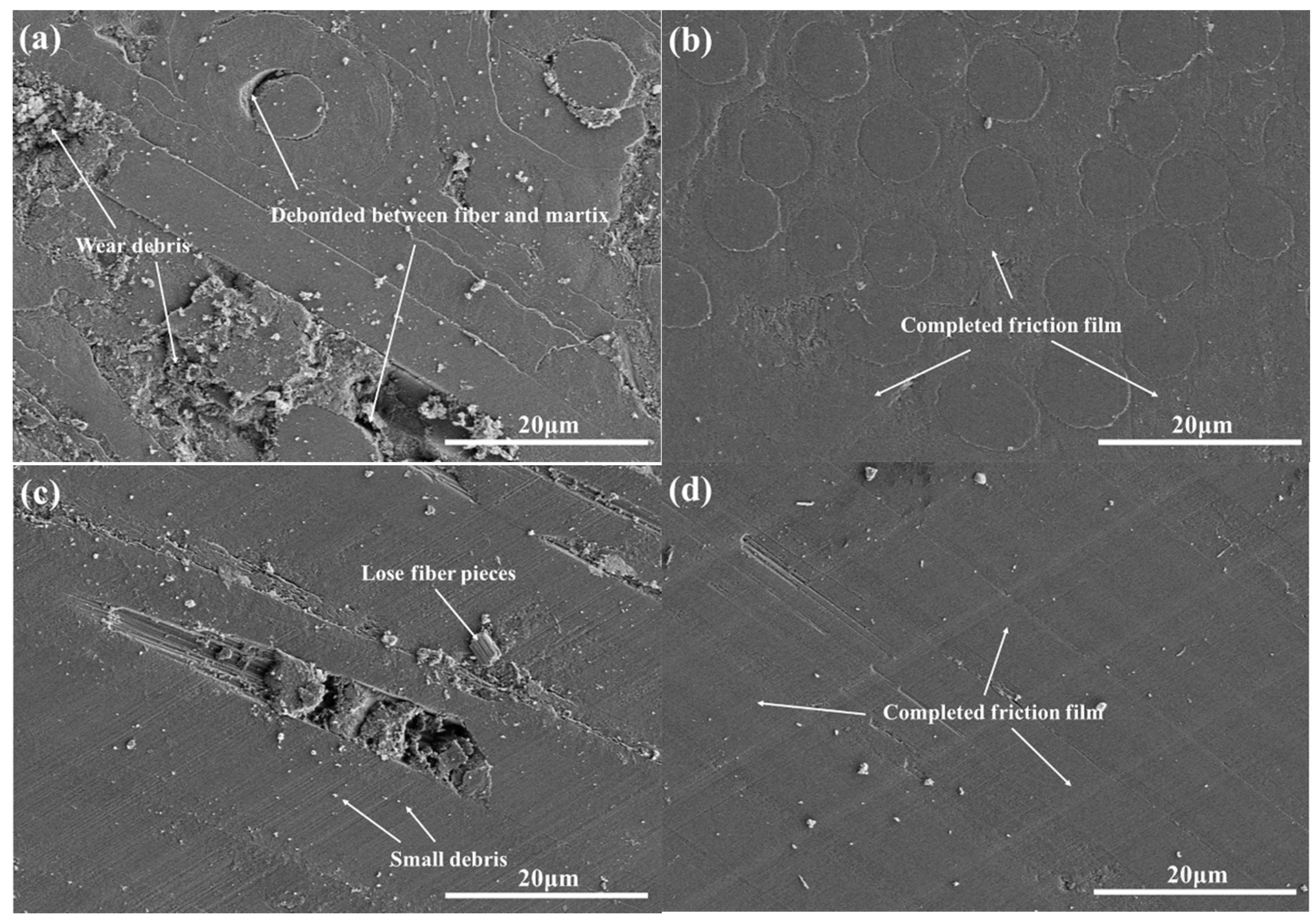

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ozcan, S.; Tezcan, J.; Filip, P. Microstructure and elastic properties of individual components of C/C composites. Carbon 2009, 47, 3403–3414. [Google Scholar] [CrossRef]

- Ozcan, S.; Tezcan, J.; Gurung, B.; Filip, P. The effect of heat treatment temperature on the interfacial shear strength of C/C composites. J. Mater. Sci. 2011, 46, 38–46. [Google Scholar] [CrossRef]

- Kasem, H.; Bonnamy, S.; Berthier, Y.; Dufrénocy, P.; Jacquemard, P. Tribological, physicochemical and thermal study of the abraupt friction transition during carbon/carbon composites friction. Wear 2009, 267, 846–852. [Google Scholar] [CrossRef]

- Vignoles, G.L.; Aspa, Y.; Quintard, M. Modelling of carbon-carbon composite ablation in rocket nozzles. Compos. Sci. Technol. 2010, 70, 1303–1311. [Google Scholar] [CrossRef]

- Lee, K.J.; Cheng, H.Z.; Chen, J.S. Effect of densification cycles on continuous friction behavior of carbon-carbon composites. Wear 2006, 260, 99–108. [Google Scholar] [CrossRef]

- Blanco, C.; Bermejo, J.; Marsh, H.; Menendez, R. Chemical and physical properties of carbon as related to brake performance. Wear 1997, 213, 1–12. [Google Scholar] [CrossRef]

- Geim, A.K. Graphene: Status and prospects. Science 2009, 324, 1530–1534. [Google Scholar] [CrossRef] [PubMed]

- Park, S.; Ruoff, R.S. Chemical methods for the production of graphenes. Nat. Nanotechnol. 2009, 4, 217–224. [Google Scholar] [CrossRef] [PubMed]

- Lee, C.; Wei, X.D.; Kysar, J.W.; Hon, J. Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science 2008, 321, 385–388. [Google Scholar] [CrossRef] [PubMed]

- Eswaraiah, V.; Balasubramaniam, K.; Ramaprabhu, S. One-pot synthesis of conducting graphene-polymer composites and their strain sensing application. Nanoscale 2012, 4, 1258–1262. [Google Scholar] [CrossRef] [PubMed]

- Lu, X.F.; Xiao, P. Effect of carbon nanofiber modification on the tribological properties of C/C composites. New Carbon Mater. 2016, 31, 55–61. [Google Scholar] [CrossRef]

- Li, G.; Yan, Q. Comparison of Friction and Wear Behavior between C/C, C/C-SiC and Metallic Composite Materials. Tribol. Lett. 2015, 60, 13–19. [Google Scholar] [CrossRef]

- Mao, Z.L.; Yang, X.J.; Zhu, S.L.; Cui, Z.D.; Lu, Y. Pack cementation processing parameters for SiC coatings on C/C for optimum tribological properties. Surface Coatings Technol. 2014, 254, 54–60. [Google Scholar] [CrossRef]

- Zhao, Y.H.; Wu, Z.K.; Bai, S.L. Study on thermal properties of graphene foam/graphene sheets filled polymer composites. Compos. Part A 2015, 72, 200–206. [Google Scholar] [CrossRef]

- Meng, Y.; Su, F.H.; Chen, Y.Z. Synthesis of nano-Cu/graphene oxide composites by supercritical CO2-assisted deposition as a novel material for reducing friction and wear. Chem. Eng. J. 2015, 281, 11–19. [Google Scholar] [CrossRef]

- Mittal, G.; Dhand, V.; Rhee, K.Y.; Park, S.J.; Lee, W.R. A review on carbon nanotubes and graphene as fillers in reinforced polymer nanocomposites. J. Ind. Eng. Chem. 2015, 21, 11–25. [Google Scholar] [CrossRef]

- Manocha, L.M.; Bhatt, H.; Manocha, S.M. Development of carbon/carbon composites by co-carbonization of phenolic resin and oxidized PAN fibers. Carbon 1996, 34, 841–849. [Google Scholar] [CrossRef]

- Ko, T.H.; Kuo, W.S.; Chang, Y.H. Influence of carbon–fiber felts on the development of carbon-carbon composites. Compos. Part A 2003, 34, 393–401. [Google Scholar] [CrossRef]

- Stankovich, S.; Piner, R.D.; Nguyen, S.T.; Ruoff, R.S. Synthesis and exfoliation of isocyanate-treated graphene oxide nanoplatelets. Carbon 2006, 44, 3342–3347. [Google Scholar] [CrossRef]

- Stankovich, S.; Piner, R.D.; Chen, X.Q.; Wu, N.Q.; Nguyen, S.T.; Ruoff, R.S. Stable aqueous dispersions of graphitic nanoplatelets via the reduction of exfoliated graphite oxide in the presence of poly(sodium 4-styrenesulfonate). J. Mater. Chem. 2006, 16, 155–158. [Google Scholar] [CrossRef]

- Hao, M.Y.; Luo, R.Y.; Hou, Z.H.; Yang, W.; Zhang, Y.; Yang, C.L. Effect of structure of pyrocarbon on the static and dynamic mechanical properties of carbon/carbon composites. Mater. Sci. Eng. A 2014, 614, 156–161. [Google Scholar] [CrossRef]

- ASTM International. Standard Test Method for Measuring Vibration-Damping Properties of Materials; ASTM E756-05; ASTM International: West Conshohocken, PA, USA, 2010. [Google Scholar]

- Wu, X.W.; Luo, R.Y. Mechanical properties investigation of carbon/carbon composites fabricated by a fast densification process. Mater. Des. 2011, 32, 2361–2364. [Google Scholar] [CrossRef]

- Aviation Industry Standard. Test Methods for Aircraft Wheel Friction Materials; HB 5434.7-2004; Aviation Industry Standard: Beijing, China, 2004. [Google Scholar]

- ASTM International. Development of Specifications for Fiber Reinforced Carbon-Carbon Composite Structures for Nuclear Applications; ASTM C1783-15; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- Ozcan, S.; Filip, P. Microstructure and wear mechanisms in C/C composites. Wear 2005, 259, 642–650. [Google Scholar] [CrossRef]

- Pascal, D.; Jacques, L.; Carpentier, L.; Loubet, J.L.; Kapsa, P. Sharp indentation behavior of carbon/carbon composites and varieties of carbon. Carbon 2002, 40, 2567–2579. [Google Scholar]

- Yang, W.; Kohyama, A.; Noda, T.; Katoh, Y.; Hinoki, T.; Araki, H.; Yu, J. Interfacial characterization of CVI–SiC/SiC composites. J. Nucl. Mater. 2002, 307–311, 1088–1092. [Google Scholar] [CrossRef]

- Zhao, F.; Huang, Y.D.; Liu, L.; Bai, Y.P.; Xu, L.W. Formation of a carbon fiber/polyhedral oligomeric silsesquioxane/carbon nanotube hybrid reinforcement and its effect on the interfacial properties of carbon fiber/epoxy composites. Carbon 2011, 49, 2624–2632. [Google Scholar] [CrossRef]

- Tzounis, L.D.S.; Rooj, S.; Fischer, D.; Mäder, E.; Das, A.; Stamm, M. High performance natural rubber composites with a hierarchical reinforcement structure of carbon nanotube modified natural fibers. Mater. Des. 2014, 58, 1–11. [Google Scholar] [CrossRef]

- Zhao, F.; Huang, Y.D. Preparation and properties of polyhedral oligomeric silsesquioxane and carbon nanotube grafted carbon fiber hierarchical reinforcing structure. J. Mater. Chem. 2011, 2, 2867–2870. [Google Scholar] [CrossRef]

- Reznik, B.; Gerthsen, D.; Hüttinger, K.J. Micro and nanostructure of the carbon matrix of infiltrated carbon fiber felts. Carbon 2001, 39, 215–229. [Google Scholar] [CrossRef]

- Zhang, J.C.; Luo, R.Y.; Xiang, Q.; Yang, C.L. Compressive fracture behavior of 3D needle-punched carbon/carbon composites. Mater. Sci. Eng. A 2011, 528, 5002–5006. [Google Scholar] [CrossRef]

- Guellali, M.; Oberacker, R.; Hoffmann, M.J. Influence of the matrix microstructure on the mechanical properties of CVI-infiltrated carbon fiber felts. Carbon 2005, 43, 1954–1960. [Google Scholar] [CrossRef]

- Dong, G.L.; Huttinger, K.J. Consideration of reaction mechanisms leading to pyrolytic carbon of different textures. Carbon 2002, 40, 2515–2528. [Google Scholar] [CrossRef]

- Thostenson, E.T.; Ren, Z.F.; Chou, T.W. Advances in the science and technology of carbon nanotubes and their composites: A review. Compos. Sci. Technol. 2001, 61, 1899–1912. [Google Scholar] [CrossRef]

- Gong, Q.M.; Li, Z.; Bai, X.; Li, D.; Liang, J. The effect of carbon nanotubes on the microstructure and morphology of pyrolytic carbon matrices of C–C composites obtained by CVI. Compos. Sci. Technol. 2005, 65, 1112–1119. [Google Scholar] [CrossRef]

- Leszek, N.; Paul, W.; Jagodzinski, P. Raman spectroscopic characterization of graphites: A reevaluation of spectra/structure correlation. Carbon 1993, 31, 1313–1317. [Google Scholar]

- Malard, L.M.; Pimenta, M.A.; Dresselhaus, G.; Dresselhaus, M.S. Raman spectroscopy in graphene. Phys. Rep. 2009, 473, 51–57. [Google Scholar] [CrossRef]

- Naslain, R.R.; Pailler, R.J.; Lamon, J.L. Single and multilayered interphases in SiC/SiC composites exposed to severe environmental conditions: An overview. Int. J. Appl. Ceram. Technol. 2010, 7, 263–275. [Google Scholar] [CrossRef]

- Jiang, D.W.; Liu, L.; Long, J.; Xing, L.X.; Huang, Y.D.; Wu, Z.J. Reinforced unsaturated polyester composites by chemically grafting amino-POSS onto carbon fibers with active double spiral structural spiral phosphodicholor. Compos. Sci. Technol. 2014, 100, 158–165. [Google Scholar] [CrossRef]

- Liu, X.Y.; Song, Y.; Li, C.M.; Wang, F.P. Synthesis and characterization of carbon fibers reinforcement with grafted graphene oxide. Chin. J. Inorg. Chem. 2012, 27, 2128–2132. [Google Scholar]

- Zhang, X.Q.; Fan, X.Y.; Yan, C.; Li, H.Z.; Zhu, Y.D.; Li, X.T. Interfacial microstructure and properties of carbon fiber composites modified with graphene oxide. ACS Appl. Mater. Interfaces 2012, 4, 1543–1552. [Google Scholar] [CrossRef] [PubMed]

- Mei, L.; He, X.D.; Li, Y.B.; Wang, R.G.; Wang, C.; Peng, Q.Y. Grafting carbon nanotubes onto carbon fiber by use of dendrimers. Mater. Lett. 2010, 64, 2505–2508. [Google Scholar] [CrossRef]

- Lin, J.H.; Huang, C.L.; Liu, C.F.; Chen, C.K.; Lin, Z.I.; Lou, C.W. Polypropylene/Short Glass Fibers Composites: Effects of coupling agents on mechanical Properties, thermal Behaviors, and morphology. Materials 2015, 8, 8279–8291. [Google Scholar] [CrossRef]

- Munz, D.; Fett, T. Ceramics: Mechanical, Properties, Failure Behaviour, Materials Selection, Corrected Edition; Springer: Berlin/Heidelberg, Germany; New York, NY, USA, 1999; pp. 139–149. [Google Scholar]

- Li, J.; Luo, R.Y.; Bi, Y.H.; Xiang, Q.; Lin, C.; Zhang, Y.F. The preparation and performance of short carbon fiber reinforced adhesive for bonding carbon/carbon composites. Carbon 2008, 46, 1957–1965. [Google Scholar] [CrossRef]

- Chen, J.; Xiao, P.; Xiong, X. The mechanical properties and thermal conductivity of carbon/carbon composites with the fiber/matrix interface modified by silicon carbide nanofibers. Mater. Des. 2015, 84, 285–290. [Google Scholar] [CrossRef]

- Zhang, H.; Guo, L.; Song, Q.; Fu, Q.G.; Li, H.; Li, K. Microstructure and flexural properties of carbon/carbon composite with in-situ grown carbon nanotube as secondary reinforcement. Prog. Nat. Sci. 2013, 23, 157–163. [Google Scholar] [CrossRef]

- Li, D.; Luo, G.; Yao, Q.; Jiang, N.; Jiang, L. High temperature compression properties and failure mechanism of 3D needle-punched carbon/carbon composites. Mater. Sci. Eng. A 2015, 21, 105–110. [Google Scholar] [CrossRef]

- Cho, C.; Holmes, J.W.; Barber, J.R. Estimation of interfacial shear in ceramic composites from frictional heating measurements. J. Am. Ceram. Soc. 1991, 74, 2802–2808. [Google Scholar] [CrossRef]

- Cho, C.; Choi, E.Y.; Beom, H.G.; Kim, C.B. Micro-frictional dissipation in fiber-reinforced ceramic matrix composites and interfacial shear estimation with a consideration of uneven fiber packing. J. Mater. Process. Technol. 2005, 162–163, 9–14. [Google Scholar] [CrossRef]

- Yasuo, K.; Yoshie, L.; Naohiro, I.; Ken’ich, O. Internal friction of carbon–carbon composites at elevated temperatures. J. Alloys Compd. 2003, 355, 148–153. [Google Scholar]

- Sato, S.; Serizawa, H.; Araki, H.; Noda, T.; Kohyama, A. Temperature dependence of internal friction and elastic modulus of SiC/SiC composites. J. Alloys Compd. 2003, 355, 142–147. [Google Scholar] [CrossRef]

- Zhang, J.; Xu, Y.D.; Zhang, L.T.; Cheng, L.F. Internal friction and dynamic modulus of three-dimensional silicon carbide-matrix composites. Mater. Lett. 2005, 59, 2535–2538. [Google Scholar] [CrossRef]

- Hou, Z.H.; Luo, R.Y.; Yang, W.; Xu, H.Z.; Han, T. Effect of fiber directionality on the static and dynamic mechanical properties of 3D SiCf/SiC composites. Mater. Sci. Eng. A 2016, 658, 263–271. [Google Scholar] [CrossRef]

- Qiao, S.R.; Shaorong, Z.; Shihong, B.; Xiaoyan, S. The internal friction of unidirectional CC composites fabricated in a magnetic field. Carbon 1997, 35, 389–392. [Google Scholar]

- Berber, S.; Kwon, Y.K.; Tomanek, D. Unusually high thermal conductivity of carbon nanotubes. Phys. Rev. Lett. 2000, 84, 4613–4616. [Google Scholar] [CrossRef] [PubMed]

- Pop, E.; Mann, D.; Wang, Q.; Goodson, K.; Dai, H.J. Thermal conductivity of an individual single-wall carbon nanotube above room temperature. Nano Lett. 2006, 6, 96–100. [Google Scholar] [CrossRef] [PubMed]

- Yun, C.; Feng, Y.B.; Qiu, T.; Yang, J.; Li, X.Y.; Yu, L. Mechanical, electrical, and thermal properties of graphene nanosheet/aluminum nitride composites. Ceram. Int. 2015, 41, 8643–8649. [Google Scholar] [CrossRef]

- Lee, K.J.; Kuo, H.H.; Chen, J.H.; Lin, N.; Ju, C.P. Effect of surface condition on tribological behavior of PAN-CVI based carbon/carbon composite. Mater. Chem. Phys. 1999, 57, 244–252. [Google Scholar] [CrossRef]

- Cai, Y.Z.; Yin, X.W.; Fan, S.W.; Zhang, L.T.; Cheng, L.F. Tribological behavior of three-dimensional needled ceramic modified carbon/carbon composites in seawater conditions. Compos. Sci. Technol. 2013, 87, 50–57. [Google Scholar] [CrossRef]

- Krenkel, W.; Berndt, F. C/C–SiC composites for space applications and advanced friction systems. Mater. Sci. Eng. A 2005, 412, 177–187. [Google Scholar] [CrossRef]

- Li, Z.; Xiao, P.; Xiong, X.; Zhu, S.H. Tribological characteristics of C/C–SiC braking composites under dry and wet conditions. Trans. Nonferr. Metal. Soc. 2008, 18, 1071–1075. [Google Scholar] [CrossRef]

- Zhang, D.Y.; Lin, P.; Dong, G.N.; Zeng, Q.F. Mechanical and tribological properties of self-lubricating laminated composites with flexible design. Mater. Des. 2013, 50, 830–838. [Google Scholar] [CrossRef]

| Testing Condition | Braking Speed (m/s) | Inertia (kg·m2) | Braking Pressure (MPa) |

|---|---|---|---|

| Normal Landing (NL) | 25 | 0.3 | 0.65 |

| Rejected Take-Off (RTO) | 28 | 0.5 | 1.25 |

| Properties | Composite C/C | Composite C/G/C |

|---|---|---|

| Flexural strength (MPa) | 106 ± 10 | 187 ± 12 |

| σ0 (MPa) | 110 | 188 |

| m * | 17.4 | 19.7 |

| Internal friction | 0.038 | 0.022 |

| Storage modulus (GPa) | 12.7 | 15.6 |

| Interlaminar shear strength (MPa) | 10.3 ± 1.5 | 14.9 ± 1.8 |

| Interfacial debonding strength (MPa) | 7.6 ± 1.6 | 20.4 ± 2.3 |

| Performance | Braking Levels | C/C Composites | C/G/C Composites |

|---|---|---|---|

| Friction coefficient | NL | 0.33 | 0.37 |

| RTO | 0.22 | 0.31 | |

| Stability coefficient | NL | 0.61 | 0.83 |

| RTO | 0.47 | 0.76 | |

| Braking energy (J·cm−2) | NL | 3210 | 3233 |

| RTO | 5237 | 5254 | |

| Maximum temperature (°C) | NL | 395 ± 24 | 381 ± 23 |

| RTO | 603 ± 31 | 539 ± 29 | |

| Mass wear loss (mg·side−1·stop−1) | NL | 5.84 | 4.96 |

| RTO | 112.54 | 98.72 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, W.; Luo, R.; Hou, Z. Effect of Interface Modified by Graphene on the Mechanical and Frictional Properties of Carbon/Graphene/Carbon Composites. Materials 2016, 9, 492. https://doi.org/10.3390/ma9060492

Yang W, Luo R, Hou Z. Effect of Interface Modified by Graphene on the Mechanical and Frictional Properties of Carbon/Graphene/Carbon Composites. Materials. 2016; 9(6):492. https://doi.org/10.3390/ma9060492

Chicago/Turabian StyleYang, Wei, Ruiying Luo, and Zhenhua Hou. 2016. "Effect of Interface Modified by Graphene on the Mechanical and Frictional Properties of Carbon/Graphene/Carbon Composites" Materials 9, no. 6: 492. https://doi.org/10.3390/ma9060492